2541d2131374ee122ebd0ccb766e64f4.ppt

- Количество слайдов: 104

MICROSURFACING AS ECO FRIENDLY TECHNOLOGY FOR MAINTENANCE Dr. Sangita Senior Scientist Flexible Pavement Division CENTRAL ROAD RESEARCH INSTITUTE NEW DELHI

MICROSURFACING AS ECO FRIENDLY TECHNOLOGY FOR MAINTENANCE Dr. Sangita Senior Scientist Flexible Pavement Division CENTRAL ROAD RESEARCH INSTITUTE NEW DELHI

PURPOSE OF MAINTENANCE • • • Improvement of Riding Quality Retardation of Deterioration Process Extension in Service Life of Pavement Saving in Road User Cost Reduction in Environmental Damage by Reduced Fuel Consumption • Avoidance of Large Capital Investment for Reconstruction

PURPOSE OF MAINTENANCE • • • Improvement of Riding Quality Retardation of Deterioration Process Extension in Service Life of Pavement Saving in Road User Cost Reduction in Environmental Damage by Reduced Fuel Consumption • Avoidance of Large Capital Investment for Reconstruction

SUGGESTED NORMS ØTo prevent noise and air pollution when road maintenance is in progress ØUtility levels to be kept at the existing levels (increase in height of pavement to be discouraged) ØGeneral road users should not be disturbed while maintenance is in progress ØKeeping in view above points microsurfacing is an environment friendly maintenance technology.

SUGGESTED NORMS ØTo prevent noise and air pollution when road maintenance is in progress ØUtility levels to be kept at the existing levels (increase in height of pavement to be discouraged) ØGeneral road users should not be disturbed while maintenance is in progress ØKeeping in view above points microsurfacing is an environment friendly maintenance technology.

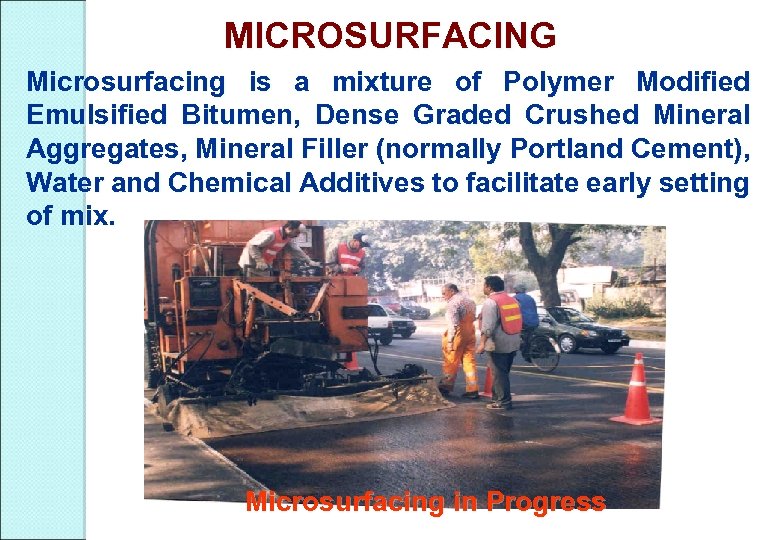

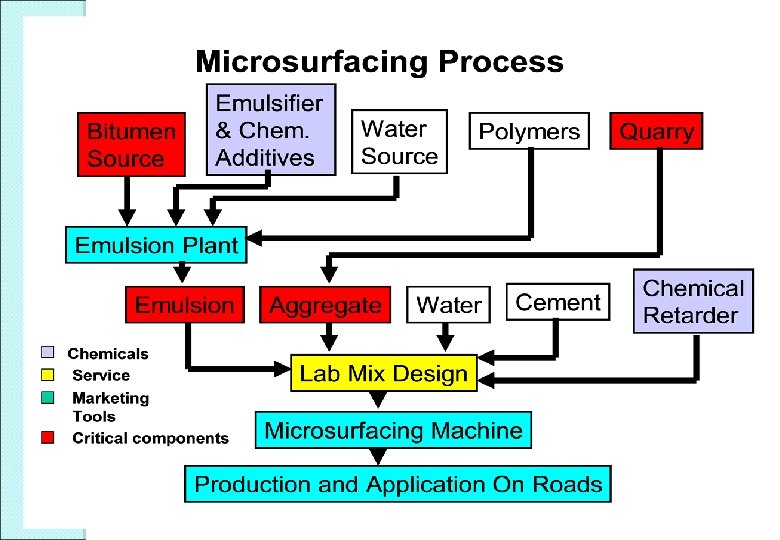

MICROSURFACING Microsurfacing is a mixture of Polymer Modified Emulsified Bitumen, Dense Graded Crushed Mineral Aggregates, Mineral Filler (normally Portland Cement), Water and Chemical Additives to facilitate early setting of mix. Microsurfacing in Progress

MICROSURFACING Microsurfacing is a mixture of Polymer Modified Emulsified Bitumen, Dense Graded Crushed Mineral Aggregates, Mineral Filler (normally Portland Cement), Water and Chemical Additives to facilitate early setting of mix. Microsurfacing in Progress

ADVANTAGE OF MICROSURFACING • Quick setting • • • Early opening to traffic Higher resistance to abrasion Can be used for Medium volume traffic corridors Fast construction Less air/noise pollution Cost effective

ADVANTAGE OF MICROSURFACING • Quick setting • • • Early opening to traffic Higher resistance to abrasion Can be used for Medium volume traffic corridors Fast construction Less air/noise pollution Cost effective

ADVANTAGE OF MICROSURFACING (Contd. ) • Prevents reflective cracking • Seals wide cracks effectively • Delays in hardening of bitumen due to environment • Better visibility at night • No rolling and compaction is required • Preservation of pavements’ structural strength

ADVANTAGE OF MICROSURFACING (Contd. ) • Prevents reflective cracking • Seals wide cracks effectively • Delays in hardening of bitumen due to environment • Better visibility at night • No rolling and compaction is required • Preservation of pavements’ structural strength

ADVANTAGES OF MICROSURFACING v. Marginal raise in pavement height v. Least environment pollution v. Increased skid resistance v. Faster laying process v. High durability due to polymer / rubber additives

ADVANTAGES OF MICROSURFACING v. Marginal raise in pavement height v. Least environment pollution v. Increased skid resistance v. Faster laying process v. High durability due to polymer / rubber additives

APPLICATIONS § Preventive and periodic maintenance § Rut filling with the help of special rut box § Improvement in skid resistance and friction on a concrete road § Filling up of minor irregularities on surface

APPLICATIONS § Preventive and periodic maintenance § Rut filling with the help of special rut box § Improvement in skid resistance and friction on a concrete road § Filling up of minor irregularities on surface

Quality Control Tests Polymer Modified Emulsion Storage Stability Grading of Filler. Grading of Aggregate Binder Content. Grading of Aggregate Recovered from Mix Residual Bitumen Content, % Wt. of dry aggregate Application Rate of dry aggregate

Quality Control Tests Polymer Modified Emulsion Storage Stability Grading of Filler. Grading of Aggregate Binder Content. Grading of Aggregate Recovered from Mix Residual Bitumen Content, % Wt. of dry aggregate Application Rate of dry aggregate

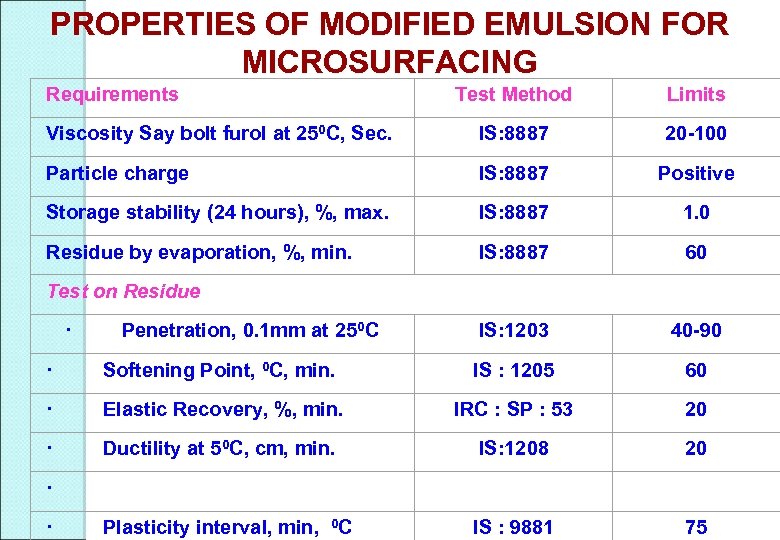

PROPERTIES OF MODIFIED EMULSION FOR MICROSURFACING Requirements Test Method Limits Viscosity Say bolt furol at 250 C, Sec. IS: 8887 20 -100 Particle charge IS: 8887 Positive Storage stability (24 hours), %, max. IS: 8887 1. 0 Residue by evaporation, %, min. IS: 8887 60 IS: 1203 40 -90 · Softening Point, 0 C, min. IS : 1205 60 · Elastic Recovery, %, min. IRC : SP : 53 20 · Ductility at 50 C, cm, min. IS: 1208 20 IS : 9881 75 Test on Residue · Penetration, 0. 1 mm at 250 C · · Plasticity interval, min, 0 C

PROPERTIES OF MODIFIED EMULSION FOR MICROSURFACING Requirements Test Method Limits Viscosity Say bolt furol at 250 C, Sec. IS: 8887 20 -100 Particle charge IS: 8887 Positive Storage stability (24 hours), %, max. IS: 8887 1. 0 Residue by evaporation, %, min. IS: 8887 60 IS: 1203 40 -90 · Softening Point, 0 C, min. IS : 1205 60 · Elastic Recovery, %, min. IRC : SP : 53 20 · Ductility at 50 C, cm, min. IS: 1208 20 IS : 9881 75 Test on Residue · Penetration, 0. 1 mm at 250 C · · Plasticity interval, min, 0 C

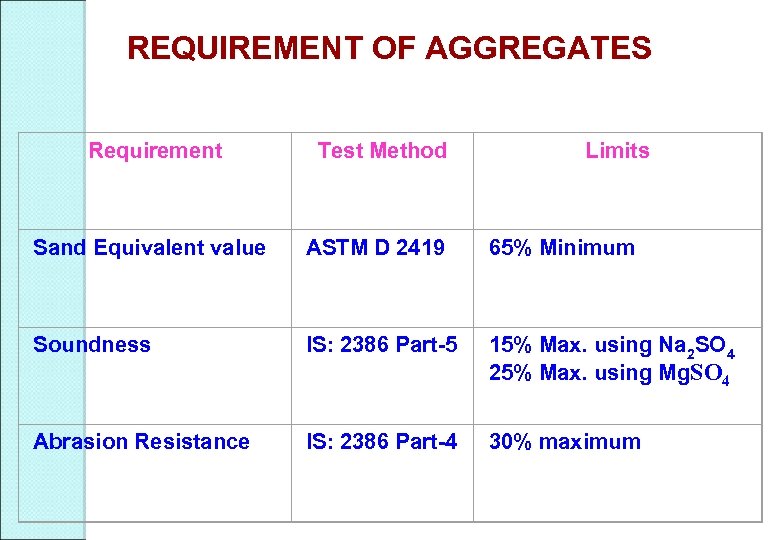

REQUIREMENT OF AGGREGATES Requirement Test Method Limits Sand Equivalent value ASTM D 2419 65% Minimum Soundness IS: 2386 Part-5 15% Max. using Na 2 SO 4 25% Max. using Mg. SO 4 Abrasion Resistance IS: 2386 Part-4 30% maximum

REQUIREMENT OF AGGREGATES Requirement Test Method Limits Sand Equivalent value ASTM D 2419 65% Minimum Soundness IS: 2386 Part-5 15% Max. using Na 2 SO 4 25% Max. using Mg. SO 4 Abrasion Resistance IS: 2386 Part-4 30% maximum

