Lesson 11.4B3Fermenters.pptx

- Количество слайдов: 24

Microbiology and Biotechnology Lesson 11. 4 B 3 April 11, 2014

Learning Objectives Students will be able to understand the process of fermentation. Students will be able to describe the components of a fermenter and the function of the parts.

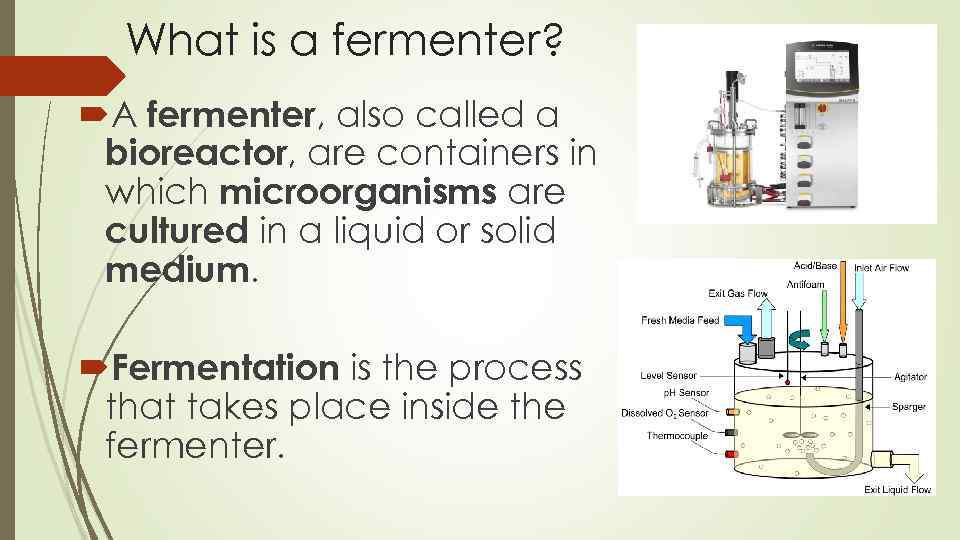

What is a fermenter? A fermenter, also called a bioreactor, are containers in which microorganisms are cultured in a liquid or solid medium. Fermentation is the process that takes place inside the fermenter.

Some basics about fermenters: Contents are stirred in most fermenters The product is = the cells (biomass), or = useful cell product conditions must be sterile to avoid contaminating the culture Scale-up - is growing a large enough sample to start the fermenter Inoculation - is adding the scaled up amount of the culture to the fermenter Inside the fermenter, the organism grows and multiplies using the nutrient medium

Inoculating and cells growing in medium

Equipment The fermenter is often made of stainless steel to avoid corrosion. What are other reasons stainless steel is good for Culturing microorganisms? corrosion

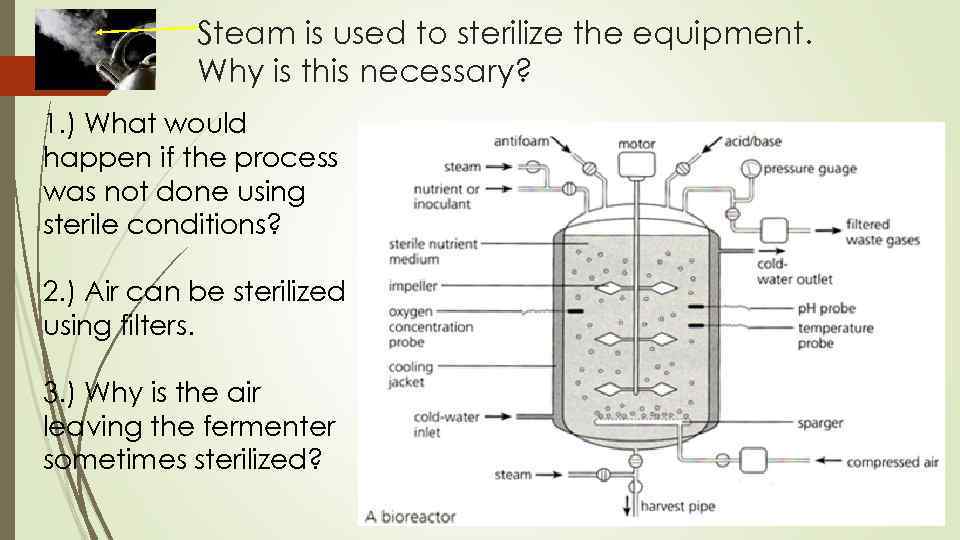

Steam is used to sterilize the equipment. Why is this necessary? 1. ) What would happen if the process was not done using sterile conditions? 2. ) Air can be sterilized using filters. 3. ) Why is the air leaving the fermenter sometimes sterilized?

