5a69287d9a0dfc8b5ecf2b865f84e12e.ppt

- Количество слайдов: 28

Migrating your Conventional Maintenance to e. Maintenance using technology

Migrating your Conventional Maintenance to e. Maintenance using technology

Introduction It is a common practice for property managers to outsource maintenance works to specialized contractors. Challenges of out-sourcing u Maintenance contracts awarded based on price alone often result in poor maintenance v Need for Benchmarking – An objective means to measure the quality of maintenance w Conventional maintenance based on SLAs and CMMS lack Transparency & Efficiency

Introduction It is a common practice for property managers to outsource maintenance works to specialized contractors. Challenges of out-sourcing u Maintenance contracts awarded based on price alone often result in poor maintenance v Need for Benchmarking – An objective means to measure the quality of maintenance w Conventional maintenance based on SLAs and CMMS lack Transparency & Efficiency

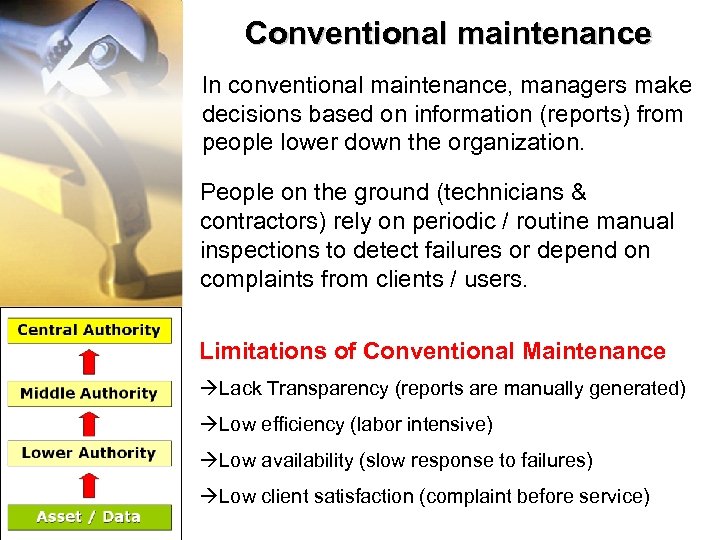

Conventional maintenance In conventional maintenance, managers make decisions based on information (reports) from people lower down the organization. People on the ground (technicians & contractors) rely on periodic / routine manual inspections to detect failures or depend on complaints from clients / users. Limitations of Conventional Maintenance Lack Transparency (reports are manually generated) Low efficiency (labor intensive) Low availability (slow response to failures) Low client satisfaction (complaint before service)

Conventional maintenance In conventional maintenance, managers make decisions based on information (reports) from people lower down the organization. People on the ground (technicians & contractors) rely on periodic / routine manual inspections to detect failures or depend on complaints from clients / users. Limitations of Conventional Maintenance Lack Transparency (reports are manually generated) Low efficiency (labor intensive) Low availability (slow response to failures) Low client satisfaction (complaint before service)

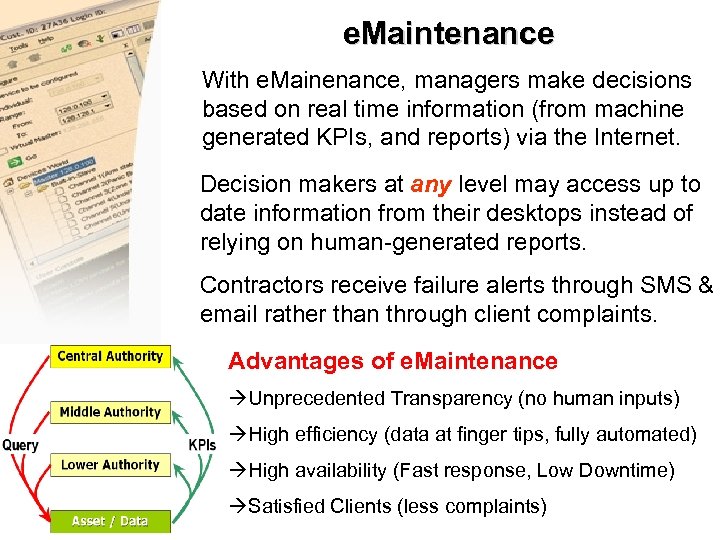

e. Maintenance With e. Mainenance, managers make decisions based on real time information (from machine generated KPIs, and reports) via the Internet. Decision makers at any level may access up to date information from their desktops instead of relying on human-generated reports. Contractors receive failure alerts through SMS & email rather than through client complaints. Advantages of e. Maintenance Unprecedented Transparency (no human inputs) High efficiency (data at finger tips, fully automated) High availability (Fast response, Low Downtime) Satisfied Clients (less complaints)

e. Maintenance With e. Mainenance, managers make decisions based on real time information (from machine generated KPIs, and reports) via the Internet. Decision makers at any level may access up to date information from their desktops instead of relying on human-generated reports. Contractors receive failure alerts through SMS & email rather than through client complaints. Advantages of e. Maintenance Unprecedented Transparency (no human inputs) High efficiency (data at finger tips, fully automated) High availability (Fast response, Low Downtime) Satisfied Clients (less complaints)

