389bbcafb66a998f70b86670ba952419.ppt

- Количество слайдов: 32

MEMS 5 -in-1 RM Slide Set #2 Reference Materials 8096 and 8097 The MEMS 5 -in-1 Test Chips – Preliminary Details Physical Measurement Laboratory Semiconductor and Dimensional Metrology Division Nanoscale Metrology Group MEMS Measurement Science and Standards Project 1 Photo taken by Curt Suplee, NIST

MEMS 5 -in-1 RM Slide Set #2 Reference Materials 8096 and 8097 The MEMS 5 -in-1 Test Chips – Preliminary Details Physical Measurement Laboratory Semiconductor and Dimensional Metrology Division Nanoscale Metrology Group MEMS Measurement Science and Standards Project 1 Photo taken by Curt Suplee, NIST

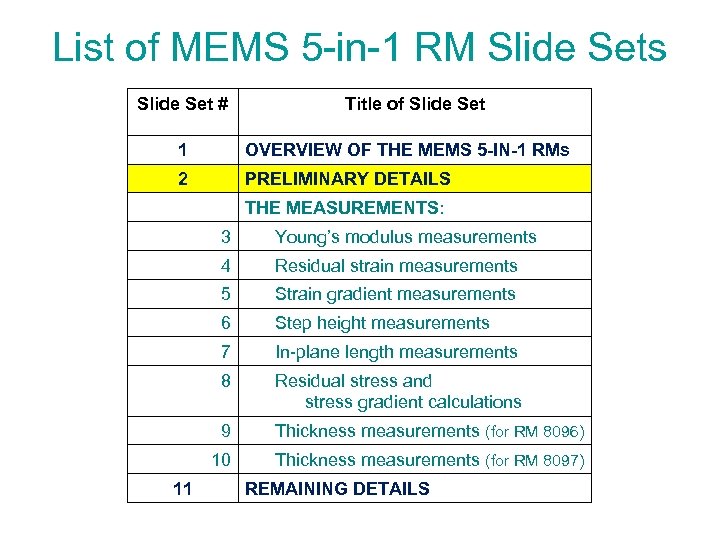

List of MEMS 5 -in-1 RM Slide Sets Slide Set # Title of Slide Set 1 OVERVIEW OF THE MEMS 5 -IN-1 RMs 2 PRELIMINARY DETAILS THE MEASUREMENTS: 3 4 Residual strain measurements 5 Strain gradient measurements 6 Step height measurements 7 In-plane length measurements 8 Residual stress and stress gradient calculations 9 Thickness measurements (for RM 8096) 10 11 Young’s modulus measurements Thickness measurements (for RM 8097) REMAINING DETAILS 2

List of MEMS 5 -in-1 RM Slide Sets Slide Set # Title of Slide Set 1 OVERVIEW OF THE MEMS 5 -IN-1 RMs 2 PRELIMINARY DETAILS THE MEASUREMENTS: 3 4 Residual strain measurements 5 Strain gradient measurements 6 Step height measurements 7 In-plane length measurements 8 Residual stress and stress gradient calculations 9 Thickness measurements (for RM 8096) 10 11 Young’s modulus measurements Thickness measurements (for RM 8097) REMAINING DETAILS 2

