f18e845ea3bfdcf4864be2b2e954645a.ppt

- Количество слайдов: 24

MEDICAL DEVICE MAINTENANCE AND SOURCES OF OBTAINING MEDICAL DEVICE- RELATED FAILURE DATA Chapter 6 Howell, Murray, Pierre

Introduction Maintenance is an important element of the engineering equipment life cycle. Failure data are the backbone of medical-related reliability studies. Provides invaluable information to professional involved with the design, manufacture and maintenance of future medical devices/equipment. This chapter presents various important aspects of medical device maintenance and sources for obtaining medical device-related failure data.

Medical Equipment Classifications Imaging and radiation therapy Life Support and therapeutic Patient diagnostics Patient environmental, transport Laboratory apparatus Miscellaneous

Medical Equipment Maintenance Indexes Used to measure different aspects of the maintenance function Indexes (6) Broad Indexes (3) Health-Care-Specific Indexes (3)

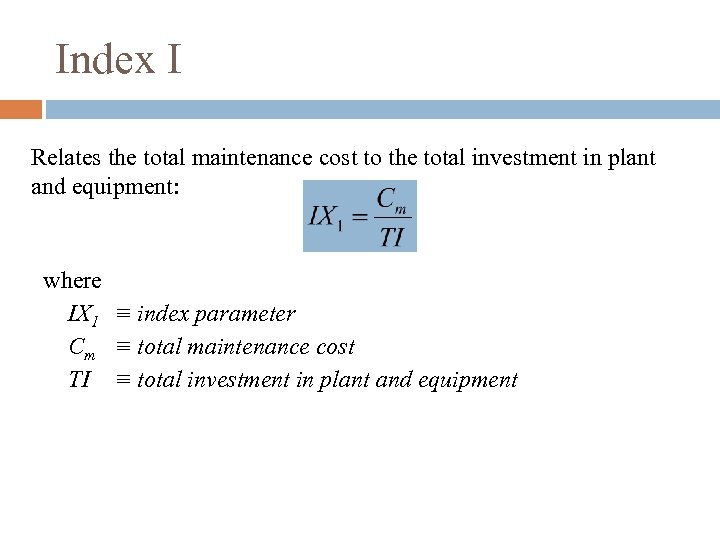

Index I Relates the total maintenance cost to the total investment in plant and equipment: where IX 1 ≡ index parameter Cm ≡ total maintenance cost TI ≡ total investment in plant and equipment

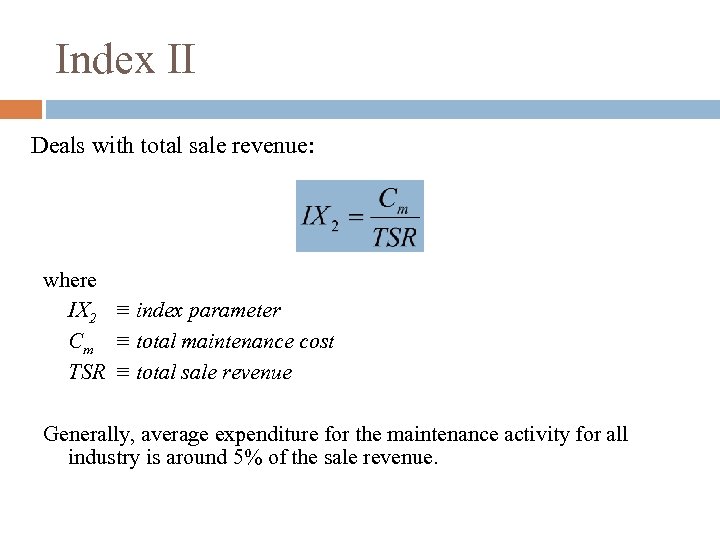

Index II Deals with total sale revenue: where IX 2 ≡ index parameter Cm ≡ total maintenance cost TSR ≡ total sale revenue Generally, average expenditure for the maintenance activity for all industry is around 5% of the sale revenue.

