e998966dca5c89b787f017063be20d1e.ppt

- Количество слайдов: 39

ME 414 : Project 1 Heating System for NASA North Pole Project May 5, 2006 Team Members Alan Benedict Jeffrey Jones Laura O’Hair Aaron Randall

ME 414 : Project 1 Heating System for NASA North Pole Project May 5, 2006 Team Members Alan Benedict Jeffrey Jones Laura O’Hair Aaron Randall

Problem Statement Your job as a Thermal Fluid Systems engineer is to deliver the housing heating system in the North Pole. 4 occupants Oxygen supply tank or circulating fresh air from outside The outside temperature in North Pole is -40 C and the desired temperature inside the housing is 25 C. You have a space of 12” in the outside walls and 8” in the interior walls.

Problem Statement Your job as a Thermal Fluid Systems engineer is to deliver the housing heating system in the North Pole. 4 occupants Oxygen supply tank or circulating fresh air from outside The outside temperature in North Pole is -40 C and the desired temperature inside the housing is 25 C. You have a space of 12” in the outside walls and 8” in the interior walls.

Deliverables • • • Lowest blower cost measured by the least system pressure drop Least material cost measured by the number of sheets used Least labor cost per the labor rates given Least operating cost measured by the cost of maintenance items and monthly natural gas, oxygen, electricity, etc usage. Most comfort to occupants measured by the least flow rate variation between registers

Deliverables • • • Lowest blower cost measured by the least system pressure drop Least material cost measured by the number of sheets used Least labor cost per the labor rates given Least operating cost measured by the cost of maintenance items and monthly natural gas, oxygen, electricity, etc usage. Most comfort to occupants measured by the least flow rate variation between registers

Supply Air System

Supply Air System

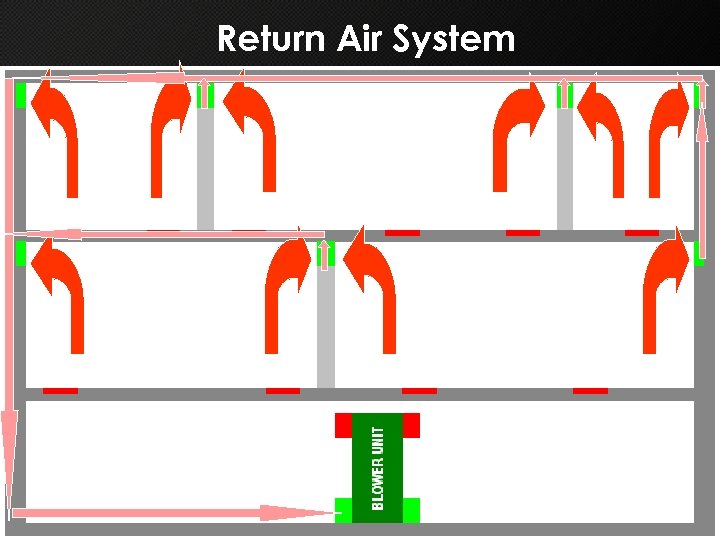

Return Air System

Return Air System

Heat Loss Calculation Assumptions • All heat loss occurs through exterior walls and roof. • The structure is perfectly sealed. No transfer of air. • There is no heat transfer between rooms. • There is not heat transfer to or from the basement.

Heat Loss Calculation Assumptions • All heat loss occurs through exterior walls and roof. • The structure is perfectly sealed. No transfer of air. • There is no heat transfer between rooms. • There is not heat transfer to or from the basement.