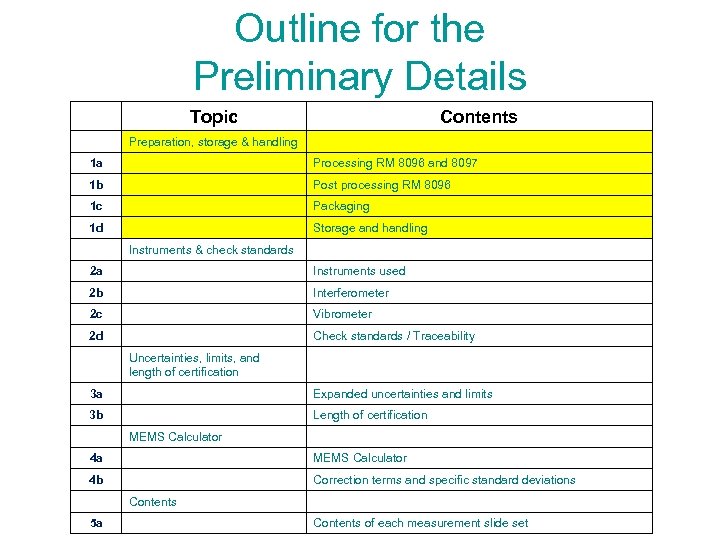

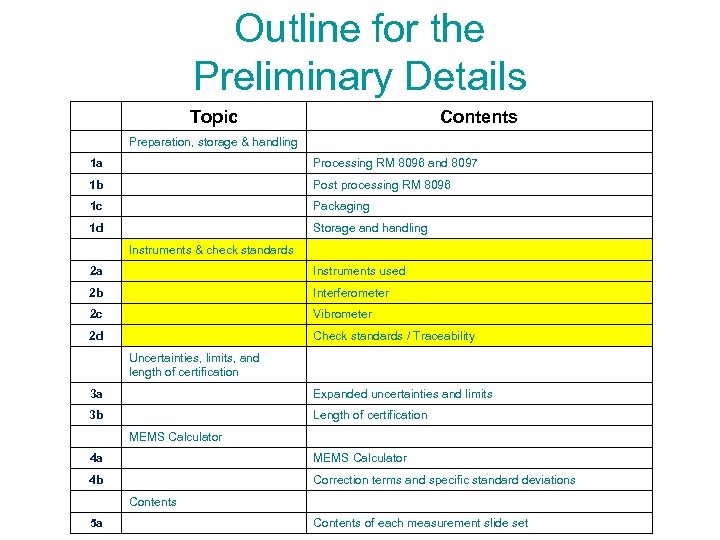

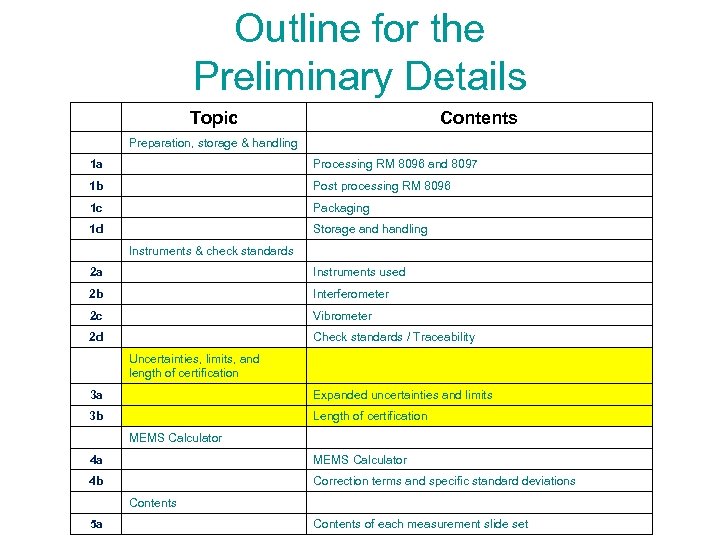

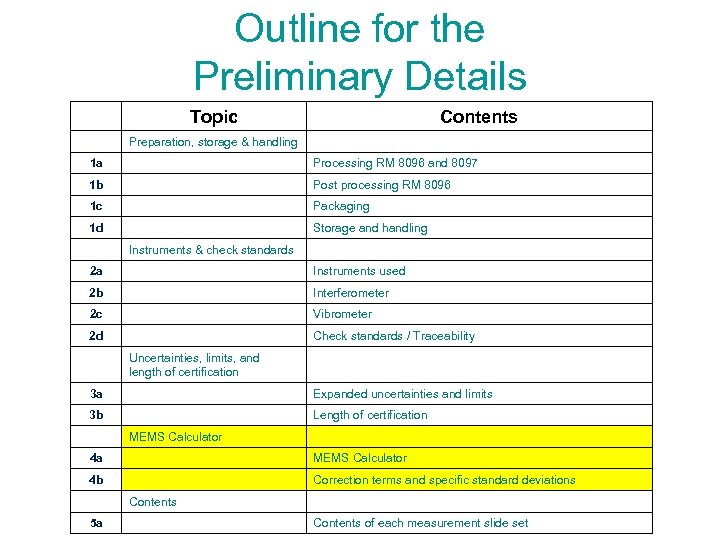

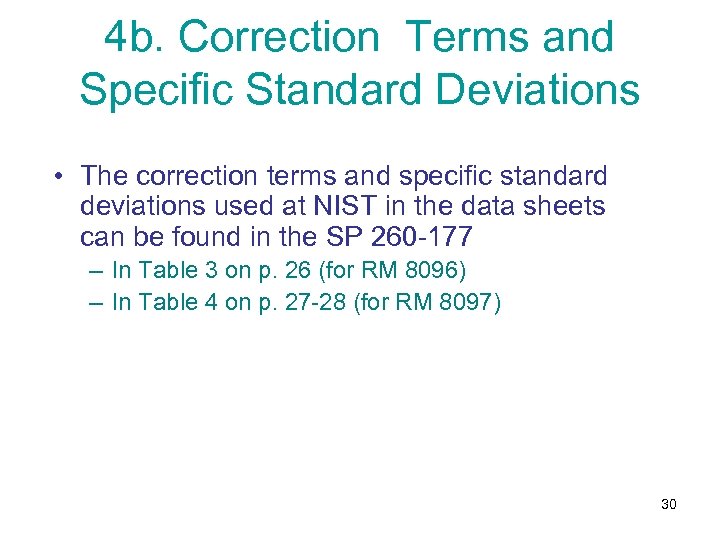

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 3 Contents of each measurement slide set

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 3 Contents of each measurement slide set

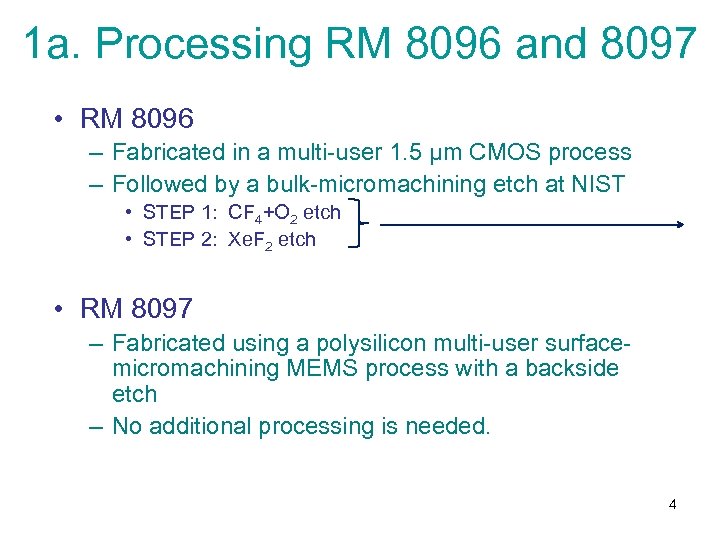

1 a. Processing RM 8096 and 8097 • RM 8096 – Fabricated in a multi-user 1. 5 µm CMOS process – Followed by a bulk-micromachining etch at NIST • STEP 1: CF 4+O 2 etch • STEP 2: Xe. F 2 etch • RM 8097 – Fabricated using a polysilicon multi-user surfacemicromachining MEMS process with a backside etch – No additional processing is needed. 4

1 a. Processing RM 8096 and 8097 • RM 8096 – Fabricated in a multi-user 1. 5 µm CMOS process – Followed by a bulk-micromachining etch at NIST • STEP 1: CF 4+O 2 etch • STEP 2: Xe. F 2 etch • RM 8097 – Fabricated using a polysilicon multi-user surfacemicromachining MEMS process with a backside etch – No additional processing is needed. 4

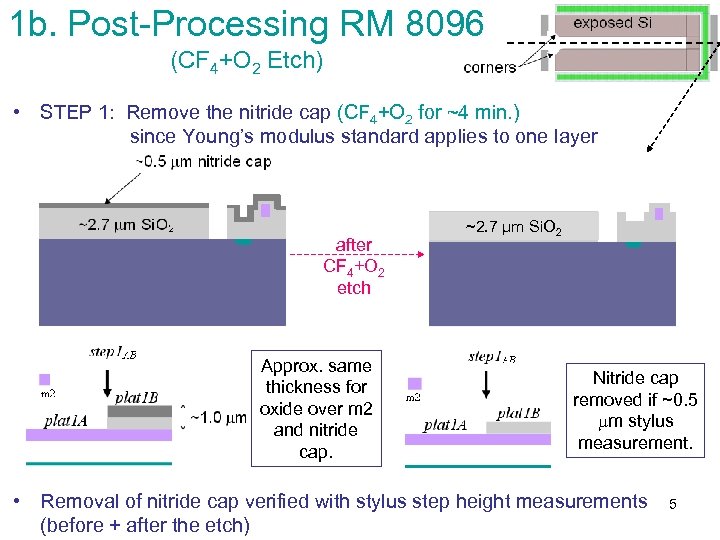

1 b. Post-Processing RM 8096 (CF 4+O 2 Etch) • STEP 1: Remove the nitride cap (CF 4+O 2 for ~4 min. ) since Young’s modulus standard applies to one layer after CF 4+O 2 etch Approx. same thickness for oxide over m 2 and nitride cap. ~2. 7 µm Si. O 2 Nitride cap removed if ~0. 5 mm stylus measurement. • Removal of nitride cap verified with stylus step height measurements (before + after the etch) 5

1 b. Post-Processing RM 8096 (CF 4+O 2 Etch) • STEP 1: Remove the nitride cap (CF 4+O 2 for ~4 min. ) since Young’s modulus standard applies to one layer after CF 4+O 2 etch Approx. same thickness for oxide over m 2 and nitride cap. ~2. 7 µm Si. O 2 Nitride cap removed if ~0. 5 mm stylus measurement. • Removal of nitride cap verified with stylus step height measurements (before + after the etch) 5

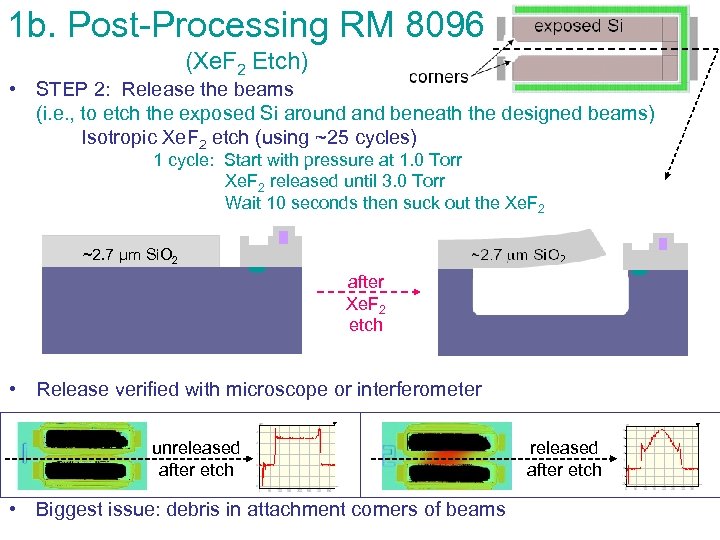

1 b. Post-Processing RM 8096 (Xe. F 2 Etch) • STEP 2: Release the beams (i. e. , to etch the exposed Si around and beneath the designed beams) Isotropic Xe. F 2 etch (using ~25 cycles) 1 cycle: Start with pressure at 1. 0 Torr Xe. F 2 released until 3. 0 Torr Wait 10 seconds then suck out the Xe. F 2 ~2. 7 µm Si. O 2 after Xe. F 2 etch • Release verified with microscope or interferometer unreleased after etch • Biggest issue: debris in attachment corners of beams released after etch 6

