Industrial Biotechnology - копия.ppt

- Количество слайдов: 59

MICROBES IN FOOD AND BEVERAGE INDUSTRIES

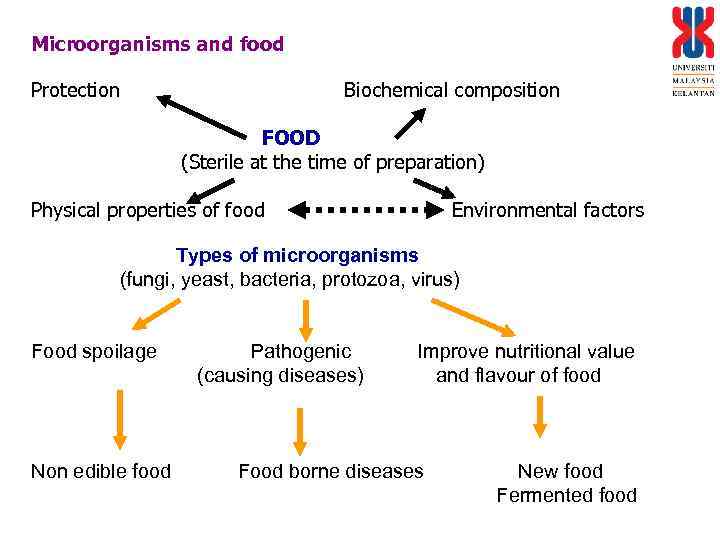

Microorganisms and food Protection Biochemical composition FOOD (Sterile at the time of preparation) Physical properties of food Environmental factors Types of microorganisms (fungi, yeast, bacteria, protozoa, virus) Food spoilage Non edible food Pathogenic (causing diseases) Improve nutritional value and flavour of food Food borne diseases New food Fermented food

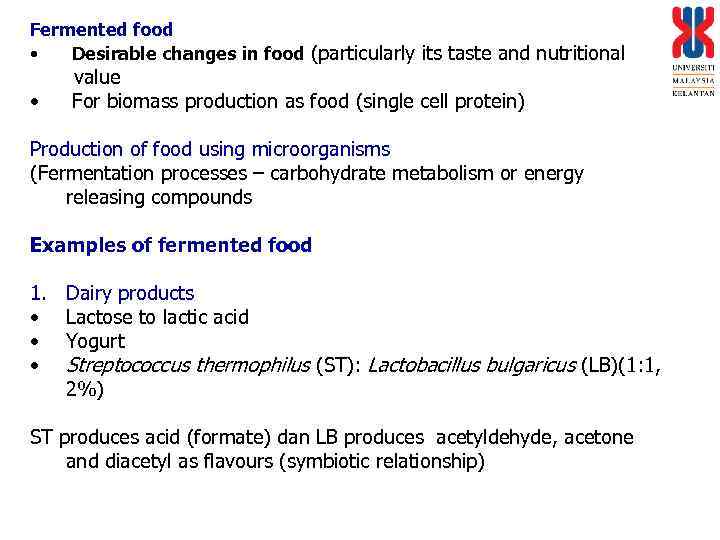

Fermented food • Desirable changes in food (particularly its taste and nutritional • value For biomass production as food (single cell protein) Production of food using microorganisms (Fermentation processes – carbohydrate metabolism or energy releasing compounds Examples of fermented food 1. • • • Dairy products Lactose to lactic acid Yogurt Streptococcus thermophilus (ST): Lactobacillus bulgaricus (LB)(1: 1, 2%) ST produces acid (formate) dan LB produces acetyldehyde, acetone and diacetyl as flavours (symbiotic relationship)

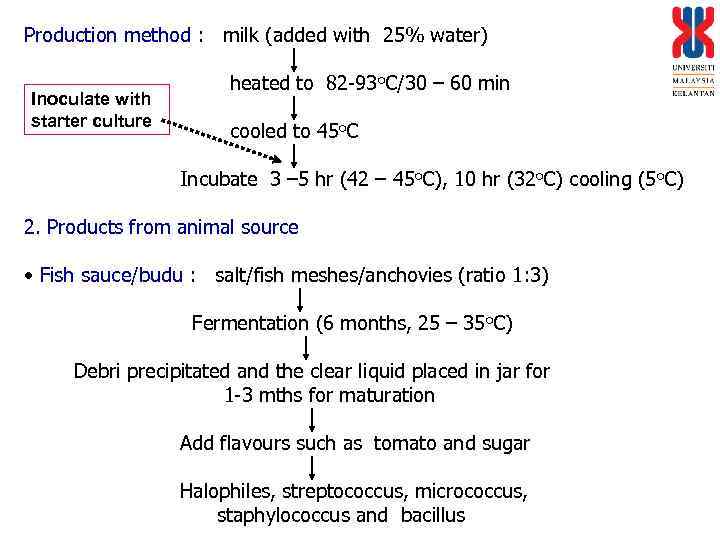

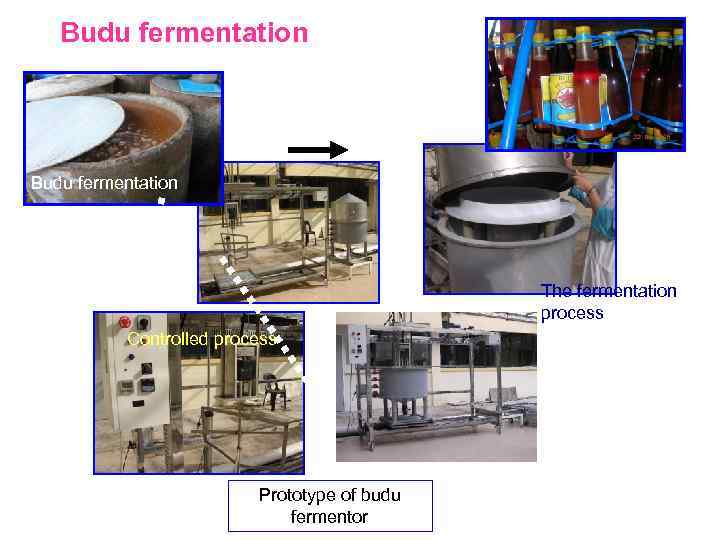

Production method : milk (added with 25% water) Inoculate with starter culture heated to 82 -93 o. C/30 – 60 min cooled to 45 o. C Incubate 3 – 5 hr (42 – 45 o. C), 10 hr (32 o. C) cooling (5 o. C) 2. Products from animal source • Fish sauce/budu : salt/fish meshes/anchovies (ratio 1: 3) Fermentation (6 months, 25 – 35 o. C) Debri precipitated and the clear liquid placed in jar for 1 -3 mths for maturation Add flavours such as tomato and sugar Halophiles, streptococcus, micrococcus, staphylococcus and bacillus

Budu fermentation The fermentation process Controlled process Prototype of budu fermentor The scale up

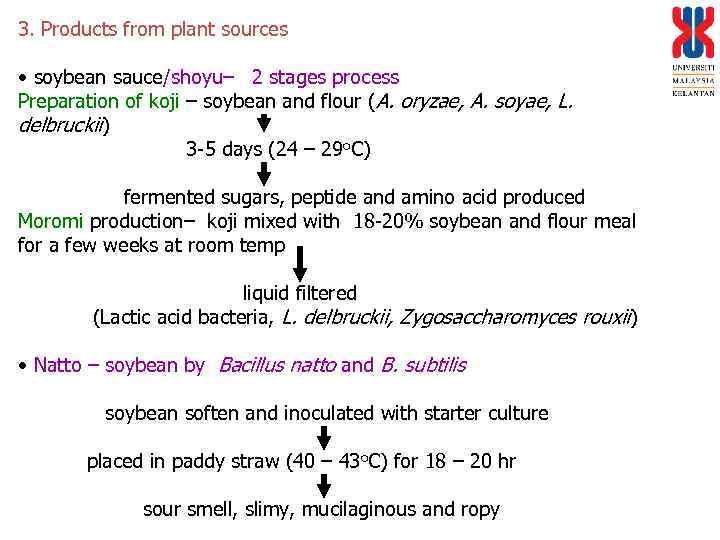

3. Products from plant sources • soybean sauce/shoyu– 2 stages process Preparation of koji – soybean and flour (A. oryzae, A. soyae, L. delbruckii) 3 -5 days (24 – 29 o. C) fermented sugars, peptide and amino acid produced Moromi production– koji mixed with 18 -20% soybean and flour meal for a few weeks at room temp liquid filtered (Lactic acid bacteria, L. delbruckii, Zygosaccharomyces rouxii) • Natto – soybean by Bacillus natto and B. subtilis soybean soften and inoculated with starter culture placed in paddy straw (40 – 43 o. C) for 18 – 20 hr sour smell, slimy, mucilaginous and ropy

