12056d93883cc10fa55c58518a762186.ppt

- Количество слайдов: 11

METHODS FOR ENHANCING PRODUCTIVITY AND WORK EFFICIENCY IN THE WORKSHOP Jyri Riives, Tauno Otto, Kaia Lõun 12 th – 15 th March 2007 XVIII Workshop, Karpacz

METHODS FOR ENHANCING PRODUCTIVITY AND WORK EFFICIENCY IN THE WORKSHOP Jyri Riives, Tauno Otto, Kaia Lõun 12 th – 15 th March 2007 XVIII Workshop, Karpacz

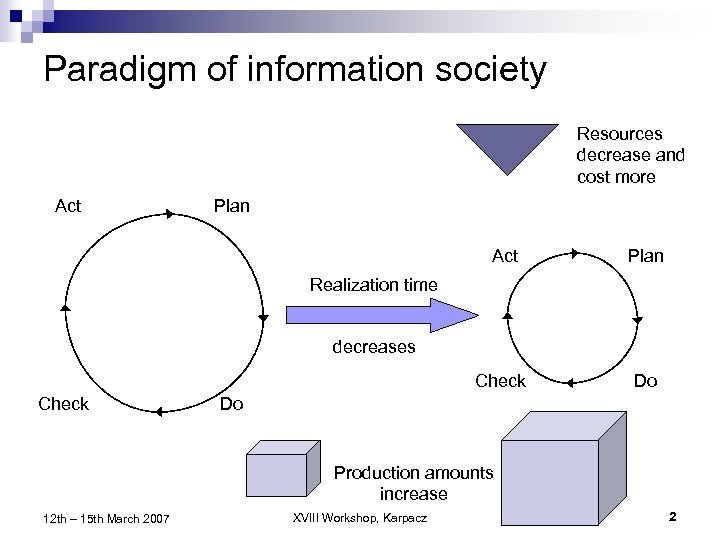

Paradigm of information society Resources decrease and cost more Act Plan Check Do Realization time decreases Check Do Production amounts increase 12 th – 15 th March 2007 XVIII Workshop, Karpacz 2

Paradigm of information society Resources decrease and cost more Act Plan Check Do Realization time decreases Check Do Production amounts increase 12 th – 15 th March 2007 XVIII Workshop, Karpacz 2

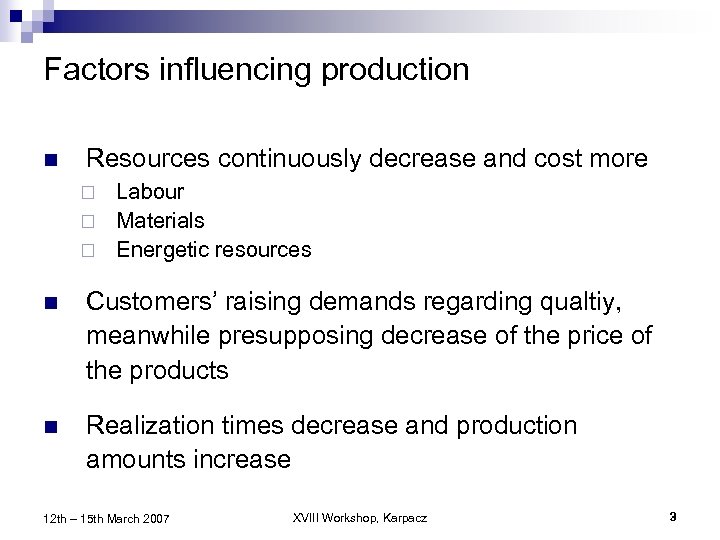

Factors influencing production n Resources continuously decrease and cost more Labour ¨ Materials ¨ Energetic resources ¨ n Customers’ raising demands regarding qualtiy, meanwhile presupposing decrease of the price of the products n Realization times decrease and production amounts increase 12 th – 15 th March 2007 XVIII Workshop, Karpacz 3

Factors influencing production n Resources continuously decrease and cost more Labour ¨ Materials ¨ Energetic resources ¨ n Customers’ raising demands regarding qualtiy, meanwhile presupposing decrease of the price of the products n Realization times decrease and production amounts increase 12 th – 15 th March 2007 XVIII Workshop, Karpacz 3