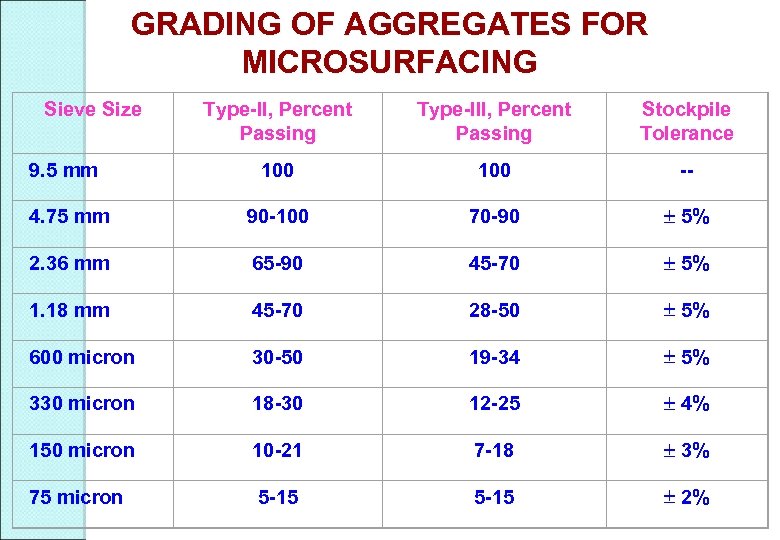

GRADING OF AGGREGATES FOR MICROSURFACING Sieve Size Type-II, Percent Passing Type-III, Percent Passing Stockpile Tolerance 9. 5 mm 100 -- 4. 75 mm 90 -100 70 -90 5% 2. 36 mm 65 -90 45 -70 5% 1. 18 mm 45 -70 28 -50 5% 600 micron 30 -50 19 -34 5% 330 micron 18 -30 12 -25 4% 150 micron 10 -21 7 -18 3% 75 micron 5 -15 2%

GRADING OF AGGREGATES FOR MICROSURFACING Sieve Size Type-II, Percent Passing Type-III, Percent Passing Stockpile Tolerance 9. 5 mm 100 -- 4. 75 mm 90 -100 70 -90 5% 2. 36 mm 65 -90 45 -70 5% 1. 18 mm 45 -70 28 -50 5% 600 micron 30 -50 19 -34 5% 330 micron 18 -30 12 -25 4% 150 micron 10 -21 7 -18 3% 75 micron 5 -15 2%

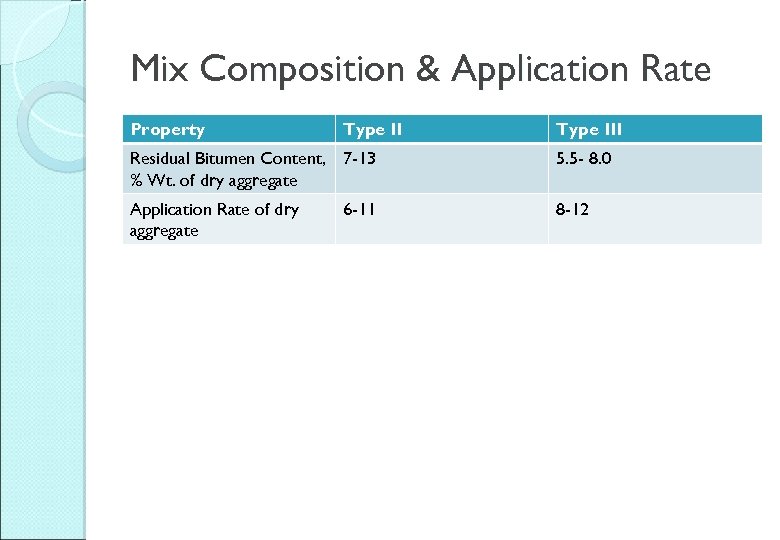

Mix Composition & Application Rate Property Type III Residual Bitumen Content, 7 -13 % Wt. of dry aggregate 5. 5 - 8. 0 Application Rate of dry aggregate 8 -12 6 -11

Mix Composition & Application Rate Property Type III Residual Bitumen Content, 7 -13 % Wt. of dry aggregate 5. 5 - 8. 0 Application Rate of dry aggregate 8 -12 6 -11

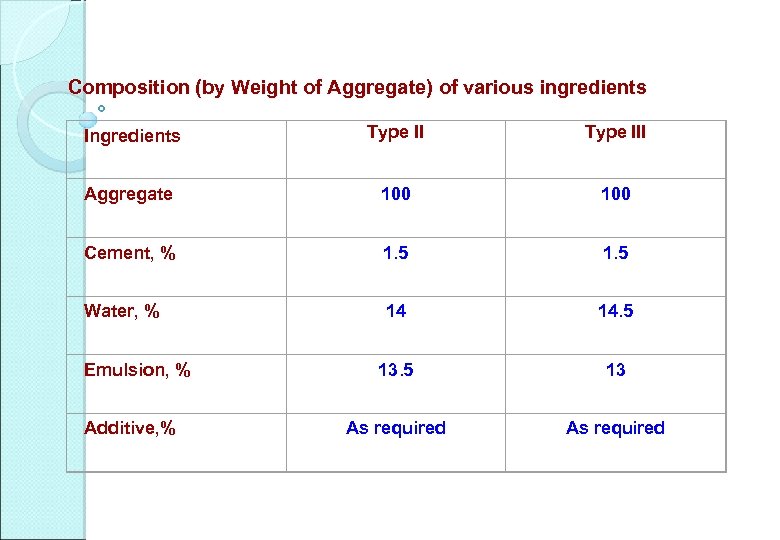

Composition (by Weight of Aggregate) of various ingredients Ingredients Type III Aggregate 100 Cement, % 1. 5 Water, % 14 14. 5 13 As required Emulsion, % Additive, %

Composition (by Weight of Aggregate) of various ingredients Ingredients Type III Aggregate 100 Cement, % 1. 5 Water, % 14 14. 5 13 As required Emulsion, % Additive, %

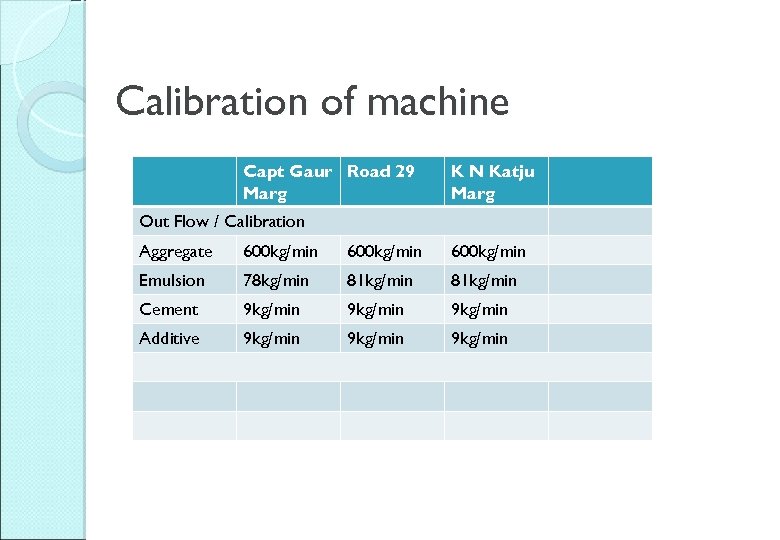

Calibration of machine Capt Gaur Road 29 Marg K N Katju Marg Out Flow / Calibration Aggregate 600 kg/min Emulsion 78 kg/min 81 kg/min Cement 9 kg/min Additive 9 kg/min

Calibration of machine Capt Gaur Road 29 Marg K N Katju Marg Out Flow / Calibration Aggregate 600 kg/min Emulsion 78 kg/min 81 kg/min Cement 9 kg/min Additive 9 kg/min

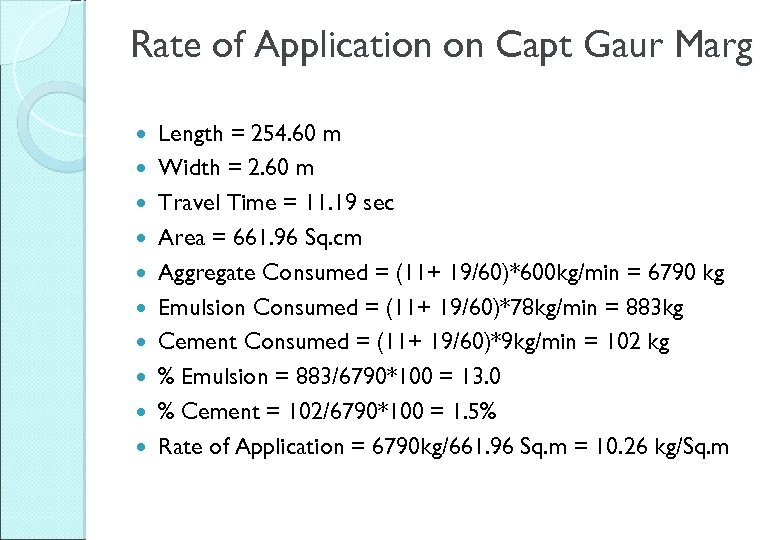

Rate of Application on Capt Gaur Marg Length = 254. 60 m Width = 2. 60 m Travel Time = 11. 19 sec Area = 661. 96 Sq. cm Aggregate Consumed = (11+ 19/60)*600 kg/min = 6790 kg Emulsion Consumed = (11+ 19/60)*78 kg/min = 883 kg Cement Consumed = (11+ 19/60)*9 kg/min = 102 kg % Emulsion = 883/6790*100 = 13. 0 % Cement = 102/6790*100 = 1. 5% Rate of Application = 6790 kg/661. 96 Sq. m = 10. 26 kg/Sq. m

Rate of Application on Capt Gaur Marg Length = 254. 60 m Width = 2. 60 m Travel Time = 11. 19 sec Area = 661. 96 Sq. cm Aggregate Consumed = (11+ 19/60)*600 kg/min = 6790 kg Emulsion Consumed = (11+ 19/60)*78 kg/min = 883 kg Cement Consumed = (11+ 19/60)*9 kg/min = 102 kg % Emulsion = 883/6790*100 = 13. 0 % Cement = 102/6790*100 = 1. 5% Rate of Application = 6790 kg/661. 96 Sq. m = 10. 26 kg/Sq. m

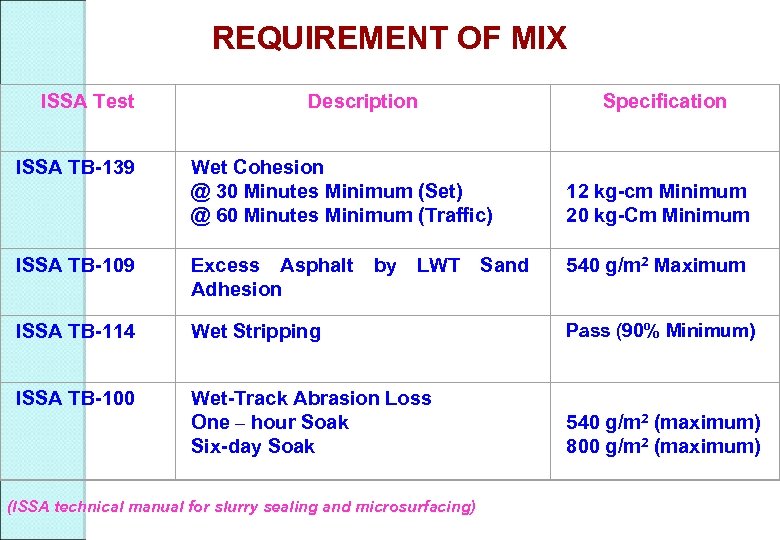

REQUIREMENT OF MIX ISSA Test Description Specification ISSA TB-139 Wet Cohesion @ 30 Minutes Minimum (Set) @ 60 Minutes Minimum (Traffic) 12 kg-cm Minimum 20 kg-Cm Minimum ISSA TB-109 Excess Asphalt Adhesion 540 g/m 2 Maximum ISSA TB-114 Wet Stripping Pass (90% Minimum) ISSA TB-100 Wet-Track Abrasion Loss One – hour Soak Six-day Soak 540 g/m 2 (maximum) 800 g/m 2 (maximum) by LWT (ISSA technical manual for slurry sealing and microsurfacing) Sand