Heat Loss Calculations • Interior Temperature • Convection Coefficients 25˚C – Interior surfaces • Exterior Temperature • Walls 4. 2 W/m 2˚C -40˚C • Roof 5. 17 W/m 2˚C – Exterior • Thermal • All surfaces Conductivity of Wall 34 W/m 2˚C 0. 8 W/m˚C

Heat Loss Calculations • Interior Temperature • Convection Coefficients 25˚C – Interior surfaces • Exterior Temperature • Walls 4. 2 W/m 2˚C -40˚C • Roof 5. 17 W/m 2˚C – Exterior • Thermal • All surfaces Conductivity of Wall 34 W/m 2˚C 0. 8 W/m˚C

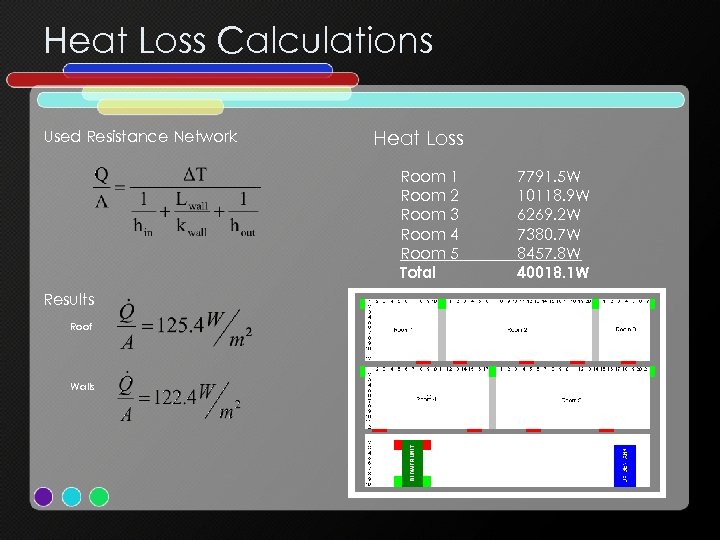

Heat Loss Calculations Used Resistance Network Heat Loss Room 1 Room 2 Room 3 Room 4 Room 5 Total Results Roof Walls 7791. 5 W 10118. 9 W 6269. 2 W 7380. 7 W 8457. 8 W 40018. 1 W

Heat Loss Calculations Used Resistance Network Heat Loss Room 1 Room 2 Room 3 Room 4 Room 5 Total Results Roof Walls 7791. 5 W 10118. 9 W 6269. 2 W 7380. 7 W 8457. 8 W 40018. 1 W

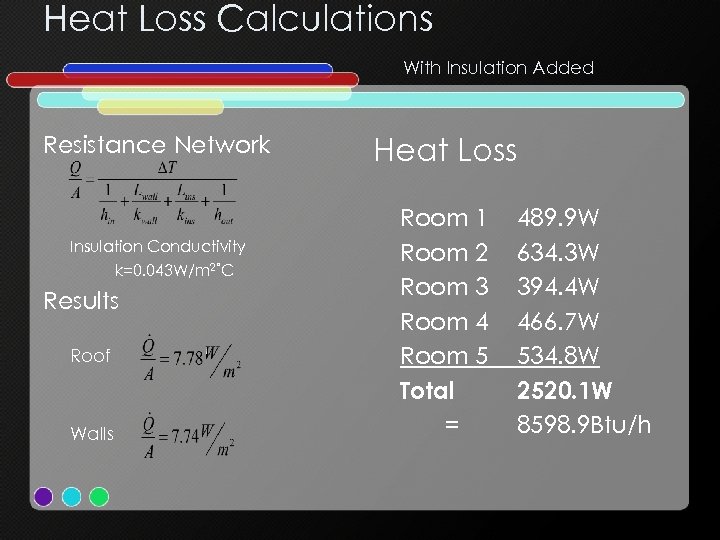

Heat Loss Calculations With Insulation Added Resistance Network Insulation Conductivity k=0. 043 W/m 2˚C Results Roof Walls Heat Loss Room 1 Room 2 Room 3 Room 4 Room 5 Total = 489. 9 W 634. 3 W 394. 4 W 466. 7 W 534. 8 W 2520. 1 W 8598. 9 Btu/h

Heat Loss Calculations With Insulation Added Resistance Network Insulation Conductivity k=0. 043 W/m 2˚C Results Roof Walls Heat Loss Room 1 Room 2 Room 3 Room 4 Room 5 Total = 489. 9 W 634. 3 W 394. 4 W 466. 7 W 534. 8 W 2520. 1 W 8598. 9 Btu/h

Heat Loss Rates • Heat loss rate through walls and roof: – 2520 W • Heat loss rate through heating of outside air: – 72 W

