5ba03058291769725d6ad174d8bdf284.ppt

- Количество слайдов: 51

Microbiological research onboard the ISS and planetary protection with a special reference to dormancy problem Natalia Novikova Institute for Biomedical Problems, Russia

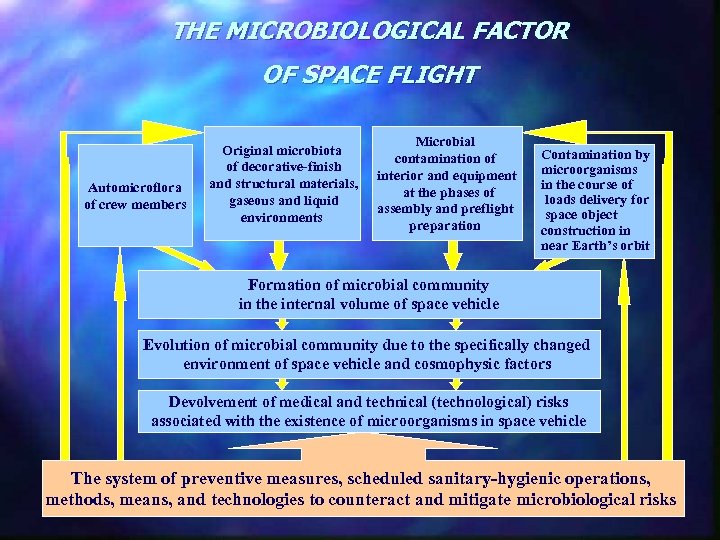

THE MICROBIOLOGICAL FACTOR OF SPACE FLIGHT Automicroflora of crew members Original microbiota of decorative-finish and structural materials, gaseous and liquid environments Microbial contamination of interior and equipment at the phases of assembly and preflight preparation Contamination by microorganisms in the course of loads delivery for space object construction in near Earth’s orbit Formation of microbial community in the internal volume of space vehicle Evolution of microbial community due to the specifically changed environment of space vehicle and cosmophysic factors Devolvement of medical and technical (technological) risks associated with the existence of microorganisms in space vehicle The system of preventive measures, scheduled sanitary-hygienic operations, methods, means, and technologies to counteract and mitigate microbiological risks

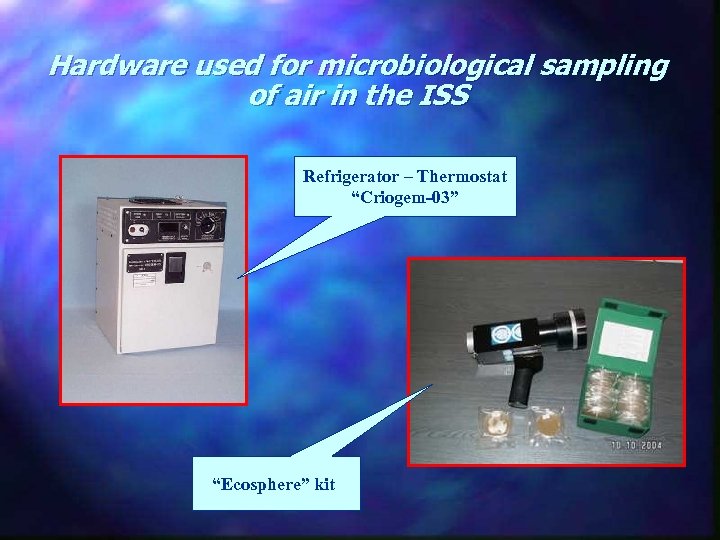

Hardware used for microbiological sampling of air in the ISS Refrigerator – Thermostat “Criogem-03” “Ecosphere” kit

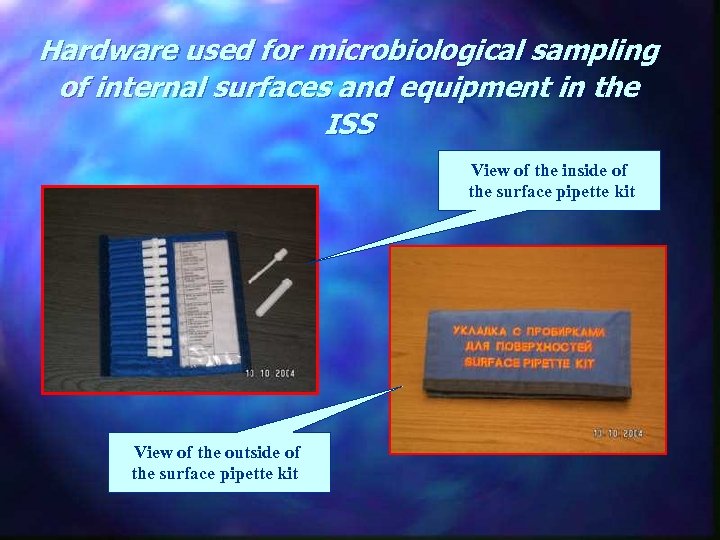

Hardware used for microbiological sampling of internal surfaces and equipment in the ISS View of the inside of the surface pipette kit View of the outside of the surface pipette kit

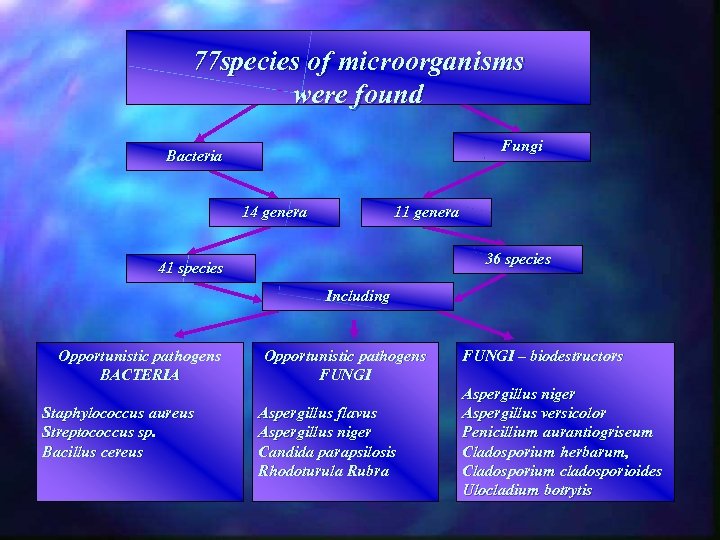

77 species of microorganisms were found Fungi Bacteria 14 genera 11 genera 36 species 41 species Including Opportunistic pathogens BACTERIA Staphylococcus aureus Streptococcus sp. Bacillus cereus Opportunistic pathogens FUNGI Aspergillus flavus Aspergillus niger Candida parapsilosis Rhodoturula Rubra FUNGI – biodestructors Aspergillus niger Aspergillus versicolor Penicillium aurantiogriseum Cladosporium herbarum, Cladosporium cladosporioides Ulocladium botrytis