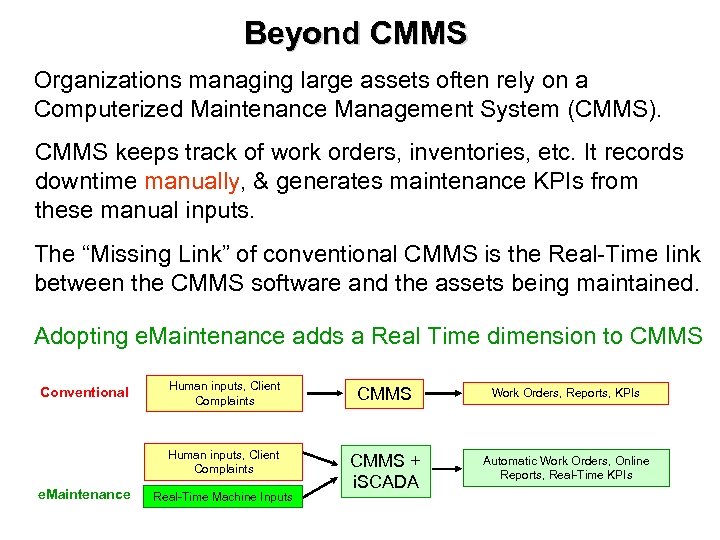

Beyond CMMS Organizations managing large assets often rely on a Computerized Maintenance Management System (CMMS). CMMS keeps track of work orders, inventories, etc. It records downtime manually, & generates maintenance KPIs from these manual inputs. The “Missing Link” of conventional CMMS is the Real-Time link between the CMMS software and the assets being maintained. Adopting e. Maintenance adds a Real Time dimension to CMMS Conventional Human inputs, Client Complaints e. Maintenance Real-Time Machine Inputs CMMS + i. SCADA Work Orders, Reports, KPIs Automatic Work Orders, Online Reports, Real-Time KPIs

Beyond CMMS Organizations managing large assets often rely on a Computerized Maintenance Management System (CMMS). CMMS keeps track of work orders, inventories, etc. It records downtime manually, & generates maintenance KPIs from these manual inputs. The “Missing Link” of conventional CMMS is the Real-Time link between the CMMS software and the assets being maintained. Adopting e. Maintenance adds a Real Time dimension to CMMS Conventional Human inputs, Client Complaints e. Maintenance Real-Time Machine Inputs CMMS + i. SCADA Work Orders, Reports, KPIs Automatic Work Orders, Online Reports, Real-Time KPIs

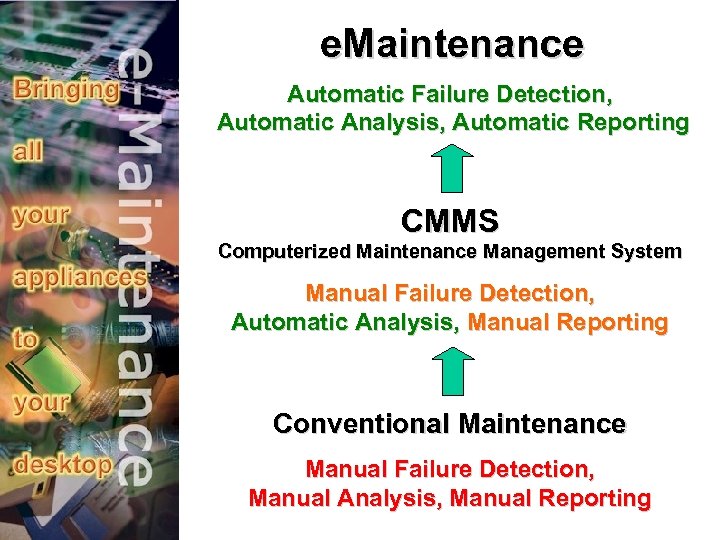

e. Maintenance Automatic Failure Detection, Automatic Analysis, Automatic Reporting CMMS Computerized Maintenance Management System Manual Failure Detection, Automatic Analysis, Manual Reporting Conventional Maintenance Manual Failure Detection, Manual Analysis, Manual Reporting

e. Maintenance Automatic Failure Detection, Automatic Analysis, Automatic Reporting CMMS Computerized Maintenance Management System Manual Failure Detection, Automatic Analysis, Manual Reporting Conventional Maintenance Manual Failure Detection, Manual Analysis, Manual Reporting

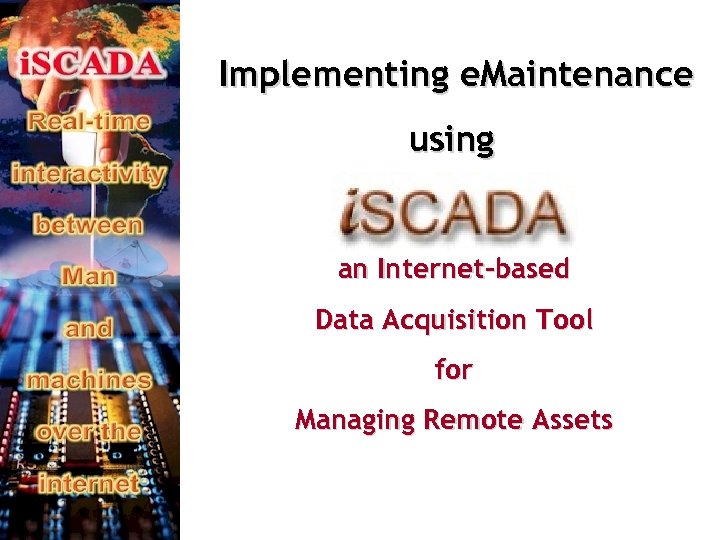

Implementing e. Maintenance using an Internet-based Data Acquisition Tool for Managing Remote Assets

