409d624f6554a00fb0f935fb65037447.ppt

- Количество слайдов: 29

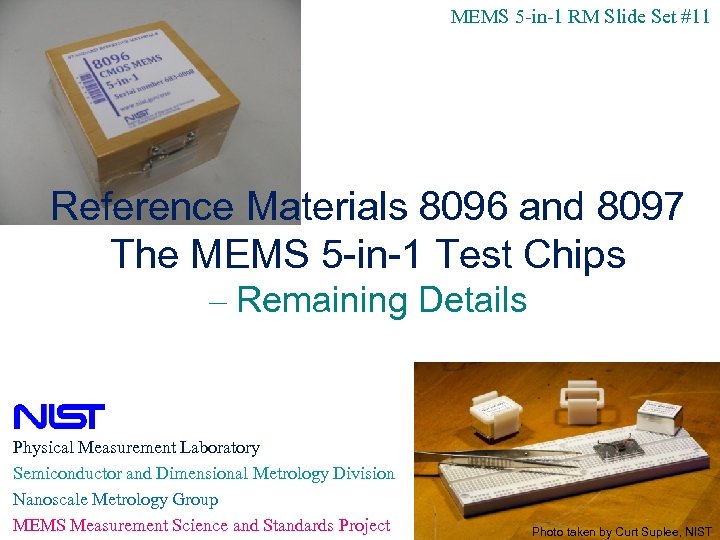

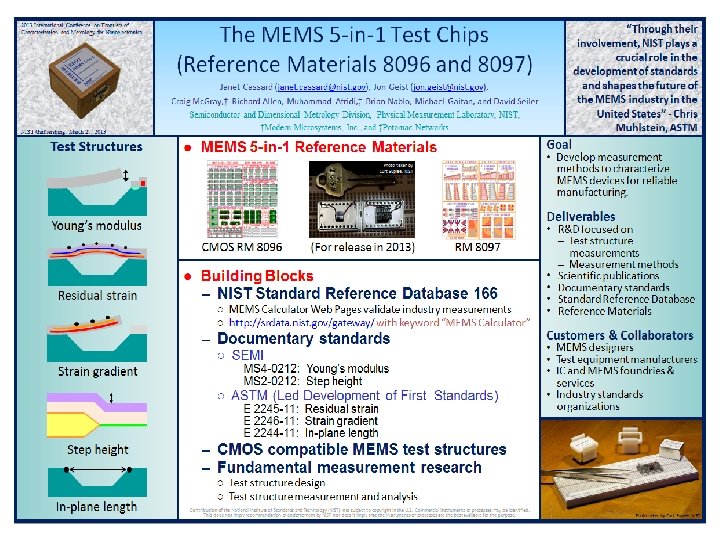

MEMS 5 -in-1 RM Slide Set #11 Reference Materials 8096 and 8097 The MEMS 5 -in-1 Test Chips – Remaining Details Physical Measurement Laboratory Semiconductor and Dimensional Metrology Division Nanoscale Metrology Group MEMS Measurement Science and Standards Project 1 Photo taken by Curt Suplee, NIST

MEMS 5 -in-1 RM Slide Set #11 Reference Materials 8096 and 8097 The MEMS 5 -in-1 Test Chips – Remaining Details Physical Measurement Laboratory Semiconductor and Dimensional Metrology Division Nanoscale Metrology Group MEMS Measurement Science and Standards Project 1 Photo taken by Curt Suplee, NIST

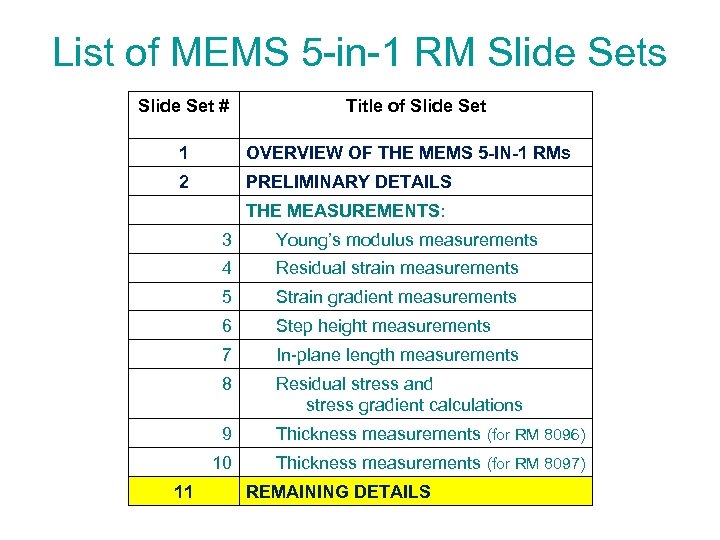

List of MEMS 5 -in-1 RM Slide Sets Slide Set # Title of Slide Set 1 OVERVIEW OF THE MEMS 5 -IN-1 RMs 2 PRELIMINARY DETAILS THE MEASUREMENTS: 3 Young’s modulus measurements 4 Residual strain measurements 5 Strain gradient measurements 6 Step height measurements 7 In-plane length measurements 8 Residual stress and stress gradient calculations 9 Thickness measurements (for RM 8096) 10 Thickness measurements (for RM 8097) 11 REMAINING DETAILS 2

List of MEMS 5 -in-1 RM Slide Sets Slide Set # Title of Slide Set 1 OVERVIEW OF THE MEMS 5 -IN-1 RMs 2 PRELIMINARY DETAILS THE MEASUREMENTS: 3 Young’s modulus measurements 4 Residual strain measurements 5 Strain gradient measurements 6 Step height measurements 7 In-plane length measurements 8 Residual stress and stress gradient calculations 9 Thickness measurements (for RM 8096) 10 Thickness measurements (for RM 8097) 11 REMAINING DETAILS 2

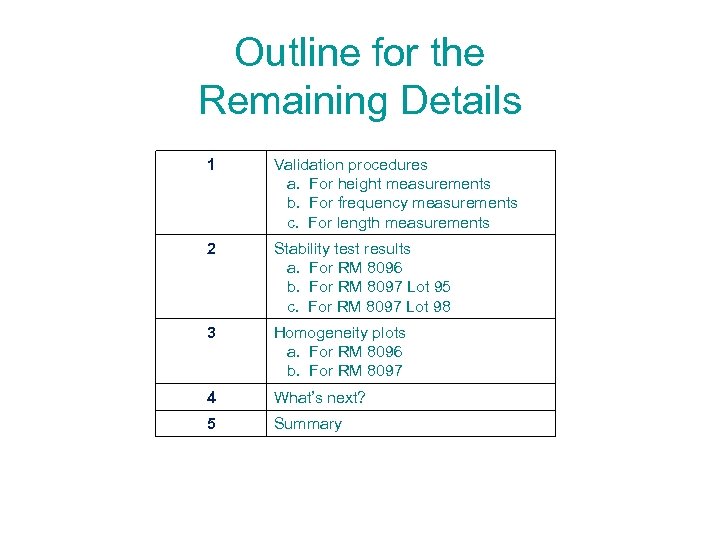

Outline for the Remaining Details 1 Validation procedures a. For height measurements b. For frequency measurements c. For length measurements 2 Stability test results a. For RM 8096 b. For RM 8097 Lot 95 c. For RM 8097 Lot 98 3 Homogeneity plots a. For RM 8096 b. For RM 8097 4 What’s next? 5 Summary 3

