e3dca12f23d2137abc3e1b442ce4d769.ppt

- Количество слайдов: 43

Mc. Graw-Hill/Irwin Copyright © 2009 by The Mc. Graw-Hill Companies, Inc. All rights reserved.

Chapter 9 A Process Capability and SPC

9 A-3 OBJECTIVES • Process Variation • Process Capability • Process Control Procedures – – Variable data Attribute data • Acceptance Sampling – Operating Characteristic Curve

9 A-4 Basic Forms of Variation Assignable variation is caused by factors that can be clearly identified and possibly managed Common variation is inherent in the production process Example: A poorly trained employee that creates variation in finished product output. Example: A molding process that always leaves “burrs” or flaws on a molded item.

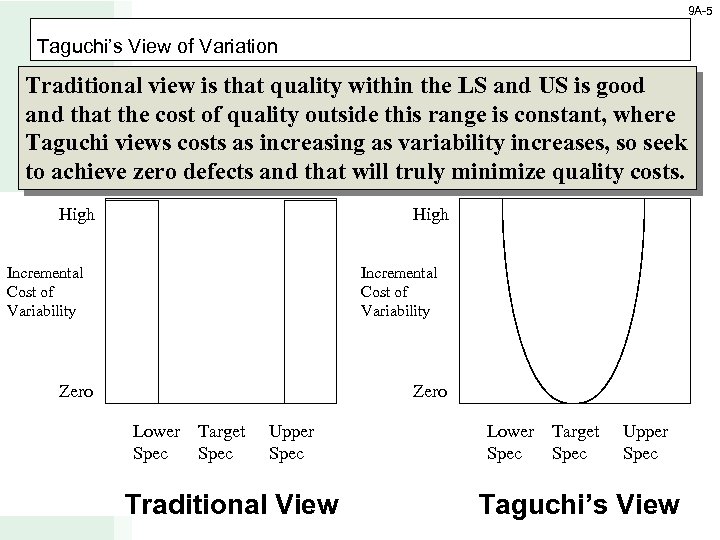

9 A-5 Taguchi’s View of Variation Traditional view is that quality within the LS and US is good and that the cost of quality outside this range is constant, where Taguchi views costs as increasing as variability increases, so seek to achieve zero defects and that will truly minimize quality costs. High Incremental Cost of Variability Zero Lower Spec Target Spec Upper Spec Traditional View Lower Spec Target Spec Upper Spec Taguchi’s View

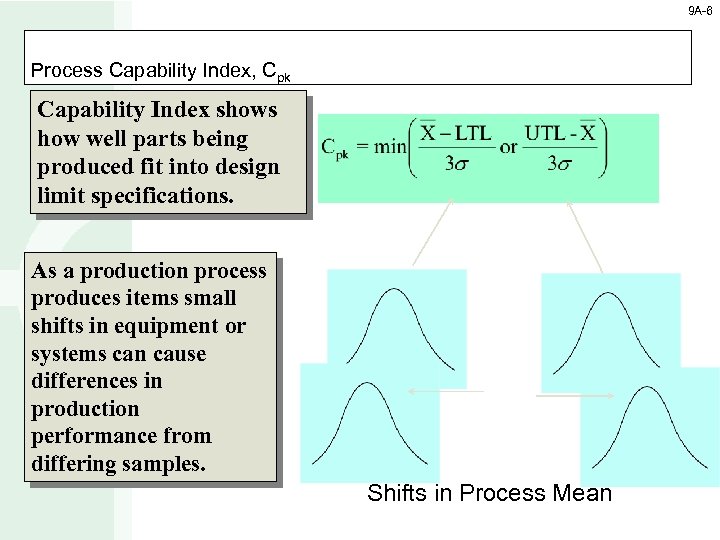

9 A-6 Process Capability Index, Cpk Capability Index shows how well parts being produced fit into design limit specifications. As a production process produces items small shifts in equipment or systems can cause differences in production performance from differing samples. Shifts in Process Mean

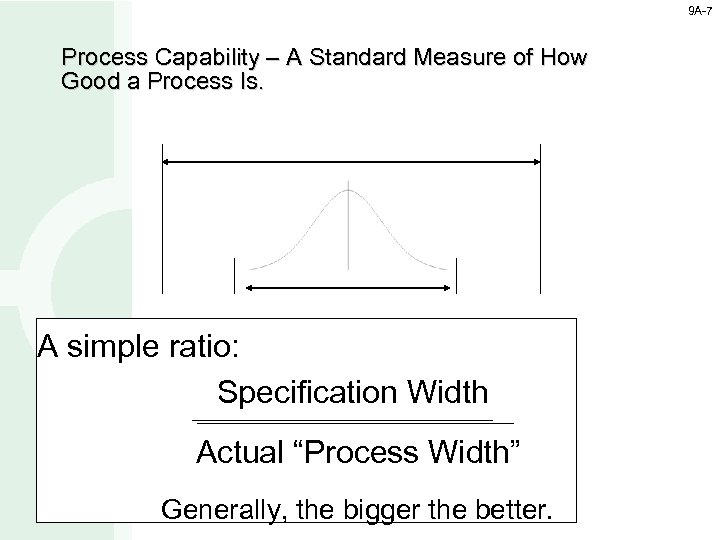

9 A-7 Process Capability – A Standard Measure of How Good a Process Is. A simple ratio: Specification Width _____________________________ Actual “Process Width” Generally, the bigger the better.