Implementing e. Maintenance using an Internet-based Data Acquisition Tool for Managing Remote Assets

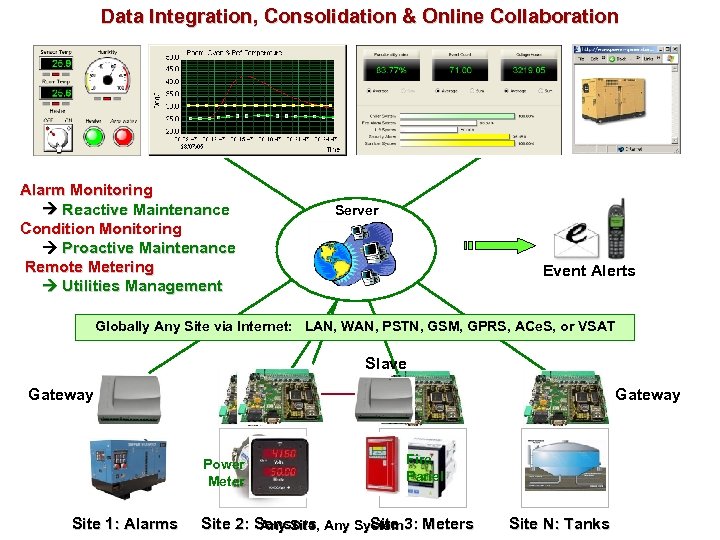

Data Integration, Consolidation & Online Collaboration Universal Access Online Collaboration Alarm Monitoring Reactive Maintenance Condition Monitoring Proactive Maintenance Remote Metering Utilities Management i. SCADA Server Architecture Event Alerts Globally Any Site via Internet: LAN, WAN, PSTN, GSM, GPRS, ACe. S, or VSAT Slave Gateway Power Meter Site 1: Alarms Fire Panel Site 2: Sensors Site 3: Meters Any Site, Any System Site N: Tanks

Data Integration, Consolidation & Online Collaboration Universal Access Online Collaboration Alarm Monitoring Reactive Maintenance Condition Monitoring Proactive Maintenance Remote Metering Utilities Management i. SCADA Server Architecture Event Alerts Globally Any Site via Internet: LAN, WAN, PSTN, GSM, GPRS, ACe. S, or VSAT Slave Gateway Power Meter Site 1: Alarms Fire Panel Site 2: Sensors Site 3: Meters Any Site, Any System Site N: Tanks

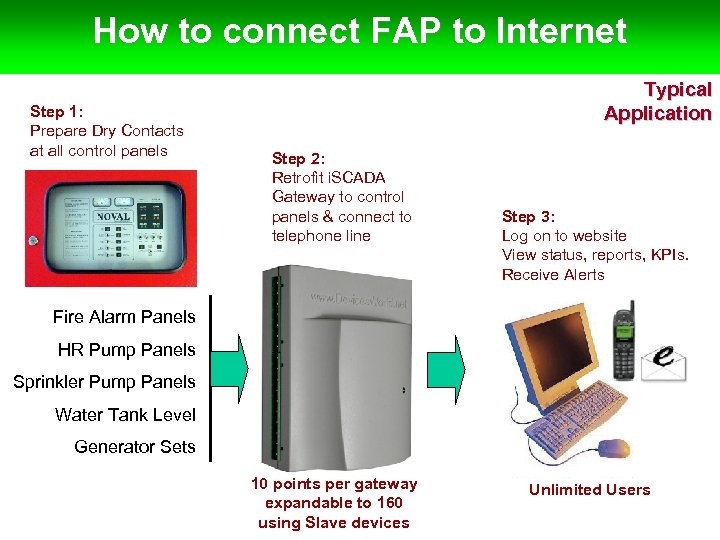

How to connect FAP to Internet Step 1: Prepare Dry Contacts at all control panels Typical Application Step 2: Retrofit i. SCADA Gateway to control panels & connect to telephone line Step 3: Log on to website View status, reports, KPIs. Receive Alerts Fire Alarm Panels HR Pump Panels Sprinkler Pump Panels Water Tank Level Generator Sets 10 points per gateway expandable to 160 using Slave devices Unlimited Users

How to connect FAP to Internet Step 1: Prepare Dry Contacts at all control panels Typical Application Step 2: Retrofit i. SCADA Gateway to control panels & connect to telephone line Step 3: Log on to website View status, reports, KPIs. Receive Alerts Fire Alarm Panels HR Pump Panels Sprinkler Pump Panels Water Tank Level Generator Sets 10 points per gateway expandable to 160 using Slave devices Unlimited Users