Heat Loss Rates • Heat loss rate through walls and roof: – 2520 W • Heat loss rate through heating of outside air: – 72 W

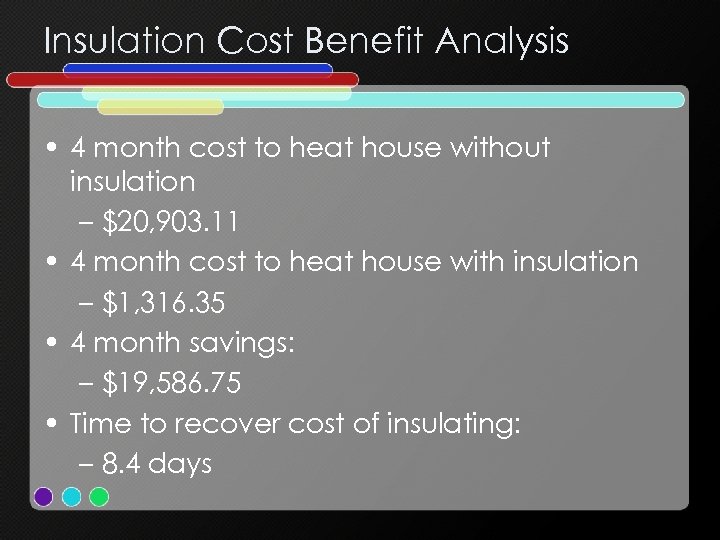

Insulation Cost Benefit Analysis • Cost to add insulation: – 12 inches in walls and roof – Total of 3501. 1 ft 3 insulation required – Cellulose insulation cost $0. 387 per ft 3 – Total cost to add insulation: $1354. 07

Insulation Cost Benefit Analysis • Cost to add insulation: – 12 inches in walls and roof – Total of 3501. 1 ft 3 insulation required – Cellulose insulation cost $0. 387 per ft 3 – Total cost to add insulation: $1354. 07

Insulation Cost Benefit Analysis • Heat loss rate without insulation: – 40, 018. 1 W • Heat loss rate with insulation: – 2, 520. 1 W • Heat loss rate reduction: – 37, 498 W or 93. 7%

Insulation Cost Benefit Analysis • Heat loss rate without insulation: – 40, 018. 1 W • Heat loss rate with insulation: – 2, 520. 1 W • Heat loss rate reduction: – 37, 498 W or 93. 7%

Insulation Cost Benefit Analysis • 4 month cost to heat house without insulation – $20, 903. 11 • 4 month cost to heat house with insulation – $1, 316. 35 • 4 month savings: – $19, 586. 75 • Time to recover cost of insulating: – 8. 4 days

Insulation Cost Benefit Analysis • 4 month cost to heat house without insulation – $20, 903. 11 • 4 month cost to heat house with insulation – $1, 316. 35 • 4 month savings: – $19, 586. 75 • Time to recover cost of insulating: – 8. 4 days

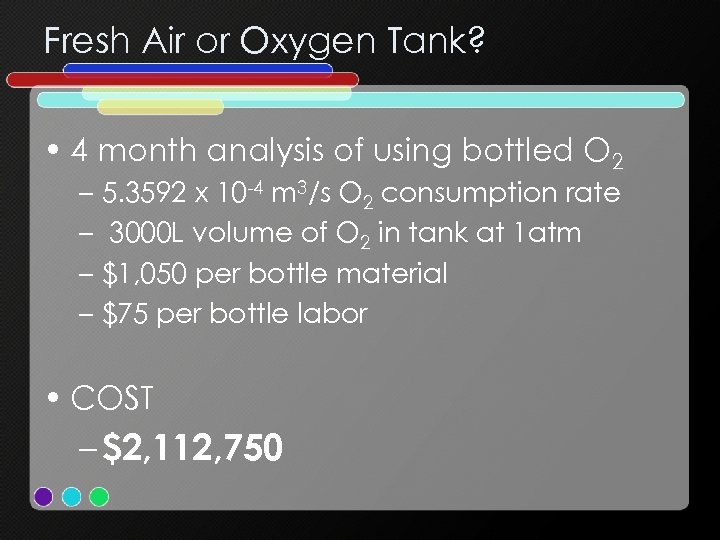

Fresh Air or Oxygen Tank? • 4 month analysis of using bottled O 2 – 5. 3592 x 10 -4 m 3/s O 2 consumption rate – 3000 L volume of O 2 in tank at 1 atm – $1, 050 per bottle material – $75 per bottle labor • COST – $2, 112, 750