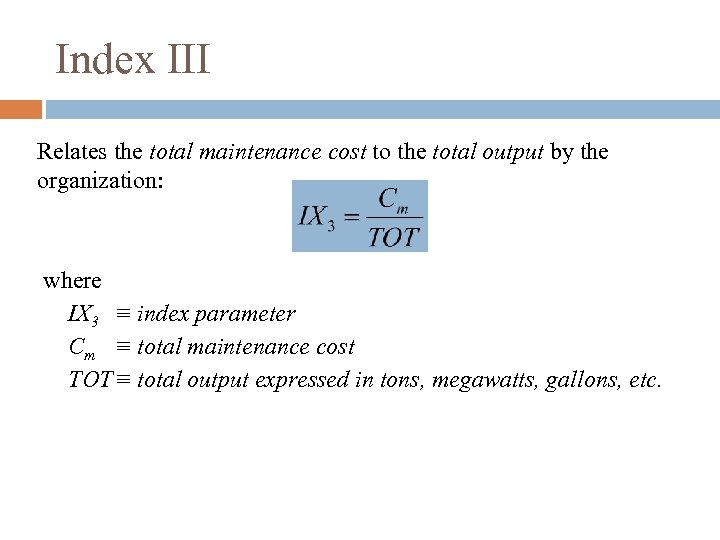

Index III Relates the total maintenance cost to the total output by the organization: where IX 3 ≡ index parameter Cm ≡ total maintenance cost TOT ≡ total output expressed in tons, megawatts, gallons, etc.

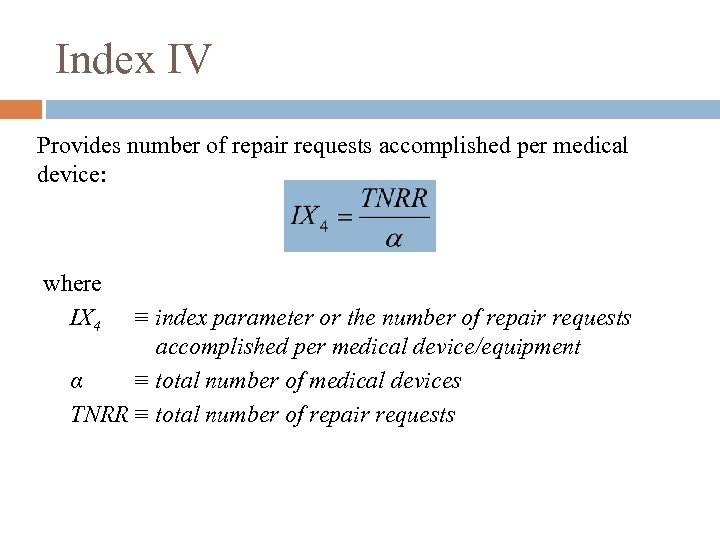

Index IV Provides number of repair requests accomplished per medical device: where IX 4 ≡ index parameter or the number of repair requests accomplished per medical device/equipment α ≡ total number of medical devices TNRR ≡ total number of repair requests

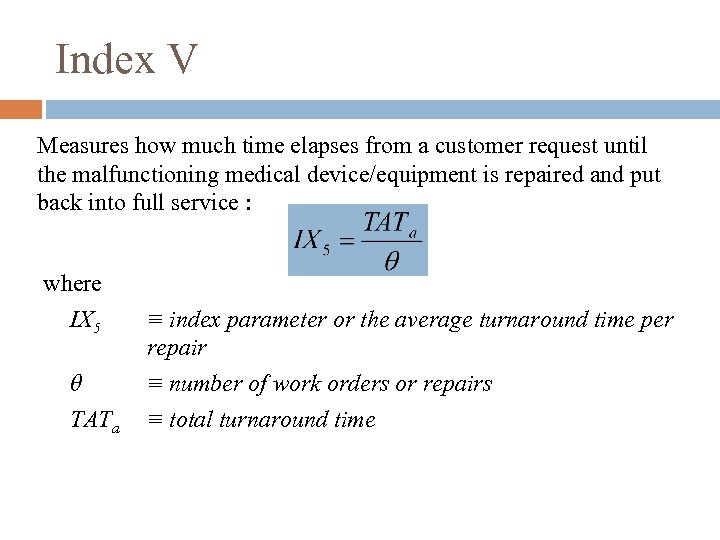

Index V Measures how much time elapses from a customer request until the malfunctioning medical device/equipment is repaired and put back into full service : where IX 5 θ TATa ≡ index parameter or the average turnaround time per repair ≡ number of work orders or repairs ≡ total turnaround time