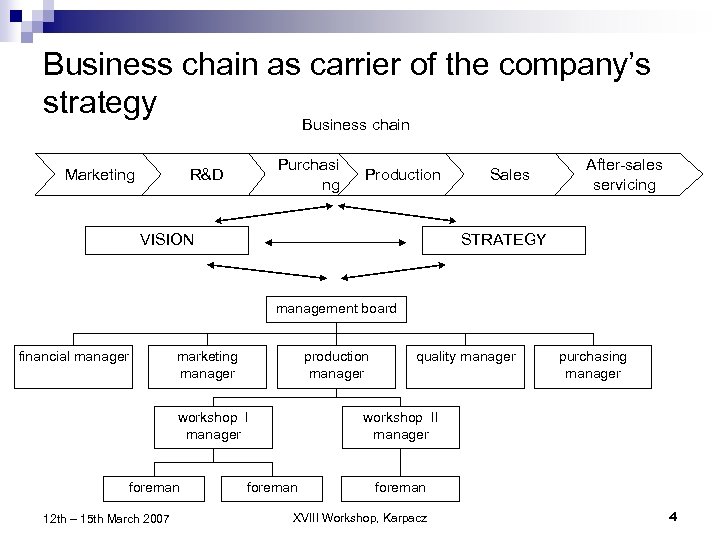

Business chain as carrier of the company’s strategy Business chain Marketing Purchasi ng R&D Production VISION Sales After-sales servicing STRATEGY management board financial manager marketing manager production manager workshop I manager foreman 12 th – 15 th March 2007 quality manager purchasing manager workshop II manager foreman XVIII Workshop, Karpacz 4

Business chain as carrier of the company’s strategy Business chain Marketing Purchasi ng R&D Production VISION Sales After-sales servicing STRATEGY management board financial manager marketing manager production manager workshop I manager foreman 12 th – 15 th March 2007 quality manager purchasing manager workshop II manager foreman XVIII Workshop, Karpacz 4

Organization as a system with measurable value 12 th – 15 th March 2007 XVIII Workshop, Karpacz 5

Organization as a system with measurable value 12 th – 15 th March 2007 XVIII Workshop, Karpacz 5

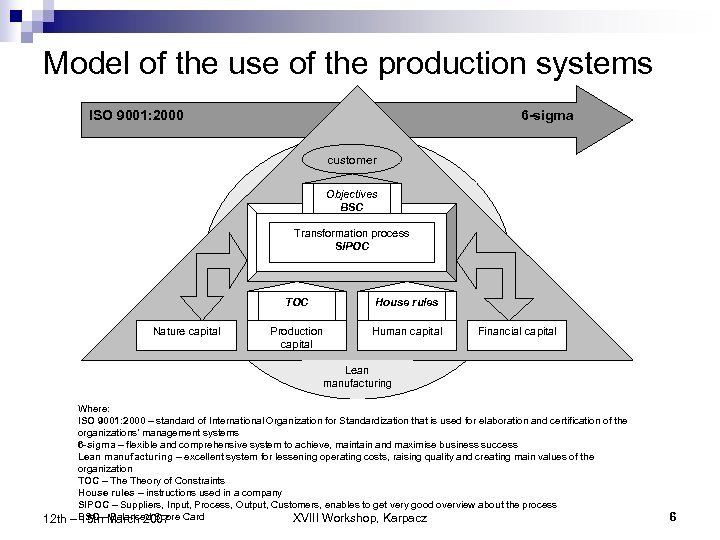

Model of the use of the production systems ISO 9001: 2000 6 -sigma customer Objectives BSC Transformation process SIPOC TOC Nature capital House rules Production capital Human capital Financial capital Lean manufacturing 12 th Where: ISO 9001: 2000 – standard of International Organization for Standardization that is used for elaboration and certification of the organizations’ management systems 6 -sigma – flexible and comprehensive system to achieve, maintain and maximise business success Lean manufacturing – excellent system for lessening operating costs, raising quality and creating main values of the organization TOC – Theory of Constraints House rules – instructions used in a company SIPOC – Suppliers, Input, Process, Output, Customers, enables to get very good overview about the process XVIII Workshop, Karpacz – BSC –March 2007 Card 15 th Balanced Score 6

Model of the use of the production systems ISO 9001: 2000 6 -sigma customer Objectives BSC Transformation process SIPOC TOC Nature capital House rules Production capital Human capital Financial capital Lean manufacturing 12 th Where: ISO 9001: 2000 – standard of International Organization for Standardization that is used for elaboration and certification of the organizations’ management systems 6 -sigma – flexible and comprehensive system to achieve, maintain and maximise business success Lean manufacturing – excellent system for lessening operating costs, raising quality and creating main values of the organization TOC – Theory of Constraints House rules – instructions used in a company SIPOC – Suppliers, Input, Process, Output, Customers, enables to get very good overview about the process XVIII Workshop, Karpacz – BSC –March 2007 Card 15 th Balanced Score 6

