8bb79c2629a1779c61d3a0a5cd1ba020.ppt

- Количество слайдов: 17

Measurement technology requirements for gas turbine propulsion systems James P Roberts Sensors and Instrumentation KTN: ISP Meeting 01/04/09 © 2009 Rolls-Royce plc The information in this document is the property of Rolls-Royce plc and may not be copied or communicated to a third party, or used for any purpose other than that for which it is supplied without the express written consent of Rolls-Royce plc. This information is given in good faith based upon the latest information available to Rolls-Royce plc, no warranty or representation is given concerning such information, which must not be taken as establishing any contractual or other commitment binding upon Rolls-Royce plc or any of its subsidiary or associated companies.

Agenda 2 l Principal drivers for measurement for gas turbine engines l Most important measureands l The challenges l Current capabilities l Future opportunities Rolls-Royce Proprietary Data © 2009 Insert filename

Agenda 3 l Principal drivers for measurement for gas turbine engines: l Why do we need to measure? l Most important measureands: l What do we need to measure? l The challenges: l l The engine environment: Where do we need to measure? The practical/operational constraints: What makes it difficult/expensive? l Current capabilities: l What can we do today? Where do we need more capability? l Future opportunities: l What can we do to fill the capability gaps? Rolls-Royce Proprietary Data © 2009 Insert filename

Why do we need to measure? Our four markets Rolls-Royce Proprietary Data © 2009 4 Insert filename

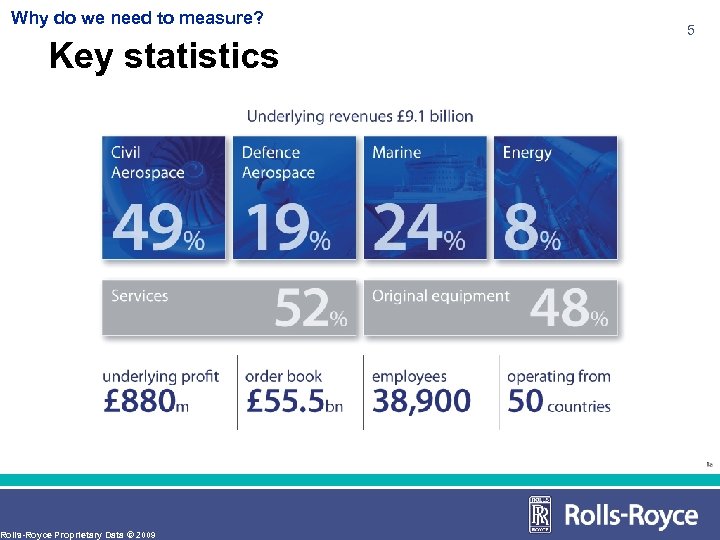

Why do we need to measure? Key statistics Rolls-Royce Proprietary Data © 2009 5 Insert filename

Why do we need to measure? Drivers for measurement for gas turbine engines Instrumentation for product development and method validation. l Instrumentation for Engine Health Monitoring (On- board and NDT) l Manufacturing process control and inspection l Sensors within the engine control system Rolls-Royce Proprietary Data © 2009 Increased maturity of technology l 6 Insert filename

Measurands of importance: What do we need to measure? l Structural measurements l Measurements to validate/monitor the integrity of the engine l Key inputs to component life and maintenance prediction l Validation of FE modelling methods Component temperatures Component vibration Engine vibration Loads and displacements l NDE/Inspection l Manufacturing and assembly process control l Performance measurements l Measurements to validate/monitor/control the efficiency of the engine l Validation of CFD and performance models of engine Gas temperatures, pressures and velocities Fuel and oil flows and properties Torque and thrust Running Clearances Emissions Noise 7 Rolls-Royce Proprietary Data © 2009 Insert filename

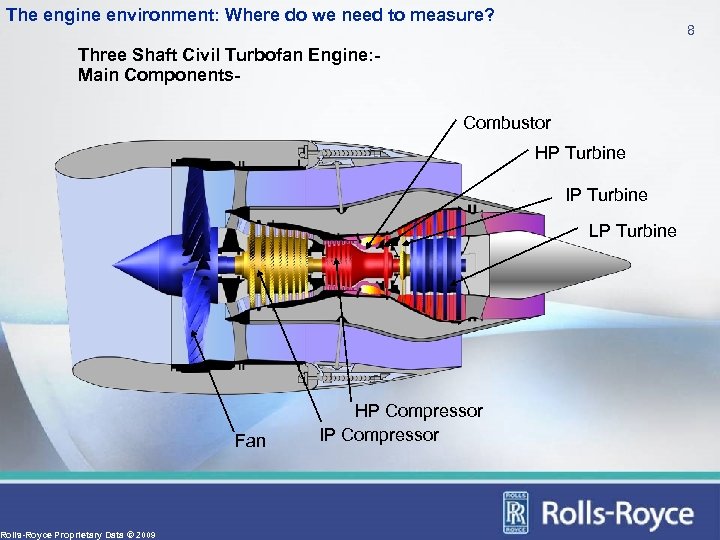

The engine environment: Where do we need to measure? 8 Three Shaft Civil Turbofan Engine: Main Components- Rolls-Royce Proprietary Data © 2009 Combustor HP Turbine IP Turbine LP Turbine Fan HP Compressor Insert filename