REQUIREMENT OF MIX ISSA Test Description Specification ISSA TB-139 Wet Cohesion @ 30 Minutes Minimum (Set) @ 60 Minutes Minimum (Traffic) 12 kg-cm Minimum 20 kg-Cm Minimum ISSA TB-109 Excess Asphalt Adhesion 540 g/m 2 Maximum ISSA TB-114 Wet Stripping Pass (90% Minimum) ISSA TB-100 Wet-Track Abrasion Loss One – hour Soak Six-day Soak 540 g/m 2 (maximum) 800 g/m 2 (maximum) by LWT (ISSA technical manual for slurry sealing and microsurfacing) Sand

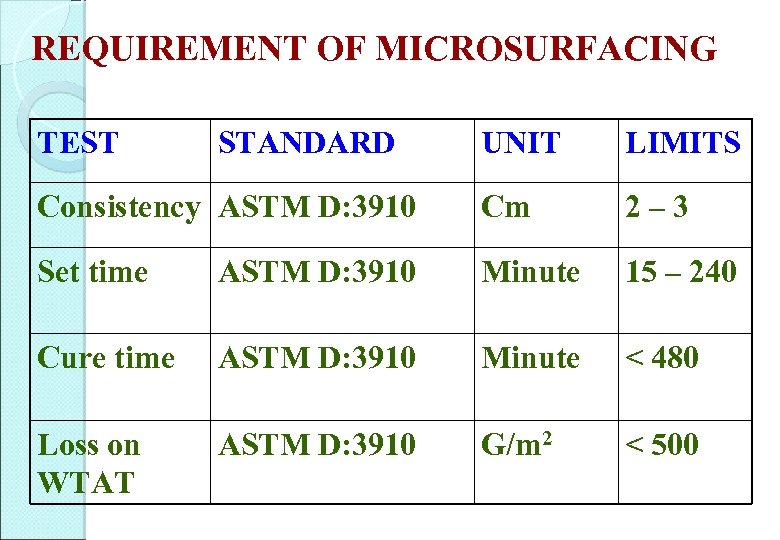

REQUIREMENT OF MICROSURFACING TEST STANDARD UNIT LIMITS Consistency ASTM D: 3910 Cm 2 – 3 Set time ASTM D: 3910 Minute 15 – 240 Cure time ASTM D: 3910 Minute < 480 Loss on WTAT ASTM D: 3910 G/m 2 < 500

REQUIREMENT OF MICROSURFACING TEST STANDARD UNIT LIMITS Consistency ASTM D: 3910 Cm 2 – 3 Set time ASTM D: 3910 Minute 15 – 240 Cure time ASTM D: 3910 Minute < 480 Loss on WTAT ASTM D: 3910 G/m 2 < 500

USAGE OF MICROSURFACING Ø Useful on Flexible as well as Rigid Pavements Ø Application in thin layer (3 -4 mm thick) Ø On top surface of flyovers and bridge decks Ø Approaches of junctions and roundabouts

USAGE OF MICROSURFACING Ø Useful on Flexible as well as Rigid Pavements Ø Application in thin layer (3 -4 mm thick) Ø On top surface of flyovers and bridge decks Ø Approaches of junctions and roundabouts

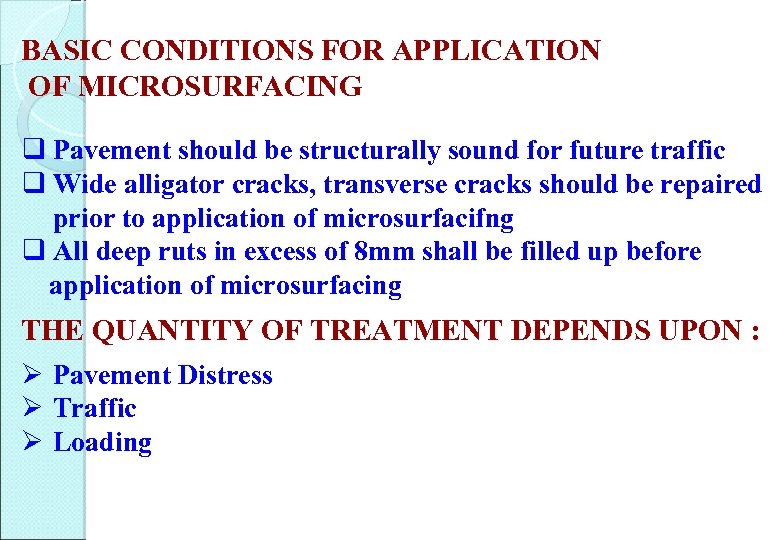

BASIC CONDITIONS FOR APPLICATION OF MICROSURFACING q Pavement should be structurally sound for future traffic q Wide alligator cracks, transverse cracks should be repaired prior to application of microsurfacifng q All deep ruts in excess of 8 mm shall be filled up before application of microsurfacing THE QUANTITY OF TREATMENT DEPENDS UPON : Ø Pavement Distress Ø Traffic Ø Loading

BASIC CONDITIONS FOR APPLICATION OF MICROSURFACING q Pavement should be structurally sound for future traffic q Wide alligator cracks, transverse cracks should be repaired prior to application of microsurfacifng q All deep ruts in excess of 8 mm shall be filled up before application of microsurfacing THE QUANTITY OF TREATMENT DEPENDS UPON : Ø Pavement Distress Ø Traffic Ø Loading

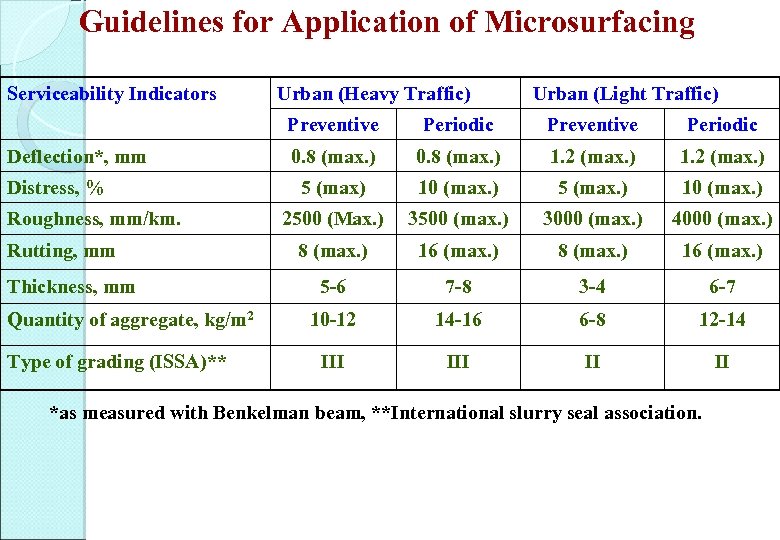

Guidelines for Application of Microsurfacing Serviceability Indicators Urban (Heavy Traffic) Urban (Light Traffic) Preventive Deflection*, mm Distress, % Roughness, mm/km. Rutting, mm Thickness, mm Quantity of aggregate, kg/m 2 Type of grading (ISSA)** Periodic Preventive Periodic 0. 8 (max. ) 1. 2 (max. ) 5 (max) 10 (max. ) 5 (max. ) 10 (max. ) 2500 (Max. ) 3500 (max. ) 3000 (max. ) 4000 (max. ) 8 (max. ) 16 (max. ) 8 (max. ) 5 -6 7 -8 3 -4 6 -7 10 -12 14 -16 6 -8 12 -14 III II II 16 (max. ) *as measured with Benkelman beam, **International slurry seal association.

Guidelines for Application of Microsurfacing Serviceability Indicators Urban (Heavy Traffic) Urban (Light Traffic) Preventive Deflection*, mm Distress, % Roughness, mm/km. Rutting, mm Thickness, mm Quantity of aggregate, kg/m 2 Type of grading (ISSA)** Periodic Preventive Periodic 0. 8 (max. ) 1. 2 (max. ) 5 (max) 10 (max. ) 5 (max. ) 10 (max. ) 2500 (Max. ) 3500 (max. ) 3000 (max. ) 4000 (max. ) 8 (max. ) 16 (max. ) 8 (max. ) 5 -6 7 -8 3 -4 6 -7 10 -12 14 -16 6 -8 12 -14 III II II 16 (max. ) *as measured with Benkelman beam, **International slurry seal association.

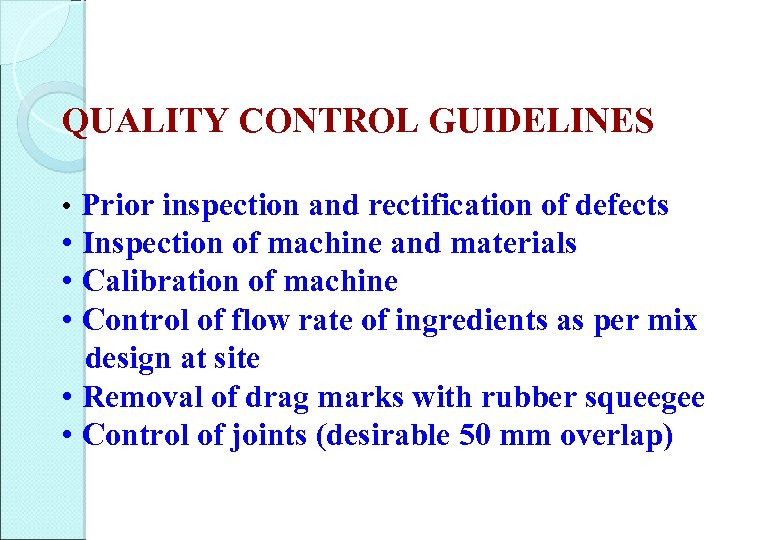

QUALITY CONTROL GUIDELINES • Prior inspection and rectification of defects • Inspection of machine and materials • Calibration of machine • Control of flow rate of ingredients as per mix design at site • Removal of drag marks with rubber squeegee • Control of joints (desirable 50 mm overlap)

QUALITY CONTROL GUIDELINES • Prior inspection and rectification of defects • Inspection of machine and materials • Calibration of machine • Control of flow rate of ingredients as per mix design at site • Removal of drag marks with rubber squeegee • Control of joints (desirable 50 mm overlap)

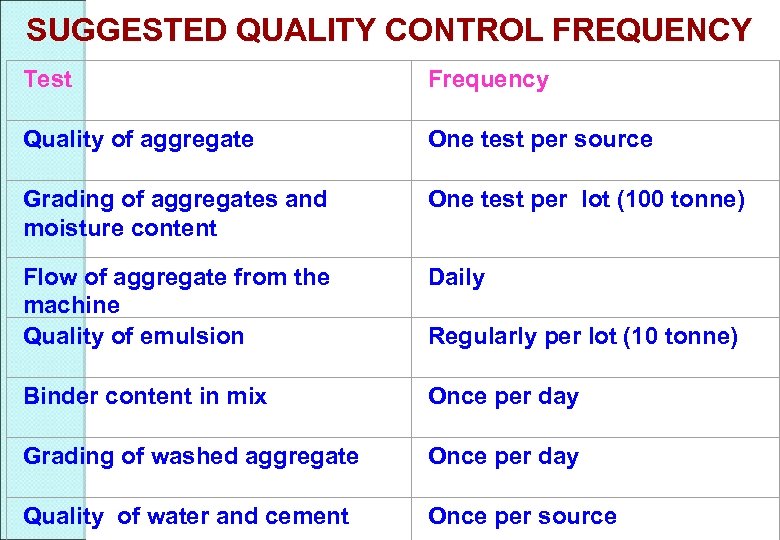

SUGGESTED QUALITY CONTROL FREQUENCY Test Frequency Quality of aggregate One test per source Grading of aggregates and moisture content One test per lot (100 tonne) Flow of aggregate from the machine Quality of emulsion Daily Binder content in mix Once per day Grading of washed aggregate Once per day Quality of water and cement Once per source Regularly per lot (10 tonne)

SUGGESTED QUALITY CONTROL FREQUENCY Test Frequency Quality of aggregate One test per source Grading of aggregates and moisture content One test per lot (100 tonne) Flow of aggregate from the machine Quality of emulsion Daily Binder content in mix Once per day Grading of washed aggregate Once per day Quality of water and cement Once per source Regularly per lot (10 tonne)

WEATHER LIMITATIONS • Not applicable for air temperature below 100 C • Applicable when pavement and air temperature above 80 C and rising • Not applicable when the finished product freezes within 24 hours

WEATHER LIMITATIONS • Not applicable for air temperature below 100 C • Applicable when pavement and air temperature above 80 C and rising • Not applicable when the finished product freezes within 24 hours