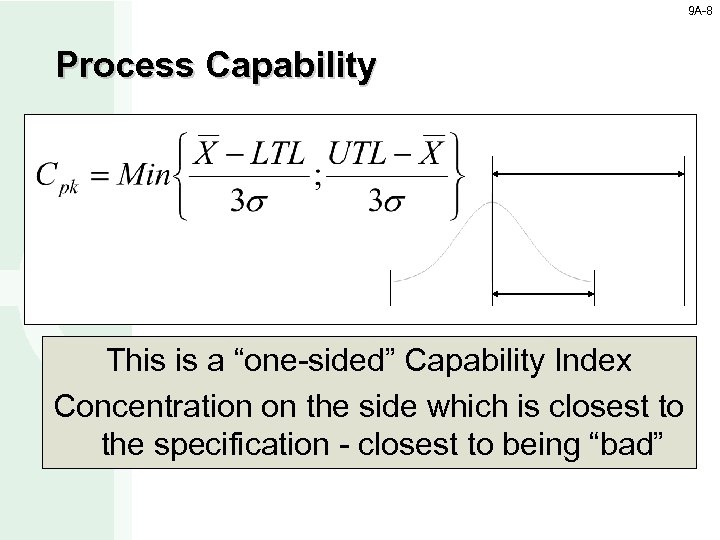

9 A-8 Process Capability This is a “one-sided” Capability Index Concentration on the side which is closest to the specification - closest to being “bad”

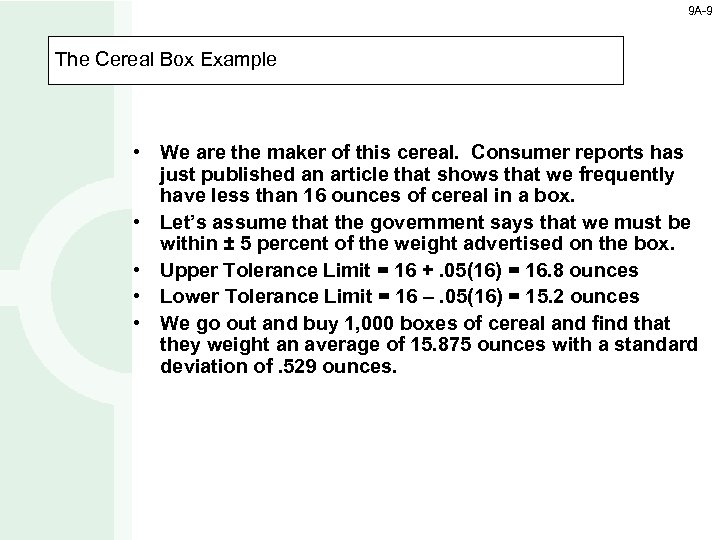

9 A-9 The Cereal Box Example • We are the maker of this cereal. Consumer reports has just published an article that shows that we frequently have less than 16 ounces of cereal in a box. • Let’s assume that the government says that we must be within ± 5 percent of the weight advertised on the box. • Upper Tolerance Limit = 16 +. 05(16) = 16. 8 ounces • Lower Tolerance Limit = 16 –. 05(16) = 15. 2 ounces • We go out and buy 1, 000 boxes of cereal and find that they weight an average of 15. 875 ounces with a standard deviation of. 529 ounces.

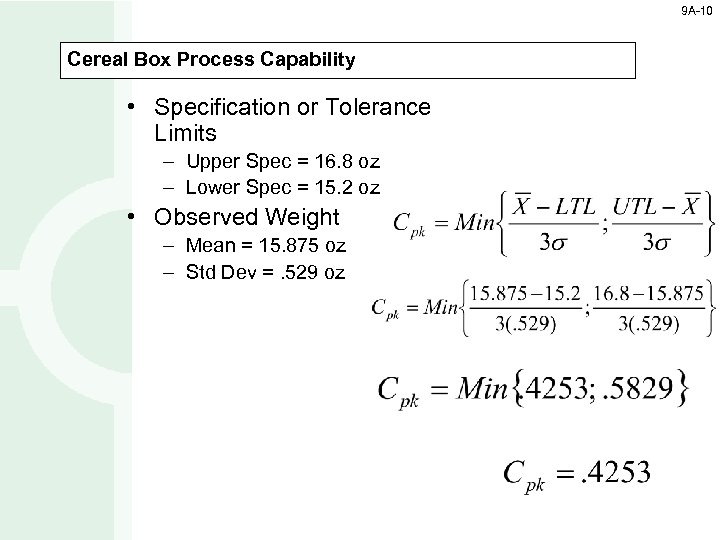

9 A-10 Cereal Box Process Capability • Specification or Tolerance Limits – Upper Spec = 16. 8 oz – Lower Spec = 15. 2 oz • Observed Weight – Mean = 15. 875 oz – Std Dev =. 529 oz

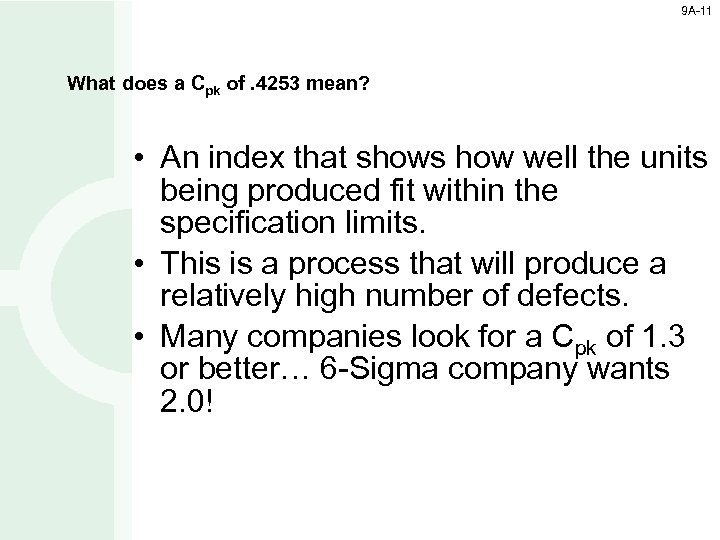

9 A-11 What does a Cpk of. 4253 mean? • An index that shows how well the units being produced fit within the specification limits. • This is a process that will produce a relatively high number of defects. • Many companies look for a Cpk of 1. 3 or better… 6 -Sigma company wants 2. 0!