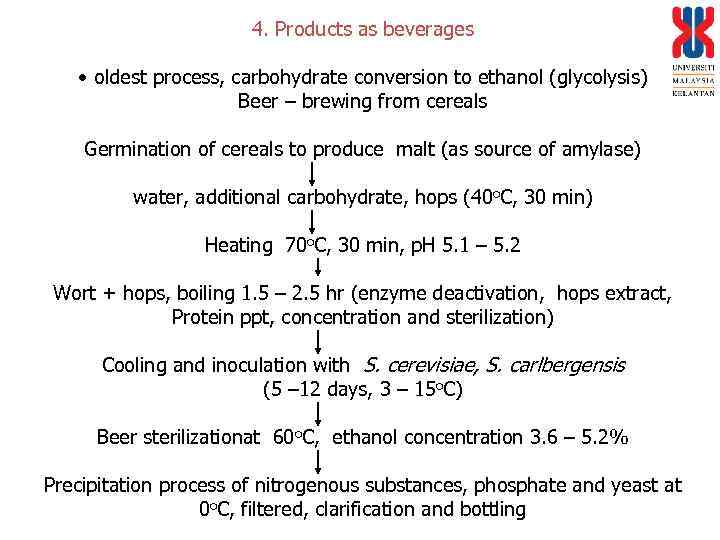

4. Products as beverages • oldest process, carbohydrate conversion to ethanol (glycolysis) Beer – brewing from cereals Germination of cereals to produce malt (as source of amylase) water, additional carbohydrate, hops (40 o. C, 30 min) Heating 70 o. C, 30 min, p. H 5. 1 – 5. 2 Wort + hops, boiling 1. 5 – 2. 5 hr (enzyme deactivation, hops extract, Protein ppt, concentration and sterilization) Cooling and inoculation with S. cerevisiae, S. carlbergensis (5 – 12 days, 3 – 15 o. C) Beer sterilizationat 60 o. C, ethanol concentration 3. 6 – 5. 2% Precipitation process of nitrogenous substances, phosphate and yeast at 0 o. C, filtered, clarification and bottling

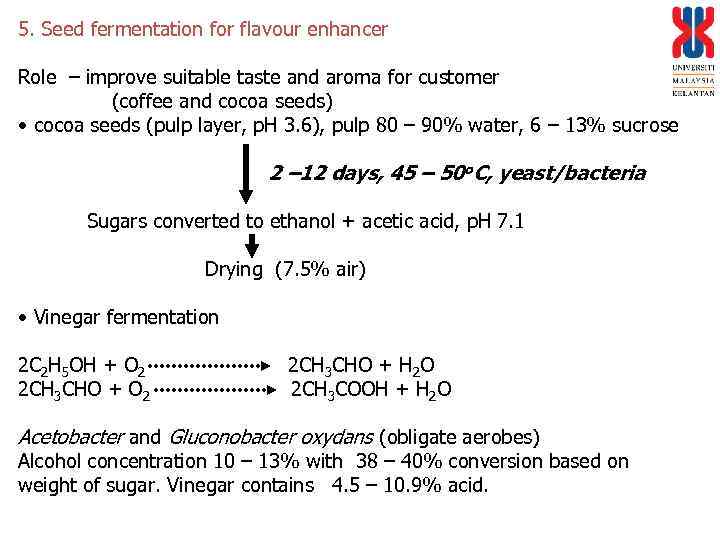

5. Seed fermentation for flavour enhancer Role – improve suitable taste and aroma for customer (coffee and cocoa seeds) • cocoa seeds (pulp layer, p. H 3. 6), pulp 80 – 90% water, 6 – 13% sucrose 2 – 12 days, 45 – 50 o. C, yeast/bacteria Sugars converted to ethanol + acetic acid, p. H 7. 1 Drying (7. 5% air) • Vinegar fermentation 2 C 2 H 5 OH + O 2 2 CH 3 CHO + H 2 O 2 CH 3 COOH + H 2 O Acetobacter and Gluconobacter oxydans (obligate aerobes) Alcohol concentration 10 – 13% with 38 – 40% conversion based on weight of sugar. Vinegar contains 4. 5 – 10. 9% acid.

Food preservation : Reasons • Slow down microbial metabolic activities • Prevent growth • Destroy microorganisms Slow down activities Prolong lag phase create unfavourable conditions Extreme condition (fatal) Consideration : Preservation must retain the flavour/texture and quality of the food including the nutritional value

PRESERVATION METHODS 1. Aseptic techniques • • • Most effective treatment without affecting food quality Food handling technique in ensuring the level of microorganism kept low Improve sanitation (improve health status at all stages of food preparation) Implementation : i. Farmers - Good health status ii. Good storage method iii. Clean instruments and apparatus – wash with clean water and detergent iv. Food outlets – sensitive to cleanliness of premise, staff and level of food preparation

2. High temperature and low temperature • High temperature – coagulation and deactivation of protein. enzymes • • Factor influencing effectiveness – spore concentration, concentration and composition of substrate and physical properties of food Thermophilic and thermoduric microorganisms Factors influencing resistance to high temperature i. iii. iv. Hereditary No/cell population sel/age/spesies/cell physiology Water content (low water more resistant) Spores are more resistant than vegetative cells, cocci are more resistant than rod High temperature method i. ii. Pastuerisation : temp < 100 o. C, Eg: milk 62. 8 o. C/30 min, wine 82 -85 o. C/min Tyndallization – 70 -80 o. C for several hr for a few days Kaedah suhu rendah • • • Refrigeration (0 -4 o. C), freeze dry – 20 - -10 o. C psychrophiles : Cladosporium, Sporotrichum, Monilia Clostridium botulinum – toxin resistant to freezing , need boiling for 10 min, Mycobacterium tuberculosis toxin stable for 2 years at 0 o. C

3. Preservation with chemicals (preservatives) • • Maintain the stability of food Properties of preservatives : will not change the food (physical or nutrition) : concentration of preservatives must be controlled to avoid resistance : preservatives must be stable • Effect of preservatives on microorganisms i. Affected the cell permeability ii. Protein deactivation iii. Gene action mechanism Microcide and Microstasis Types of preservatives 1. 2. 3. Salt or sugars – changing osmotic pressure Acid (acid acetic, propionic, sorbic, benzoic) Nitrite/nitrate

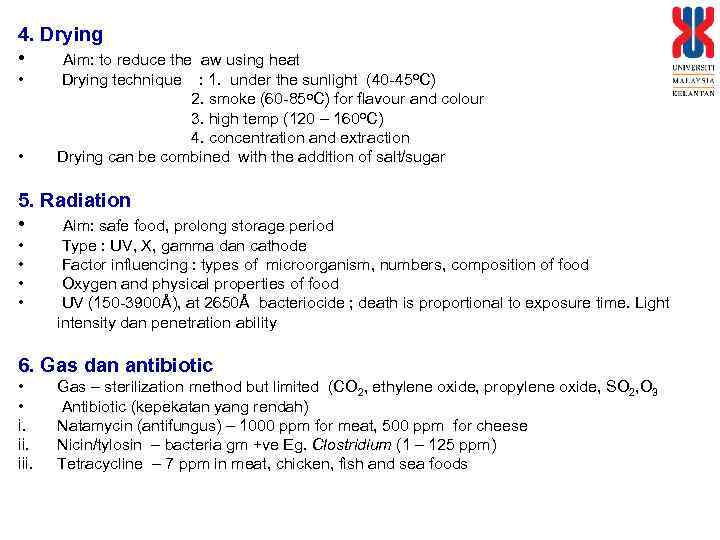

4. Drying • Aim: to reduce the • • aw using heat Drying technique : 1. under the sunlight (40 -45 o. C) 2. smoke (60 -85 o. C) for flavour and colour 3. high temp (120 – 160 o. C) 4. concentration and extraction Drying can be combined with the addition of salt/sugar 5. Radiation • Aim: safe food, prolong storage period • • Type : UV, X, gamma dan cathode Factor influencing : types of microorganism, numbers, composition of food Oxygen and physical properties of food UV (150 -3900Å), at 2650Å bacteriocide ; death is proportional to exposure time. Light intensity dan penetration ability 6. Gas dan antibiotic • • i. iii. Gas – sterilization method but limited (CO 2, ethylene oxide, propylene oxide, SO 2, O 3 Antibiotic (kepekatan yang rendah) Natamycin (antifungus) – 1000 ppm for meat, 500 ppm for cheese Nicin/tylosin – bacteria gm +ve Eg. Clostridium (1 – 125 ppm) Tetracycline – 7 ppm in meat, chicken, fish and sea foods

Products from Food Biotechnology • Beverages (beer and wines) • Preparation of bread and yeast extract • Fruit juice industry • Vegetables for infants food • Improvement of low quality vegetables • Dairy products (Homofermentative lactic acid bacteria) • Sweetener and the sugar industry • Lipid modification for food industry • Production of flavours from fermentation processes • Single cell Protein –microbial biomass • Mushroom production and algae as food source • Vinegar production (acetic acid)

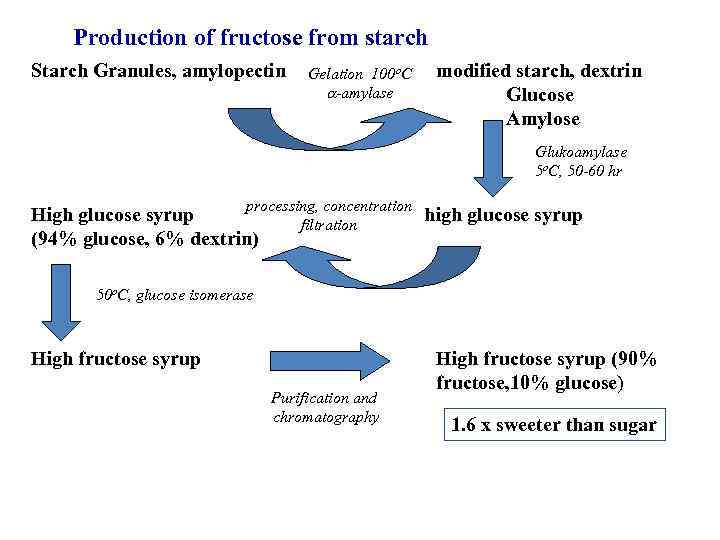

Production of fructose from starch Starch Granules, amylopectin Gelation 100 o. C -amylase modified starch, dextrin Glucose Amylose Glukoamylase 5 o. C, 50 -60 hr processing, concentration High glucose syrup high glucose syrup filtration (94% glucose, 6% dextrin) 50 o. C, glucose isomerase High fructose syrup Purification and chromatography High fructose syrup (90% fructose, 10% glucose) 1. 6 x sweeter than sugar