Tack Coat • Required only in case of extremely dry surfaces or concrete pavements • Tack coat should consist of one part emulsified bitumen / three parts water • Emulsified bitumen shall be slow setting grade • Should applied with a standard distributor • Distributor shall be capable of applying the diluted emulsion at a rate of 0. 2 to 0. 3 litre / m 2

Tack Coat • Required only in case of extremely dry surfaces or concrete pavements • Tack coat should consist of one part emulsified bitumen / three parts water • Emulsified bitumen shall be slow setting grade • Should applied with a standard distributor • Distributor shall be capable of applying the diluted emulsion at a rate of 0. 2 to 0. 3 litre / m 2

COST ASPECTS OF MICROSURFACING IN COMPARISON WITH CONVENTIONAL HOT MIX RENEWAL PER LANE – KM (3500 M 2 ) IS : Ø 40 mm Thick Bituminous Concrete ~ 5 lakhs Ø 8 mm Microsurfacing ~ 3 lakhs SAVINGS IN LAYING OF MICROSURFACING ØAggregates ~ 75 % Unit cost/m 2 Ø 8 mm thick Microsurfacing ~ Rs. 100 Ø 40 mm thick BC ~ Rs. Ø Savings ~ 35 %

COST ASPECTS OF MICROSURFACING IN COMPARISON WITH CONVENTIONAL HOT MIX RENEWAL PER LANE – KM (3500 M 2 ) IS : Ø 40 mm Thick Bituminous Concrete ~ 5 lakhs Ø 8 mm Microsurfacing ~ 3 lakhs SAVINGS IN LAYING OF MICROSURFACING ØAggregates ~ 75 % Unit cost/m 2 Ø 8 mm thick Microsurfacing ~ Rs. 100 Ø 40 mm thick BC ~ Rs. Ø Savings ~ 35 %

WORKS EXECUTED IN DELHI The Microsurfacing technology has been recently introduced in India and following roads in Delhi has been resurfaced with this technology: • Prithvi Raj Road • Windsor Palace Roundabout • August-kranti Marg • Outer Ring Road Number 26 • Joseph Tito Marg • Ashram Flyover • Obrai Hotel Flyover

WORKS EXECUTED IN DELHI The Microsurfacing technology has been recently introduced in India and following roads in Delhi has been resurfaced with this technology: • Prithvi Raj Road • Windsor Palace Roundabout • August-kranti Marg • Outer Ring Road Number 26 • Joseph Tito Marg • Ashram Flyover • Obrai Hotel Flyover

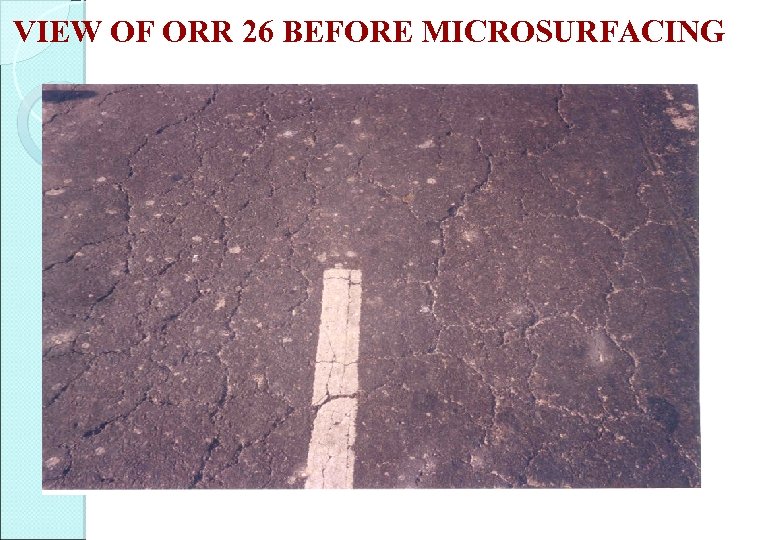

VIEW OF ORR 26 BEFORE MICROSURFACING

VIEW OF ORR 26 BEFORE MICROSURFACING

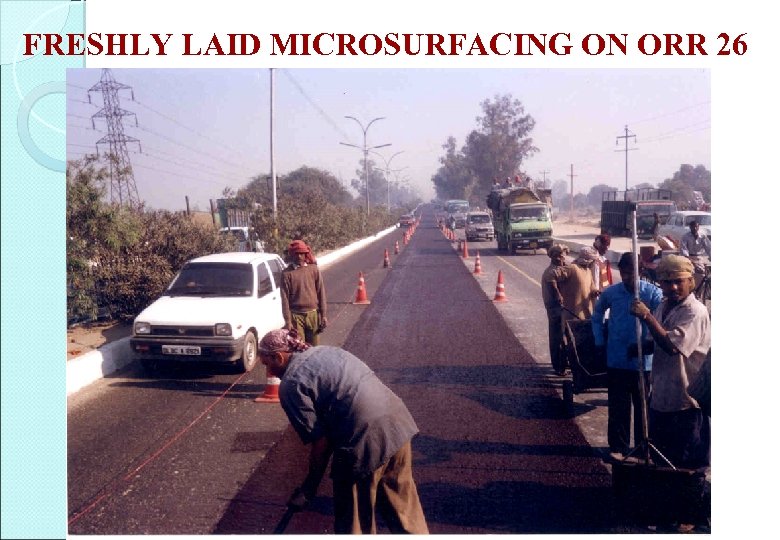

FRESHLY LAID MICROSURFACING ON ORR 26

FRESHLY LAID MICROSURFACING ON ORR 26

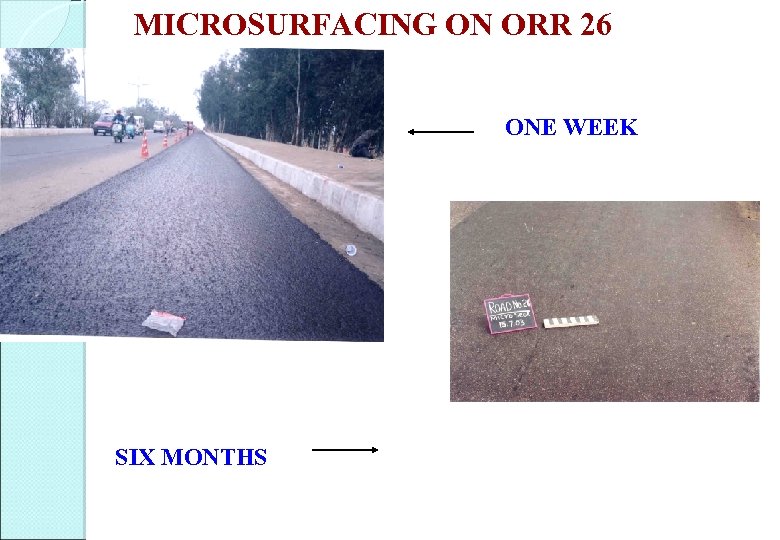

MICROSURFACING ON ORR 26 ONE WEEK SIX MONTHS

MICROSURFACING ON ORR 26 ONE WEEK SIX MONTHS

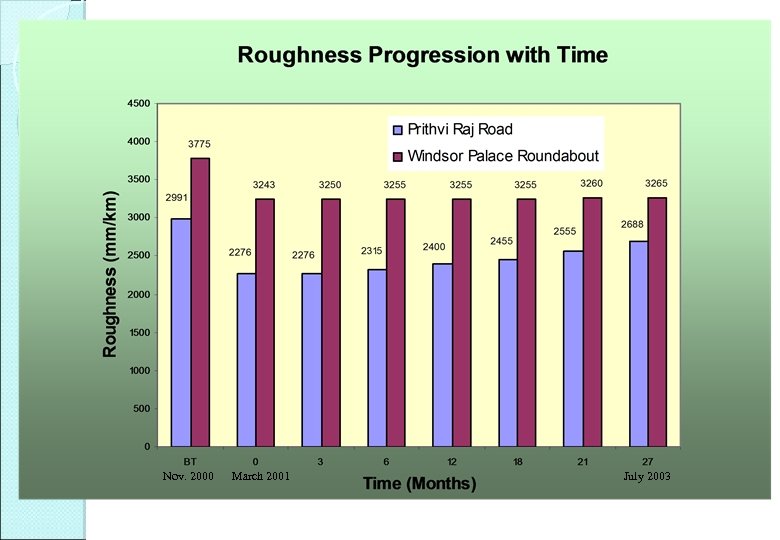

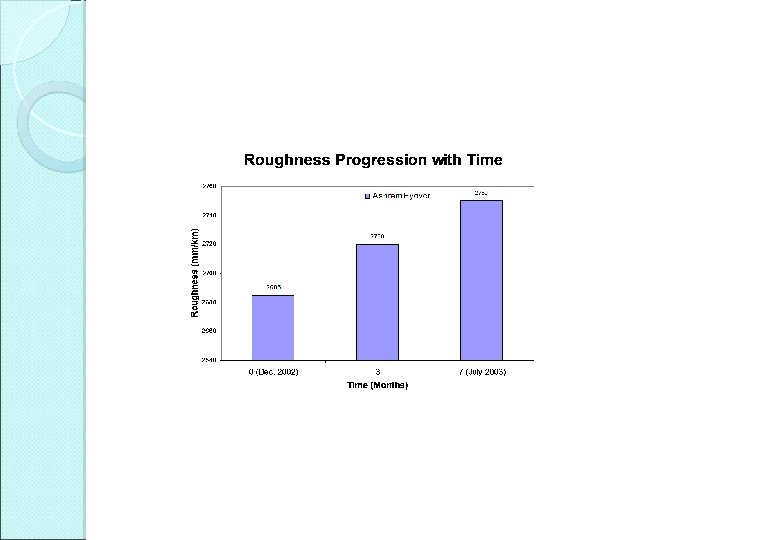

Nov. 2000 March 2001 July 2003

Nov. 2000 March 2001 July 2003

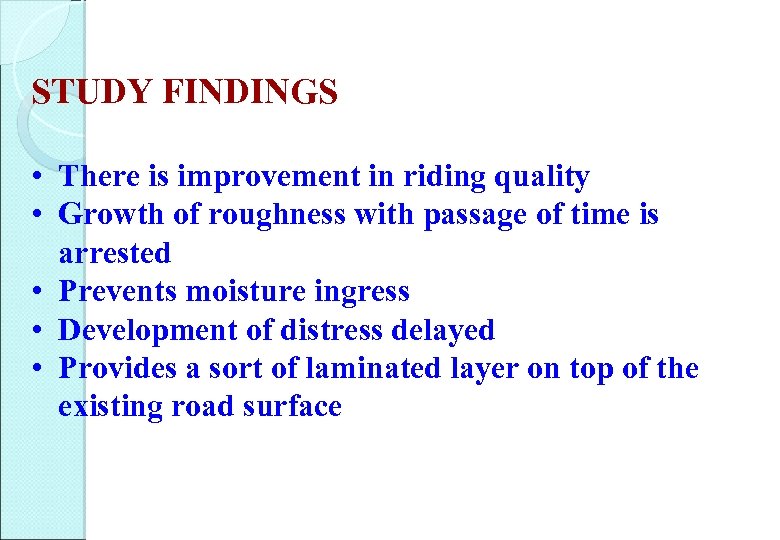

STUDY FINDINGS • There is improvement in riding quality • Growth of roughness with passage of time is arrested • Prevents moisture ingress • Development of distress delayed • Provides a sort of laminated layer on top of the existing road surface

STUDY FINDINGS • There is improvement in riding quality • Growth of roughness with passage of time is arrested • Prevents moisture ingress • Development of distress delayed • Provides a sort of laminated layer on top of the existing road surface