Outline for the Remaining Details 1 Validation procedures a. For height measurements b. For frequency measurements c. For length measurements 2 Stability test results a. For RM 8096 b. For RM 8097 Lot 95 c. For RM 8097 Lot 98 3 Homogeneity plots a. For RM 8096 b. For RM 8097 4 What’s next? 5 Summary 3

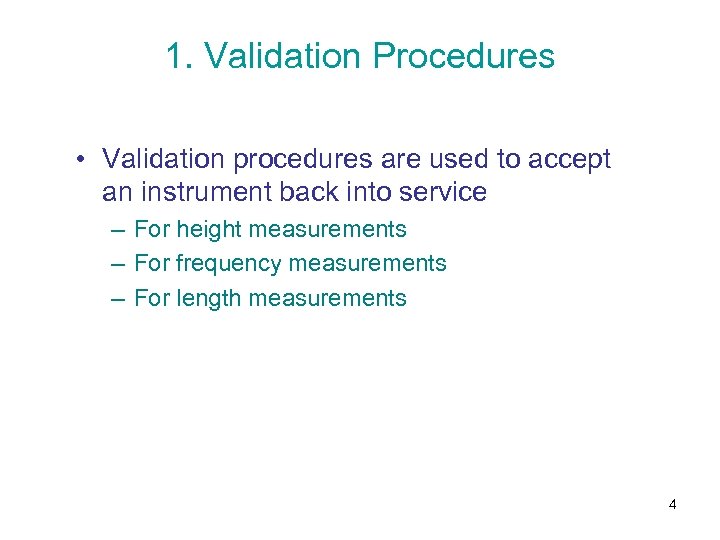

1. Validation Procedures • Validation procedures are used to accept an instrument back into service – For height measurements – For frequency measurements – For length measurements 4

1. Validation Procedures • Validation procedures are used to accept an instrument back into service – For height measurements – For frequency measurements – For length measurements 4

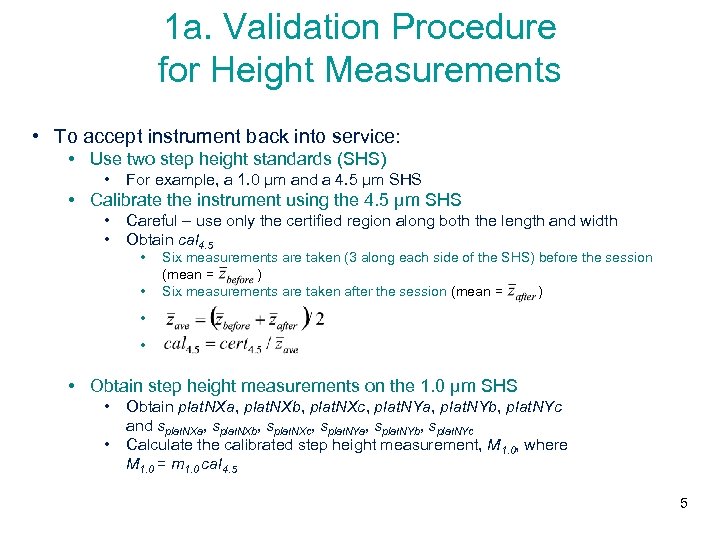

1 a. Validation Procedure for Height Measurements • To accept instrument back into service: • Use two step height standards (SHS) • For example, a 1. 0 µm and a 4. 5 µm SHS • Calibrate the instrument using the 4. 5 µm SHS • • Careful – use only the certified region along both the length and width Obtain cal 4. 5 • • Six measurements are taken (3 along each side of the SHS) before the session (mean = ) Six measurements are taken after the session (mean = ) • • • Obtain step height measurements on the 1. 0 µm SHS • • Obtain plat. NXa, plat. NXb, plat. NXc, plat. NYa, plat. NYb, plat. NYc and splat. NXa, splat. NXb, splat. NXc, splat. NYa, splat. NYb, splat. NYc Calculate the calibrated step height measurement, M 1. 0, where M 1. 0 = m 1. 0 cal 4. 5 5

1 a. Validation Procedure for Height Measurements • To accept instrument back into service: • Use two step height standards (SHS) • For example, a 1. 0 µm and a 4. 5 µm SHS • Calibrate the instrument using the 4. 5 µm SHS • • Careful – use only the certified region along both the length and width Obtain cal 4. 5 • • Six measurements are taken (3 along each side of the SHS) before the session (mean = ) Six measurements are taken after the session (mean = ) • • • Obtain step height measurements on the 1. 0 µm SHS • • Obtain plat. NXa, plat. NXb, plat. NXc, plat. NYa, plat. NYb, plat. NYc and splat. NXa, splat. NXb, splat. NXc, splat. NYa, splat. NYb, splat. NYc Calculate the calibrated step height measurement, M 1. 0, where M 1. 0 = m 1. 0 cal 4. 5 5