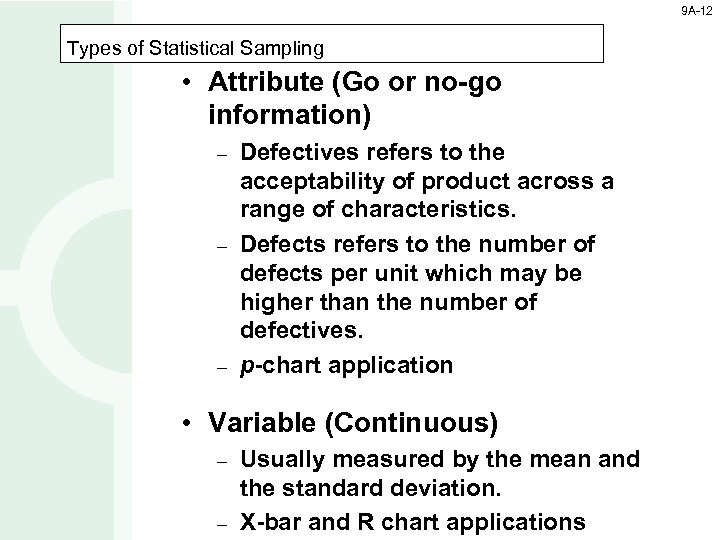

9 A-12 Types of Statistical Sampling • Attribute (Go or no-go information) – – – Defectives refers to the acceptability of product across a range of characteristics. Defects refers to the number of defects per unit which may be higher than the number of defectives. p-chart application • Variable (Continuous) – – Usually measured by the mean and the standard deviation. X-bar and R chart applications

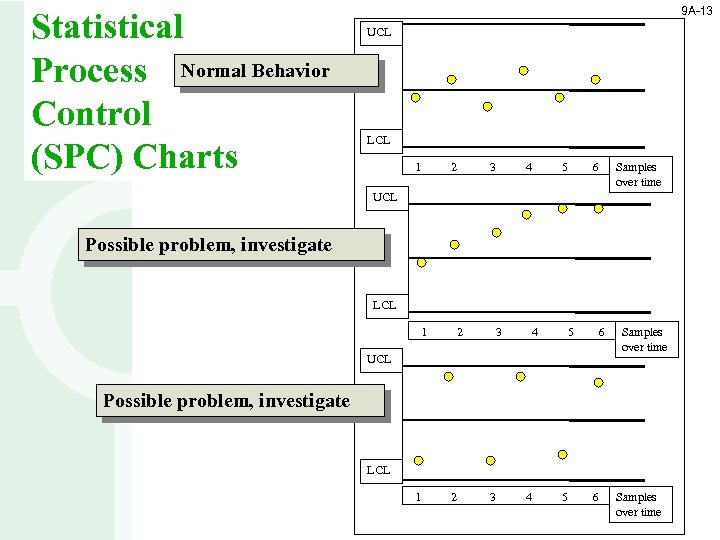

Statistical Process Normal Behavior Control (SPC) Charts 9 A-13 UCL LCL 1 2 3 4 5 6 Samples over time UCL Possible problem, investigate LCL 1 2 3 4 5 6 UCL Samples over time Possible problem, investigate LCL 1 2 3 4 5 6 Samples over time