1 b. Post-Processing RM 8096 (Xe. F 2 Etch) • STEP 2: Release the beams (i. e. , to etch the exposed Si around and beneath the designed beams) Isotropic Xe. F 2 etch (using ~25 cycles) 1 cycle: Start with pressure at 1. 0 Torr Xe. F 2 released until 3. 0 Torr Wait 10 seconds then suck out the Xe. F 2 ~2. 7 µm Si. O 2 after Xe. F 2 etch • Release verified with microscope or interferometer unreleased after etch • Biggest issue: debris in attachment corners of beams released after etch 6

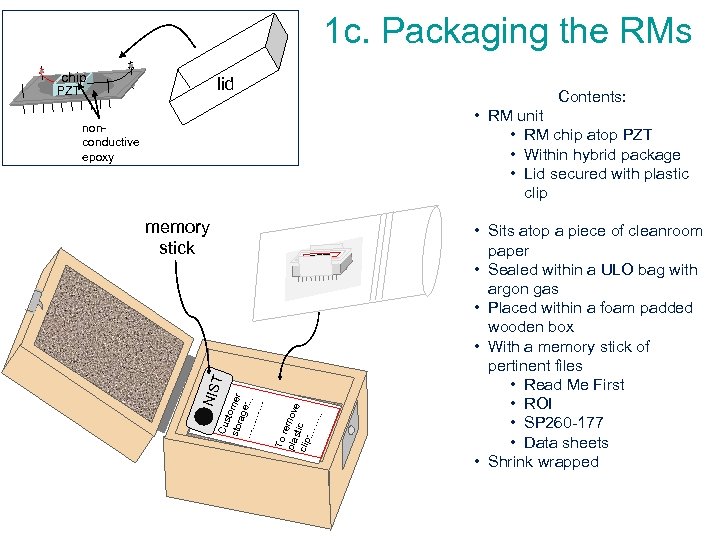

1 c. Packaging the RMs chip lid PZT Contents: • RM unit • RM chip atop PZT • Within hybrid package • Lid secured with plastic clip nonconductive epoxy memory stick To re pla move stic clip : ……. . Cus t sto omer rag …… e: . . …… NIS T NIST RM 8096 • Sits atop a piece of cleanroom paper • Sealed within a ULO bag with argon gas • Placed within a foam padded wooden box • With a memory stick of pertinent files • Read Me First • ROI • SP 260 -177 • Data sheets • Shrink wrapped 7

1 c. Packaging the RMs chip lid PZT Contents: • RM unit • RM chip atop PZT • Within hybrid package • Lid secured with plastic clip nonconductive epoxy memory stick To re pla move stic clip : ……. . Cus t sto omer rag …… e: . . …… NIS T NIST RM 8096 • Sits atop a piece of cleanroom paper • Sealed within a ULO bag with argon gas • Placed within a foam padded wooden box • With a memory stick of pertinent files • Read Me First • ROI • SP 260 -177 • Data sheets • Shrink wrapped 7

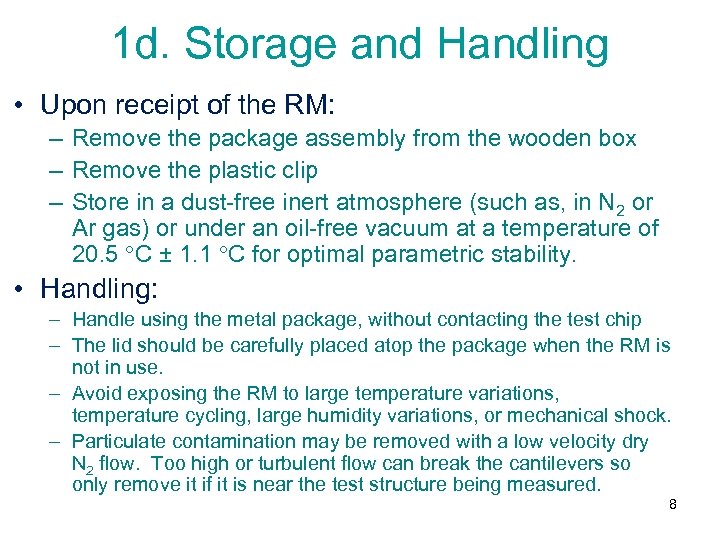

1 d. Storage and Handling • Upon receipt of the RM: – Remove the package assembly from the wooden box – Remove the plastic clip – Store in a dust-free inert atmosphere (such as, in N 2 or Ar gas) or under an oil-free vacuum at a temperature of 20. 5 C ± 1. 1 C for optimal parametric stability. • Handling: – Handle using the metal package, without contacting the test chip – The lid should be carefully placed atop the package when the RM is not in use. – Avoid exposing the RM to large temperature variations, temperature cycling, large humidity variations, or mechanical shock. – Particulate contamination may be removed with a low velocity dry N 2 flow. Too high or turbulent flow can break the cantilevers so only remove it if it is near the test structure being measured. 8

1 d. Storage and Handling • Upon receipt of the RM: – Remove the package assembly from the wooden box – Remove the plastic clip – Store in a dust-free inert atmosphere (such as, in N 2 or Ar gas) or under an oil-free vacuum at a temperature of 20. 5 C ± 1. 1 C for optimal parametric stability. • Handling: – Handle using the metal package, without contacting the test chip – The lid should be carefully placed atop the package when the RM is not in use. – Avoid exposing the RM to large temperature variations, temperature cycling, large humidity variations, or mechanical shock. – Particulate contamination may be removed with a low velocity dry N 2 flow. Too high or turbulent flow can break the cantilevers so only remove it if it is near the test structure being measured. 8

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 9 Contents of each measurement slide set

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 9 Contents of each measurement slide set

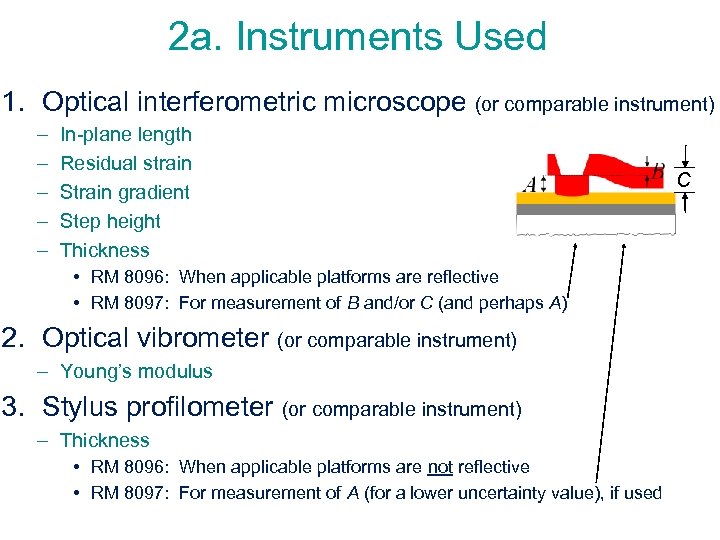

2 a. Instruments Used 1. Optical interferometric microscope (or comparable instrument) – – – In-plane length Residual strain Strain gradient Step height Thickness C • RM 8096: When applicable platforms are reflective • RM 8097: For measurement of B and/or C (and perhaps A) 2. Optical vibrometer (or comparable instrument) – Young’s modulus 3. Stylus profilometer (or comparable instrument) – Thickness • RM 8096: When applicable platforms are not reflective • RM 8097: For measurement of A (for a lower uncertainty value), if used 10

