MCWF interface issues & interim guidance for estimates 5 June 07

MCWF interface issues & interim guidance for estimates 5 June 07

Welded Interface issues • • What are the clamping requirements? RESOLVED with bolts. Clamping requirement – baseline is to add 2 bolts (located to minimize the max span between bolts) to A-A, A-B, and B-C interfaces to provide clamping pressure during welding to minimize distortion. Affected jobs include the following: – – – • • Add boring/tapping holes to punchlist job (1459). Assume 2 man-days (1 calendar day) per hole. [Chrzanowski] Add cost of bolts to 1431. [Dudek] Add time to install prior to welding under 1810. Expected reduction from 20 days per joint to 15 days total. [Viola] Can we use butt welds in all locations? YES. What should be assumed for NDT? Qualify welds, and then do visual inspection after each pass and die pen. on finished welds. Check with RK and EWI. How long will it take for each joint? MV will reduce time to 15 days (is currently 20 per joint) for all 5 welds in a field period in Job #1810. Considering that these joints will be welded, do we need tight fitting bushings everywhere? What is the minimum number needed? – – – Cost est. per flange to measure and drill in place is 10 days. Brad’s concern and reason for maintaining all bushings: will the castings “walk” relative to each other due to repeated heating and cool-down cycles? Base estimate on 2 bushings per flange on end bolts. • • Assume double eccentric bushings with one section being steel and other being G 10 CR. ~$300 each. What should be assumed on the C-C bolting? – – Adding 3 bolts t&b will reduce deflections on IL from. 020 to. 009. In any case, the first bolt needs to be bigger. Assume 3 bolts t&b for estimate – ask Kevin to run 1 bolt t&b with the one bolt as far down as possible. (Job 1431 for buying bolts; 1459 for drilling the holes; installing in 7503 PLUS design time in 1421. Sliders: design in 1421; hardware in 1431; installing in 7503.

Welded Interface issues • • What are the clamping requirements? RESOLVED with bolts. Clamping requirement – baseline is to add 2 bolts (located to minimize the max span between bolts) to A-A, A-B, and B-C interfaces to provide clamping pressure during welding to minimize distortion. Affected jobs include the following: – – – • • Add boring/tapping holes to punchlist job (1459). Assume 2 man-days (1 calendar day) per hole. [Chrzanowski] Add cost of bolts to 1431. [Dudek] Add time to install prior to welding under 1810. Expected reduction from 20 days per joint to 15 days total. [Viola] Can we use butt welds in all locations? YES. What should be assumed for NDT? Qualify welds, and then do visual inspection after each pass and die pen. on finished welds. Check with RK and EWI. How long will it take for each joint? MV will reduce time to 15 days (is currently 20 per joint) for all 5 welds in a field period in Job #1810. Considering that these joints will be welded, do we need tight fitting bushings everywhere? What is the minimum number needed? – – – Cost est. per flange to measure and drill in place is 10 days. Brad’s concern and reason for maintaining all bushings: will the castings “walk” relative to each other due to repeated heating and cool-down cycles? Base estimate on 2 bushings per flange on end bolts. • • Assume double eccentric bushings with one section being steel and other being G 10 CR. ~$300 each. What should be assumed on the C-C bolting? – – Adding 3 bolts t&b will reduce deflections on IL from. 020 to. 009. In any case, the first bolt needs to be bigger. Assume 3 bolts t&b for estimate – ask Kevin to run 1 bolt t&b with the one bolt as far down as possible. (Job 1431 for buying bolts; 1459 for drilling the holes; installing in 7503 PLUS design time in 1421. Sliders: design in 1421; hardware in 1431; installing in 7503.

Clamping for welds • Clamps will be water-jet cut “shoes” (slide on hard clamp) fitted to the shape of the flanges. – Concern: flange surface facing clamps is not machined – how to fit it? ? – Estimate is 20 days/coil –currently in MV’s estimate (job #1810). • • • Concern is twisting due to weld shrinkage. Clamps would be there until weld tacks are made and then removed. Alternative: A bolt within 18”. – 2 m-d for first; 1 for second. • Actual welding of 2 castings is probably the only definitive test. – If distortion did occur, it would spring back after welds were ground out. • • We should ask EWI about clamping. Rob notes that W 7 X claims to have a deep understanding of weld distortion and control.

Clamping for welds • Clamps will be water-jet cut “shoes” (slide on hard clamp) fitted to the shape of the flanges. – Concern: flange surface facing clamps is not machined – how to fit it? ? – Estimate is 20 days/coil –currently in MV’s estimate (job #1810). • • • Concern is twisting due to weld shrinkage. Clamps would be there until weld tacks are made and then removed. Alternative: A bolt within 18”. – 2 m-d for first; 1 for second. • Actual welding of 2 castings is probably the only definitive test. – If distortion did occur, it would spring back after welds were ground out. • • We should ask EWI about clamping. Rob notes that W 7 X claims to have a deep understanding of weld distortion and control.

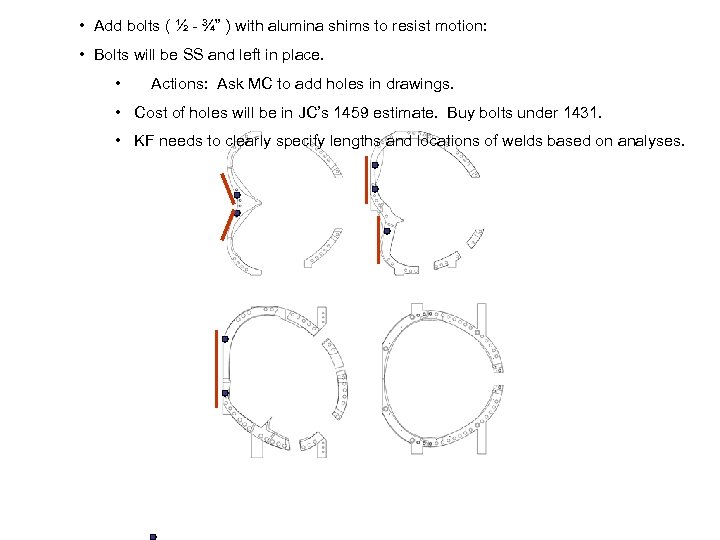

• Add bolts ( ½ - ¾” ) with alumina shims to resist motion: • Bolts will be SS and left in place. • Actions: Ask MC to add holes in drawings. • Cost of holes will be in JC’s 1459 estimate. Buy bolts under 1431. • KF needs to clearly specify lengths and locations of welds based on analyses.

• Add bolts ( ½ - ¾” ) with alumina shims to resist motion: • Bolts will be SS and left in place. • Actions: Ask MC to add holes in drawings. • Cost of holes will be in JC’s 1459 estimate. Buy bolts under 1431. • KF needs to clearly specify lengths and locations of welds based on analyses.