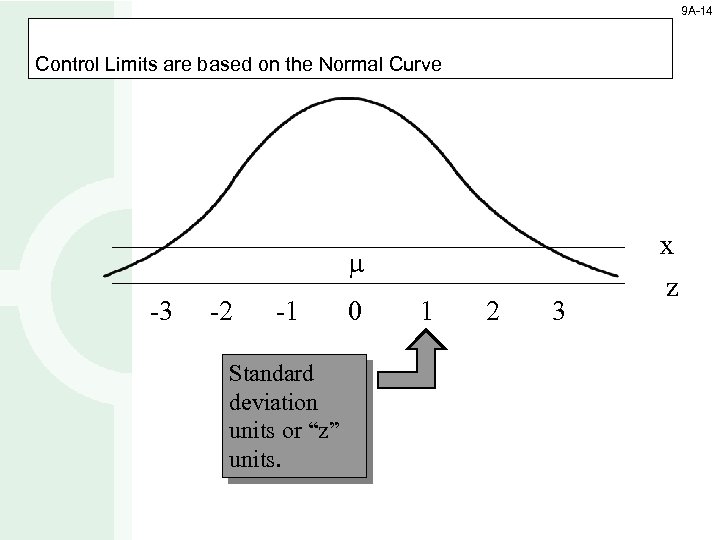

9 A-14 Control Limits are based on the Normal Curve m -3 -2 -1 Standard deviation units or “z” units. 0 1 2 3 x z

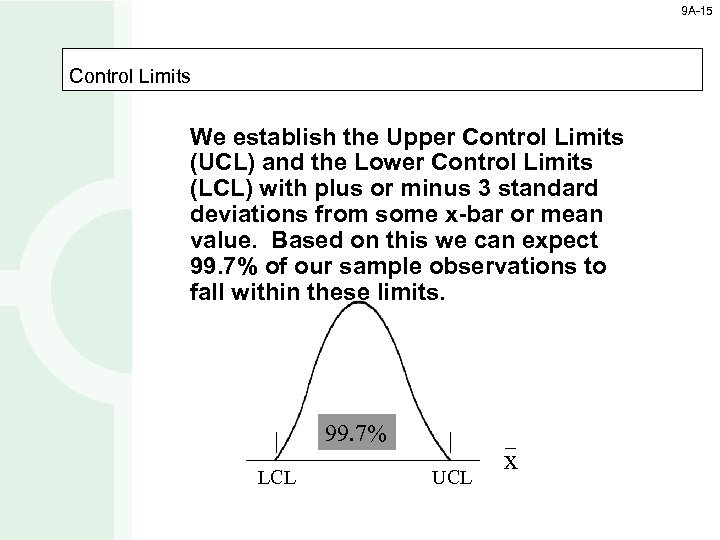

9 A-15 Control Limits We establish the Upper Control Limits (UCL) and the Lower Control Limits (LCL) with plus or minus 3 standard deviations from some x-bar or mean value. Based on this we can expect 99. 7% of our sample observations to fall within these limits. 99. 7% LCL UCL x

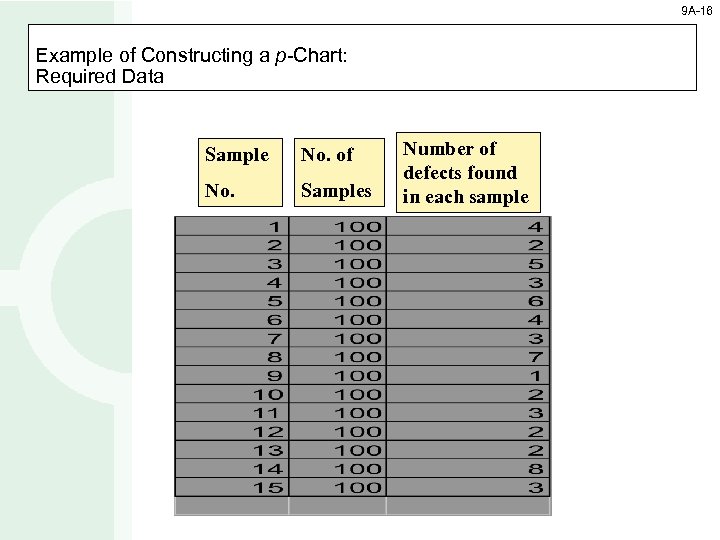

9 A-16 Example of Constructing a p-Chart: Required Data Sample No. of No. Samples Number of defects found in each sample

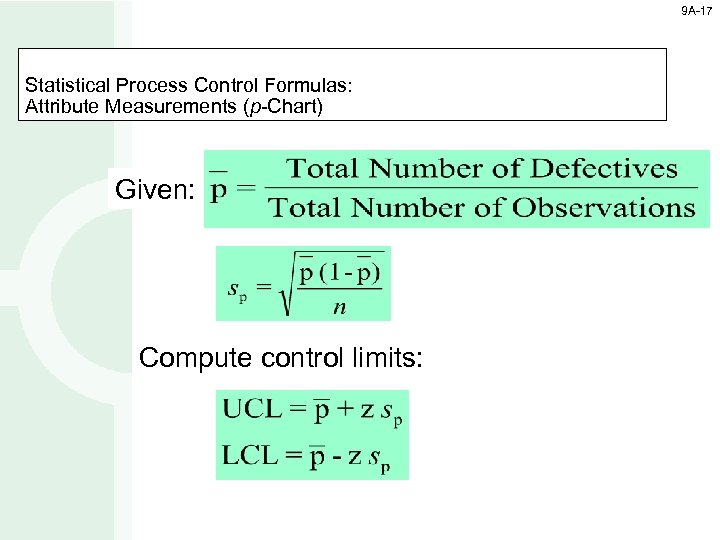

9 A-17 Statistical Process Control Formulas: Attribute Measurements (p-Chart) Given: Compute control limits:

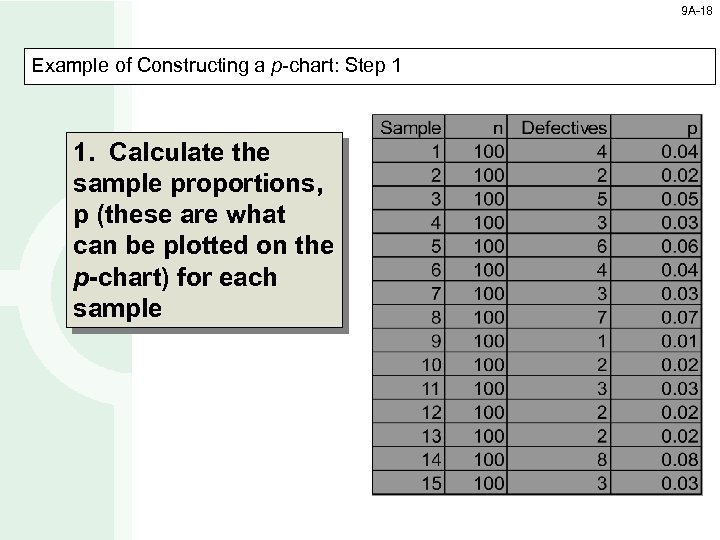

9 A-18 Example of Constructing a p-chart: Step 1 1. Calculate the sample proportions, p (these are what can be plotted on the p-chart) for each sample

