02d27af13b858b70c117530f81549c5f.ppt

- Количество слайдов: 48

MECHATRONICS PROGETTO del CONTROLLO di MACCHINE AUTOMATICHE per l’IMPACCHETTAMENTO (MOTION CONTROL for PACKAGING MACHINES) Davide Borghi Mechatronics

MECHATRONICS PROGETTO del CONTROLLO di MACCHINE AUTOMATICHE per l’IMPACCHETTAMENTO (MOTION CONTROL for PACKAGING MACHINES) Davide Borghi Mechatronics

The Course characteristics: multi-discipline contents Course Goal: “speak the same language” and be able to design the machine “as a whole” (not mechanics and motors separately). Course Limitations: no time to go deeply in each subject, so I will try to give you the tools and hints to investigate further; not everybody is interested to deepen every subject, so don’t worry if sometimes you miss some parts… Mechatronics

The Course characteristics: multi-discipline contents Course Goal: “speak the same language” and be able to design the machine “as a whole” (not mechanics and motors separately). Course Limitations: no time to go deeply in each subject, so I will try to give you the tools and hints to investigate further; not everybody is interested to deepen every subject, so don’t worry if sometimes you miss some parts… Mechatronics

Index Mechatronics in the Packaging World Mechatronics on packaging machines …bits of history Where is the Performance Limit? (motor => electronics => mechanics) Multiaxes systems (e. g. : A 3 -Flex, DIMC, PT) Programming Interface: RS-Logix 5000 IEC 1131 -3 Application Program Example Brushless Motors Electric Motor’s Choice (kinematic chain, torque characteristics, field weakening - deflussaggio) Stator Re-Winding (riavvolgim. motore) Brushless motors technology Resolvers and Encoders Linear Motors Torque Motors (1/2) PID Control PID Theory Serial (Rockwell Kinetix) and Parallel (Danaher SAM) PID Digital PID & Feed Forward Vibrations Analysis Control-Motor-Load relationships Bandwidth PID – bandwidth relationships Vibration measurements Sizing Planetary gearboxes versus direct-drive Servo-System Design EMC hints Trouble Shooting of a rig solution (in fase di prima verifica) Packaging Machines Motion Architecture Mechatronics

Index Mechatronics in the Packaging World Mechatronics on packaging machines …bits of history Where is the Performance Limit? (motor => electronics => mechanics) Multiaxes systems (e. g. : A 3 -Flex, DIMC, PT) Programming Interface: RS-Logix 5000 IEC 1131 -3 Application Program Example Brushless Motors Electric Motor’s Choice (kinematic chain, torque characteristics, field weakening - deflussaggio) Stator Re-Winding (riavvolgim. motore) Brushless motors technology Resolvers and Encoders Linear Motors Torque Motors (1/2) PID Control PID Theory Serial (Rockwell Kinetix) and Parallel (Danaher SAM) PID Digital PID & Feed Forward Vibrations Analysis Control-Motor-Load relationships Bandwidth PID – bandwidth relationships Vibration measurements Sizing Planetary gearboxes versus direct-drive Servo-System Design EMC hints Trouble Shooting of a rig solution (in fase di prima verifica) Packaging Machines Motion Architecture Mechatronics

Index (2/2) Drives AC brushless drive DC brushless drive Resolver to Digital Converter Regenerative breaking (Recupero in rete) Control Strategies Clark&Park Transforms IPxx Protection Servo System Trouble. Shooting on the field THE END Mechatronics

Index (2/2) Drives AC brushless drive DC brushless drive Resolver to Digital Converter Regenerative breaking (Recupero in rete) Control Strategies Clark&Park Transforms IPxx Protection Servo System Trouble. Shooting on the field THE END Mechatronics

Bibliography 1. Luciano Bonometti: “Convertitori di Potenza e Servomotori Brushless”, Editoriale Delfino, Milano, 1996 2. Hughes: "Electric Motors and Drives", 1993, Heinemann, 348 pp. , codice RS: 912076 3. CYMEX: Cyber Motion Explorer, CD-ROM, Alpha getriebebau Gmb. H info@alphagetriebe. de 4. “THE MOTION BOOK” version 4. 0, Rockwell Automation/Allen-Bradley – 2004 www. ab. com/motion 5. “DSP Solution for Permanent Magnet Synchronous Motor”, Texas Instruments 6. Ashish Tewari, “Modern Control Design With MATLAB and SIMULINK” 7. Dean C. Karnopp, Donald L. Margolis, Ronald C. Rosenberg “System Dynamics : Modeling and Simulation of Mechatronic Systems” 8. D. M. Auslander, J. R. Ridgely, J. D. Ringgenberg, David M. Auslander “Control Software for Mechanical Systems: Object Oreiented Design in a Real Time World” 9. Gabriele Canini, Cesare Fantuzzi “Controllo del moto per macchine automatiche”, Pitagora Editrice, Bologna 2003 10. Claudio Melchiorri “Traiettorie per azionamenti elettrici”, Progetto Leonardo, Bologna 2000 11. “Tecniche di misura digitale lineare e angolare”, Heidenhain 12. 13. “Intelligent Control Systems Using Soft-Computing Methodologies”, Ali Zilouchian, Mo Jamshidi, CRC Press Mechatronics

Bibliography 1. Luciano Bonometti: “Convertitori di Potenza e Servomotori Brushless”, Editoriale Delfino, Milano, 1996 2. Hughes: "Electric Motors and Drives", 1993, Heinemann, 348 pp. , codice RS: 912076 3. CYMEX: Cyber Motion Explorer, CD-ROM, Alpha getriebebau Gmb. H info@alphagetriebe. de 4. “THE MOTION BOOK” version 4. 0, Rockwell Automation/Allen-Bradley – 2004 www. ab. com/motion 5. “DSP Solution for Permanent Magnet Synchronous Motor”, Texas Instruments 6. Ashish Tewari, “Modern Control Design With MATLAB and SIMULINK” 7. Dean C. Karnopp, Donald L. Margolis, Ronald C. Rosenberg “System Dynamics : Modeling and Simulation of Mechatronic Systems” 8. D. M. Auslander, J. R. Ridgely, J. D. Ringgenberg, David M. Auslander “Control Software for Mechanical Systems: Object Oreiented Design in a Real Time World” 9. Gabriele Canini, Cesare Fantuzzi “Controllo del moto per macchine automatiche”, Pitagora Editrice, Bologna 2003 10. Claudio Melchiorri “Traiettorie per azionamenti elettrici”, Progetto Leonardo, Bologna 2000 11. “Tecniche di misura digitale lineare e angolare”, Heidenhain 12. 13. “Intelligent Control Systems Using Soft-Computing Methodologies”, Ali Zilouchian, Mo Jamshidi, CRC Press Mechatronics

