3866cb9b9e2f32d8604f881a9ed200e2.ppt

- Количество слайдов: 38

Mc. Graw-Hill/Irwin 11 -1 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved.

Chapter 11 Sourcing 11 -2

Key Concepts • The Strategic Sourcing Plan • Discovering Potential Suppliers • Evaluating Potential Suppliers • Selecting Suppliers » Bidding Versus Negotiation » Reverse Auctions » Two-Step Bidding/Negotiation » The Solicitation » Weighted-Factor Analysis » Responsibility for Source Selection • Developing Suppliers • Managing Suppliers 11 -3

Key Concepts • Additional Strategic Issues » Early Supplier Involvement » Supply Base Reduction » Single Versus Multiple Sourcing » Share of Supplier’s Capacity » Local, National and International Sourcing » Manufacturer or Distributor » “Green” Supply Management » Minority- And Women-Owned Business Enterprises » Ethical Considerations » Reciprocity 11 -4

The Strategic Sourcing Plan • World class Supply Management requires supply management to develop a strategic sourcing plan that details how supply management will discover, evaluate, select, develop and manage a viable supplier base 11 -5

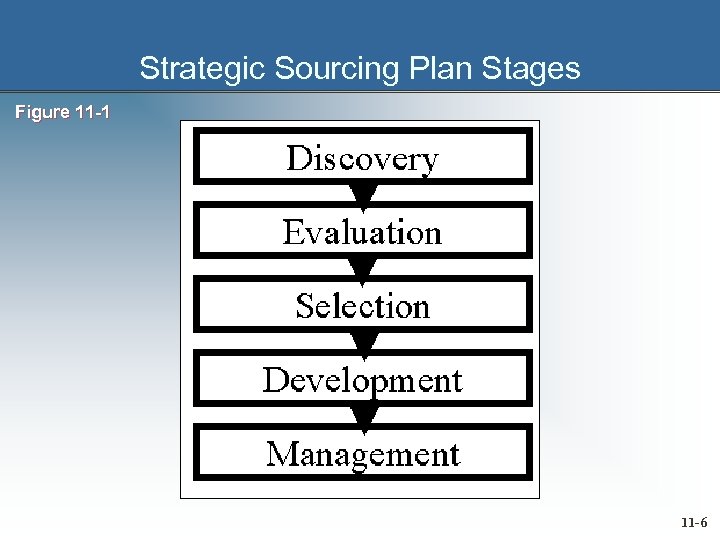

Strategic Sourcing Plan Stages Figure 11 -1 11 -6

Discovery • Supplier Web Sites • Supplier Information Files • Filing of Mailing Pieces • Sales Personnel • Supplier Catalogs • Trade Shows • Trade Registers & Directories • Company Personnel • Trade Journals • Phone Directories • Other Supply Management Departments • Professional Organizations 11 -7

Evaluating Potential Suppliers • Supplier Surveys • Financial Condition Analysis • Third Party Evaluators • Evaluation Conference • Facility Visits • Quality Capability Analysis • Capacity Capability Analysis • Management Capability Analysis • Service Capability Analysis • Flexibility Capability Analysis • Information Technology Capability Analysis 11 -8

Selecting Suppliers • Bidding Versus Negotiation • Reverse Auctions • Two-Step Bidding/Negotiation • The Solicitation • Weighted-Factor Analysis • Responsibility for Source Selection 11 -9

Bidding versus Negotiation • Few topics generate more passionate discussions than bidding versus negotiation • The selection of bidding or negotiation should be decided by using objective criteria, a total cost perspective and sound supply management logic 11 -10

Prerequisites to Bidding • Dollar value must be large • Specifications must be clear • Market must consist of an adequate number of sellers • Sellers must be qualified and want the contract • Time available must be sufficient 11 -11

Conditions Demanding Negotiation • Impossible to estimate costs with a high degree of certainty • Price is not the only important variable • Purchasing firm anticipates a need to make changes in the specification • Special tooling of setup costs are major factors 11 -12

Even if the previous list is met… here are two arguments for Negotiation • The negotiation process is far more likely to lead to a complete understanding of all issues of the procurement • Competitive bidding tends to result in sacrifices in product quality, development efforts, and other vital services 11 -13

Reverse Auctions In contrast to competitive bidding, reverse auctions produce “real-time” interaction. Though effective for achieving cost savings, reverse auctions are not appropriate for all situations. Reverse bid process can have an adverse affect on long-term relationships. 11 -14

Two-Step Bidding/Negotiation • Used in situations where inadequate specifications preclude the initial use of traditional competitive bidding • The two steps are: » Step 1: Technical Proposals – IFBs for Step 2 are sent only to those sellers who submitted acceptable technical proposals » Step 2: Price Bidding 11 -15

The Solicitation • IFB • RFP • Item description • Info on quantities • Delivery schedules • Special terms and conditions • Standard terms and conditions 11 -16

Weighted Factor Analysis • Steps to developing » Develop factors to serve as criteria » Develop sub-factors or performance factors » Develop a scoring factor » Score or evaluate the supplier 11 -17

Developing Suppliers • Development of suppliers is one of the greatest untapped frontiers in supply chain management • Even suppliers recognized as the “best of the best” require investment on the part of the buying firm to realize the full benefit of the collaborative relationship • This important topic is addressed in detail in the chapter on Supplier Development 11 -18

Managing Suppliers • Managers must ensure the suppliers perform as required. • Suppliers must meet the firm’s long-term needs. • If suppliers are unlikely to meet future requirements the firm may: » Assist with financing / technological assistance. » Develop new sources. » Be required to develop the capability internally. 11 -19