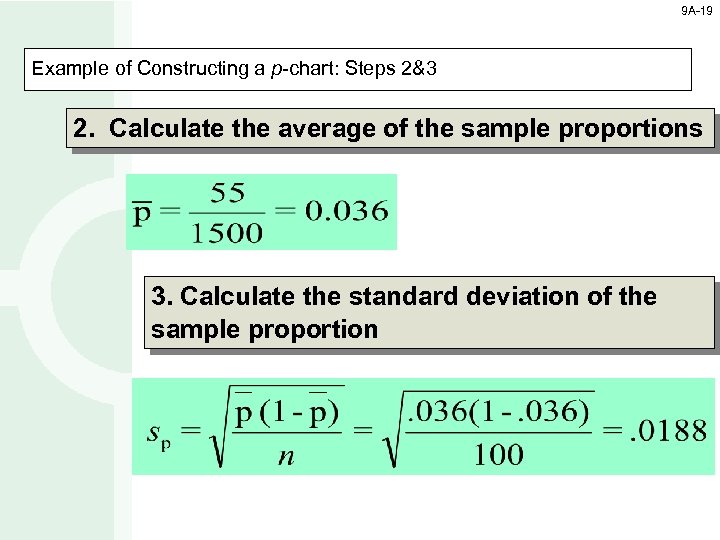

9 A-19 Example of Constructing a p-chart: Steps 2&3 2. Calculate the average of the sample proportions 3. Calculate the standard deviation of the sample proportion

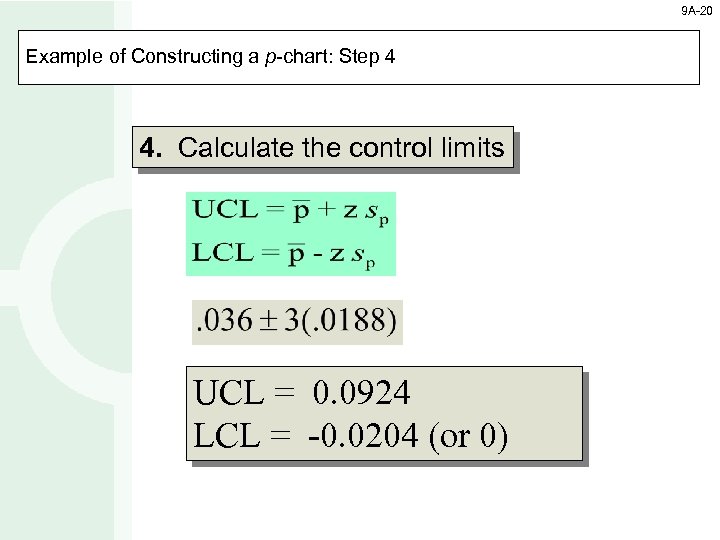

9 A-20 Example of Constructing a p-chart: Step 4 4. Calculate the control limits UCL = 0. 0924 LCL = -0. 0204 (or 0)

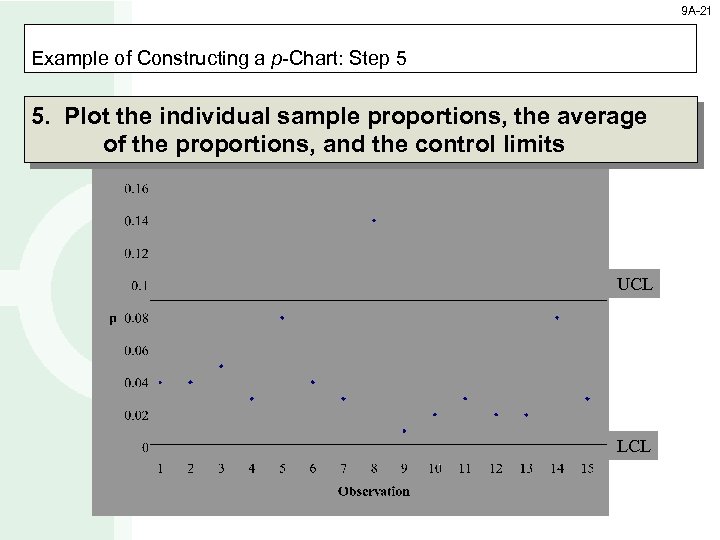

9 A-21 Example of Constructing a p-Chart: Step 5 5. Plot the individual sample proportions, the average of the proportions, and the control limits UCL LCL