SURFACE CONDITION OF NH-44 BEFORE TREATMENT

SURFACE CONDITION OF NH-44 BEFORE TREATMENT

CALIBRATION OF MICROSURFACING PAVER IN PROGRESS

CALIBRATION OF MICROSURFACING PAVER IN PROGRESS

LAYING IN PROGRESS

LAYING IN PROGRESS

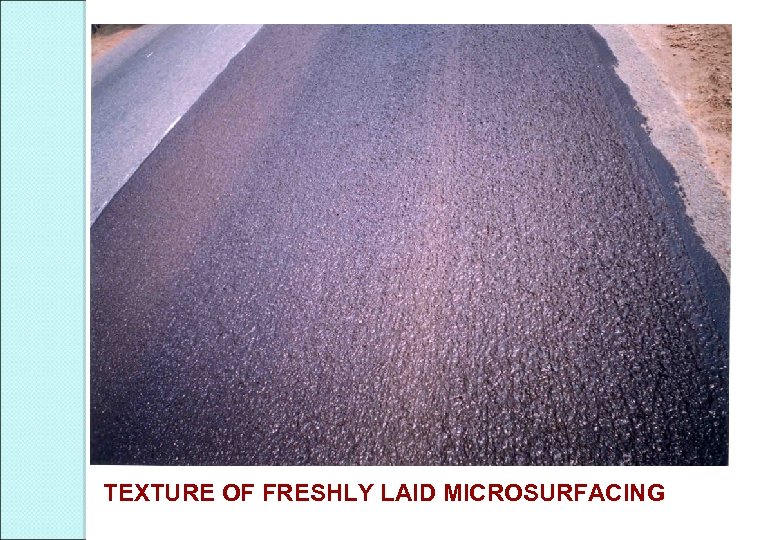

TEXTURE OF FRESHLY LAID MICROSURFACING

TEXTURE OF FRESHLY LAID MICROSURFACING

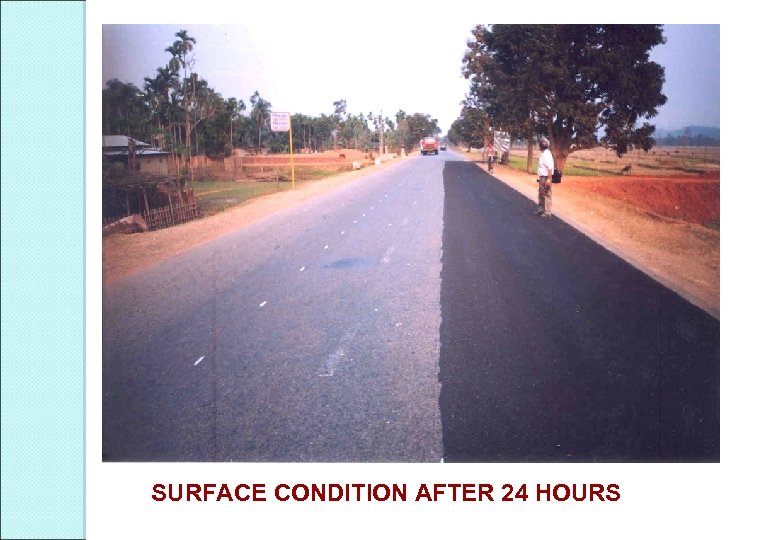

SURFACE CONDITION AFTER 24 HOURS

SURFACE CONDITION AFTER 24 HOURS

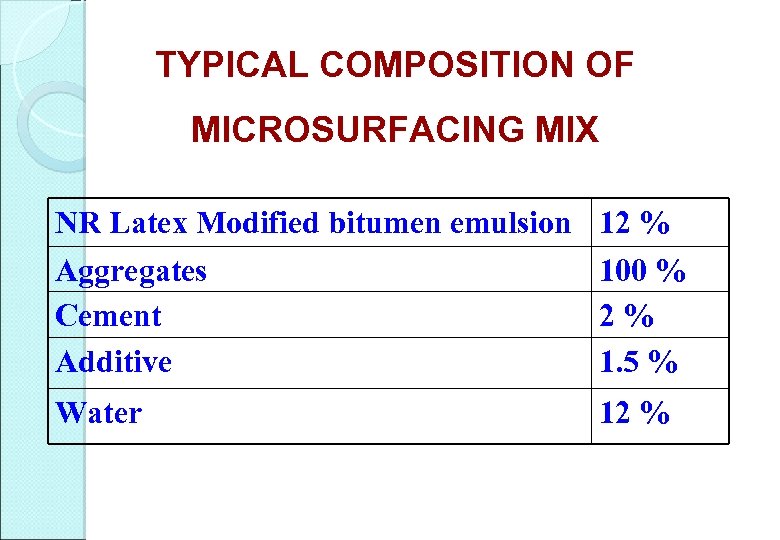

TYPICAL COMPOSITION OF MICROSURFACING MIX NR Latex Modified bitumen emulsion Aggregates Cement Additive 12 % 100 % 2 % 1. 5 % Water 12 %

TYPICAL COMPOSITION OF MICROSURFACING MIX NR Latex Modified bitumen emulsion Aggregates Cement Additive 12 % 100 % 2 % 1. 5 % Water 12 %

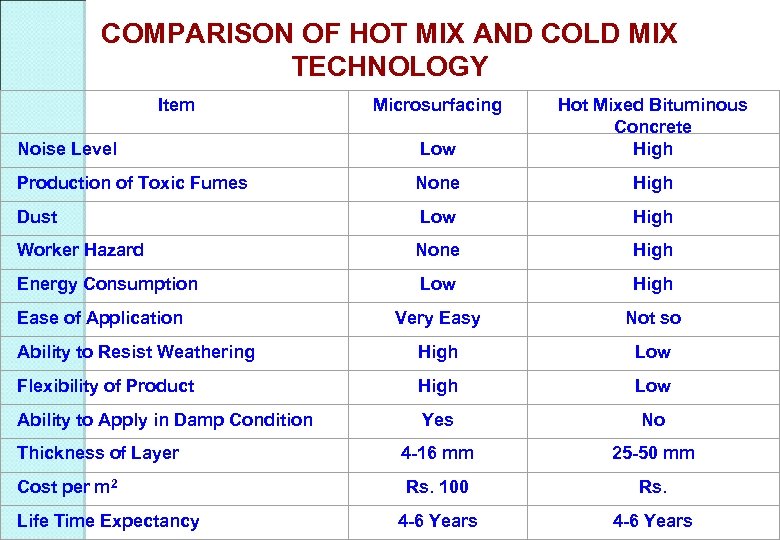

COMPARISON OF HOT MIX AND COLD MIX TECHNOLOGY Noise Level Low Hot Mixed Bituminous Concrete High Production of Toxic Fumes None High Dust Low High Worker Hazard None High Energy Consumption Low High Very Easy Not so Ability to Resist Weathering High Low Flexibility of Product High Low Ability to Apply in Damp Condition Yes No Thickness of Layer 4 -16 mm 25 -50 mm Cost per m 2 Rs. 100 Rs. 4 -6 Years Item Ease of Application Life Time Expectancy Microsurfacing

COMPARISON OF HOT MIX AND COLD MIX TECHNOLOGY Noise Level Low Hot Mixed Bituminous Concrete High Production of Toxic Fumes None High Dust Low High Worker Hazard None High Energy Consumption Low High Very Easy Not so Ability to Resist Weathering High Low Flexibility of Product High Low Ability to Apply in Damp Condition Yes No Thickness of Layer 4 -16 mm 25 -50 mm Cost per m 2 Rs. 100 Rs. 4 -6 Years Item Ease of Application Life Time Expectancy Microsurfacing

PWD has decided to resurface number of roads in Delhi using Microsurfacing. So far, the work has been executed on the following roads. v Siri Fort Road Link Road between NH-8 & Samalkha Chowk, Ambedkar Road New Delhi Road No. 29 Pashim Vihar Dr. K. N. Katju Marg Rohini Rao Tula Ram Marg Nizzamuddin Bridge to Noida More Road No. 42 A Deepali Chowk, Rohini. Ashram Chowk to Nizzamudin Rajghat (Ring Road) Captain Gaur Marg

PWD has decided to resurface number of roads in Delhi using Microsurfacing. So far, the work has been executed on the following roads. v Siri Fort Road Link Road between NH-8 & Samalkha Chowk, Ambedkar Road New Delhi Road No. 29 Pashim Vihar Dr. K. N. Katju Marg Rohini Rao Tula Ram Marg Nizzamuddin Bridge to Noida More Road No. 42 A Deepali Chowk, Rohini. Ashram Chowk to Nizzamudin Rajghat (Ring Road) Captain Gaur Marg

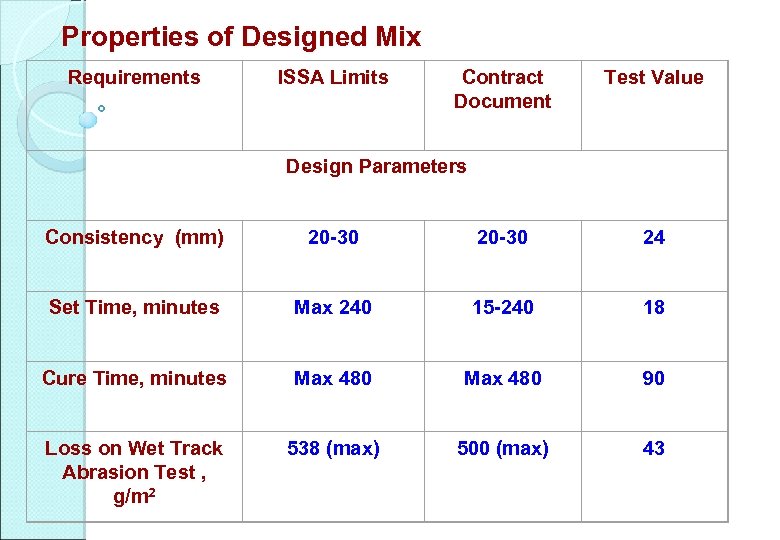

Properties of Designed Mix Requirements ISSA Limits Contract Document Test Value Design Parameters Consistency (mm) 20 -30 24 Set Time, minutes Max 240 15 -240 18 Cure Time, minutes Max 480 90 Loss on Wet Track Abrasion Test , g/m 2 538 (max) 500 (max) 43

Properties of Designed Mix Requirements ISSA Limits Contract Document Test Value Design Parameters Consistency (mm) 20 -30 24 Set Time, minutes Max 240 15 -240 18 Cure Time, minutes Max 480 90 Loss on Wet Track Abrasion Test , g/m 2 538 (max) 500 (max) 43

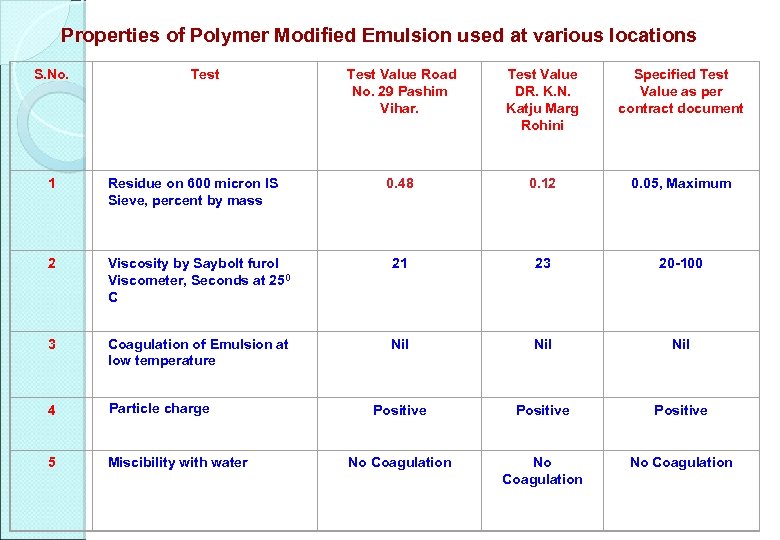

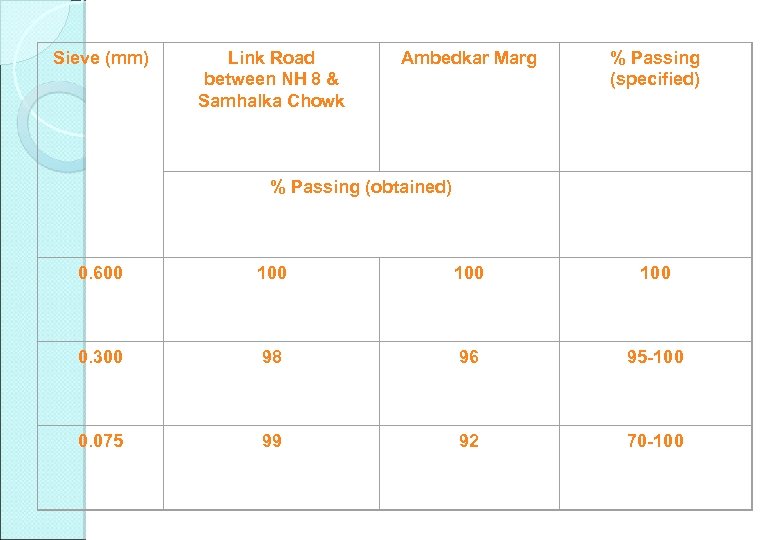

Properties of Polymer Modified Emulsion used at various locations S. No. Test Value Road No. 29 Pashim Vihar. Test Value DR. K. N. Katju Marg Rohini Specified Test Value as per contract document 0. 48 0. 12 0. 05, Maximum 1 Residue on 600 micron IS Sieve, percent by mass 2 Viscosity by Saybolt furol Viscometer, Seconds at 250 C 21 23 20 -100 3 Coagulation of Emulsion at low temperature Nil Nil 4 Particle charge Positive 5 Miscibility with water No Coagulation