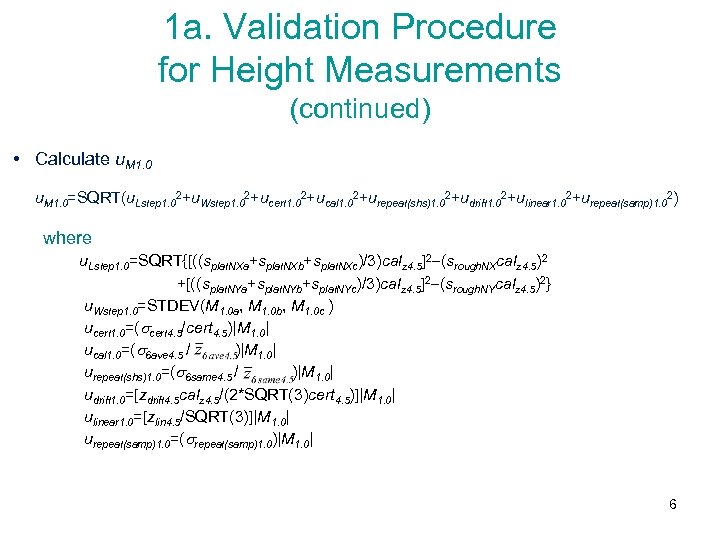

1 a. Validation Procedure for Height Measurements (continued) • Calculate u. M 1. 0=SQRT(u. Lstep 1. 02+u. Wstep 1. 02+ucert 1. 02+ucal 1. 02+urepeat(shs)1. 02+udrift 1. 02+ulinear 1. 02+urepeat(samp)1. 02) where u. Lstep 1. 0=SQRT{[((splat. NXa+splat. NXb+splat. NXc)/3)calz 4. 5]2 (srough. NXcalz 4. 5)2 +[((splat. NYa+splat. NYb+splat. NYc)/3)calz 4. 5]2 (srough. NYcalz 4. 5)2} u. Wstep 1. 0=STDEV(M 1. 0 a, M 1. 0 b, M 1. 0 c ) ucert 1. 0=( cert 4. 5/cert 4. 5)|M 1. 0| ucal 1. 0=( 6 ave 4. 5 / )|M 1. 0| urepeat(shs)1. 0=( 6 same 4. 5 / )|M 1. 0| udrift 1. 0=[zdrift 4. 5 calz 4. 5/(2*SQRT(3)cert 4. 5)]|M 1. 0| ulinear 1. 0=[zlin 4. 5/SQRT(3)]|M 1. 0| urepeat(samp)1. 0=( repeat(samp)1. 0)|M 1. 0| 6

1 a. Validation Procedure for Height Measurements (continued) • Calculate u. M 1. 0=SQRT(u. Lstep 1. 02+u. Wstep 1. 02+ucert 1. 02+ucal 1. 02+urepeat(shs)1. 02+udrift 1. 02+ulinear 1. 02+urepeat(samp)1. 02) where u. Lstep 1. 0=SQRT{[((splat. NXa+splat. NXb+splat. NXc)/3)calz 4. 5]2 (srough. NXcalz 4. 5)2 +[((splat. NYa+splat. NYb+splat. NYc)/3)calz 4. 5]2 (srough. NYcalz 4. 5)2} u. Wstep 1. 0=STDEV(M 1. 0 a, M 1. 0 b, M 1. 0 c ) ucert 1. 0=( cert 4. 5/cert 4. 5)|M 1. 0| ucal 1. 0=( 6 ave 4. 5 / )|M 1. 0| urepeat(shs)1. 0=( 6 same 4. 5 / )|M 1. 0| udrift 1. 0=[zdrift 4. 5 calz 4. 5/(2*SQRT(3)cert 4. 5)]|M 1. 0| ulinear 1. 0=[zlin 4. 5/SQRT(3)]|M 1. 0| urepeat(samp)1. 0=( repeat(samp)1. 0)|M 1. 0| 6

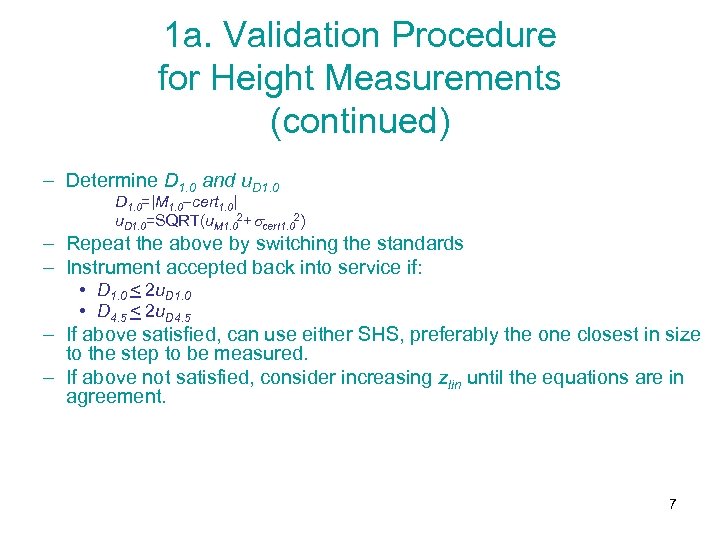

1 a. Validation Procedure for Height Measurements (continued) – Determine D 1. 0 and u. D 1. 0=|M 1. 0 cert 1. 0| u. D 1. 0=SQRT(u. M 1. 02+ cert 1. 02) – Repeat the above by switching the standards – Instrument accepted back into service if: • D 1. 0 < 2 u. D 1. 0 • D 4. 5 < 2 u. D 4. 5 – If above satisfied, can use either SHS, preferably the one closest in size to the step to be measured. – If above not satisfied, consider increasing zlin until the equations are in agreement. 7

1 a. Validation Procedure for Height Measurements (continued) – Determine D 1. 0 and u. D 1. 0=|M 1. 0 cert 1. 0| u. D 1. 0=SQRT(u. M 1. 02+ cert 1. 02) – Repeat the above by switching the standards – Instrument accepted back into service if: • D 1. 0 < 2 u. D 1. 0 • D 4. 5 < 2 u. D 4. 5 – If above satisfied, can use either SHS, preferably the one closest in size to the step to be measured. – If above not satisfied, consider increasing zlin until the equations are in agreement. 7

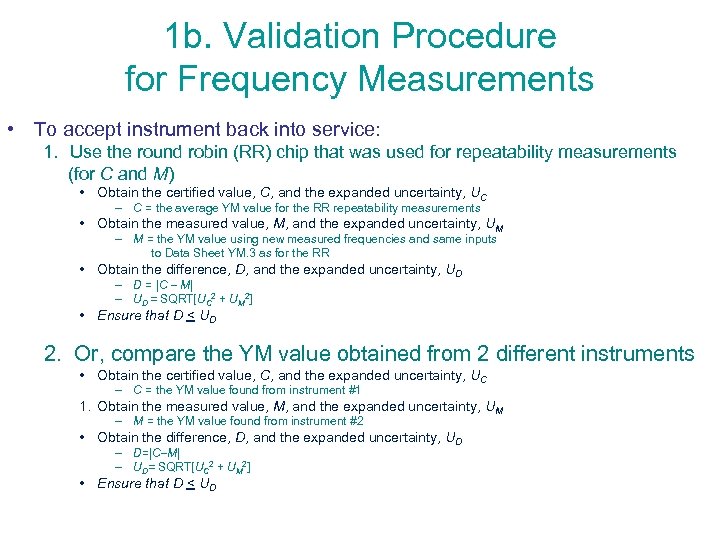

1 b. Validation Procedure for Frequency Measurements • To accept instrument back into service: 1. Use the round robin (RR) chip that was used for repeatability measurements (for C and M) • Obtain the certified value, C, and the expanded uncertainty, UC – C = the average YM value for the RR repeatability measurements • Obtain the measured value, M, and the expanded uncertainty, UM – M = the YM value using new measured frequencies and same inputs to Data Sheet YM. 3 as for the RR • Obtain the difference, D, and the expanded uncertainty, UD – D = |C M| – UD = SQRT[UC 2 + UM 2] • Ensure that D < UD 2. Or, compare the YM value obtained from 2 different instruments • Obtain the certified value, C, and the expanded uncertainty, UC – C = the YM value found from instrument #1 1. Obtain the measured value, M, and the expanded uncertainty, UM – M = the YM value found from instrument #2 • Obtain the difference, D, and the expanded uncertainty, UD – D=|C M| – UD= SQRT[UC 2 + UM 2] • Ensure that D < UD 8

