0b1aea3063700c81419b79daaeed8c6a.ppt

- Количество слайдов: 55

Metal Finishing (Electroplating) P 2 Workshop Part 1 Ohio EPA Division of Hazardous Waste Management Office of Pollution Prevention

Metal Finishing (Electroplating) P 2 Workshop Part 1 Ohio EPA Division of Hazardous Waste Management Office of Pollution Prevention

What’s in it for Me? • Understanding of Metal Finishing Unit Processes • Skills for Identifying Process Optimization (P 2!) Opportunities • Knowledge of Tools and Resources for Providing Technical Assistance

What’s in it for Me? • Understanding of Metal Finishing Unit Processes • Skills for Identifying Process Optimization (P 2!) Opportunities • Knowledge of Tools and Resources for Providing Technical Assistance

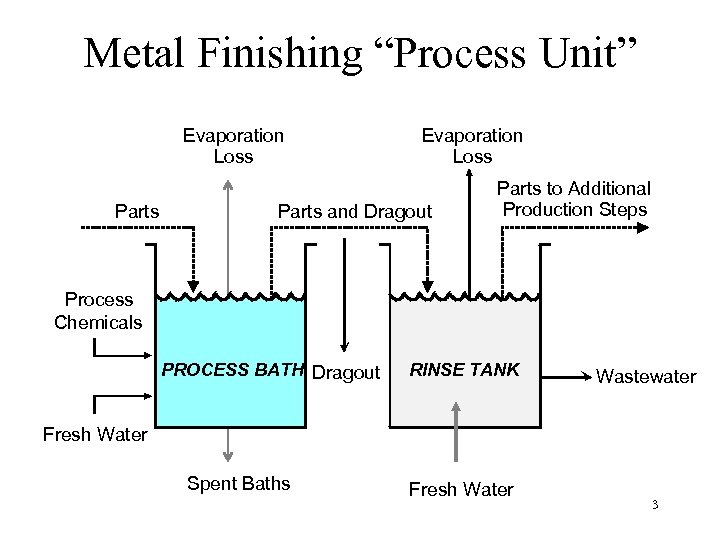

Metal Finishing “Process Unit” Evaporation Loss Parts and Dragout Parts to Additional Production Steps Process Chemicals PROCESS BATH Dragout RINSE TANK Wastewater Fresh Water Spent Baths Fresh Water 3

Metal Finishing “Process Unit” Evaporation Loss Parts and Dragout Parts to Additional Production Steps Process Chemicals PROCESS BATH Dragout RINSE TANK Wastewater Fresh Water Spent Baths Fresh Water 3

Metal Finishing Processes 1. Surface Preparation and Cleaning: Ø alkaline cleaning Ø electropolishing Ø oxide removal 2. Metal Plating: Ø electroplating Ø electroless plating 3. Protection and Finishing Treatments: Ø anodizing Ø chromate conversion Ø phosphating

Metal Finishing Processes 1. Surface Preparation and Cleaning: Ø alkaline cleaning Ø electropolishing Ø oxide removal 2. Metal Plating: Ø electroplating Ø electroless plating 3. Protection and Finishing Treatments: Ø anodizing Ø chromate conversion Ø phosphating

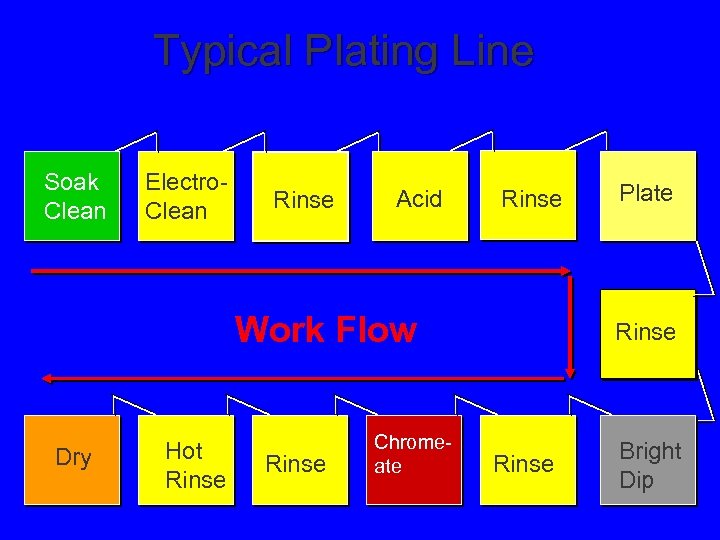

Typical Plating Line Soak Clean Electro. Clean Rinse Acid Rinse Work Flow Dry Hot Rinse Chromeate Plate Rinse Bright Dip

Typical Plating Line Soak Clean Electro. Clean Rinse Acid Rinse Work Flow Dry Hot Rinse Chromeate Plate Rinse Bright Dip

Common Metal Finishing Wastes • • Rinse water effluent Spent plating baths Spent alkaline and acidic etchants and cleaners Spent strippers Solvent degreasers Waste and process bath treatment sludges Miscellaneous wastes (filters, empty containers, floor grates, off-spec chemicals) * Some of these may be Persistent Bioaccumulative Toxic substances such as Cadmium, Chromium, Copper, Lead, Nickel, Zinc & Cyanide

Common Metal Finishing Wastes • • Rinse water effluent Spent plating baths Spent alkaline and acidic etchants and cleaners Spent strippers Solvent degreasers Waste and process bath treatment sludges Miscellaneous wastes (filters, empty containers, floor grates, off-spec chemicals) * Some of these may be Persistent Bioaccumulative Toxic substances such as Cadmium, Chromium, Copper, Lead, Nickel, Zinc & Cyanide

P 2 Principles for Metal Finishing ü Use the least toxic/easiest to manage chemicals ü Extract the most life (use) out of process chemistries ü Keep process chemistry solutions where they belong: in the tanks ü Return as much escaping solution (dragout) as possible to the tanks ü Use the least amount of rinse water required for good rinsing 7

P 2 Principles for Metal Finishing ü Use the least toxic/easiest to manage chemicals ü Extract the most life (use) out of process chemistries ü Keep process chemistry solutions where they belong: in the tanks ü Return as much escaping solution (dragout) as possible to the tanks ü Use the least amount of rinse water required for good rinsing 7

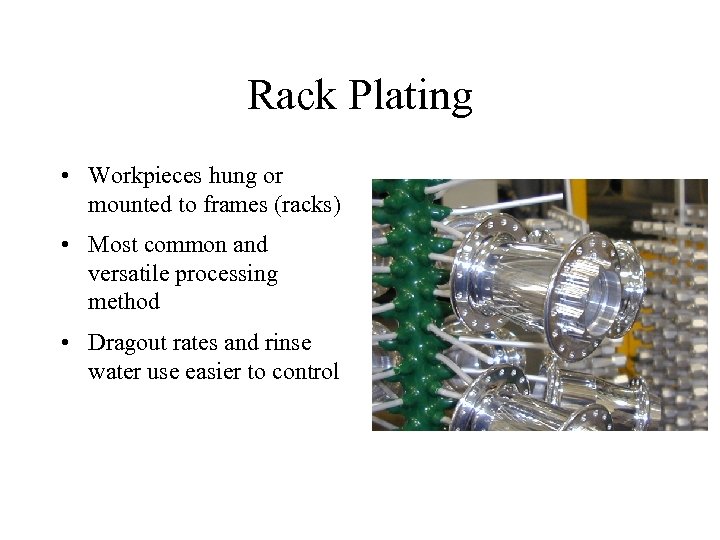

Rack Plating • Workpieces hung or mounted to frames (racks) • Most common and versatile processing method • Dragout rates and rinse water use easier to control

