0283eed67126c407924d7e8c3752db29.ppt

- Количество слайдов: 46

Matthias Mekschrat Logistical applications and optimizations h_DA WS 2011 Logistical applications and optimizations 1

Matthias Mekschrat Logistical applications and optimizations h_DA WS 2011 Logistical applications and optimizations 1

Matthias Mekschrat overview Introduction October 28 - definition of business processes November 11 - overview of logistical business processes November 18 - functionality of purchase and supply processes December 02 - functionality of production processes December 16 - functionality of sales and distribution processes January 20 - special problems within the supply chain handling h_DA WS 2011 Logistical applications and optimizations 2

Matthias Mekschrat overview Introduction October 28 - definition of business processes November 11 - overview of logistical business processes November 18 - functionality of purchase and supply processes December 02 - functionality of production processes December 16 - functionality of sales and distribution processes January 20 - special problems within the supply chain handling h_DA WS 2011 Logistical applications and optimizations 2

Matthias Mekschrat Review on the last session You have learned about the main functionality of purchase support processes 1. Marketplaces and e-procurement 2. Vendor evaluation 3. Supplier relationship management You have learned about the main functionality of purchase execution processes 1. Purchase requirements 2. Bidding 3. Purchase order 4. Delivery and payment You have developed a supply plan You have learned about the main parts of a material requirement planning 1. Stock minus by forecast, sales orders or reservations 2. Stock plus by production orders and purchase orders You have developed an actual disposition list You have learned about vendor managed inventory as an example of purchase optimization h_DA WS 2011 Logistical applications and optimizations 3

Matthias Mekschrat Review on the last session You have learned about the main functionality of purchase support processes 1. Marketplaces and e-procurement 2. Vendor evaluation 3. Supplier relationship management You have learned about the main functionality of purchase execution processes 1. Purchase requirements 2. Bidding 3. Purchase order 4. Delivery and payment You have developed a supply plan You have learned about the main parts of a material requirement planning 1. Stock minus by forecast, sales orders or reservations 2. Stock plus by production orders and purchase orders You have developed an actual disposition list You have learned about vendor managed inventory as an example of purchase optimization h_DA WS 2011 Logistical applications and optimizations 3

Matthias Mekschrat About this lecture All sessions are split into 2 blocks: from 08: 30 to 10: 00 and from 10: 15 to 11: 45 Each session starts with a short review of the last lectures subjects Next I will give you a short theoretical overview of the days subject Next you probably will develop 3 different subjects in a brainstorming session in 3 groups Each group will then present the results of their discussions I will present theoretical explanations for the discussed subjects Then I will show a example solution for a potential written test question Finally I will give a summary of the key messages for this session h_DA WS 2011 Logistical applications and optimizations 4

Matthias Mekschrat About this lecture All sessions are split into 2 blocks: from 08: 30 to 10: 00 and from 10: 15 to 11: 45 Each session starts with a short review of the last lectures subjects Next I will give you a short theoretical overview of the days subject Next you probably will develop 3 different subjects in a brainstorming session in 3 groups Each group will then present the results of their discussions I will present theoretical explanations for the discussed subjects Then I will show a example solution for a potential written test question Finally I will give a summary of the key messages for this session h_DA WS 2011 Logistical applications and optimizations 4

Matthias Mekschrat overview Introduction October 28 - definition of business processes November 11 - overview of logistical business processes November 18 - functionality of purchase and supply processes December 02 - functionality of production processes December 16 - functionality of sales and distribution processes January 20 - special problems within the supply chain handling h_DA WS 2011 Logistical applications and optimizations 5

Matthias Mekschrat overview Introduction October 28 - definition of business processes November 11 - overview of logistical business processes November 18 - functionality of purchase and supply processes December 02 - functionality of production processes December 16 - functionality of sales and distribution processes January 20 - special problems within the supply chain handling h_DA WS 2011 Logistical applications and optimizations 5

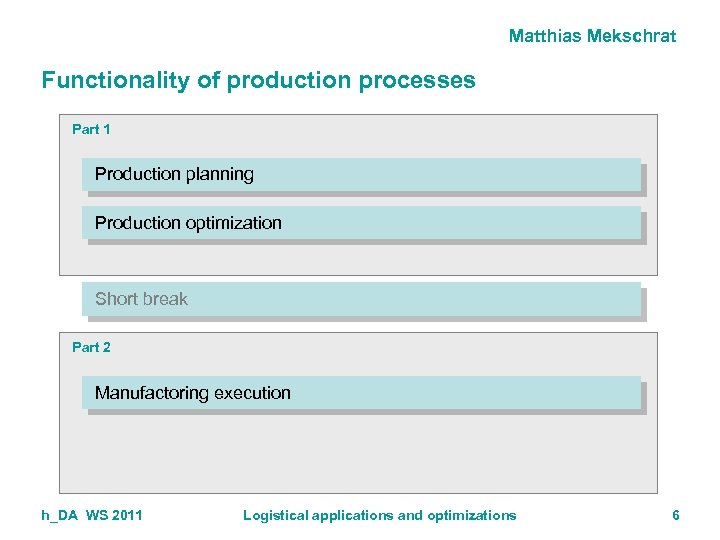

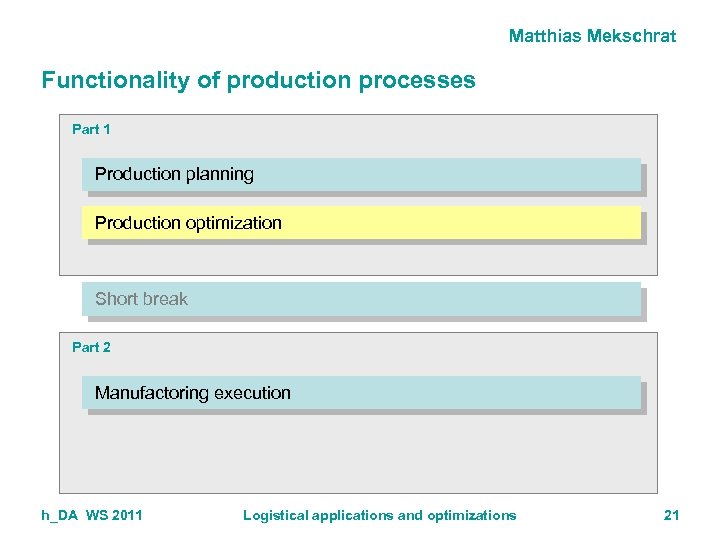

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 6

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 6

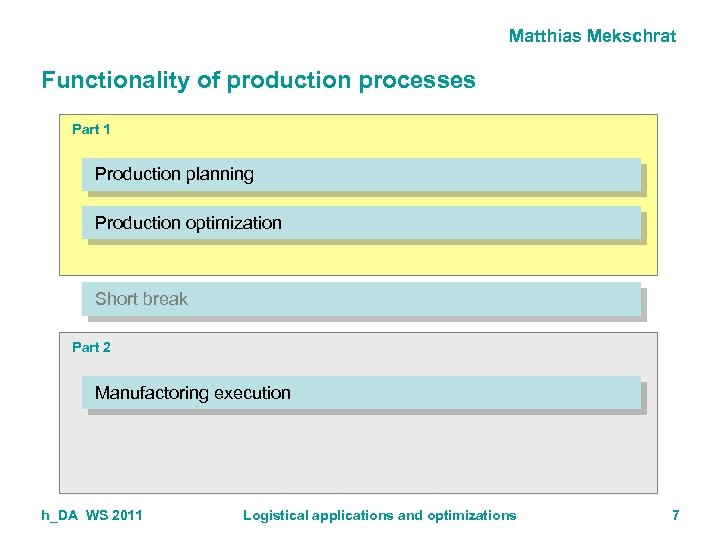

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 7

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 7

Matthias Mekschrat Functionality of production processes, Part 1 Problems and potentials Production is the core process of any manufactoring company. Therefore a well design production IT process is a very high potential. The coordination of production processes with other core logistical processes such as purchase, disposition, distribution and sales is essential for a lean supply chain organisation. The „vertical integration“ provides the interaction of both production planning and production execution processes. The challenge and the aim is the fully IT covered „paperless production“ h_DA WS 2011 Logistical applications and optimizations 8