Bibliography: internet links 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. Bosch internet site: http: //app 10. bosch. de//en/default. htm Danaher Motion internet site: http: //www. danaher. com/ Elau internet site: http: //www. elau. de/english/framesets/frhomenic. htm HDD internet site: http: //www. hdd. se/ Kollmorgen internet site: http: //www. kollmorgen. de/, http: //www. kollmorgen. com/ Mektron – Pacific Scientific internet site: http: //www. mektroninc. com/pacsci. html Pacific Scientific internet site: http: //www. industry. net/c/mn/017 k 3 Parker internet site: http: //www. parker-emd. com/uk/ Rexroth – Indramat internet site: http: //www. indramat. com/ Texas Instruments internet sites: http: //www. ti. com/, http: //www. ti. com/sc/momentum/dm 2 sa 2 x 6 t 4, B&R internet site: http: //www. br-automation. com/welcome. htm Baldor internet site: http: //www. baldor. com/ Festo internet sites: http: //www. festo. com/, http: //www. festo. com/food/eng/index. htm GE-Fanuc internet site: http: //www. gefanuc. com/index. asp Hydra. Force Hydraulic Cartridge Valves internet site: http: //www. hydraforce. com/ Rockwell Automation internet site: http: //www. automation. rockwell. com/ SERCOS related links: http: //www. sercos. com/links. htm Siemens Machine Control Systems – Packaging internet site: http: //www. aut. sea. siemens. com/machine/systems/packaging. html Stegmann encoders: http: //www. stegmann. de/english/html/produkte/index. html Mechatronics

Bibliography: internet links 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. Bosch internet site: http: //app 10. bosch. de//en/default. htm Danaher Motion internet site: http: //www. danaher. com/ Elau internet site: http: //www. elau. de/english/framesets/frhomenic. htm HDD internet site: http: //www. hdd. se/ Kollmorgen internet site: http: //www. kollmorgen. de/, http: //www. kollmorgen. com/ Mektron – Pacific Scientific internet site: http: //www. mektroninc. com/pacsci. html Pacific Scientific internet site: http: //www. industry. net/c/mn/017 k 3 Parker internet site: http: //www. parker-emd. com/uk/ Rexroth – Indramat internet site: http: //www. indramat. com/ Texas Instruments internet sites: http: //www. ti. com/, http: //www. ti. com/sc/momentum/dm 2 sa 2 x 6 t 4, B&R internet site: http: //www. br-automation. com/welcome. htm Baldor internet site: http: //www. baldor. com/ Festo internet sites: http: //www. festo. com/, http: //www. festo. com/food/eng/index. htm GE-Fanuc internet site: http: //www. gefanuc. com/index. asp Hydra. Force Hydraulic Cartridge Valves internet site: http: //www. hydraforce. com/ Rockwell Automation internet site: http: //www. automation. rockwell. com/ SERCOS related links: http: //www. sercos. com/links. htm Siemens Machine Control Systems – Packaging internet site: http: //www. aut. sea. siemens. com/machine/systems/packaging. html Stegmann encoders: http: //www. stegmann. de/english/html/produkte/index. html Mechatronics

Why Automation? The machine makes FAULTS that can be: 1. 2. 3. 4. Detected Measured Corrected Predicted Man makes ERRORS that, not always, can be: 1. 2. 3. 4. Detected Measured Corrected Predicted Mechatronics

Why Automation? The machine makes FAULTS that can be: 1. 2. 3. 4. Detected Measured Corrected Predicted Man makes ERRORS that, not always, can be: 1. 2. 3. 4. Detected Measured Corrected Predicted Mechatronics

Mechatronics: what’s in a name… Mechanical system control is undergoing a revolution in which the primary determinant is becoming the control software. This is enabled by developments in electronics and computer technology. Mechatronics (Yaskawa Electric, 1970): “new kind of mechanical system where the electronics take the decision-making function formerly performed by mechanical components…” Mechatronics (now, 2004): …there has been a shift from electronics to software as primary decision-making software, the definition thus becoming: “The application of complex automatic decision-making to the operation of physical systems”. Real time software differs from conventional software in that its results must not only be numerically and logically correct: they must also be delivered at the correct time; it must embody the concept of duration. Mechatronics

Mechatronics: what’s in a name… Mechanical system control is undergoing a revolution in which the primary determinant is becoming the control software. This is enabled by developments in electronics and computer technology. Mechatronics (Yaskawa Electric, 1970): “new kind of mechanical system where the electronics take the decision-making function formerly performed by mechanical components…” Mechatronics (now, 2004): …there has been a shift from electronics to software as primary decision-making software, the definition thus becoming: “The application of complex automatic decision-making to the operation of physical systems”. Real time software differs from conventional software in that its results must not only be numerically and logically correct: they must also be delivered at the correct time; it must embody the concept of duration. Mechatronics

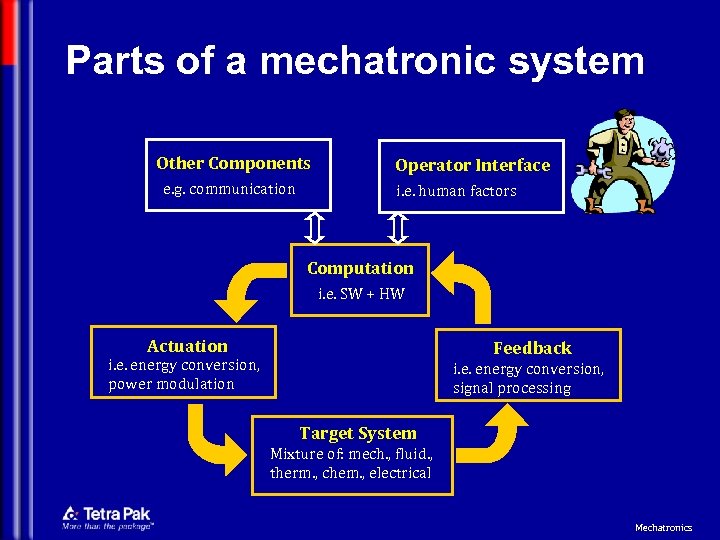

Parts of a mechatronic system Other Components e. g. communication Operator Interface i. e. human factors Computation i. e. SW + HW Actuation Feedback i. e. energy conversion, power modulation i. e. energy conversion, signal processing Target System Mixture of: mech. , fluid. , therm. , chem. , electrical Mechatronics

