4d11e43d98646d278c285d28f43ba69a.ppt

- Количество слайдов: 24

Micro. Mist. TM Scrubbing Systems Wet Scrubber Advanced Scrubbing Technology General Product Description

About Enviro. Care International • Formed in 1980 as a Pollution Control Engineering Systems and Services Company • Micro. Mist Scrubbbing Technology Applied all Over the World in Pulp & Paper, Power, Steel, Municipal Waste and Many More • In-house Engineering and Manufacturing Expertise • Over 15 Patents on Atomization and Pollution Control Technologies

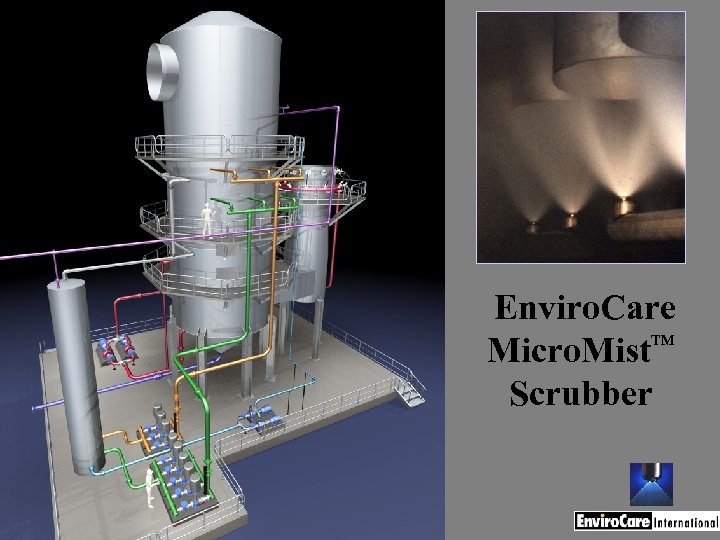

Enviro. Care Micro. Mist™ Scrubber

Benefits of Micro. Mist. TM Scrubbing Technology • Lower Energy Consumption. Micro. Mist Scrubber Typically Operates With Less Than 25” W. C. of Total Pressure Drop • Lower Equipment Costs • High Capture Efficiencies on Acid Gasses & Submicron Particulate • High Capture Efficiencies on Condensables • Retrofit Existing Equipment = Minimal Outage Time • Proven Results!

What’s Different? • • Sequence of Components and “Events” Quenching and Sub-Cooling Patented Scrubbing with Fine Droplets Use of Proprietary Dual-Orifice Impingement (DOI) Trays and Highly Efficient Mist Eliminators with Irrigation Lower System Pressure Drop Ability to Scrub Fine Particulate, Acid Gases, Condensables, and Heavy Metals in “One System” Water Management and Experience Operational Flexibility for Varying Gas Flow