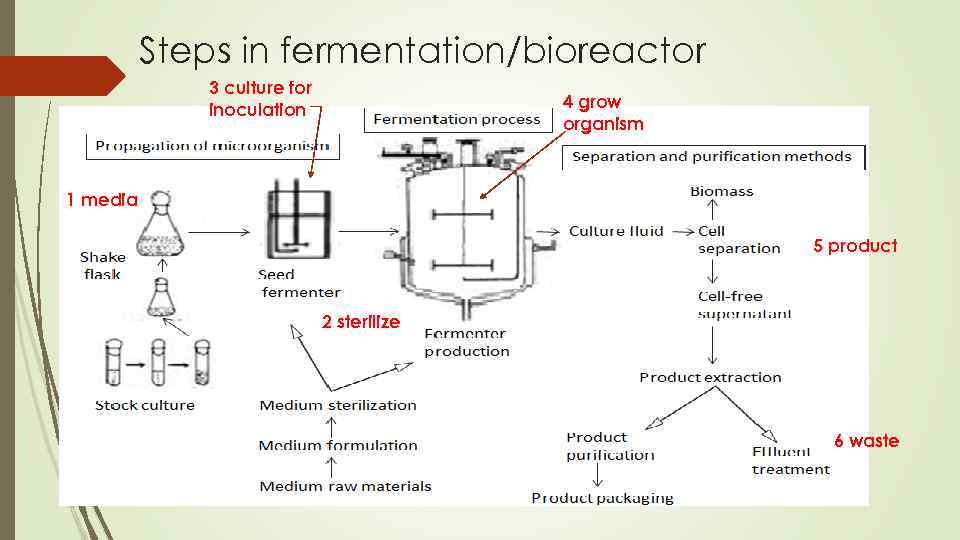

Steps in fermentation/bioreactor 3 culture for inoculation 4 grow organism 1 media 5 product 2 sterilize 6 waste

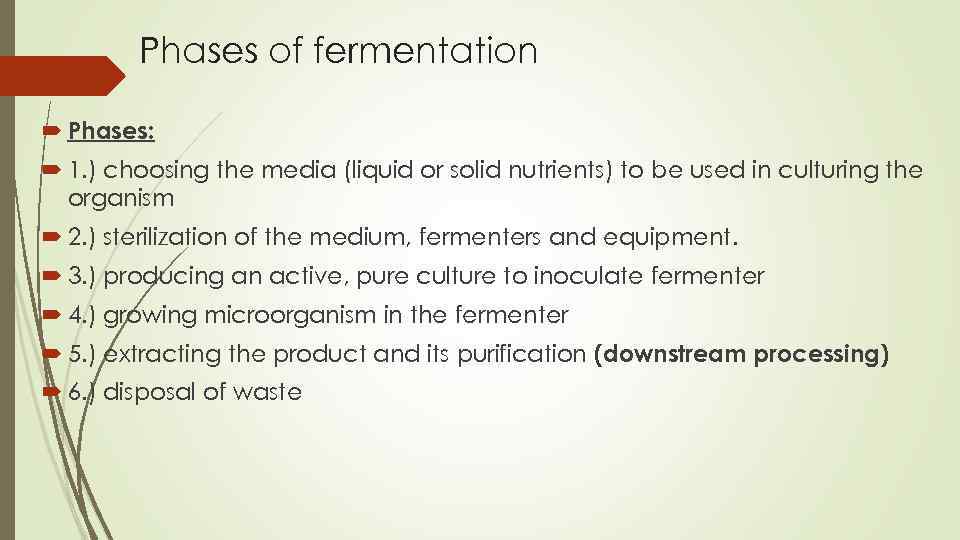

Phases of fermentation Phases: 1. ) choosing the media (liquid or solid nutrients) to be used in culturing the organism 2. ) sterilization of the medium, fermenters and equipment. 3. ) producing an active, pure culture to inoculate fermenter 4. ) growing microorganism in the fermenter 5. ) extracting the product and its purification (downstream processing) 6. ) disposal of waste