2 a. Instruments Used 1. Optical interferometric microscope (or comparable instrument) – – – In-plane length Residual strain Strain gradient Step height Thickness C • RM 8096: When applicable platforms are reflective • RM 8097: For measurement of B and/or C (and perhaps A) 2. Optical vibrometer (or comparable instrument) – Young’s modulus 3. Stylus profilometer (or comparable instrument) – Thickness • RM 8096: When applicable platforms are not reflective • RM 8097: For measurement of A (for a lower uncertainty value), if used 10

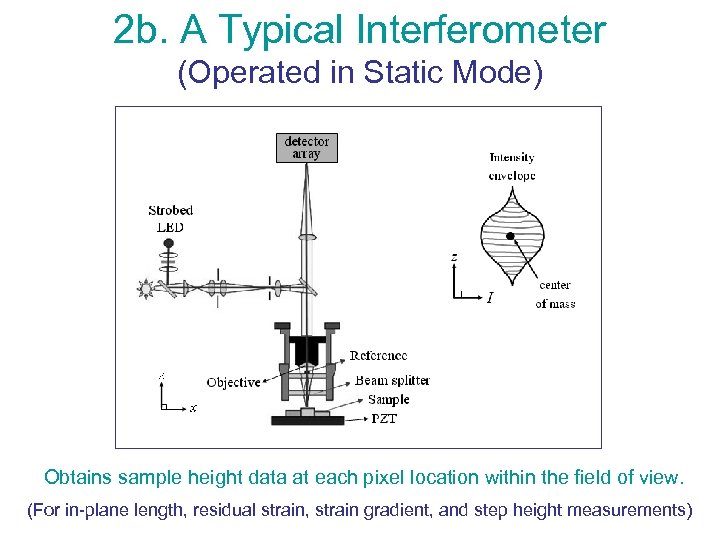

2 b. A Typical Interferometer (Operated in Static Mode) Obtains sample height data at each pixel location within the field of view. 11 (For in-plane length, residual strain, strain gradient, and step height measurements)

2 b. A Typical Interferometer (Operated in Static Mode) Obtains sample height data at each pixel location within the field of view. 11 (For in-plane length, residual strain, strain gradient, and step height measurements)

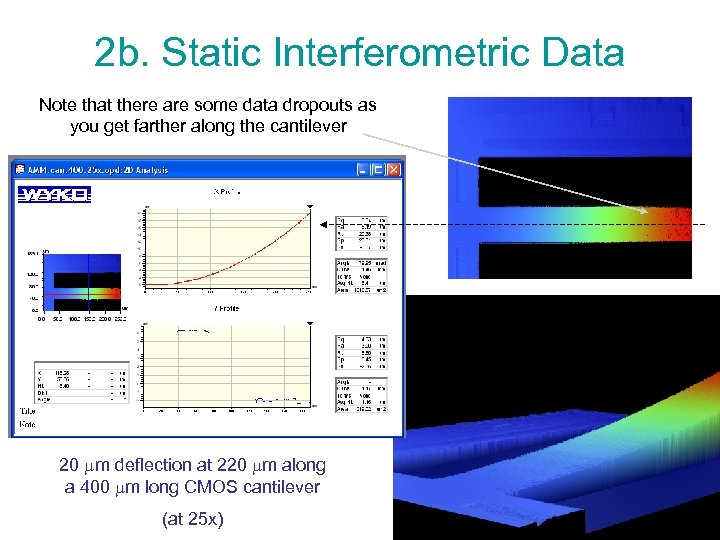

2 b. Static Interferometric Data Note that there are some data dropouts as you get farther along the cantilever 20 mm deflection at 220 mm along a 400 mm long CMOS cantilever (at 25 x) 12

2 b. Static Interferometric Data Note that there are some data dropouts as you get farther along the cantilever 20 mm deflection at 220 mm along a 400 mm long CMOS cantilever (at 25 x) 12

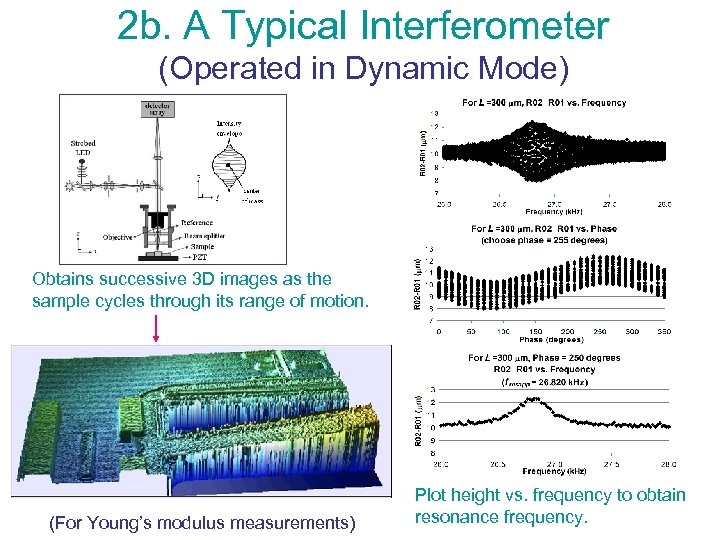

2 b. A Typical Interferometer (Operated in Dynamic Mode) Obtains successive 3 D images as the sample cycles through its range of motion. (For Young’s modulus measurements) Plot height vs. frequency to obtain 13 resonance frequency.

2 b. A Typical Interferometer (Operated in Dynamic Mode) Obtains successive 3 D images as the sample cycles through its range of motion. (For Young’s modulus measurements) Plot height vs. frequency to obtain 13 resonance frequency.

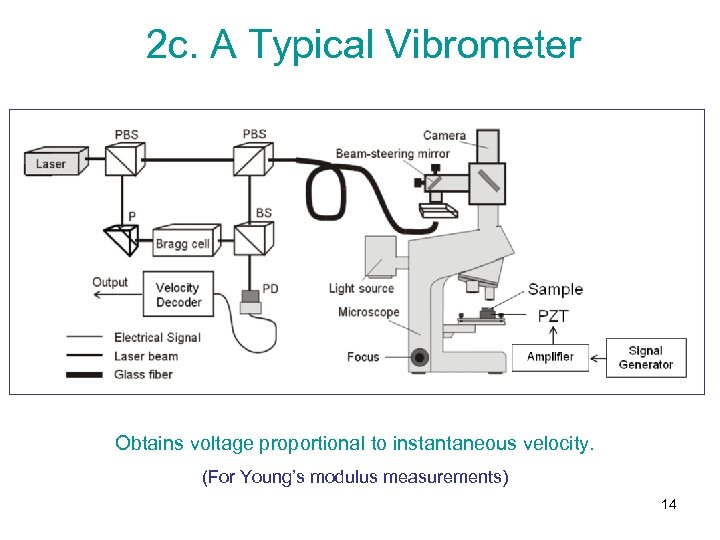

2 c. A Typical Vibrometer Obtains voltage proportional to instantaneous velocity. (For Young’s modulus measurements) 14

2 c. A Typical Vibrometer Obtains voltage proportional to instantaneous velocity. (For Young’s modulus measurements) 14