Matthias Mekschrat Functionality of production processes, Part 1 Problems and potentials Production is the core process of any manufactoring company. Therefore a well design production IT process is a very high potential. The coordination of production processes with other core logistical processes such as purchase, disposition, distribution and sales is essential for a lean supply chain organisation. The „vertical integration“ provides the interaction of both production planning and production execution processes. The challenge and the aim is the fully IT covered „paperless production“ h_DA WS 2011 Logistical applications and optimizations 8

Matthias Mekschrat Functionality of production processes, Part 1 Learning targets Understand the main functionality of production planning system Understand the main functionality of production optimization system Understand the interaction with other processes Understand the important inputs and outputs of each component Understand the involved acting logical business units h_DA WS 2011 Logistical applications and optimizations 9

Matthias Mekschrat Functionality of production processes, Part 1 Learning targets Understand the main functionality of production planning system Understand the main functionality of production optimization system Understand the interaction with other processes Understand the important inputs and outputs of each component Understand the involved acting logical business units h_DA WS 2011 Logistical applications and optimizations 9

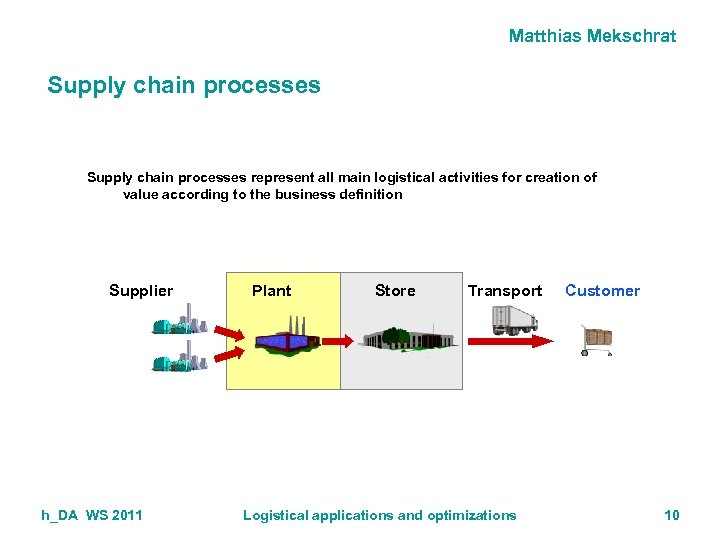

Matthias Mekschrat Supply chain processes represent all main logistical activities for creation of value according to the business definition Supplier h_DA WS 2011 Plant Store Transport Logistical applications and optimizations Customer 10

Matthias Mekschrat Supply chain processes represent all main logistical activities for creation of value according to the business definition Supplier h_DA WS 2011 Plant Store Transport Logistical applications and optimizations Customer 10

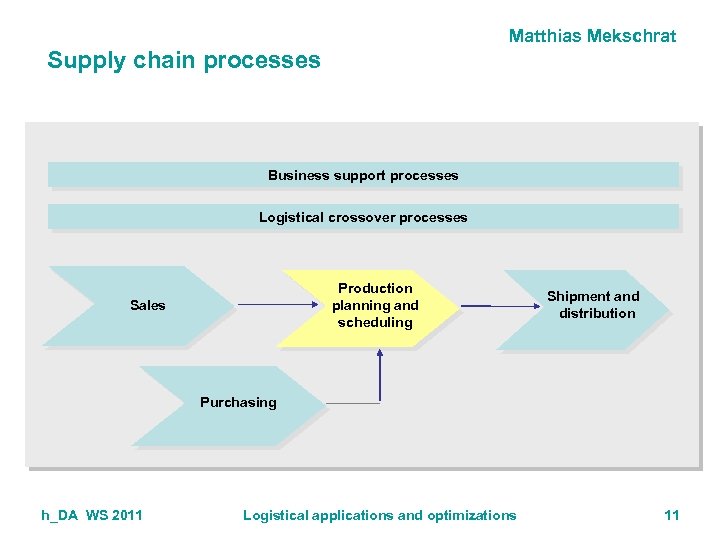

Matthias Mekschrat Supply chain processes Business support processes Logistical crossover processes Production planning and scheduling Sales Shipment and distribution Purchasing h_DA WS 2011 Logistical applications and optimizations 11

Matthias Mekschrat Supply chain processes Business support processes Logistical crossover processes Production planning and scheduling Sales Shipment and distribution Purchasing h_DA WS 2011 Logistical applications and optimizations 11

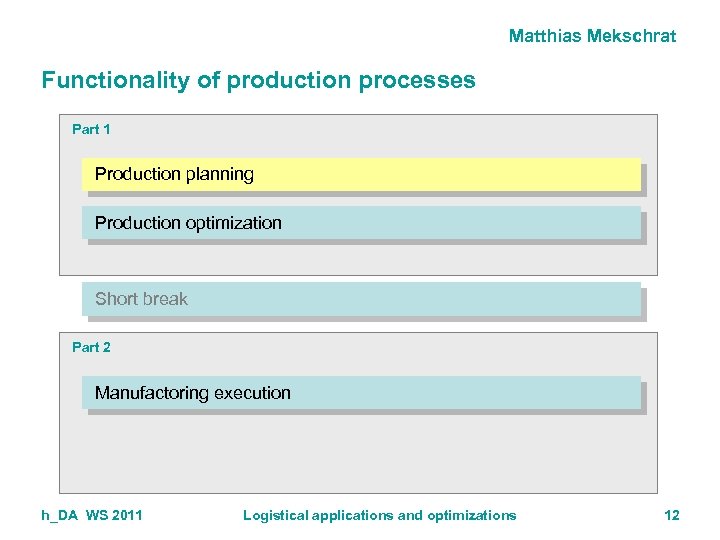

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 12

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 12

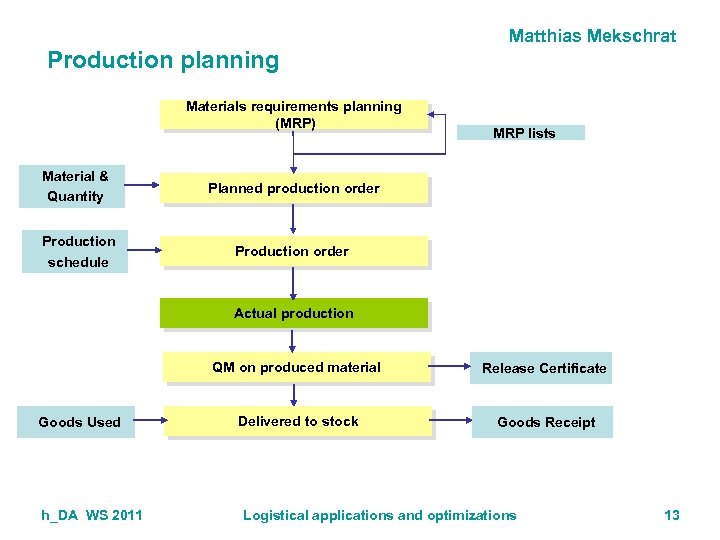

Matthias Mekschrat Production planning Materials requirements planning (MRP) Material & Quantity Planned production order Production schedule MRP lists Production order Actual production QM on produced material Goods Used h_DA WS 2011 Release Certificate Delivered to stock Goods Receipt Logistical applications and optimizations 13