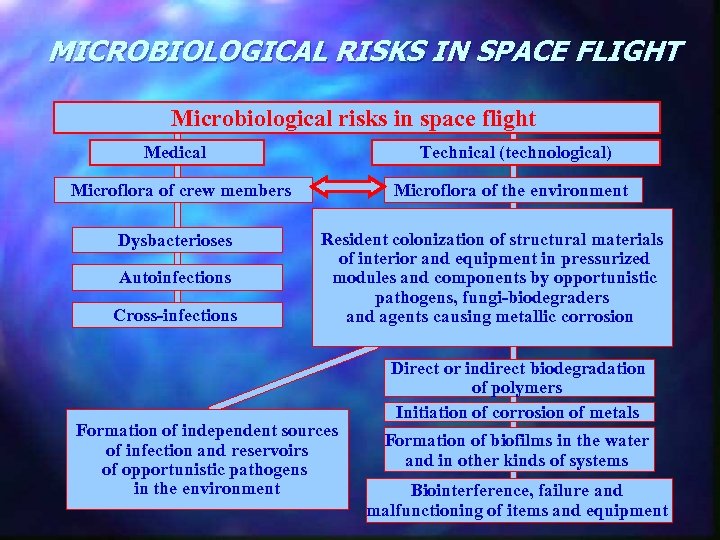

MICROBIOLOGICAL RISKS IN SPACE FLIGHT Microbiological risks in space flight Medical Technical (technological) Microflora of crew members Dysbacterioses Autoinfections Cross-infections Microflora of the environment Resident colonization of structural materials of interior and equipment in pressurized modules and components by opportunistic pathogens, fungi-biodegraders and agents causing metallic corrosion Formation of independent sources of infection and reservoirs of opportunistic pathogens in the environment Direct or indirect biodegradation of polymers Initiation of corrosion of metals Formation of biofilms in the water and in other kinds of systems Biointerference, failure and malfunctioning of items and equipment

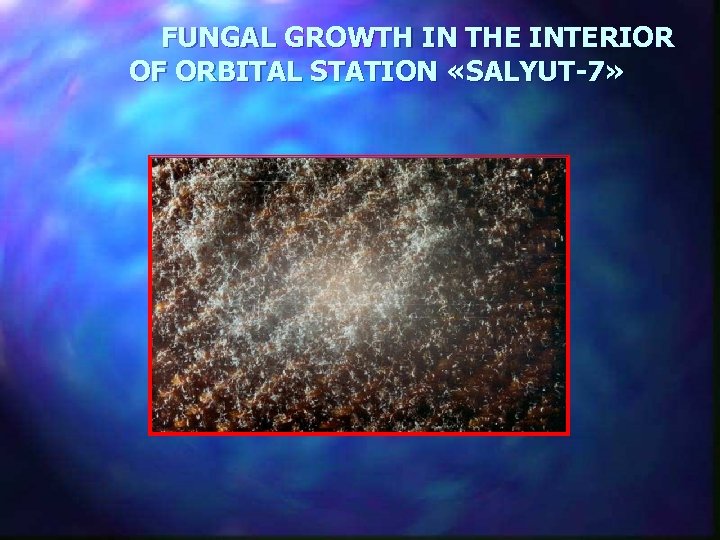

FUNGAL GROWTH IN THE INTERIOR OF ORBITAL STATION «SALYUT-7»