Rack Plating • Workpieces hung or mounted to frames (racks) • Most common and versatile processing method • Dragout rates and rinse water use easier to control

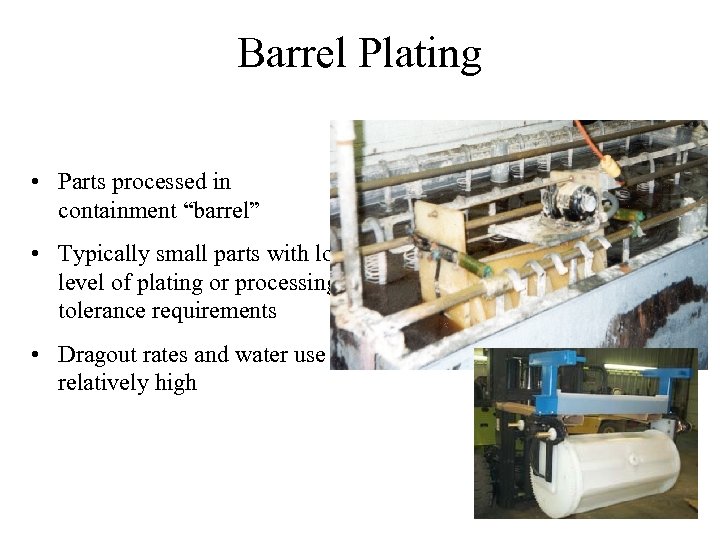

Barrel Plating • Parts processed in containment “barrel” • Typically small parts with low level of plating or processing tolerance requirements • Dragout rates and water use relatively high

Barrel Plating • Parts processed in containment “barrel” • Typically small parts with low level of plating or processing tolerance requirements • Dragout rates and water use relatively high

Manual Plating • Process steps performed by hand • Smaller size parts, lower production

Manual Plating • Process steps performed by hand • Smaller size parts, lower production

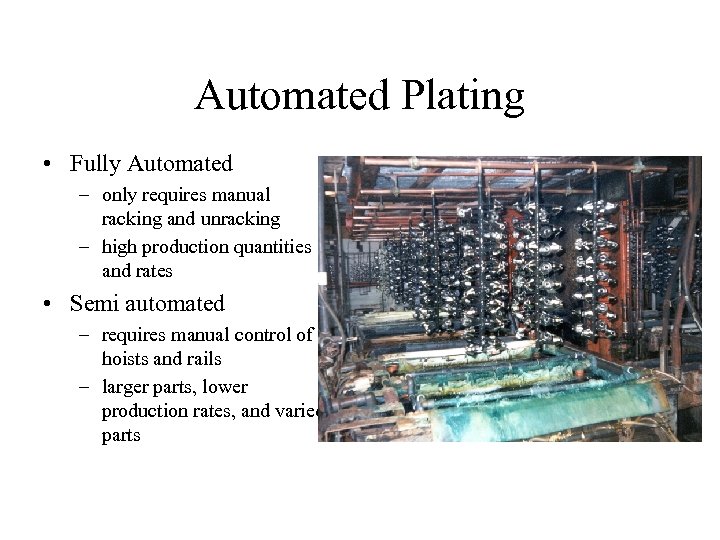

Automated Plating • Fully Automated – only requires manual racking and unracking – high production quantities and rates • Semi automated – requires manual control of hoists and rails – larger parts, lower production rates, and varied parts

Automated Plating • Fully Automated – only requires manual racking and unracking – high production quantities and rates • Semi automated – requires manual control of hoists and rails – larger parts, lower production rates, and varied parts

Keys to Identifying P 2 Opportunities at Metal Finishing Facilities • Basics of Metal Finishing – does the facility monitor and measure their plating or coating solutions, how are additions made – does the facility have specifications for each part they finish, mil thickness, quality standards? – does the facility have procedures and training in place for coating time, withdrawal rate, drain time, rinsing, part orientation? – does the facility know addition and flow rates for water in their cleaning and plating solutions and rinses?

Keys to Identifying P 2 Opportunities at Metal Finishing Facilities • Basics of Metal Finishing – does the facility monitor and measure their plating or coating solutions, how are additions made – does the facility have specifications for each part they finish, mil thickness, quality standards? – does the facility have procedures and training in place for coating time, withdrawal rate, drain time, rinsing, part orientation? – does the facility know addition and flow rates for water in their cleaning and plating solutions and rinses?

Measuring and Understanding Dragout 13

Measuring and Understanding Dragout 13

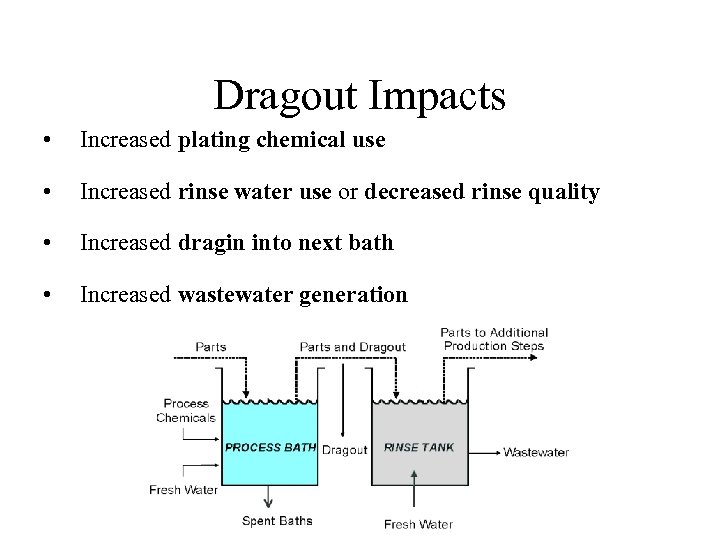

Dragout Impacts • Increased plating chemical use • Increased rinse water use or decreased rinse quality • Increased dragin into next bath • Increased wastewater generation

Dragout Impacts • Increased plating chemical use • Increased rinse water use or decreased rinse quality • Increased dragin into next bath • Increased wastewater generation

Dragout Impacts (continued) • Increased WWTS treatment chemicals • Increased WWTS filter cake • Increased WWTS effluent metal concentration

Dragout Impacts (continued) • Increased WWTS treatment chemicals • Increased WWTS filter cake • Increased WWTS effluent metal concentration

Dragout Measurement • Direct volume measurement (dragout volume drained from parts) • Metal concentration/conductivity in rinse tanks • Wastewater contaminant concentration 16