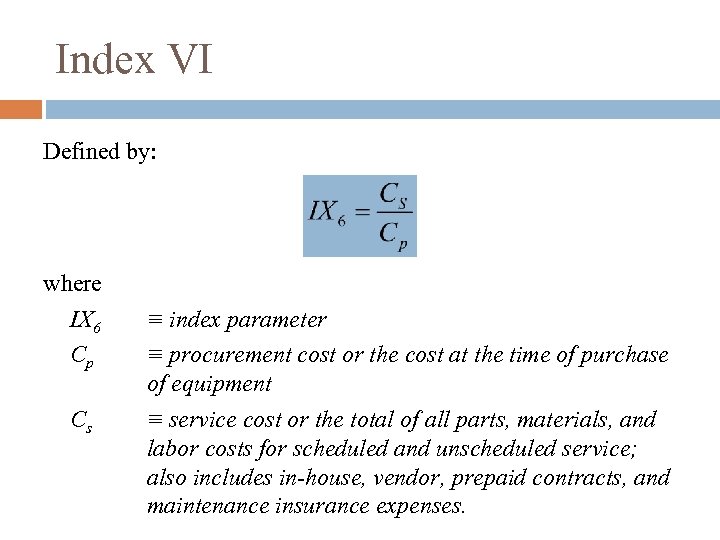

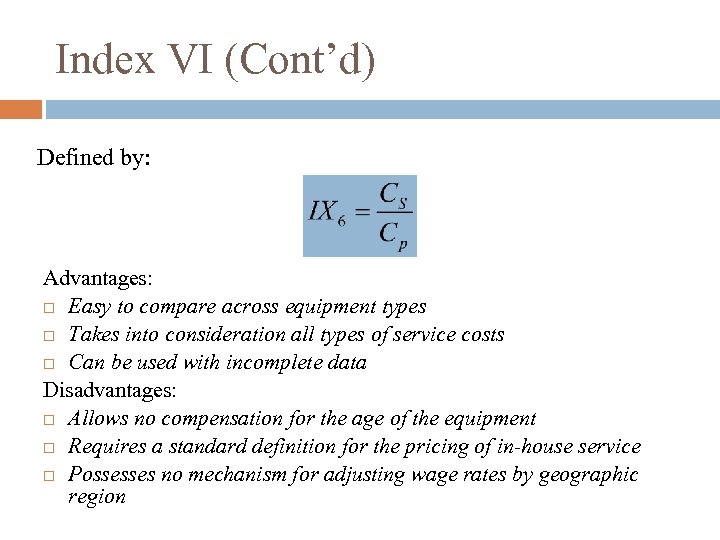

Index VI Defined by: where IX 6 Cp Cs ≡ index parameter ≡ procurement cost or the cost at the time of purchase of equipment ≡ service cost or the total of all parts, materials, and labor costs for scheduled and unscheduled service; also includes in-house, vendor, prepaid contracts, and maintenance insurance expenses.

Index VI (Cont’d) Defined by: Advantages: Easy to compare across equipment types Takes into consideration all types of service costs Can be used with incomplete data Disadvantages: Allows no compensation for the age of the equipment Requires a standard definition for the pricing of in-house service Possesses no mechanism for adjusting wage rates by geographic region