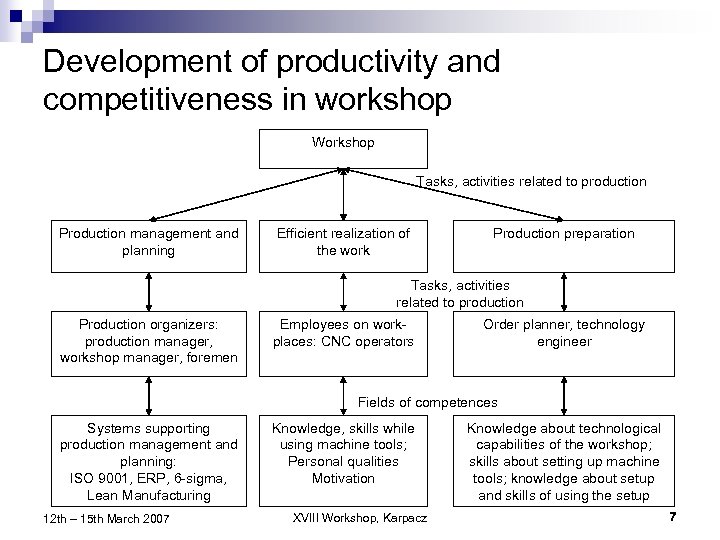

Development of productivity and competitiveness in workshop Workshop Tasks, activities related to production Production management and planning Efficient realization of the work Production preparation Tasks, activities related to production Production organizers: production manager, workshop manager, foremen Employees on workplaces: CNC operators Order planner, technology engineer Fields of competences Systems supporting production management and planning: ISO 9001, ERP, 6 -sigma, Lean Manufacturing 12 th – 15 th March 2007 Knowledge, skills while using machine tools; Personal qualities Motivation XVIII Workshop, Karpacz Knowledge about technological capabilities of the workshop; skills about setting up machine tools; knowledge about setup and skills of using the setup 7

Development of productivity and competitiveness in workshop Workshop Tasks, activities related to production Production management and planning Efficient realization of the work Production preparation Tasks, activities related to production Production organizers: production manager, workshop manager, foremen Employees on workplaces: CNC operators Order planner, technology engineer Fields of competences Systems supporting production management and planning: ISO 9001, ERP, 6 -sigma, Lean Manufacturing 12 th – 15 th March 2007 Knowledge, skills while using machine tools; Personal qualities Motivation XVIII Workshop, Karpacz Knowledge about technological capabilities of the workshop; skills about setting up machine tools; knowledge about setup and skills of using the setup 7

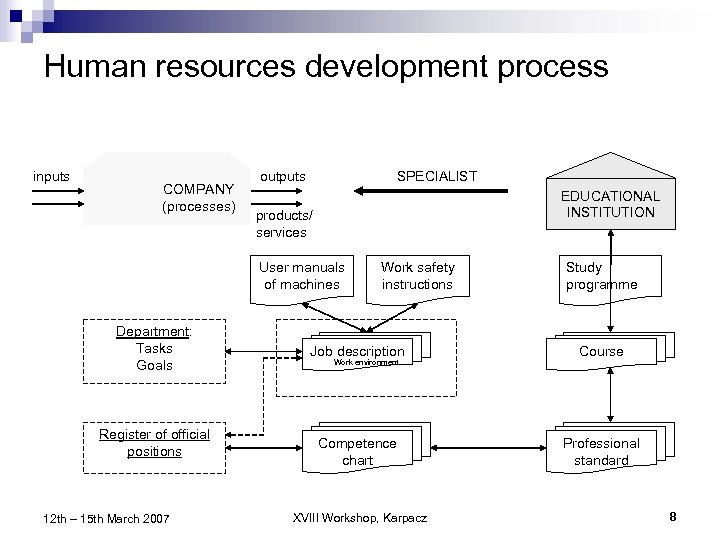

Human resources development process inputs COMPANY (processes) outputs SPECIALIST EDUCATIONAL INSTITUTION products/ services User manuals of machines Department: Tasks Goals Register of official positions 12 th – 15 th March 2007 Work safety instructions Study programme Job description Course Competence chart Professional standard Work environment XVIII Workshop, Karpacz 8