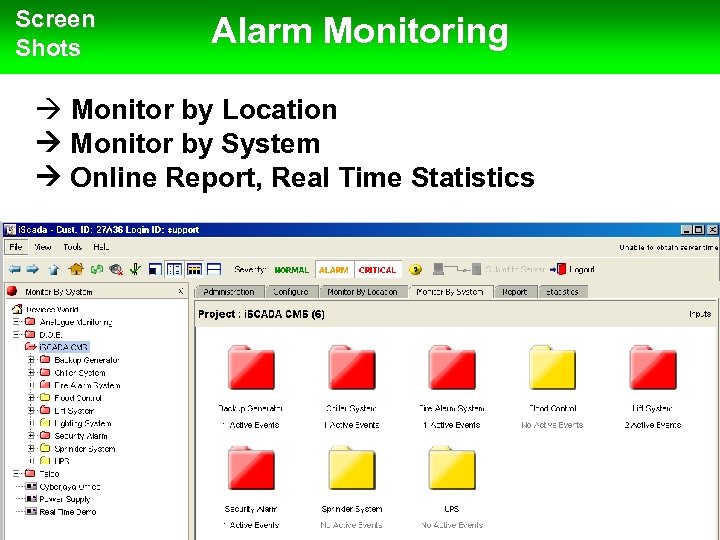

Screen Shots Alarm Monitoring Monitor by Location Monitor by System Online Report, Real Time Statistics

Screen Shots Alarm Monitoring Monitor by Location Monitor by System Online Report, Real Time Statistics

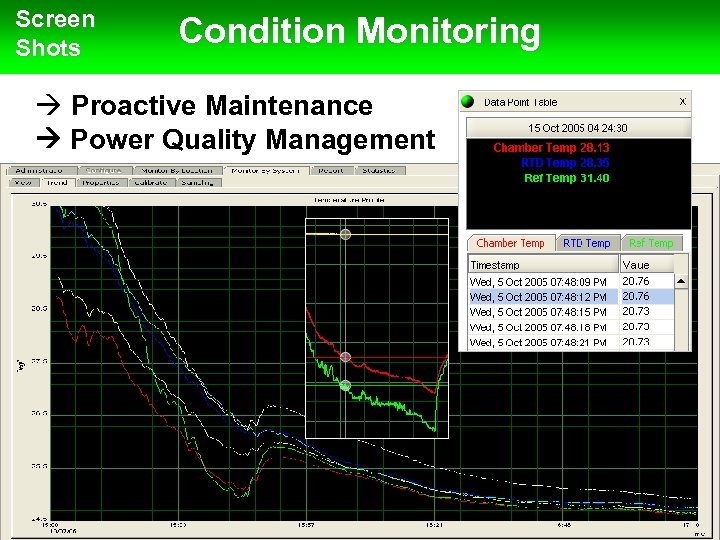

Screen Shots Condition Monitoring Proactive Maintenance Power Quality Management

Screen Shots Condition Monitoring Proactive Maintenance Power Quality Management

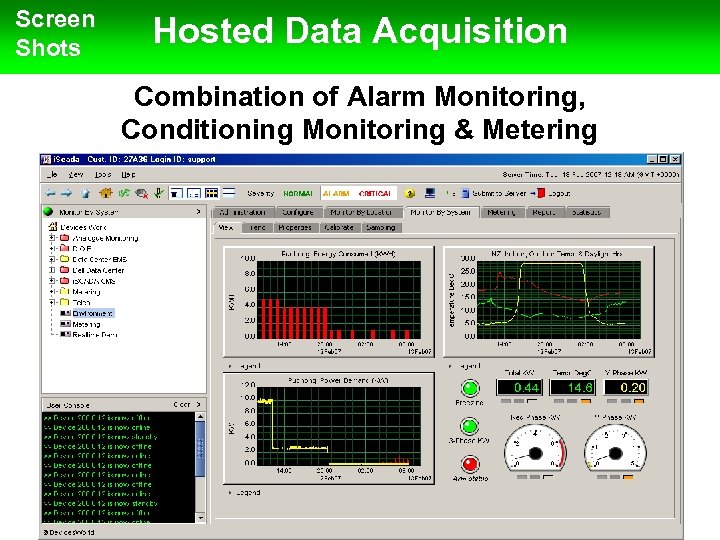

Screen Shots Hosted Data Acquisition Combination of Alarm Monitoring, Conditioning Monitoring & Metering

Screen Shots Hosted Data Acquisition Combination of Alarm Monitoring, Conditioning Monitoring & Metering

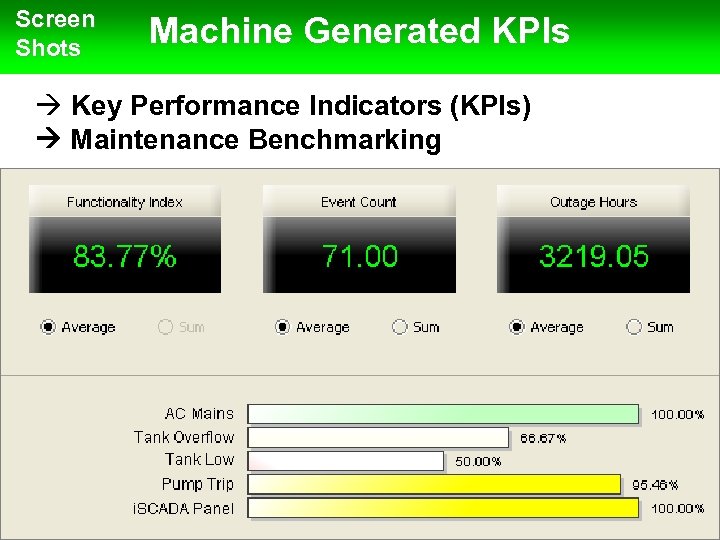

Screen Shots Machine Generated KPIs Key Performance Indicators (KPIs) Maintenance Benchmarking

Screen Shots Machine Generated KPIs Key Performance Indicators (KPIs) Maintenance Benchmarking

Benefits of e. Maintenance Transparency Everything was recorded automatically without human intervention. Reports & statistics are available online to top management in real time. Efficiency Reduces manpower for fault detection and paper work Availability Automatic detection and SMS enables quick actions to be taken. This improves the overall availability of our systems.

