94981f19b9f0e8ffe2f0f9a18e405120.ppt

- Количество слайдов: 9

MICROSYSTEMS FOR SELECTIVE GAS SENSING Ulrike Lehmann, MICROSENS Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 1

MICROSYSTEMS FOR SELECTIVE GAS SENSING Ulrike Lehmann, MICROSENS Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 1

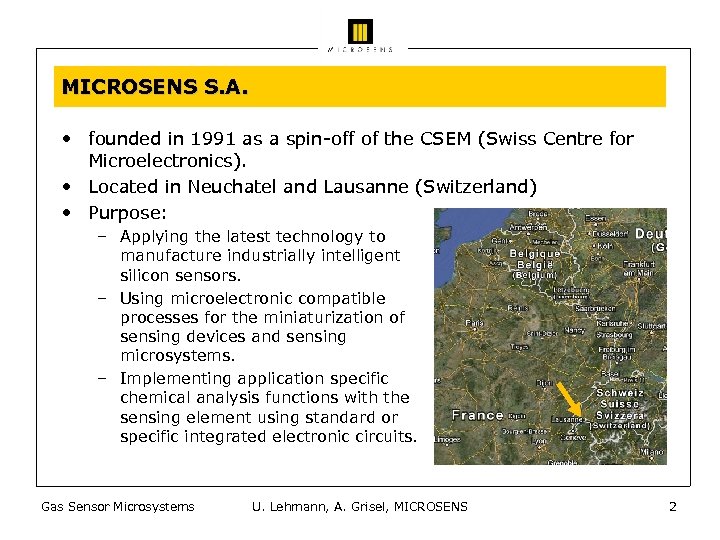

MICROSENS S. A. • founded in 1991 as a spin-off of the CSEM (Swiss Centre for Microelectronics). • Located in Neuchatel and Lausanne (Switzerland) • Purpose: – Applying the latest technology to manufacture industrially intelligent silicon sensors. – Using microelectronic compatible processes for the miniaturization of sensing devices and sensing microsystems. – Implementing application specific chemical analysis functions with the sensing element using standard or specific integrated electronic circuits. Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 2

MICROSENS S. A. • founded in 1991 as a spin-off of the CSEM (Swiss Centre for Microelectronics). • Located in Neuchatel and Lausanne (Switzerland) • Purpose: – Applying the latest technology to manufacture industrially intelligent silicon sensors. – Using microelectronic compatible processes for the miniaturization of sensing devices and sensing microsystems. – Implementing application specific chemical analysis functions with the sensing element using standard or specific integrated electronic circuits. Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 2

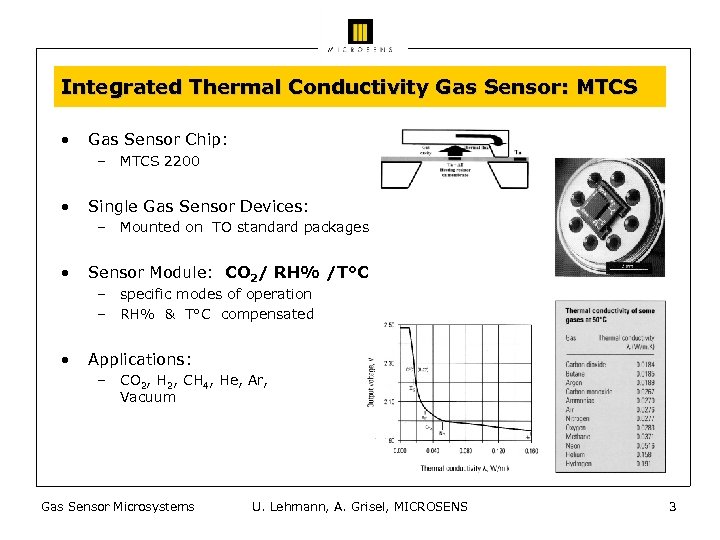

Integrated Thermal Conductivity Gas Sensor: MTCS • Gas Sensor Chip: – MTCS 2200 • Single Gas Sensor Devices: – Mounted on TO standard packages • Sensor Module: CO 2/ RH% /T°C – specific modes of operation – RH% & T°C compensated • Applications: – CO 2, H 2, CH 4, He, Ar, Vacuum Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 3