Dragout Measurement • Direct volume measurement (dragout volume drained from parts) • Metal concentration/conductivity in rinse tanks • Wastewater contaminant concentration 16

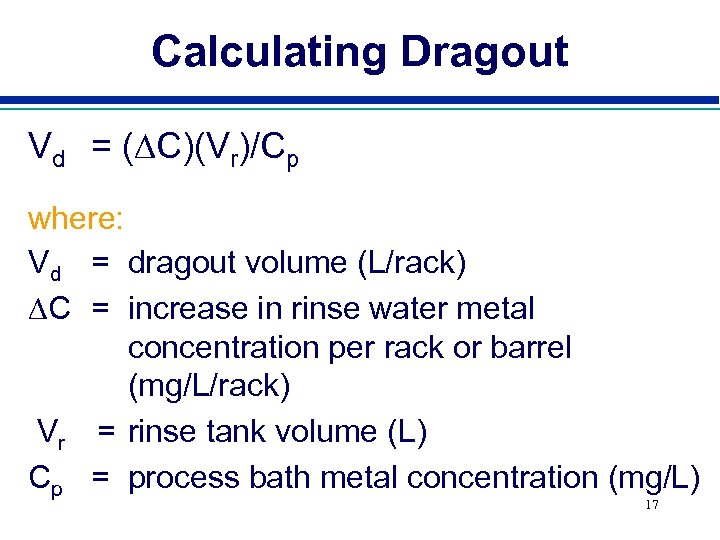

Calculating Dragout Vd = (DC)(Vr)/Cp where: Vd = dragout volume (L/rack) DC = increase in rinse water metal concentration per rack or barrel (mg/L/rack) Vr = rinse tank volume (L) Cp = process bath metal concentration (mg/L) 17

Calculating Dragout Vd = (DC)(Vr)/Cp where: Vd = dragout volume (L/rack) DC = increase in rinse water metal concentration per rack or barrel (mg/L/rack) Vr = rinse tank volume (L) Cp = process bath metal concentration (mg/L) 17

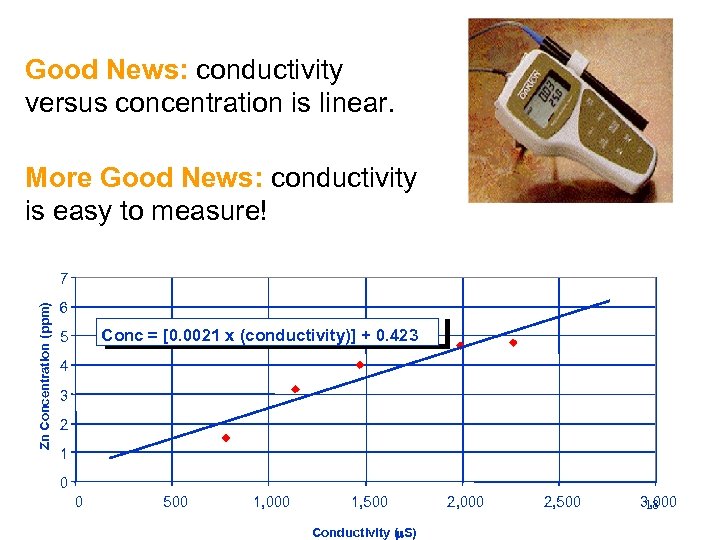

Good News: conductivity versus concentration is linear. More Good News: conductivity is easy to measure! Zn Concentration (ppm) 7 6 Conc = [0. 0021 x (conductivity)] + 0. 423 5 4 3 2 1 0 0 500 1, 000 1, 500 Conductivity (m. S) 2, 000 2, 500 3, 000 18

Good News: conductivity versus concentration is linear. More Good News: conductivity is easy to measure! Zn Concentration (ppm) 7 6 Conc = [0. 0021 x (conductivity)] + 0. 423 5 4 3 2 1 0 0 500 1, 000 1, 500 Conductivity (m. S) 2, 000 2, 500 3, 000 18

Using Dragout Measurements • Estimate costs of dragout for particular parts • Make cost/benefit decisions – – – Lower dragout vs. slower withdrawal rates Lower dragout vs. longer hang time Worker training Incentive programs WWTS Recovery technologies • Benchmarking 19

Using Dragout Measurements • Estimate costs of dragout for particular parts • Make cost/benefit decisions – – – Lower dragout vs. slower withdrawal rates Lower dragout vs. longer hang time Worker training Incentive programs WWTS Recovery technologies • Benchmarking 19

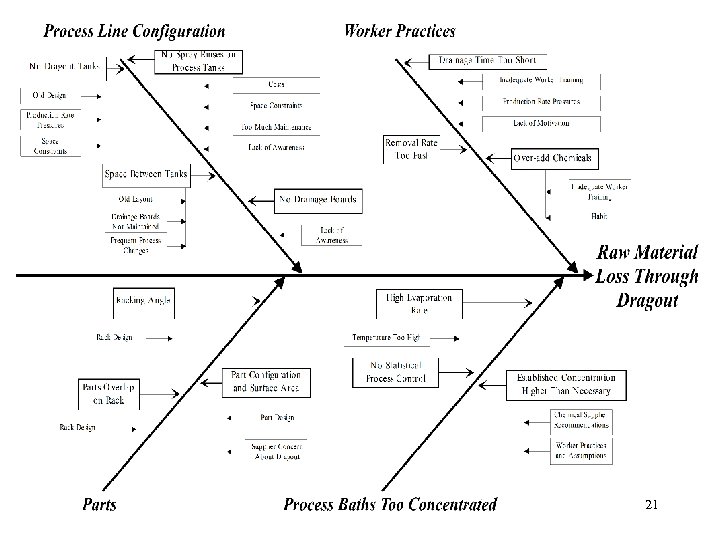

Dragout Reduction Techniques 20

Dragout Reduction Techniques 20

21

21

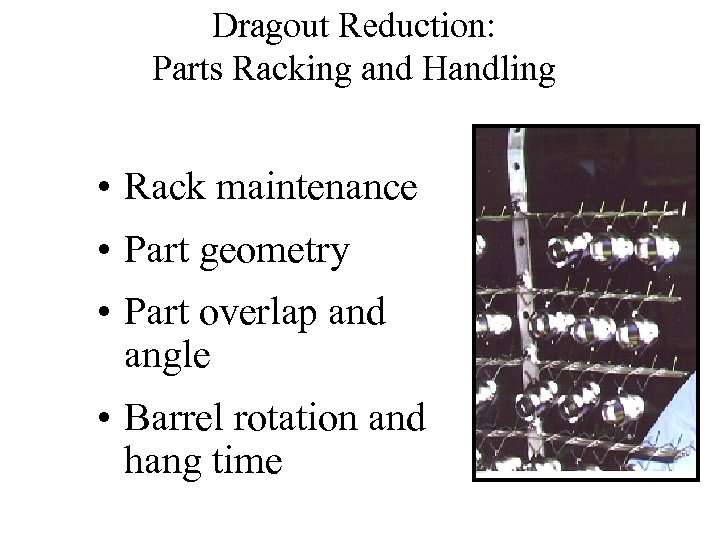

Dragout Reduction: Parts Racking and Handling • Rack maintenance • Part geometry • Part overlap and angle • Barrel rotation and hang time

