084164ff664382282d46801a157405c8.ppt

- Количество слайдов: 7

Messier-Dowty Ltd Light metals division strategy meeting Messier-Bugatti-Dowty Use of Titanium on Landing Gears 12 th December 2013 Jean-Philippe Villain-Chastre SAFRAN and MESSIER-BUGATTI names are marks owned respectively by SAFRAN and Messier-Bugatti-Dowty companies. The mark DOWTY is used under license. This document and the information herein are proprietary to Messier-Bugatti-Dowty, They must not be copied or communicated to a third party without the prior written authorization of Messier-Bugatti-Dowty.

MESSIER-BUGATTI-DOWTY AT A GLANCE è A Safran Group company: § § An international high technology group Revenues exceeding 10 billion euros 54, 900 employees in over 50 countries 3 core businesses: è Messier-Bugatti-Dowty: § 4 Operational Divisions (Landing Gear, Wheels & Brakes, MRO, Systems Equipment) § Worlwide presence (6250 employees accross 3 continents) § World Leader in Landing Gear Systems ú Over 20, 500 aircraft equipped ú 33 airframer customers ú 3, 000 commercial/military operators ú Over 35, 000 landings per day ú One landing every 2. 5 seconds ú 90 military and commercial programs This document and the information herein are proprietary to Messier-Bugatti-Dowty, They must not be copied or communicated to a third party without the prior written authorization of Messier-Bugatti-Dowty.

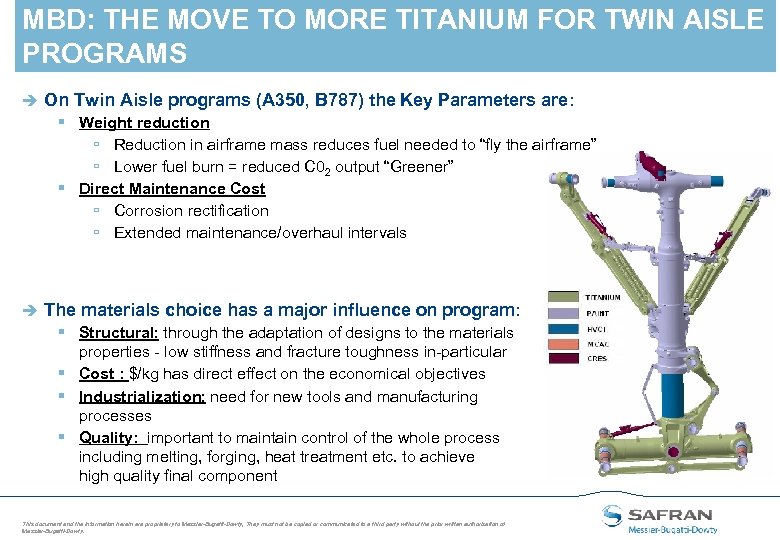

MBD: THE MOVE TO MORE TITANIUM FOR TWIN AISLE PROGRAMS è On Twin Aisle programs (A 350, B 787) the Key Parameters are: § Weight reduction ú Reduction in airframe mass reduces fuel needed to “fly the airframe” ú Lower fuel burn = reduced C 02 output “Greener” § Direct Maintenance Cost ú Corrosion rectification ú Extended maintenance/overhaul intervals è The materials choice has a major influence on program: § Structural: through the adaptation of designs to the materials properties - low stiffness and fracture toughness in-particular § Cost : $/kg has direct effect on the economical objectives § Industrialization: need for new tools and manufacturing processes § Quality: important to maintain control of the whole process including melting, forging, heat treatment etc. to achieve high quality final component This document and the information herein are proprietary to Messier-Bugatti-Dowty, They must not be copied or communicated to a third party without the prior written authorization of Messier-Bugatti-Dowty.

