6afef547290a73ded1d581bcddb778ff.ppt

- Количество слайдов: 66

Metal Casting • Process in which molten metal is poured into a mold (shaped after the part to be manufactured), then allowed to cool and solidify. Engr 241 0

Metal Casting • Process in which molten metal is poured into a mold (shaped after the part to be manufactured), then allowed to cool and solidify. Engr 241 0

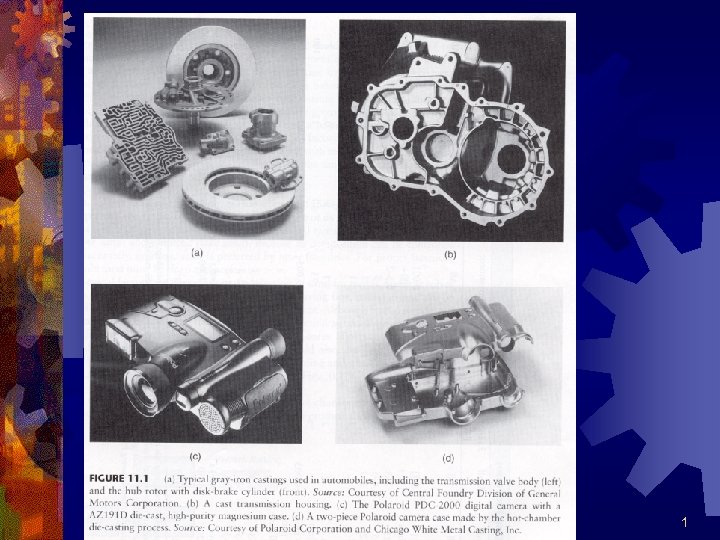

Engr 241 1

Engr 241 1

Metal Casting (cont. ) • After solidification occurs the part is removed from the mold to cool further. • The main objective is to produce parts free of defects and with the desired properties. Engr 241 2

Metal Casting (cont. ) • After solidification occurs the part is removed from the mold to cool further. • The main objective is to produce parts free of defects and with the desired properties. Engr 241 2

Process Characteristics • Complex shapes that may have internal cavities • Large or small parts. • Can use materials which are otherwise hard to shape. • Economical. • Near net shape manufacturing. Engr 241 3

Process Characteristics • Complex shapes that may have internal cavities • Large or small parts. • Can use materials which are otherwise hard to shape. • Economical. • Near net shape manufacturing. Engr 241 3

Considerations • Solidification – mold design and material effect cooling rate (Heat transfer). • Metal flow into mold cavity – Flow. Engr 241 4

Considerations • Solidification – mold design and material effect cooling rate (Heat transfer). • Metal flow into mold cavity – Flow. Engr 241 4

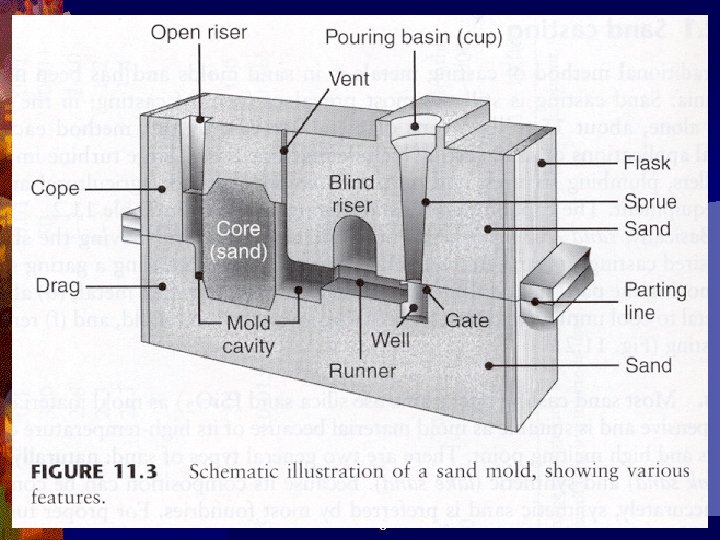

Fluid Flow • Basic Casting System • Pouring basin (cup). • Sprue, runners- channels • Gate- entry point for mold • Riser- reservoir Engr 241 5

Fluid Flow • Basic Casting System • Pouring basin (cup). • Sprue, runners- channels • Gate- entry point for mold • Riser- reservoir Engr 241 5

Engr 241 6

Engr 241 6

Defects • Metallic projections. • flash, fins, swells. • Cavities. • blow holes, pinholes, shrinkage. • Discontinuities. • cracks, • cold or hot tearing – constrained from shrinking freely • cold shuts. - interface from two streams of liquid meeting Engr 241 7

Defects • Metallic projections. • flash, fins, swells. • Cavities. • blow holes, pinholes, shrinkage. • Discontinuities. • cracks, • cold or hot tearing – constrained from shrinking freely • cold shuts. - interface from two streams of liquid meeting Engr 241 7

Defects (Continued) • Defective surface. • folds, laps, scars, adhering sand, oxide. • Incomplete casting. • misruns, insufficient metal, runout. • Incorrect dimensions or shape. • Inclusions. • non-metallic - slag Engr 241 8

Defects (Continued) • Defective surface. • folds, laps, scars, adhering sand, oxide. • Incomplete casting. • misruns, insufficient metal, runout. • Incorrect dimensions or shape. • Inclusions. • non-metallic - slag Engr 241 8