Dragout Reduction: Parts Racking and Handling • Rack maintenance • Part geometry • Part overlap and angle • Barrel rotation and hang time

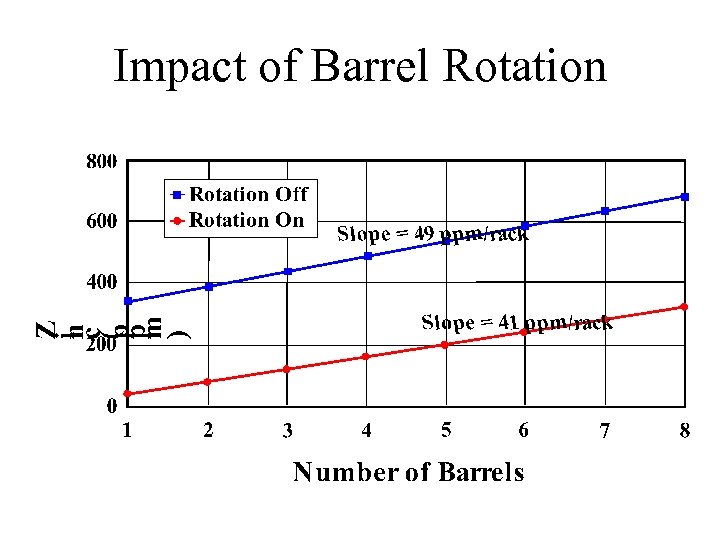

Impact of Barrel Rotation

Impact of Barrel Rotation

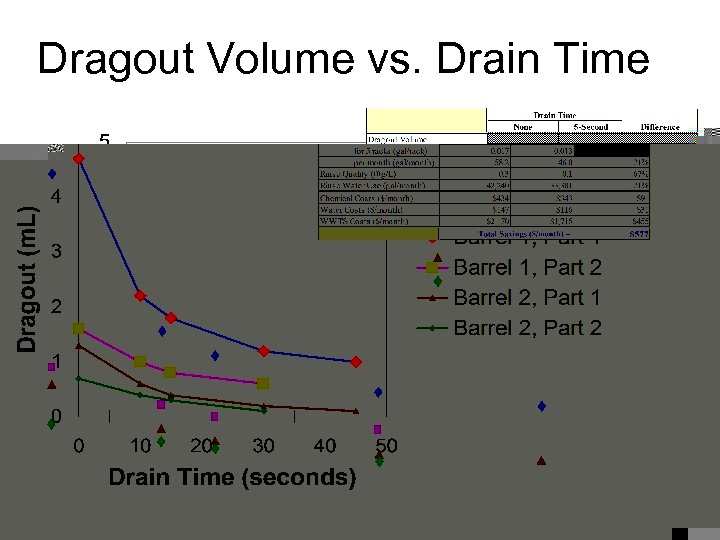

Dragout Volume vs. Drain Time

Dragout Volume vs. Drain Time

Dragout Reduction: Worker Practices • Withdrawal rate • Drainage time • Tilting • Use hang bars and other devices

Dragout Reduction: Worker Practices • Withdrawal rate • Drainage time • Tilting • Use hang bars and other devices

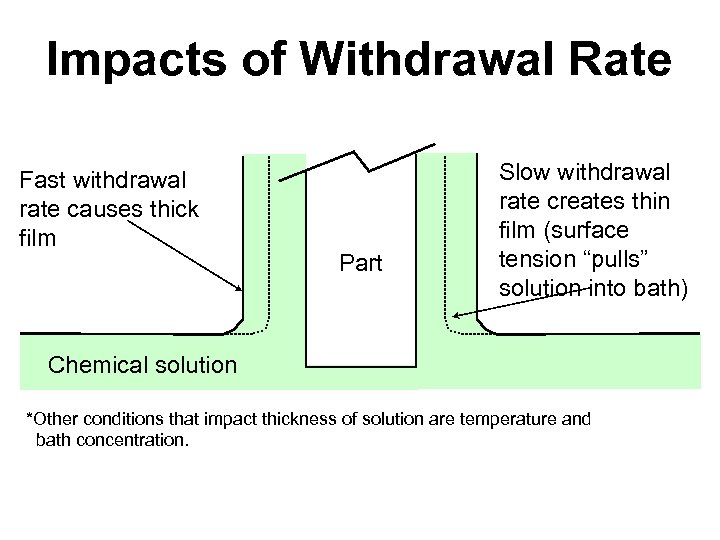

Impacts of Withdrawal Rate Fast withdrawal rate causes thick film Part Slow withdrawal rate creates thin film (surface tension “pulls” solution into bath) Chemical solution *Other conditions that impact thickness of solution are temperature and bath concentration.

Impacts of Withdrawal Rate Fast withdrawal rate causes thick film Part Slow withdrawal rate creates thin film (surface tension “pulls” solution into bath) Chemical solution *Other conditions that impact thickness of solution are temperature and bath concentration.

Dragout Reduction: Process Layout, Maintenance • Tank spacing and drain boards • Tank sequence • Dragout tanks (with or without sprays) • Spray rinses

Dragout Reduction: Process Layout, Maintenance • Tank spacing and drain boards • Tank sequence • Dragout tanks (with or without sprays) • Spray rinses

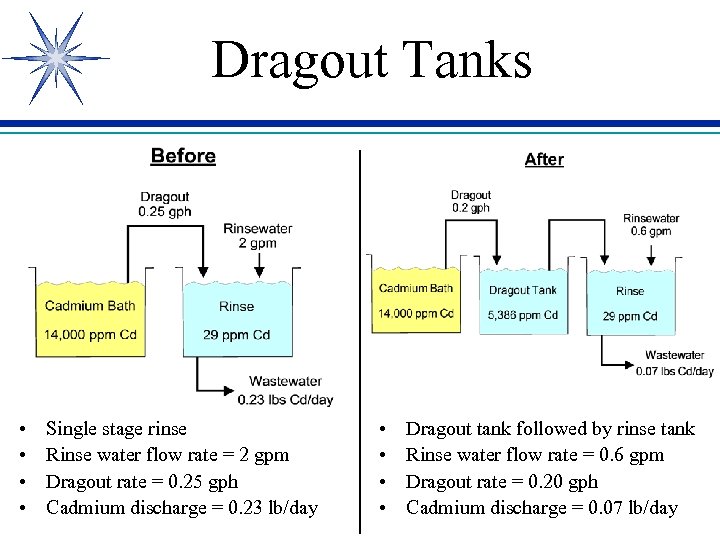

Dragout Tanks • • Single stage rinse Rinse water flow rate = 2 gpm Dragout rate = 0. 25 gph Cadmium discharge = 0. 23 lb/day • • Dragout tank followed by rinse tank Rinse water flow rate = 0. 6 gpm Dragout rate = 0. 20 gph Cadmium discharge = 0. 07 lb/day