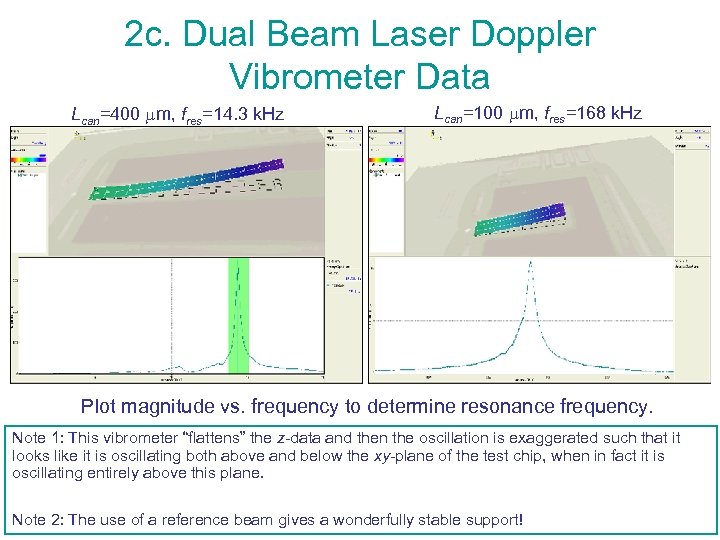

2 c. Dual Beam Laser Doppler Vibrometer Data Lcan=400 mm, fres=14. 3 k. Hz Lcan=100 mm, fres=168 k. Hz Plot magnitude vs. frequency to determine resonance frequency. Note 1: This vibrometer “flattens” the z-data and then the oscillation is exaggerated such that it looks like it is oscillating both above and below the xy-plane of the test chip, when in fact it is oscillating entirely above this plane. Note 2: The use of a reference beam gives a wonderfully stable support! 15

2 c. Dual Beam Laser Doppler Vibrometer Data Lcan=400 mm, fres=14. 3 k. Hz Lcan=100 mm, fres=168 k. Hz Plot magnitude vs. frequency to determine resonance frequency. Note 1: This vibrometer “flattens” the z-data and then the oscillation is exaggerated such that it looks like it is oscillating both above and below the xy-plane of the test chip, when in fact it is oscillating entirely above this plane. Note 2: The use of a reference beam gives a wonderfully stable support! 15

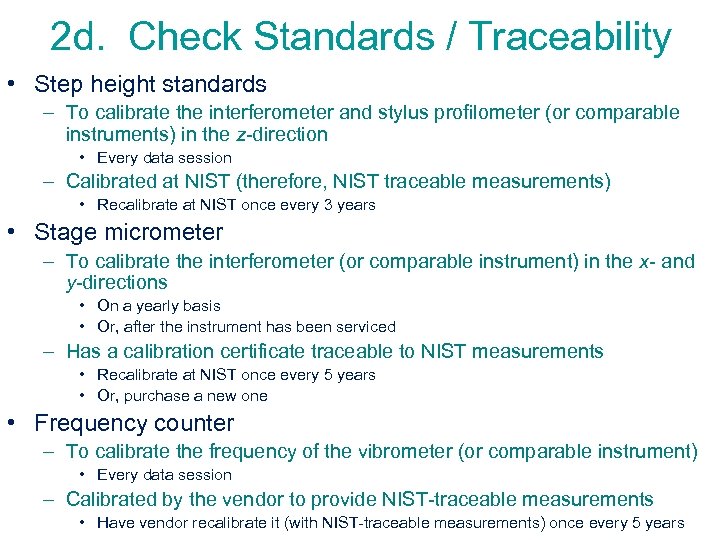

2 d. Check Standards / Traceability • Step height standards – To calibrate the interferometer and stylus profilometer (or comparable instruments) in the z-direction • Every data session – Calibrated at NIST (therefore, NIST traceable measurements) • Recalibrate at NIST once every 3 years • Stage micrometer – To calibrate the interferometer (or comparable instrument) in the x- and y-directions • On a yearly basis • Or, after the instrument has been serviced – Has a calibration certificate traceable to NIST measurements • Recalibrate at NIST once every 5 years • Or, purchase a new one • Frequency counter – To calibrate the frequency of the vibrometer (or comparable instrument) • Every data session – Calibrated by the vendor to provide NIST-traceable measurements 16 • Have vendor recalibrate it (with NIST-traceable measurements) once every 5 years

2 d. Check Standards / Traceability • Step height standards – To calibrate the interferometer and stylus profilometer (or comparable instruments) in the z-direction • Every data session – Calibrated at NIST (therefore, NIST traceable measurements) • Recalibrate at NIST once every 3 years • Stage micrometer – To calibrate the interferometer (or comparable instrument) in the x- and y-directions • On a yearly basis • Or, after the instrument has been serviced – Has a calibration certificate traceable to NIST measurements • Recalibrate at NIST once every 5 years • Or, purchase a new one • Frequency counter – To calibrate the frequency of the vibrometer (or comparable instrument) • Every data session – Calibrated by the vendor to provide NIST-traceable measurements 16 • Have vendor recalibrate it (with NIST-traceable measurements) once every 5 years

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 17 Contents of each measurement slide set

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 17 Contents of each measurement slide set

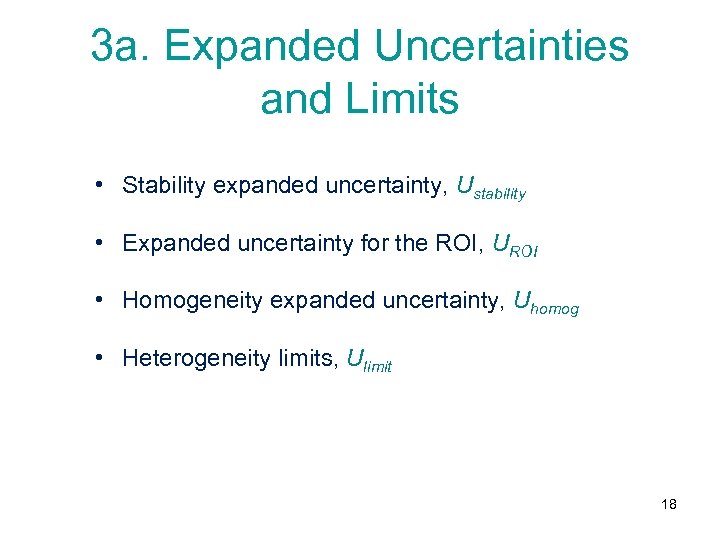

3 a. Expanded Uncertainties and Limits • Stability expanded uncertainty, Ustability • Expanded uncertainty for the ROI, UROI • Homogeneity expanded uncertainty, Uhomog • Heterogeneity limits, Ulimit 18

3 a. Expanded Uncertainties and Limits • Stability expanded uncertainty, Ustability • Expanded uncertainty for the ROI, UROI • Homogeneity expanded uncertainty, Uhomog • Heterogeneity limits, Ulimit 18

![3 a. Stability Expanded Uncertainty, Ustability • From SP 260 -177 [Eq. (30)]: • 3 a. Stability Expanded Uncertainty, Ustability • From SP 260 -177 [Eq. (30)]: •](https://present5.com/presentation/389bbcafb66a998f70b86670ba952419/image-19.jpg) 3 a. Stability Expanded Uncertainty, Ustability • From SP 260 -177 [Eq. (30)]: • If assume UM=UR=Uave, then • For a uniform distribution, UR=exp. unc. reference value UM=exp. unc. of new measured value UD=exp. unc. of difference where D=|M R| • Stability expanded uncertainty • (multiply by two, since the initial value is considered the “lowest” value and not the midpoint) • Use for material parameters (YM, RS, SG, RStress, and Stress. G) • For dimensional parameters (SH, IPL, and T), assume Ustability = 0. 0 µm 19 • Can assume that Ustability. For. P 1=Ustability. For. P 2

3 a. Stability Expanded Uncertainty, Ustability • From SP 260 -177 [Eq. (30)]: • If assume UM=UR=Uave, then • For a uniform distribution, UR=exp. unc. reference value UM=exp. unc. of new measured value UD=exp. unc. of difference where D=|M R| • Stability expanded uncertainty • (multiply by two, since the initial value is considered the “lowest” value and not the midpoint) • Use for material parameters (YM, RS, SG, RStress, and Stress. G) • For dimensional parameters (SH, IPL, and T), assume Ustability = 0. 0 µm 19 • Can assume that Ustability. For. P 1=Ustability. For. P 2