1 b. Validation Procedure for Frequency Measurements • To accept instrument back into service: 1. Use the round robin (RR) chip that was used for repeatability measurements (for C and M) • Obtain the certified value, C, and the expanded uncertainty, UC – C = the average YM value for the RR repeatability measurements • Obtain the measured value, M, and the expanded uncertainty, UM – M = the YM value using new measured frequencies and same inputs to Data Sheet YM. 3 as for the RR • Obtain the difference, D, and the expanded uncertainty, UD – D = |C M| – UD = SQRT[UC 2 + UM 2] • Ensure that D < UD 2. Or, compare the YM value obtained from 2 different instruments • Obtain the certified value, C, and the expanded uncertainty, UC – C = the YM value found from instrument #1 1. Obtain the measured value, M, and the expanded uncertainty, UM – M = the YM value found from instrument #2 • Obtain the difference, D, and the expanded uncertainty, UD – D=|C M| – UD= SQRT[UC 2 + UM 2] • Ensure that D < UD 8

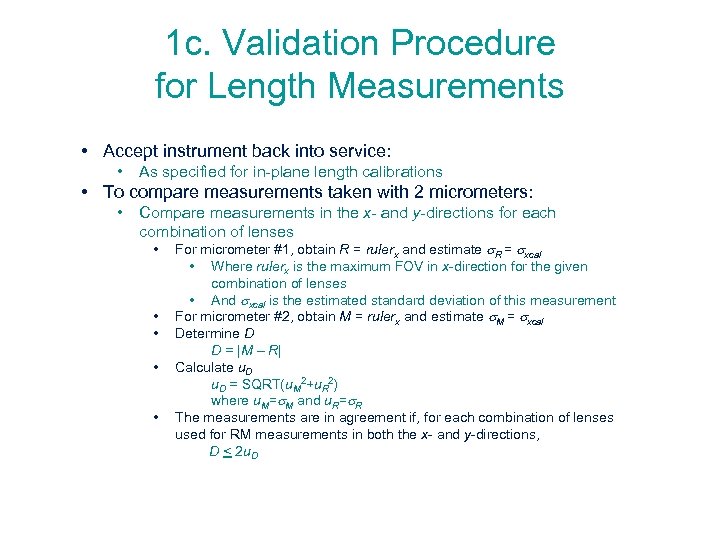

1 c. Validation Procedure for Length Measurements • Accept instrument back into service: • As specified for in-plane length calibrations • To compare measurements taken with 2 micrometers: • Compare measurements in the x- and y-directions for each combination of lenses For micrometer #1, obtain R = rulerx and estimate R = xcal • Where rulerx is the maximum FOV in x-direction for the given combination of lenses • And xcal is the estimated standard deviation of this measurement • For micrometer #2, obtain M = rulerx and estimate M = xcal • Determine D D = |M R| • Calculate u. D = SQRT(u. M 2+u. R 2) where u. M= M and u. R= R • The measurements are in agreement if, for each combination of lenses used for RM measurements in both the x- and y-directions, D < 2 u. D • 9

1 c. Validation Procedure for Length Measurements • Accept instrument back into service: • As specified for in-plane length calibrations • To compare measurements taken with 2 micrometers: • Compare measurements in the x- and y-directions for each combination of lenses For micrometer #1, obtain R = rulerx and estimate R = xcal • Where rulerx is the maximum FOV in x-direction for the given combination of lenses • And xcal is the estimated standard deviation of this measurement • For micrometer #2, obtain M = rulerx and estimate M = xcal • Determine D D = |M R| • Calculate u. D = SQRT(u. M 2+u. R 2) where u. M= M and u. R= R • The measurements are in agreement if, for each combination of lenses used for RM measurements in both the x- and y-directions, D < 2 u. D • 9

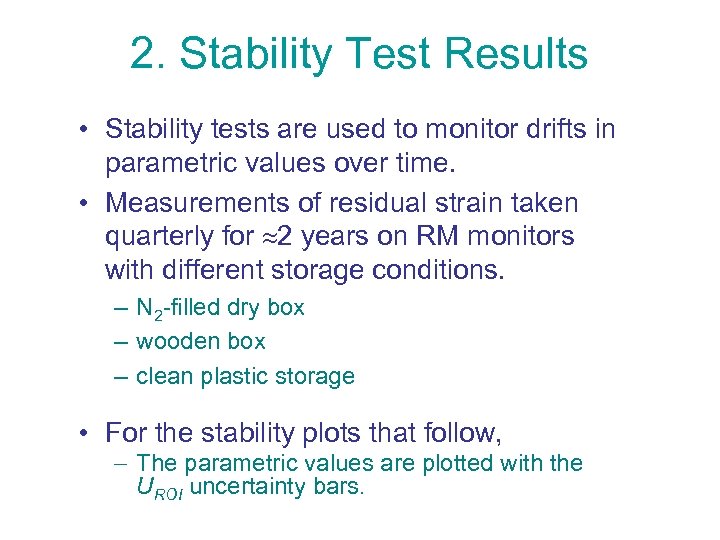

2. Stability Test Results • Stability tests are used to monitor drifts in parametric values over time. • Measurements of residual strain taken quarterly for 2 years on RM monitors with different storage conditions. – N 2 -filled dry box – wooden box – clean plastic storage • For the stability plots that follow, The parametric values are plotted with the UROI uncertainty bars. 10

2. Stability Test Results • Stability tests are used to monitor drifts in parametric values over time. • Measurements of residual strain taken quarterly for 2 years on RM monitors with different storage conditions. – N 2 -filled dry box – wooden box – clean plastic storage • For the stability plots that follow, The parametric values are plotted with the UROI uncertainty bars. 10

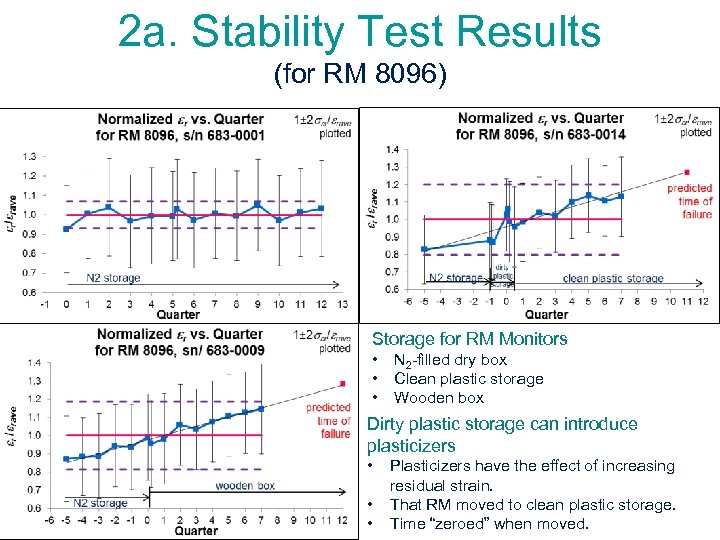

2 a. Stability Test Results (for RM 8096) Storage for RM Monitors • • • N 2 -filled dry box Clean plastic storage Wooden box Dirty plastic storage can introduce plasticizers • • • Plasticizers have the effect of increasing residual strain. 11 That RM moved to clean plastic storage. Time “zeroed” when moved.