Dragout Tanks • • Single stage rinse Rinse water flow rate = 2 gpm Dragout rate = 0. 25 gph Cadmium discharge = 0. 23 lb/day • • Dragout tank followed by rinse tank Rinse water flow rate = 0. 6 gpm Dragout rate = 0. 20 gph Cadmium discharge = 0. 07 lb/day

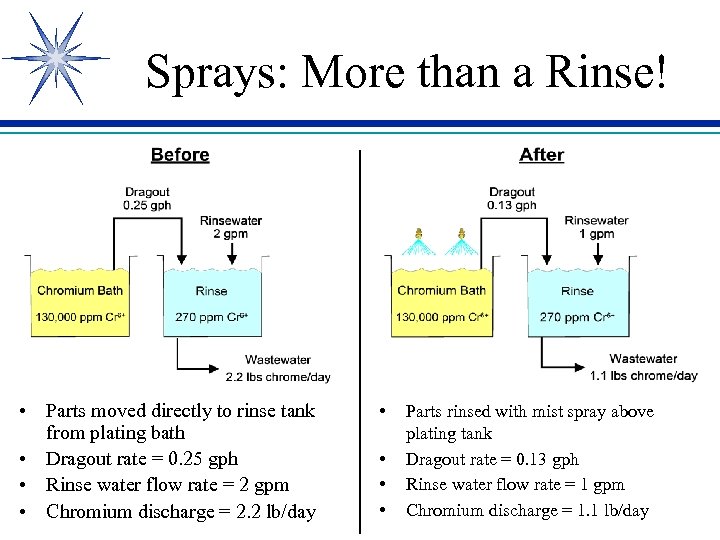

Sprays: More than a Rinse! • Parts moved directly to rinse tank from plating bath • Dragout rate = 0. 25 gph • Rinse water flow rate = 2 gpm • Chromium discharge = 2. 2 lb/day • • Parts rinsed with mist spray above plating tank Dragout rate = 0. 13 gph Rinse water flow rate = 1 gpm Chromium discharge = 1. 1 lb/day

Sprays: More than a Rinse! • Parts moved directly to rinse tank from plating bath • Dragout rate = 0. 25 gph • Rinse water flow rate = 2 gpm • Chromium discharge = 2. 2 lb/day • • Parts rinsed with mist spray above plating tank Dragout rate = 0. 13 gph Rinse water flow rate = 1 gpm Chromium discharge = 1. 1 lb/day

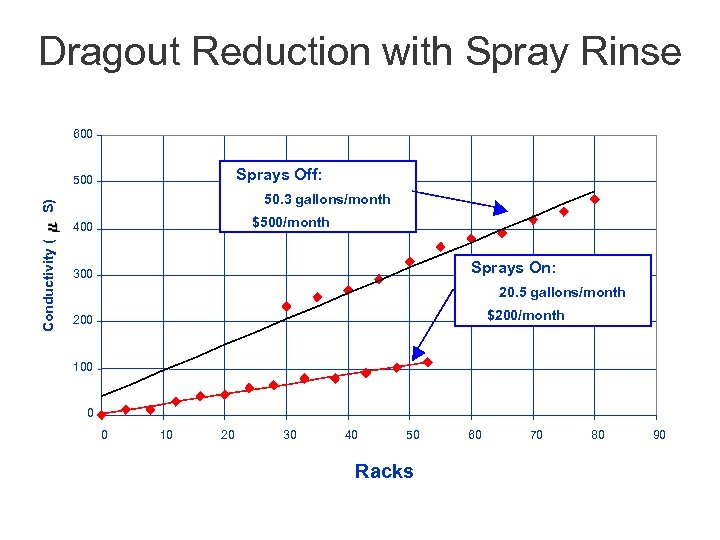

Dragout Reduction with Spray Rinse 600 Sprays Off: 500 S) 50. 3 gallons/month $500/month Conductivity ( 400 Sprays On: 300 20. 5 gallons/month $200/month 200 100 0 0 10 20 30 40 50 Racks 60 70 80 90

Dragout Reduction with Spray Rinse 600 Sprays Off: 500 S) 50. 3 gallons/month $500/month Conductivity ( 400 Sprays On: 300 20. 5 gallons/month $200/month 200 100 0 0 10 20 30 40 50 Racks 60 70 80 90

Conductivity Control Systems 31

Conductivity Control Systems 31

Keys to Identifying P 2 Opportunities at Metal Finishing Facilities • Conductivity Control – does the facility use conductivity measurement to manage their rinse system(s)? – if they have a system, what type is it, how do they operate it, what are their results? – if they do not have system do they know the relative costs and benefits of installing one?

Keys to Identifying P 2 Opportunities at Metal Finishing Facilities • Conductivity Control – does the facility use conductivity measurement to manage their rinse system(s)? – if they have a system, what type is it, how do they operate it, what are their results? – if they do not have system do they know the relative costs and benefits of installing one?

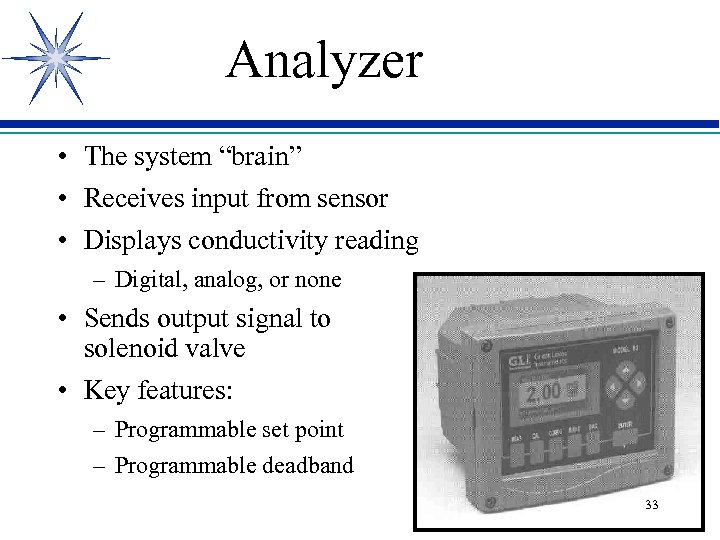

Analyzer • The system “brain” • Receives input from sensor • Displays conductivity reading – Digital, analog, or none • Sends output signal to solenoid valve • Key features: – Programmable set point – Programmable deadband 33

Analyzer • The system “brain” • Receives input from sensor • Displays conductivity reading – Digital, analog, or none • Sends output signal to solenoid valve • Key features: – Programmable set point – Programmable deadband 33

Conventional Sensor • The sensor has an anode and cathode which is placed in a solution • Electrical potential is measured between these electrodes • Prone to fouling • $150 -250 34

Conventional Sensor • The sensor has an anode and cathode which is placed in a solution • Electrical potential is measured between these electrodes • Prone to fouling • $150 -250 34