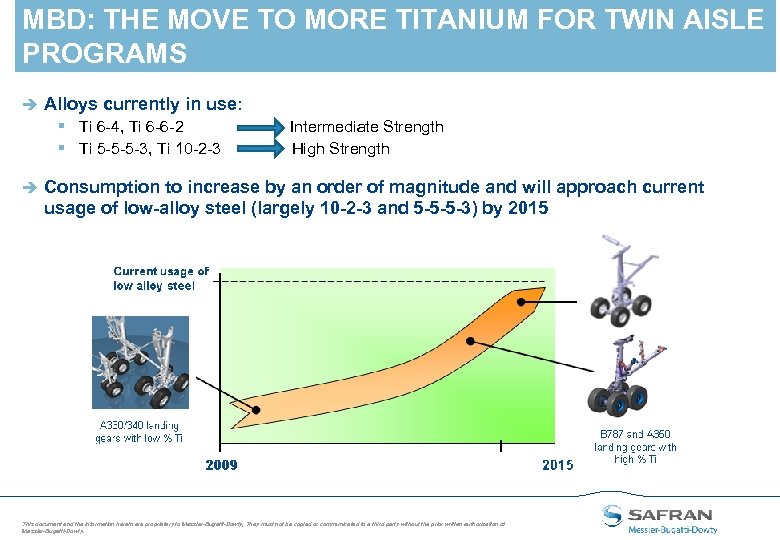

MBD: THE MOVE TO MORE TITANIUM FOR TWIN AISLE PROGRAMS è Alloys currently in use: § Ti 6 -4, Ti 6 -6 -2 § Ti 5 -5 -5 -3, Ti 10 -2 -3 è Intermediate Strength High Strength Consumption to increase by an order of magnitude and will approach current usage of low-alloy steel (largely 10 -2 -3 and 5 -5 -5 -3) by 2015 This document and the information herein are proprietary to Messier-Bugatti-Dowty, They must not be copied or communicated to a third party without the prior written authorization of Messier-Bugatti-Dowty.

TITANIUM SUPPLY CHAIN DEVELOPMENTS OPPORTUNITIES FOR MBD è Requirement for over 2 000 tonnes of high strength titanium per year ( for structural components on twin aisle programs only) è On average, 75% of Forging is removed for final detail parts: high Buy to Fly ratios § MBD interested in improved near net shape processes è Limited worldwide Supply Chain for High Strength Titanium (for MBD) § Currently no Titanium Supply Chain in UK è MBD Gloucester is a Safran worldwide Centre of Excellence for Titanium Machining (continuous development of expertise through TSB funded projects and through extensive collaboration with Catapult Centres) § MBD will benefit from a more local Supply Chain specialised in Titanium: Asset for UK Aerospace Industry This document and the information herein are proprietary to Messier-Bugatti-Dowty, They must not be copied or communicated to a third party without the prior written authorization of Messier-Bugatti-Dowty.

TITANIUM FOR LANDING GEARS: APPLICATION FOR FUTURE SINGLE AISLE/SHORT RANGE AIRCRAFTS è On future Single Aisle programs (replacement of A 320, B 737. . ) the Key Parameters are: § Cost ú Reduction of landing gear cost through use of lower cost material (Steel 300 M, aluminium. . ) § Direct Maintenance Cost ú Reduction of corrosion through use of non-corrosive material / improvement of Special Processes è Business Case is open for use of Titanium on such Programs : § If titanium can be produced at lower cost (higher material cost offset by little requirements for Special Processes) § If Buy to Fly ratio can be improved § If titanium production lead time can be reduced § High volumes programs need to be supported: ú 27, 000 100+ seats aircraft by 2031, worth $3. 7 tr ú 24, 000 business jets by 2031, worth $648 bn ú Total civil aerospace market > $4. 5 tr This document and the information herein are proprietary to Messier-Bugatti-Dowty, They must not be copied or communicated to a third party without the prior written authorization of Messier-Bugatti-Dowty.

èQuestions? This document and the information herein are proprietary to Messier-Bugatti-Dowty, They must not be copied or communicated to a third party without the prior written authorization of Messier-Bugatti-Dowty.

084164ff664382282d46801a157405c8.ppt