Parts of a mechatronic system Other Components e. g. communication Operator Interface i. e. human factors Computation i. e. SW + HW Actuation Feedback i. e. energy conversion, power modulation i. e. energy conversion, signal processing Target System Mixture of: mech. , fluid. , therm. , chem. , electrical Mechatronics

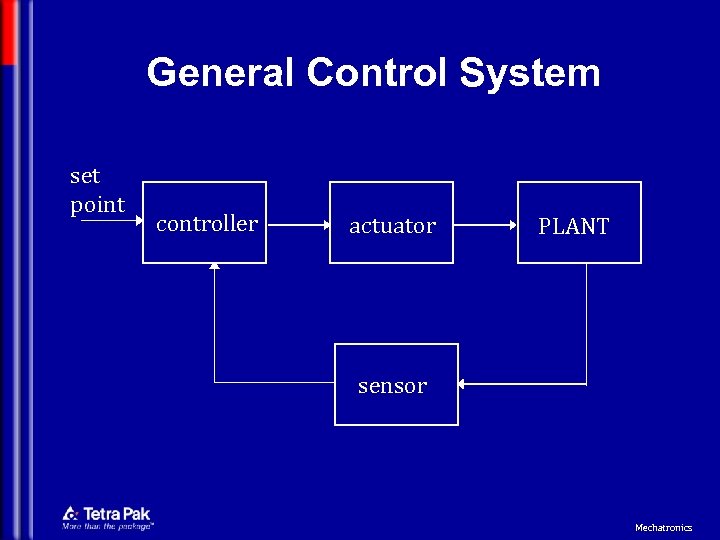

General Control System set point controller actuator PLANT sensor Mechatronics

General Control System set point controller actuator PLANT sensor Mechatronics

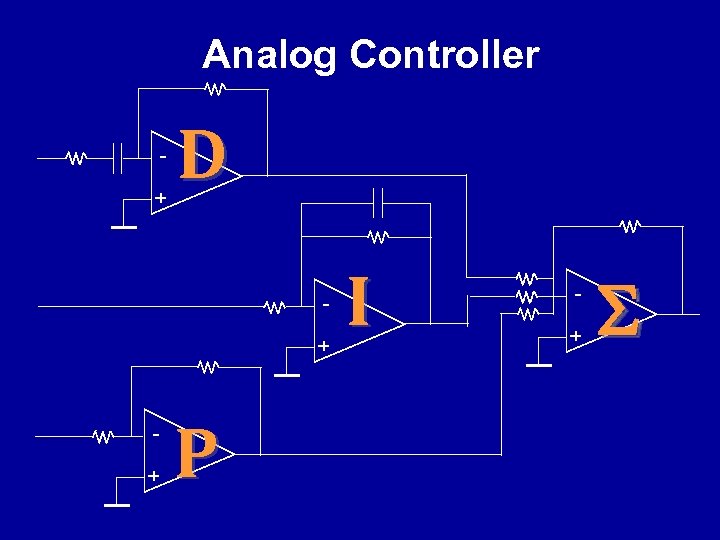

Analog Controller + D + + P I + S

Analog Controller + D + + P I + S

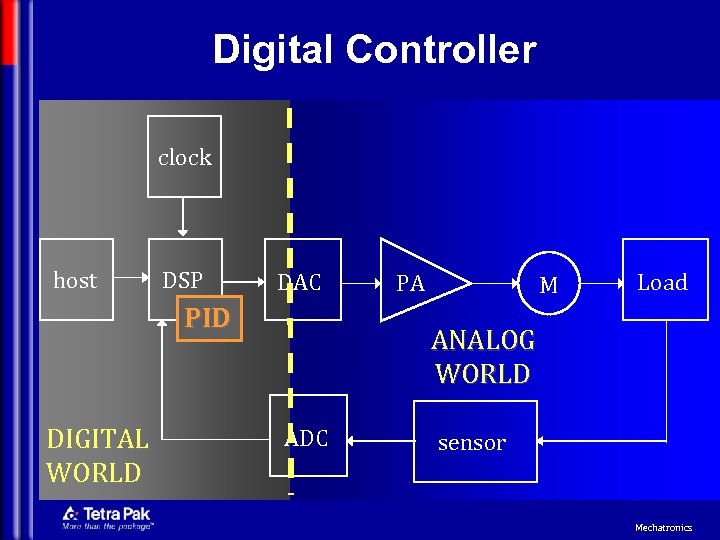

Digital Controller clock host DSP DAC PID DIGITAL WORLD PA M Load ANALOG WORLD ADC sensor Mechatronics

Digital Controller clock host DSP DAC PID DIGITAL WORLD PA M Load ANALOG WORLD ADC sensor Mechatronics

ANALOG vs. DIGITAL Controllers Cons Pros ANALOG DIGITAL Huge bandwidth (no sampling) Resolution Easy design Diagnostics Programmable (SW) Not depending on environment (temp. , pressure, humidity, …) Deterministic behaviour Advanced Algorithms * Memory HMI Time-dep. Performances Temperature drift HW design: no easy change Trimmers Quantization (discr. represent. ) Truncation (16 x 16=32 bit) Limit Cycles Register Overflow Sampling Rate Mechatronics

ANALOG vs. DIGITAL Controllers Cons Pros ANALOG DIGITAL Huge bandwidth (no sampling) Resolution Easy design Diagnostics Programmable (SW) Not depending on environment (temp. , pressure, humidity, …) Deterministic behaviour Advanced Algorithms * Memory HMI Time-dep. Performances Temperature drift HW design: no easy change Trimmers Quantization (discr. represent. ) Truncation (16 x 16=32 bit) Limit Cycles Register Overflow Sampling Rate Mechatronics

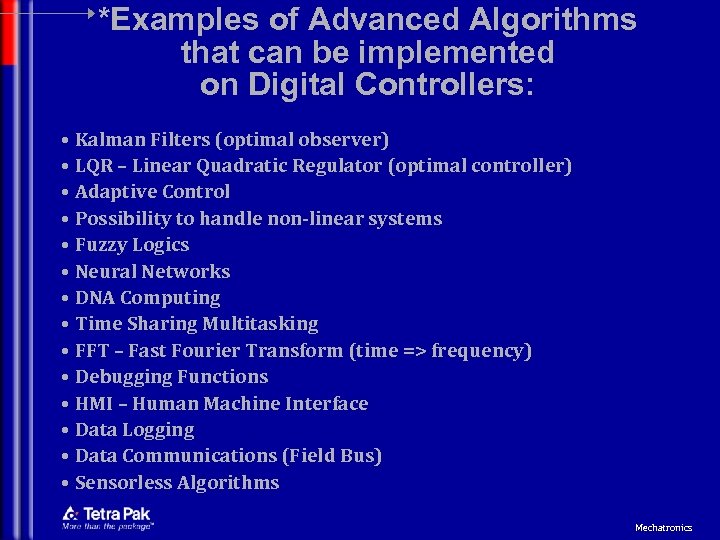

*Examples of Advanced Algorithms that can be implemented on Digital Controllers: • Kalman Filters (optimal observer) • LQR – Linear Quadratic Regulator (optimal controller) • Adaptive Control • Possibility to handle non-linear systems • Fuzzy Logics • Neural Networks • DNA Computing • Time Sharing Multitasking • FFT – Fast Fourier Transform (time => frequency) • Debugging Functions • HMI – Human Machine Interface • Data Logging • Data Communications (Field Bus) • Sensorless Algorithms Mechatronics