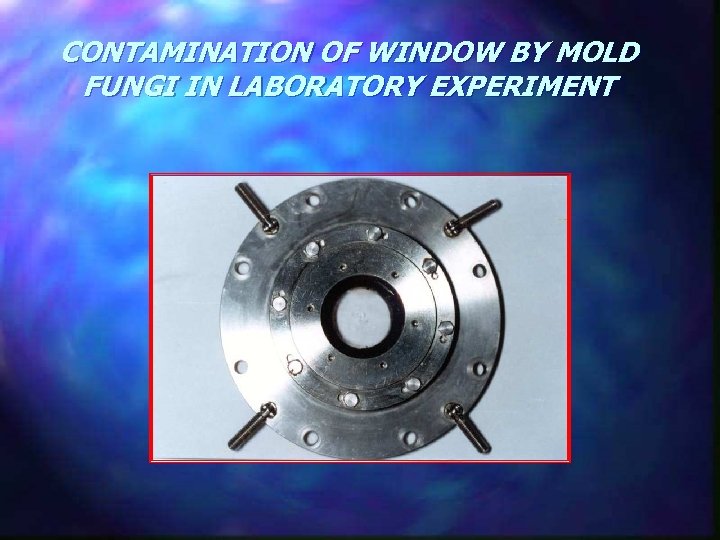

CONTAMINATION OF WINDOW BY MOLD FUNGI IN LABORATORY EXPERIMENT

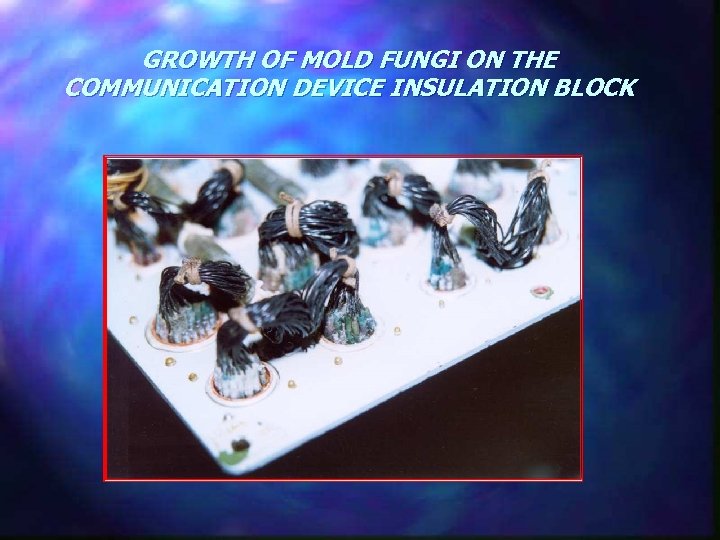

GROWTH OF MOLD FUNGI ON THE COMMUNICATION DEVICE WHITE AND BLACK TUBES

GROWTH OF MOLD FUNGI ON THE COMMUNICATION DEVICE INSULATION BLOCK

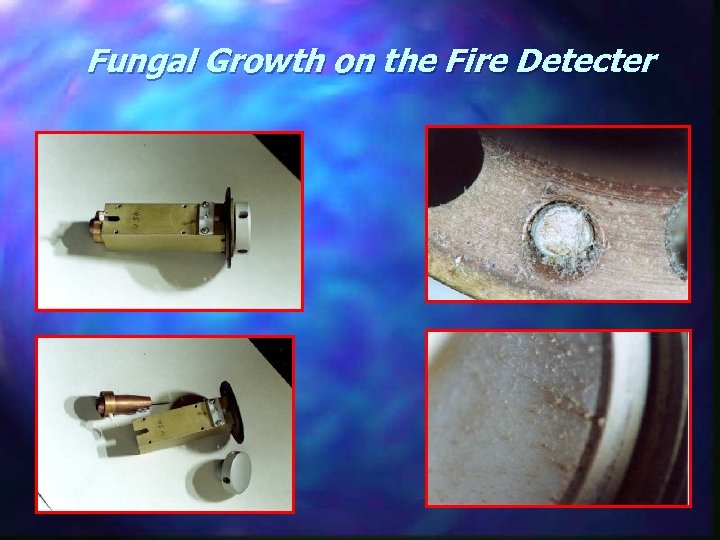

Fungal Growth on the Fire Detecter

Biocorrosion of the Fire Detecter Needle

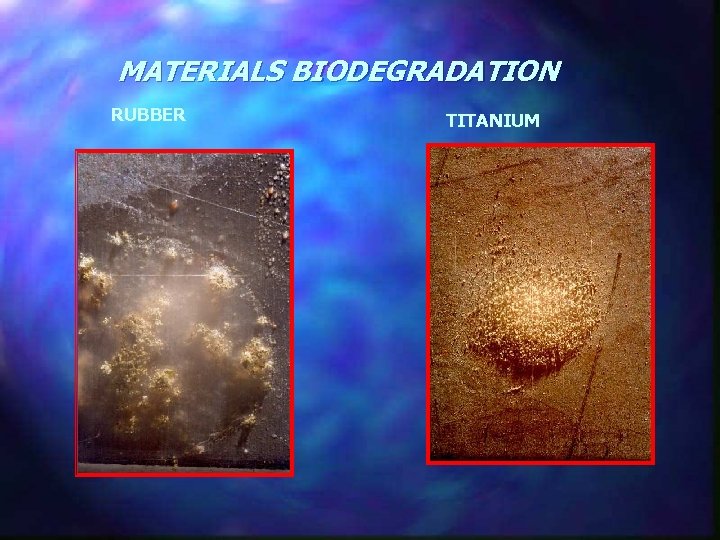

MATERIALS BIODEGRADATION RUBBER TITANIUM

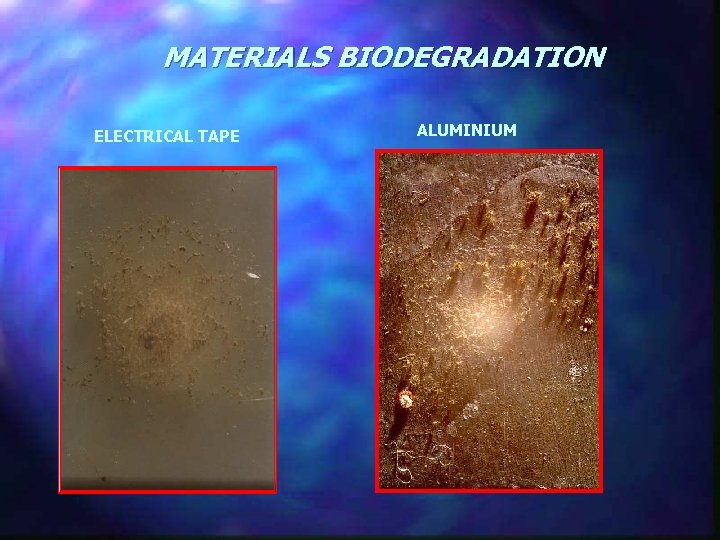

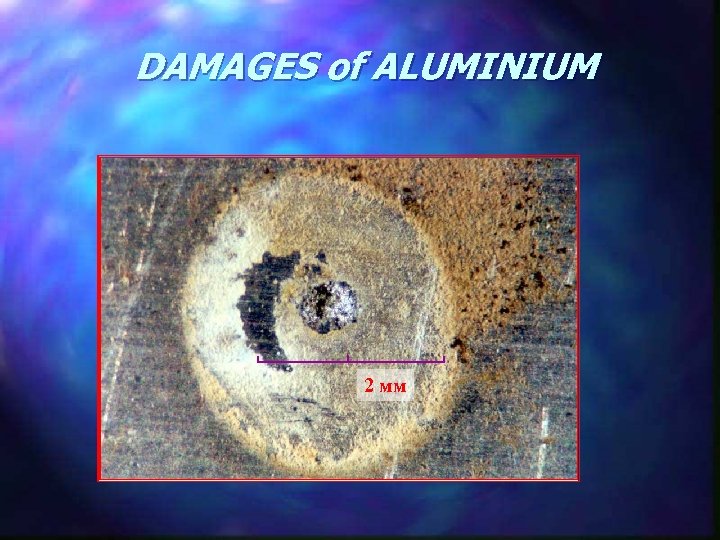

MATERIALS BIODEGRADATION ELECTRICAL TAPE ALUMINIUM

DAMAGES of ALUMINIUM 2 мм

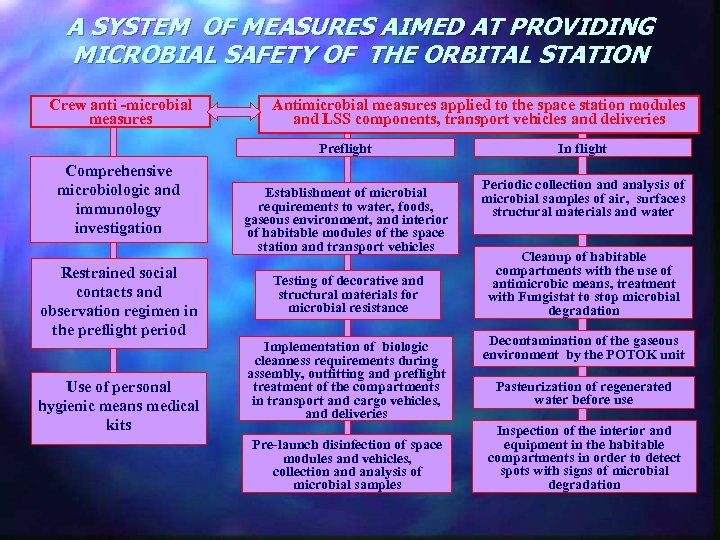

A SYSTEM OF MEASURES AIMED AT PROVIDING MICROBIAL SAFETY OF THE ORBITAL STATION Crew anti -microbial measures Antimicrobial measures applied to the space station modules and LSS components, transport vehicles and deliveries Preflight Comprehensive microbiologic and immunology investigation Restrained social contacts and observation regimen in the preflight period Use of personal hygienic means medical kits Establishment of microbial requirements to water, foods, gaseous environment, and interior of habitable modules of the space station and transport vehicles Testing of decorative and structural materials for microbial resistance Implementation of biologic cleanness requirements during assembly, outfitting and preflight treatment of the compartments in transport and cargo vehicles, and deliveries Pre-launch disinfection of space modules and vehicles, collection and analysis of microbial samples In flight Periodic collection and analysis of microbial samples of air, surfaces structural materials and water Cleanup of habitable compartments with the use of antimicrobic means, treatment with Fungistat to stop microbial degradation Decontamination of the gaseous environment by the POTOK unit Pasteurization of regenerated water before use Inspection of the interior and equipment in the habitable compartments in order to detect spots with signs of microbial degradation

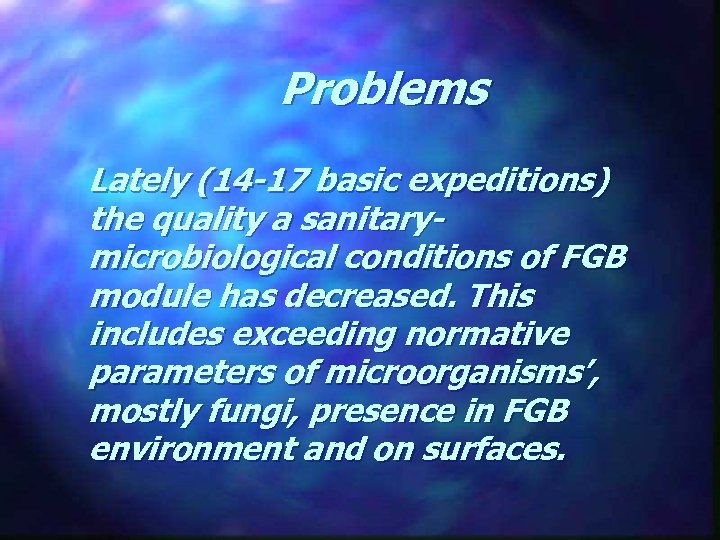

Problems Lately (14 -17 basic expeditions) the quality a sanitarymicrobiological conditions of FGB module has decreased. This includes exceeding normative parameters of microorganisms’, mostly fungi, presence in FGB environment and on surfaces.