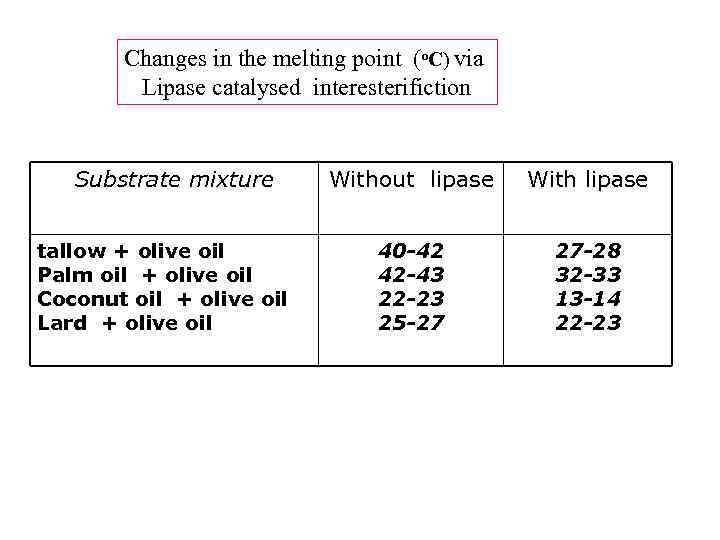

Changes in the melting point (o. C) via Lipase catalysed interesterifiction Substrate mixture tallow + olive oil Palm oil + olive oil Coconut oil + olive oil Lard + olive oil Without lipase With lipase 40 -42 42 -43 22 -23 25 -27 27 -28 32 -33 13 -14 22 -23

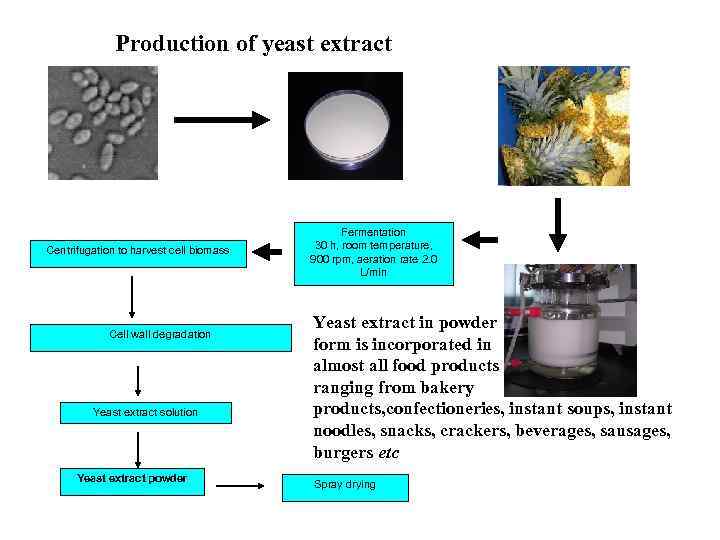

Production of yeast extract Centrifugation to harvest cell biomass Cell wall degradation Yeast extract solution Yeast extract powder Fermentation 30 h, room temperature, 900 rpm, aeration rate 2. 0 L/min Yeast extract in powder form is incorporated in almost all food products ranging from bakery products, confectioneries, instant soups, instant noodles, snacks, crackers, beverages, sausages, burgers etc Spray drying

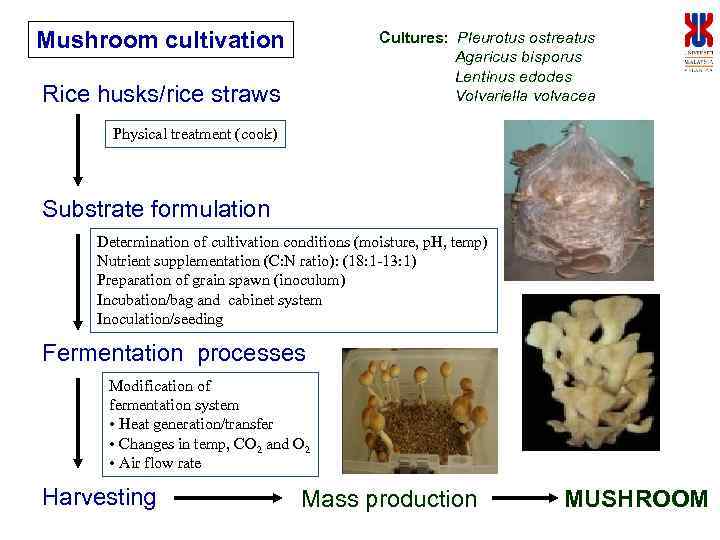

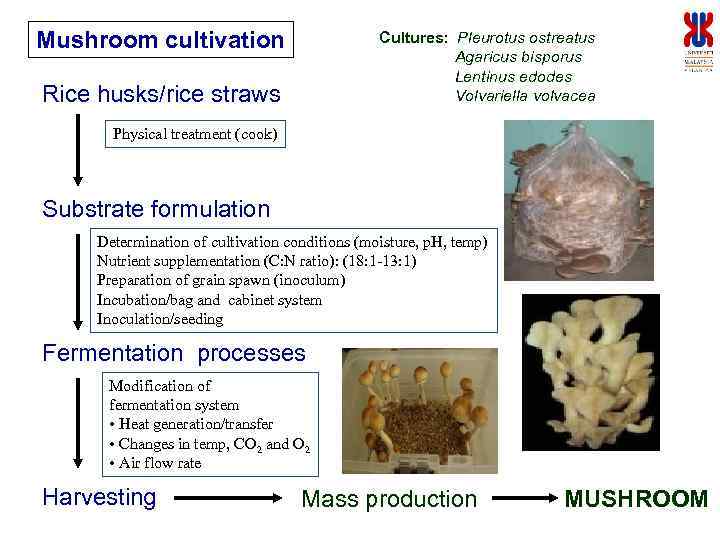

Mushroom cultivation Cultures: Pleurotus ostreatus Agaricus bisporus Lentinus edodes Volvariella volvacea Rice husks/rice straws Physical treatment (cook) Substrate formulation Determination of cultivation conditions (moisture, p. H, temp) Nutrient supplementation (C: N ratio): (18: 1 -13: 1) Preparation of grain spawn (inoculum) Incubation/bag and cabinet system Inoculation/seeding Fermentation processes Modification of fermentation system • Heat generation/transfer • Changes in temp, CO 2 and O 2 • Air flow rate Harvesting Mass production MUSHROOM

BIOTRANSFORMATION OF LIGNOCELLULOSIC MATERIALS AND DEGRADATION OF XENOBIOTIC COMPOUNDS

INTRODUCTION Lignocellulolytic materials and xenobiotic compounds – Poorly degraded by microorganisms, especially xenobiotic compounds Lignocellulolytic materials • Malaysia produces 500 million tons of agrowastes per year with 10% increase per year • Majority from oil pam industry (50% of the agrowaste materials) • Lignocellulolytic materials consist of cellulose, hemicellulose and lignin Xenobiotic compounds • Chemicals which are either poorly degraded by microorganisms • Recalcitrant • Toxic and causes pollution in the ecosystems

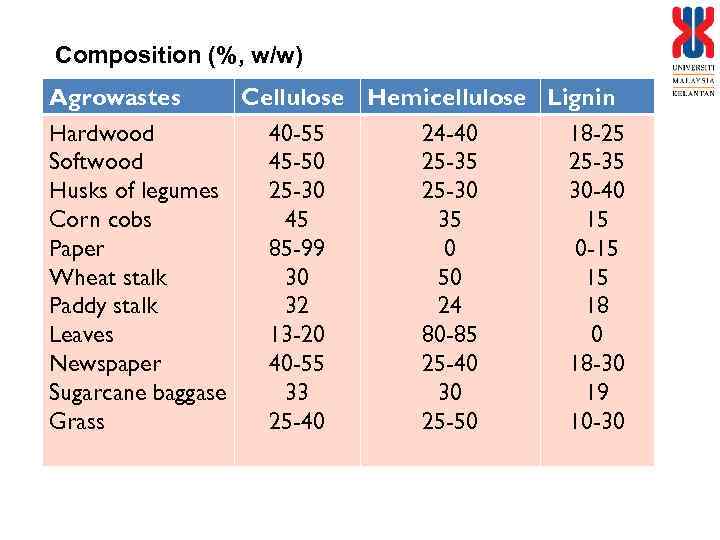

Composition (%, w/w) Agrowastes Hardwood Softwood Husks of legumes Corn cobs Paper Wheat stalk Paddy stalk Leaves Newspaper Sugarcane baggase Grass Cellulose Hemicellulose Lignin 40 -55 45 -50 25 -30 45 85 -99 30 32 13 -20 40 -55 33 25 -40 24 -40 25 -35 25 -30 35 0 50 24 80 -85 25 -40 30 25 -50 18 -25 25 -35 30 -40 15 0 -15 15 18 0 18 -30 19 10 -30