*Examples of Advanced Algorithms that can be implemented on Digital Controllers: • Kalman Filters (optimal observer) • LQR – Linear Quadratic Regulator (optimal controller) • Adaptive Control • Possibility to handle non-linear systems • Fuzzy Logics • Neural Networks • DNA Computing • Time Sharing Multitasking • FFT – Fast Fourier Transform (time => frequency) • Debugging Functions • HMI – Human Machine Interface • Data Logging • Data Communications (Field Bus) • Sensorless Algorithms Mechatronics

“Il Mondo del Packaging” Solid Food others… Semi-Solid Toys Food Pastorized Cigarettes Liquid Food Tissues Aseptic Personal Liquid Food Care Beve. Chocolate Beauty Care rages Pharmaceutical Mechatronics

“Il Mondo del Packaging” Solid Food others… Semi-Solid Toys Food Pastorized Cigarettes Liquid Food Tissues Aseptic Personal Liquid Food Care Beve. Chocolate Beauty Care rages Pharmaceutical Mechatronics

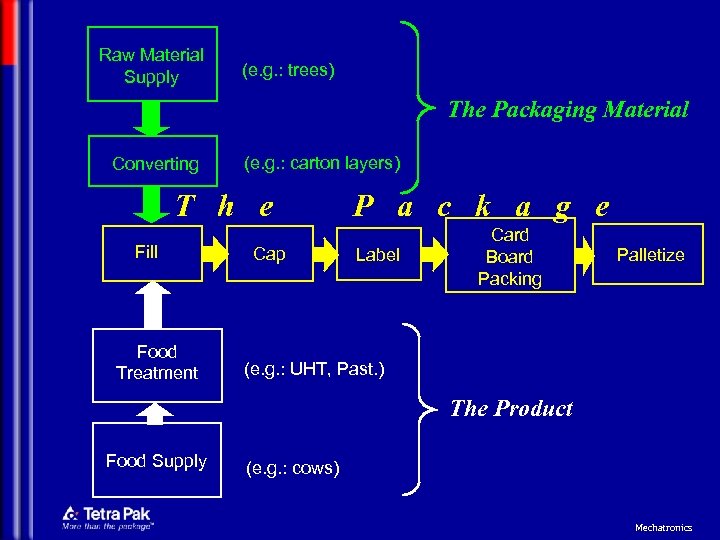

Raw Material Supply (e. g. : trees) The Packaging Material Converting (e. g. : carton layers) T h e Fill Food Treatment Cap P a c k a g e Label Card Board Packing Palletize (e. g. : UHT, Past. ) The Product Food Supply (e. g. : cows) Mechatronics

Raw Material Supply (e. g. : trees) The Packaging Material Converting (e. g. : carton layers) T h e Fill Food Treatment Cap P a c k a g e Label Card Board Packing Palletize (e. g. : UHT, Past. ) The Product Food Supply (e. g. : cows) Mechatronics