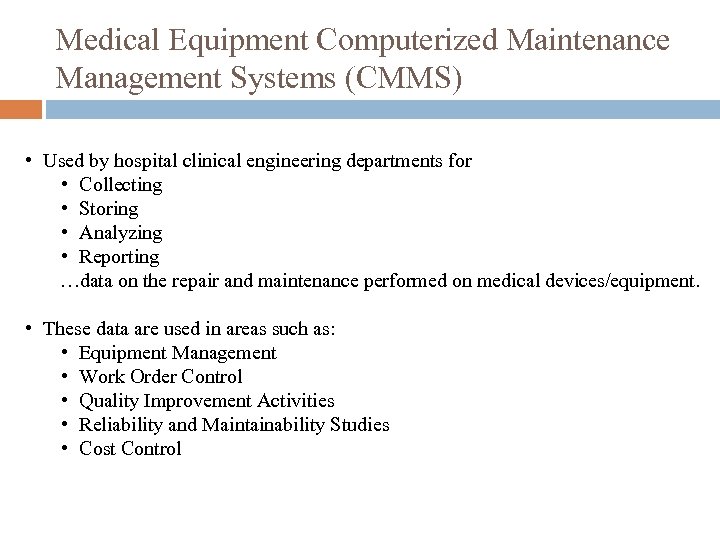

Medical Equipment Computerized Maintenance Management Systems (CMMS) • Used by hospital clinical engineering departments for • Collecting • Storing • Analyzing • Reporting …data on the repair and maintenance performed on medical devices/equipment. • These data are used in areas such as: • Equipment Management • Work Order Control • Quality Improvement Activities • Reliability and Maintainability Studies • Cost Control

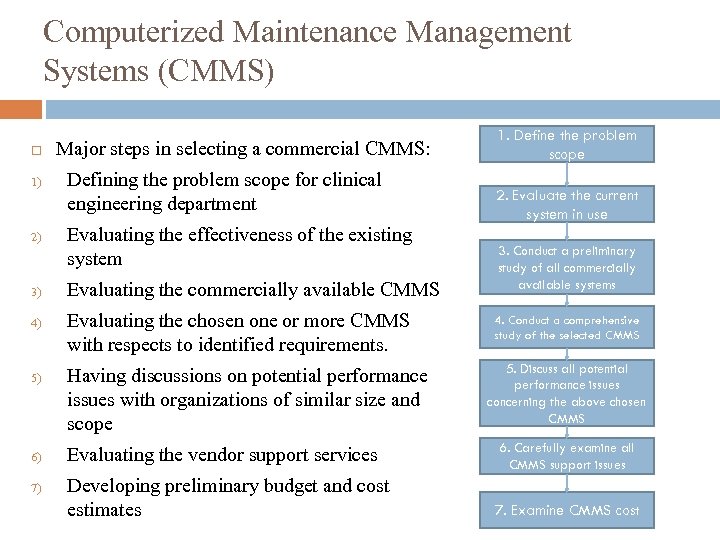

Computerized Maintenance Management Systems (CMMS) 1) 2) 3) 4) 5) 6) 7) Major steps in selecting a commercial CMMS: Defining the problem scope for clinical engineering department Evaluating the effectiveness of the existing system Evaluating the commercially available CMMS Evaluating the chosen one or more CMMS with respects to identified requirements. Having discussions on potential performance issues with organizations of similar size and scope Evaluating the vendor support services Developing preliminary budget and cost estimates 1. Define the problem scope 2. Evaluate the current system in use 3. Conduct a preliminary study of all commercially available systems 4. Conduct a comprehensive study of the selected CMMS 5. Discuss all potential performance issues concerning the above chosen CMMS 6. Carefully examine all CMMS support issues 7. Examine CMMS cost

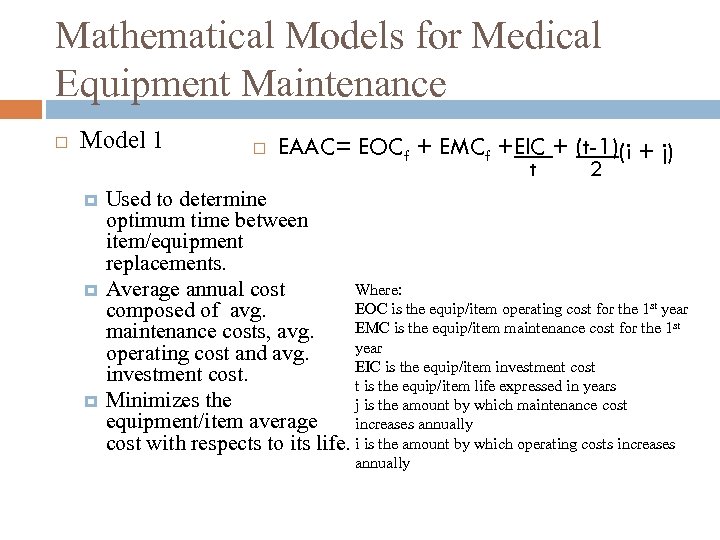

Mathematical Models for Medical Equipment Maintenance Model 1 EAAC= EOCf + EMCf +EIC + (t-1) (i + j) t 2 Used to determine optimum time between item/equipment replacements. Where: Average annual cost EOC is the equip/item operating cost for the 1 st year composed of avg. EMC is the equip/item maintenance cost for the 1 st maintenance costs, avg. year operating cost and avg. EIC is the equip/item investment cost. t is the equip/item life expressed in years Minimizes the j is the amount by which maintenance cost equipment/item average increases annually cost with respects to its life. i is the amount by which operating costs increases annually