Electrodeless Sensor • Uses two parallel torroids • Non-conductive casing (polypropylene or PVDF) • No electrodes; no fouling • Can measure full range of conductivity • $435 -635 35

Electrodeless Sensor • Uses two parallel torroids • Non-conductive casing (polypropylene or PVDF) • No electrodes; no fouling • Can measure full range of conductivity • $435 -635 35

Sensor Installation • Sensor placement – Halfway down from top of water level – Away from stagnant areas – Away from clean water inlet – In final stage of multistage counterflow rinse • Good circulation of rinse water – Mechanical mixing – Double dipping parts 36

Sensor Installation • Sensor placement – Halfway down from top of water level – Away from stagnant areas – Away from clean water inlet – In final stage of multistage counterflow rinse • Good circulation of rinse water – Mechanical mixing – Double dipping parts 36

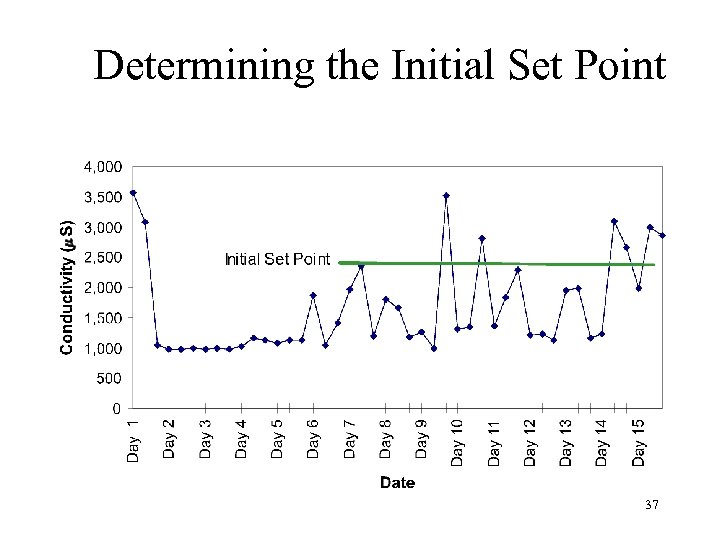

Determining the Initial Set Point 37

Determining the Initial Set Point 37

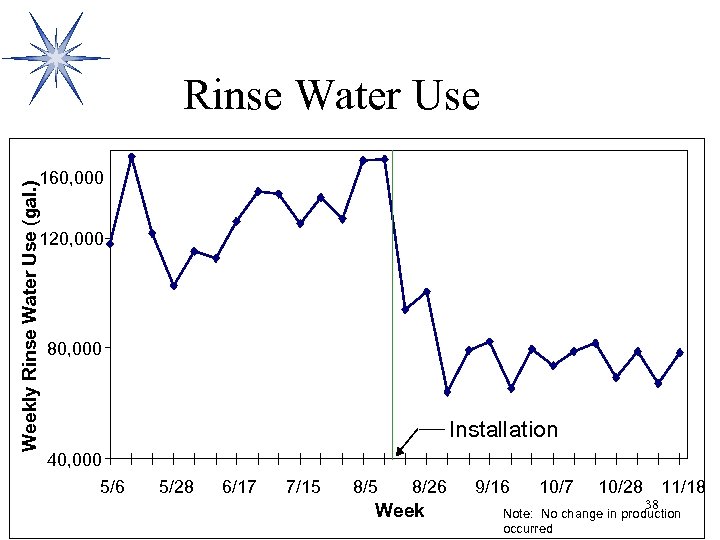

Rinse Water Use Weekly Rinse Water Use (gal. ) 160, 000 120, 000 80, 000 Installation 40, 000 5/6 5/28 6/17 7/15 8/26 Week 9/16 10/7 10/28 38 11/18 Note: No change in production occurred

Rinse Water Use Weekly Rinse Water Use (gal. ) 160, 000 120, 000 80, 000 Installation 40, 000 5/6 5/28 6/17 7/15 8/26 Week 9/16 10/7 10/28 38 11/18 Note: No change in production occurred

Spray Rinse Systems and Design 39

Spray Rinse Systems and Design 39

Benefits of Reducing Rinse Water • Lower water bills and sewer fees • Wastewater treatment impacts – Lower treatment chemical costs – Higher retention time – Less O&M requirements • Decreased sludge generation

Benefits of Reducing Rinse Water • Lower water bills and sewer fees • Wastewater treatment impacts – Lower treatment chemical costs – Higher retention time – Less O&M requirements • Decreased sludge generation

Techniques that Improve Rinse Efficiency • Agitation – – Rack motion Forced air and/or forced water Sprays Double dipping • Flow Controls and Water Quality – Flow restrictors – Conductivity control systems – Tap water vs. deionized water

Techniques that Improve Rinse Efficiency • Agitation – – Rack motion Forced air and/or forced water Sprays Double dipping • Flow Controls and Water Quality – Flow restrictors – Conductivity control systems – Tap water vs. deionized water

Techniques that Improve Rinse Efficiency • Tank Design – Size (not bigger than necessary) – Eliminate short-circuiting • Tank Layout – Multiple tanks – Countercurrent rinses are extremely efficient • 90% reduction compared to a single rinse • Most old shops can not accommodate the larger “footprint”

Techniques that Improve Rinse Efficiency • Tank Design – Size (not bigger than necessary) – Eliminate short-circuiting • Tank Layout – Multiple tanks – Countercurrent rinses are extremely efficient • 90% reduction compared to a single rinse • Most old shops can not accommodate the larger “footprint”

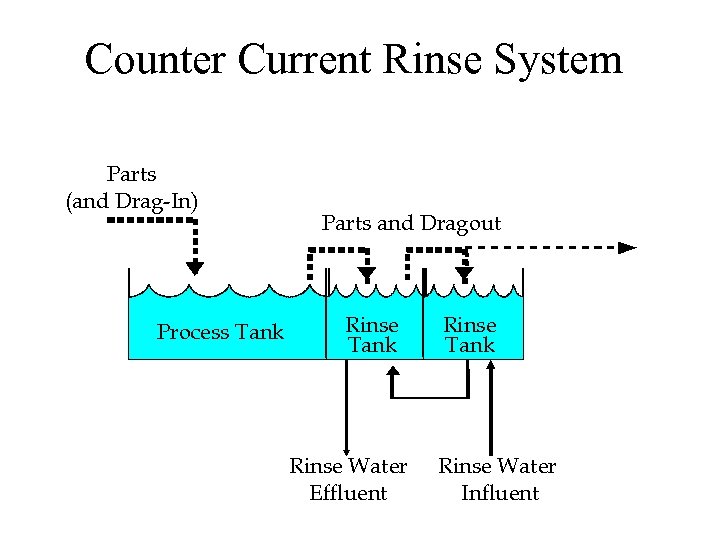

Counter Current Rinse System Parts (and Drag-In) Process Tank Parts and Dragout Rinse Tank Rinse Water Effluent Rinse Tank Rinse Water Influent

Counter Current Rinse System Parts (and Drag-In) Process Tank Parts and Dragout Rinse Tank Rinse Water Effluent Rinse Tank Rinse Water Influent