Benefits of e. Maintenance Transparency Everything was recorded automatically without human intervention. Reports & statistics are available online to top management in real time. Efficiency Reduces manpower for fault detection and paper work Availability Automatic detection and SMS enables quick actions to be taken. This improves the overall availability of our systems.

Benefits of i. SCADA Low cost of data transmission Since all communications between devices, server and users are Internet based, this translates into the lowest compared to all other systems. Devices can be placed anywhere in the world, and users can seamlessly communicate with their devices from any Internet connection. Consolidation & Integration of information Since all data is stored in a central database in the Internet, users have global access to consolidated data from many systems or locations. In pointto-point systems, data resides in a particular physical location (typically a control room), and access is restricted. Data from any Vendor systems can be integrated into a single i. SCADA application. Fast & Easy Deployment User friendly hardware interfaces with a wide range of legacy appliances and transducers. Managed services eliminate cost and complexities of owning and maintaining server and software. Universally accepted User Interface Web-based solutions like i. SCADA have a universally accepted, familiar and user-friendly Graphical User Interface (GUI). This takes the complexities out of sophisticated engineering solutions, and places information in the hands of managers and other decision makers. It also flattens the learning curve for engineers.

Benefits of i. SCADA Low cost of data transmission Since all communications between devices, server and users are Internet based, this translates into the lowest compared to all other systems. Devices can be placed anywhere in the world, and users can seamlessly communicate with their devices from any Internet connection. Consolidation & Integration of information Since all data is stored in a central database in the Internet, users have global access to consolidated data from many systems or locations. In pointto-point systems, data resides in a particular physical location (typically a control room), and access is restricted. Data from any Vendor systems can be integrated into a single i. SCADA application. Fast & Easy Deployment User friendly hardware interfaces with a wide range of legacy appliances and transducers. Managed services eliminate cost and complexities of owning and maintaining server and software. Universally accepted User Interface Web-based solutions like i. SCADA have a universally accepted, familiar and user-friendly Graphical User Interface (GUI). This takes the complexities out of sophisticated engineering solutions, and places information in the hands of managers and other decision makers. It also flattens the learning curve for engineers.

Thank You Q & A Real Time Demo

Thank You Q & A Real Time Demo

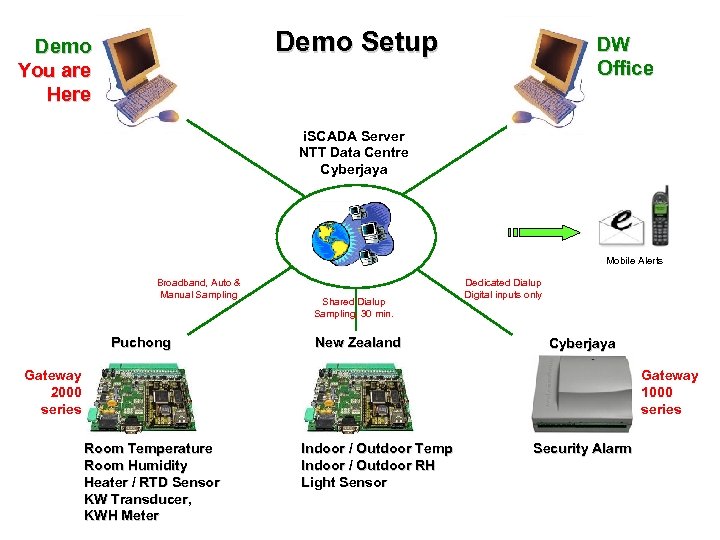

Demo Setup Demo You are Here DW Office i. SCADA Server NTT Data Centre Cyberjaya Mobile Alerts Broadband, Auto & Manual Sampling Puchong Shared Dialup Sampling, 30 min. New Zealand Dedicated Dialup Digital inputs only Cyberjaya Gateway 2000 series Room Temperature Room Humidity Heater / RTD Sensor KW Transducer, KWH Meter Gateway 1000 series Indoor / Outdoor Temp Indoor / Outdoor RH Light Sensor Security Alarm

Demo Setup Demo You are Here DW Office i. SCADA Server NTT Data Centre Cyberjaya Mobile Alerts Broadband, Auto & Manual Sampling Puchong Shared Dialup Sampling, 30 min. New Zealand Dedicated Dialup Digital inputs only Cyberjaya Gateway 2000 series Room Temperature Room Humidity Heater / RTD Sensor KW Transducer, KWH Meter Gateway 1000 series Indoor / Outdoor Temp Indoor / Outdoor RH Light Sensor Security Alarm

Featured Clients & Applications DBKL: Cheras Building Maintenance JKR: Melaka, Perak, Selangor, Kedah Building Maintenance, Hospitals’ Data Centre Ui. TM: Dungun, Kuantan, Alor Gajah, S. A. Fire Protection, Electrical & e. Maintenance UTM: Skudai, City Campus KL Water Retriculation, Lifts, PABX, Environment NTU: Singapore & SFC: Kuching Sea Turtle Incubation Temperature Research Logica CMG: PJ & Singapore Data Center Monitoring HSBC: KL Chiller Management