Molds Engr 241 9

Molds Engr 241 9

Expendable molds. • made of sand, plaster, or ceramics (mixed with bonding agents/binders). • broken up to remove casting. Engr 241 10

Expendable molds. • made of sand, plaster, or ceramics (mixed with bonding agents/binders). • broken up to remove casting. Engr 241 10

Permanent molds • used repeatedly. • made from metals which maintain strength at high temperatures. Engr 241 11

Permanent molds • used repeatedly. • made from metals which maintain strength at high temperatures. Engr 241 11

Composite molds. • two or more types of materials. • used to improve mold strength, cooling rates, cost of process. Engr 241 12

Composite molds. • two or more types of materials. • used to improve mold strength, cooling rates, cost of process. Engr 241 12

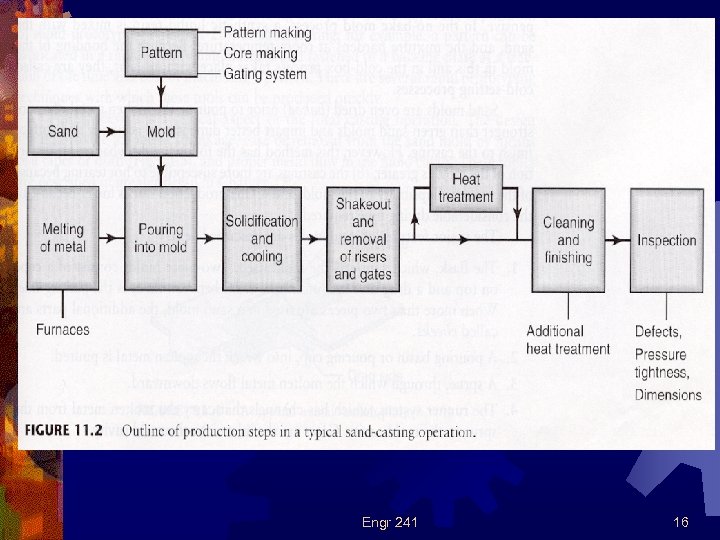

Sand Casting • Consists in placing a pattern in sand to make an imprint, incorporating a gating system, filling the cavity with molten metal, letting it cool, breaking the mold to remove the casting. Engr 241 13

Sand Casting • Consists in placing a pattern in sand to make an imprint, incorporating a gating system, filling the cavity with molten metal, letting it cool, breaking the mold to remove the casting. Engr 241 13

Characteristics • Traditional casting method. • Loose tolerances. • “poor” surface finish. • low cost. Engr 241 14

Characteristics • Traditional casting method. • Loose tolerances. • “poor” surface finish. • low cost. Engr 241 14

Examples of products • Engine blocks • Pump housings • Cylinder heads Engr 241 15

Examples of products • Engine blocks • Pump housings • Cylinder heads Engr 241 15

Engr 241 16

Engr 241 16

Sands • Silica based (Si. O 2), inexpensive, resistance to high temperature. Engr 241 17

Sands • Silica based (Si. O 2), inexpensive, resistance to high temperature. Engr 241 17

Sands (Cont. ) • Mulling- mixing sand with additives - conditioning • Clay used as cohesive agent to aid in bonding sand particles Engr 241 18

Sands (Cont. ) • Mulling- mixing sand with additives - conditioning • Clay used as cohesive agent to aid in bonding sand particles Engr 241 18

3 Types of Sand Molds • 1. Green Sand: • sand, clay, and water. • least expensive. • Can dry mold surfaces – called “skin dried” Engr 241 19

3 Types of Sand Molds • 1. Green Sand: • sand, clay, and water. • least expensive. • Can dry mold surfaces – called “skin dried” Engr 241 19

2 Cold-box: • organic and inorganic binders added. • greater dimensional accuracy. • greater cost. Engr 241 20

2 Cold-box: • organic and inorganic binders added. • greater dimensional accuracy. • greater cost. Engr 241 20

3 No-bake: • synthetic liquid resin mixed with sand. • Cold-setting process- bonding of mold takes place without heat • Petrobond Engr 241 21

3 No-bake: • synthetic liquid resin mixed with sand. • Cold-setting process- bonding of mold takes place without heat • Petrobond Engr 241 21