Fresh Air or Oxygen Tank? • 4 month analysis of using bottled O 2 – 5. 3592 x 10 -4 m 3/s O 2 consumption rate – 3000 L volume of O 2 in tank at 1 atm – $1, 050 per bottle material – $75 per bottle labor • COST – $2, 112, 750

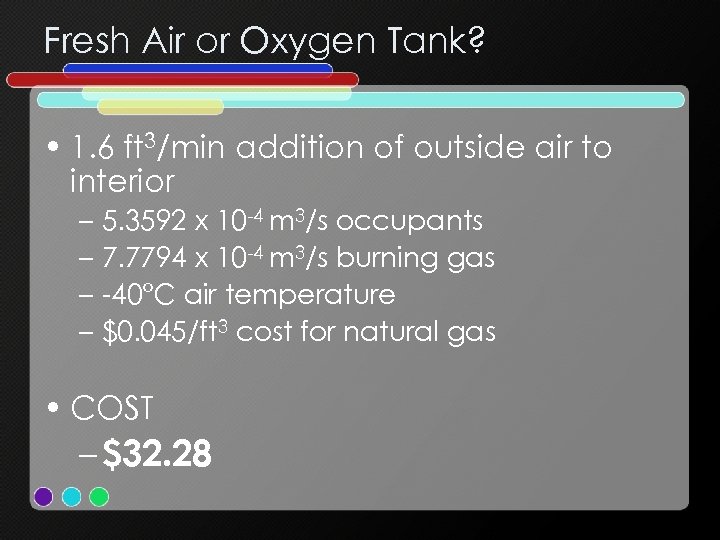

Fresh Air or Oxygen Tank? • 1. 6 ft 3/min addition of outside air to interior – 5. 3592 x 10 -4 m 3/s occupants – 7. 7794 x 10 -4 m 3/s burning gas – -40°C air temperature – $0. 045/ft 3 cost for natural gas • COST – $32. 28

Fresh Air or Oxygen Tank? • 1. 6 ft 3/min addition of outside air to interior – 5. 3592 x 10 -4 m 3/s occupants – 7. 7794 x 10 -4 m 3/s burning gas – -40°C air temperature – $0. 045/ft 3 cost for natural gas • COST – $32. 28

Furnace and Blower • Gibson KG 6 RA Series Specifications – 45000 Btu/h – 80% Efficiency – Cost of $543

Furnace and Blower • Gibson KG 6 RA Series Specifications – 45000 Btu/h – 80% Efficiency – Cost of $543

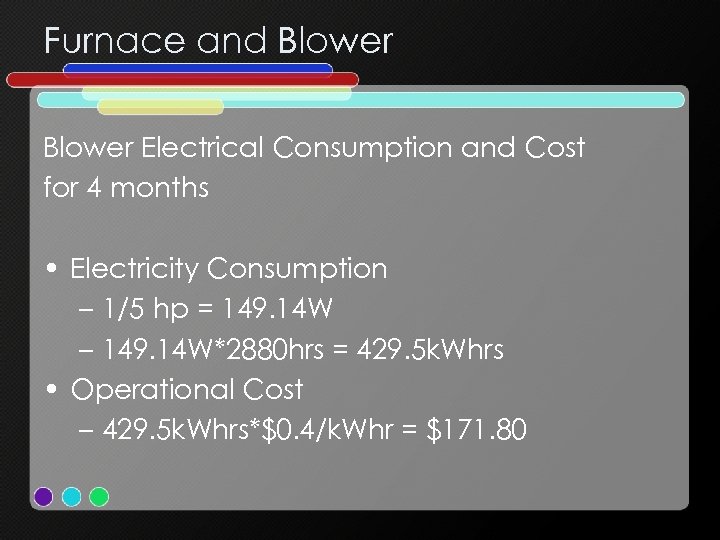

Furnace and Blower Electrical Consumption and Cost for 4 months • Electricity Consumption – 1/5 hp = 149. 14 W – 149. 14 W*2880 hrs = 429. 5 k. Whrs • Operational Cost – 429. 5 k. Whrs*$0. 4/k. Whr = $171. 80