Human resources development process inputs COMPANY (processes) outputs SPECIALIST EDUCATIONAL INSTITUTION products/ services User manuals of machines Department: Tasks Goals Register of official positions 12 th – 15 th March 2007 Work safety instructions Study programme Job description Course Competence chart Professional standard Work environment XVIII Workshop, Karpacz 8

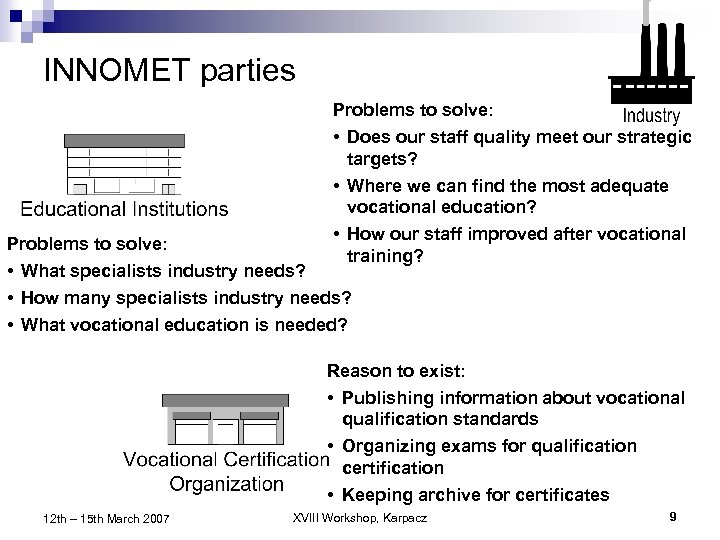

INNOMET parties Problems to solve: • Does our staff quality meet our strategic targets? • Where we can find the most adequate vocational education? • How our staff improved after vocational training? • What specialists industry needs? • How many specialists industry needs? • What vocational education is needed? Reason to exist: • Publishing information about vocational qualification standards • Organizing exams for qualification certification • Keeping archive for certificates 12 th – 15 th March 2007 XVIII Workshop, Karpacz 9

INNOMET parties Problems to solve: • Does our staff quality meet our strategic targets? • Where we can find the most adequate vocational education? • How our staff improved after vocational training? • What specialists industry needs? • How many specialists industry needs? • What vocational education is needed? Reason to exist: • Publishing information about vocational qualification standards • Organizing exams for qualification certification • Keeping archive for certificates 12 th – 15 th March 2007 XVIII Workshop, Karpacz 9

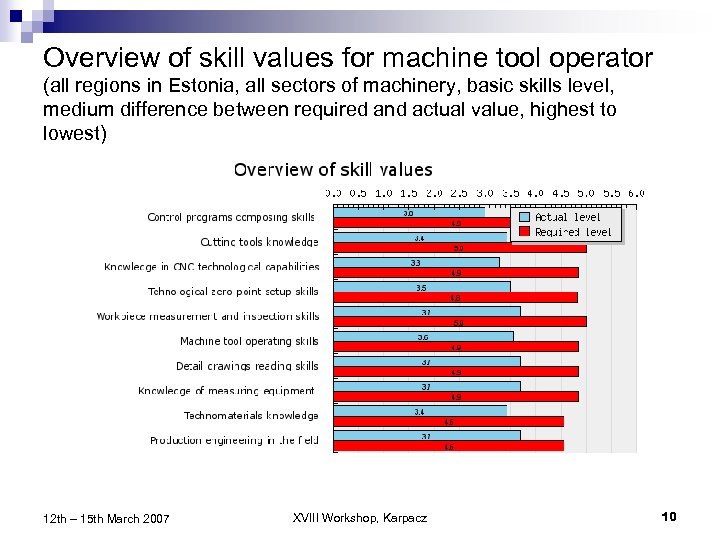

Overview of skill values for machine tool operator (all regions in Estonia, all sectors of machinery, basic skills level, medium difference between required and actual value, highest to lowest) 12 th – 15 th March 2007 XVIII Workshop, Karpacz 10

Overview of skill values for machine tool operator (all regions in Estonia, all sectors of machinery, basic skills level, medium difference between required and actual value, highest to lowest) 12 th – 15 th March 2007 XVIII Workshop, Karpacz 10

Thank you! www. innomet. ee/innomet 12 th – 15 th March 2007 XVIII Workshop, Karpacz 11

Thank you! www. innomet. ee/innomet 12 th – 15 th March 2007 XVIII Workshop, Karpacz 11