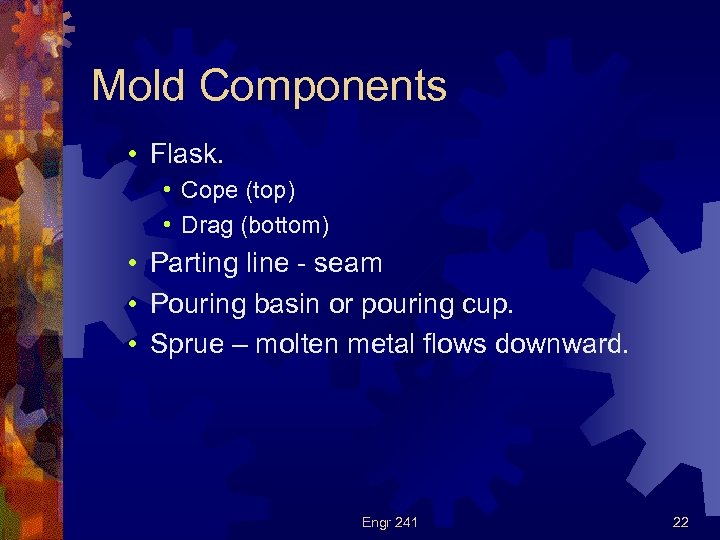

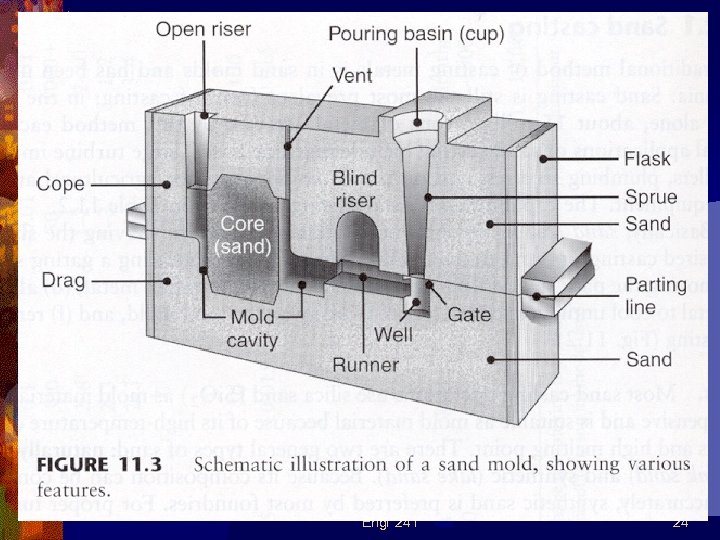

Mold Components • Flask. • Cope (top) • Drag (bottom) • Parting line - seam • Pouring basin or pouring cup. • Sprue – molten metal flows downward. Engr 241 22

Mold Components • Flask. • Cope (top) • Drag (bottom) • Parting line - seam • Pouring basin or pouring cup. • Sprue – molten metal flows downward. Engr 241 22

Mold components (cont. ) • • Runner and gates. Risers (blind and open). Cores – form hollow regions Vents – vent gasses Engr 241 23

Mold components (cont. ) • • Runner and gates. Risers (blind and open). Cores – form hollow regions Vents – vent gasses Engr 241 23

Engr 241 24

Engr 241 24

Patterns • Used to create sand molds • Made of wood, aluminum, steel, plastic, cast iron. Engr 241 25

Patterns • Used to create sand molds • Made of wood, aluminum, steel, plastic, cast iron. Engr 241 25

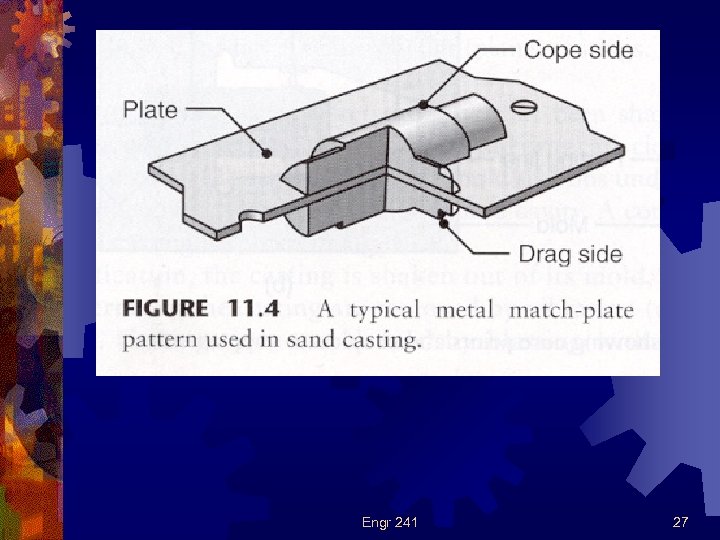

Types of mold patterns • One piece (loose pattern). • simple shapes, low quantity production. • Split pattern • Two piece patterns, complex shapes. • Match plate • Split patterns secured to plate Engr 241 26

Types of mold patterns • One piece (loose pattern). • simple shapes, low quantity production. • Split pattern • Two piece patterns, complex shapes. • Match plate • Split patterns secured to plate Engr 241 26