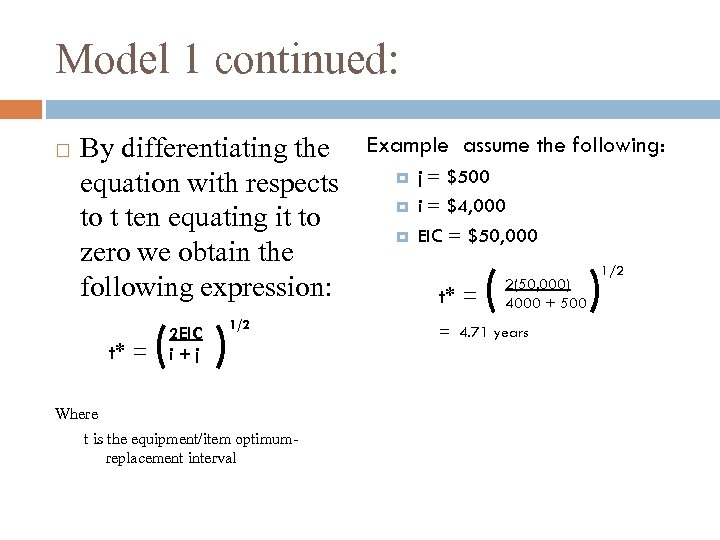

Model 1 continued: By differentiating the Example assume the following: j = $500 equation with respects i = $4, 000 to t ten equating it to EIC = $50, 000 zero we obtain the 1/2 2(50, 000) following expression: t* = 4000 + 500 t* = ( ) 2 EIC i+j ( 1/2 Where t is the equipment/item optimumreplacement interval = 4. 71 years )

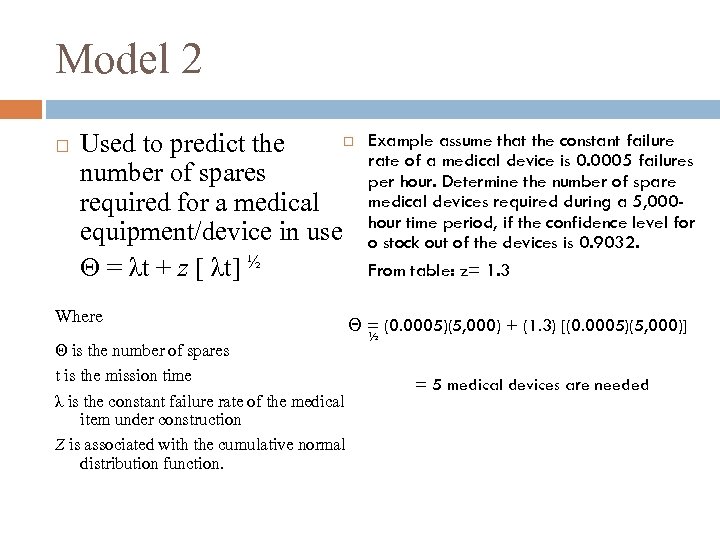

Model 2 Used to predict the number of spares required for a medical equipment/device in use Θ = λt + z [ λt] ½ Where Θ is the number of spares t is the mission time λ is the constant failure rate of the medical item under construction Z is associated with the cumulative normal distribution function. Example assume that the constant failure rate of a medical device is 0. 0005 failures per hour. Determine the number of spare medical devices required during a 5, 000 hour time period, if the confidence level for o stock out of the devices is 0. 9032. From table: z= 1. 3 Θ = (0. 0005)(5, 000) + (1. 3) [(0. 0005)(5, 000)] ½ = 5 medical devices are needed