Matthias Mekschrat Production planning Materials requirements planning (MRP) Material & Quantity Planned production order Production schedule MRP lists Production order Actual production QM on produced material Goods Used h_DA WS 2011 Release Certificate Delivered to stock Goods Receipt Logistical applications and optimizations 13

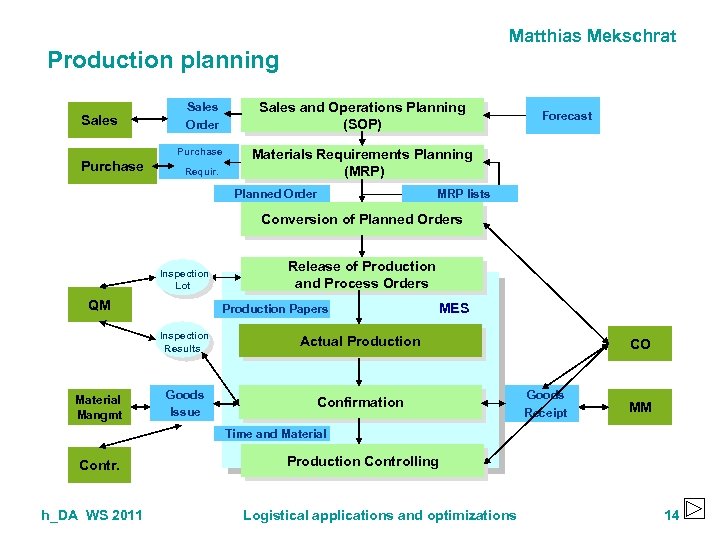

Matthias Mekschrat Production planning Purchase Sales and Operations Planning (SOP) Purchase Sales Order Materials Requirements Planning (MRP) Requir. Planned Order Forecast MRP lists Conversion of Planned Orders Inspection Lot QM Release of Production and Process Orders Production Papers Inspection Results Material Mangmt Actual Production Goods Issue MES Confirmation CO Goods Receipt MM Time and Material Contr. h_DA WS 2011 Production Controlling Logistical applications and optimizations 14

Matthias Mekschrat Production planning Purchase Sales and Operations Planning (SOP) Purchase Sales Order Materials Requirements Planning (MRP) Requir. Planned Order Forecast MRP lists Conversion of Planned Orders Inspection Lot QM Release of Production and Process Orders Production Papers Inspection Results Material Mangmt Actual Production Goods Issue MES Confirmation CO Goods Receipt MM Time and Material Contr. h_DA WS 2011 Production Controlling Logistical applications and optimizations 14

Matthias Mekschrat Production planning Sales and operations planning (Demand planning) Sales orders and forecasts are the two entries into the MRP process Sales orders are automatically delivered by the sales processes Productions directly to stock without sales orders are usually on the basis of experience leading to a forecast Forcast and sales orders are compensated Forcasts are usually done by sales departments in cooperation with at least the main customers Forcasts might as well be based on mathematical models interpreting the sales historie and extrapolating the privious data h_DA WS 2011 Logistical applications and optimizations 15

Matthias Mekschrat Production planning Sales and operations planning (Demand planning) Sales orders and forecasts are the two entries into the MRP process Sales orders are automatically delivered by the sales processes Productions directly to stock without sales orders are usually on the basis of experience leading to a forecast Forcast and sales orders are compensated Forcasts are usually done by sales departments in cooperation with at least the main customers Forcasts might as well be based on mathematical models interpreting the sales historie and extrapolating the privious data h_DA WS 2011 Logistical applications and optimizations 15

Matthias Mekschrat Production planning Material requirement planning (MRP) Sales orders and forecasts are the two entries into the MRP process According to the BOM the MRP produces reservations on the next level of dispoosition The MRP produces planned production orders or purchase requirements Planned production orders and purchase requirements are the systems suggestions according to the existing master data Rules for lot sizes and production times are described in the master data Usually the MRP is done by a disposition department h_DA WS 2011 Logistical applications and optimizations 16

Matthias Mekschrat Production planning Material requirement planning (MRP) Sales orders and forecasts are the two entries into the MRP process According to the BOM the MRP produces reservations on the next level of dispoosition The MRP produces planned production orders or purchase requirements Planned production orders and purchase requirements are the systems suggestions according to the existing master data Rules for lot sizes and production times are described in the master data Usually the MRP is done by a disposition department h_DA WS 2011 Logistical applications and optimizations 16

Matthias Mekschrat Production planning Conversion of planned production orders Usually the conversion of planned orders into production orders is done by a production department With the conversion the status of the production operation is changed from suggestion to actual plan h_DA WS 2011 Logistical applications and optimizations 17

Matthias Mekschrat Production planning Conversion of planned production orders Usually the conversion of planned orders into production orders is done by a production department With the conversion the status of the production operation is changed from suggestion to actual plan h_DA WS 2011 Logistical applications and optimizations 17

Matthias Mekschrat Production planning Release of production orders Usually the release of production orders is done by a production department The release of production orders changes the status from „actual planned“ to „start working“ With the release of a production order production papers are printed to be passed to the working floor for execution With the release of a production order the preparation of the quality management is triggered too With the release of a production order allocation of input material is triggered too h_DA WS 2011 Logistical applications and optimizations 18

Matthias Mekschrat Production planning Release of production orders Usually the release of production orders is done by a production department The release of production orders changes the status from „actual planned“ to „start working“ With the release of a production order production papers are printed to be passed to the working floor for execution With the release of a production order the preparation of the quality management is triggered too With the release of a production order allocation of input material is triggered too h_DA WS 2011 Logistical applications and optimizations 18

Matthias Mekschrat Production planning Conformation of production orders Usually the conformation of production orders is done by a production department The conformation of production orders changes the status from „start working“ to „working (partly) terminated“ With the confirmation of a production order the used time and material is booked and the stock is reduced With the confirmation of a production order the produced amount of material is booked to the stock With the confirmation of a production order quality management is started While the quality management is in process, the produced material is kept pending in the quality check inventory h_DA WS 2011 Logistical applications and optimizations 19

Matthias Mekschrat Production planning Conformation of production orders Usually the conformation of production orders is done by a production department The conformation of production orders changes the status from „start working“ to „working (partly) terminated“ With the confirmation of a production order the used time and material is booked and the stock is reduced With the confirmation of a production order the produced amount of material is booked to the stock With the confirmation of a production order quality management is started While the quality management is in process, the produced material is kept pending in the quality check inventory h_DA WS 2011 Logistical applications and optimizations 19