Engr 241 27

Engr 241 27

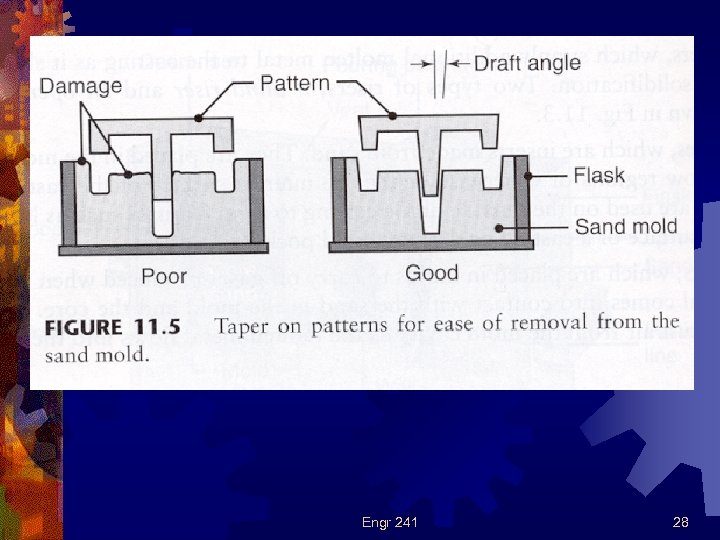

Engr 241 28

Engr 241 28

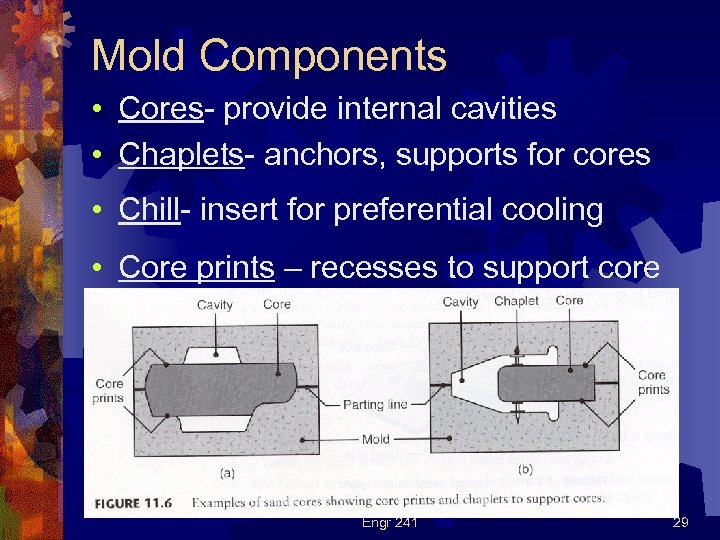

Mold Components • Cores- provide internal cavities • Chaplets- anchors, supports for cores • Chill- insert for preferential cooling • Core prints – recesses to support core Engr 241 29

Mold Components • Cores- provide internal cavities • Chaplets- anchors, supports for cores • Chill- insert for preferential cooling • Core prints – recesses to support core Engr 241 29

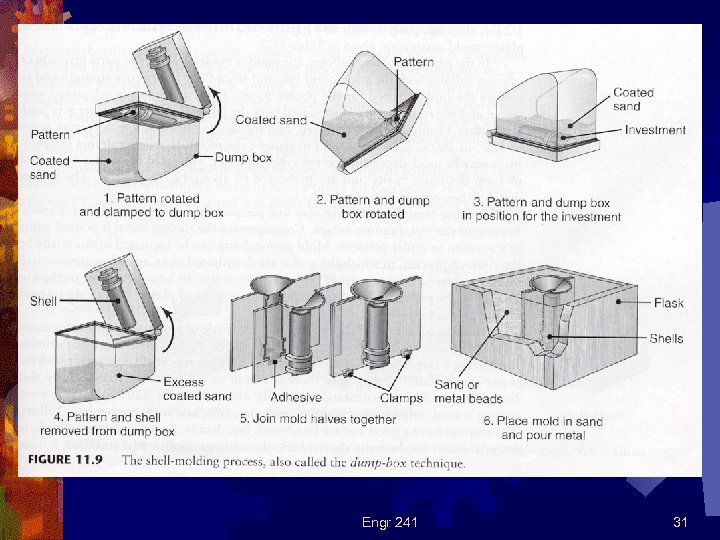

Shell Mold Casting • • • Pattern coated with sand binder Cured in oven Shell removed Left with hollow shell for filling Close tolerance good surface finish, low cost. Engr 241 30

Shell Mold Casting • • • Pattern coated with sand binder Cured in oven Shell removed Left with hollow shell for filling Close tolerance good surface finish, low cost. Engr 241 30

Engr 241 31

Engr 241 31

Shell molding: • Close tolerances • Good surface finish • Low cost Engr 241 32

Shell molding: • Close tolerances • Good surface finish • Low cost Engr 241 32

Plaster-Mold Casting • • Plaster of paris with talc and silica flour. Mixed with water Poured over pattern Plaster sets – pattern removed Engr 241 33

Plaster-Mold Casting • • Plaster of paris with talc and silica flour. Mixed with water Poured over pattern Plaster sets – pattern removed Engr 241 33

Plaster–mold casting(cont. ) • Mold dried in oven • Poured in vacuum or under pressure due to low permeability • Low permeability (gas cannot escape) Engr 241 34

Plaster–mold casting(cont. ) • Mold dried in oven • Poured in vacuum or under pressure due to low permeability • Low permeability (gas cannot escape) Engr 241 34

Plaster mold casting characteristics: • Plaster can only withstand about 2200 deg F. • Good surface and details. • “Lower” temperature alloys (Mg, Al, Zn) Engr 241 35

Plaster mold casting characteristics: • Plaster can only withstand about 2200 deg F. • Good surface and details. • “Lower” temperature alloys (Mg, Al, Zn) Engr 241 35

Ceramic-Mold Casting Similar to plaster mold casting but utilizes refractory mold materials of zircon, aluminum oxide and fused silica • Good dimensional accuracy and surface finish, but expensive. Engr 241 36

Ceramic-Mold Casting Similar to plaster mold casting but utilizes refractory mold materials of zircon, aluminum oxide and fused silica • Good dimensional accuracy and surface finish, but expensive. Engr 241 36

Expendable-Pattern Casting • Also known as Lost Foam, Evaporativepattern, or Lost Pattern Casting Engr 241 37

Expendable-Pattern Casting • Also known as Lost Foam, Evaporativepattern, or Lost Pattern Casting Engr 241 37

Process: • Polystyrene pattern coated with refractory slurry • Polystyrene pattern buried in silica sand within flask • Sprue extending out of sand Engr 241 38

Process: • Polystyrene pattern coated with refractory slurry • Polystyrene pattern buried in silica sand within flask • Sprue extending out of sand Engr 241 38

Process (cont. ) • Flask vibrated to settle sand around pattern • Molten metal poured over sprue • Polystyrene vaporizes as metal fills cavity Engr 241 39