Featured Clients & Applications DBKL: Cheras Building Maintenance JKR: Melaka, Perak, Selangor, Kedah Building Maintenance, Hospitals’ Data Centre Ui. TM: Dungun, Kuantan, Alor Gajah, S. A. Fire Protection, Electrical & e. Maintenance UTM: Skudai, City Campus KL Water Retriculation, Lifts, PABX, Environment NTU: Singapore & SFC: Kuching Sea Turtle Incubation Temperature Research Logica CMG: PJ & Singapore Data Center Monitoring HSBC: KL Chiller Management

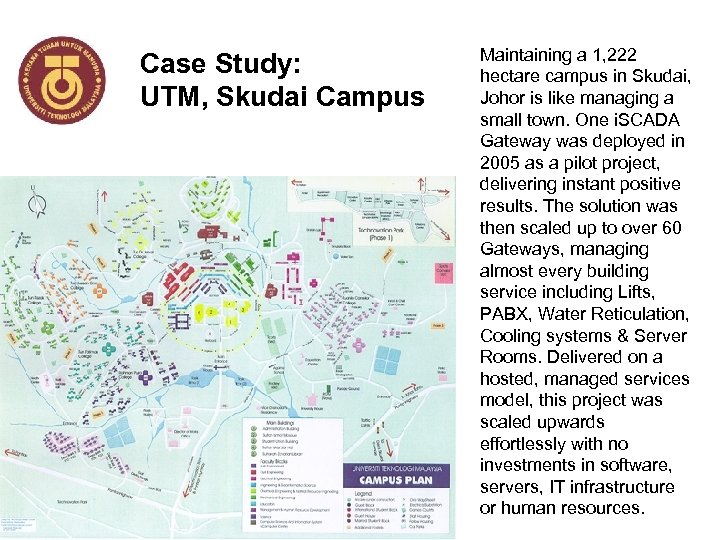

Case Study: UTM, Skudai Campus Maintaining a 1, 222 hectare campus in Skudai, Johor is like managing a small town. One i. SCADA Gateway was deployed in 2005 as a pilot project, delivering instant positive results. The solution was then scaled up to over 60 Gateways, managing almost every building service including Lifts, PABX, Water Reticulation, Cooling systems & Server Rooms. Delivered on a hosted, managed services model, this project was scaled upwards effortlessly with no investments in software, servers, IT infrastructure or human resources.

Case Study: UTM, Skudai Campus Maintaining a 1, 222 hectare campus in Skudai, Johor is like managing a small town. One i. SCADA Gateway was deployed in 2005 as a pilot project, delivering instant positive results. The solution was then scaled up to over 60 Gateways, managing almost every building service including Lifts, PABX, Water Reticulation, Cooling systems & Server Rooms. Delivered on a hosted, managed services model, this project was scaled upwards effortlessly with no investments in software, servers, IT infrastructure or human resources.

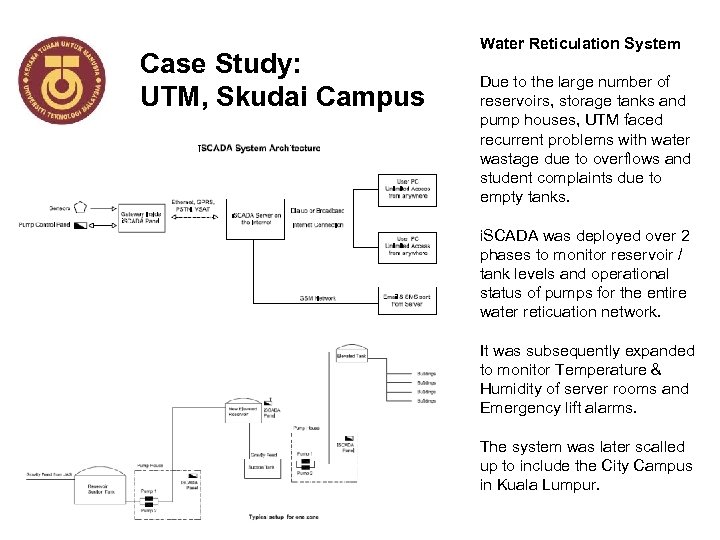

Case Study: UTM, Skudai Campus Water Reticulation System Due to the large number of reservoirs, storage tanks and pump houses, UTM faced recurrent problems with water wastage due to overflows and student complaints due to empty tanks. i. SCADA was deployed over 2 phases to monitor reservoir / tank levels and operational status of pumps for the entire water reticuation network. It was subsequently expanded to monitor Temperature & Humidity of server rooms and Emergency lift alarms. The system was later scalled up to include the City Campus in Kuala Lumpur.

Case Study: UTM, Skudai Campus Water Reticulation System Due to the large number of reservoirs, storage tanks and pump houses, UTM faced recurrent problems with water wastage due to overflows and student complaints due to empty tanks. i. SCADA was deployed over 2 phases to monitor reservoir / tank levels and operational status of pumps for the entire water reticuation network. It was subsequently expanded to monitor Temperature & Humidity of server rooms and Emergency lift alarms. The system was later scalled up to include the City Campus in Kuala Lumpur.