Furnace and Blower Electrical Consumption and Cost for 4 months • Electricity Consumption – 1/5 hp = 149. 14 W – 149. 14 W*2880 hrs = 429. 5 k. Whrs • Operational Cost – 429. 5 k. Whrs*$0. 4/k. Whr = $171. 80

Materials • Duct Diameter – 7. 43 inches – 3 ducts per each 90” X 70” sheet

Materials • Duct Diameter – 7. 43 inches – 3 ducts per each 90” X 70” sheet

Materials • Total sheets – 9 • 90 degree bends – 6 • Branches – 9 • Registers – 9

Materials • Total sheets – 9 • 90 degree bends – 6 • Branches – 9 • Registers – 9

Material and Labor Costs CIRCULAR DUCTS • Material: – $2, 250. 00 • Labor: – $2, 400. 00 • Total – $4, 650. 00 SQUARE DUCTS • Material: – $3, 250. 00 • Labor: – $2, 600. 00 • Total – $5, 850. 00

Material and Labor Costs CIRCULAR DUCTS • Material: – $2, 250. 00 • Labor: – $2, 400. 00 • Total – $4, 650. 00 SQUARE DUCTS • Material: – $3, 250. 00 • Labor: – $2, 600. 00 • Total – $5, 850. 00

Problems not Overcome • Flowmaster – Flow rates in pump do not coincide with branch flow rate – Flow rates don’t produce results as expected

Problems not Overcome • Flowmaster – Flow rates in pump do not coincide with branch flow rate – Flow rates don’t produce results as expected

Flow Output of Pump Lower than First Branch

Flow Output of Pump Lower than First Branch

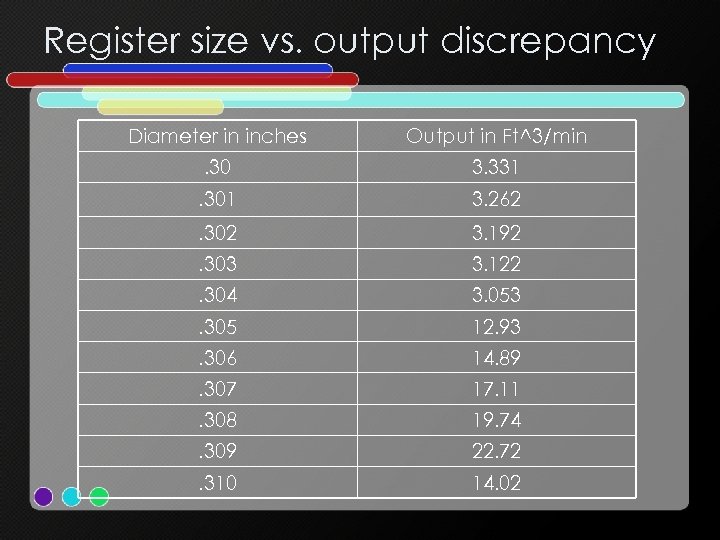

Register size vs. output discrepancy Diameter in inches Output in Ft^3/min . 30 3. 331 . 301 3. 262 . 302 3. 192 . 303 3. 122 . 304 3. 053 . 305 12. 93 . 306 14. 89 . 307 17. 11 . 308 19. 74 . 309 22. 72 . 310 14. 02

Register size vs. output discrepancy Diameter in inches Output in Ft^3/min . 30 3. 331 . 301 3. 262 . 302 3. 192 . 303 3. 122 . 304 3. 053 . 305 12. 93 . 306 14. 89 . 307 17. 11 . 308 19. 74 . 309 22. 72 . 310 14. 02

Conclusion • Least Pressure Drop not achievable through Flowmaster • Least material cost calculated at $4147 • Least labor cost calculated at $2400 • Least operating cost calculated at $1488 • Flow rate variation between registers not achievable through Flowmaster

Conclusion • Least Pressure Drop not achievable through Flowmaster • Least material cost calculated at $4147 • Least labor cost calculated at $2400 • Least operating cost calculated at $1488 • Flow rate variation between registers not achievable through Flowmaster

Questions?