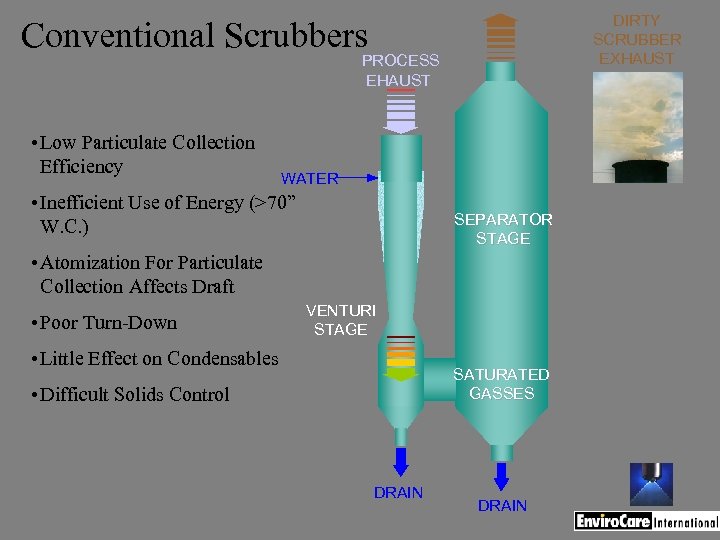

DIRTY SCRUBBER EXHAUST Conventional Scrubbers PROCESS EHAUST • Low Particulate Collection Efficiency WATER • Inefficient Use of Energy (>70” W. C. ) SEPARATOR STAGE • Atomization For Particulate Collection Affects Draft • Poor Turn-Down VENTURI STAGE • Little Effect on Condensables SATURATED GASSES • Difficult Solids Control DRAIN

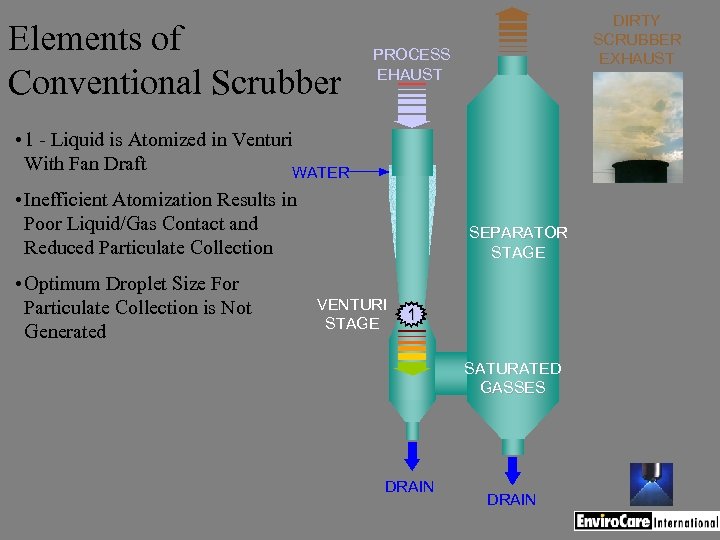

Elements of Conventional Scrubber DIRTY SCRUBBER EXHAUST PROCESS EHAUST • 1 - Liquid is Atomized in Venturi With Fan Draft WATER • Inefficient Atomization Results in Poor Liquid/Gas Contact and Reduced Particulate Collection • Optimum Droplet Size For Particulate Collection is Not Generated SEPARATOR STAGE VENTURI STAGE 1 SATURATED GASSES DRAIN

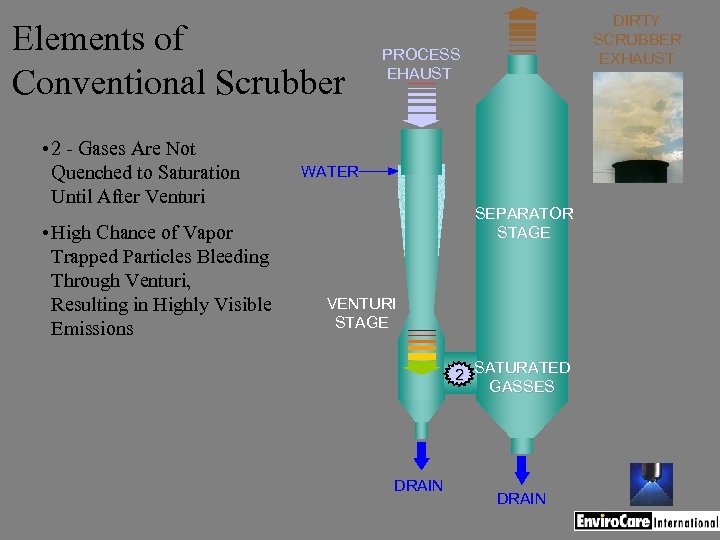

Elements of Conventional Scrubber • 2 - Gases Are Not Quenched to Saturation Until After Venturi • High Chance of Vapor Trapped Particles Bleeding Through Venturi, Resulting in Highly Visible Emissions DIRTY SCRUBBER EXHAUST PROCESS EHAUST WATER SEPARATOR STAGE VENTURI STAGE 2 SATURATED GASSES DRAIN