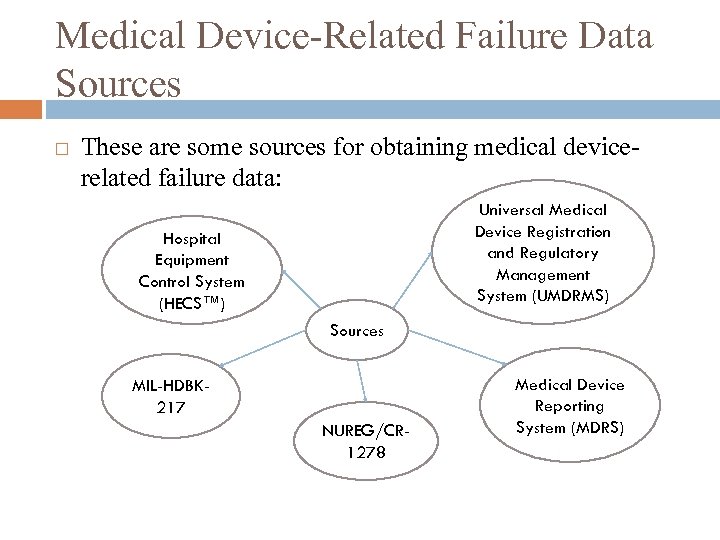

Medical Device-Related Failure Data Sources These are some sources for obtaining medical devicerelated failure data: Universal Medical Device Registration and Regulatory Management System (UMDRMS) Hospital Equipment Control System (HECS™) Sources MIL-HDBK 217 NUREG/CR 1278 Medical Device Reporting System (MDRS)

Hospital Equipment Control System (HECMS™) Provides effective support and analysis of clinical engineering-related operations through detailed work scheduling of items. Provides objective and good quality data on the basis of satisfactory statistical foundation. Provides cost-effective, economic, financial, productivity data within the framework of each hospital. Provides new information support, including data on the relative reliability of competing brands and models of clinical equipment.

(MDRS) The Medical Device Reporting System It is managed by the Center for Devices and Radiological Health, Food and Drug Administration (FDA). It contains reports filed by device manufacturers concerning patient deaths and serious injuries allegedly involving their manufactured items, as well as failure of such items that may have caused serious injuries or deaths.

(UMDRMS) The University Medical Device Registration and Regulatory Management System It was developed by ECRI (Emergency Care Research Institute) and is designed to facilitate items such as tracking products for recall, safety, and reliability statistics and inventory control.

MIL-HDBK-217 It was developed by the U. S Department of Defense It is widely used in the industrial sector to predict the failure rate of a given piece of equipment. It contains generic failure rates for various parts, particularly the electronic ones, and a large number of mathematical models to predict failure rates of various types of parts in their actual use environment. This document can also be used to predict failure rates of medical equipment/devices or their parts.

NUREG/CR-1278 It was developed by the U. S. Nuclear Regulatory Commission to perform human reliability analysis with emphasis on nuclear power plant applications. The document contains failure data on various types of tasks performed by humans. The information contained in the document could be quite useful analyzing medical devices in regard to the occurrence of human error.

Organizations for Obtaining Medical Device-Related Failure Data There are many organizations that can be quite useful, directly or indirectly, in obtaining medical device-related failure data: Center for Devices and Radiological Health, Food and Drug Administration, 1390 Piccard Drive, Rockville, Maryland 20857 Emergency Care Research Institute (ECRI), 5200 Butler Parkway, Plymouth Meeting, Pennsylvania 19462 Parts Reliability Information Center (PRINCE), George C. Marshall Space Flight Center, Huntsville, Alabama 35812 Reliability Analysis Center, Griffiss AFB, U. S Department of commerce, 5285 Port Royal, Springfield, Virginia 22161

Medical Device Failure-Related Data A wide variety of failure-related data, directly or indirectly, concerned with medical equipment/devices is available in the published literature. There are two types, directly or indirectly, of failurerelated data: Medical device specific data are concerned with the preproduction cause of a total of 1, 143 medical device recalls for the period 1983 to 1987. The causes of these recalls were grouped under 7 distinct categories: device and process(design and software), component, label, and package (design). The general component-related failure data.

f18e845ea3bfdcf4864be2b2e954645a.ppt