Integrated Thermal Conductivity Gas Sensor: MTCS • Gas Sensor Chip: – MTCS 2200 • Single Gas Sensor Devices: – Mounted on TO standard packages • Sensor Module: CO 2/ RH% /T°C – specific modes of operation – RH% & T°C compensated • Applications: – CO 2, H 2, CH 4, He, Ar, Vacuum Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 3

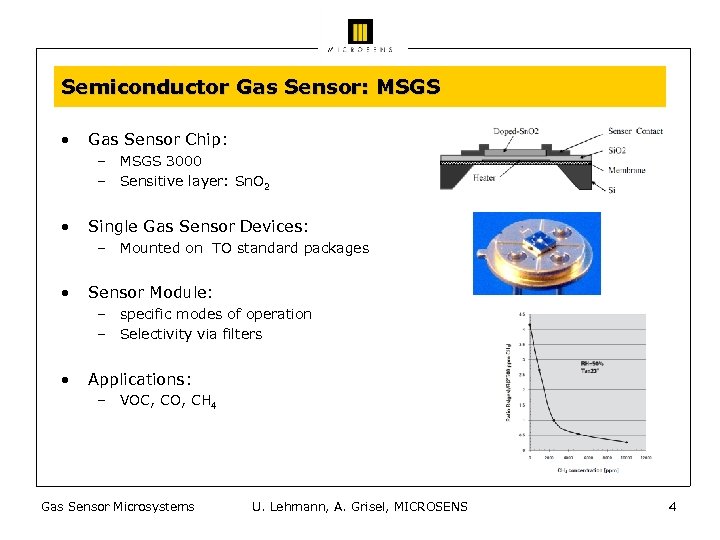

Semiconductor Gas Sensor: MSGS • Gas Sensor Chip: – MSGS 3000 – Sensitive layer: Sn. O 2 • Single Gas Sensor Devices: – Mounted on TO standard packages • Sensor Module: – specific modes of operation – Selectivity via filters • Applications: – VOC, CO, CH 4 Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 4

Semiconductor Gas Sensor: MSGS • Gas Sensor Chip: – MSGS 3000 – Sensitive layer: Sn. O 2 • Single Gas Sensor Devices: – Mounted on TO standard packages • Sensor Module: – specific modes of operation – Selectivity via filters • Applications: – VOC, CO, CH 4 Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 4

MSGS Portable Gas Analysis System • Increasing importance of monitoring air quality – Indoor air, outdoor air, breath – Measuring Volatile Organic Compounds (VOC) – Challenge: Multitude of components • Sn. O 2 gas sensors for detection of VOCs – Gas sample pre-treatment to increase sensor selectivity • Gas chromatography as standard application for characterizing mixed gas samples – Separation of sample compounds by their travelling time through a capillary Easy to use and portable gas analysis system Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 5

MSGS Portable Gas Analysis System • Increasing importance of monitoring air quality – Indoor air, outdoor air, breath – Measuring Volatile Organic Compounds (VOC) – Challenge: Multitude of components • Sn. O 2 gas sensors for detection of VOCs – Gas sample pre-treatment to increase sensor selectivity • Gas chromatography as standard application for characterizing mixed gas samples – Separation of sample compounds by their travelling time through a capillary Easy to use and portable gas analysis system Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 5