2 a. Stability Test Results (for RM 8096) Storage for RM Monitors • • • N 2 -filled dry box Clean plastic storage Wooden box Dirty plastic storage can introduce plasticizers • • • Plasticizers have the effect of increasing residual strain. 11 That RM moved to clean plastic storage. Time “zeroed” when moved.

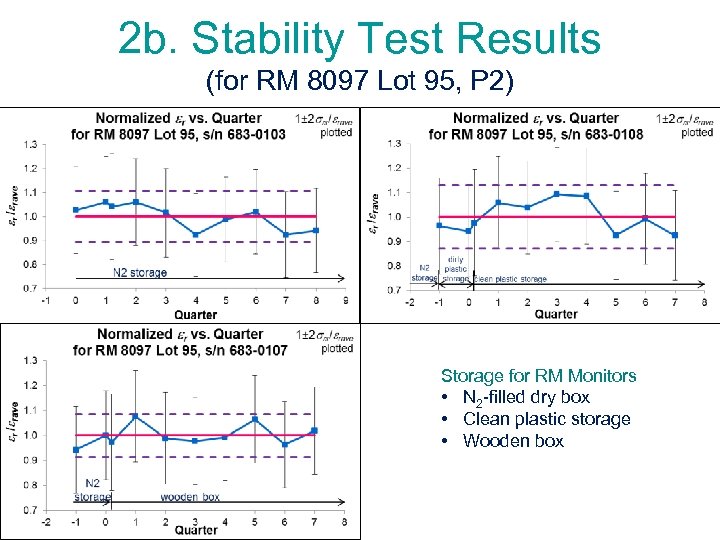

2 b. Stability Test Results (for RM 8097 Lot 95, P 2) Storage for RM Monitors • N 2 -filled dry box • Clean plastic storage • Wooden box 12

2 b. Stability Test Results (for RM 8097 Lot 95, P 2) Storage for RM Monitors • N 2 -filled dry box • Clean plastic storage • Wooden box 12

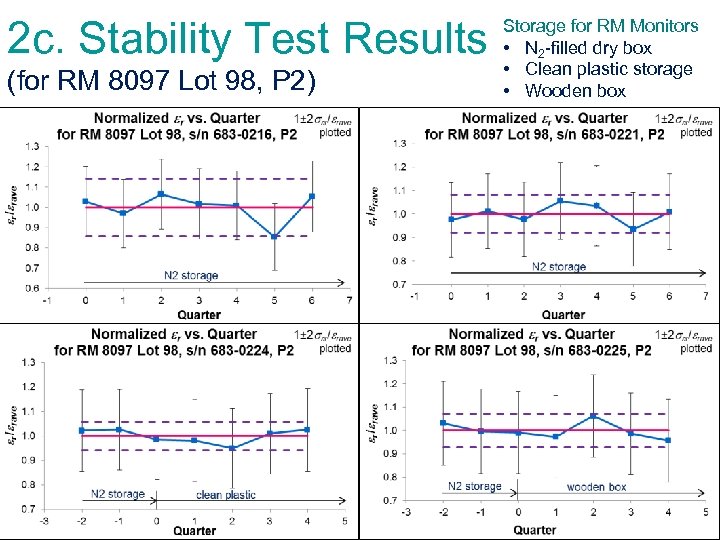

2 c. Stability Test Results (for RM 8097 Lot 98, P 2) Storage for RM Monitors • N 2 -filled dry box • Clean plastic storage • Wooden box 13

2 c. Stability Test Results (for RM 8097 Lot 98, P 2) Storage for RM Monitors • N 2 -filled dry box • Clean plastic storage • Wooden box 13

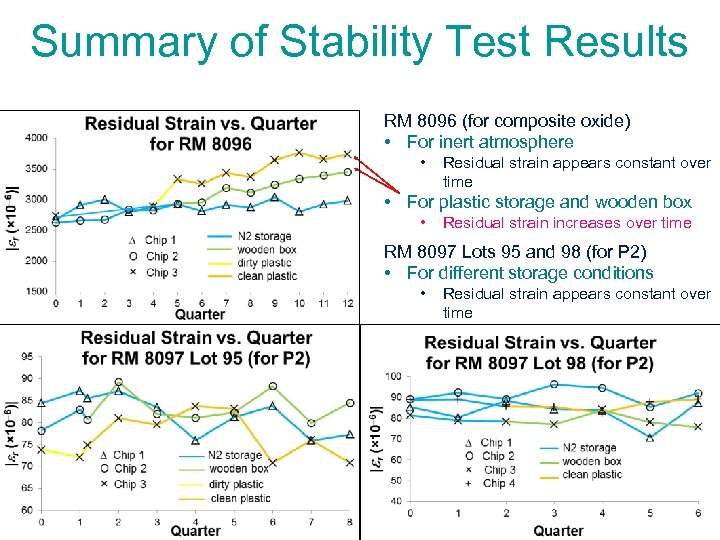

Summary of Stability Test Results RM 8096 (for composite oxide) • For inert atmosphere • Residual strain appears constant over time • For plastic storage and wooden box • Residual strain increases over time RM 8097 Lots 95 and 98 (for P 2) • For different storage conditions • Residual strain appears constant over time 14

Summary of Stability Test Results RM 8096 (for composite oxide) • For inert atmosphere • Residual strain appears constant over time • For plastic storage and wooden box • Residual strain increases over time RM 8097 Lots 95 and 98 (for P 2) • For different storage conditions • Residual strain appears constant over time 14