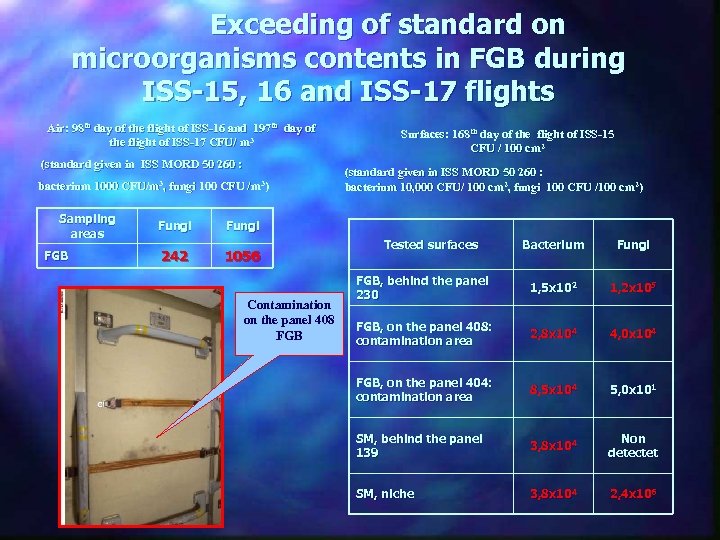

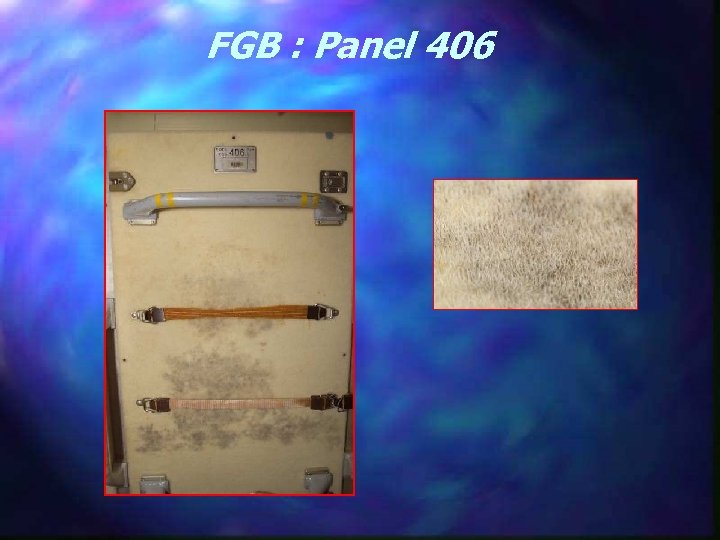

Exceeding of standard on microorganisms contents in FGB during ISS-15, 16 and ISS-17 flights Air: 98 th day of the flight of ISS-16 and 197 th day of the flight of ISS-17 CFU/ m 3 ISS-1 CFU/ (standard given in ISS MORD 50 260 : (standard bacterium 1000 CFU/m 3, fungi 100 CFU /m 3) CFU/ /m Sampling areas FGB Fungi 1056 (standard given in ISS MORD 50 260 : bacterium 10, 000 CFU/ 100 cm 2, fungi 100 CFU /100 cm 2) CFU/ Fungi 242 Surfaces: 168 th day of the flight of ISS-15 CFU / 100 cm 2 Contamination on the panel 408 FGB Tested surfaces Bacterium Fungi FGB, behind the panel 230 1, 5 х102 1, 2 х105 FGB, on the panel 408: contamination area 2, 8 х104 4, 0 х104 FGB, on the panel 404: contamination area 8, 5 х104 5, 0 х101 SM, behind the panel 139 3, 8 х104 Non detectet SM, niche 3, 8 х104 2, 4 х106

Reasons n Unauthorized usage of FGB for washdowns and wet towels and clothes drying by crew members

FGB : Panel 406

Problem solutions KIT FUNGISTAT

Problem solutions “Potok 150 MK” n Apparently the onboard operation of the air sterilization device “Potok 150 MK” was beneficial for the reduction of microbial air contamination of SM. n In January 2009 the second “Potok 150 MK” was delivered to ISS and was disposed in FGB.

POTOK 150 MK unit for International Space Station, module Zvezda

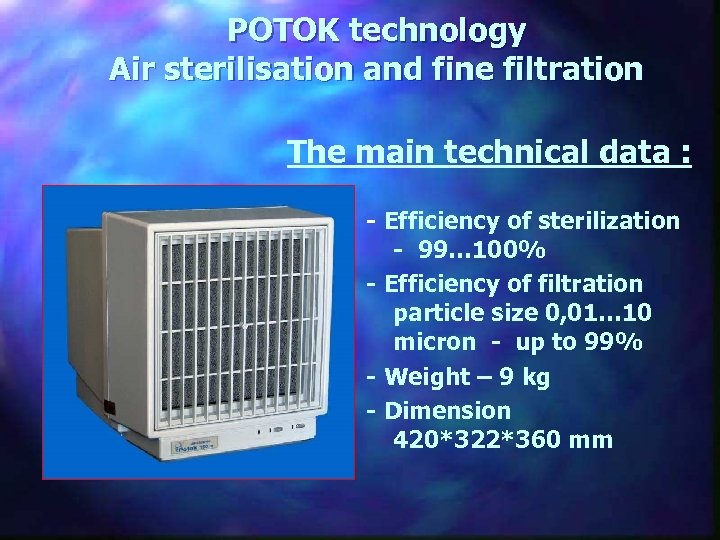

POTOK technology Air sterilisation and fine filtration The main technical data : - Efficiency of sterilization - 99… 100% - Efficiency of filtration particle size 0, 01… 10 micron - up to 99% - Weight – 9 kg - Dimension 420*322*360 mm

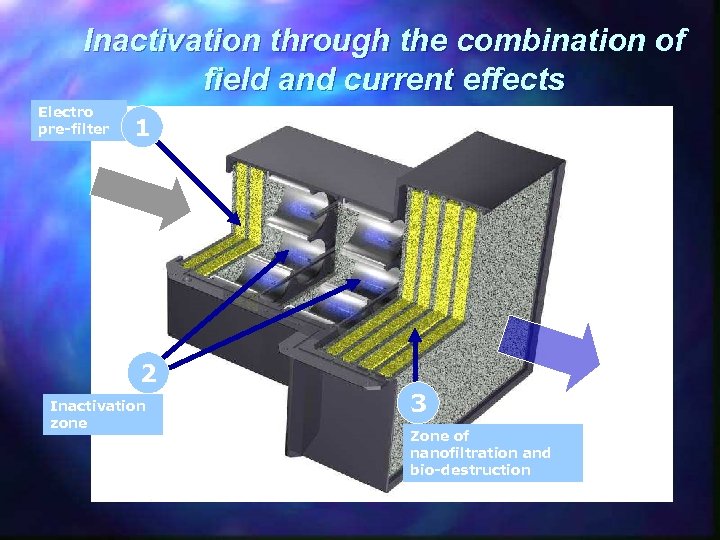

Inactivation through the combination of field and current effects Electro pre-filter 1 2 Inactivation zone 3 Zone of nanofiltration and bio-destruction