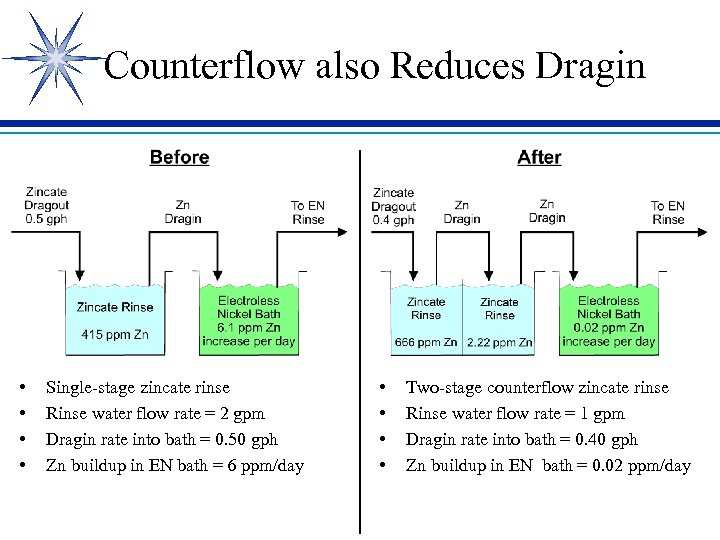

Counterflow also Reduces Dragin • • Single-stage zincate rinse Rinse water flow rate = 2 gpm Dragin rate into bath = 0. 50 gph Zn buildup in EN bath = 6 ppm/day • • Two-stage counterflow zincate rinse Rinse water flow rate = 1 gpm Dragin rate into bath = 0. 40 gph Zn buildup in EN bath = 0. 02 ppm/day

Counterflow also Reduces Dragin • • Single-stage zincate rinse Rinse water flow rate = 2 gpm Dragin rate into bath = 0. 50 gph Zn buildup in EN bath = 6 ppm/day • • Two-stage counterflow zincate rinse Rinse water flow rate = 1 gpm Dragin rate into bath = 0. 40 gph Zn buildup in EN bath = 0. 02 ppm/day

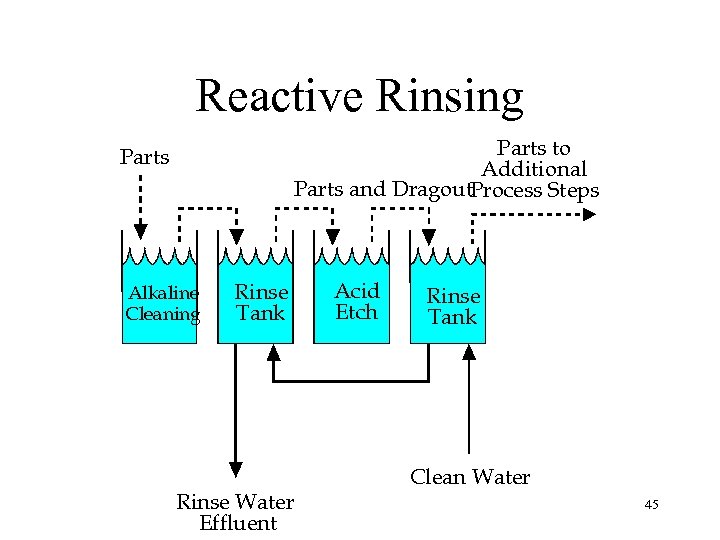

Reactive Rinsing Parts to Additional Parts and Dragout. Process Steps Parts Alkaline Cleaning Rinse Tank Rinse Water Effluent Acid Etch Rinse Tank Clean Water 45

Reactive Rinsing Parts to Additional Parts and Dragout. Process Steps Parts Alkaline Cleaning Rinse Tank Rinse Water Effluent Acid Etch Rinse Tank Clean Water 45

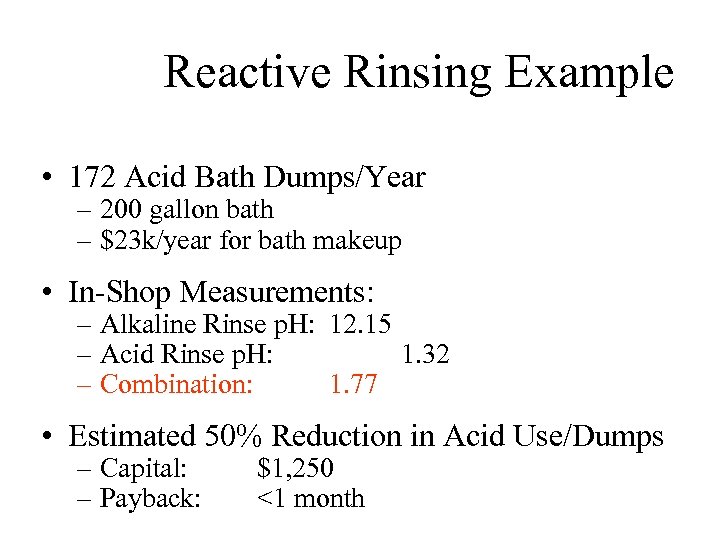

Reactive Rinsing Example • 172 Acid Bath Dumps/Year – 200 gallon bath – $23 k/year for bath makeup • In-Shop Measurements: – Alkaline Rinse p. H: 12. 15 – Acid Rinse p. H: 1. 32 – Combination: 1. 77 • Estimated 50% Reduction in Acid Use/Dumps – Capital: – Payback: $1, 250 <1 month

Reactive Rinsing Example • 172 Acid Bath Dumps/Year – 200 gallon bath – $23 k/year for bath makeup • In-Shop Measurements: – Alkaline Rinse p. H: 12. 15 – Acid Rinse p. H: 1. 32 – Combination: 1. 77 • Estimated 50% Reduction in Acid Use/Dumps – Capital: – Payback: $1, 250 <1 month

Spray Rinse Systems and Design 47

Spray Rinse Systems and Design 47

Keys to Identifying P 2 Opportunities at Metal Finishing Facilities • Rinse Tank Optimization & Spray Rinsing – are any measures in place to extend the life of the rinse baths, skimmers, agitation, sludge removal, water treatment? – are spray rinses utilized, if so, where are they located, how are they operated and why? – are rinse tanks utilizing counter current flow, are there flow restrictors or controls? – is the quality of the rinse water monitored or measured? – has the facility experimented with different rinse configurations, flows, or sprays?

Keys to Identifying P 2 Opportunities at Metal Finishing Facilities • Rinse Tank Optimization & Spray Rinsing – are any measures in place to extend the life of the rinse baths, skimmers, agitation, sludge removal, water treatment? – are spray rinses utilized, if so, where are they located, how are they operated and why? – are rinse tanks utilizing counter current flow, are there flow restrictors or controls? – is the quality of the rinse water monitored or measured? – has the facility experimented with different rinse configurations, flows, or sprays?