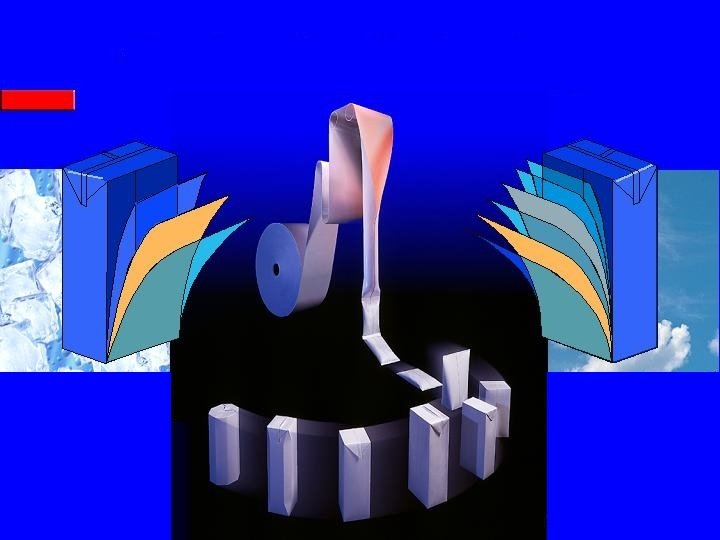

Mechatronics

Mechatronics

Openings Mechatronics

Openings Mechatronics

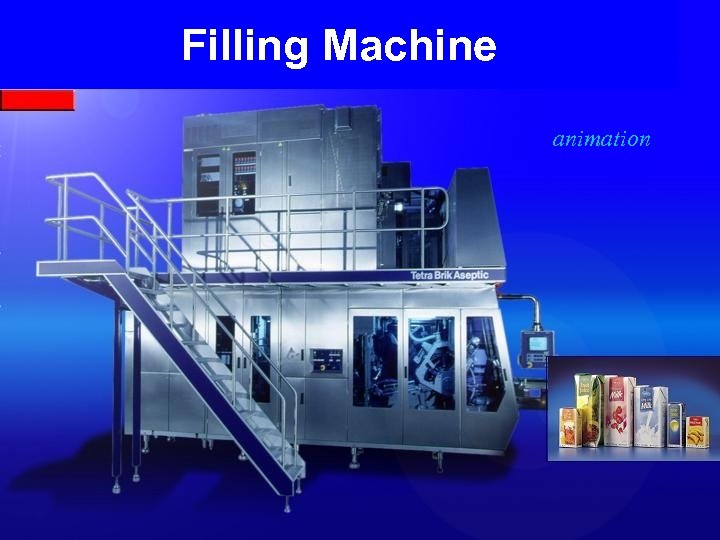

Filling Machine animation Mechatronics

Filling Machine animation Mechatronics

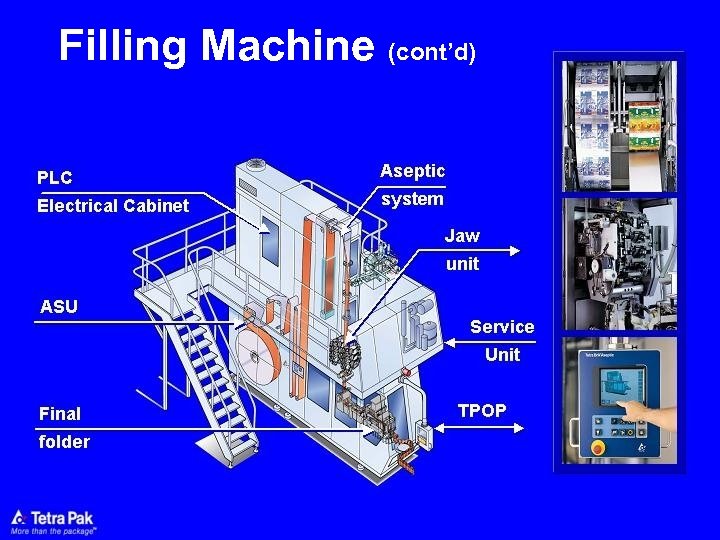

Filling Machine (cont’d) Mechatronics

Filling Machine (cont’d) Mechatronics

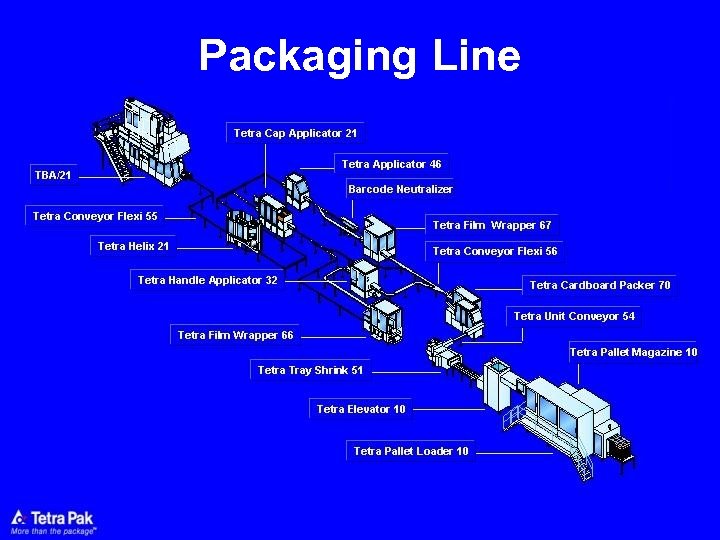

Packaging Line Mechatronics

Packaging Line Mechatronics

Esempio di Packaging Line Mechatronics

Esempio di Packaging Line Mechatronics

. . . at the customer site Mechatronics

. . . at the customer site Mechatronics

Distribution Equipment Macchine automatiche situate dopo la macchina riempitrice (filling machine) • • Accumulators Cap Applicators Card-Board Packers Film Wrappers Handle Applicators Straw Applicators etc. . Mechatronics

Distribution Equipment Macchine automatiche situate dopo la macchina riempitrice (filling machine) • • Accumulators Cap Applicators Card-Board Packers Film Wrappers Handle Applicators Straw Applicators etc. . Mechatronics

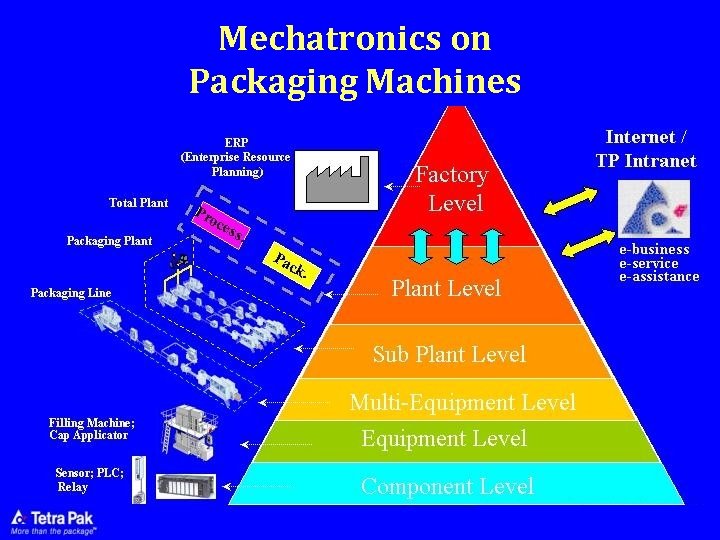

Mechatronics on Packaging Machines Mechatronics

Mechatronics on Packaging Machines Mechatronics

Packaging Line Monitoring System modem Automatic data logging Data transfer - modem/diskette Data analysis - off line software An excellent tool to analyse and improve performance & quality Mechatronics

Packaging Line Monitoring System modem Automatic data logging Data transfer - modem/diskette Data analysis - off line software An excellent tool to analyse and improve performance & quality Mechatronics

3 Generations of Motion Control ü I Generation: Fully ANALOG ü II Generation : ANALOG and DIGITAL ü III Generation : Fully DIGITAL and INTEGRATED with STANDARD IEC 1131 -3 programming languages Mechatronics

3 Generations of Motion Control ü I Generation: Fully ANALOG ü II Generation : ANALOG and DIGITAL ü III Generation : Fully DIGITAL and INTEGRATED with STANDARD IEC 1131 -3 programming languages Mechatronics

Bits of history… The Typewriter Servo : Packaging Machines = Electronics : Typewriter n Mechanical n Electromechanical n Electric n Electronic Word Processor n PC with impact Printer n PC with laser printer n PC with ink jet printer n Email n chronology Mechatronics

Bits of history… The Typewriter Servo : Packaging Machines = Electronics : Typewriter n Mechanical n Electromechanical n Electric n Electronic Word Processor n PC with impact Printer n PC with laser printer n PC with ink jet printer n Email n chronology Mechatronics