Matthias Mekschrat Production planning Production controlling usually is done by the controlling department Production controlling is based on the figures delivered to the system in the confirmation process With the controlling of a production order the moving internal average price of the material is adjusted h_DA WS 2011 Logistical applications and optimizations 20

Matthias Mekschrat Production planning Production controlling usually is done by the controlling department Production controlling is based on the figures delivered to the system in the confirmation process With the controlling of a production order the moving internal average price of the material is adjusted h_DA WS 2011 Logistical applications and optimizations 20

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 21

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 21

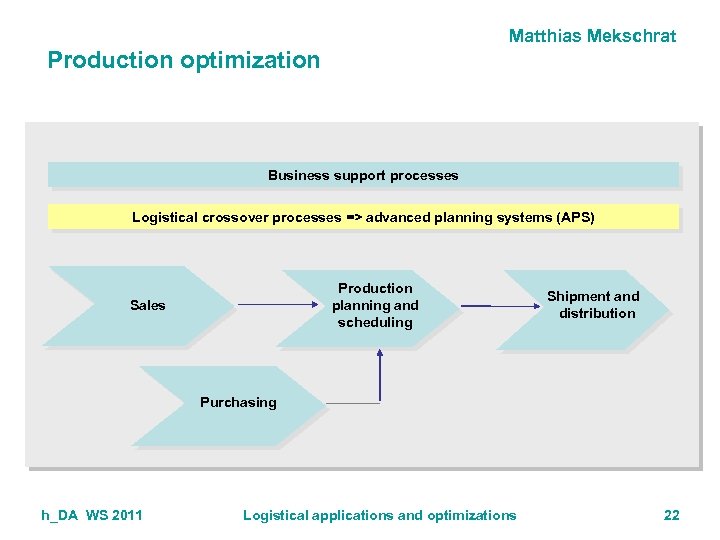

Matthias Mekschrat Production optimization Business support processes Logistical crossover processes => advanced planning systems (APS) Production planning and scheduling Sales Shipment and distribution Purchasing h_DA WS 2011 Logistical applications and optimizations 22

Matthias Mekschrat Production optimization Business support processes Logistical crossover processes => advanced planning systems (APS) Production planning and scheduling Sales Shipment and distribution Purchasing h_DA WS 2011 Logistical applications and optimizations 22

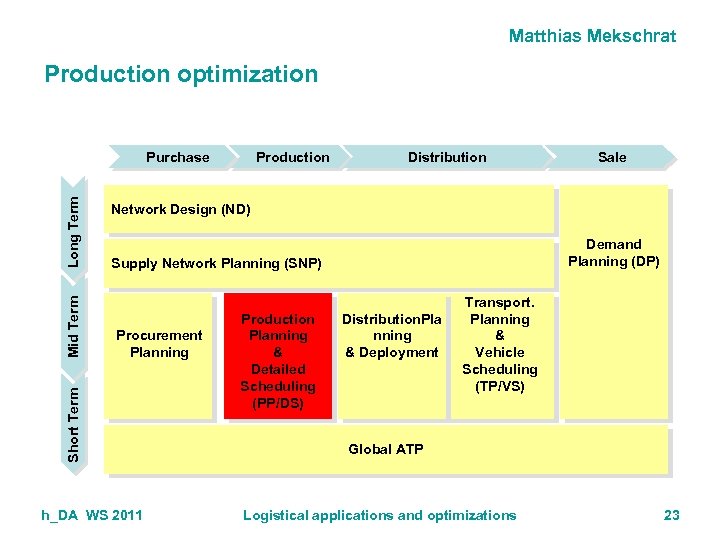

Matthias Mekschrat Production optimization Production Distribution Sale Network Design (ND) Demand Planning (DP) Supply Network Planning (SNP) Procurement Planning Short Term Mid Term Long Term Purchase h_DA WS 2011 Production Planning & Detailed Scheduling (PP/DS) Distribution. Pla nning & Deployment Transport. Planning & Vehicle Scheduling (TP/VS) Global ATP Logistical applications and optimizations 23

Matthias Mekschrat Production optimization Production Distribution Sale Network Design (ND) Demand Planning (DP) Supply Network Planning (SNP) Procurement Planning Short Term Mid Term Long Term Purchase h_DA WS 2011 Production Planning & Detailed Scheduling (PP/DS) Distribution. Pla nning & Deployment Transport. Planning & Vehicle Scheduling (TP/VS) Global ATP Logistical applications and optimizations 23

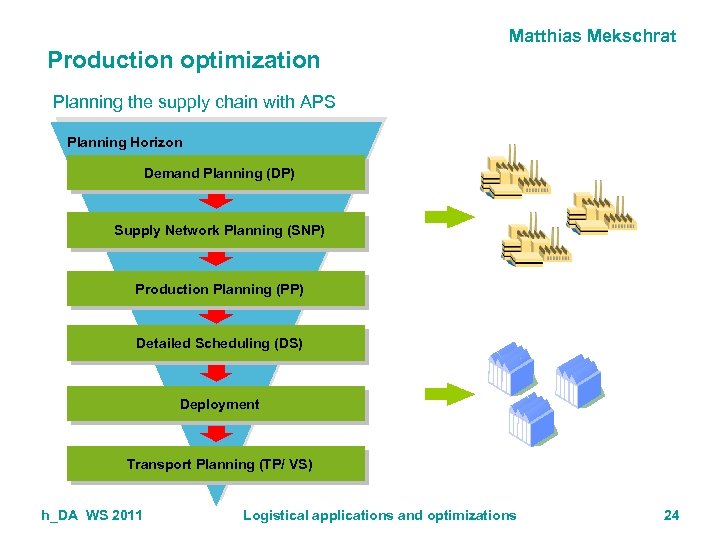

Matthias Mekschrat Production optimization Planning the supply chain with APS Planning Horizon Demand Planning (DP) Supply Network Planning (SNP) Production Planning (PP) Detailed Scheduling (DS) Deployment Transport Planning (TP/ VS) h_DA WS 2011 Logistical applications and optimizations 24

Matthias Mekschrat Production optimization Planning the supply chain with APS Planning Horizon Demand Planning (DP) Supply Network Planning (SNP) Production Planning (PP) Detailed Scheduling (DS) Deployment Transport Planning (TP/ VS) h_DA WS 2011 Logistical applications and optimizations 24

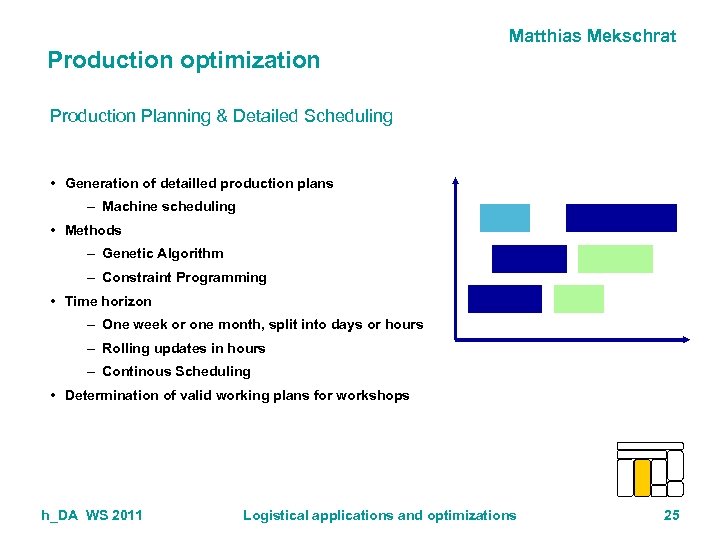

Matthias Mekschrat Production optimization Production Planning & Detailed Scheduling • Generation of detailled production plans – Machine scheduling • Methods – Genetic Algorithm – Constraint Programming • Time horizon – One week or one month, split into days or hours – Rolling updates in hours – Continous Scheduling • Determination of valid working plans for workshops h_DA WS 2011 Logistical applications and optimizations 25