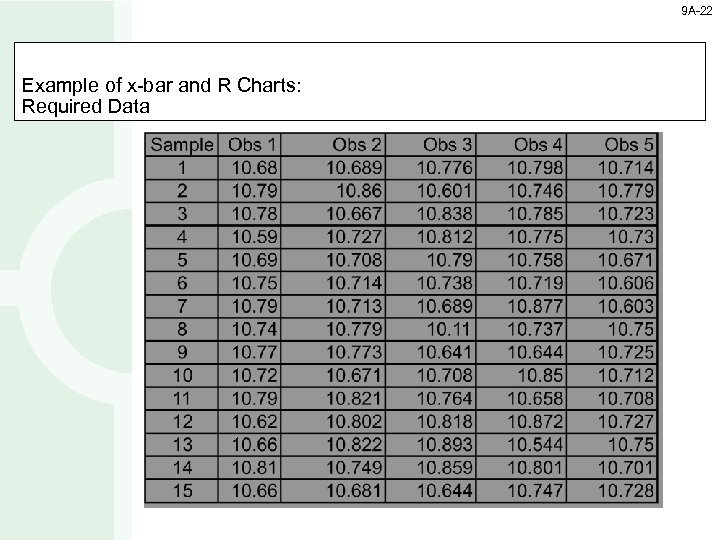

9 A-22 Example of x-bar and R Charts: Required Data

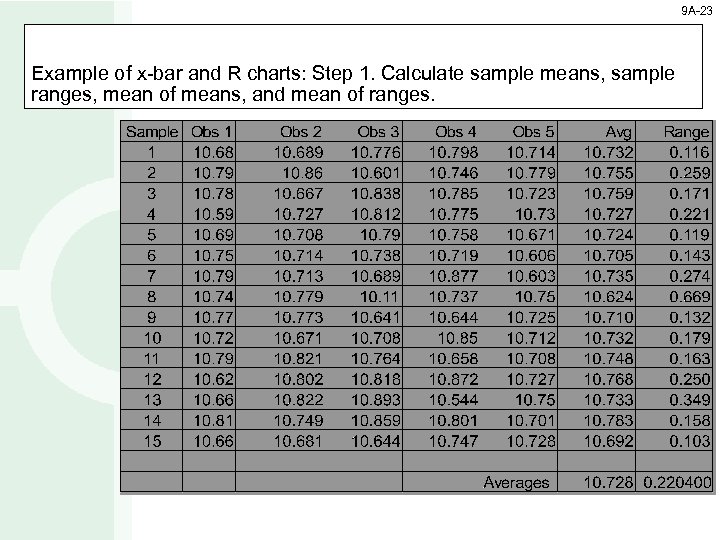

9 A-23 Example of x-bar and R charts: Step 1. Calculate sample means, sample ranges, mean of means, and mean of ranges.

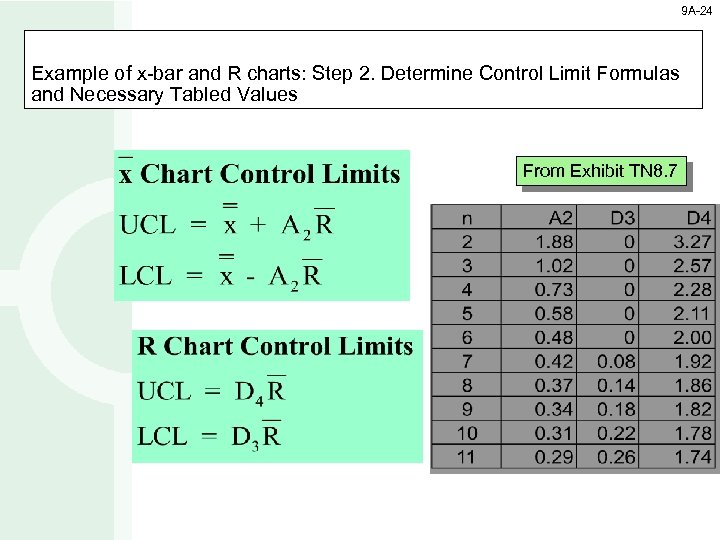

9 A-24 Example of x-bar and R charts: Step 2. Determine Control Limit Formulas and Necessary Tabled Values From Exhibit TN 8. 7

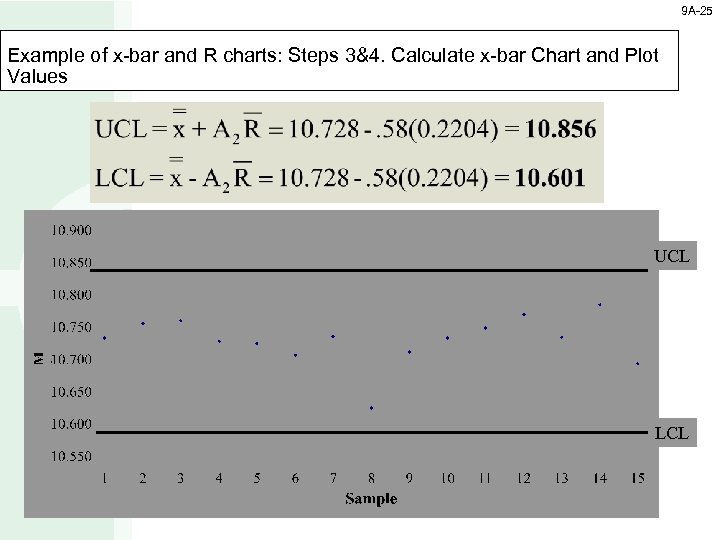

9 A-25 Example of x-bar and R charts: Steps 3&4. Calculate x-bar Chart and Plot Values UCL LCL

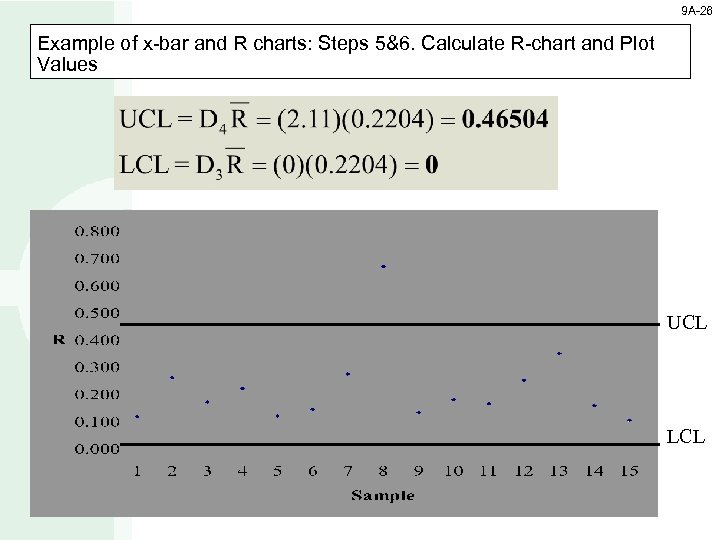

9 A-26 Example of x-bar and R charts: Steps 5&6. Calculate R-chart and Plot Values UCL LCL

9 A-27 Basic Forms of Statistical Sampling for Quality Control • Acceptance Sampling is sampling to accept or reject the immediate lot of product at hand • Statistical Process Control is sampling to determine if the process is within acceptable limits