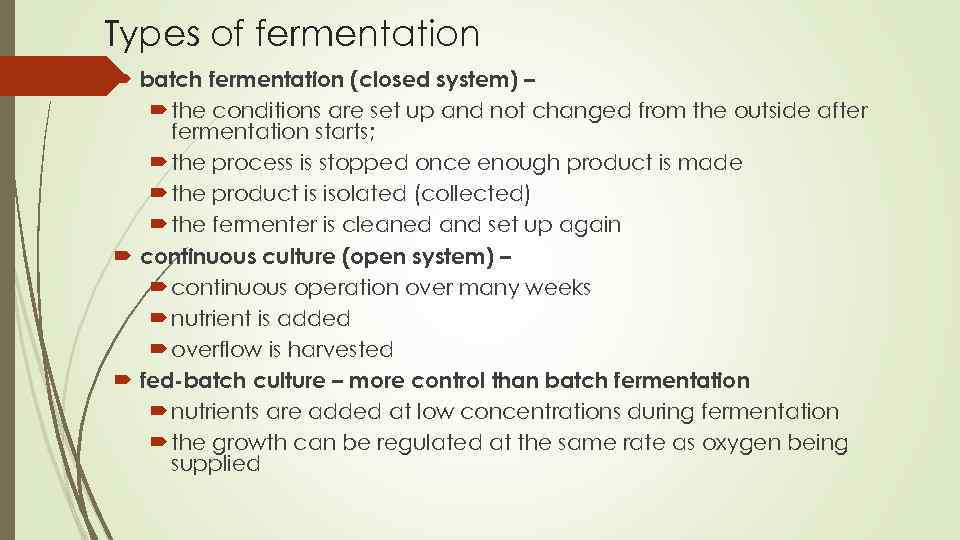

Types of fermentation batch fermentation (closed system) – the conditions are set up and not changed from the outside after fermentation starts; the process is stopped once enough product is made the product is isolated (collected) the fermenter is cleaned and set up again continuous culture (open system) – continuous operation over many weeks nutrient is added overflow is harvested fed-batch culture – more control than batch fermentation nutrients are added at low concentrations during fermentation the growth can be regulated at the same rate as oxygen being supplied

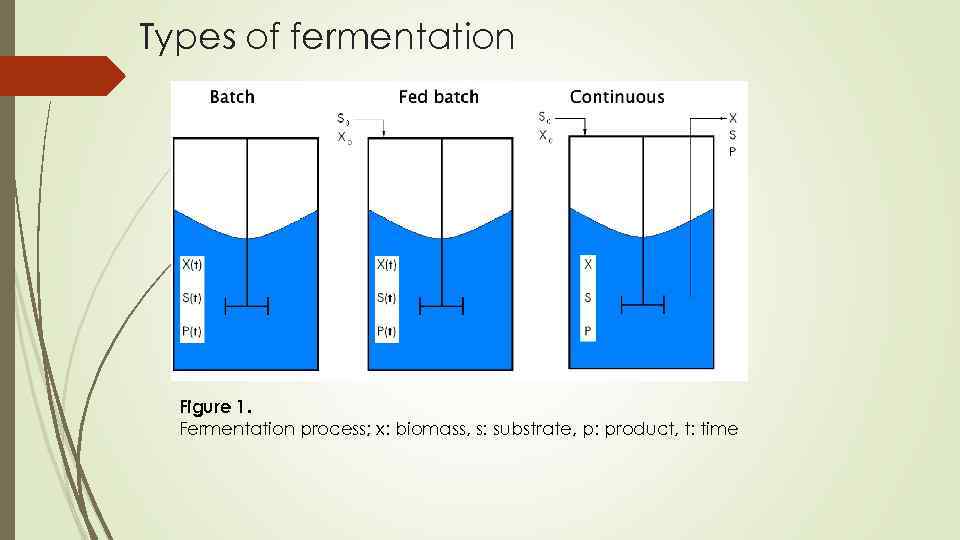

Types of fermentation Figure 1. Fermentation process; x: biomass, s: substrate, p: product, t: time