Matthias Mekschrat Production optimization Production Planning & Detailed Scheduling • Generation of detailled production plans – Machine scheduling • Methods – Genetic Algorithm – Constraint Programming • Time horizon – One week or one month, split into days or hours – Rolling updates in hours – Continous Scheduling • Determination of valid working plans for workshops h_DA WS 2011 Logistical applications and optimizations 25

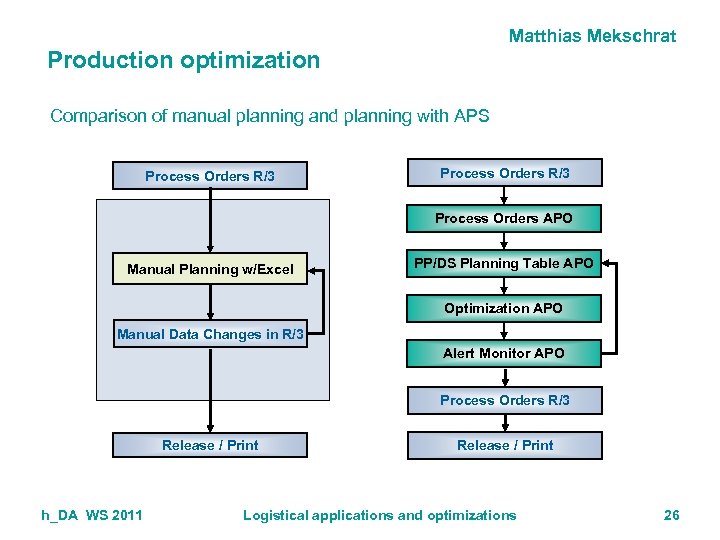

Matthias Mekschrat Production optimization Comparison of manual planning and planning with APS Process Orders R/3 Process Orders APO Manual Planning w/Excel PP/DS Planning Table APO Optimization APO Manual Data Changes in R/3 Alert Monitor APO Process Orders R/3 Release / Print h_DA WS 2011 Release / Print Logistical applications and optimizations 26

Matthias Mekschrat Production optimization Comparison of manual planning and planning with APS Process Orders R/3 Process Orders APO Manual Planning w/Excel PP/DS Planning Table APO Optimization APO Manual Data Changes in R/3 Alert Monitor APO Process Orders R/3 Release / Print h_DA WS 2011 Release / Print Logistical applications and optimizations 26

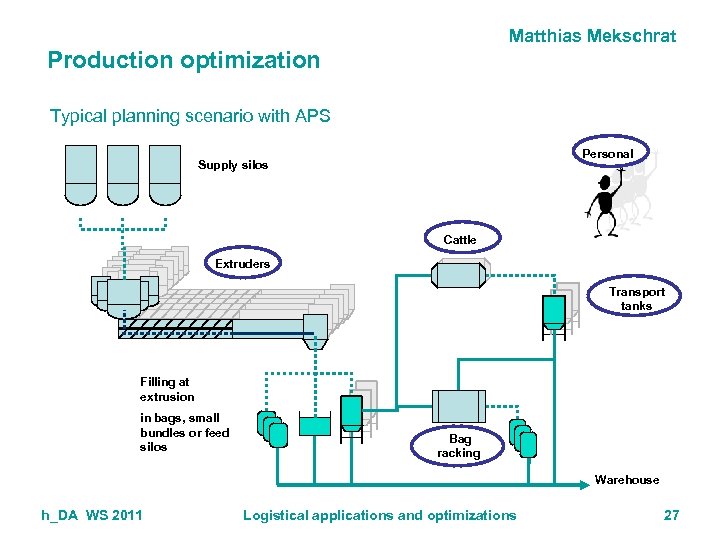

Matthias Mekschrat Production optimization Typical planning scenario with APS Personal Supply silos Cattle Extruders Transport tanks Filling at extrusion in bags, small bundles or feed silos Bag racking Warehouse h_DA WS 2011 Logistical applications and optimizations 27

Matthias Mekschrat Production optimization Typical planning scenario with APS Personal Supply silos Cattle Extruders Transport tanks Filling at extrusion in bags, small bundles or feed silos Bag racking Warehouse h_DA WS 2011 Logistical applications and optimizations 27

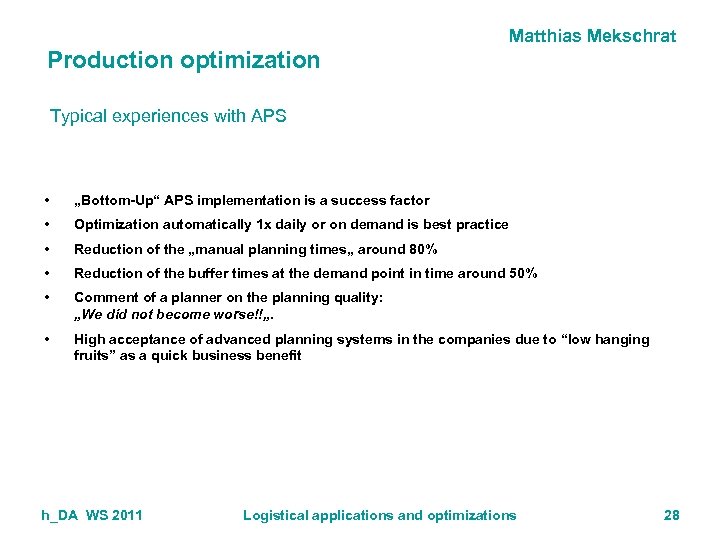

Matthias Mekschrat Production optimization Typical experiences with APS • „Bottom-Up“ APS implementation is a success factor • Optimization automatically 1 x daily or on demand is best practice • Reduction of the „manual planning times„ around 80% • Reduction of the buffer times at the demand point in time around 50% • Comment of a planner on the planning quality: „We did not become worse!!„. • High acceptance of advanced planning systems in the companies due to “low hanging fruits” as a quick business benefit h_DA WS 2011 Logistical applications and optimizations 28

Matthias Mekschrat Production optimization Typical experiences with APS • „Bottom-Up“ APS implementation is a success factor • Optimization automatically 1 x daily or on demand is best practice • Reduction of the „manual planning times„ around 80% • Reduction of the buffer times at the demand point in time around 50% • Comment of a planner on the planning quality: „We did not become worse!!„. • High acceptance of advanced planning systems in the companies due to “low hanging fruits” as a quick business benefit h_DA WS 2011 Logistical applications and optimizations 28