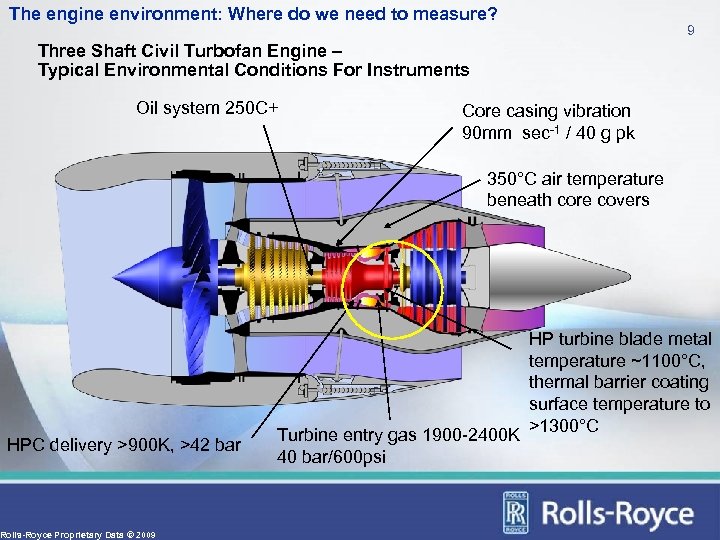

The engine environment: Where do we need to measure? 9 Three Shaft Civil Turbofan Engine – Typical Environmental Conditions For Instruments Oil system 250 C+ Core casing vibration 90 mm sec-1 / 40 g pk 350°C air temperature beneath core covers HPC delivery >900 K, >42 bar Rolls-Royce Proprietary Data © 2009 Turbine entry gas 1900 -2400 K 40 bar/600 psi HP turbine blade metal temperature ~1100°C, thermal barrier coating surface temperature to >1300°C Insert filename

The challenges of large volumes of instrumentation on development engines: 10 The practical/operational constraints: What makes it difficult/expensive? l Historically every measurement point is led out to test facility signal conditioning: - 1000 thermocouples (low bandwidth) - 1500 pneumatic lines (low bandwidth) - 500 s/g, accelerometers, dynamic pressures etc (up to 40 k. Hz) l Instrumentation leadout ‘ties’ the modular engine together l Leadout routing involves large design effort l Very difficult to swap out failed instruments l Leadout material can be expensive l 12 km t/c cable fitted to a single engine l Potential for large time and cost savings Rolls-Royce Proprietary Data © 2009 Insert filename

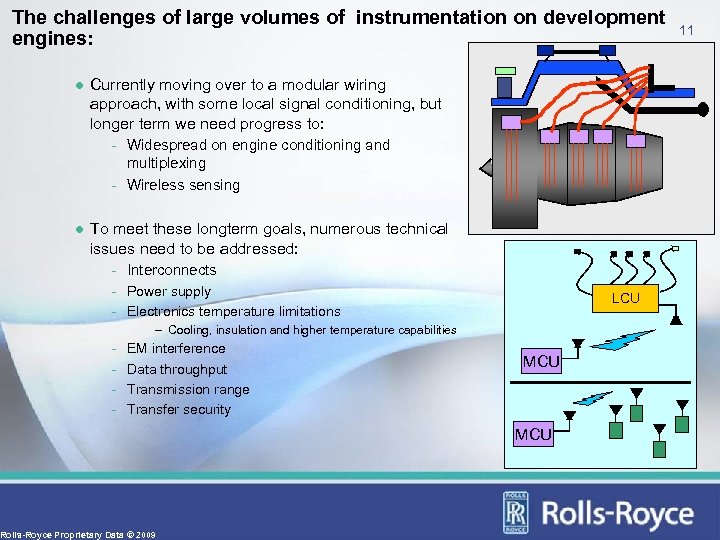

The challenges of large volumes of instrumentation on development engines: l 11 Currently moving over to a modular wiring approach, with some local signal conditioning, but longer term we need progress to: - Widespread on engine conditioning and multiplexing - Wireless sensing l To meet these longterm goals, numerous technical issues need to be addressed: - Interconnects - Power supply LCU - Electronics temperature limitations – Cooling, insulation and higher temperature capabilities - EM interference - Data throughput MCU - Transmission range - Transfer security Rolls-Royce Proprietary Data © 2009 MCU Insert filename