Flue Gas Clean Gas Micro. Mist. TM Scrubber • High Particulate Collection Efficiency (>99. 5%) • High Capture Efficiency of Acids & Condensables (>98. 9%) • High Capture Efficiency of Heavy Metals (95% - 99% + ) • Efficient Use of Energy (System ∆P <25” WC) • Atomization for Particulate Collection Independent of Draft • Excellent Turn-Down • Solids Control & Segregation

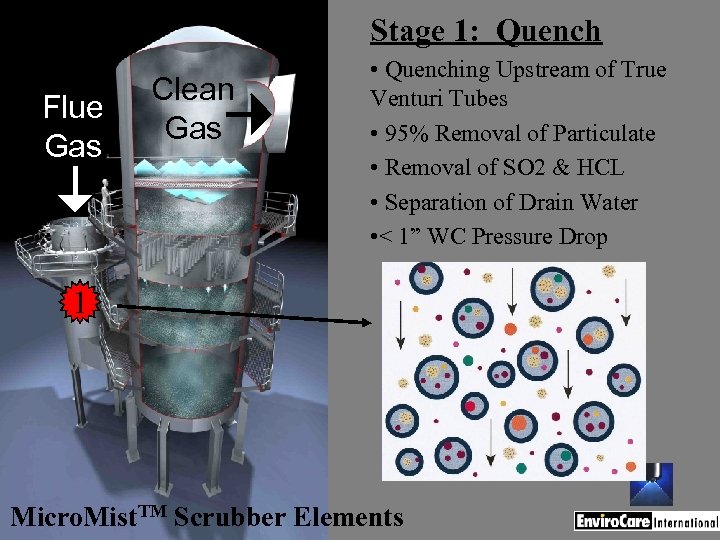

Stage 1: Quench Flue Gas Clean Gas • Quenching Upstream of True Venturi Tubes • 95% Removal of Particulate • Removal of SO 2 & HCL • Separation of Drain Water • < 1” WC Pressure Drop 1 Micro. Mist. TM Scrubber Elements

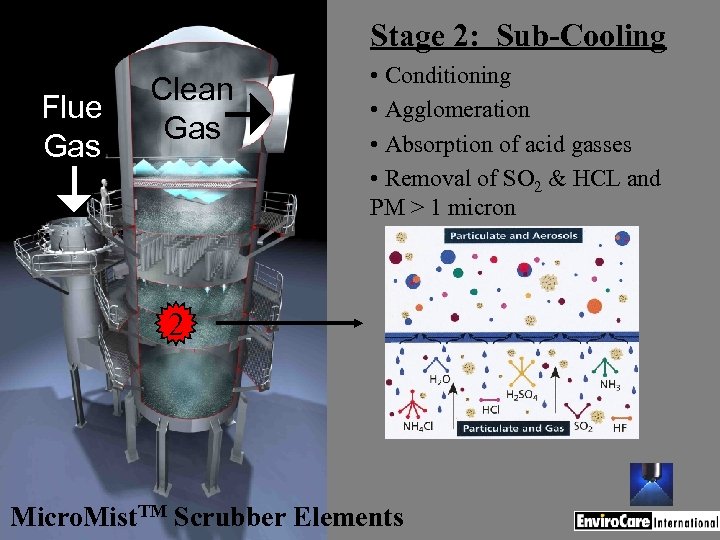

Stage 2: Sub-Cooling Flue Gas Clean Gas • Conditioning • Agglomeration • Absorption of acid gasses • Removal of SO 2 & HCL and PM > 1 micron 2 Micro. Mist. TM Scrubber Elements