Questions?

ME 414 : Project 2 Heat Exchanger Optimization May 5, 2006 Team Members Alan Benedict Jeffrey Jones Laura O’Hair Aaron Randall

ME 414 : Project 2 Heat Exchanger Optimization May 5, 2006 Team Members Alan Benedict Jeffrey Jones Laura O’Hair Aaron Randall

Problem Statement Design a heat exchanger to meet the customer requirements for heat transfer and maximum dimensions, while optimizing the weight and pressure losses in both the tube and shell sides.

Problem Statement Design a heat exchanger to meet the customer requirements for heat transfer and maximum dimensions, while optimizing the weight and pressure losses in both the tube and shell sides.

Project Definition • Chemical Specifications: – Temperature must be reduced from 35°C to 25°C – Mass flow rate is 80, 000 kg/hr – Material properties closely approximate that of water • Cooling Water Specifications: – Treated city water at 20°C – Mass flow rate is not fixed – Exit temperature is function of design

Project Definition • Chemical Specifications: – Temperature must be reduced from 35°C to 25°C – Mass flow rate is 80, 000 kg/hr – Material properties closely approximate that of water • Cooling Water Specifications: – Treated city water at 20°C – Mass flow rate is not fixed – Exit temperature is function of design

Customer Requirements • Must cool the chemical from 35 C to 25 C • Heat exchanger length can not exceed 7 m • Heat exchanger shell diameter can not exceed 2 m • Minimize heat exchanger shell and tube weight • Minimize heat exchanger pressure drop

Customer Requirements • Must cool the chemical from 35 C to 25 C • Heat exchanger length can not exceed 7 m • Heat exchanger shell diameter can not exceed 2 m • Minimize heat exchanger shell and tube weight • Minimize heat exchanger pressure drop

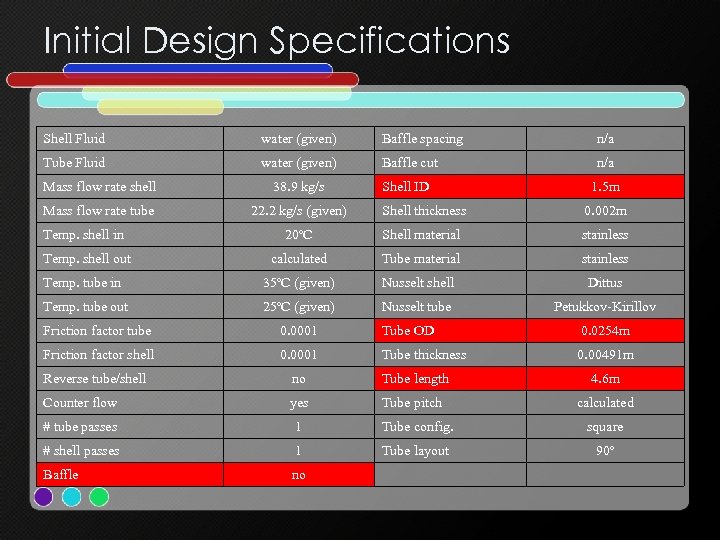

Initial Design Specifications Shell Fluid water (given) Baffle spacing n/a Tube Fluid water (given) Baffle cut n/a Mass flow rate shell 38. 9 kg/s Shell ID 1. 5 m Mass flow rate tube 22. 2 kg/s (given) Shell thickness 0. 002 m Temp. shell in 20ºC Shell material stainless Temp. shell out calculated Tube material stainless Temp. tube in 35ºC (given) Nusselt shell Dittus Temp. tube out 25ºC (given) Nusselt tube Petukkov-Kirillov Friction factor tube 0. 0001 Tube OD 0. 0254 m Friction factor shell 0. 0001 Tube thickness 0. 00491 m Reverse tube/shell no Tube length 4. 6 m Counter flow yes Tube pitch calculated # tube passes 1 Tube config. square # shell passes 1 Tube layout 90º Baffle no