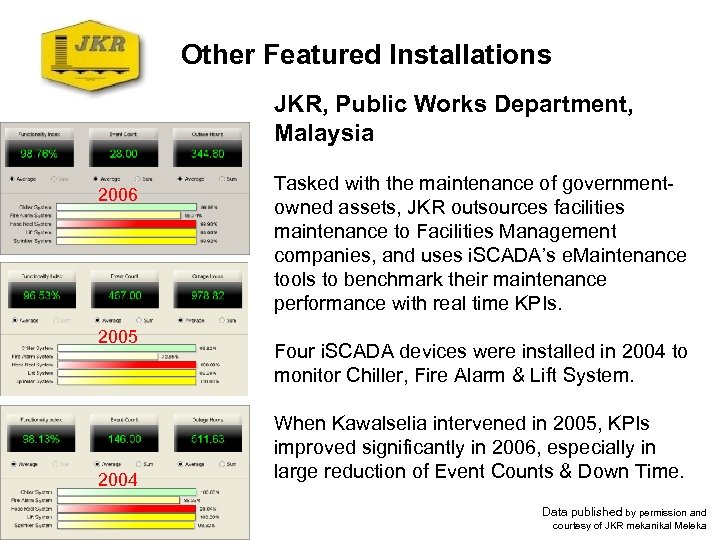

Other Featured Installations JKR, Public Works Department, Malaysia 2006 2005 2004 Tasked with the maintenance of governmentowned assets, JKR outsources facilities maintenance to Facilities Management companies, and uses i. SCADA’s e. Maintenance tools to benchmark their maintenance performance with real time KPIs. Four i. SCADA devices were installed in 2004 to monitor Chiller, Fire Alarm & Lift System. When Kawalselia intervened in 2005, KPIs improved significantly in 2006, especially in large reduction of Event Counts & Down Time. Data published by permission and courtesy of JKR mekanikal Meleka

Other Featured Installations JKR, Public Works Department, Malaysia 2006 2005 2004 Tasked with the maintenance of governmentowned assets, JKR outsources facilities maintenance to Facilities Management companies, and uses i. SCADA’s e. Maintenance tools to benchmark their maintenance performance with real time KPIs. Four i. SCADA devices were installed in 2004 to monitor Chiller, Fire Alarm & Lift System. When Kawalselia intervened in 2005, KPIs improved significantly in 2006, especially in large reduction of Event Counts & Down Time. Data published by permission and courtesy of JKR mekanikal Meleka

Other Featured Installations Logica CMG (MNC) Ensuring that critical data centers in Malaysia & Singapore operate with the highest availability, Devices World’s end-to-end supervised i. SCADA solution was their platform of choice to reliably deliver instant SMS and Email alerts, compared to traditional unsupervised pointto-point SMS solutions. Malaysian Data Center (Up. Town Petaling Jaya) i. SCADA deployed in January 2005 Singapore Data Center (Singapore) i. SCADA deployed in November 2005 Monitors UPS system, Electrical System, Room Temperature, Precision Air Conditioners, Fire System & Water Detection System

Other Featured Installations Logica CMG (MNC) Ensuring that critical data centers in Malaysia & Singapore operate with the highest availability, Devices World’s end-to-end supervised i. SCADA solution was their platform of choice to reliably deliver instant SMS and Email alerts, compared to traditional unsupervised pointto-point SMS solutions. Malaysian Data Center (Up. Town Petaling Jaya) i. SCADA deployed in January 2005 Singapore Data Center (Singapore) i. SCADA deployed in November 2005 Monitors UPS system, Electrical System, Room Temperature, Precision Air Conditioners, Fire System & Water Detection System

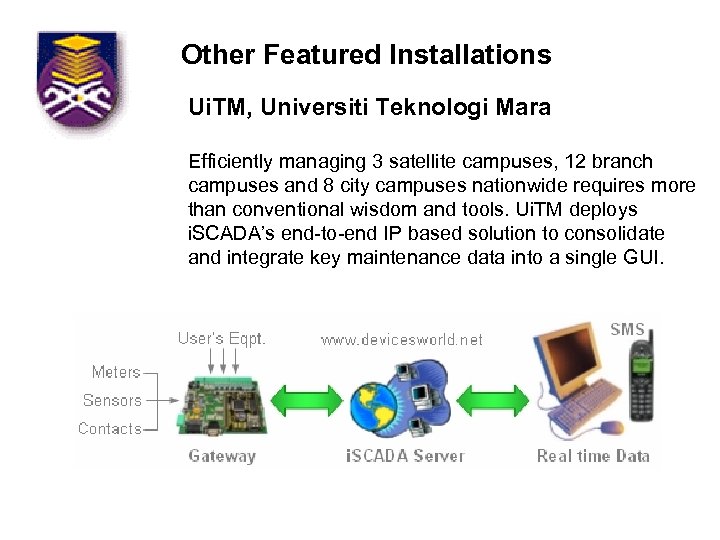

Other Featured Installations Ui. TM, Universiti Teknologi Mara Efficiently managing 3 satellite campuses, 12 branch campuses and 8 city campuses nationwide requires more than conventional wisdom and tools. Ui. TM deploys i. SCADA’s end-to-end IP based solution to consolidate and integrate key maintenance data into a single GUI.