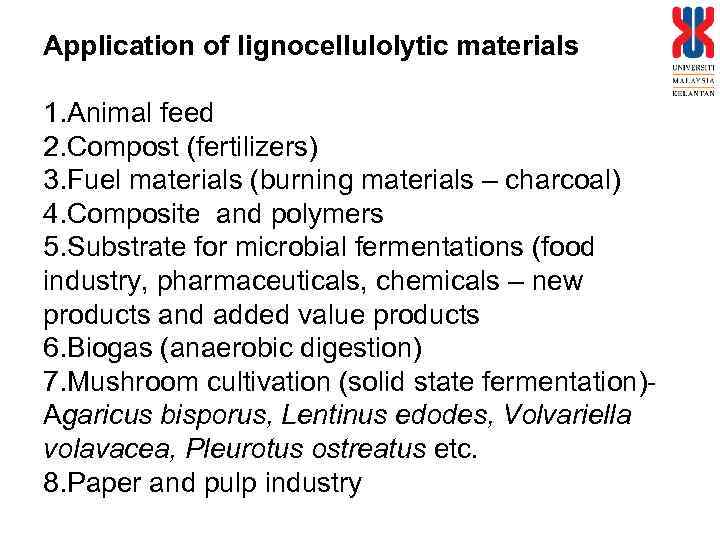

Application of lignocellulolytic materials 1. Animal feed 2. Compost (fertilizers) 3. Fuel materials (burning materials – charcoal) 4. Composite and polymers 5. Substrate for microbial fermentations (food industry, pharmaceuticals, chemicals – new products and added value products 6. Biogas (anaerobic digestion) 7. Mushroom cultivation (solid state fermentation)Agaricus bisporus, Lentinus edodes, Volvariella volavacea, Pleurotus ostreatus etc. 8. Paper and pulp industry

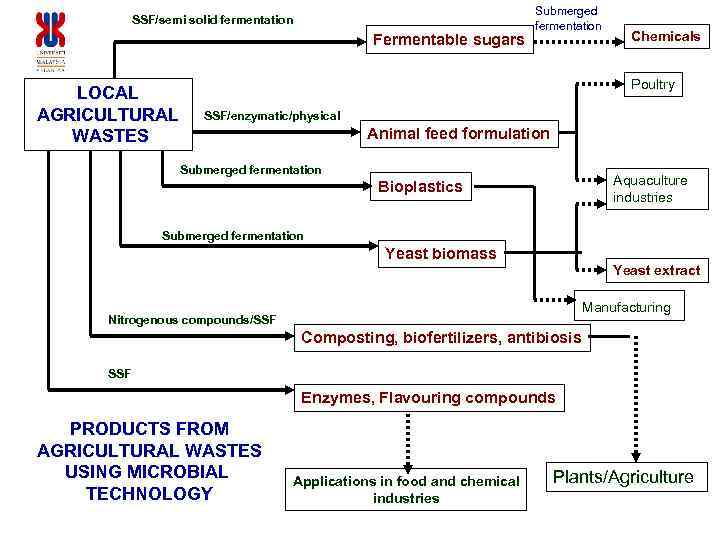

SSF/semi solid fermentation Fermentable sugars LOCAL AGRICULTURAL WASTES Submerged fermentation Chemicals Poultry SSF/enzymatic/physical Animal feed formulation Submerged fermentation Aquaculture industries Bioplastics Submerged fermentation Yeast biomass Yeast extract Manufacturing Nitrogenous compounds/SSF Composting, biofertilizers, antibiosis SSF Enzymes, Flavouring compounds PRODUCTS FROM AGRICULTURAL WASTES USING MICROBIAL TECHNOLOGY Applications in food and chemical industries Plants/Agriculture

Mushroom cultivation Cultures: Pleurotus ostreatus Agaricus bisporus Lentinus edodes Volvariella volvacea Rice husks/rice straws Physical treatment (cook) Substrate formulation Determination of cultivation conditions (moisture, p. H, temp) Nutrient supplementation (C: N ratio): (18: 1 -13: 1) Preparation of grain spawn (inoculum) Incubation/bag and cabinet system Inoculation/seeding Fermentation processes Modification of fermentation system • Heat generation/transfer • Changes in temp, CO 2 and O 2 • Air flow rate Harvesting Mass production MUSHROOM

Xenobiotic materials 1. Halogenated Aliphatic compounds (Eg. 2 -monochloropropionic acid, 1, 2 -dichloroethane, perchloroethane , bromo-iodoalkane etc. ) 2. Chlorinated polycyclic hydrocarbon (DDT, 4 -chlorobiphenyl, PCB etc. 3. Chlorinated aromatic hydrocarbon ( 2, 6 -dichlorotoluene, dichlorobenzoic acid, 4 -chlorophenol , 3, 4 -dichloroaniline, 4 chlorophenylacetate etc. 4. Chlorinated phenol 5. Polychlorinated biphenyl 6. DDT group 7. Dioxin 8. Polycyclic aromatic hydrocarbon 9. Halide alkyl 10. Nitrotoluene group 11. Chloroaniline 12. Dyes 13. Chlorolignin

ENVIRONMENTAL MICROBIAL TECHNOLOGY

ISSUES ON ENVIRONMENTAL IMPACTS • Pollutions from conventional chemical methods Environmental friendly, biological methods via biotechnology Alternative methods for wastes utilization (biocatalysts/enzymes) biological ______________________________ Why biological method? • Cheap, safe and effective • Utilization of agrowastes for the production of added value and commercial products • Viable large scale operation of enzymatic hydrolysis with low production cost • Environmental friendly system/process • Reproducible, efficient, low operational approach, non-detrimental approach good quality products • Management of agricultural solid wastes

Environmental Microbiology/Biotechnology • Concept of services • Industrial and domestic waste treatment ( the use of biological method in waste treatment and environmental management • Research areas 1. 2. 3. 4. 5. 6. Industrial design for waste treatment system Bioremediation – the use of microbes in removing the effect of pollution Inoculum development for biodegradation Bioleaching – Mining industries Treatment of oil spills Conservation of environment using microbes

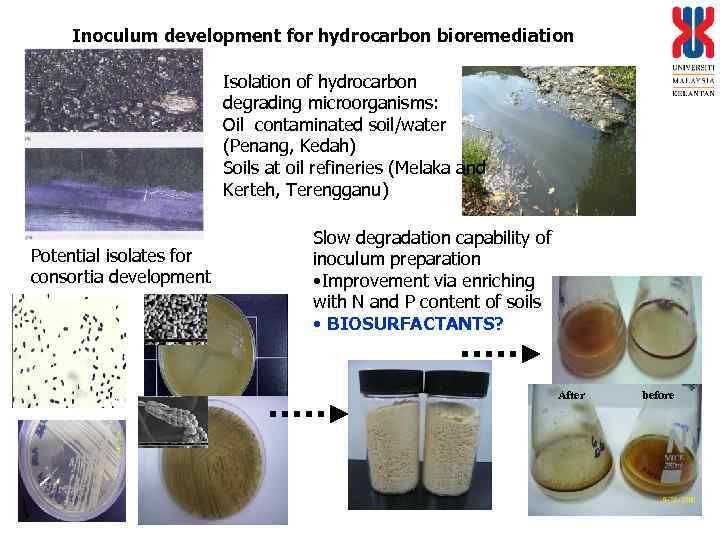

Inoculum development for hydrocarbon bioremediation Isolation of hydrocarbon degrading microorganisms: Oil contaminated soil/water (Penang, Kedah) Soils at oil refineries (Melaka and Kerteh, Terengganu) Potential isolates for consortia development Slow degradation capability of inoculum preparation • Improvement via enriching with N and P content of soils • BIOSURFACTANTS? After before

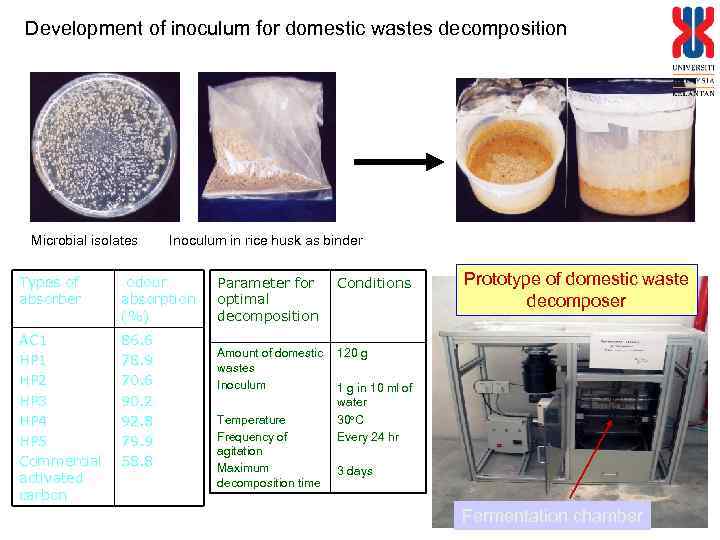

Development of inoculum for domestic wastes decomposition Microbial isolates Inoculum in rice husk as binder Types of absorber odour absorption (%) AC 1 HP 2 HP 3 HP 4 HP 5 Commercial activated carbon 86. 6 78. 9 70. 6 90. 2 92. 8 79. 9 58. 8 Parameter for optimal decomposition Conditions Amount of domestic wastes Inoculum Prototype of domestic waste decomposer 120 g Temperature Frequency of agitation Maximum decomposition time 1 g in 10 ml of water 30 o. C Every 24 hr 3 days Fermentation chamber

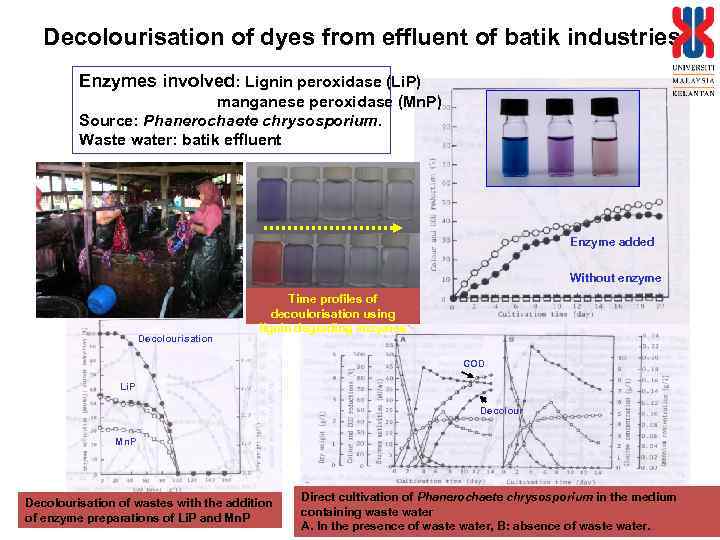

Decolourisation of dyes from effluent of batik industries Enzymes involved: Lignin peroxidase (Li. P) manganese peroxidase (Mn. P) Source: Phanerochaete chrysosporium. Waste water: batik effluent Enzyme added Without enzyme Decolourisation Time profiles of decoulorisation using lignin degrading enzymes COD Li. P Decolour Mn. P Decolourisation of wastes with the addition of enzyme preparations of Li. P and Mn. P Direct cultivation of Phanerochaete chrysosporium in the medium containing waste water A. In the presence of waste water, B: absence of waste water.