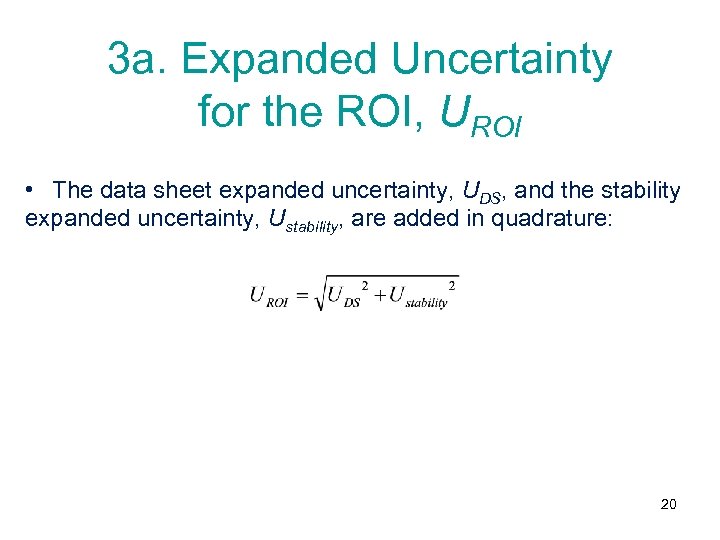

3 a. Expanded Uncertainty for the ROI, UROI • The data sheet expanded uncertainty, UDS, and the stability expanded uncertainty, Ustability, are added in quadrature: 20

3 a. Expanded Uncertainty for the ROI, UROI • The data sheet expanded uncertainty, UDS, and the stability expanded uncertainty, Ustability, are added in quadrature: 20

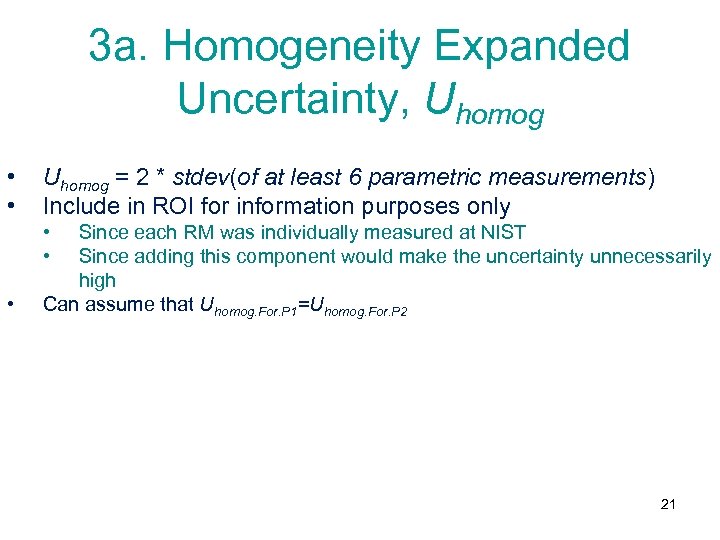

3 a. Homogeneity Expanded Uncertainty, Uhomog • • Uhomog = 2 * stdev(of at least 6 parametric measurements) Include in ROI for information purposes only • • • Since each RM was individually measured at NIST Since adding this component would make the uncertainty unnecessarily high Can assume that Uhomog. For. P 1=Uhomog. For. P 2 21

3 a. Homogeneity Expanded Uncertainty, Uhomog • • Uhomog = 2 * stdev(of at least 6 parametric measurements) Include in ROI for information purposes only • • • Since each RM was individually measured at NIST Since adding this component would make the uncertainty unnecessarily high Can assume that Uhomog. For. P 1=Uhomog. For. P 2 21

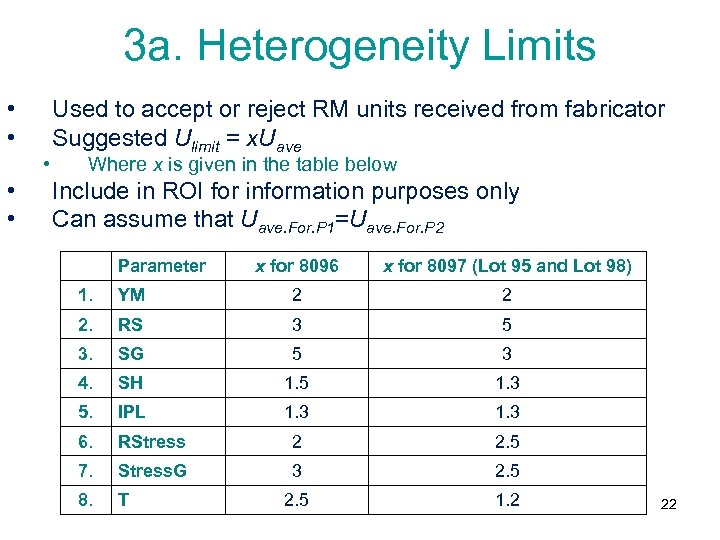

3 a. Heterogeneity Limits • • • Used to accept or reject RM units received from fabricator Suggested Ulimit = x. Uave Where x is given in the table below Include in ROI for information purposes only Can assume that Uave. For. P 1=Uave. For. P 2 Parameter x for 8096 x for 8097 (Lot 95 and Lot 98) 1. YM 2 2 2. RS 3 5 3. SG 5 3 4. SH 1. 5 1. 3 5. IPL 1. 3 6. RStress 2 2. 5 7. Stress. G 3 2. 5 8. T 2. 5 1. 2 22

3 a. Heterogeneity Limits • • • Used to accept or reject RM units received from fabricator Suggested Ulimit = x. Uave Where x is given in the table below Include in ROI for information purposes only Can assume that Uave. For. P 1=Uave. For. P 2 Parameter x for 8096 x for 8097 (Lot 95 and Lot 98) 1. YM 2 2 2. RS 3 5 3. SG 5 3 4. SH 1. 5 1. 3 5. IPL 1. 3 6. RStress 2 2. 5 7. Stress. G 3 2. 5 8. T 2. 5 1. 2 22

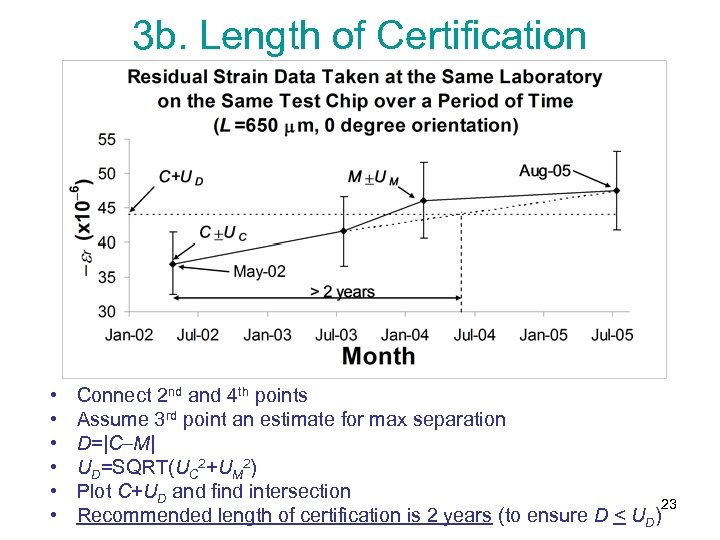

3 b. Length of Certification • • • Connect 2 nd and 4 th points Assume 3 rd point an estimate for max separation D=|C M| UD=SQRT(UC 2+UM 2) Plot C+UD and find intersection 23 Recommended length of certification is 2 years (to ensure D < UD)

3 b. Length of Certification • • • Connect 2 nd and 4 th points Assume 3 rd point an estimate for max separation D=|C M| UD=SQRT(UC 2+UM 2) Plot C+UD and find intersection 23 Recommended length of certification is 2 years (to ensure D < UD)