Process (cont. ) • Flask vibrated to settle sand around pattern • Molten metal poured over sprue • Polystyrene vaporizes as metal fills cavity Engr 241 39

Engr 241 40

Engr 241 40

Expendable Foam Advantages • • simple process, no parting lines, or risers inexpensive flasks, minimum finishing polystyrene is cheap and gives good detail. economical for long production runs (pattern mold cost). • can be automated. Engr 241 41

Expendable Foam Advantages • • simple process, no parting lines, or risers inexpensive flasks, minimum finishing polystyrene is cheap and gives good detail. economical for long production runs (pattern mold cost). • can be automated. Engr 241 41

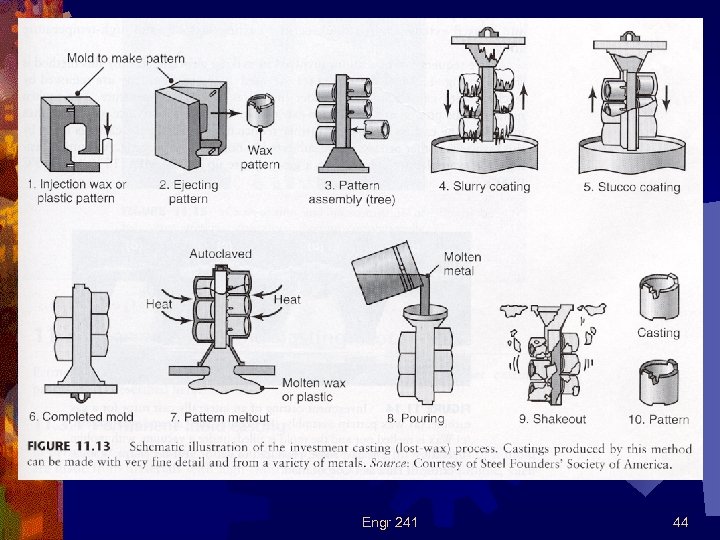

Investment Casting Process • Inject wax (plastic) in to metal die (pattern shape) • Wax pattern dipped to coat in refractory slurry – dries to form hard shell Engr 241 42

Investment Casting Process • Inject wax (plastic) in to metal die (pattern shape) • Wax pattern dipped to coat in refractory slurry – dries to form hard shell Engr 241 42

Investment casting (cont. ) • Wax melted out of hardened shell • Molds connected to tree with central sprue • Molten metal poured in • Mold destroyed to expose solidified parts Engr 241 43

Investment casting (cont. ) • Wax melted out of hardened shell • Molds connected to tree with central sprue • Molten metal poured in • Mold destroyed to expose solidified parts Engr 241 43

Engr 241 44

Engr 241 44

Characteristics • • High quality Good surface finish Good detail Expensive process Engr 241 45

Characteristics • • High quality Good surface finish Good detail Expensive process Engr 241 45

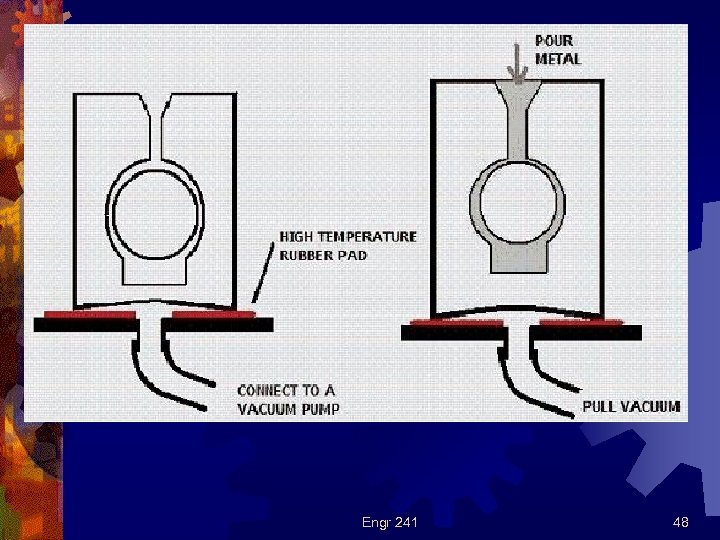

Vacuum Casting • Counter-gravity low pressure process. • Sand urethane molded over metal die. • Gate is on the bottom. Engr 241 46

Vacuum Casting • Counter-gravity low pressure process. • Sand urethane molded over metal die. • Gate is on the bottom. Engr 241 46

Vacuum Casting (cont. ) • Immersed into molten metal, which is drawn into mold cavity. • Thin wall, complex shapes, uniform properties, high volume, low cost. Engr 241 47

Vacuum Casting (cont. ) • Immersed into molten metal, which is drawn into mold cavity. • Thin wall, complex shapes, uniform properties, high volume, low cost. Engr 241 47

Engr 241 48

Engr 241 48

Die Casting • Type of permanent die casting • Molten metal is forced into a permanent mold (die) at high pressure. • Dies are steel or graphite • Two types of die casting Engr 241 49

Die Casting • Type of permanent die casting • Molten metal is forced into a permanent mold (die) at high pressure. • Dies are steel or graphite • Two types of die casting Engr 241 49