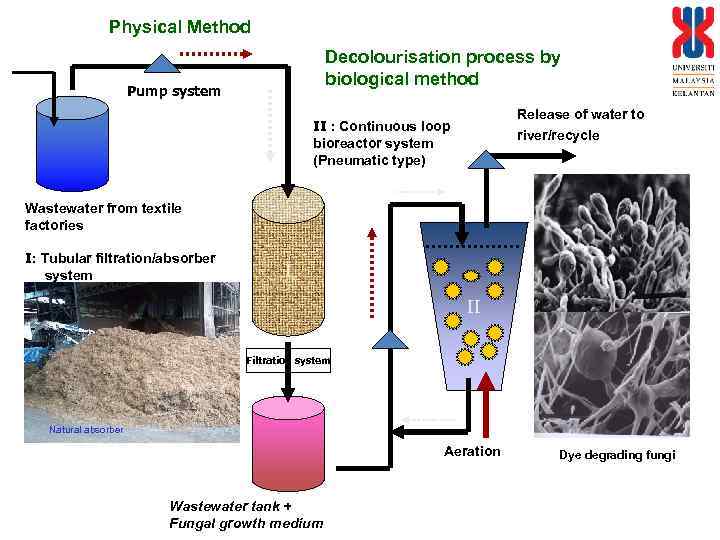

Physical Method Decolourisation process by biological method Pump system Release of water to river/recycle II : Continuous loop bioreactor system (Pneumatic type) Wastewater from textile factories I: Tubular filtration/absorber system I II Filtration system Natural absorber Aeration Wastewater tank + Fungal growth medium Dye degrading fungi

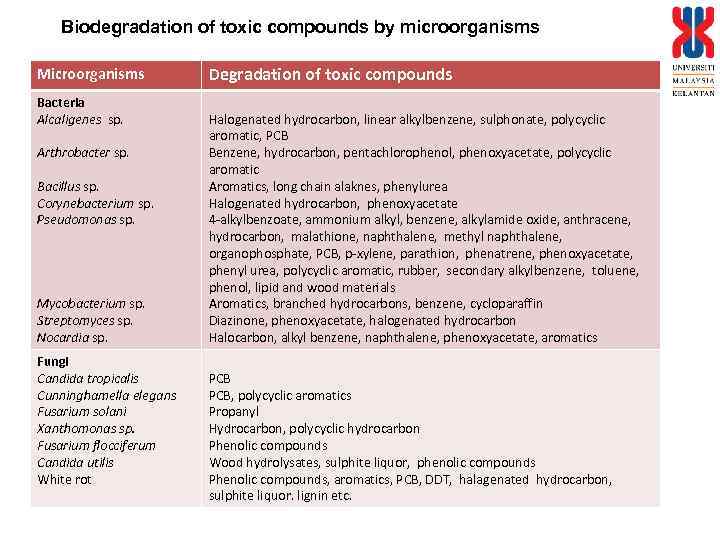

Biodegradation of toxic compounds by microorganisms Microorganisms Bacteria Alcaligenes sp. Arthrobacter sp. Bacillus sp. Corynebacterium sp. Pseudomonas sp. Mycobacterium sp. Streptomyces sp. Nocardia sp. Fungi Candida tropicalis Cunninghamella elegans Fusarium solani Xanthomonas sp. Fusarium flocciferum Candida utilis White rot Degradation of toxic compounds Halogenated hydrocarbon, linear alkylbenzene, sulphonate, polycyclic aromatic, PCB Benzene, hydrocarbon, pentachlorophenol, phenoxyacetate, polycyclic aromatic Aromatics, long chain alaknes, phenylurea Halogenated hydrocarbon, phenoxyacetate 4 -alkylbenzoate, ammonium alkyl, benzene, alkylamide oxide, anthracene, hydrocarbon, malathione, naphthalene, methyl naphthalene, organophosphate, PCB, p-xylene, parathion, phenatrene, phenoxyacetate, phenyl urea, polycyclic aromatic, rubber, secondary alkylbenzene, toluene, phenol, lipid and wood materials Aromatics, branched hydrocarbons, benzene, cycloparaffin Diazinone, phenoxyacetate, halogenated hydrocarbon Halocarbon, alkyl benzene, naphthalene, phenoxyacetate, aromatics PCB, polycyclic aromatics Propanyl Hydrocarbon, polycyclic hydrocarbon Phenolic compounds Wood hydrolysates, sulphite liquor, phenolic compounds Phenolic compounds, aromatics, PCB, DDT, halagenated hydrocarbon, sulphite liquor. lignin etc.

MICROBIOLOGY IN THE MINING AND PETROLEUM INDUSTRY

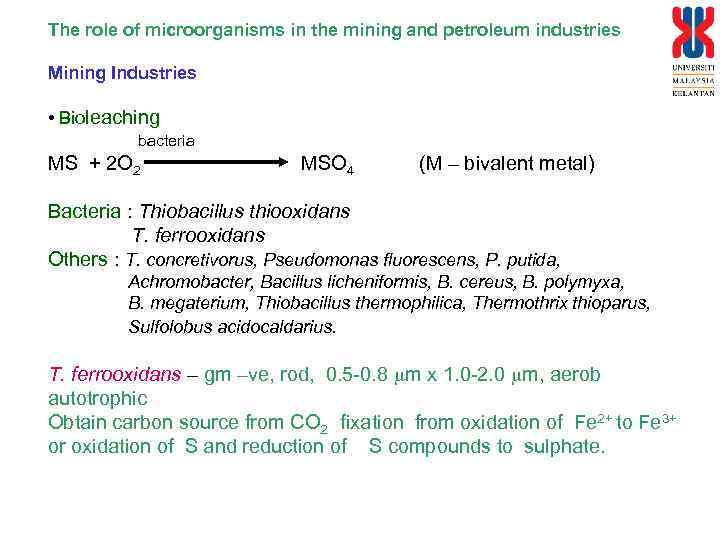

The role of microorganisms in the mining and petroleum industries Mining Industries • Bioleaching bacteria MS + 2 O 2 MSO 4 (M – bivalent metal) Bacteria : Thiobacillus thiooxidans T. ferrooxidans Others : T. concretivorus, Pseudomonas fluorescens, P. putida, Achromobacter, Bacillus licheniformis, B. cereus, B. polymyxa, B. megaterium, Thiobacillus thermophilica, Thermothrix thioparus, Sulfolobus acidocaldarius. T. ferrooxidans – gm –ve, rod, 0. 5 -0. 8 m x 1. 0 -2. 0 m, aerob autotrophic Obtain carbon source from CO 2 fixation from oxidation of Fe 2+ to Fe 3+ or oxidation of S and reduction of S compounds to sulphate.

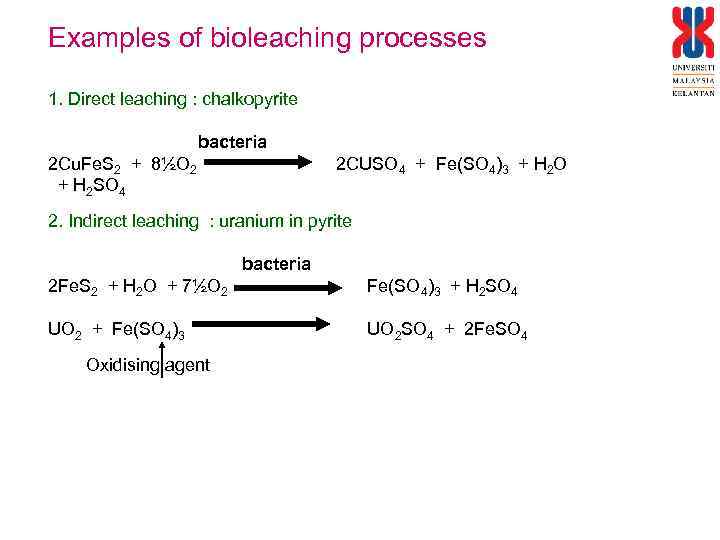

Examples of bioleaching processes 1. Direct leaching : chalkopyrite bacteria 2 Cu. Fe. S 2 + 8½O 2 + H 2 SO 4 2 CUSO 4 + Fe(SO 4)3 + H 2 O 2. Indirect leaching : uranium in pyrite bacteria 2 Fe. S 2 + H 2 O + 7½O 2 Fe(SO 4)3 + H 2 SO 4 UO 2 + Fe(SO 4)3 UO 2 SO 4 + 2 Fe. SO 4 Oxidising agent