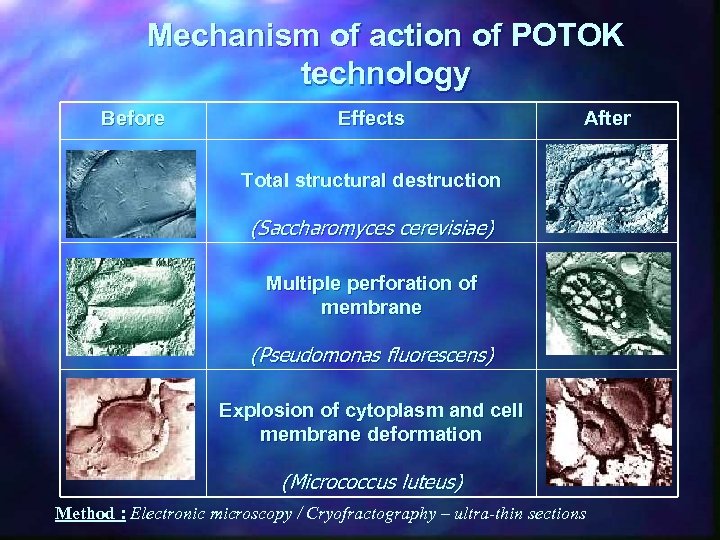

Mechanism of action of POTOK technology Before Effects After Total structural destruction (Saccharomyces cerevisiae) Multiple perforation of membrane (Pseudomonas fluorescens) Explosion of cytoplasm and cell membrane deformation (Micrococcus luteus) Method : Electronic microscopy / Cryofractography – ultra-thin sections

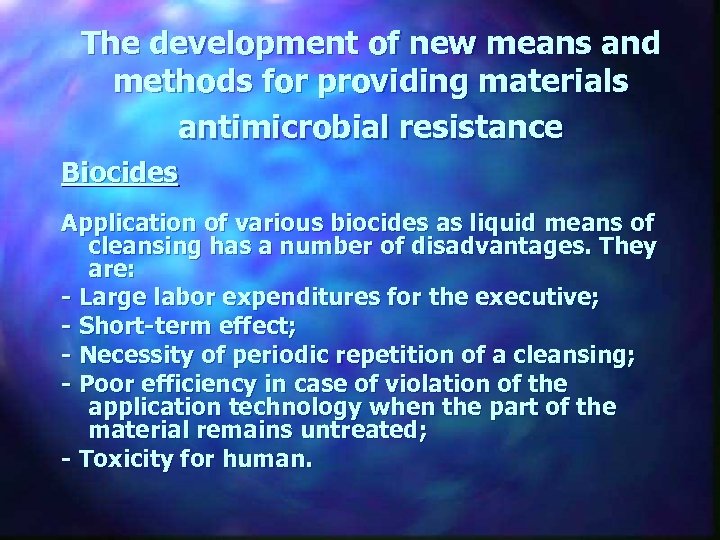

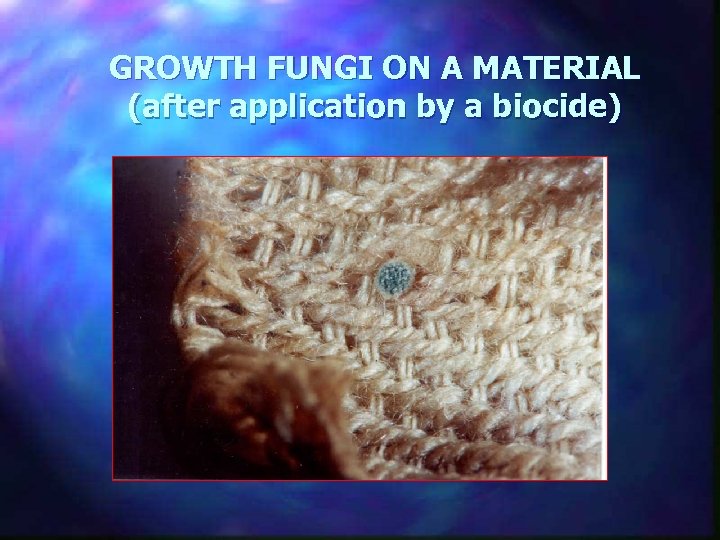

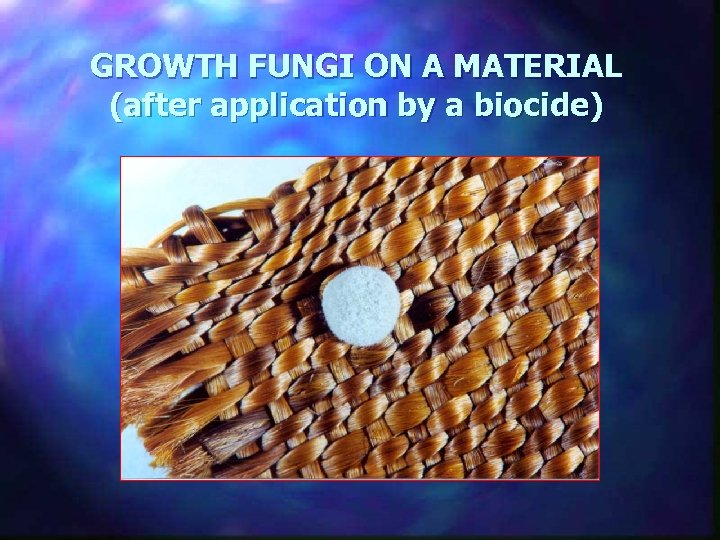

The development of new means and methods for providing materials antimicrobial resistance Biocides Application of various biocides as liquid means of cleansing has a number of disadvantages. They are: - Large labor expenditures for the executive; - Short-term effect; - Necessity of periodic repetition of a cleansing; - Poor efficiency in case of violation of the application technology when the part of the material remains untreated; - Toxicity for human.

GROWTH FUNGI ON A MATERIAL (after application by a biocide)

GROWTH FUNGI ON A MATERIAL (after application by a biocide)

New method for protection n n The most perspective model of protection is the creation of such material where the biocide is fixed with its surface and forms molecular layer. The advantages of this method are the following: - the technological characteristics of the material in its volume do not change; - high concentration of a biocide is formed on the surface; - due to chemical bond with the surface of material the prolonged effect of protection is provided.

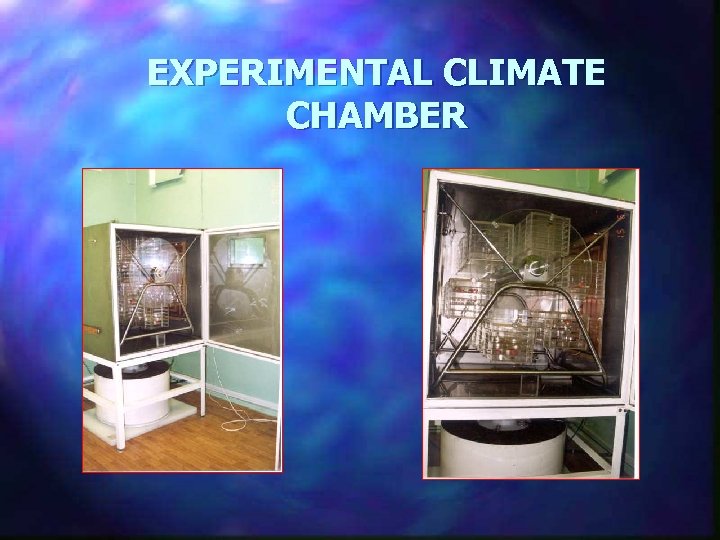

EXPERIMENTAL CLIMATE CHAMBER

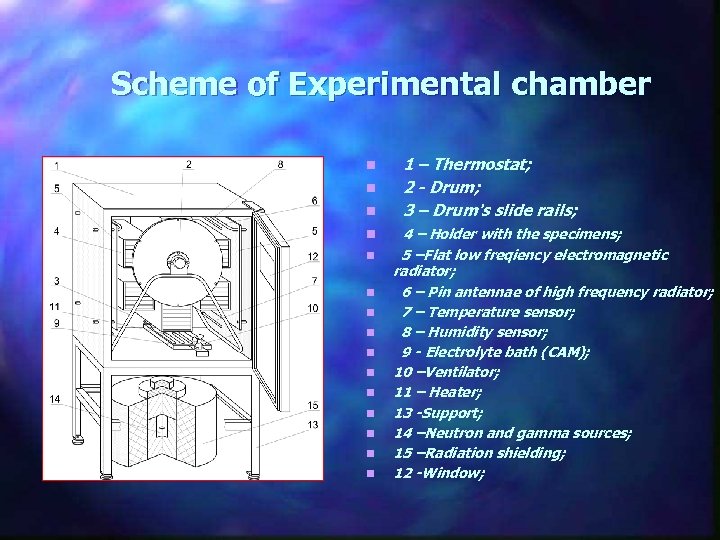

Scheme of Experimental chamber n n n n 1 – Thermostat; 2 - Drum; 3 – Drum's slide rails; 4 – Holder with the specimens; 5 –Flat low freqiency electromagnetic radiator; 6 – Pin antennae of high frequency radiator; 7 – Temperature sensor; 8 – Humidity sensor; 9 - Electrolyte bath (CAM); 10 –Ventilator; 11 – Heater; 13 -Support; 14 –Neutron and gamma sources; 15 –Radiation shielding; 12 -Window;