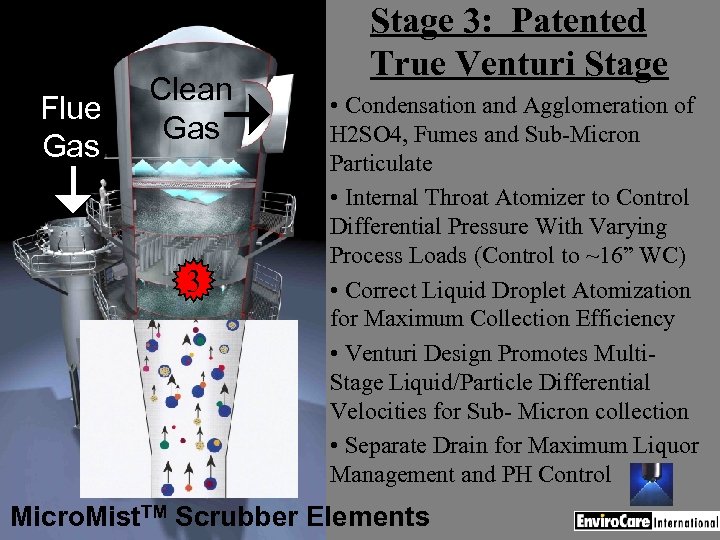

Flue Gas Clean Gas 3 Stage 3: Patented True Venturi Stage • Condensation and Agglomeration of H 2 SO 4, Fumes and Sub-Micron Particulate • Internal Throat Atomizer to Control Differential Pressure With Varying Process Loads (Control to ~16” WC) • Correct Liquid Droplet Atomization for Maximum Collection Efficiency • Venturi Design Promotes Multi. Stage Liquid/Particle Differential Velocities for Sub- Micron collection • Separate Drain for Maximum Liquor Management and PH Control Micro. Mist. TM Scrubber Elements

Venturi Tubes are “Ideal” Venturi Design Incorporating Maximum Particle/Droplet Collisions and Pressure Recovery

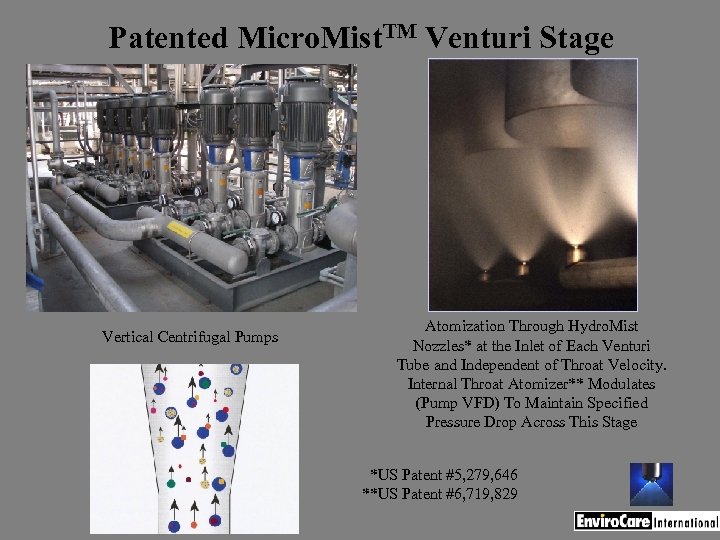

Patented Micro. Mist. TM Venturi Stage Vertical Centrifugal Pumps Atomization Through Hydro. Mist Nozzles* at the Inlet of Each Venturi Tube and Independent of Throat Velocity. Internal Throat Atomizer** Modulates (Pump VFD) To Maintain Specified Pressure Drop Across This Stage *US Patent #5, 279, 646 **US Patent #6, 719, 829