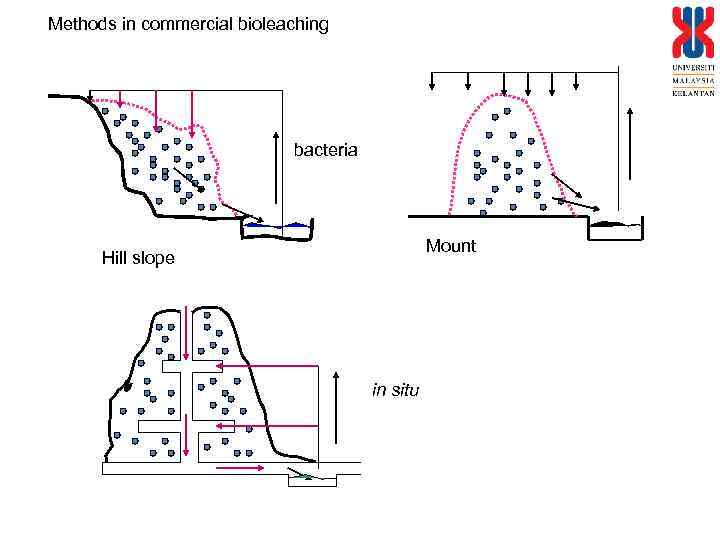

Methods in commercial bioleaching bacteria Mount Hill slope in situ

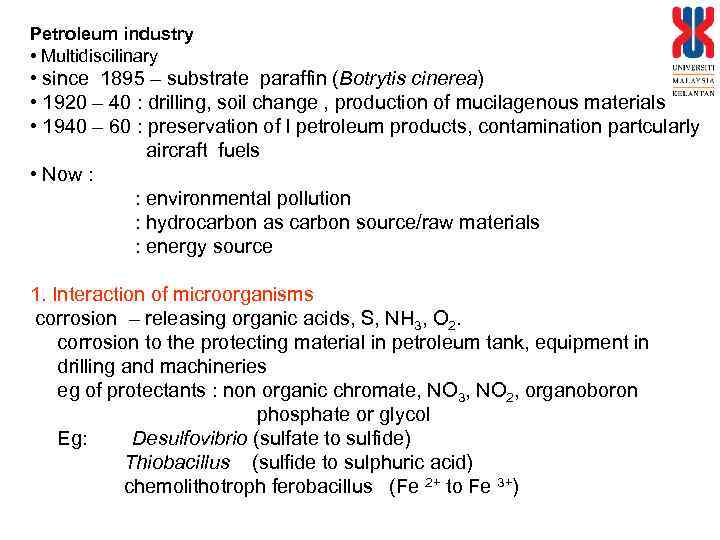

Petroleum industry • Multidiscilinary • since 1895 – substrate paraffin (Botrytis cinerea) • 1920 – 40 : drilling, soil change , production of mucilagenous materials • 1940 – 60 : preservation of l petroleum products, contamination partcularly aircraft fuels • Now : : environmental pollution : hydrocarbon as carbon source/raw materials : energy source 1. Interaction of microorganisms corrosion – releasing organic acids, S, NH 3, O 2. corrosion to the protecting material in petroleum tank, equipment in drilling and machineries eg of protectants : non organic chromate, NO 3, NO 2, organoboron phosphate or glycol Eg: Desulfovibrio (sulfate to sulfide) Thiobacillus (sulfide to sulphuric acid) chemolithotroph ferobacillus (Fe 2+ to Fe 3+)

Spoilage activities : formation of sludge and spoilage to the tank connection and equipment Bacteria: Pseudomonas, Enterobacter, Bacillus Fungi : Hormodendrum, Cladosporium, Penicillium, Aspergillus, Spicaria, Helminthosporium Control Protectant using polysulphide

2. Degradation of petroleum products Changes – viscosity, volatility, decolourisation, odour and anticorrosive characteristics a. Asphalt (bitumen) • Comprises of asfaltin • Pseudomonas, Flavobacterium, Micrococcus, Mycobacterium b. Domestic fuels • Contamination in the presence of water • Affected the operation of engines of machines c. • • • Aircraft fuels Kerosene (boiling point 65 – 225 o. C) Aliphatic Hydrocarbon Pseudomonas, Enterobacter, Aspergillus, Helminthosporium

3. Petroleum recovery Recovery method Normally recovers 40 – 60% of the total petroleum reservoir Microorganisms injected into the permeable rock together with the nutrients untuk enhance growth for the production of • acid • surfactant Surfactant : polyelectrolyte Xanthomonas campestris Characteristics: withstands temperature of 80 – 120 o. C, salinity 15%

4. Spillage of petroleum and petrochemicals Oil spillage The changing process on petroleum causes 20 – 60% loss of characteristics in 24 hr Increasing spillage – affected the health of life Control Physical Biological (the use of microorganisms) – slow process provide nutrientz to improve the growth and microbial activities : oil and sources of N & P

MICROBIAL PROCESSES IN AGRICULTURE

Importance of microorganisms in agriculture • Biocontrol (control of biological vectors) • Biofertilizers a. Controls of biological vectors • 1914 (Bacillus popilliae) • Bacillus thuringiensis – fast effect, does not affect the plant, higher animals, stable for along period of time • Enhances agricultural productivity b. Source of biological vectors • Bacteria (Bacillus as spores (paraspora) and toxic crystals) produce by fermentation processes • Virus – high specificity Inclusion bodies – nuclear polyhedroses, cytoplasmic polyhedroses, granulose, and polymorphic – produce using living caterpillars • Fungi (Phycomycetes and deuteromycetes) – mycelium, spores and toxin • Protozoa – potential but low stabilty

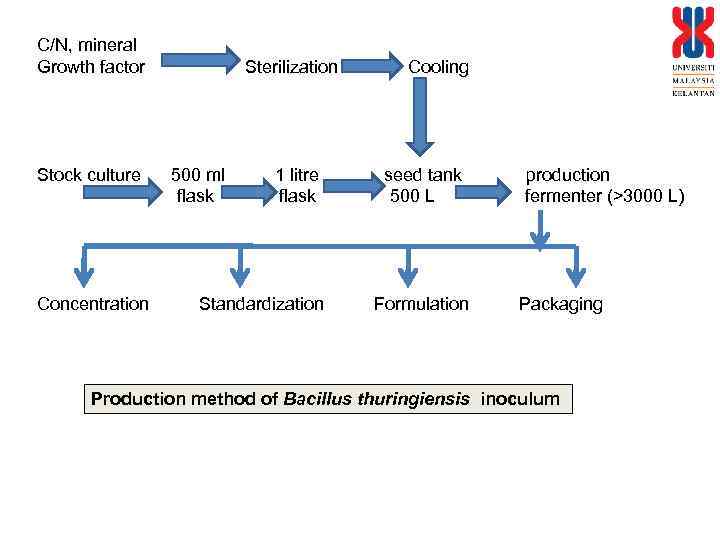

C/N, mineral Growth factor Stock culture Concentration Sterilization 500 ml flask 1 litre flask Standardization Cooling seed tank 500 L Formulation production fermenter (>3000 L) Packaging Production method of Bacillus thuringiensis inoculum

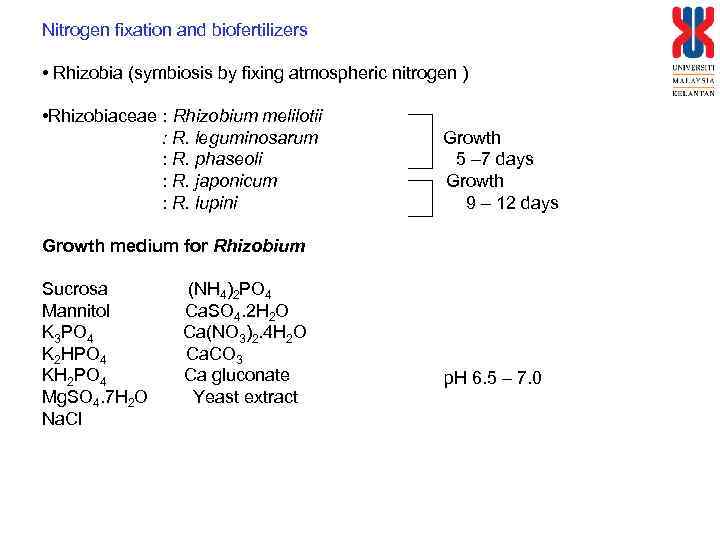

Nitrogen fixation and biofertilizers • Rhizobia (symbiosis by fixing atmospheric nitrogen ) • Rhizobiaceae : Rhizobium melilotii : R. leguminosarum : R. phaseoli : R. japonicum : R. lupini Growth 5 – 7 days Growth 9 – 12 days Growth medium for Rhizobium Sucrosa Mannitol K 3 PO 4 K 2 HPO 4 KH 2 PO 4 Mg. SO 4. 7 H 2 O Na. Cl (NH 4)2 PO 4 Ca. SO 4. 2 H 2 O Ca(NO 3)2. 4 H 2 O Ca. CO 3 Ca gluconate Yeast extract p. H 6. 5 – 7. 0