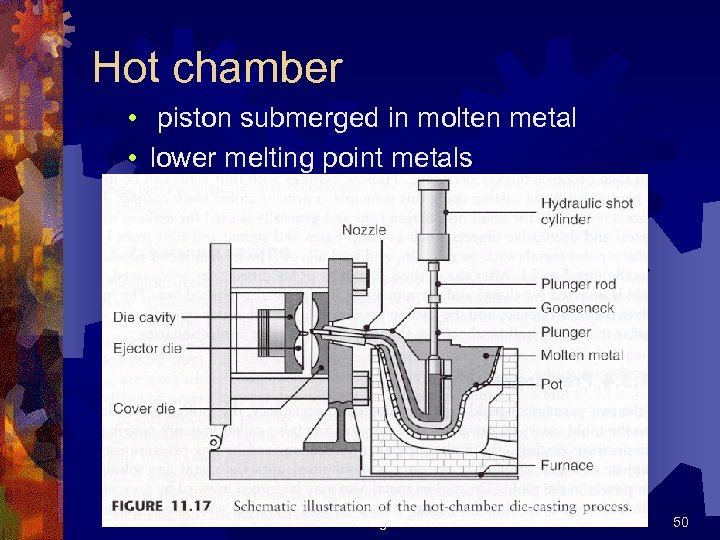

Hot chamber • piston submerged in molten metal • lower melting point metals Engr 241 50

Hot chamber • piston submerged in molten metal • lower melting point metals Engr 241 50

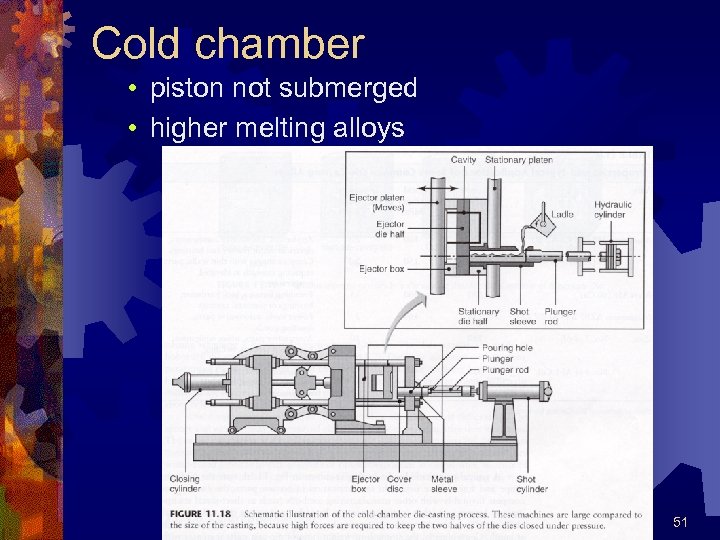

Cold chamber • piston not submerged • higher melting alloys Engr 241 51

Cold chamber • piston not submerged • higher melting alloys Engr 241 51

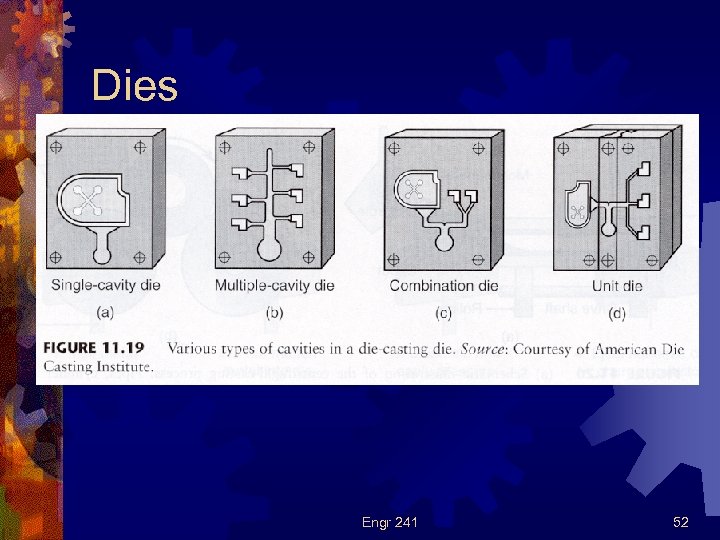

Dies Engr 241 52

Dies Engr 241 52

Characteristics • • High production rates high quality parts Close dimensional tolerances complex shapes, good surface (net shape). Engr 241 53

Characteristics • • High production rates high quality parts Close dimensional tolerances complex shapes, good surface (net shape). Engr 241 53

Slush casting • Metal poured in • Allowed to cool until outer skin solidifies and thickens to desired size • Excess metal poured out Engr 241 54

Slush casting • Metal poured in • Allowed to cool until outer skin solidifies and thickens to desired size • Excess metal poured out Engr 241 54

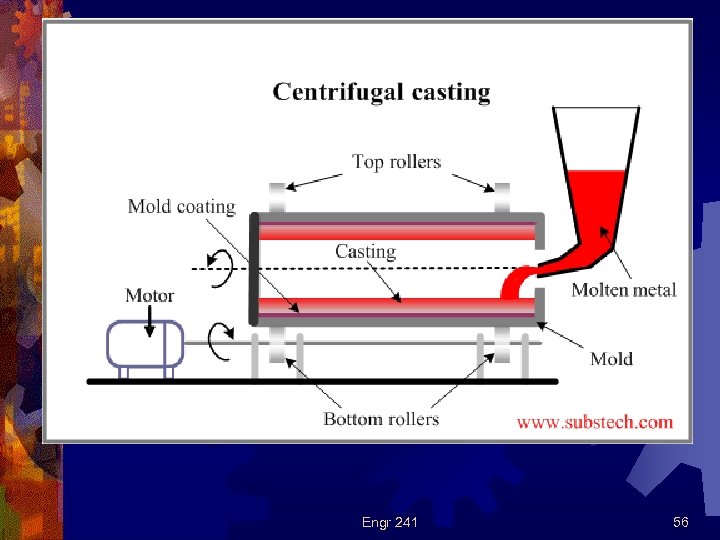

Centrifugal casting • • Produces hollow cylindrical parts Street lamp posts Gun barrels Etc. Engr 241 55