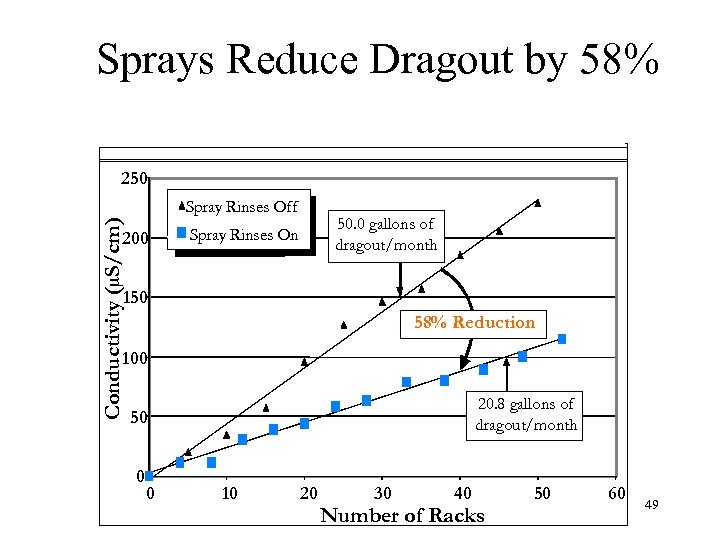

Sprays Reduce Dragout by 58% 250 Conductivity (µS/cm) Spray Rinses Off 200 50. 0 gallons of dragout/month Spray Rinses On 150 58% Reduction 100 20. 8 gallons of dragout/month 50 0 0 10 20 30 40 Number of Racks 50 60 49

Sprays Reduce Dragout by 58% 250 Conductivity (µS/cm) Spray Rinses Off 200 50. 0 gallons of dragout/month Spray Rinses On 150 58% Reduction 100 20. 8 gallons of dragout/month 50 0 0 10 20 30 40 Number of Racks 50 60 49

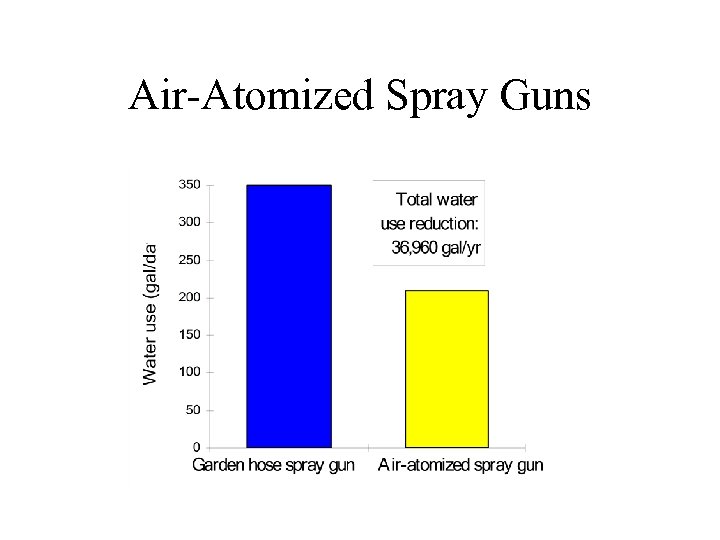

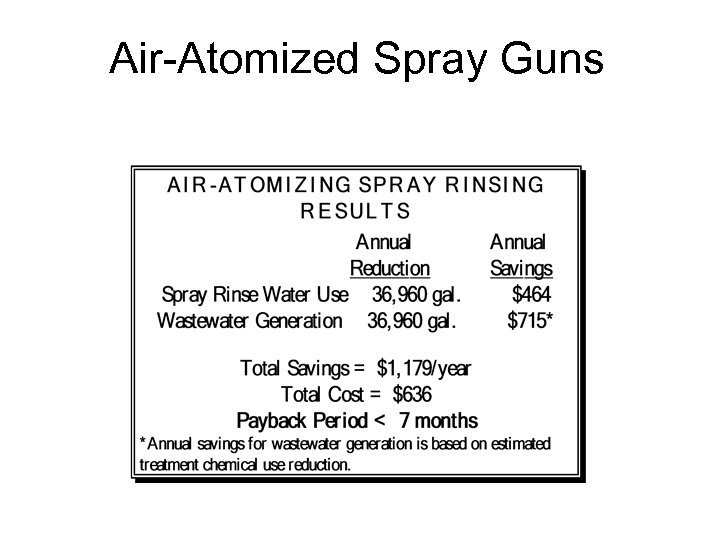

Air-Atomized Spray Guns

Air-Atomized Spray Guns

Air-Atomized Spray Guns

Air-Atomized Spray Guns

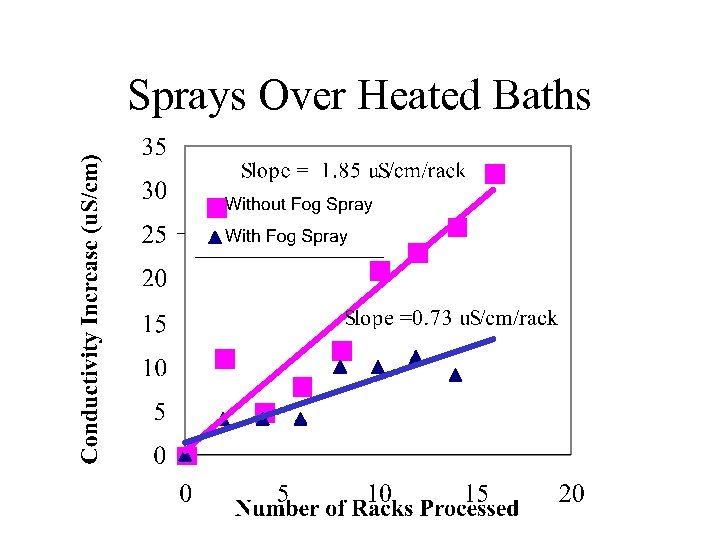

Sprays Over Heated Baths

Sprays Over Heated Baths

Sprays Over Heated Baths

Sprays Over Heated Baths

Tools and Resources for Assistance 54

Tools and Resources for Assistance 54

Available Tools • Metal Finishing P 2 Videos 1. DHWM Preserving the Legacy Series: “The Metal Plating and Finishing Industries” 2. USEPA “Pollution Prevention for Metal Platers: Drag-out Reduction” • Advanced P 2 Technical Assistance - TECHSOLVE P 2 IRIS “Metal Finishing” http: //www. techsolve. org/iamsorg/p 2 iris/metalfinish/default. html U. S. EPA/NAMF/AESF - Strategic Goals Program http: //www. strategicgoals. org/

Available Tools • Metal Finishing P 2 Videos 1. DHWM Preserving the Legacy Series: “The Metal Plating and Finishing Industries” 2. USEPA “Pollution Prevention for Metal Platers: Drag-out Reduction” • Advanced P 2 Technical Assistance - TECHSOLVE P 2 IRIS “Metal Finishing” http: //www. techsolve. org/iamsorg/p 2 iris/metalfinish/default. html U. S. EPA/NAMF/AESF - Strategic Goals Program http: //www. strategicgoals. org/