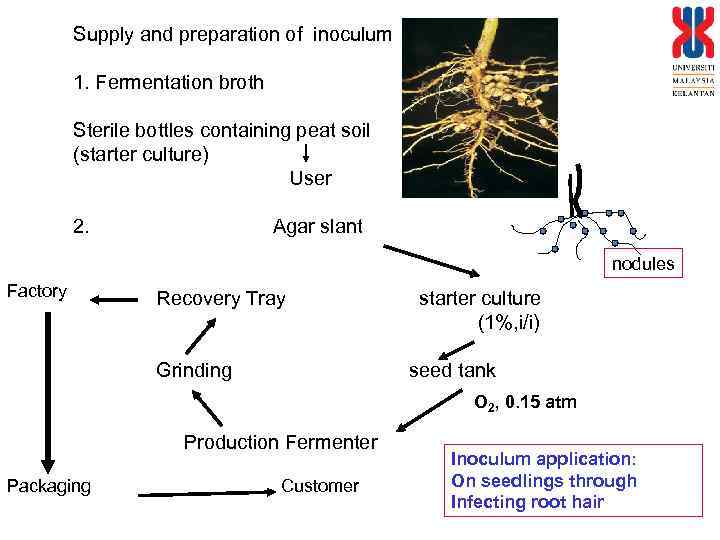

Supply and preparation of inoculum 1. Fermentation broth Sterile bottles containing peat soil (starter culture) User 2. Agar slant nodules Factory Recovery Tray Grinding starter culture (1%, i/i) seed tank O 2, 0. 15 atm Production Fermenter Packaging Customer Inoculum application: On seedlings through Infecting root hair

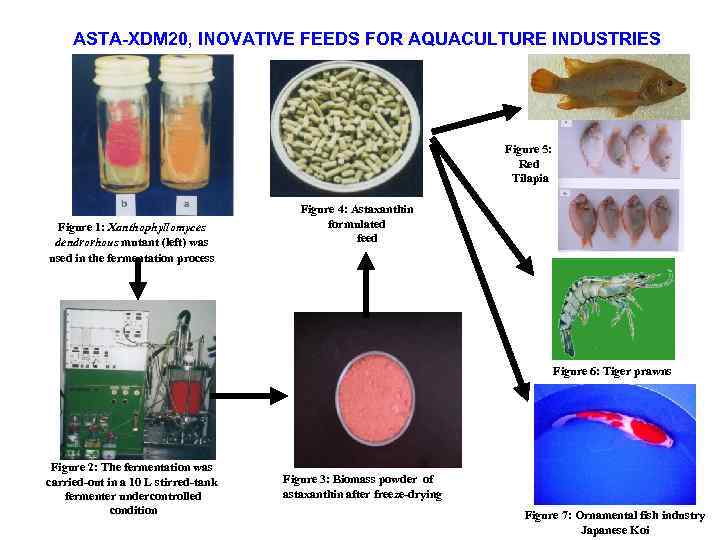

ASTA-XDM 20, INOVATIVE FEEDS FOR AQUACULTURE INDUSTRIES Figure 5: Red Tilapia Figure 1: Xanthophyllomyces dendrorhous mutant (left) was used in the fermentation process Figure 4: Astaxanthin formulated feed Figure 6: Tiger prawns Figure 2: The fermentation was carried-out in a 10 L stirred-tank fermenter undercontrolled condition Figure 3: Biomass powder of astaxanthin after freeze-drying Figure 7: Ornamental fish industry Japanese Koi

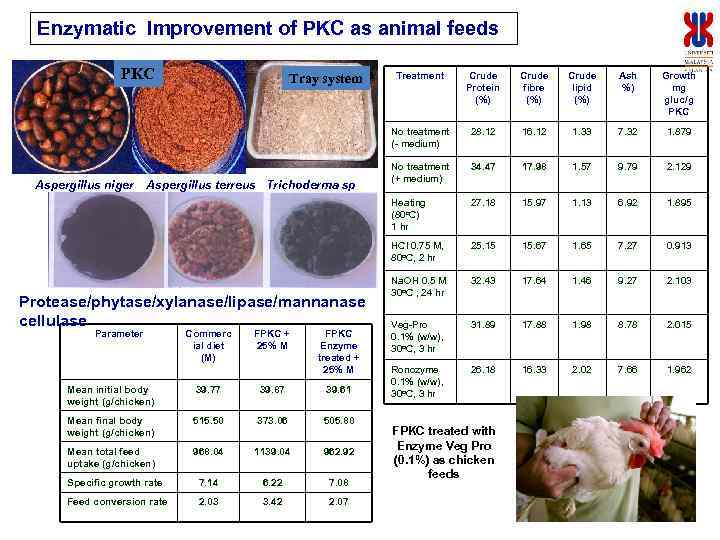

Enzymatic Improvement of PKC as animal feeds PKC Protease/phytase/xylanase/lipase/mannanase cellulase Parameter Commerc ial diet (M) FPKC + 25% M FPKC Enzyme treated + 25% M Mean initial body weight (g/chicken) 39. 77 39. 87 39. 61 Mean final body weight (g/chicken) 515. 50 373. 06 505. 80 Mean total feed uptake (g/chicken) 968. 04 1139. 04 962. 92 Specific growth rate 7. 14 6. 22 7. 08 Feed conversion rate 2. 03 3. 42 2. 07 Crude fibre (%) Crude lipid (%) Ash %) Growth mg gluc/g PKC 28. 12 16. 12 1. 33 7. 32 1. 879 No treatment (+ medium) 34. 47 17. 98 1. 57 9. 79 2. 129 27. 18 15. 97 1. 13 6. 92 1. 895 HCl 0. 75 M, 80 o. C, 2 hr Aspergillus terreus Trichoderma sp. Crude Protein (%) Heating (80 o. C) 1 hr Aspergillus niger Treatment No treatment (- medium) Tray system 25. 15 15. 67 1. 65 7. 27 0. 913 Na. OH 0. 5 M 30 o. C , 24 hr 32. 43 17. 64 1. 46 9. 27 2. 103 Veg-Pro 0. 1% (w/w), 30 o. C, 3 hr 31. 89 17. 88 1. 98 8. 78 2. 015 Ronozyme 0. 1% (w/w), 30 o. C, 3 hr 26. 18 16. 33 2. 02 7. 66 1. 962 FPKC treated with Enzyme Veg Pro (0. 1%) as chicken feeds

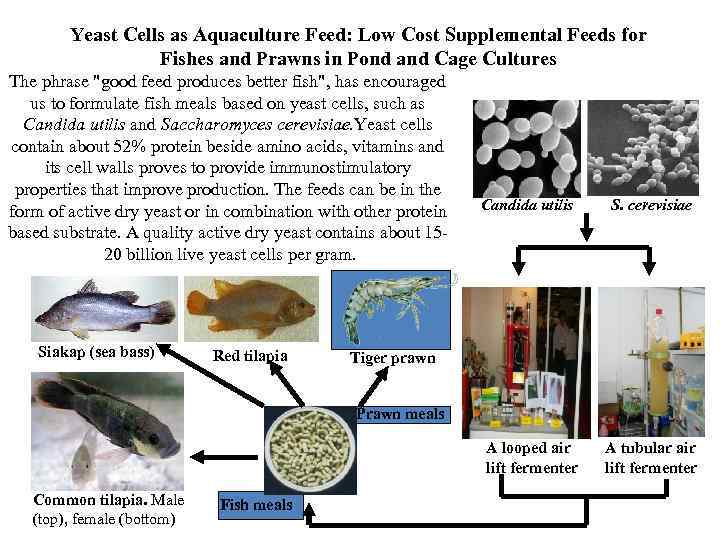

Yeast Cells as Aquaculture Feed: Low Cost Supplemental Feeds for Fishes and Prawns in Pond and Cage Cultures The phrase "good feed produces better fish", has encouraged us to formulate fish meals based on yeast cells, such as Candida utilis and Saccharomyces cerevisiae. Yeast cells contain about 52% protein beside amino acids, vitamins and its cell walls proves to provide immunostimulatory properties that improve production. The feeds can be in the form of active dry yeast or in combination with other protein based substrate. A quality active dry yeast contains about 1520 billion live yeast cells per gram. Red tilapia S. cerevisiae A looped air lift fermenter Siakap (sea bass) Candida utilis A tubular air lift fermenter Tiger prawn Prawn meals Common tilapia. Male (top), female (bottom) Fish meals

Tissue Culture technology for fruits production

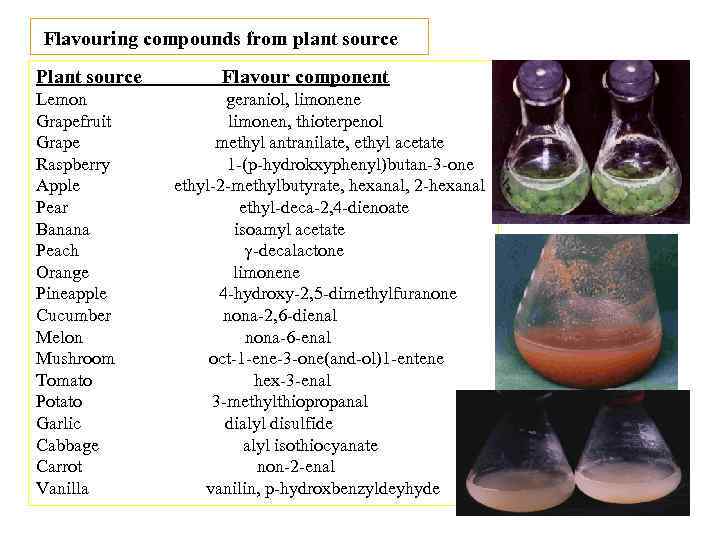

Flavouring compounds from plant source Plant source Lemon Grapefruit Grape Raspberry Apple Pear Banana Peach Orange Pineapple Cucumber Melon Mushroom Tomato Potato Garlic Cabbage Carrot Vanilla Flavour component geraniol, limonene limonen, thioterpenol methyl antranilate, ethyl acetate 1 -(p-hydrokxyphenyl)butan-3 -one ethyl-2 -methylbutyrate, hexanal, 2 -hexanal ethyl-deca-2, 4 -dienoate isoamyl acetate -decalactone limonene 4 -hydroxy-2, 5 -dimethylfuranone nona-2, 6 -dienal nona-6 -enal oct-1 -ene-3 -one(and-ol)1 -entene hex-3 -enal 3 -methylthiopropanal dialyl disulfide alyl isothiocyanate non-2 -enal vanilin, p-hydroxbenzyldeyhyde