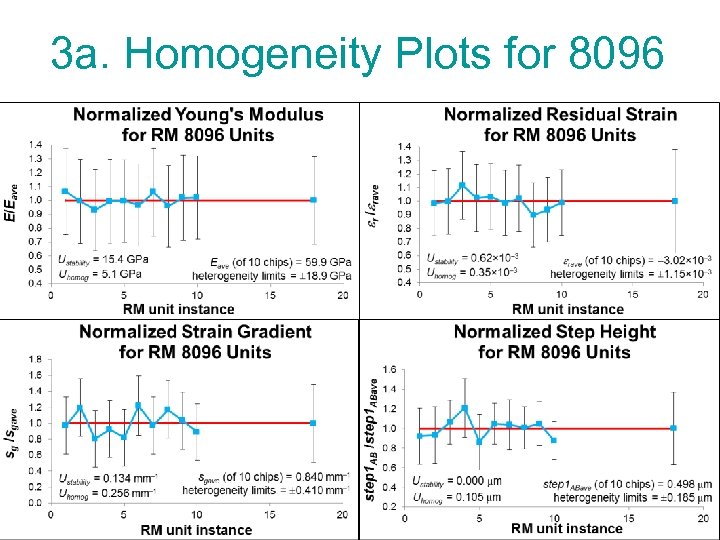

3. Homogeneity Plots • Homogeneity plots are used to determine whether or not the chips are acceptable candidates for use as RMs – Is the fabrication process sufficiently homogeneous? 15

3. Homogeneity Plots • Homogeneity plots are used to determine whether or not the chips are acceptable candidates for use as RMs – Is the fabrication process sufficiently homogeneous? 15

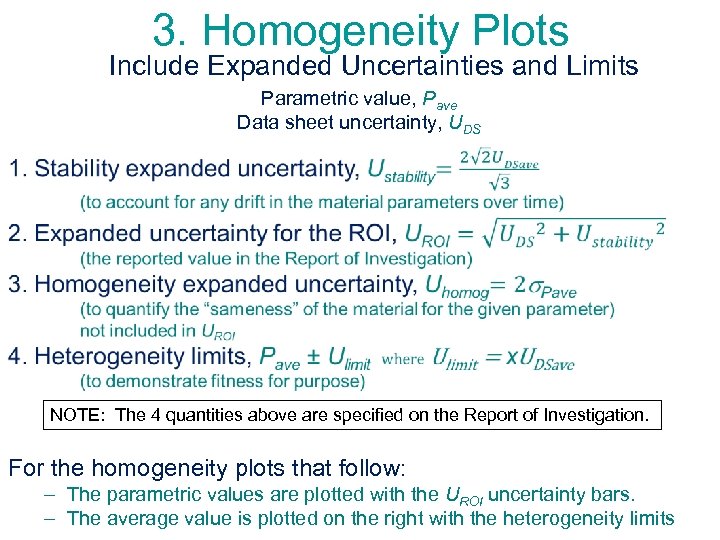

3. Homogeneity Plots Include Expanded Uncertainties and Limits Parametric value, Pave Data sheet uncertainty, UDS NOTE: The 4 quantities above are specified on the Report of Investigation. For the homogeneity plots that follow: – The parametric values are plotted with the UROI uncertainty bars. 16 – The average value is plotted on the right with the heterogeneity limits

3. Homogeneity Plots Include Expanded Uncertainties and Limits Parametric value, Pave Data sheet uncertainty, UDS NOTE: The 4 quantities above are specified on the Report of Investigation. For the homogeneity plots that follow: – The parametric values are plotted with the UROI uncertainty bars. 16 – The average value is plotted on the right with the heterogeneity limits