Initial Design Specifications Shell Fluid water (given) Baffle spacing n/a Tube Fluid water (given) Baffle cut n/a Mass flow rate shell 38. 9 kg/s Shell ID 1. 5 m Mass flow rate tube 22. 2 kg/s (given) Shell thickness 0. 002 m Temp. shell in 20ºC Shell material stainless Temp. shell out calculated Tube material stainless Temp. tube in 35ºC (given) Nusselt shell Dittus Temp. tube out 25ºC (given) Nusselt tube Petukkov-Kirillov Friction factor tube 0. 0001 Tube OD 0. 0254 m Friction factor shell 0. 0001 Tube thickness 0. 00491 m Reverse tube/shell no Tube length 4. 6 m Counter flow yes Tube pitch calculated # tube passes 1 Tube config. square # shell passes 1 Tube layout 90º Baffle no

Initial Results • Desired heat transfer rate of 928, 502 W • Calculated heat transfer rate of 924, 068 W • Difference of 4, 434 W • Desired-to-calculated ratio 0. 995

Initial Results • Desired heat transfer rate of 928, 502 W • Calculated heat transfer rate of 924, 068 W • Difference of 4, 434 W • Desired-to-calculated ratio 0. 995

First DOE Results

First DOE Results

Initial Design Specifications Shell Fluid water (given) Baffle spacing n/a Tube Fluid water (given) Baffle cut n/a Mass flow rate shell 38. 9 kg/s Shell ID 1. 5 m Mass flow rate tube 22. 2 kg/s (given) Shell thickness 0. 002 m Temp. shell in 20ºC Shell material stainless Temp. shell out calculated Tube material stainless Temp. tube in 35ºC (given) Nusselt shell Dittus Temp. tube out 25ºC (given) Nusselt tube Petukkov-Kirillov Friction factor tube 0. 0001 Tube OD 0. 0254 m Friction factor shell 0. 0001 Tube thickness 0. 00491 m Reverse tube/shell no Tube length 4. 6 m Counter flow yes Tube pitch calculated # tube passes 1 Tube config. square # shell passes 1 Tube layout 90º Baffle no

Initial Design Specifications Shell Fluid water (given) Baffle spacing n/a Tube Fluid water (given) Baffle cut n/a Mass flow rate shell 38. 9 kg/s Shell ID 1. 5 m Mass flow rate tube 22. 2 kg/s (given) Shell thickness 0. 002 m Temp. shell in 20ºC Shell material stainless Temp. shell out calculated Tube material stainless Temp. tube in 35ºC (given) Nusselt shell Dittus Temp. tube out 25ºC (given) Nusselt tube Petukkov-Kirillov Friction factor tube 0. 0001 Tube OD 0. 0254 m Friction factor shell 0. 0001 Tube thickness 0. 00491 m Reverse tube/shell no Tube length 4. 6 m Counter flow yes Tube pitch calculated # tube passes 1 Tube config. square # shell passes 1 Tube layout 90º Baffle no