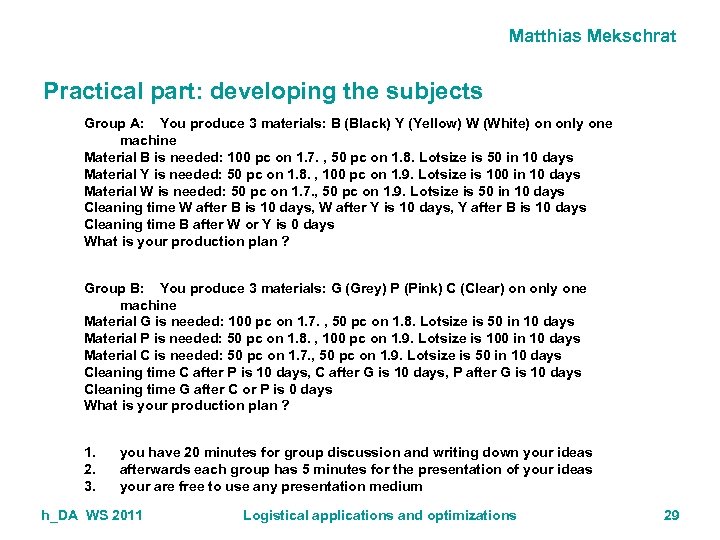

Matthias Mekschrat Practical part: developing the subjects Group A: You produce 3 materials: B (Black) Y (Yellow) W (White) on only one machine Material B is needed: 100 pc on 1. 7. , 50 pc on 1. 8. Lotsize is 50 in 10 days Material Y is needed: 50 pc on 1. 8. , 100 pc on 1. 9. Lotsize is 100 in 10 days Material W is needed: 50 pc on 1. 7. , 50 pc on 1. 9. Lotsize is 50 in 10 days Cleaning time W after B is 10 days, W after Y is 10 days, Y after B is 10 days Cleaning time B after W or Y is 0 days What is your production plan ? Group B: You produce 3 materials: G (Grey) P (Pink) C (Clear) on only one machine Material G is needed: 100 pc on 1. 7. , 50 pc on 1. 8. Lotsize is 50 in 10 days Material P is needed: 50 pc on 1. 8. , 100 pc on 1. 9. Lotsize is 100 in 10 days Material C is needed: 50 pc on 1. 7. , 50 pc on 1. 9. Lotsize is 50 in 10 days Cleaning time C after P is 10 days, C after G is 10 days, P after G is 10 days Cleaning time G after C or P is 0 days What is your production plan ? 1. 2. 3. you have 20 minutes for group discussion and writing down your ideas afterwards each group has 5 minutes for the presentation of your ideas your are free to use any presentation medium h_DA WS 2011 Logistical applications and optimizations 29

Matthias Mekschrat Practical part: developing the subjects Group A: You produce 3 materials: B (Black) Y (Yellow) W (White) on only one machine Material B is needed: 100 pc on 1. 7. , 50 pc on 1. 8. Lotsize is 50 in 10 days Material Y is needed: 50 pc on 1. 8. , 100 pc on 1. 9. Lotsize is 100 in 10 days Material W is needed: 50 pc on 1. 7. , 50 pc on 1. 9. Lotsize is 50 in 10 days Cleaning time W after B is 10 days, W after Y is 10 days, Y after B is 10 days Cleaning time B after W or Y is 0 days What is your production plan ? Group B: You produce 3 materials: G (Grey) P (Pink) C (Clear) on only one machine Material G is needed: 100 pc on 1. 7. , 50 pc on 1. 8. Lotsize is 50 in 10 days Material P is needed: 50 pc on 1. 8. , 100 pc on 1. 9. Lotsize is 100 in 10 days Material C is needed: 50 pc on 1. 7. , 50 pc on 1. 9. Lotsize is 50 in 10 days Cleaning time C after P is 10 days, C after G is 10 days, P after G is 10 days Cleaning time G after C or P is 0 days What is your production plan ? 1. 2. 3. you have 20 minutes for group discussion and writing down your ideas afterwards each group has 5 minutes for the presentation of your ideas your are free to use any presentation medium h_DA WS 2011 Logistical applications and optimizations 29

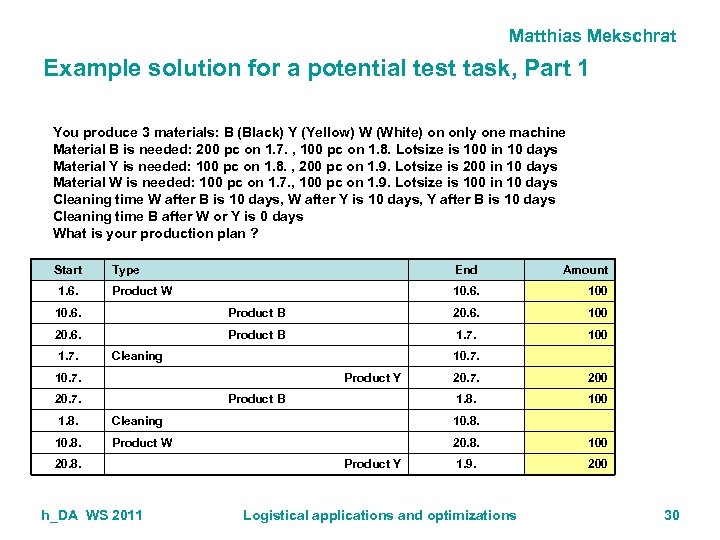

Matthias Mekschrat Example solution for a potential test task, Part 1 You produce 3 materials: B (Black) Y (Yellow) W (White) on only one machine Material B is needed: 200 pc on 1. 7. , 100 pc on 1. 8. Lotsize is 100 in 10 days Material Y is needed: 100 pc on 1. 8. , 200 pc on 1. 9. Lotsize is 200 in 10 days Material W is needed: 100 pc on 1. 7. , 100 pc on 1. 9. Lotsize is 100 in 10 days Cleaning time W after B is 10 days, W after Y is 10 days, Y after B is 10 days Cleaning time B after W or Y is 0 days What is your production plan ? Start 1. 6. Type End Amount Product W 10. 6. 100 10. 6. Product B 20. 6. 100 20. 6. Product B 1. 7. 100 1. 7. Cleaning 10. 7. Product Y 20. 7. 200 1. 8. Product B 20. 7. 100 1. 8. Cleaning 10. 8. Product W 20. 8. 100 1. 9. 200 20. 8. h_DA WS 2011 Product Y Logistical applications and optimizations 30

Matthias Mekschrat Example solution for a potential test task, Part 1 You produce 3 materials: B (Black) Y (Yellow) W (White) on only one machine Material B is needed: 200 pc on 1. 7. , 100 pc on 1. 8. Lotsize is 100 in 10 days Material Y is needed: 100 pc on 1. 8. , 200 pc on 1. 9. Lotsize is 200 in 10 days Material W is needed: 100 pc on 1. 7. , 100 pc on 1. 9. Lotsize is 100 in 10 days Cleaning time W after B is 10 days, W after Y is 10 days, Y after B is 10 days Cleaning time B after W or Y is 0 days What is your production plan ? Start 1. 6. Type End Amount Product W 10. 6. 100 10. 6. Product B 20. 6. 100 20. 6. Product B 1. 7. 100 1. 7. Cleaning 10. 7. Product Y 20. 7. 200 1. 8. Product B 20. 7. 100 1. 8. Cleaning 10. 8. Product W 20. 8. 100 1. 9. 200 20. 8. h_DA WS 2011 Product Y Logistical applications and optimizations 30