Selection of material samples n II. ALUMINUM FOIL AMG-6 ORGANIC GLASS (Polymethylmethacrylate)

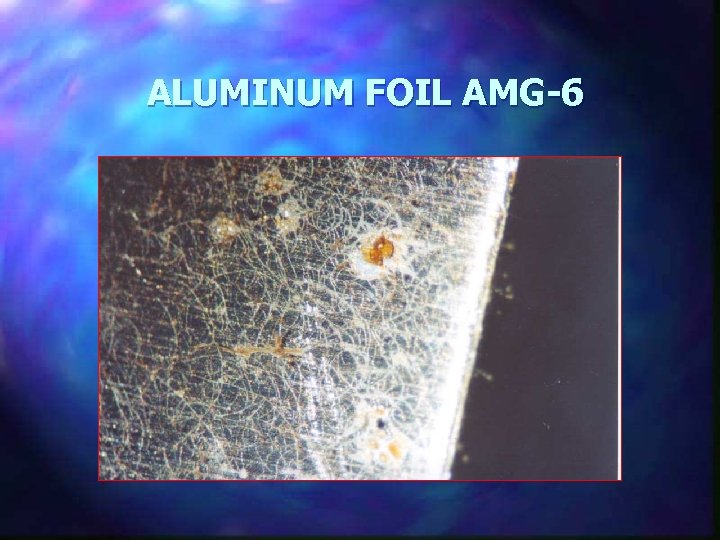

ALUMINUM FOIL AMG-6

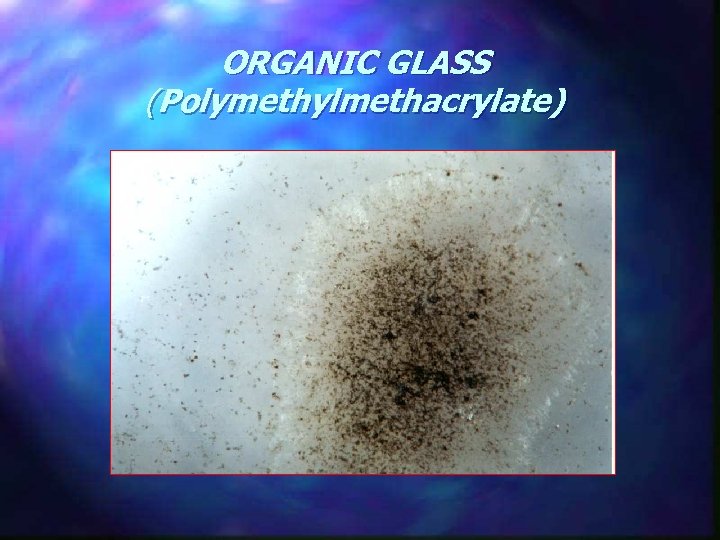

ORGANIC GLASS (Polymethylmethacrylate)

Result of the research n n Anti-microbial film coatings with different biocide concentration have been developed and prepared. On the basis of these complexes compositions have been derived and coatings have been formed on the substrates from aluminum allow and polymethylmetacrillate (PMMA).

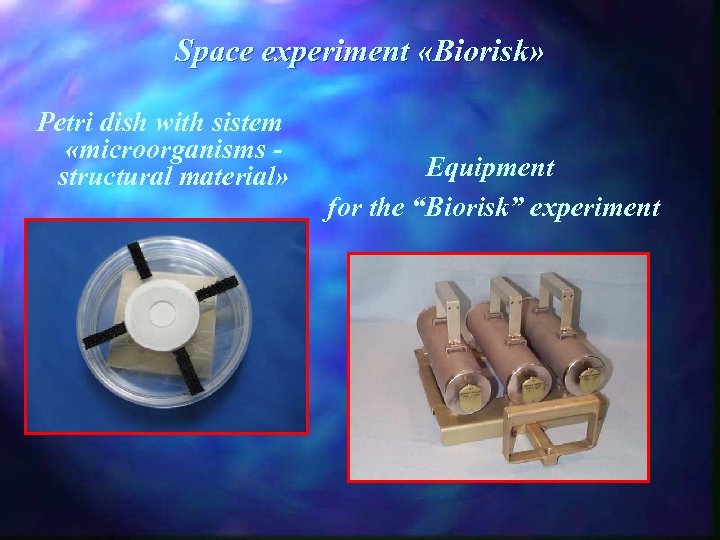

Space experiment «Biorisk» Petri dish with sistem «microorganisms - structural material» Equipment for the “Biorisk” experiment