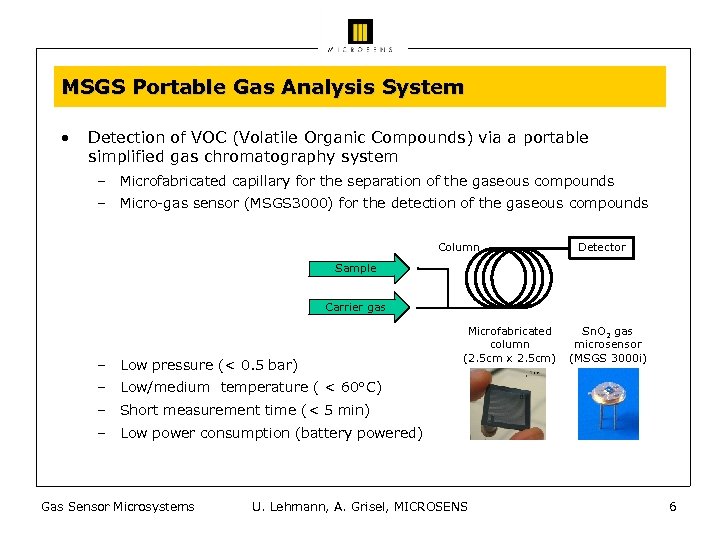

MSGS Portable Gas Analysis System • Detection of VOC (Volatile Organic Compounds) via a portable simplified gas chromatography system – Microfabricated capillary for the separation of the gaseous compounds – Micro-gas sensor (MSGS 3000) for the detection of the gaseous compounds Column Detector Sample Carrier gas – Low pressure (< 0. 5 bar) Microfabricated column (2. 5 cm x 2. 5 cm) Sn. O 2 gas microsensor (MSGS 3000 i) – Low/medium temperature ( < 60°C) – Short measurement time (< 5 min) – Low power consumption (battery powered) Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 6

MSGS Portable Gas Analysis System • Detection of VOC (Volatile Organic Compounds) via a portable simplified gas chromatography system – Microfabricated capillary for the separation of the gaseous compounds – Micro-gas sensor (MSGS 3000) for the detection of the gaseous compounds Column Detector Sample Carrier gas – Low pressure (< 0. 5 bar) Microfabricated column (2. 5 cm x 2. 5 cm) Sn. O 2 gas microsensor (MSGS 3000 i) – Low/medium temperature ( < 60°C) – Short measurement time (< 5 min) – Low power consumption (battery powered) Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 6

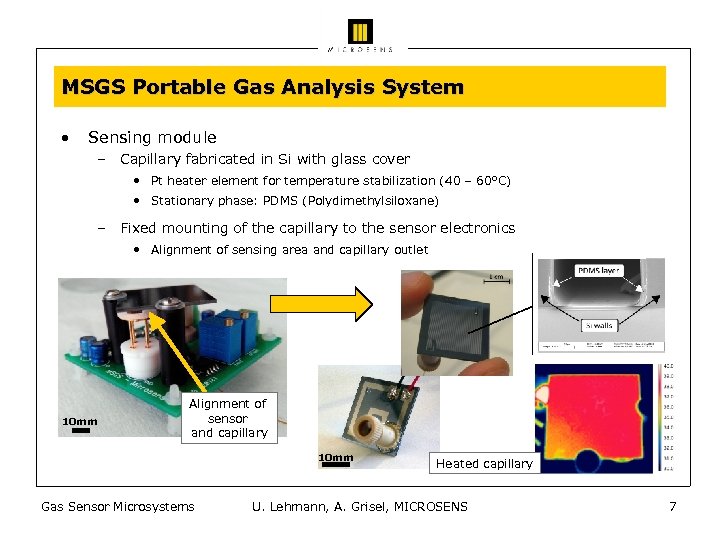

MSGS Portable Gas Analysis System • Sensing module – Capillary fabricated in Si with glass cover • Pt heater element for temperature stabilization (40 – 60°C) • Stationary phase: PDMS (Polydimethylsiloxane) – Fixed mounting of the capillary to the sensor electronics • Alignment of sensing area and capillary outlet 10 mm Alignment of sensor and capillary 10 mm Gas Sensor Microsystems Heated capillary U. Lehmann, A. Grisel, MICROSENS 7

MSGS Portable Gas Analysis System • Sensing module – Capillary fabricated in Si with glass cover • Pt heater element for temperature stabilization (40 – 60°C) • Stationary phase: PDMS (Polydimethylsiloxane) – Fixed mounting of the capillary to the sensor electronics • Alignment of sensing area and capillary outlet 10 mm Alignment of sensor and capillary 10 mm Gas Sensor Microsystems Heated capillary U. Lehmann, A. Grisel, MICROSENS 7