Matthias Mekschrat Summary and key messages, Part 1 Production optimization very high and quick benefits Production planning is mandatory for any Production optimization The main challenge within production optimization is the modelling of the system Reliable master and transaction data are indespensable Literature 1. Stadtler, Kilger – Supply chain management and advanced planning, Springer Verlag, Berlin Heidelberg, 2000 2. Dangelmaier, Busch (Hrsg. ) – (in german) Integriertes Supply Chain Management, Gabler Verlag, Wiesbaden, 5/2004 h_DA WS 2011 Logistical applications and optimizations 31

Matthias Mekschrat Summary and key messages, Part 1 Production optimization very high and quick benefits Production planning is mandatory for any Production optimization The main challenge within production optimization is the modelling of the system Reliable master and transaction data are indespensable Literature 1. Stadtler, Kilger – Supply chain management and advanced planning, Springer Verlag, Berlin Heidelberg, 2000 2. Dangelmaier, Busch (Hrsg. ) – (in german) Integriertes Supply Chain Management, Gabler Verlag, Wiesbaden, 5/2004 h_DA WS 2011 Logistical applications and optimizations 31

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 32

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 32

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 33

Matthias Mekschrat Functionality of production processes Part 1 Production planning Production optimization Short break Part 2 Manufactoring execution h_DA WS 2011 Logistical applications and optimizations 33

Matthias Mekschrat Functionality of production processes, Part 2 Problems and potentials The link between production planning at the ERP level and production execution at the shop floor level is seldom realised If the production planning and the production execution is connected mainly selfdeveloped interfaces are used h_DA WS 2011 Logistical applications and optimizations 34

Matthias Mekschrat Functionality of production processes, Part 2 Problems and potentials The link between production planning at the ERP level and production execution at the shop floor level is seldom realised If the production planning and the production execution is connected mainly selfdeveloped interfaces are used h_DA WS 2011 Logistical applications and optimizations 34

Matthias Mekschrat Functionality of production processes, Part 2 Learning targets Understand the needed components for a MES (Manufactoring Execution System) Understand the importance to customize the actual constellation Understand the importance of standard interfaces to the ERP system Understand the important inputs and outputs of each component Understand the involved acting logical business units h_DA WS 2011 Logistical applications and optimizations 35

Matthias Mekschrat Functionality of production processes, Part 2 Learning targets Understand the needed components for a MES (Manufactoring Execution System) Understand the importance to customize the actual constellation Understand the importance of standard interfaces to the ERP system Understand the important inputs and outputs of each component Understand the involved acting logical business units h_DA WS 2011 Logistical applications and optimizations 35

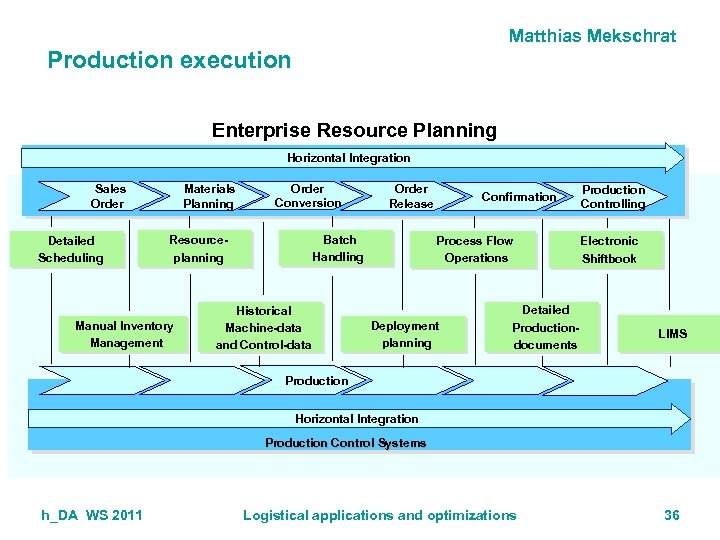

Matthias Mekschrat Production execution Enterprise Resource Planning Horizontal Integration Sales Order Detailed Scheduling Materials Planning Order Conversion Batch Handling Resourceplanning Manual Inventory Management Order Release Historical Machine-data and Control-data Confirmation Process Flow Operations Deployment planning Detailed Productiondocuments Production Controlling Electronic Shiftbook LIMS Production Horizontal Integration Production Control Systems h_DA WS 2011 Logistical applications and optimizations 36

Matthias Mekschrat Production execution Enterprise Resource Planning Horizontal Integration Sales Order Detailed Scheduling Materials Planning Order Conversion Batch Handling Resourceplanning Manual Inventory Management Order Release Historical Machine-data and Control-data Confirmation Process Flow Operations Deployment planning Detailed Productiondocuments Production Controlling Electronic Shiftbook LIMS Production Horizontal Integration Production Control Systems h_DA WS 2011 Logistical applications and optimizations 36

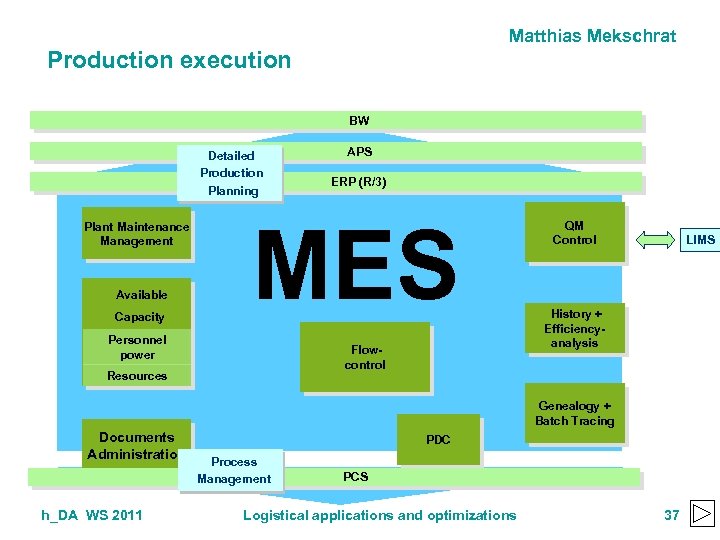

Matthias Mekschrat Production execution BW Detailed Production Planning Plant Maintenance Management Available Capacity APS ERP (R/3) MES Personnel power Flowcontrol Resources QM Control LIMS History + Efficiencyanalysis Genealogy + Batch Tracing Documents Administration h_DA WS 2011 PDC Process Management PCS Logistical applications and optimizations 37

Matthias Mekschrat Production execution BW Detailed Production Planning Plant Maintenance Management Available Capacity APS ERP (R/3) MES Personnel power Flowcontrol Resources QM Control LIMS History + Efficiencyanalysis Genealogy + Batch Tracing Documents Administration h_DA WS 2011 PDC Process Management PCS Logistical applications and optimizations 37