3 a. Homogeneity Plots for 8096 17

3 a. Homogeneity Plots for 8096 17

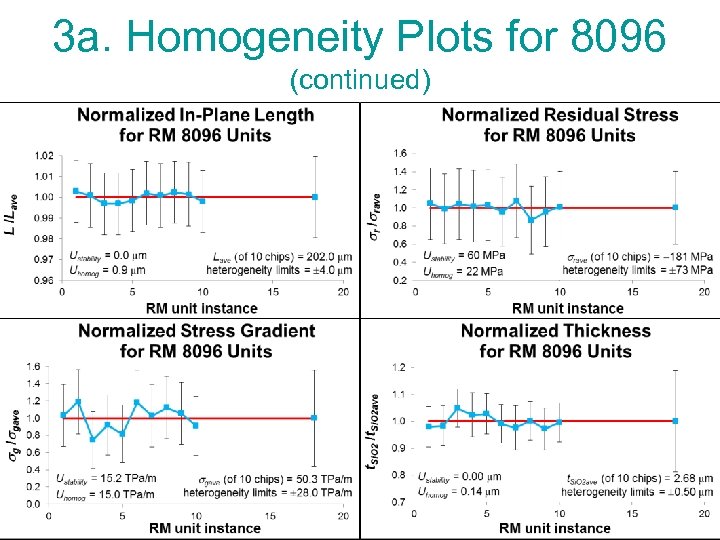

3 a. Homogeneity Plots for 8096 (continued) 18

3 a. Homogeneity Plots for 8096 (continued) 18

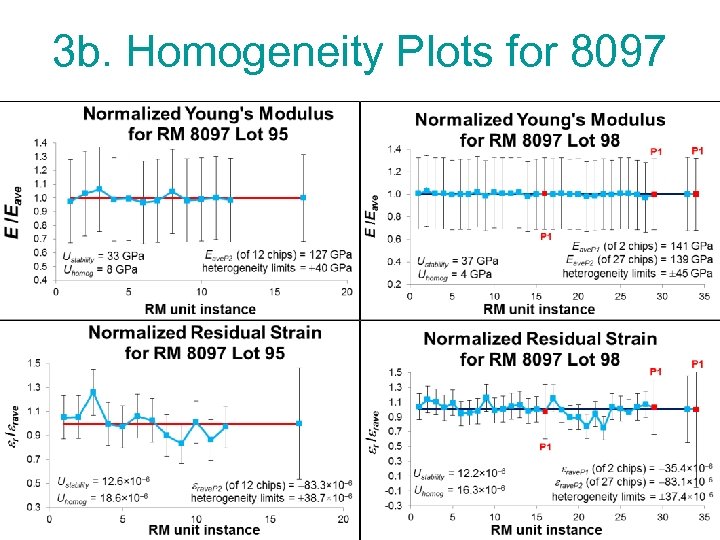

3 b. Homogeneity Plots for 8097 19

3 b. Homogeneity Plots for 8097 19

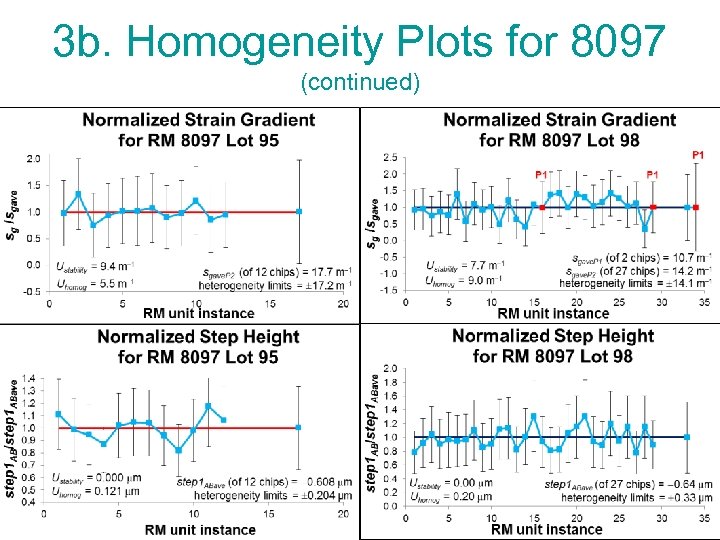

3 b. Homogeneity Plots for 8097 (continued) 20

3 b. Homogeneity Plots for 8097 (continued) 20

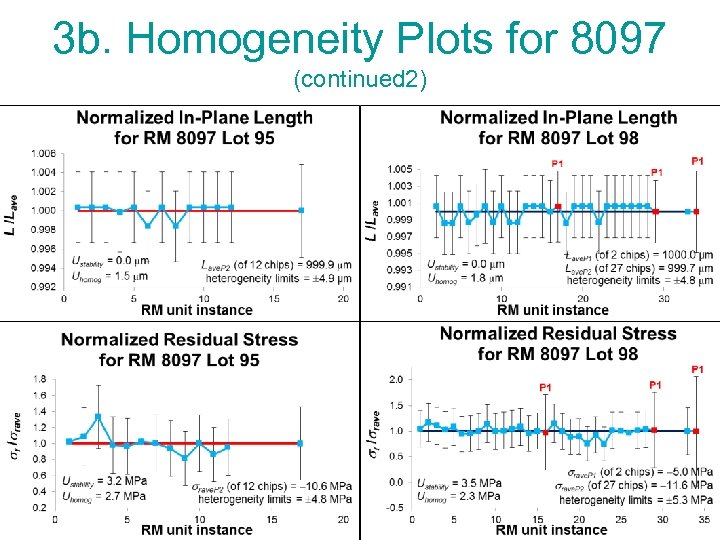

3 b. Homogeneity Plots for 8097 (continued 2) 21

3 b. Homogeneity Plots for 8097 (continued 2) 21

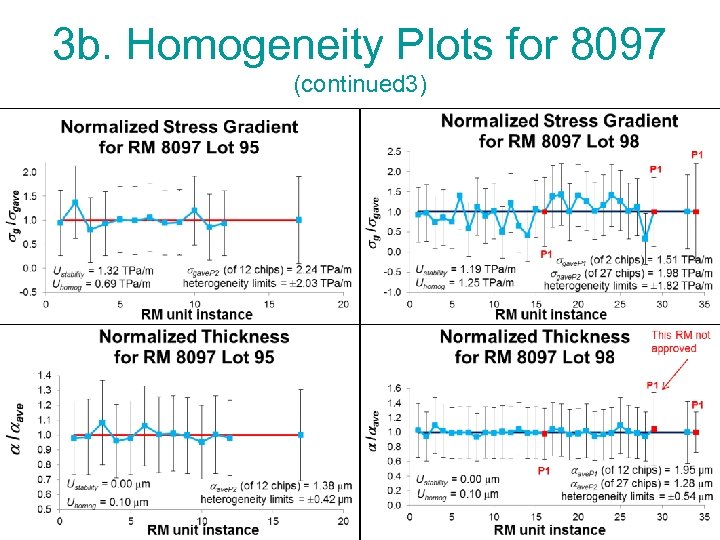

3 b. Homogeneity Plots for 8097 (continued 3) 22

3 b. Homogeneity Plots for 8097 (continued 3) 22

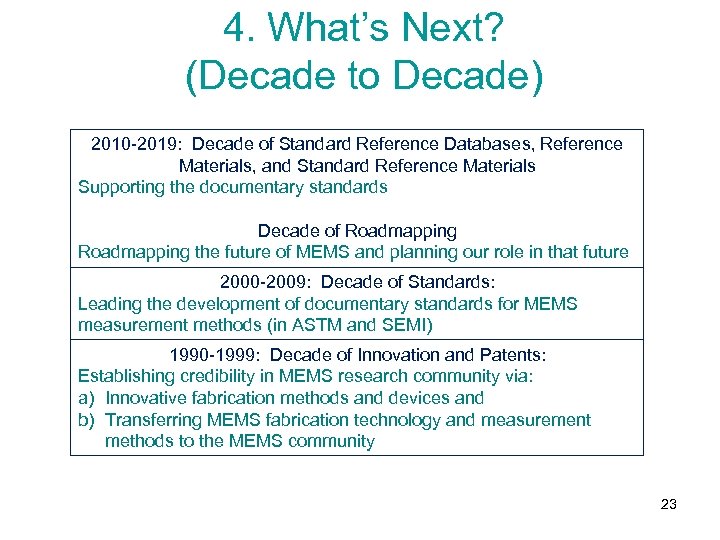

4. What’s Next? (Decade to Decade) 2010 -2019: Decade of Standard Reference Databases, Reference Materials, and Standard Reference Materials Supporting the documentary standards Decade of Roadmapping the future of MEMS and planning our role in that future 2000 -2009: Decade of Standards: Leading the development of documentary standards for MEMS measurement methods (in ASTM and SEMI) 1990 -1999: Decade of Innovation and Patents: Establishing credibility in MEMS research community via: a) Innovative fabrication methods and devices and b) Transferring MEMS fabrication technology and measurement methods to the MEMS community 23

4. What’s Next? (Decade to Decade) 2010 -2019: Decade of Standard Reference Databases, Reference Materials, and Standard Reference Materials Supporting the documentary standards Decade of Roadmapping the future of MEMS and planning our role in that future 2000 -2009: Decade of Standards: Leading the development of documentary standards for MEMS measurement methods (in ASTM and SEMI) 1990 -1999: Decade of Innovation and Patents: Establishing credibility in MEMS research community via: a) Innovative fabrication methods and devices and b) Transferring MEMS fabrication technology and measurement methods to the MEMS community 23

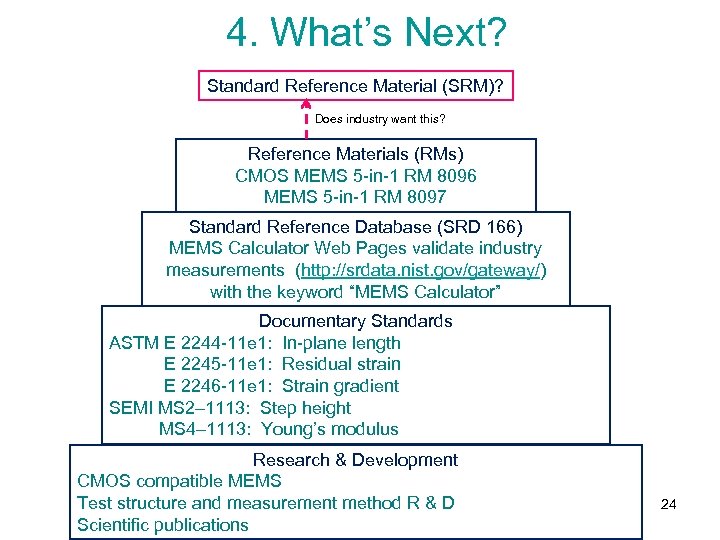

4. What’s Next? Standard Reference Material (SRM)? Does industry want this? Reference Materials (RMs) CMOS MEMS 5 -in-1 RM 8096 MEMS 5 -in-1 RM 8097 Standard Reference Database (SRD 166) MEMS Calculator Web Pages validate industry measurements (http: //srdata. nist. gov/gateway/) with the keyword “MEMS Calculator” Documentary Standards ASTM E 2244 -11 e 1: In-plane length E 2245 -11 e 1: Residual strain E 2246 -11 e 1: Strain gradient SEMI MS 2– 1113: Step height MS 4– 1113: Young’s modulus Research & Development CMOS compatible MEMS Test structure and measurement method R & D Scientific publications 24