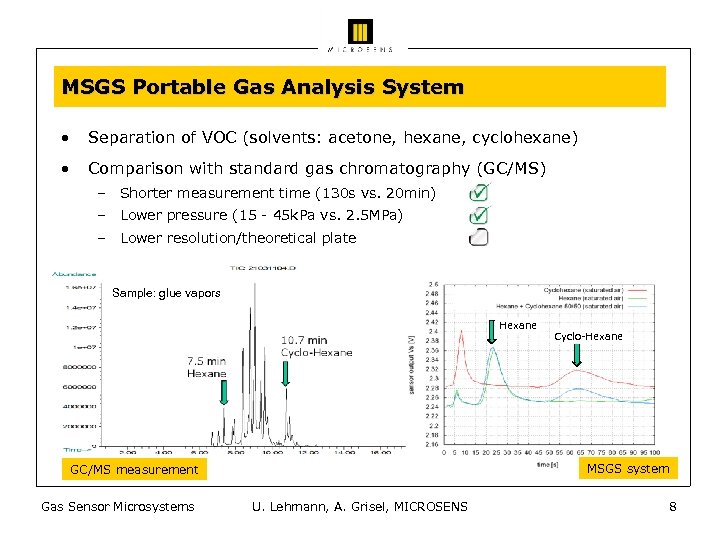

MSGS Portable Gas Analysis System • Separation of VOC (solvents: acetone, hexane, cyclohexane) • Comparison with standard gas chromatography (GC/MS) – Shorter measurement time (130 s vs. 20 min) – Lower pressure (15 - 45 k. Pa vs. 2. 5 MPa) – Lower resolution/theoretical plate Sample: glue vapors Hexane MSGS system GC/MS measurement Gas Sensor Microsystems Cyclo-Hexane U. Lehmann, A. Grisel, MICROSENS 8

MSGS Portable Gas Analysis System • Separation of VOC (solvents: acetone, hexane, cyclohexane) • Comparison with standard gas chromatography (GC/MS) – Shorter measurement time (130 s vs. 20 min) – Lower pressure (15 - 45 k. Pa vs. 2. 5 MPa) – Lower resolution/theoretical plate Sample: glue vapors Hexane MSGS system GC/MS measurement Gas Sensor Microsystems Cyclo-Hexane U. Lehmann, A. Grisel, MICROSENS 8

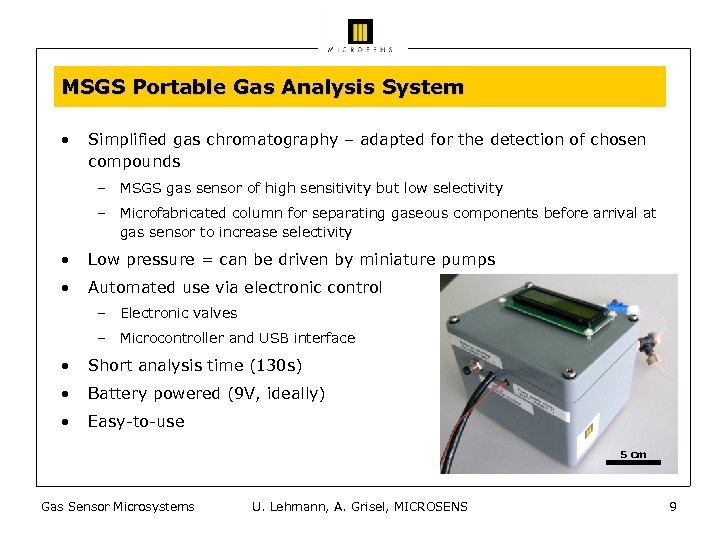

MSGS Portable Gas Analysis System • Simplified gas chromatography – adapted for the detection of chosen compounds – MSGS gas sensor of high sensitivity but low selectivity – Microfabricated column for separating gaseous components before arrival at gas sensor to increase selectivity • Low pressure = can be driven by miniature pumps • Automated use via electronic control – Electronic valves – Microcontroller and USB interface • Short analysis time (130 s) • Battery powered (9 V, ideally) • Easy-to-use 5 cm Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 9

MSGS Portable Gas Analysis System • Simplified gas chromatography – adapted for the detection of chosen compounds – MSGS gas sensor of high sensitivity but low selectivity – Microfabricated column for separating gaseous components before arrival at gas sensor to increase selectivity • Low pressure = can be driven by miniature pumps • Automated use via electronic control – Electronic valves – Microcontroller and USB interface • Short analysis time (130 s) • Battery powered (9 V, ideally) • Easy-to-use 5 cm Gas Sensor Microsystems U. Lehmann, A. Grisel, MICROSENS 9