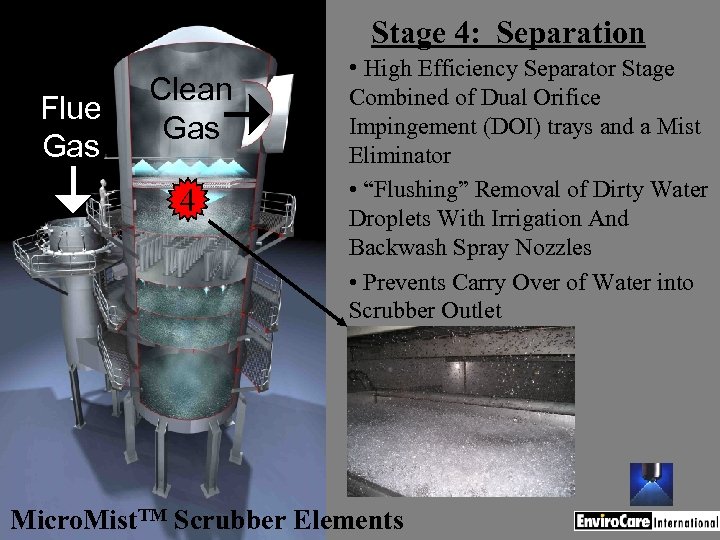

Stage 4: Separation Flue Gas Clean Gas 4 • High Efficiency Separator Stage Combined of Dual Orifice Impingement (DOI) trays and a Mist Eliminator • “Flushing” Removal of Dirty Water Droplets With Irrigation And Backwash Spray Nozzles • Prevents Carry Over of Water into Scrubber Outlet Micro. Mist. TM Scrubber Elements

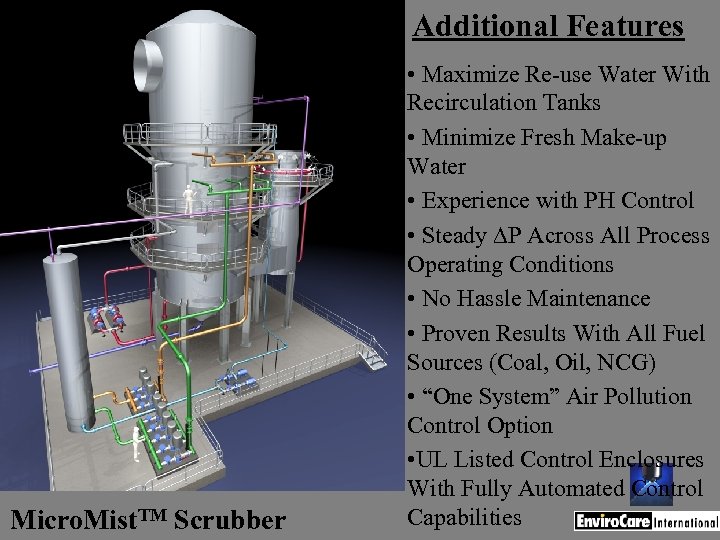

Additional Features Micro. Mist. TM Scrubber • Maximize Re-use Water With Recirculation Tanks • Minimize Fresh Make-up Water • Experience with PH Control • Steady ∆P Across All Process Operating Conditions • No Hassle Maintenance • Proven Results With All Fuel Sources (Coal, Oil, NCG) • “One System” Air Pollution Control Option • UL Listed Control Enclosures With Fully Automated Control Capabilities

Micro. Mist. TM Scrubber Flue Gas Clean Gas • High Particulate Collection Efficiency (>99. 5%) • High Capture Efficiency of Acids & Condensables (>98. 9%) • High Capture Efficiency of Heavy Metals (95% - 99% + ) • Efficient Use of Energy (System ∆P <25” WC) • Atomization for Particulate Collection Independent of Draft • Excellent Turn-Down • Solids Control & Segregation