Centrifugal casting • • Produces hollow cylindrical parts Street lamp posts Gun barrels Etc. Engr 241 55

Engr 241 56

Engr 241 56

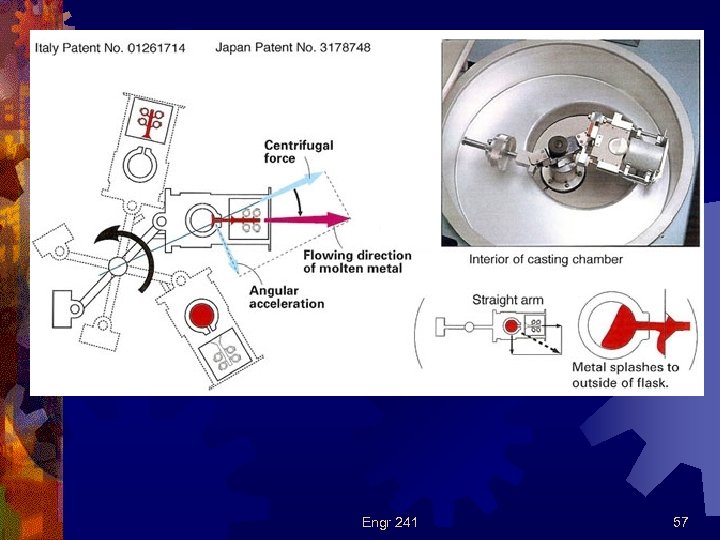

Engr 241 57

Engr 241 57

Squeeze casting • Solidification of molten metal under high pressure • Combination of casting and forging Engr 241 58

Squeeze casting • Solidification of molten metal under high pressure • Combination of casting and forging Engr 241 58

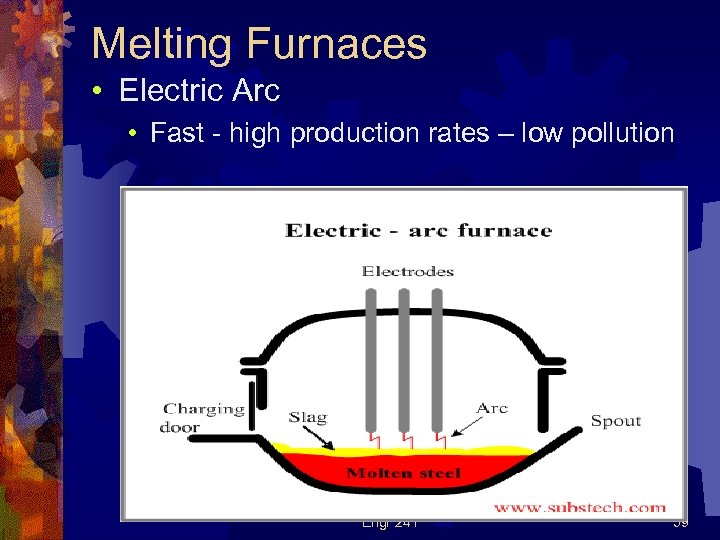

Melting Furnaces • Electric Arc • Fast - high production rates – low pollution Engr 241 59

Melting Furnaces • Electric Arc • Fast - high production rates – low pollution Engr 241 59

Engr 241 60

Engr 241 60

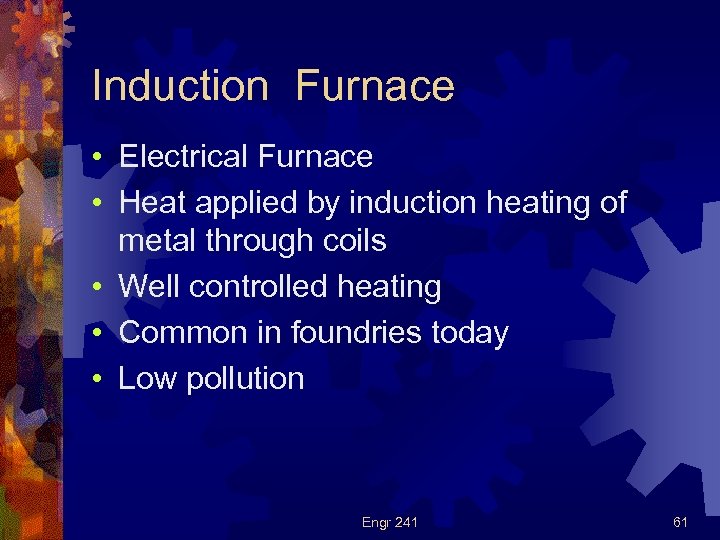

Induction Furnace • Electrical Furnace • Heat applied by induction heating of metal through coils • Well controlled heating • Common in foundries today • Low pollution Engr 241 61

Induction Furnace • Electrical Furnace • Heat applied by induction heating of metal through coils • Well controlled heating • Common in foundries today • Low pollution Engr 241 61