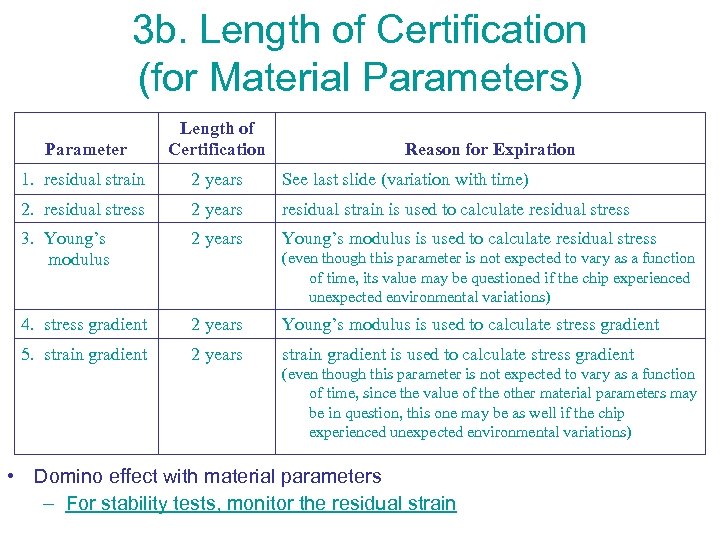

3 b. Length of Certification (for Material Parameters) Parameter Length of Certification 1. residual strain 2 years See last slide (variation with time) 2. residual stress 2 years residual strain is used to calculate residual stress 3. Young’s modulus 2 years Young’s modulus is used to calculate residual stress 4. stress gradient 2 years Young’s modulus is used to calculate stress gradient 5. strain gradient 2 years strain gradient is used to calculate stress gradient Reason for Expiration (even though this parameter is not expected to vary as a function of time, its value may be questioned if the chip experienced unexpected environmental variations) (even though this parameter is not expected to vary as a function of time, since the value of the other material parameters may be in question, this one may be as well if the chip experienced unexpected environmental variations) • Domino effect with material parameters – For stability tests, monitor the residual strain 24

3 b. Length of Certification (for Material Parameters) Parameter Length of Certification 1. residual strain 2 years See last slide (variation with time) 2. residual stress 2 years residual strain is used to calculate residual stress 3. Young’s modulus 2 years Young’s modulus is used to calculate residual stress 4. stress gradient 2 years Young’s modulus is used to calculate stress gradient 5. strain gradient 2 years strain gradient is used to calculate stress gradient Reason for Expiration (even though this parameter is not expected to vary as a function of time, its value may be questioned if the chip experienced unexpected environmental variations) (even though this parameter is not expected to vary as a function of time, since the value of the other material parameters may be in question, this one may be as well if the chip experienced unexpected environmental variations) • Domino effect with material parameters – For stability tests, monitor the residual strain 24

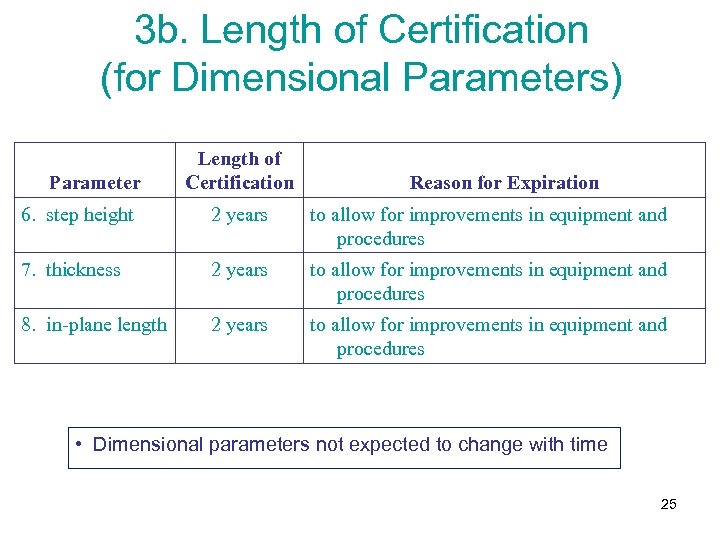

3 b. Length of Certification (for Dimensional Parameters) Parameter Length of Certification Reason for Expiration 6. step height 2 years to allow for improvements in equipment and procedures 7. thickness 2 years to allow for improvements in equipment and procedures 8. in-plane length 2 years to allow for improvements in equipment and procedures • Dimensional parameters not expected to change with time 25

3 b. Length of Certification (for Dimensional Parameters) Parameter Length of Certification Reason for Expiration 6. step height 2 years to allow for improvements in equipment and procedures 7. thickness 2 years to allow for improvements in equipment and procedures 8. in-plane length 2 years to allow for improvements in equipment and procedures • Dimensional parameters not expected to change with time 25

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 26 Contents of each measurement slide set

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 26 Contents of each measurement slide set

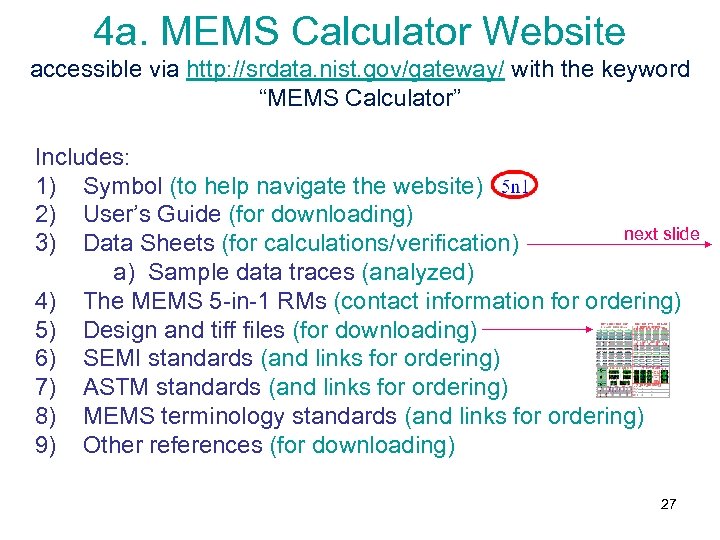

4 a. MEMS Calculator Website accessible via http: //srdata. nist. gov/gateway/ with the keyword “MEMS Calculator” Includes: 1) Symbol (to help navigate the website) 2) User’s Guide (for downloading) next slide 3) Data Sheets (for calculations/verification) a) Sample data traces (analyzed) 4) The MEMS 5 -in-1 RMs (contact information for ordering) 5) Design and tiff files (for downloading) 6) SEMI standards (and links for ordering) 7) ASTM standards (and links for ordering) 8) MEMS terminology standards (and links for ordering) 9) Other references (for downloading) 27

4 a. MEMS Calculator Website accessible via http: //srdata. nist. gov/gateway/ with the keyword “MEMS Calculator” Includes: 1) Symbol (to help navigate the website) 2) User’s Guide (for downloading) next slide 3) Data Sheets (for calculations/verification) a) Sample data traces (analyzed) 4) The MEMS 5 -in-1 RMs (contact information for ordering) 5) Design and tiff files (for downloading) 6) SEMI standards (and links for ordering) 7) ASTM standards (and links for ordering) 8) MEMS terminology standards (and links for ordering) 9) Other references (for downloading) 27