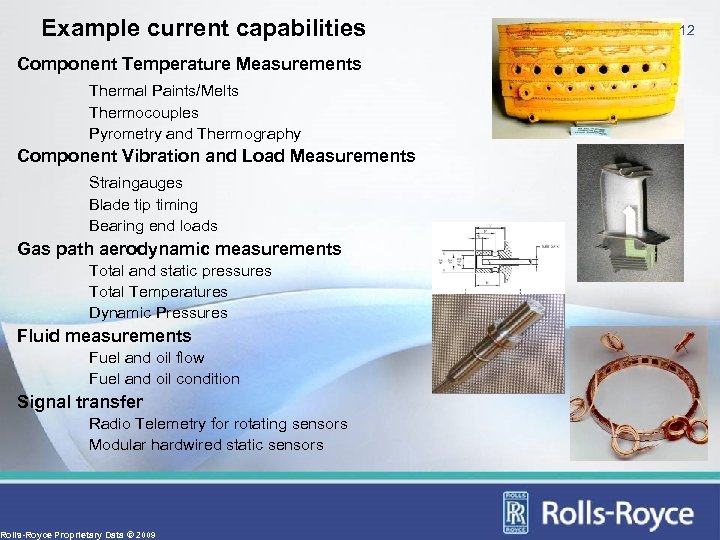

Example current capabilities 12 Component Temperature Measurements Thermal Paints/Melts Thermocouples Pyrometry and Thermography Component Vibration and Load Measurements Straingauges Blade tip timing Bearing end loads Gas path aerodynamic measurements Total and static pressures Total Temperatures Dynamic Pressures Fluid measurements Fuel and oil flow Fuel and oil condition Signal transfer Radio Telemetry for rotating sensors Modular hardwired static sensors Rolls-Royce Proprietary Data © 2009 Insert filename

Example opportunities to improve current capabilities 13 Component Temperature Measurements Thermal Paints/Melts Thermocouples Pyrometry and Thermography Improved/automated reading methods Higher temperature capabilities, stability Accuracy, resolution, intrusiveness Component Vibration and Load Measurements Straingauges Blade tip timing Bearing end loads High temperature life ‘Smart bearings? ’ Gas path aerodynamic measurements Total and static pressures Total Temperatures Dynamic Pressures Higher temperature, accuracy Fluid measurements Fuel and oil flow Fuel and oil condition Accuracy, multiphase flows, oil films Oil health, Fuel quality Signal transfer Radio Telemetry for rotating sensors Modular hardwired static sensors Rolls-Royce Proprietary Data © 2009 Smaller higher temperature electronics Wired and wireless networks Insert filename

l Future opportunities: l 14 What can we do to fill the capability gaps? l Pre-competitive work with other OEMs to define agreed measurement capability gaps l Involvement of academia and the supply chain to identify opportunities to close the gaps l Collaborative research to provide validated solutions Rolls-Royce Proprietary Data © 2009 Insert filename

Gas Turbine Engine Measurement Requirements: 15 Industry groups co-ordinating requirements and pre-competitive collaborative measurement R+D for gas turbine instrumentation l EU: EVI-GTI - European Virtual Institute for Gas Turbine Instrumentation - Engine Companies including: RRplc, RRD, Alstom, Safran(Snecma, Turbomeca), MTU, ABB Turbo, Siemens, Fiat Avio, Volvo. - INPA registered in Belgium, Administrated by VKI - Instr research, supply and application companies. - website: //www. evi-gti. com l USA: PIWG - Propulsion Instrumentation Working Group - Engine Companies including: P+W, GE, Honeywell, RRC, Seimens Westinghouse, Williams International. - Users: including: NASA, AEDC, AFRL, NAWCAD, NETL - Strategy Advisory Board: Accademia, researchers and supply chain - website: //www. piwg. org/ Rolls-Royce Proprietary Data © 2009 Insert filename

Collaborative research examples 16 UK: ODESSA (complete) l DTI ‘Micro and Nano’ call l Oxsensis, CCLRC and Rolls-Royce. l Development of 1000 C dynamic pressure sensor. Through to in-engine validation. EU: HEATTOP (on-going) l ‘STREP’ in Call 3 of EU Framework 6: 42 month prog from August 2006 l Full Title: “Accurate High Temperature Engine Aero-Thermal Measurements for Gas-Turbine Life Optimization, Performance and Condition Monitoring” l Partners: RR, Volvo, Siemens, Kema, VKI, Vibometer (CH), Vibrometer (UK), Auxitrol, Onera, CESI, Farran, Oxsensis, AOS, IPHT, Oxford, Cambridge, Lund. l Main topics: High temperature gas path temperature and pressure measurement, plus tip clearance. Development through to in-engine validation. UK: WITNESSS (on-going) l ‘Gathering Data in Complex Environments’ call l Agusta. Westland, Airbus UK, BAE, Bombardier, GE Aviation, Qinetiq, QM Systems, Rolls-Royce, SLI Ltd, TRW Conekt, Ultra Electronics BCF. l Wireless sensor deployment in aerospace environments. UK: WIDAGATE (on-going) l TSB ‘Gathering Data in Complex Environments’ call l Selex, Strathclyde Univ, UCL, Rolls-Royce. l Modelling of wireless networks in the on-engine environment. Rolls-Royce Proprietary Data © 2009 Insert filename

Summary 17 l High quality measurements are vital for the validation, inservice monitoring and control of propulsion gas turbines. l The gas turbine environment provides extreme challenges for measurement technology. l Collaborative research between academia, the instrumentation supply chain and the end users can develop and validate the new measurement technology needed. Rolls-Royce Proprietary Data © 2009 Insert filename

8bb79c2629a1779c61d3a0a5cd1ba020.ppt