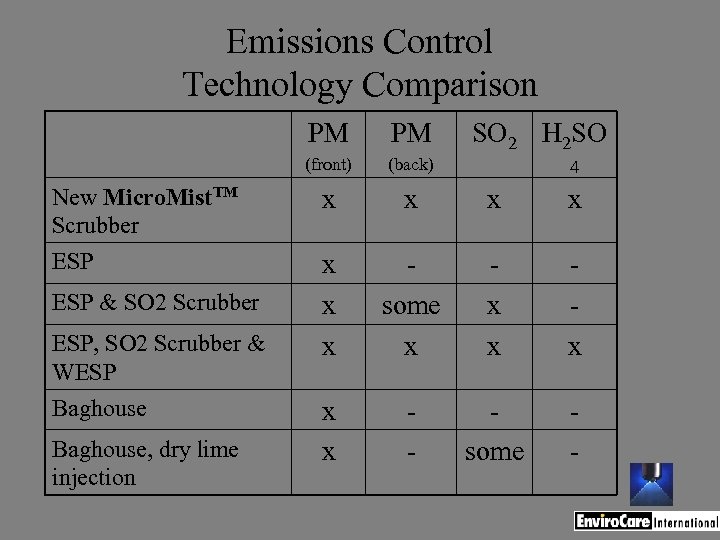

Emissions Control Technology Comparison PM PM (front) (back) New Micro. Mist. TM Scrubber x x ESP x x x some x x x - some - ESP & SO 2 Scrubber ESP, SO 2 Scrubber & WESP Baghouse, dry lime injection SO 2 H 2 SO 4

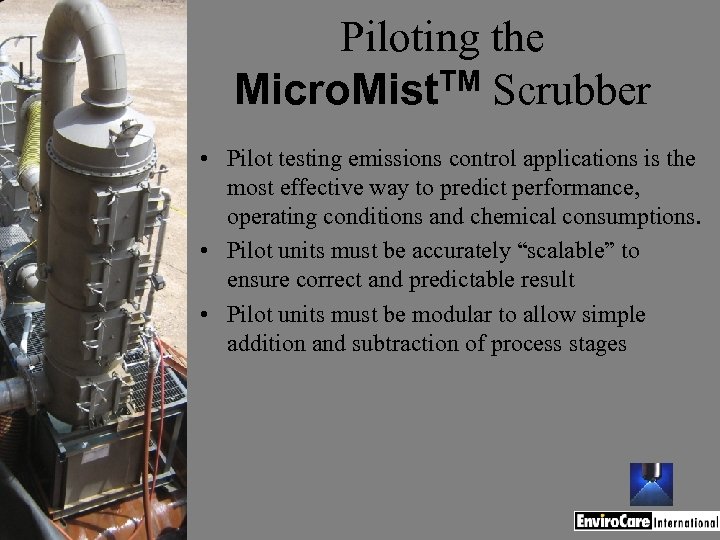

Piloting the Micro. Mist. TM Scrubber • Pilot testing emissions control applications is the most effective way to predict performance, operating conditions and chemical consumptions. • Pilot units must be accurately “scalable” to ensure correct and predictable result • Pilot units must be modular to allow simple addition and subtraction of process stages