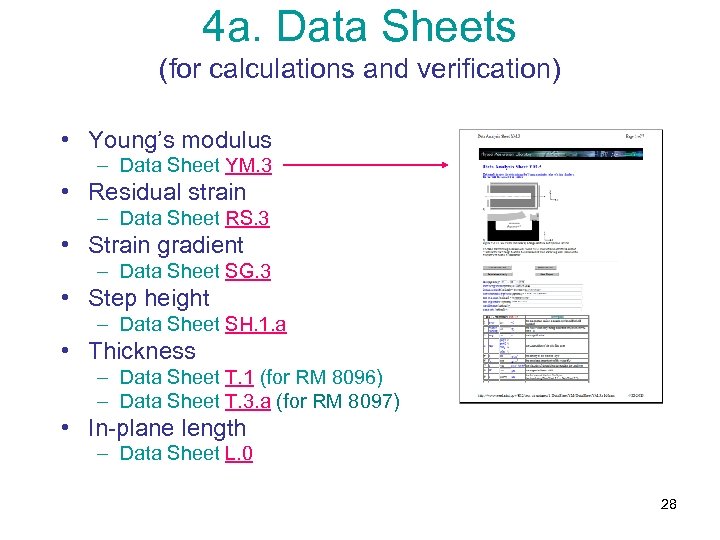

4 a. Data Sheets (for calculations and verification) • Young’s modulus – Data Sheet YM. 3 • Residual strain – Data Sheet RS. 3 • Strain gradient – Data Sheet SG. 3 • Step height – Data Sheet SH. 1. a • Thickness – Data Sheet T. 1 (for RM 8096) – Data Sheet T. 3. a (for RM 8097) • In-plane length – Data Sheet L. 0 28

4 a. Data Sheets (for calculations and verification) • Young’s modulus – Data Sheet YM. 3 • Residual strain – Data Sheet RS. 3 • Strain gradient – Data Sheet SG. 3 • Step height – Data Sheet SH. 1. a • Thickness – Data Sheet T. 1 (for RM 8096) – Data Sheet T. 3. a (for RM 8097) • In-plane length – Data Sheet L. 0 28

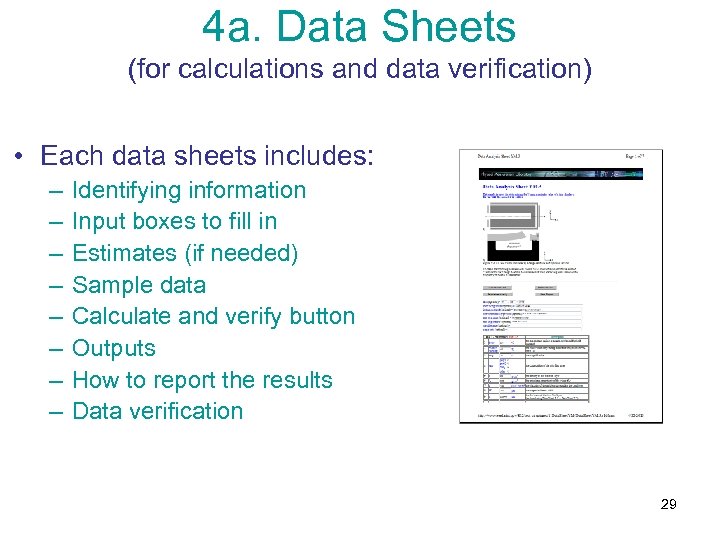

4 a. Data Sheets (for calculations and data verification) • Each data sheets includes: – – – – Identifying information Input boxes to fill in Estimates (if needed) Sample data Calculate and verify button Outputs How to report the results Data verification 29

4 a. Data Sheets (for calculations and data verification) • Each data sheets includes: – – – – Identifying information Input boxes to fill in Estimates (if needed) Sample data Calculate and verify button Outputs How to report the results Data verification 29

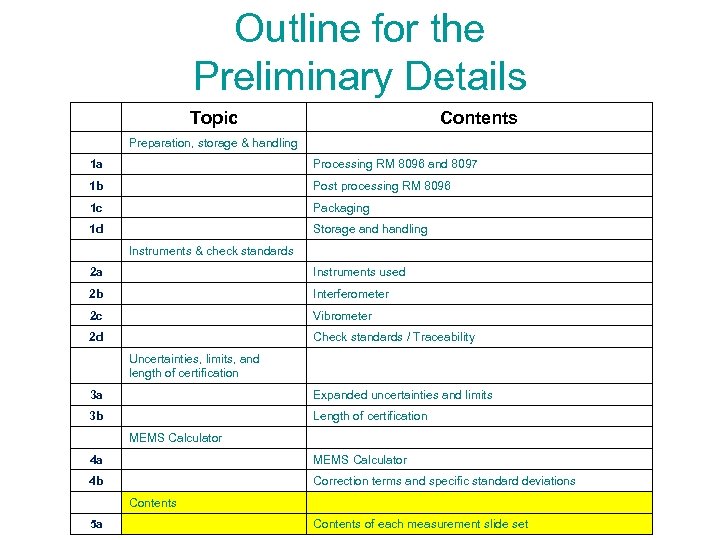

4 b. Correction Terms and Specific Standard Deviations • The correction terms and specific standard deviations used at NIST in the data sheets can be found in the SP 260 -177 – In Table 3 on p. 26 (for RM 8096) – In Table 4 on p. 27 -28 (for RM 8097) 30

4 b. Correction Terms and Specific Standard Deviations • The correction terms and specific standard deviations used at NIST in the data sheets can be found in the SP 260 -177 – In Table 3 on p. 26 (for RM 8096) – In Table 4 on p. 27 -28 (for RM 8097) 30

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 31 Contents of each measurement slide set

Outline for the Preliminary Details Topic Contents Preparation, storage & handling 1 a Processing RM 8096 and 8097 1 b Post processing RM 8096 1 c Packaging 1 d Storage and handling Instruments & check standards 2 a Instruments used 2 b Interferometer 2 c Vibrometer 2 d Check standards / Traceability Uncertainties, limits, and length of certification 3 a Expanded uncertainties and limits 3 b Length of certification MEMS Calculator 4 a MEMS Calculator 4 b Correction terms and specific standard deviations Contents 5 a 31 Contents of each measurement slide set

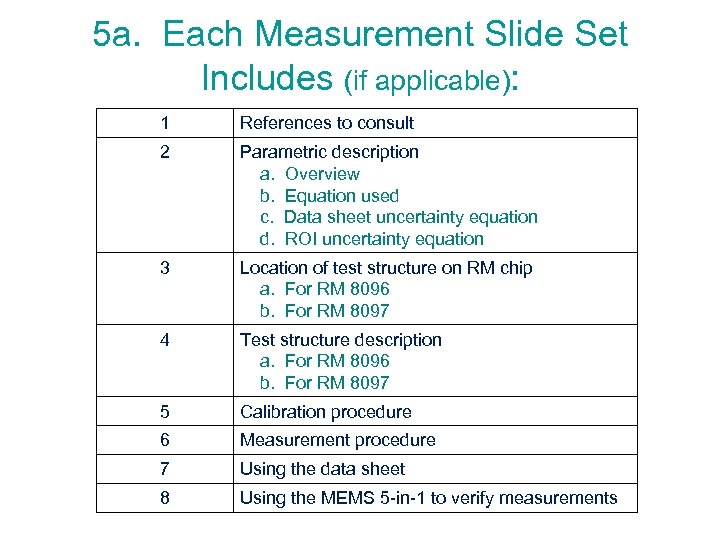

5 a. Each Measurement Slide Set Includes (if applicable): 1 References to consult 2 Parametric description a. Overview b. Equation used c. Data sheet uncertainty equation d. ROI uncertainty equation 3 Location of test structure on RM chip a. For RM 8096 b. For RM 8097 4 Test structure description a. For RM 8096 b. For RM 8097 5 Calibration procedure 6 Measurement procedure 7 Using the data sheet 8 Using the MEMS 5 -in-1 to verify measurements 32

5 a. Each Measurement Slide Set Includes (if applicable): 1 References to consult 2 Parametric description a. Overview b. Equation used c. Data sheet uncertainty equation d. ROI uncertainty equation 3 Location of test structure on RM chip a. For RM 8096 b. For RM 8097 4 Test structure description a. For RM 8096 b. For RM 8097 5 Calibration procedure 6 Measurement procedure 7 Using the data sheet 8 Using the MEMS 5 -in-1 to verify measurements 32