4. What’s Next? Standard Reference Material (SRM)? Does industry want this? Reference Materials (RMs) CMOS MEMS 5 -in-1 RM 8096 MEMS 5 -in-1 RM 8097 Standard Reference Database (SRD 166) MEMS Calculator Web Pages validate industry measurements (http: //srdata. nist. gov/gateway/) with the keyword “MEMS Calculator” Documentary Standards ASTM E 2244 -11 e 1: In-plane length E 2245 -11 e 1: Residual strain E 2246 -11 e 1: Strain gradient SEMI MS 2– 1113: Step height MS 4– 1113: Young’s modulus Research & Development CMOS compatible MEMS Test structure and measurement method R & D Scientific publications 24

4. What’s Next? (What Would NIST Do? ) • If there is a high demand for the RMs: • Consider making more • Pass off to an interested company for them to make more? • Develop a plan as to how to do this fairly (if more than 1 company) • Chip design – on-line • Materials used – provide them with the e. Docs (which are public documents) which includes the list of vendors, etc. ? • Calibration/measurement/analysis – in standards supplemented by the SP 260 • Data. Sheets – on line for use • Data. Sheets (htm files) and figures – request from NIST (free of charge) or make available for download (also available with the purchase of an RM) • Draft Data. Sheets (htm files) with read and write capabilities for text files and figures – request from NIST (free of charge) or make downloadable • Miscellaneous (e. g. , handling/storage/assembly of material/shipment/etc. ) – in e. Docs and SP 260 • How would they report their values (like on ROIs)? Is an ROI associated exclusively with NIST? • How would their customers believe their values? Would they need to be 25 accredited somehow?

4. What’s Next? (What Would NIST Do? ) • If there is a high demand for the RMs: • Consider making more • Pass off to an interested company for them to make more? • Develop a plan as to how to do this fairly (if more than 1 company) • Chip design – on-line • Materials used – provide them with the e. Docs (which are public documents) which includes the list of vendors, etc. ? • Calibration/measurement/analysis – in standards supplemented by the SP 260 • Data. Sheets – on line for use • Data. Sheets (htm files) and figures – request from NIST (free of charge) or make available for download (also available with the purchase of an RM) • Draft Data. Sheets (htm files) with read and write capabilities for text files and figures – request from NIST (free of charge) or make downloadable • Miscellaneous (e. g. , handling/storage/assembly of material/shipment/etc. ) – in e. Docs and SP 260 • How would they report their values (like on ROIs)? Is an ROI associated exclusively with NIST? • How would their customers believe their values? Would they need to be 25 accredited somehow?

4. What’s Next? (What Would NIST Do? - continued) • If there is a high demand for the RMs (continued): • Consider turning the RMs into SRMs • Via designing using SOI • Oxide and silicon layers may each be 70 nm • • • Can put next to linewidth structures Can achieve a tighter control on the thickness measurements Cantilevers/beams may require holes in them Will the cantilevers and fixed-fixed beams bend enough? Can reasonable images be obtained with the interferometer and vibrometer? • Look into this…. . 26

4. What’s Next? (What Would NIST Do? - continued) • If there is a high demand for the RMs (continued): • Consider turning the RMs into SRMs • Via designing using SOI • Oxide and silicon layers may each be 70 nm • • • Can put next to linewidth structures Can achieve a tighter control on the thickness measurements Cantilevers/beams may require holes in them Will the cantilevers and fixed-fixed beams bend enough? Can reasonable images be obtained with the interferometer and vibrometer? • Look into this…. . 26

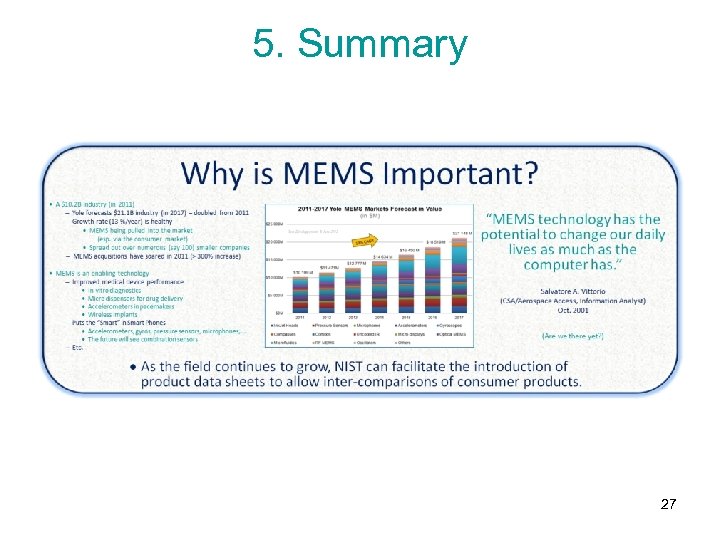

5. Summary 27

5. Summary 27

28

28

5. Summary (Uses of the MEMS 5 -in-1) • To validate use of the documentary standards (so companies can compare their in-house measurements taken on the RM with NIST measurements) Photo taken by Curt Suplee, NIST • To characterize or validate a process • To take local measurements • To compare measurements meaningfully (e. g. , between suppliers and customers) • To trouble-shoot a process (to improve yield and track failure sources to speed development) • To calibrate an instrument Intended for • MEMS designers • Test equipment manufacturers – Who may want to buy in bulk to sell with their instruments 29 • IC and MEMS foundries and services

5. Summary (Uses of the MEMS 5 -in-1) • To validate use of the documentary standards (so companies can compare their in-house measurements taken on the RM with NIST measurements) Photo taken by Curt Suplee, NIST • To characterize or validate a process • To take local measurements • To compare measurements meaningfully (e. g. , between suppliers and customers) • To trouble-shoot a process (to improve yield and track failure sources to speed development) • To calibrate an instrument Intended for • MEMS designers • Test equipment manufacturers – Who may want to buy in bulk to sell with their instruments 29 • IC and MEMS foundries and services