9 A-28 Acceptance Sampling • Purposes – – Determine quality level Ensure quality is within predetermined level • Advantages – – – Economy Less handling damage Fewer inspectors Upgrading of the inspection job Applicability to destructive testing Entire lot rejection (motivation for improvement)

9 A-29 Acceptance Sampling (Continued) • Disadvantages – – – Risks of accepting “bad” lots and rejecting “good” lots Added planning and documentation Sample provides less information than 100 -percent inspection

9 A-30 Acceptance Sampling: Single Sampling Plan A simple goal Determine (1) how many units, n, to sample from a lot, and (2) the maximum number of defective items, c, that can be found in the sample before the lot is rejected

9 A-31 Risk • Acceptable Quality Level (AQL) – Max. acceptable percentage of defectives defined by producer • The a (Producer’s risk) – The probability of rejecting a good lot • Lot Tolerance Percent Defective (LTPD) – Percentage of defectives that defines consumer’s rejection point • The (Consumer’s risk) – The probability of accepting a bad lot

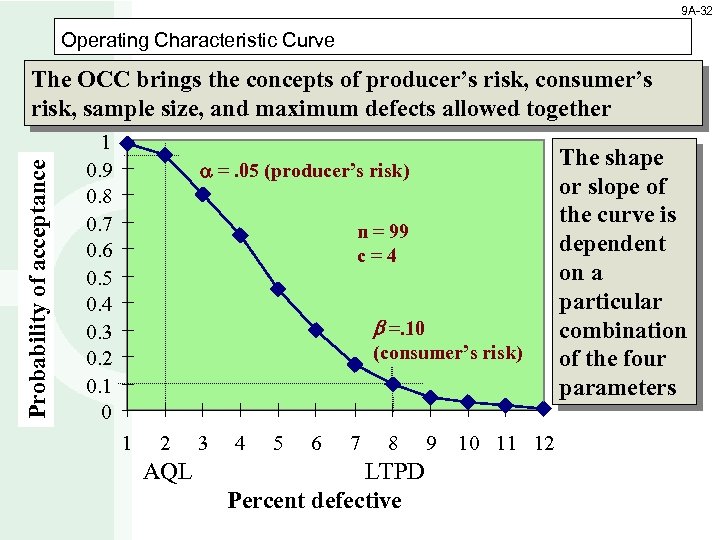

9 A-32 Operating Characteristic Curve Probability of acceptance The OCC brings the concepts of producer’s risk, consumer’s risk, sample size, and maximum defects allowed together 1 0. 9 0. 8 0. 7 0. 6 0. 5 0. 4 0. 3 0. 2 0. 1 0 a =. 05 (producer’s risk) n = 99 c=4 =. 10 (consumer’s risk) 1 2 AQL 3 4 5 6 7 8 LTPD Percent defective 9 10 11 12 The shape or slope of the curve is dependent on a particular combination of the four parameters

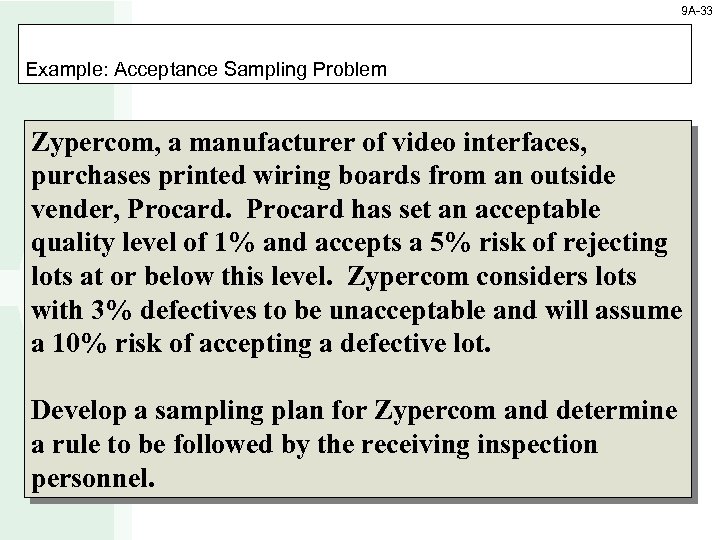

9 A-33 Example: Acceptance Sampling Problem Zypercom, a manufacturer of video interfaces, purchases printed wiring boards from an outside vender, Procard has set an acceptable quality level of 1% and accepts a 5% risk of rejecting lots at or below this level. Zypercom considers lots with 3% defectives to be unacceptable and will assume a 10% risk of accepting a defective lot. Develop a sampling plan for Zypercom and determine a rule to be followed by the receiving inspection personnel.