Other Featured Installations Ui. TM, Universiti Teknologi Mara Efficiently managing 3 satellite campuses, 12 branch campuses and 8 city campuses nationwide requires more than conventional wisdom and tools. Ui. TM deploys i. SCADA’s end-to-end IP based solution to consolidate and integrate key maintenance data into a single GUI.

Nationwide Data Cosolidation Ui. TM e. Maintenance i. SCADA deployment Dungun Fire, Lift Sg. Buloh Fire, Electrical, Water, Sewage Kuantan Fire Shah Alam Fire, Water Alor Gajah Fire, Water, Electrical

Nationwide Data Cosolidation Ui. TM e. Maintenance i. SCADA deployment Dungun Fire, Lift Sg. Buloh Fire, Electrical, Water, Sewage Kuantan Fire Shah Alam Fire, Water Alor Gajah Fire, Water, Electrical

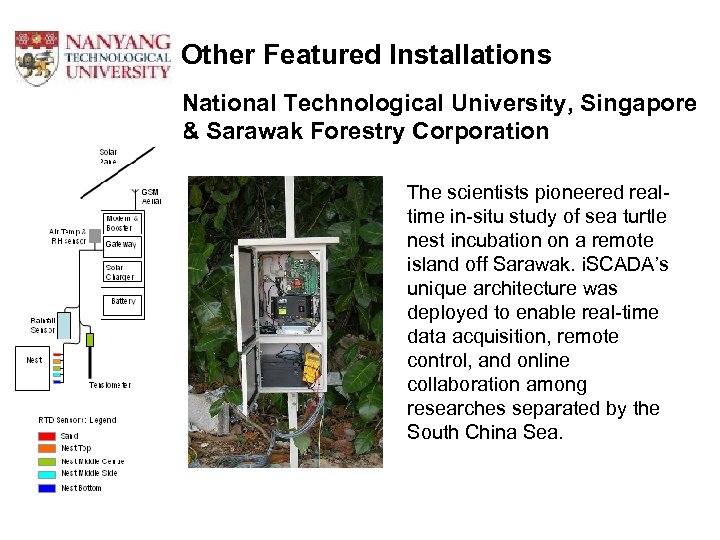

Other Featured Installations National Technological University, Singapore & Sarawak Forestry Corporation The scientists pioneered realtime in-situ study of sea turtle nest incubation on a remote island off Sarawak. i. SCADA’s unique architecture was deployed to enable real-time data acquisition, remote control, and online collaboration among researches separated by the South China Sea.

Other Featured Installations National Technological University, Singapore & Sarawak Forestry Corporation The scientists pioneered realtime in-situ study of sea turtle nest incubation on a remote island off Sarawak. i. SCADA’s unique architecture was deployed to enable real-time data acquisition, remote control, and online collaboration among researches separated by the South China Sea.

Other Featured Installations HSBC, Kuala Lumpur A simple yet effective application for energy management. i. SCADA was used to provide online trending of instantaneous power demand (KW) for their centralized cooling system. Facility Manager, Cofreth Sdn Bhd, used the trending tools to manage load optimization to avoid exceeding peek demand set by TNB.

Other Featured Installations HSBC, Kuala Lumpur A simple yet effective application for energy management. i. SCADA was used to provide online trending of instantaneous power demand (KW) for their centralized cooling system. Facility Manager, Cofreth Sdn Bhd, used the trending tools to manage load optimization to avoid exceeding peek demand set by TNB.

Other Featured Installations Devices World, New Zealand Monitoring offices in three locations – Puchong, Cyberjaya and Dunedin, New Zealand. One gateway is installed in each of the 3 offices monitoring the following: Security Alarm, Heat Pump Performance, Daylight Hours, Power Demand (KW), Energy Consumption (KWH) remote metering, Office Environment (Temperature & Humidity).

Other Featured Installations Devices World, New Zealand Monitoring offices in three locations – Puchong, Cyberjaya and Dunedin, New Zealand. One gateway is installed in each of the 3 offices monitoring the following: Security Alarm, Heat Pump Performance, Daylight Hours, Power Demand (KW), Energy Consumption (KWH) remote metering, Office Environment (Temperature & Humidity).

Maintenance Benchmarking Paper presented at IFE International Conference Putra World Trade Center, Kuala Lumpur, 5 -6 th October 2004 “Benchmarking the Fire Maintenance Industry & Towards e. Maintenance” Discusses the need, means and benefits of maintenance benchmarking using real-time M 2 M (machine-to-machine) technologies. Targeted at the fire safety industry, the principles expounded is applicable to the general maintenance industry. Click to Download Paper http: //www. devicesworld. net/download/iscada_paper_benchmarking. pdf Other maintenance papers Fire Certificate: An issue of maintenance from the technical & legal perspective e. Maintenance: Servicing & Maintenance of Fire Alarm Systems

Maintenance Benchmarking Paper presented at IFE International Conference Putra World Trade Center, Kuala Lumpur, 5 -6 th October 2004 “Benchmarking the Fire Maintenance Industry & Towards e. Maintenance” Discusses the need, means and benefits of maintenance benchmarking using real-time M 2 M (machine-to-machine) technologies. Targeted at the fire safety industry, the principles expounded is applicable to the general maintenance industry. Click to Download Paper http: //www. devicesworld. net/download/iscada_paper_benchmarking. pdf Other maintenance papers Fire Certificate: An issue of maintenance from the technical & legal perspective e. Maintenance: Servicing & Maintenance of Fire Alarm Systems