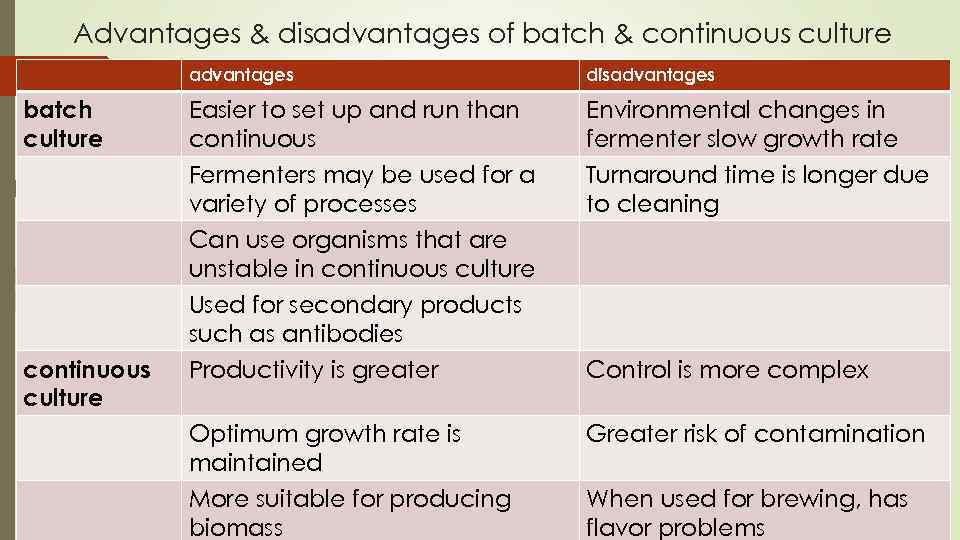

Advantages & disadvantages of batch & continuous culture advantages Easier to set up and run than continuous Environmental changes in fermenter slow growth rate Fermenters may be used for a variety of processes batch culture disadvantages Turnaround time is longer due to cleaning Can use organisms that are unstable in continuous culture Used for secondary products such as antibodies continuous culture Productivity is greater Control is more complex Optimum growth rate is maintained More suitable for producing biomass Greater risk of contamination When used for brewing, has flavor problems

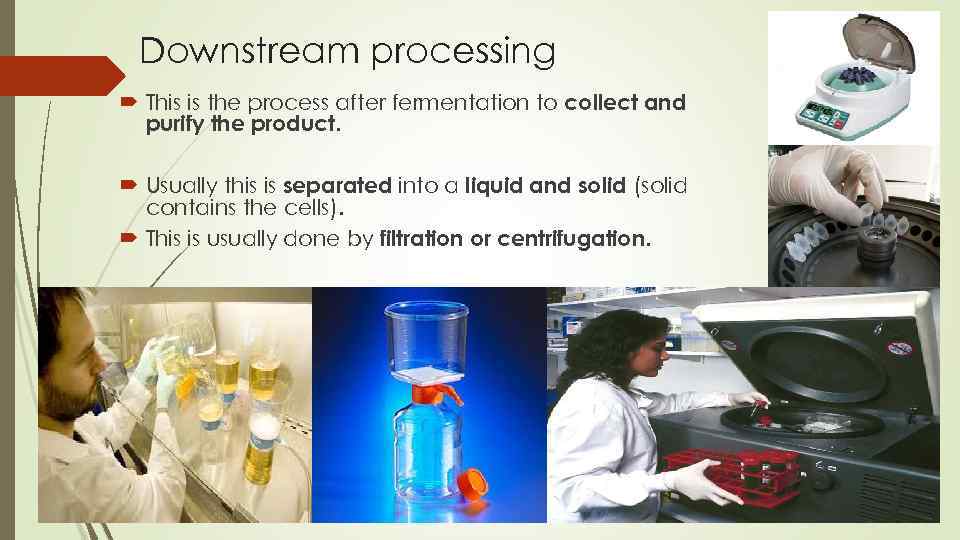

Downstream processing This is the process after fermentation to collect and purify the product. Usually this is separated into a liquid and solid (solid contains the cells). This is usually done by filtration or centrifugation.

What are some products made from this process? antibiotics (Ex. penicillin) monoclonal antibodies insulin cells (biomass) Fermentation of foods Yeast – bread, beer, wine Lactic acid fermentation – dairy products: yogurt, cheese Single cell protein (SCP) – protein from growth of microorganisms (yeast, bacteria, algae, fungi); used for human consumption or animal feed

What would be some advantages of using microorganisms as a food source?