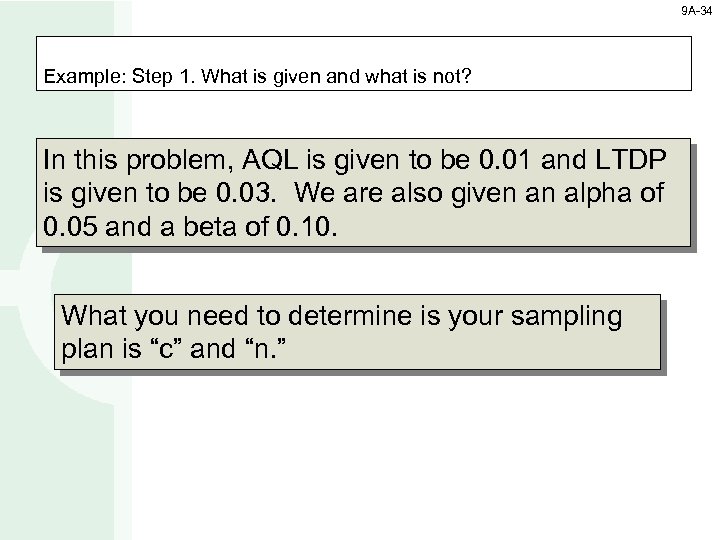

9 A-34 Example: Step 1. What is given and what is not? In this problem, AQL is given to be 0. 01 and LTDP is given to be 0. 03. We are also given an alpha of 0. 05 and a beta of 0. 10. What you need to determine is your sampling plan is “c” and “n. ”

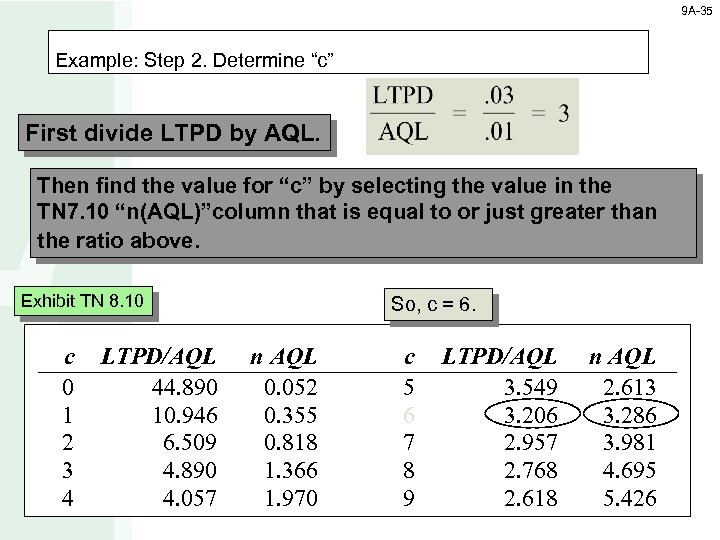

9 A-35 Example: Step 2. Determine “c” First divide LTPD by AQL. Then find the value for “c” by selecting the value in the TN 7. 10 “n(AQL)”column that is equal to or just greater than the ratio above. Exhibit TN 8. 10 c 0 1 2 3 4 LTPD/AQL 44. 890 10. 946 6. 509 4. 890 4. 057 So, c = 6. n AQL 0. 052 0. 355 0. 818 1. 366 1. 970 c 5 6 7 8 9 LTPD/AQL 3. 549 3. 206 2. 957 2. 768 2. 618 n AQL 2. 613 3. 286 3. 981 4. 695 5. 426

9 A-36 Question Bowl A methodology that is used to show well parts being produced fit into a range specified by design limits is which of the following? a. Capability index b. Producer’s risk c. Consumer’s risk d. AQL e. None of the above Answer: a. Capability index

9 A-37 Question Bowl On a quality control chart if one of the values plotted falls outside a boundary it should signal to the production manager to do which of the following? a. System is out of control, should be stopped and fixed b. System is out of control, but can still be operated without any concern c. System is only out of control if the number of observations falling outside the boundary exceeds statistical expectations d. System is OK as is e. None of the above Answer: c. System is only out of control if the number of observations falling outside the boundary exceeds statistical expectations

9 A-38 Question Bowl You want to prepare a p chart and you observe 200 samples with 10 in each, and find 5 defective units. What is the resulting “fraction defective”? a. 25 b. 2. 5 c. 0. 0025 d. 0. 00025 e. Can not be computed on data above Answer: c. 0. 0025 (5/(2000 x 10)=0. 0025)

9 A-39 Question Bowl You want to prepare an x-bar chart. If the number of observations in a “subgroup” is 10, what is the appropriate “factor” used in the computation of the UCL and LCL? a. 1. 88 b. 0. 31 c. 0. 22 d. 1. 78 e. None of the above Answer: b. 0. 31

9 A-40 Question Bowl You want to prepare an R chart. If the number of observations in a “subgroup” is 5, what is the appropriate “factor” used in the computation of the LCL? a. 0 b. 0. 88 Answer: a. 0 c. 1. 88 d. 2. 11 e. None of the above

9 A-41 Question Bowl You want to prepare an R chart. If the number of observations in a “subgroup” is 3, what is the appropriate “factor” used in the computation of the UCL? a. 0. 87 b. 1. 00 c. 1. 88 d. 2. 11 e. None of the above Answer: e. None of the above

9 A-42 Question Bowl The maximum number of defectives that can be found in a sample before the lot is rejected is denoted in acceptance sampling as which of the following? a. Alpha b. Beta c. AQL Answer: d. c e. None of the above

9 A-43 End of Chapter 9 A 1 -43

e3dca12f23d2137abc3e1b442ce4d769.ppt