Additional Strategic Issues • Early Supplier Involvement • Supply Base Reduction • Single Versus Multiple Sourcing • Share of Supplier’s Capacity • Local, National and International Sourcing • Manufacturer or Distributor • “Green” Supply Management • Minority- And Women-Owned Business Enterprises • Ethical Considerations • Reciprocity 11 -20

Early Supplier Involvement • Early supplier involvement (ESI) is an approach in supply management to bring the expertise and collaborative synergy of suppliers into the design process • ESI seeks to find “win-win” opportunities • Today, early supplier involvement (ESI) is an accepted way of life at many proactive firms and a requirement for WCSM 11 -21

ESI Opportunities • Materials • Processes • Services • Packaging • Technology • Transportation • Specifications and Tolerances • Redesigns • Standards • Design Cycle Time • Order Quantities • Inventory Reductions • Assembly Changes • Lead Time 11 -22

Reasons for Utilizing ESI • Get supplier inputs before the design is frozen • Capitalize on the latest technology • Save time since design cycles are getting shorter • Let the supplier know that it is part of the team 11 -23

Supply Base Reduction • Supply base reduction is achieved through both reducing variety and increasing consolidation • Two benefits of supply base reduction cited by John Deere are: » increased leverage with suppliers » better focus and supplier integration in product development • Increased leverage is also due to the increased involvement with the suppliers which builds goodwill and trust 11 -24

Considerations for Single Sourcing • Lower total cost results from higher volume • Quality considerations dictate • Buyer obtains more influence with the supplier • Lower costs to source, process, expedite, inspect • Just-in-time requirements • Significantly lower freight costs may result • Special tooling is required • Total system inventory will be reduced • Supplier will have an improved commitment • Improved interdependency and risk sharing result • Time to market is critical 11 -25

Dual Sourcing Using the “ 70 -30” Approach • 70 percent of the volume is awarded to one supplier • 30 percent to a second supplier • Economies of scale are obtained from the “big supplier” • The “little supplier” provides competition • When the “big supplier” fails to perform the percentages may be reversed by the buyer 11 -26

Considerations for Multiple Sourcing • Protect the buyer during bad times • Maintain competition • Provide a back-up source • Meet local content requirements • Meet customer’s volume requirements • When the customer is a small player in the market for a specific item • Avoid complacency on the part of a supplier • When the technology path is uncertain • Suppliers tend to “leapfrog” in technology 11 -27

Share of Supplier’s Capacity • Many firms try to not exceed more than 15 to 25 percent of any one supplier’s capacity • This issue became all too real in the early 2000 s » Many companies cancelled orders that had long supplier lead times, which resulted in suppliers being caught with, in some cases, hundreds of millions of dollars of work-inprocess 11 -28

Local, National and International Sourcing • The lines between local, national, and international sourcing have become blurred in the last 30 years • Local source » Firm’s headquarters and all facilities are located in the city or region where the materials or services will be used • National source » The source is headquartered within the country and has facilities in multiple regions throughout the country • International source » Firm is headquartered outside of the buying firm’s country, but this does not define the location of operations 11 -29

Local Buying Advantages • Closer cooperation between buyer and seller is possible • Delivery dates are more certain • Lower prices can result from consolidated transportation and insurance • Shorter lead times reduce inventory • Rush orders are filled faster • Disputes are usually more easily resolved • Implied social responsibilities to the community are fulfilled 11 -30

National Buying Advantages • Economies of scale • Superior technical assistance • Better handling of fluctuating demand • Shortages are less likely 11 -31

Manufacturer or Distributor • Potential Benefits of a Distributor over Buying Direct from the Manufacturer » Economy of scale » Reduction of orders » Reduction of paperwork » Special services » Technical advice » Credit 11 -32

“Green” Supply Management • Recycled materials • Environmental issues • Liability issues 11 -33

Minority- And Women-Owned Business Enterprises • Many forces motivate a buying firm to ensure that MWBE businesses receive a share of the firm’s business, such as: » Federal and state legislation » Set-aside quotas in government appropriations » Actions of regulatory bodies » Firm’s “corporate social consciousness” » Customer base includes MWBE businesses and their employees » Bottom-line profitability » Good business sense 11 -34

Ethical Considerations • Conflicts of interest » Exists when supply managers must divide their loyalty between the firm which employs them and another firm » Such conflicts always should be avoided in all source selection decisions 11 -35

Reciprocity • Reciprocity exists when supply managers give preference to suppliers that are also customers • It is entirely legal to buy from one’s customers at fair market prices, without economic threat, and without the intent of restricting competition • Reciprocity can become illegal when the activity restricts competition and trade 11 -36

Reasons to Not Engage in Reciprocity • Reciprocity doesn't follow sound principles of buying and selling • Companies may relax their competitive efforts as a result of reduced competition • Sales departments may develop a false sense of security • New customers may be hard to find because of pre-established relationships with competitors • Company reputations may be impaired because of bad publicity • Conspiracy and restraint-of-trade situations can develop, with their attendant legal dangers 11 -37

Concluding Remarks • The increase in long-term collaborative relationships is highlighting the need to develop strategic sourcing plans • The plan aids in source selection by detailing how suppliers will be discovered, evaluated, selected, developed and managed • The plan should be developed in a collaborative environment that includes all relevant functional area representatives and supply chain members 11 -38

3866cb9b9e2f32d8604f881a9ed200e2.ppt