Advantages Use less land than crops Grow rapidly Fewer ethical issues High protein content Independent of climate change Some can grow on waste materials and help recycle or clean up waste

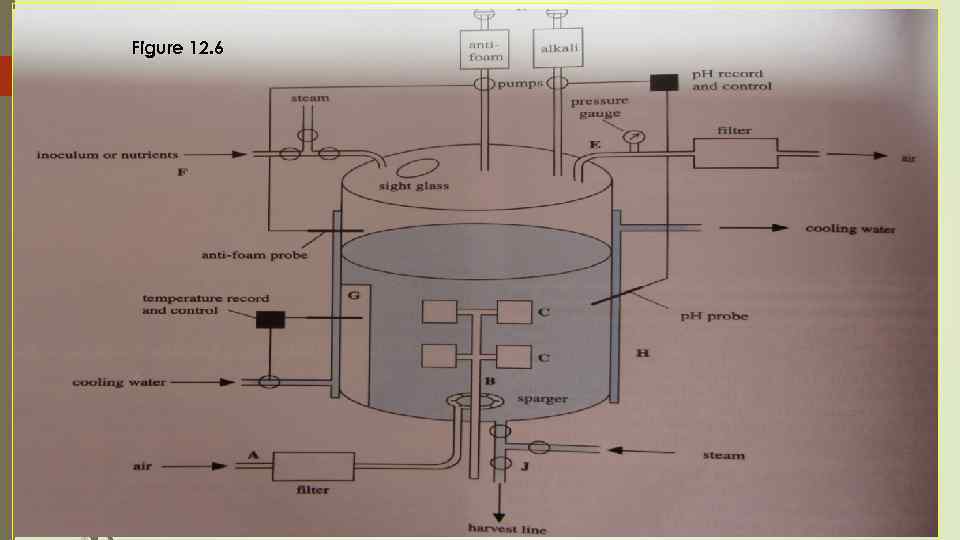

Figure 12. 6

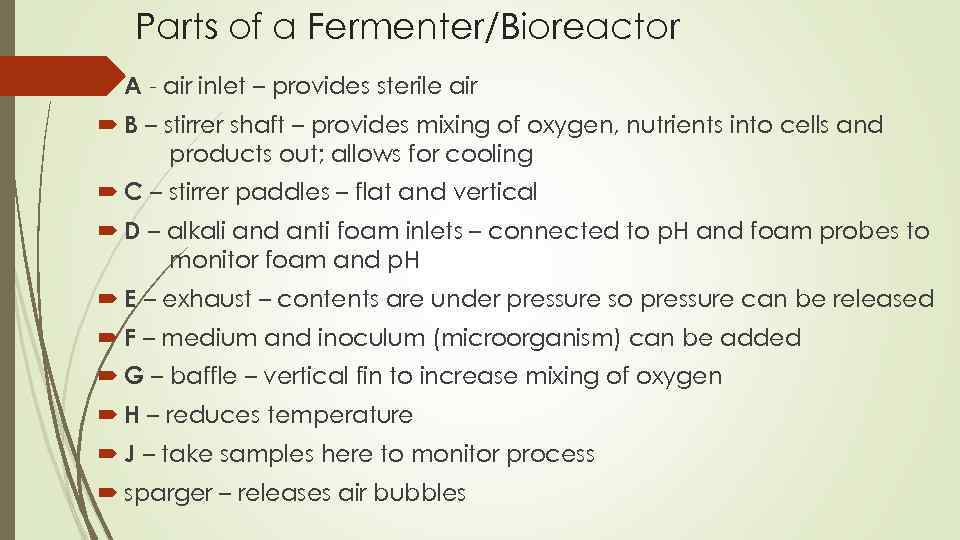

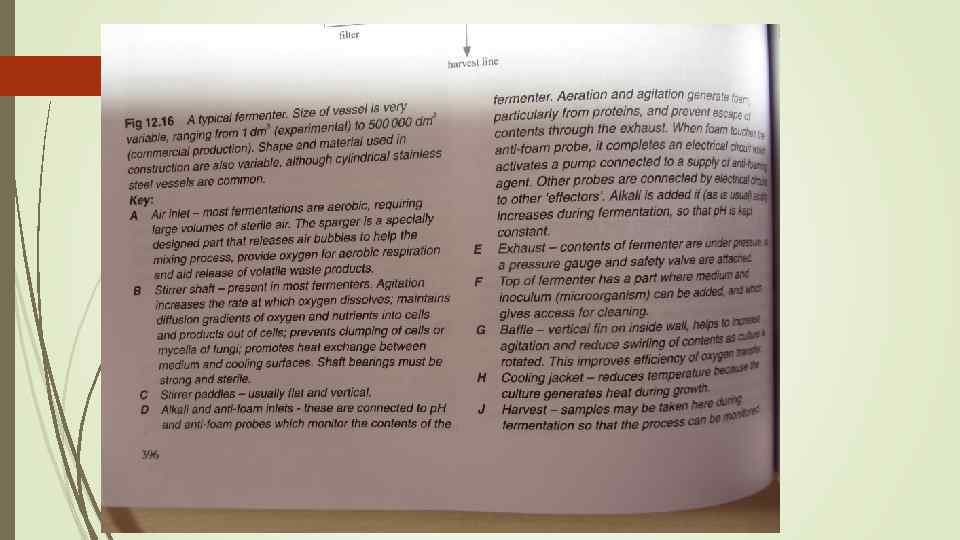

Parts of a Fermenter/Bioreactor A - air inlet – provides sterile air B – stirrer shaft – provides mixing of oxygen, nutrients into cells and products out; allows for cooling C – stirrer paddles – flat and vertical D – alkali and anti foam inlets – connected to p. H and foam probes to monitor foam and p. H E – exhaust – contents are under pressure so pressure can be released F – medium and inoculum (microorganism) can be added G – baffle – vertical fin to increase mixing of oxygen H – reduces temperature J – take samples here to monitor process sparger – releases air bubbles