WASTE TREATMENT SYSTEMS FOR FERMENTATION INDUSTRIES

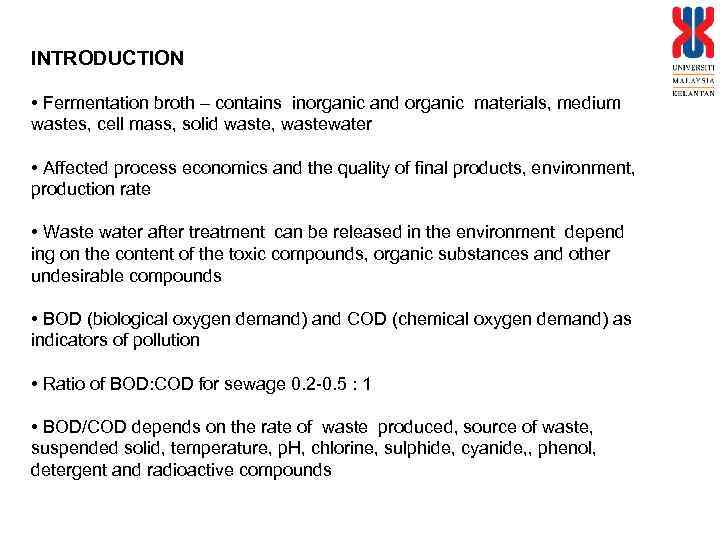

INTRODUCTION • Fermentation broth – contains inorganic and organic materials, medium wastes, cell mass, solid waste, wastewater • Affected process economics and the quality of final products, environment, production rate • Waste water after treatment can be released in the environment depend ing on the content of the toxic compounds, organic substances and other undesirable compounds • BOD (biological oxygen demand) and COD (chemical oxygen demand) as indicators of pollution • Ratio of BOD: COD for sewage 0. 2 -0. 5 : 1 • BOD/COD depends on the rate of waste produced, source of waste, suspended solid, temperature, p. H, chlorine, sulphide, cyanide, , phenol, detergent and radioactive compounds

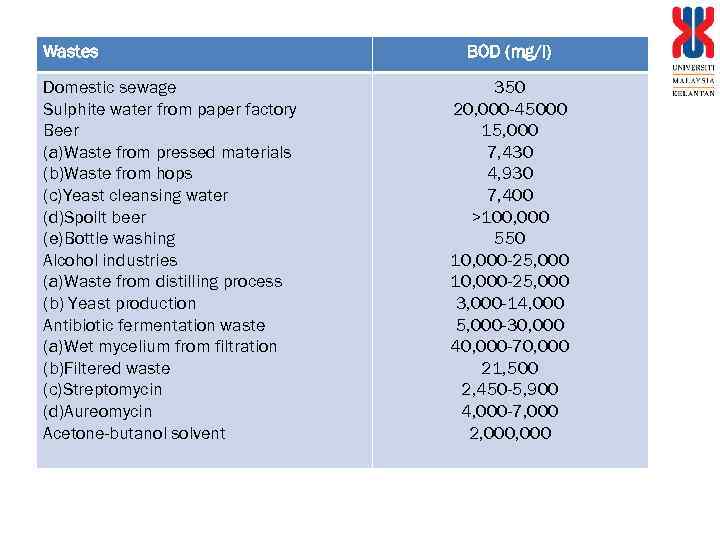

Wastes Domestic sewage Sulphite water from paper factory Beer (a)Waste from pressed materials (b)Waste from hops (c)Yeast cleansing water (d)Spoilt beer (e)Bottle washing Alcohol industries (a)Waste from distilling process (b) Yeast production Antibiotic fermentation waste (a)Wet mycelium from filtration (b)Filtered waste (c)Streptomycin (d)Aureomycin Acetone-butanol solvent BOD (mg/l) 350 20, 000 -45000 15, 000 7, 430 4, 930 7, 400 >100, 000 550 10, 000 -25, 000 3, 000 -14, 000 5, 000 -30, 000 40, 000 -70, 000 21, 500 2, 450 -5, 900 4, 000 -7, 000 2, 000

METHODS IN TREATMENT OF INDUSTRIAL WASTES DIRECT DISPOSAL a)Sea or rivers – depends on the degree of dilution when the waste id released BOD 20 mg/l and suspended solid of 30 mg/l. b) Oxidation ponds - shallow water of 1 – 2 m deep, sodium nitrate added to supply oxygen. , as secondary treatment before released in the environment c) Disposal in wells – unused wells, water holes or mining holes. A well with 500 m deep is used to treat 900 kg acetic acid, 900 kg ammonium acetate, 900 kg sodium acetate, 760 kg sodium chloride, 450 kg sodium bromide, and 225 kg ammonium bromide. The mixture has p. H 4 -5 and BOD 40, 000 – 100, 000 mg/l d) Waste tretament by Municipal Council - depends i. Waste provided does not affect the existing system ii. Waste does not contain compounds/substances which are undegradable iii. The waste can be managed by the treatment plant in terms of its volume and contents

TREATMENT PROCESSES (Physical, Chemical and Biological Methods) A)Physical method Removal of suspended solid before other treatments. Reduces BOD and the solid cell mass can be disposed or burned B) Chemical Method : coagulation or flocculation Coagulation – rapid process Flocculation – slow process with agitation of low rate to form aggregates/flocs Chemical used : Fe 2(SO 4)3, Al 2(SO 4)3 (alum), or ca(OH)2 Aggregates/floc form the sludge which be removed, dewater and further treated C) Biological Method : Aerobic process (trickling filter and activated sludge processes) Anaerobic process (anaerobic digestion)

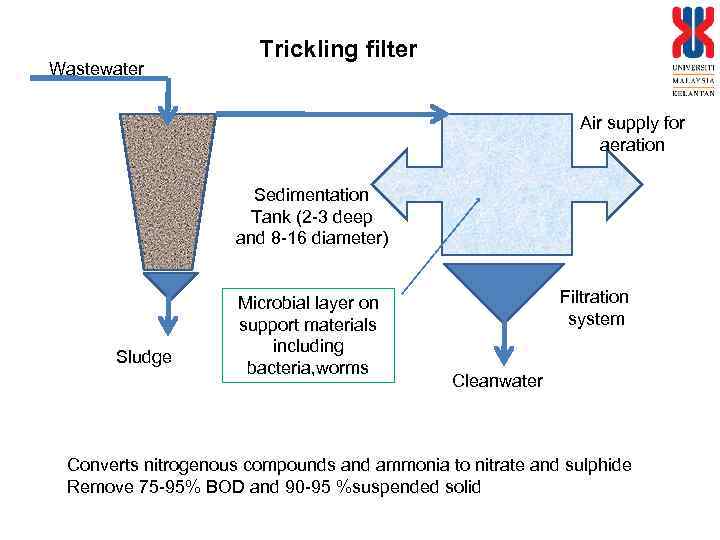

Wastewater Trickling filter Air supply for aeration Sedimentation Tank (2 -3 deep and 8 -16 diameter) Sludge Microbial layer on support materials including bacteria, worms Filtration system Cleanwater Converts nitrogenous compounds and ammonia to nitrate and sulphide Remove 75 -95% BOD and 90 -95 %suspended solid

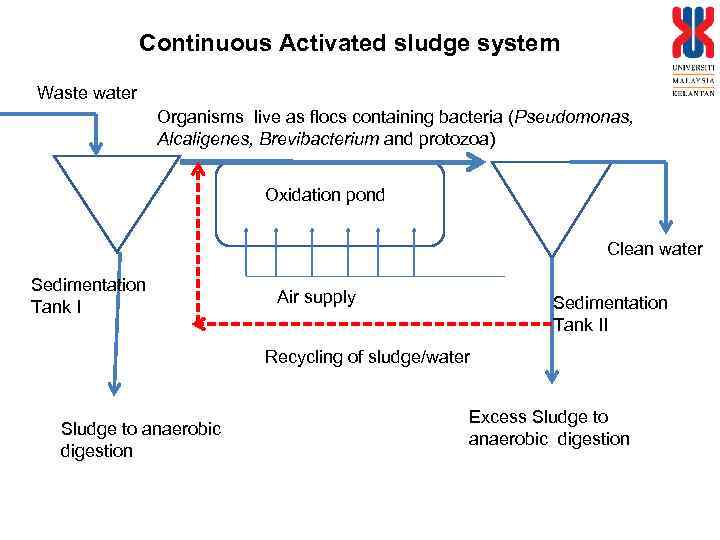

Continuous Activated sludge system Waste water Organisms live as flocs containing bacteria (Pseudomonas, Alcaligenes, Brevibacterium and protozoa) Oxidation pond Clean water Sedimentation Tank I Air supply Sedimentation Tank II Recycling of sludge/water Sludge to anaerobic digestion Excess Sludge to anaerobic digestion

Industrial Biotechnology - копия.ppt