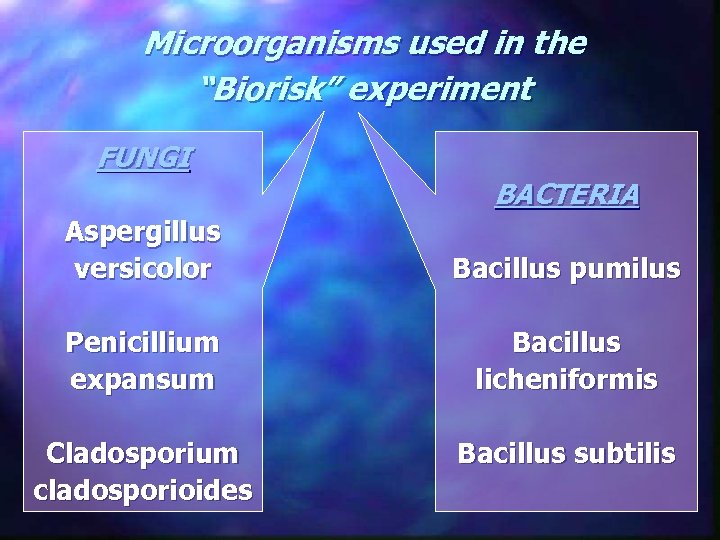

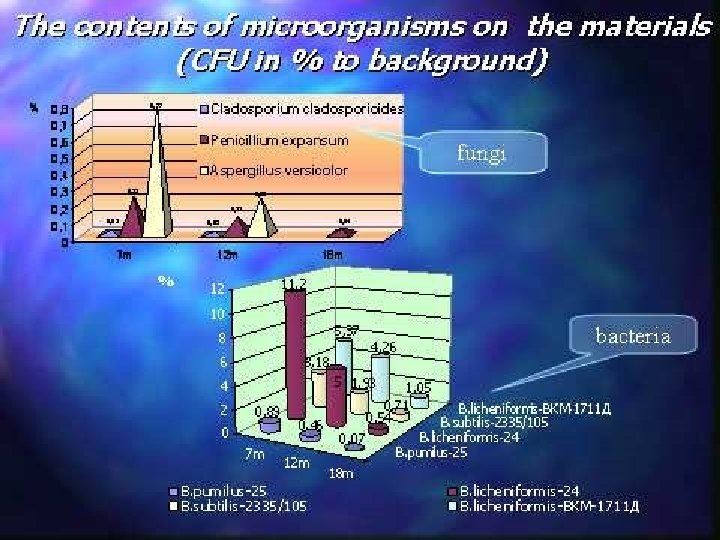

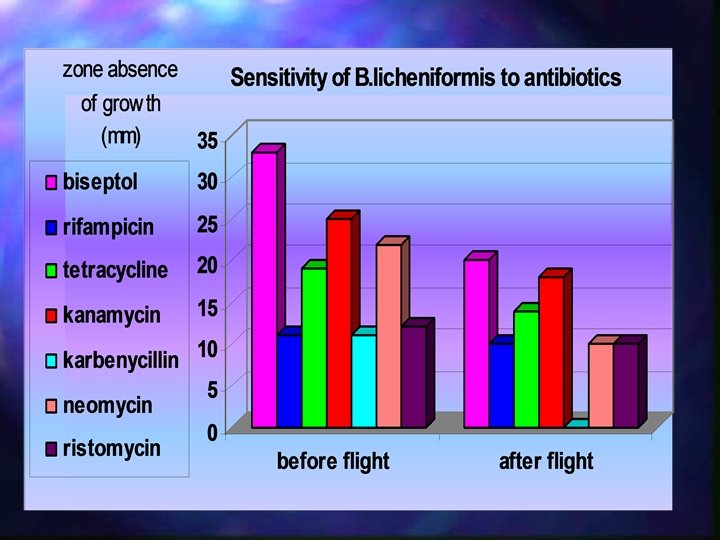

Microorganisms used in the “Biorisk” experiment FUNGI BACTERIA Aspergillus versicolor Bacillus pumilus Penicillium expansum Bacillus licheniformis Cladosporium cladosporioides Bacillus subtilis

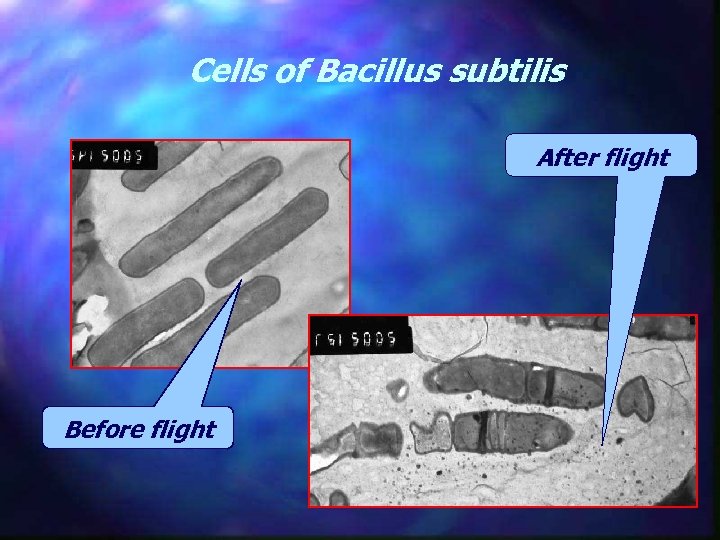

Cells of Bacillus subtilis After flight Before flight

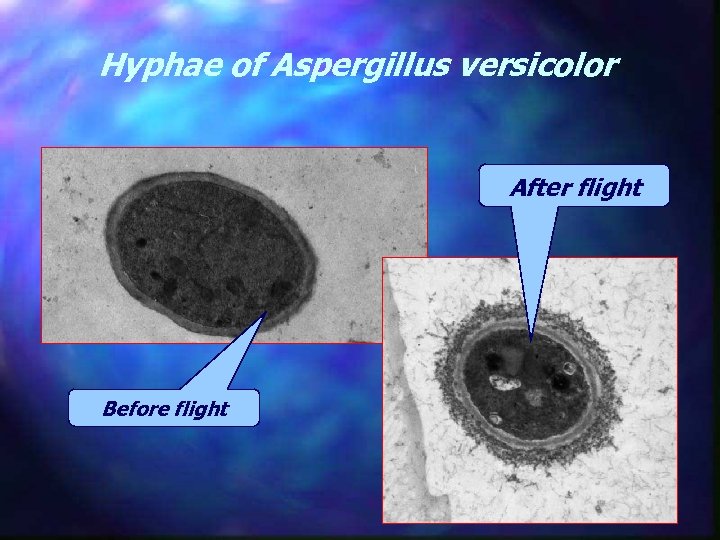

Hyphae of Aspergillus versicolor After flight Before flight

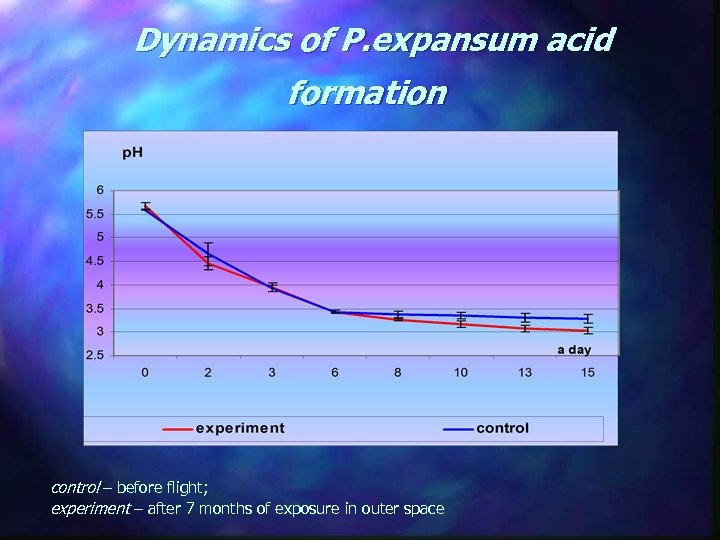

Dynamics of P. expansum acid formation control – before flight; experiment – after 7 months of exposure in outer space

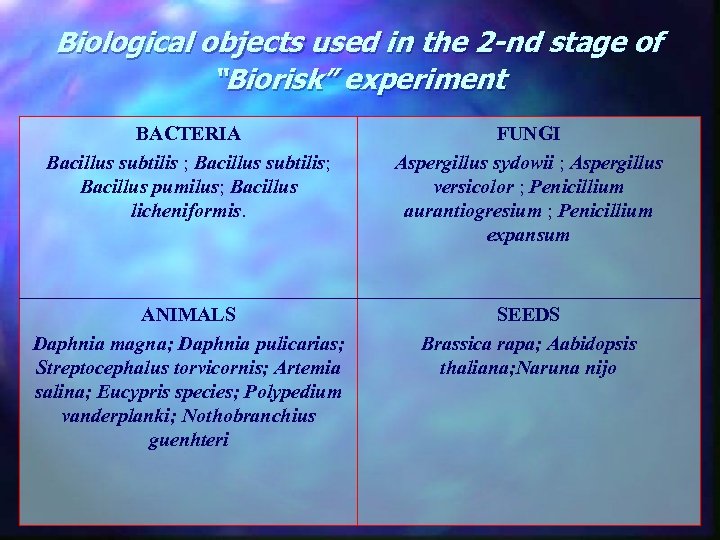

Biological objects used in the 2 -nd stage of “Biorisk” experiment BACTERIA Bacillus subtilis ; Bacillus subtilis; Bacillus pumilus; Bacillus licheniformis. FUNGI Aspergillus sydowii ; Aspergillus versicolor ; Penicillium aurantiogresium ; Penicillium expansum ANIMALS Daphnia magna; Daphnia pulicarias; Streptocephalus torvicornis; Artemia salina; Eucypris species; Polypedium vanderplanki; Nothobranchius guenhteri SEEDS Brassica rapa; Aabidopsis thaliana; Naruna nijo