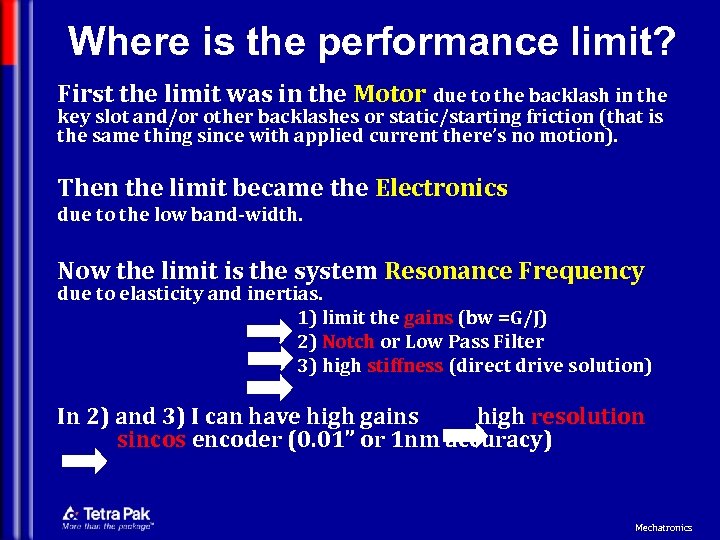

Where is the performance limit? First the limit was in the Motor due to the backlash in the key slot and/or other backlashes or static/starting friction (that is the same thing since with applied current there’s no motion). Then the limit became the Electronics due to the low band-width. Now the limit is the system Resonance Frequency due to elasticity and inertias. 1) limit the gains (bw =G/J) 2) Notch or Low Pass Filter 3) high stiffness (direct drive solution) In 2) and 3) I can have high gains high resolution sincos encoder (0. 01” or 1 nm accuracy) Mechatronics

Where is the performance limit? First the limit was in the Motor due to the backlash in the key slot and/or other backlashes or static/starting friction (that is the same thing since with applied current there’s no motion). Then the limit became the Electronics due to the low band-width. Now the limit is the system Resonance Frequency due to elasticity and inertias. 1) limit the gains (bw =G/J) 2) Notch or Low Pass Filter 3) high stiffness (direct drive solution) In 2) and 3) I can have high gains high resolution sincos encoder (0. 01” or 1 nm accuracy) Mechatronics

Multiaxes Systems Industrywide Interface Industry Guideline Compliant Machine Interface Motion Network Drive M Sensor Network Drive M Machine Controller Drive M Drive OEM Core Competency M Mechatronics

Multiaxes Systems Industrywide Interface Industry Guideline Compliant Machine Interface Motion Network Drive M Sensor Network Drive M Machine Controller Drive M Drive OEM Core Competency M Mechatronics

Modular Software & Software modeling Machine supervisor Machine controller Module Module supervisior Sub Module Sub Module Sub Module Sub Module Mechatronics

Modular Software & Software modeling Machine supervisor Machine controller Module Module supervisior Sub Module Sub Module Sub Module Sub Module Mechatronics

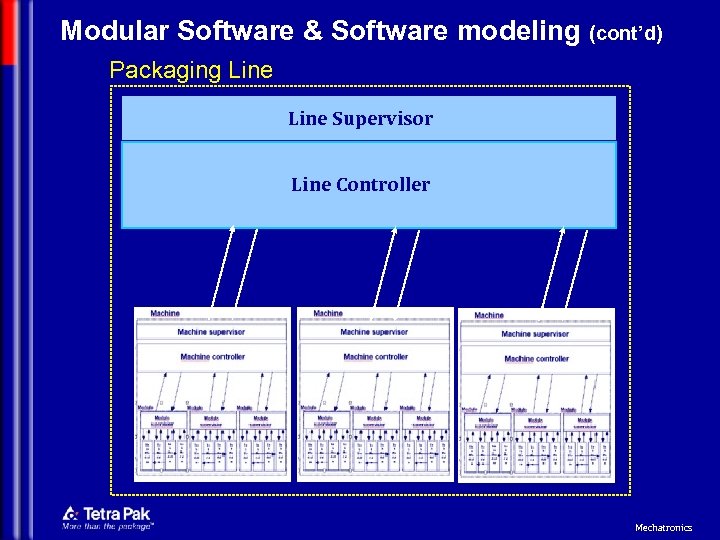

Modular Software & Software modeling (cont’d) Packaging Line Supervisor Line Controller Mechatronics

Modular Software & Software modeling (cont’d) Packaging Line Supervisor Line Controller Mechatronics

Multiaxes Systems (cont’d) animazione Packaging Machine: 3 -50 axes: toward 100 axes machines on the long run (Human Body: 150 axes, i. e. 300 muscles with 2 muscles to give one complete degree of freedom) Each motor has a: • winding (power) cable • feedback cable (encoder or resolver) • PTC temperature sensor wirings and, if present, brake wirings Each power cable is attached to a drive (one drive generally drives one motor). Mechatronics

Multiaxes Systems (cont’d) animazione Packaging Machine: 3 -50 axes: toward 100 axes machines on the long run (Human Body: 150 axes, i. e. 300 muscles with 2 muscles to give one complete degree of freedom) Each motor has a: • winding (power) cable • feedback cable (encoder or resolver) • PTC temperature sensor wirings and, if present, brake wirings Each power cable is attached to a drive (one drive generally drives one motor). Mechatronics

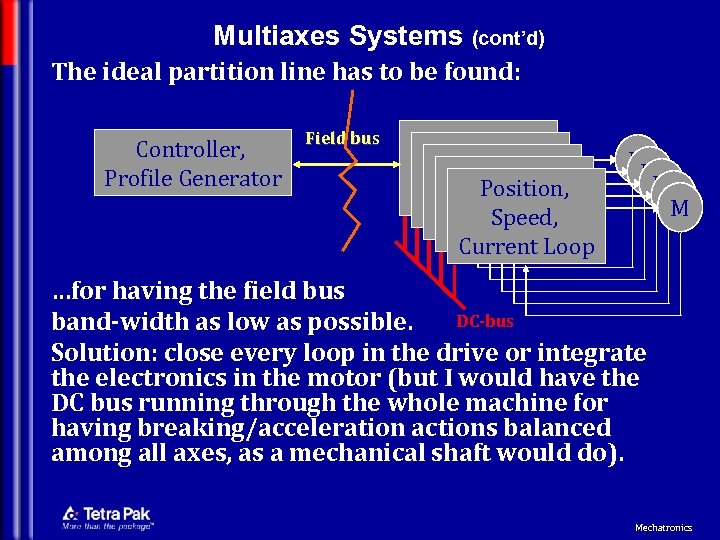

Multiaxes Systems (cont’d) The ideal partition line has to be found: Controller, Profile Generator Field bus Position, Speed, Position, Speed, Current Loop Current Loop M M M …for having the field bus DC-bus band-width as low as possible. Solution: close every loop in the drive or integrate the electronics in the motor (but I would have the DC bus running through the whole machine for having breaking/acceleration actions balanced among all axes, as a mechanical shaft would do). Mechatronics