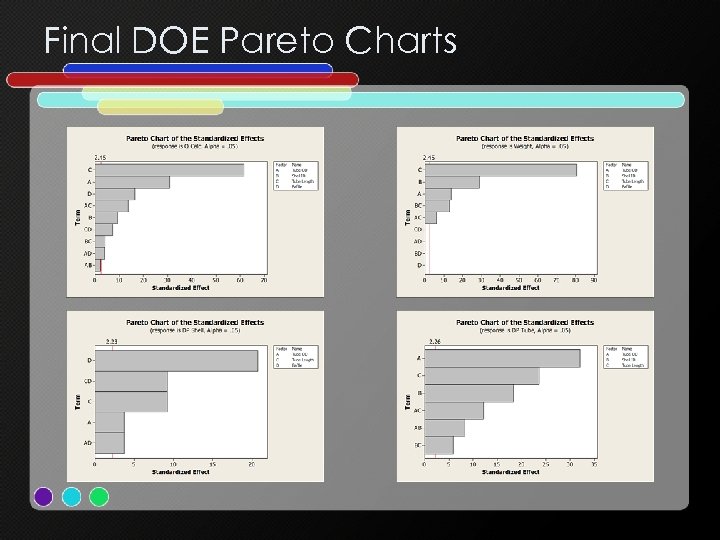

Final DOE Pareto Charts

Final DOE Pareto Charts

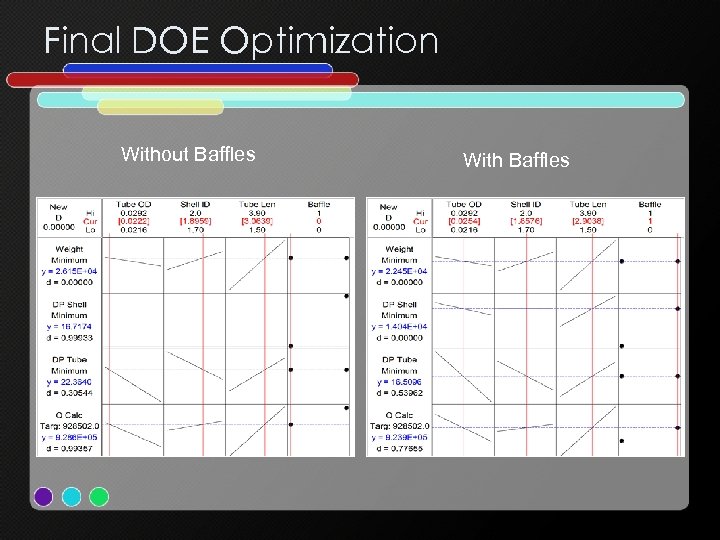

Final DOE Optimization Without Baffles With Baffles

Final DOE Optimization Without Baffles With Baffles

Specifications for Optimized Heat Exchanger • • • Counter flow design Stainless steel material for shell and tube Single pass shell Single pass tube Tube OD of 2. 22 cm (standard size) Tube length of 3. 06 m Tube thickness of 2. 40 mm Tube pitch of 3. 18 cm Square tube configuration with 90° layout angle Shell ID of 1. 90 m No baffles

Specifications for Optimized Heat Exchanger • • • Counter flow design Stainless steel material for shell and tube Single pass shell Single pass tube Tube OD of 2. 22 cm (standard size) Tube length of 3. 06 m Tube thickness of 2. 40 mm Tube pitch of 3. 18 cm Square tube configuration with 90° layout angle Shell ID of 1. 90 m No baffles

Final Results Final DOE Initial 1 st DOE Heat Transfer (k. W) 924. 1 1020. 8 929. 9 Tube-Side Pressure Loss (Pa) 37. 54 8. 15 22. 36 Shell-Side Pressure Loss (Pa) 23. 7 14, 500 16. 72 22, 902 32, 035 26, 150 Weight (kg)

Final Results Final DOE Initial 1 st DOE Heat Transfer (k. W) 924. 1 1020. 8 929. 9 Tube-Side Pressure Loss (Pa) 37. 54 8. 15 22. 36 Shell-Side Pressure Loss (Pa) 23. 7 14, 500 16. 72 22, 902 32, 035 26, 150 Weight (kg)

Conclusion • Met requirement to cool the chemical from 35 C to 25 C • Tube length of 3. 06 m<7 m • Shell diameter of 1. 9 m<2 m • Minimized heat exchanger shell and tube weight 26, 150 kg • Minimized pressure drop – Shell side 16. 72 Pa – Tube side 22. 36 Pa

Conclusion • Met requirement to cool the chemical from 35 C to 25 C • Tube length of 3. 06 m<7 m • Shell diameter of 1. 9 m<2 m • Minimized heat exchanger shell and tube weight 26, 150 kg • Minimized pressure drop – Shell side 16. 72 Pa – Tube side 22. 36 Pa

Questions?

Questions?