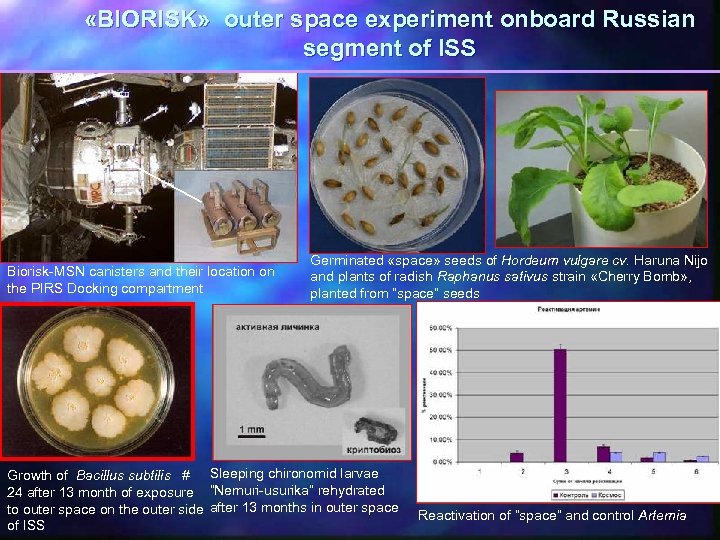

«BIORISK» outer space experiment onboard Russian segment of ISS Biorisk-MSN canisters and their location on the PIRS Docking compartment Germinated «space» seeds of Hordeum vulgare cv. Haruna Nijo and plants of radish Raphanus sativus strain «Cherry Bomb» , planted from “space” seeds Growth of Bacillus subtilis # Sleeping chironomid larvae 24 after 13 month of exposure “Nemuri-usurika” rehydrated to outer space on the outer side after 13 months in outer space of ISS Reactivation of “space” and control Artemia

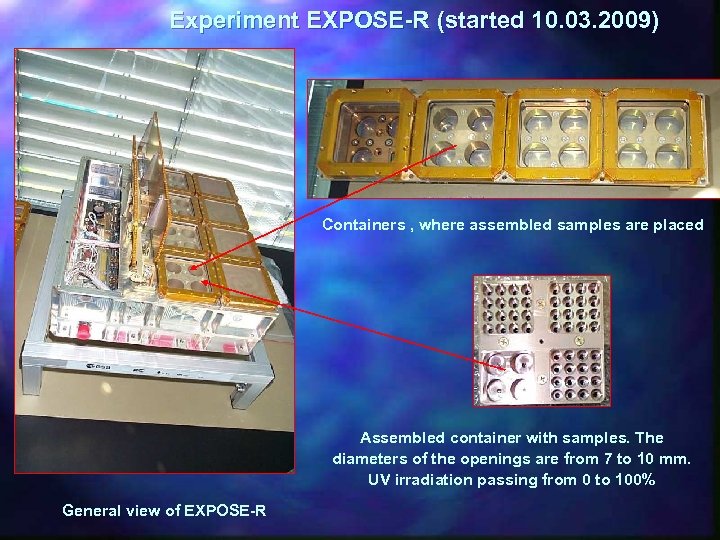

Experiment EXPOSE-R (started 10. 03. 2009) Containers , where assembled samples are placed Assembled container with samples. The diameters of the openings are from 7 to 10 mm. UV irradiation passing from 0 to 100% General view of EXPOSE-R

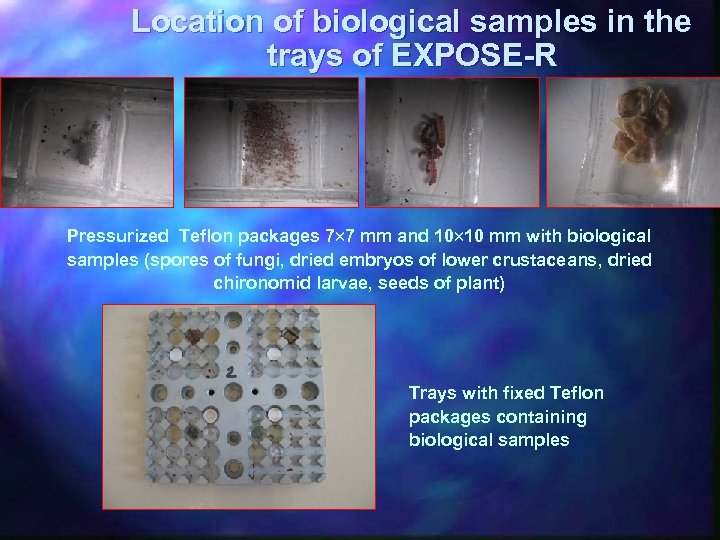

Location of biological samples in the trays of EXPOSE-R Pressurized Teflon packages 7 7 mm and 10 10 mm with biological samples (spores of fungi, dried embryos of lower crustaceans, dried chironomid larvae, seeds of plant) Trays with fixed Teflon packages containing biological samples

THE PROGRAM OF “PHOBOS-GRUNT” n In October this year, in the frame of “Phobos-Grunt” program, Russian automatic spacecraft with sample return mission will be launched to Phobos, one of the moons of Mars. The main aim of this experiment is to return a soil sample from Phobos to Earth. At the same time, containers containing more than 60 different biological samples in latent forms will be installed in the same spacecraft for further returning to Earth, together with the Phobos soil sample. At the moment we conduct preparation of the biological samples for this flight.

THE PROGRAM OF “PHOBOS-GRUNT” The goal of this experiment is Investigation of the survivability of resting stages of different organisms under conditions of long -duration space flight to solving different tasks related to planetary quarantine and astrobiology.

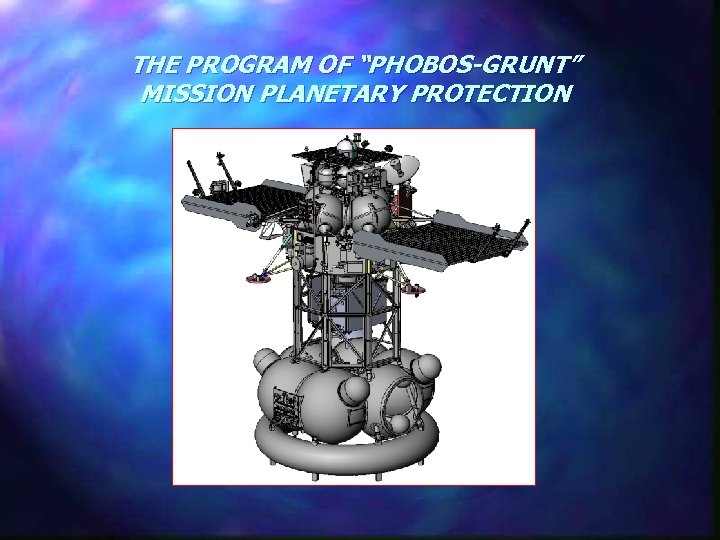

THE PROGRAM OF “PHOBOS-GRUNT” MISSION PLANETARY PROTECTION

Thank you for your attention!

5ba03058291769725d6ad174d8bdf284.ppt