Properties of Polymer Modified Emulsion used at various locations S. No. Test Value Road No. 29 Pashim Vihar. Test Value DR. K. N. Katju Marg Rohini Specified Test Value as per contract document 0. 48 0. 12 0. 05, Maximum 1 Residue on 600 micron IS Sieve, percent by mass 2 Viscosity by Saybolt furol Viscometer, Seconds at 250 C 21 23 20 -100 3 Coagulation of Emulsion at low temperature Nil Nil 4 Particle charge Positive 5 Miscibility with water No Coagulation

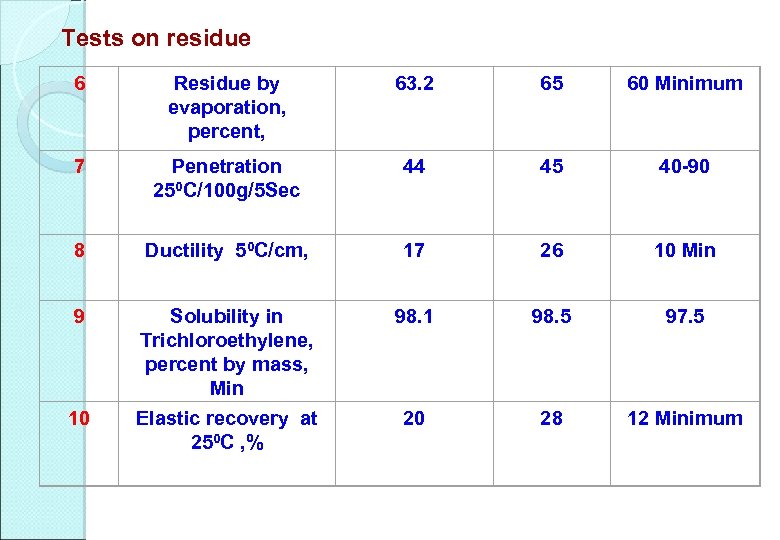

Tests on residue 6 Residue by evaporation, percent, 63. 2 65 60 Minimum 7 Penetration 250 C/100 g/5 Sec 44 45 40 -90 8 Ductility 50 C/cm, 17 26 10 Min 9 Solubility in Trichloroethylene, percent by mass, Min Elastic recovery at 250 C , % 98. 1 98. 5 97. 5 20 28 12 Minimum 10

Tests on residue 6 Residue by evaporation, percent, 63. 2 65 60 Minimum 7 Penetration 250 C/100 g/5 Sec 44 45 40 -90 8 Ductility 50 C/cm, 17 26 10 Min 9 Solubility in Trichloroethylene, percent by mass, Min Elastic recovery at 250 C , % 98. 1 98. 5 97. 5 20 28 12 Minimum 10

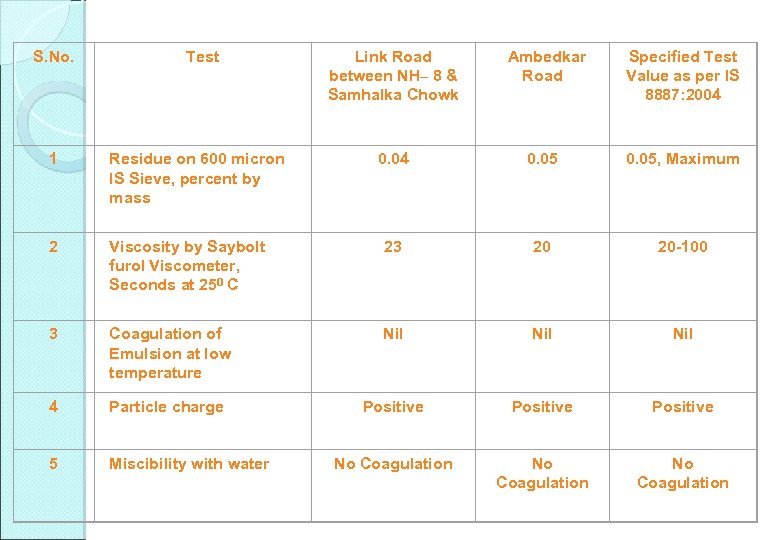

S. No. Test Link Road between NH– 8 & Samhalka Chowk Ambedkar Road Specified Test Value as per IS 8887: 2004 0. 05, Maximum 1 Residue on 600 micron IS Sieve, percent by mass 2 Viscosity by Saybolt furol Viscometer, Seconds at 250 C 23 20 20 -100 3 Coagulation of Emulsion at low temperature Nil Nil 4 Particle charge Positive 5 Miscibility with water No Coagulation

S. No. Test Link Road between NH– 8 & Samhalka Chowk Ambedkar Road Specified Test Value as per IS 8887: 2004 0. 05, Maximum 1 Residue on 600 micron IS Sieve, percent by mass 2 Viscosity by Saybolt furol Viscometer, Seconds at 250 C 23 20 20 -100 3 Coagulation of Emulsion at low temperature Nil Nil 4 Particle charge Positive 5 Miscibility with water No Coagulation

Tests on residue 6 Residue by evaporation, percent, 62. 3 61 60 Minimum 7 Penetration 250 C/100 g/5 Sec 40 48 40 -90 8 Ductility 50 C/cm, 15 13 10 Min 9 Solubility in Trichloroethylene, percent by mass, Min 97. 8 98 97. 5 10 Elastic recovery, 250 C , % 21 16 12 Minimum

Tests on residue 6 Residue by evaporation, percent, 62. 3 61 60 Minimum 7 Penetration 250 C/100 g/5 Sec 40 48 40 -90 8 Ductility 50 C/cm, 15 13 10 Min 9 Solubility in Trichloroethylene, percent by mass, Min 97. 8 98 97. 5 10 Elastic recovery, 250 C , % 21 16 12 Minimum

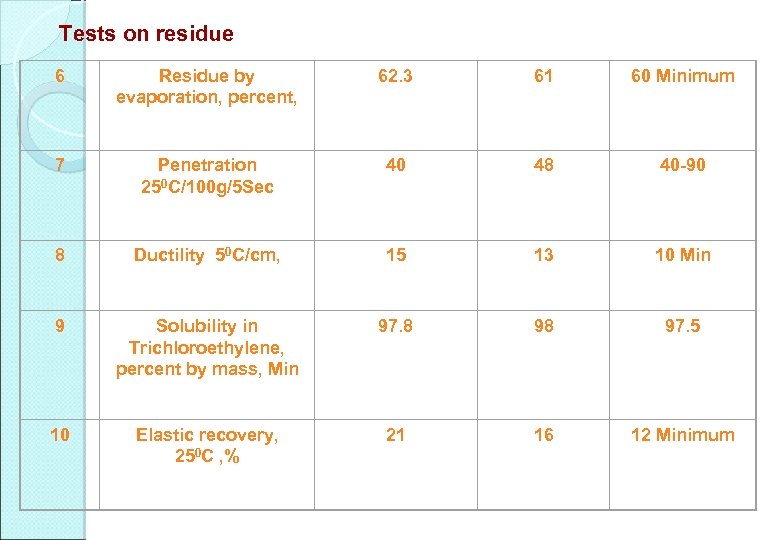

Grading obtained for mineral filler (Cement) Sieve (mm) Road No. 29 Pashim Vihar DR. K. N. Katju Marg, Rohini % Passing (specified) % Passing (obtained) 0. 600 100 100 0. 300 100 95 -100 0. 075 91 93 70 -100

Grading obtained for mineral filler (Cement) Sieve (mm) Road No. 29 Pashim Vihar DR. K. N. Katju Marg, Rohini % Passing (specified) % Passing (obtained) 0. 600 100 100 0. 300 100 95 -100 0. 075 91 93 70 -100

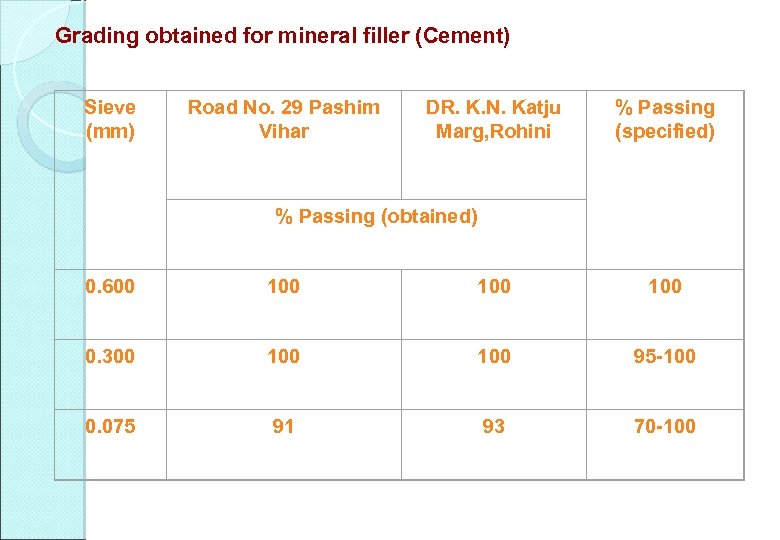

Sieve (mm) Link Road between NH 8 & Samhalka Chowk Ambedkar Marg % Passing (obtained) % Passing (specified) 0. 600 100 100 0. 300 98 96 95 -100 0. 075 99 92 70 -100

Sieve (mm) Link Road between NH 8 & Samhalka Chowk Ambedkar Marg % Passing (obtained) % Passing (specified) 0. 600 100 100 0. 300 98 96 95 -100 0. 075 99 92 70 -100

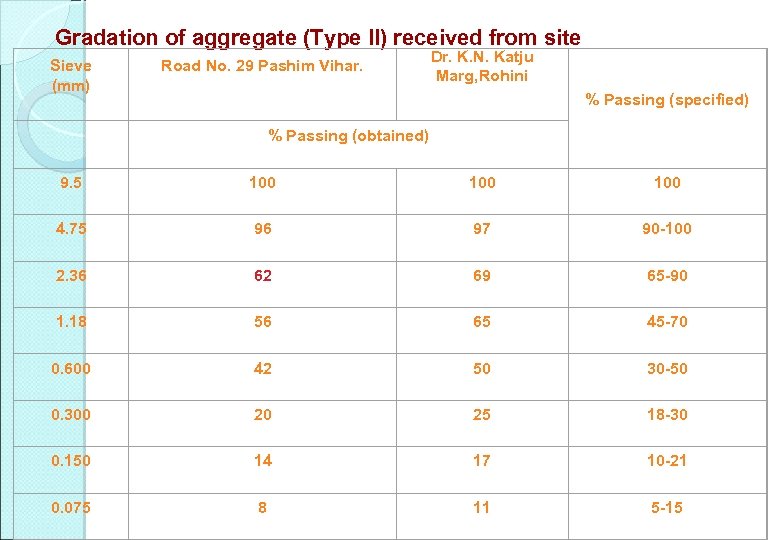

Gradation of aggregate (Type II) received from site Dr. K. N. Katju Sieve Road No. 29 Pashim Vihar. Marg, Rohini (mm) % Passing (specified) % Passing (obtained) 9. 5 100 100 4. 75 96 97 90 -100 2. 36 62 69 65 -90 1. 18 56 65 45 -70 0. 600 42 50 30 -50 0. 300 20 25 18 -30 0. 150 14 17 10 -21 0. 075 8 11 5 -15