Multiaxes Systems (cont’d) The ideal partition line has to be found: Controller, Profile Generator Field bus Position, Speed, Position, Speed, Current Loop Current Loop M M M …for having the field bus DC-bus band-width as low as possible. Solution: close every loop in the drive or integrate the electronics in the motor (but I would have the DC bus running through the whole machine for having breaking/acceleration actions balanced among all axes, as a mechanical shaft would do). Mechatronics

Programming Interface With a field bus, the axis becomes only an object of the bus: I can connect the PC to any bus point for monitoring/accessing any bus device Mechatronics

Programming Interface With a field bus, the axis becomes only an object of the bus: I can connect the PC to any bus point for monitoring/accessing any bus device Mechatronics

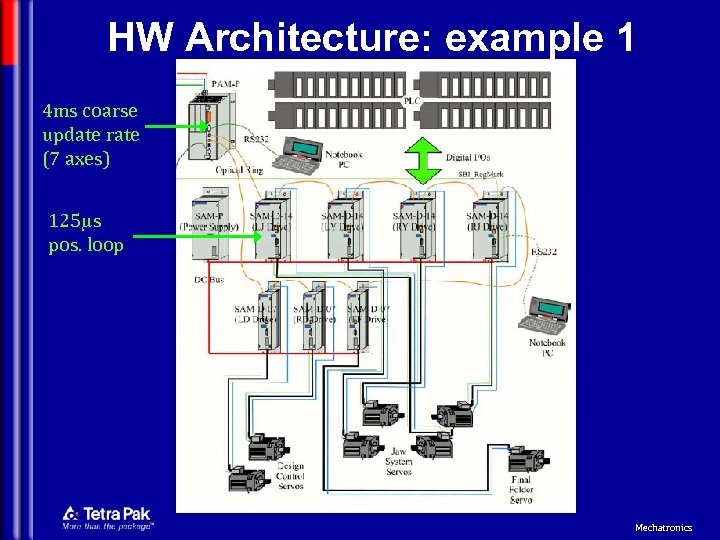

HW Architecture: example 1 4 ms coarse update rate (7 axes) 125 ms pos. loop Mechatronics

HW Architecture: example 1 4 ms coarse update rate (7 axes) 125 ms pos. loop Mechatronics

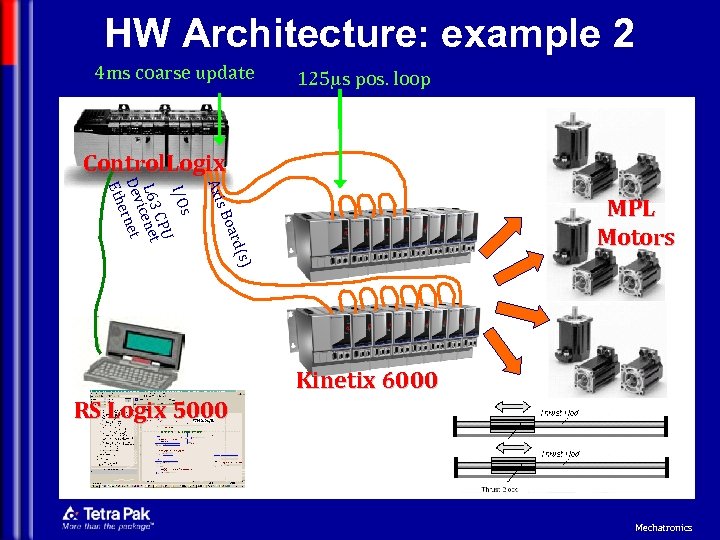

HW Architecture: example 2 4 ms coarse update 125 ms pos. loop Control. Logix Axi (s) ard s Bo s I/O CPU L 63 cenet i Dev rnet e Eth MPL Motors Kinetix 6000 RS Logix 5000 Mechatronics

HW Architecture: example 2 4 ms coarse update 125 ms pos. loop Control. Logix Axi (s) ard s Bo s I/O CPU L 63 cenet i Dev rnet e Eth MPL Motors Kinetix 6000 RS Logix 5000 Mechatronics

SW: IEC 1131 -3 General Approach • LADDER for process logics with boolean and continuous environment • SFC when pending from motion commands to be terminated • ST when heavy bunch of code need to be written in a “linear” form • FBD for continuous algorithms such as design PID Mechatronics

SW: IEC 1131 -3 General Approach • LADDER for process logics with boolean and continuous environment • SFC when pending from motion commands to be terminated • ST when heavy bunch of code need to be written in a “linear” form • FBD for continuous algorithms such as design PID Mechatronics