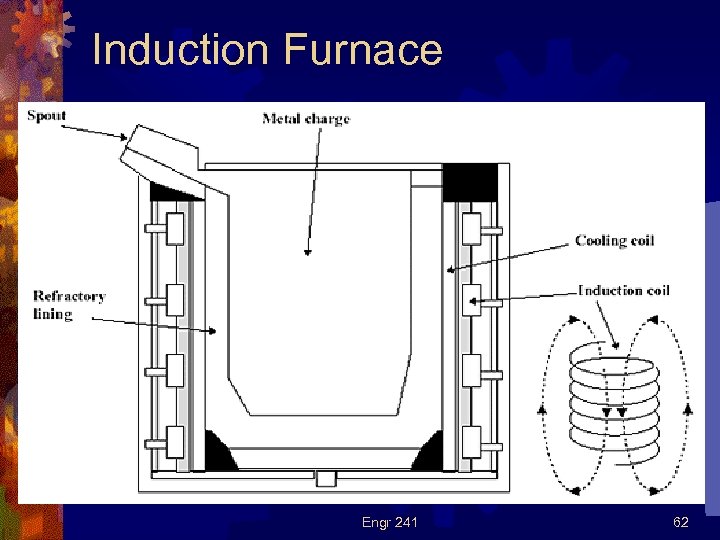

Induction Furnace Engr 241 62

Induction Furnace Engr 241 62

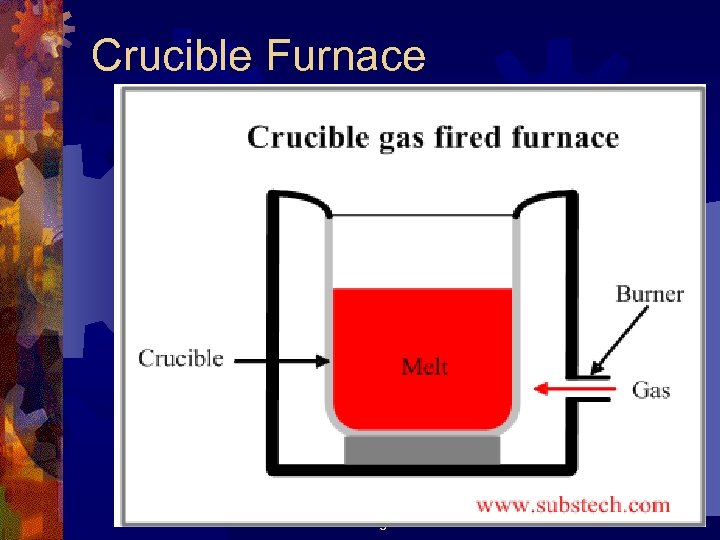

Crucible Furnace Engr 241 63

Crucible Furnace Engr 241 63

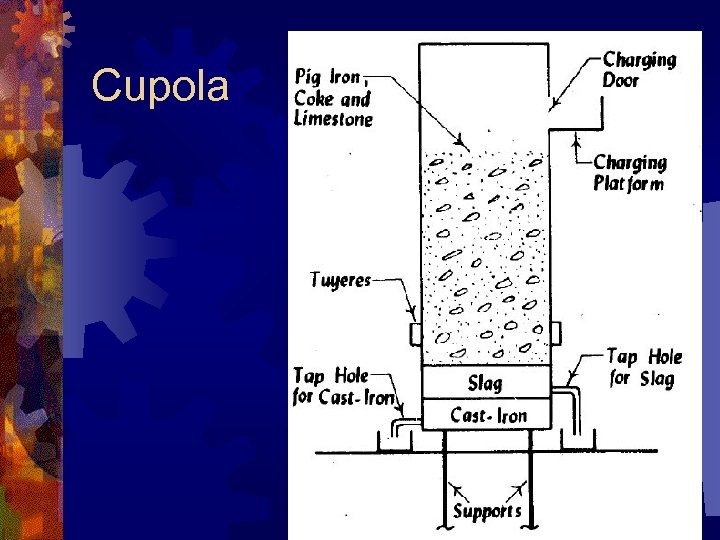

Cupola Engr 241 64

Cupola Engr 241 64

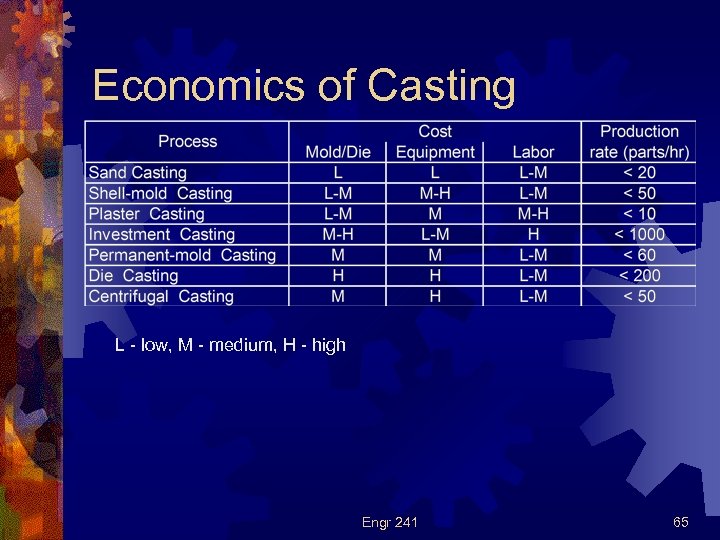

Economics of Casting L - low, M - medium, H - high Engr 241 65

Economics of Casting L - low, M - medium, H - high Engr 241 65