Gradation of aggregate (Type II) received from site Dr. K. N. Katju Sieve Road No. 29 Pashim Vihar. Marg, Rohini (mm) % Passing (specified) % Passing (obtained) 9. 5 100 100 4. 75 96 97 90 -100 2. 36 62 69 65 -90 1. 18 56 65 45 -70 0. 600 42 50 30 -50 0. 300 20 25 18 -30 0. 150 14 17 10 -21 0. 075 8 11 5 -15

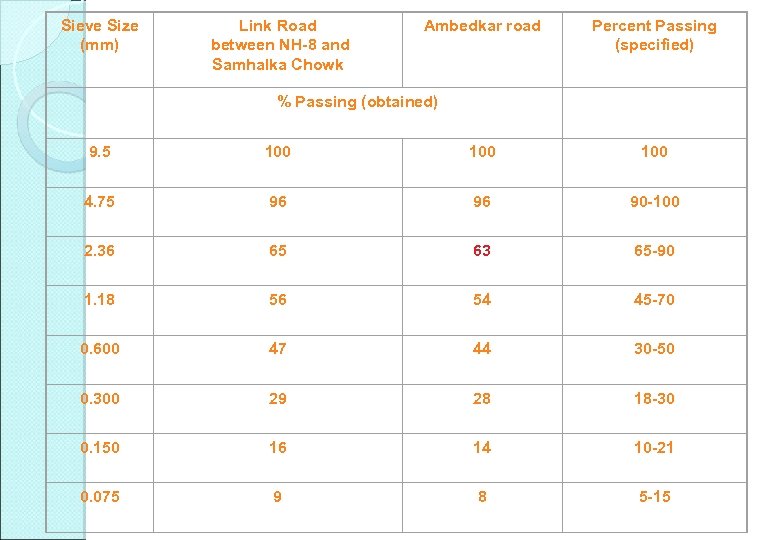

Sieve Size (mm) Link Road between NH-8 and Samhalka Chowk Ambedkar road % Passing (obtained) Percent Passing (specified) 9. 5 100 4. 75 96 96 90 -100 2. 36 65 63 65 -90 1. 18 56 54 45 -70 0. 600 47 44 30 -50 0. 300 29 28 18 -30 0. 150 16 14 10 -21 0. 075 100 9 8 5 -15

Sieve Size (mm) Link Road between NH-8 and Samhalka Chowk Ambedkar road % Passing (obtained) Percent Passing (specified) 9. 5 100 4. 75 96 96 90 -100 2. 36 65 63 65 -90 1. 18 56 54 45 -70 0. 600 47 44 30 -50 0. 300 29 28 18 -30 0. 150 16 14 10 -21 0. 075 100 9 8 5 -15

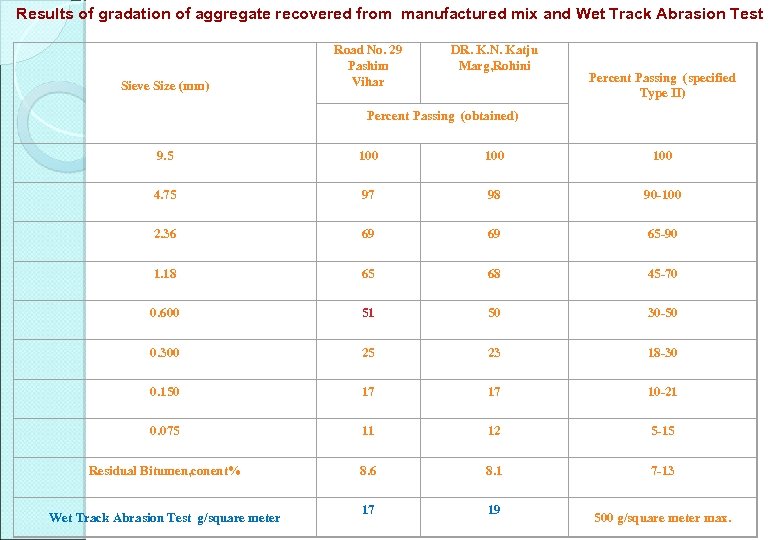

Results of gradation of aggregate recovered from manufactured mix and Wet Track Abrasion Test Sieve Size (mm) Road No. 29 Pashim Vihar DR. K. N. Katju Marg, Rohini Percent Passing (specified Type II) Percent Passing (obtained) 9. 5 100 100 4. 75 97 98 90 -100 2. 36 69 69 65 -90 1. 18 65 68 45 -70 0. 600 51 50 30 -50 0. 300 25 23 18 -30 0. 150 17 17 10 -21 0. 075 11 12 5 -15 Residual Bitumen, conent% 8. 6 8. 1 7 -13 17 19 Wet Track Abrasion Test g/square meter 500 g/square meter max.

Results of gradation of aggregate recovered from manufactured mix and Wet Track Abrasion Test Sieve Size (mm) Road No. 29 Pashim Vihar DR. K. N. Katju Marg, Rohini Percent Passing (specified Type II) Percent Passing (obtained) 9. 5 100 100 4. 75 97 98 90 -100 2. 36 69 69 65 -90 1. 18 65 68 45 -70 0. 600 51 50 30 -50 0. 300 25 23 18 -30 0. 150 17 17 10 -21 0. 075 11 12 5 -15 Residual Bitumen, conent% 8. 6 8. 1 7 -13 17 19 Wet Track Abrasion Test g/square meter 500 g/square meter max.

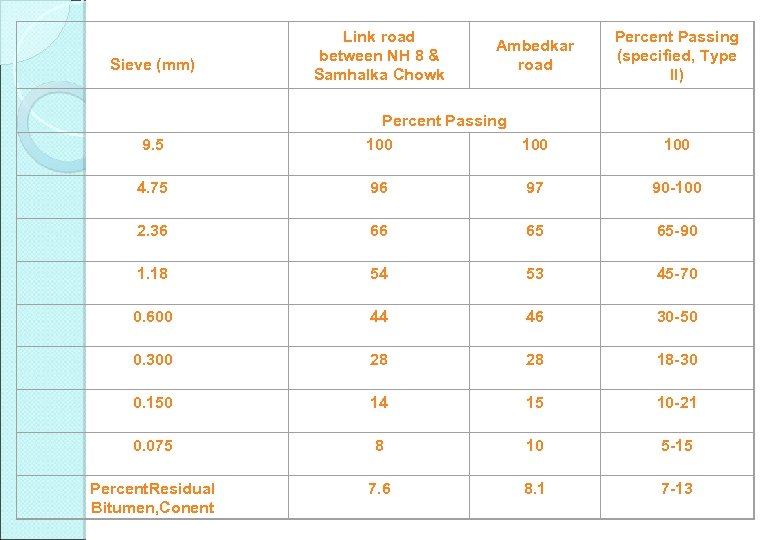

Sieve (mm) Link road between NH 8 & Samhalka Chowk Ambedkar road Percent Passing (specified, Type II) Percent Passing 9. 5 100 100 4. 75 96 97 90 -100 2. 36 66 65 65 -90 1. 18 54 53 45 -70 0. 600 44 46 30 -50 0. 300 28 28 18 -30 0. 150 14 15 10 -21 0. 075 8 10 5 -15 Percent. Residual Bitumen, Conent 7. 6 8. 1 7 -13

Sieve (mm) Link road between NH 8 & Samhalka Chowk Ambedkar road Percent Passing (specified, Type II) Percent Passing 9. 5 100 100 4. 75 96 97 90 -100 2. 36 66 65 65 -90 1. 18 54 53 45 -70 0. 600 44 46 30 -50 0. 300 28 28 18 -30 0. 150 14 15 10 -21 0. 075 8 10 5 -15 Percent. Residual Bitumen, Conent 7. 6 8. 1 7 -13

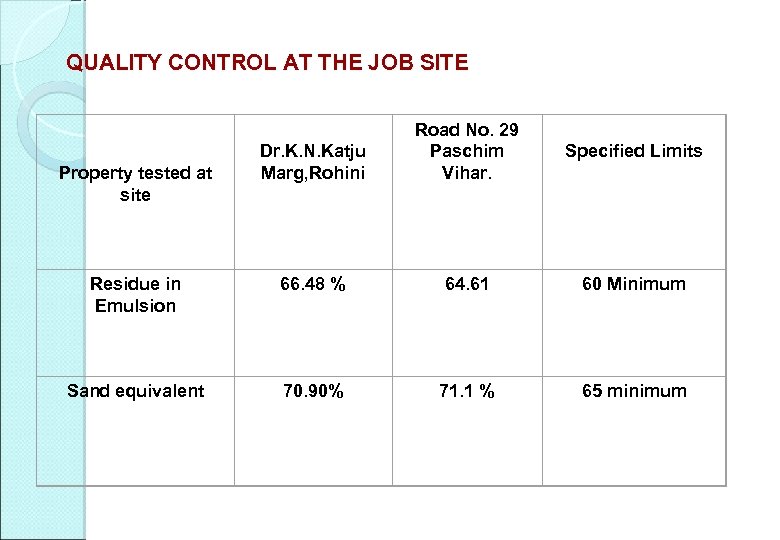

QUALITY CONTROL AT THE JOB SITE Dr. K. N. Katju Marg, Rohini Road No. 29 Paschim Vihar. Residue in Emulsion 66. 48 % 64. 61 60 Minimum Sand equivalent 70. 90% 71. 1 % 65 minimum Property tested at site Specified Limits

QUALITY CONTROL AT THE JOB SITE Dr. K. N. Katju Marg, Rohini Road No. 29 Paschim Vihar. Residue in Emulsion 66. 48 % 64. 61 60 Minimum Sand equivalent 70. 90% 71. 1 % 65 minimum Property tested at site Specified Limits

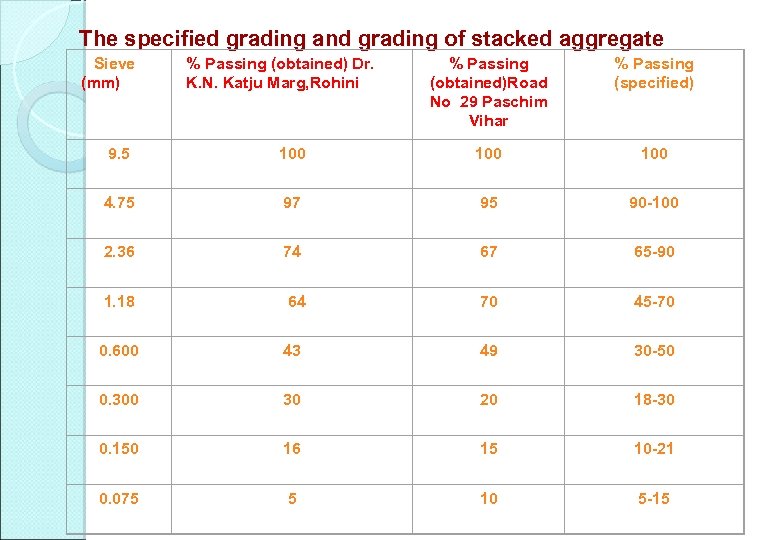

The specified grading and grading of stacked aggregate Sieve (mm) % Passing (obtained) Dr. K. N. Katju Marg, Rohini % Passing (obtained)Road No 29 Paschim Vihar % Passing (specified) 9. 5 100 100 4. 75 97 95 90 -100 2. 36 74 67 65 -90 70 45 -70 1. 18 64 0. 600 43 49 30 -50 0. 300 30 20 18 -30 0. 150 16 15 10 -21 0. 075 5 10 5 -15

The specified grading and grading of stacked aggregate Sieve (mm) % Passing (obtained) Dr. K. N. Katju Marg, Rohini % Passing (obtained)Road No 29 Paschim Vihar % Passing (specified) 9. 5 100 100 4. 75 97 95 90 -100 2. 36 74 67 65 -90 70 45 -70 1. 18 64 0. 600 43 49 30 -50 0. 300 30 20 18 -30 0. 150 16 15 10 -21 0. 075 5 10 5 -15

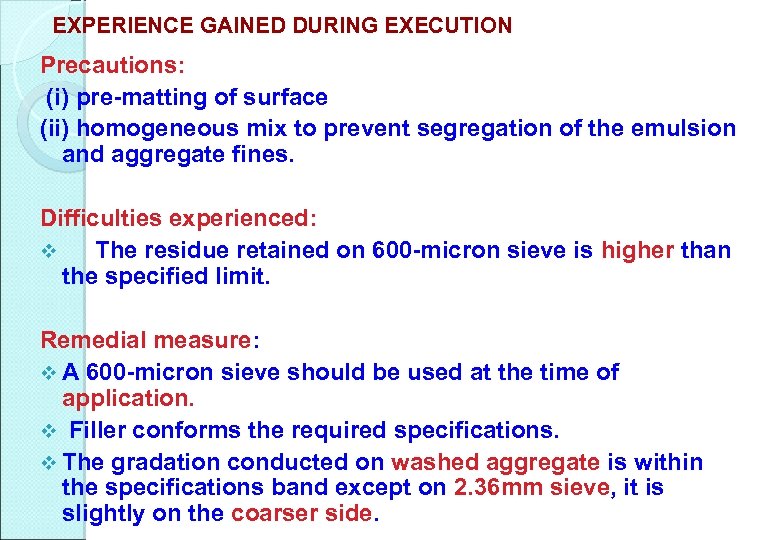

EXPERIENCE GAINED DURING EXECUTION Precautions: (i) pre-matting of surface (ii) homogeneous mix to prevent segregation of the emulsion and aggregate fines. Difficulties experienced: v The residue retained on 600 -micron sieve is higher than the specified limit. Remedial measure: v A 600 -micron sieve should be used at the time of application. v Filler conforms the required specifications. v The gradation conducted on washed aggregate is within the specifications band except on 2. 36 mm sieve, it is slightly on the coarser side.