Mechatronics

Mechatronics

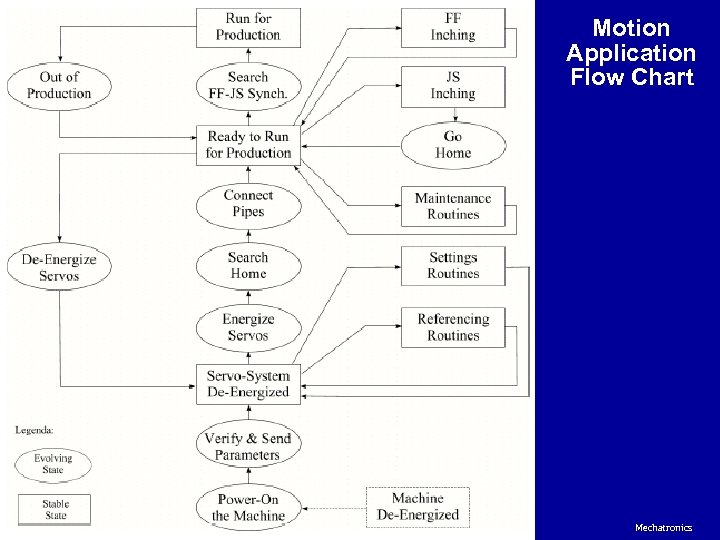

Motion Application Flow Chart Mechatronics

Motion Application Flow Chart Mechatronics

Motion Application Flow Chart DETAILED Mechatronics

Motion Application Flow Chart DETAILED Mechatronics

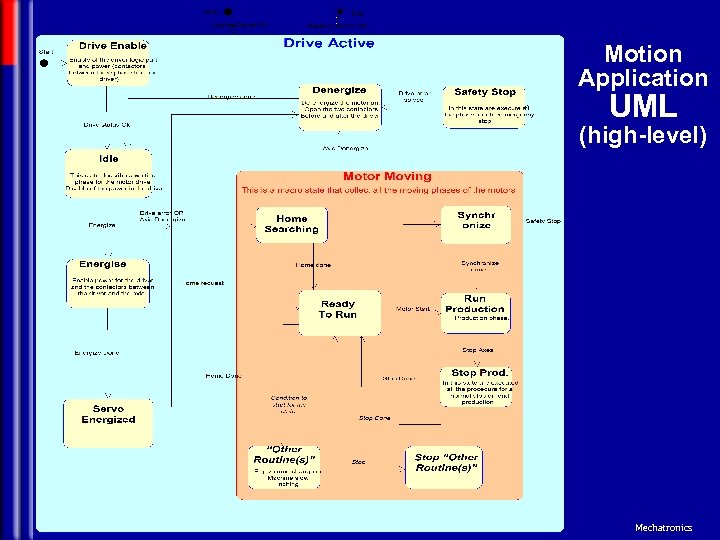

Motion Application UML (high-level) Mechatronics

Motion Application UML (high-level) Mechatronics

SFC Application Main (example 1) Mechatronics

SFC Application Main (example 1) Mechatronics

A 3 -Flex Rockwell SW Architecture (example 1) Periodic Task Very high priority ST Error Detection ST Error Manager SFC Error Handler ST Single Instructions Periodic Task High priority ST SFC Main SFC Home Search. , ON-OFF servos, SFC run-stop prod. , Motion Control Periodic or Cont. Task Low priority ST PLC Logics SFC resets mainten. -service routines SFC Single Instructions ST JSRs Group of move. s Single move. s Ladder Single Instructions Mechatronics

A 3 -Flex Rockwell SW Architecture (example 1) Periodic Task Very high priority ST Error Detection ST Error Manager SFC Error Handler ST Single Instructions Periodic Task High priority ST SFC Main SFC Home Search. , ON-OFF servos, SFC run-stop prod. , Motion Control Periodic or Cont. Task Low priority ST PLC Logics SFC resets mainten. -service routines SFC Single Instructions ST JSRs Group of move. s Single move. s Ladder Single Instructions Mechatronics

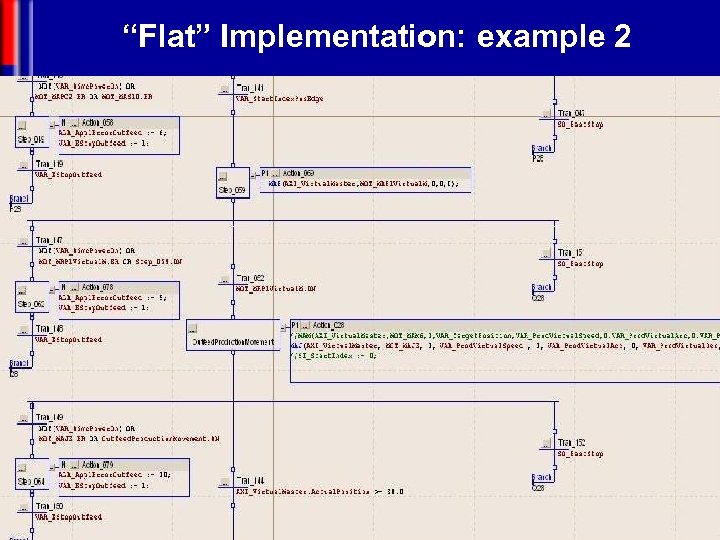

“Flat” Implementation: example 2 Mechatronics

“Flat” Implementation: example 2 Mechatronics

Structured Text Code Sample ST (not IEC 1131 -3) Language Mechatronics

Structured Text Code Sample ST (not IEC 1131 -3) Language Mechatronics

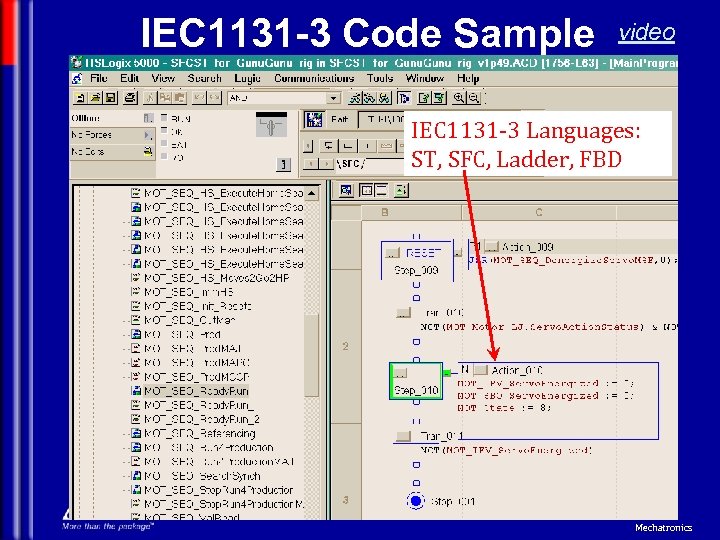

IEC 1131 -3 Code Sample video IEC 1131 -3 Languages: ST, SFC, Ladder, FBD Mechatronics

IEC 1131 -3 Code Sample video IEC 1131 -3 Languages: ST, SFC, Ladder, FBD Mechatronics

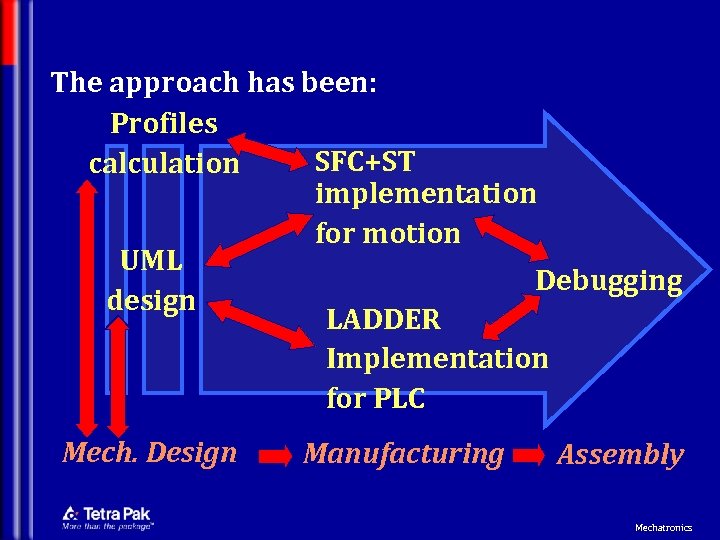

The approach has been: Profiles SFC+ST calculation implementation for motion UML Debugging design LADDER Implementation for PLC Mech. Design Manufacturing Assembly Mechatronics

The approach has been: Profiles SFC+ST calculation implementation for motion UML Debugging design LADDER Implementation for PLC Mech. Design Manufacturing Assembly Mechatronics