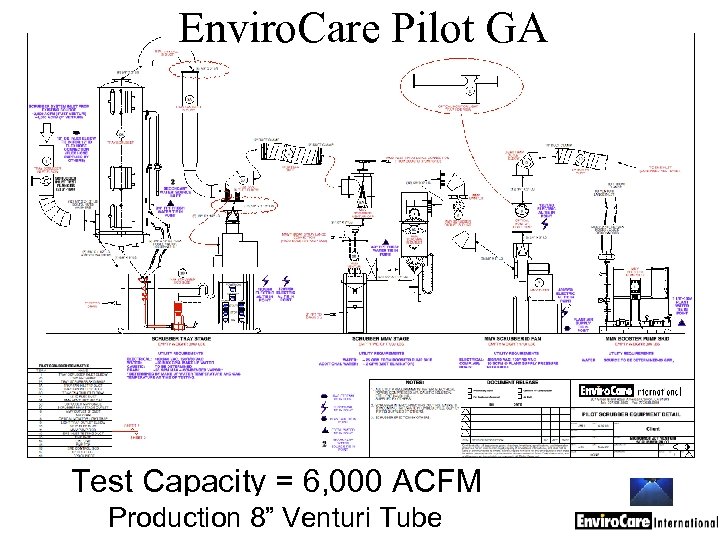

Enviro. Care Pilot GA Test Capacity = 6, 000 ACFM Production 8” Venturi Tube

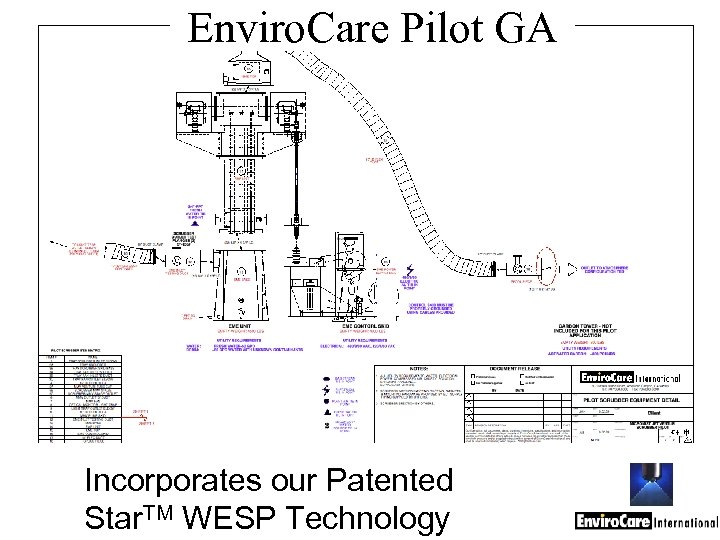

Enviro. Care Pilot GA Incorporates our Patented Star. TM WESP Technology

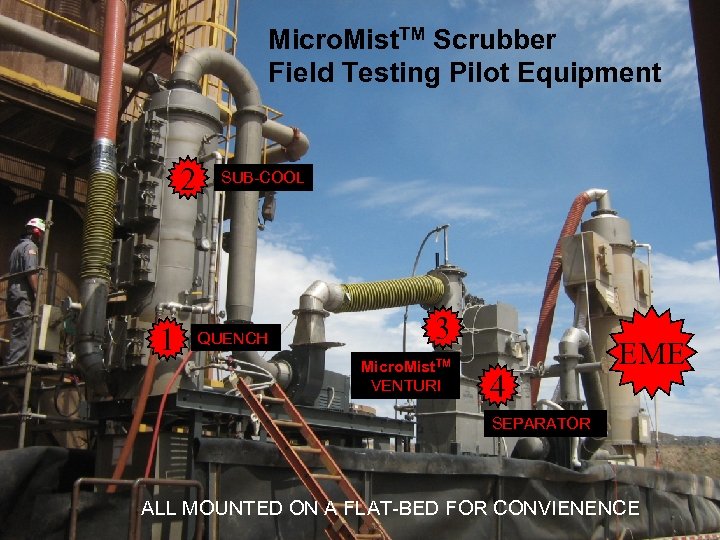

Micro. Mist. TM Scrubber Field Testing Pilot Equipment 2 1 SUB-COOL QUENCH 3 Micro. Mist. TM VENTURI 4 EME SEPARATOR ALL MOUNTED ON A FLAT-BED FOR CONVIENENCE

Why try Enviro. Care’s Micro. Mist. TM Scrubber Pilot? • Cost Effective Method to Prove Efficiency • All Equipment Arrives on Site Together • Easy, Convenient, and Compact • Enviro. Care Engineering Assistance • Includes All Required Instrumentation • Includes Production 8” Venturi Tube in MMV Stage • Test Ports in Multiple Locations • Enviro. Care Field Service Technicians • “One System” Solution To Pollution Control

ANY QUESTIONS? Email us: info@envirocare. com

4d11e43d98646d278c285d28f43ba69a.ppt