EXPERIENCE GAINED DURING EXECUTION Precautions: (i) pre-matting of surface (ii) homogeneous mix to prevent segregation of the emulsion and aggregate fines. Difficulties experienced: v The residue retained on 600 -micron sieve is higher than the specified limit. Remedial measure: v A 600 -micron sieve should be used at the time of application. v Filler conforms the required specifications. v The gradation conducted on washed aggregate is within the specifications band except on 2. 36 mm sieve, it is slightly on the coarser side.

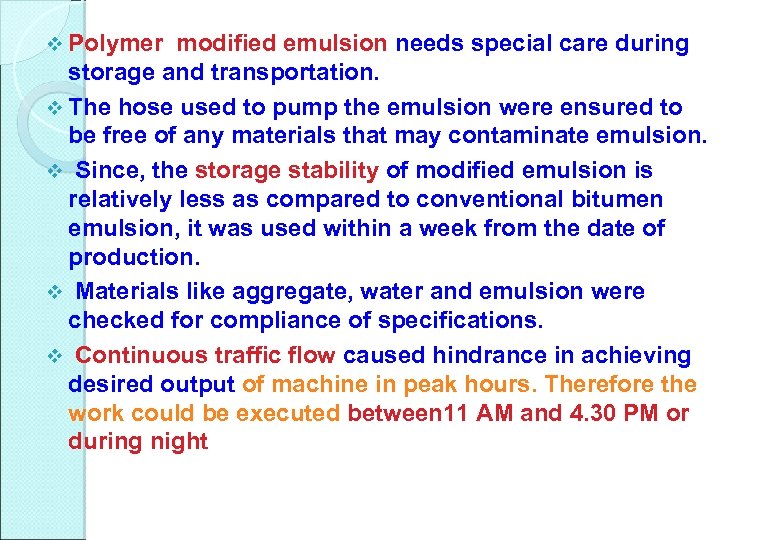

v Polymer modified emulsion needs special care during storage and transportation. v The hose used to pump the emulsion were ensured to be free of any materials that may contaminate emulsion. v Since, the storage stability of modified emulsion is relatively less as compared to conventional bitumen emulsion, it was used within a week from the date of production. v Materials like aggregate, water and emulsion were checked for compliance of specifications. v Continuous traffic flow caused hindrance in achieving desired output of machine in peak hours. Therefore the work could be executed between 11 AM and 4. 30 PM or during night

v Polymer modified emulsion needs special care during storage and transportation. v The hose used to pump the emulsion were ensured to be free of any materials that may contaminate emulsion. v Since, the storage stability of modified emulsion is relatively less as compared to conventional bitumen emulsion, it was used within a week from the date of production. v Materials like aggregate, water and emulsion were checked for compliance of specifications. v Continuous traffic flow caused hindrance in achieving desired output of machine in peak hours. Therefore the work could be executed between 11 AM and 4. 30 PM or during night

KN Katzu Marg Before Microsurfacing

KN Katzu Marg Before Microsurfacing

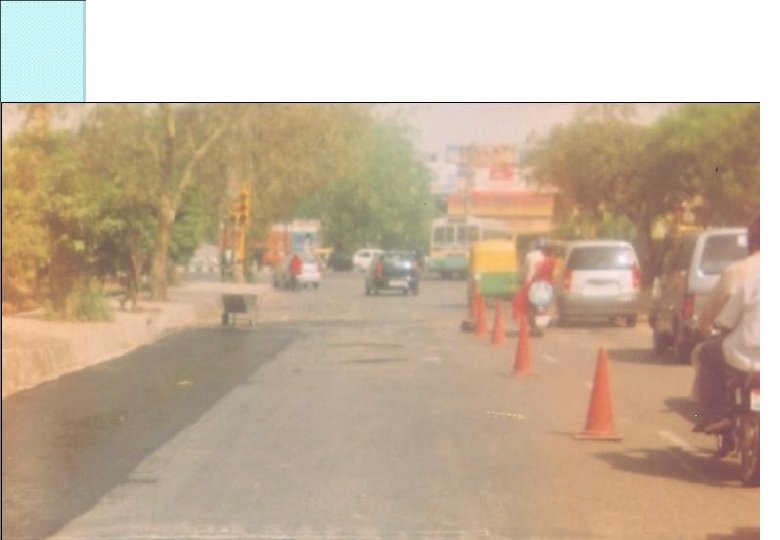

KN Katzu Marg Microsurfacing Execution

KN Katzu Marg Microsurfacing Execution

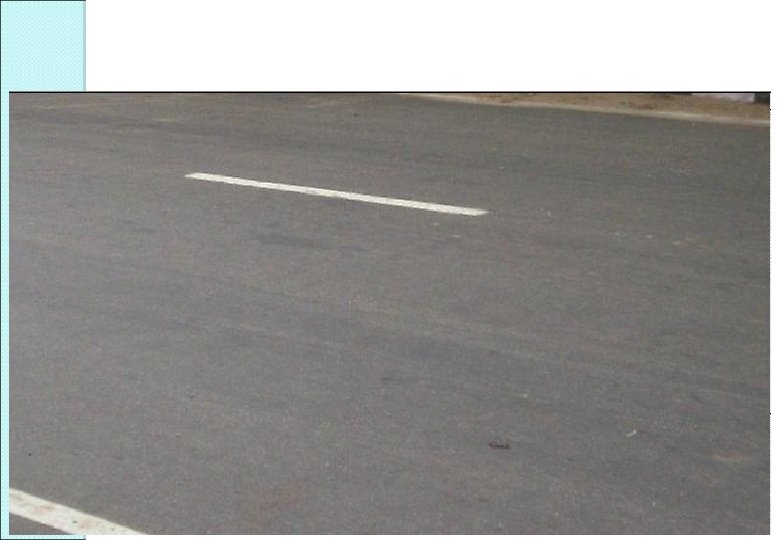

KN Katzu Marg After Microsurfacing

KN Katzu Marg After Microsurfacing

Road No. 29 Before Microsurfacing

Road No. 29 Before Microsurfacing

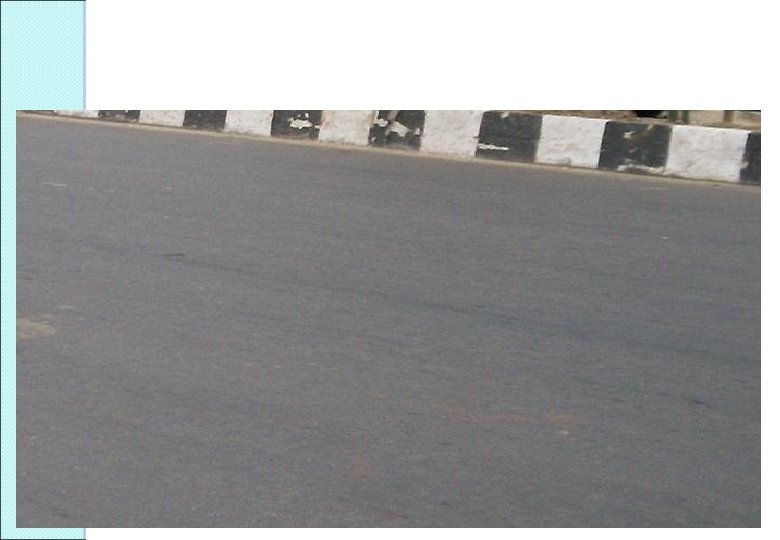

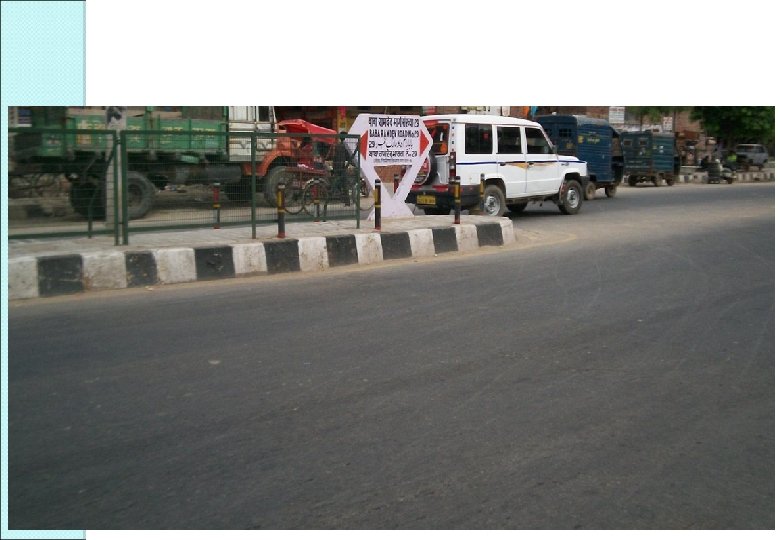

Road No. 29 After Microsurfacing

Road No. 29 After Microsurfacing

The technology has been demonstrated on eleven sections and various locations laid in Delhi. Area covered; 6. 0 Lakh Sqm, Length ; 30 Km. approx Performance of these sections will be monitored for three years as a part of an in-house R & D project

The technology has been demonstrated on eleven sections and various locations laid in Delhi. Area covered; 6. 0 Lakh Sqm, Length ; 30 Km. approx Performance of these sections will be monitored for three years as a part of an in-house R & D project

CONCLUSIONS The ingredients and manufactured mix have complied to specifications cited in the contract document finalized by PWD, Delhi as well as ISSA specifications. Effective quality control plays a vital role in success of Microsurfacing projects. Microsurfacing could be an alternative to thin hot mix renewals in maintenance of urban roads in environment friendly manner and to save energy.

CONCLUSIONS The ingredients and manufactured mix have complied to specifications cited in the contract document finalized by PWD, Delhi as well as ISSA specifications. Effective quality control plays a vital role in success of Microsurfacing projects. Microsurfacing could be an alternative to thin hot mix renewals in maintenance of urban roads in environment friendly manner and to save energy.

CONCLUSIONS • Its an environmental friendly technology • Energy efficient road maintenance technology • Savings in the materials • Cost effective application • Completely mechanized operation • Widely applicable for urban roads due to its ability in thin layer application • Can cover large lengths in a day (a typical M. S. Machine can lay about 3. 5 lane Km in 8 hours) • Life expectancy is about 4 -6 years

CONCLUSIONS • Its an environmental friendly technology • Energy efficient road maintenance technology • Savings in the materials • Cost effective application • Completely mechanized operation • Widely applicable for urban roads due to its ability in thin layer application • Can cover large lengths in a day (a typical M. S. Machine can lay about 3. 5 lane Km in 8 hours) • Life expectancy is about 4 -6 years

THANK YOU

THANK YOU