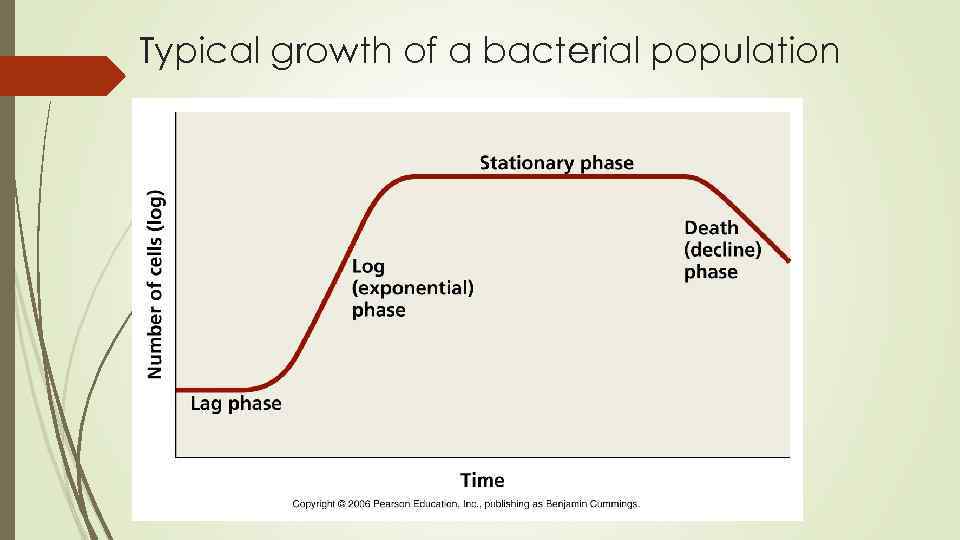

Typical growth of a bacterial population

Questions 1. ) If a person wanted to grow a lot of cells quickly, which would be better, batch or continuous culture? 2. ) If the p. H probe stopped working during the fermentation process, how would this effect the cells and any products? 3. ) If a contaminant were in the inoculant at the beginning of the process, what would the results of the process be? 4. ) A technician at a pharmaceutical company took out the filter on the air outlet to clean it and forgot to put it back in before using the fermenter with genetically modified bacteria. Is this a problem? Explain.

Resources http: //www. intechopen. com/books/biomass-now-sustainable-growth-anduse/continuous-agave-juice-fermentation-for-producing-bioethanol Biology and Science 1 and 2; Taylor, Green, and Stout; Cambridge

Lesson 11.4B3Fermenters.pptx