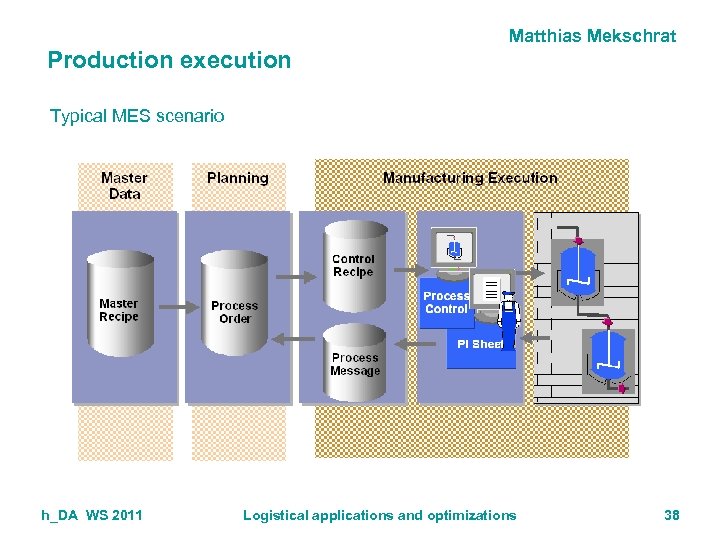

Matthias Mekschrat Production execution Typical MES scenario h_DA WS 2011 Logistical applications and optimizations 38

Matthias Mekschrat Production execution Typical MES scenario h_DA WS 2011 Logistical applications and optimizations 38

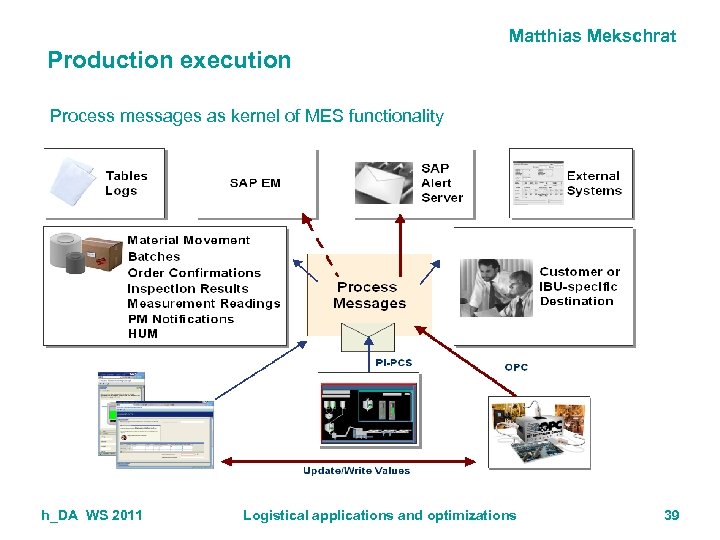

Matthias Mekschrat Production execution Process messages as kernel of MES functionality h_DA WS 2011 Logistical applications and optimizations 39

Matthias Mekschrat Production execution Process messages as kernel of MES functionality h_DA WS 2011 Logistical applications and optimizations 39

Matthias Mekschrat Production execution Typical MES fuctionality Maintenance management n Maintenance of tools and machines n periodical or preventive maintenance n Spare part procurement QM n Monitoring the production quality n Integration in LIMS Document administration n job instruction n Drawings n production papers h_DA WS 2011 Logistical applications and optimizations 40

Matthias Mekschrat Production execution Typical MES fuctionality Maintenance management n Maintenance of tools and machines n periodical or preventive maintenance n Spare part procurement QM n Monitoring the production quality n Integration in LIMS Document administration n job instruction n Drawings n production papers h_DA WS 2011 Logistical applications and optimizations 40

Matthias Mekschrat Production execution Typical MES fuctionality Available Capacity n employees (time- and attendance recording, also completion confirmation) n resources Process management n. Production monitoring in a pokier sense n. Descision support in case of error n. Machine control n. Can be adopted by MES, but also through FLS h_DA WS 2011 Logistical applications and optimizations 41

Matthias Mekschrat Production execution Typical MES fuctionality Available Capacity n employees (time- and attendance recording, also completion confirmation) n resources Process management n. Production monitoring in a pokier sense n. Descision support in case of error n. Machine control n. Can be adopted by MES, but also through FLS h_DA WS 2011 Logistical applications and optimizations 41

Matthias Mekschrat Production execution Typical MES fuctionality History and Service analysis n conditioning and archiving of operating data n Analysis of resource workload and –availability n Key Performance Indicator (KPI) Genealogy and batch tracing n product tracking n Batch tracing n Tracing of components Sequential control n monitoring and control of the production flow h_DA WS 2011 Logistical applications and optimizations 42

Matthias Mekschrat Production execution Typical MES fuctionality History and Service analysis n conditioning and archiving of operating data n Analysis of resource workload and –availability n Key Performance Indicator (KPI) Genealogy and batch tracing n product tracking n Batch tracing n Tracing of components Sequential control n monitoring and control of the production flow h_DA WS 2011 Logistical applications and optimizations 42

Matthias Mekschrat Production execution Benefits by using a MES system n closing the gap between office- and machinery world n increase of the efficiency, flexibility, competitive position, delivery reliability n MES provides the vertical integration between business economics and production + logistics n augments operational readiness of the manufacturing facilities by abbreviated response times in exceptional cases n online coupling of business economics and production n enables completely continious business processes n complete integration of IT by grouping of single solutions and definined interfaces between ERP – MES – FLS n simple integration of new functions resp. connection of new production plans n advanced & optimized process flows n wider, transparent pools n increase of the decision certainty h_DA WS 2011 Logistical applications and optimizations 43

Matthias Mekschrat Production execution Benefits by using a MES system n closing the gap between office- and machinery world n increase of the efficiency, flexibility, competitive position, delivery reliability n MES provides the vertical integration between business economics and production + logistics n augments operational readiness of the manufacturing facilities by abbreviated response times in exceptional cases n online coupling of business economics and production n enables completely continious business processes n complete integration of IT by grouping of single solutions and definined interfaces between ERP – MES – FLS n simple integration of new functions resp. connection of new production plans n advanced & optimized process flows n wider, transparent pools n increase of the decision certainty h_DA WS 2011 Logistical applications and optimizations 43

Matthias Mekschrat Production execution Criteria on requirements for the asortment of MES n n n n Flexible expansion Analysis-, planning- and simulation options Integration of existing application scenery well-engineered technical solutions Investment- and implementation effort running operation expenses acceptance of the users h_DA WS 2011 Logistical applications and optimizations 44

Matthias Mekschrat Production execution Criteria on requirements for the asortment of MES n n n n Flexible expansion Analysis-, planning- and simulation options Integration of existing application scenery well-engineered technical solutions Investment- and implementation effort running operation expenses acceptance of the users h_DA WS 2011 Logistical applications and optimizations 44

Matthias Mekschrat Summary and key messages, Part 2 MES is the mayor challenge to integrate the shop floor and the ERP systems The functionality of MES systems may very according to the supplier The interfaces are the most complicated structures and should be provided by the supplier of the MES systems The functionality must be selectable according to the users demand Literature 1. Stadtler, Kilger – Supply chain management and advanced planning, Springer Verlag, Berlin Heidelberg, 2000 2. Dangelmaier, Busch (Hrsg. ) – (in german) Integriertes Supply Chain Management, Gabler Verlag, Wiesbaden, 5/2004 h_DA WS 2011 Logistical applications and optimizations 45

Matthias Mekschrat Summary and key messages, Part 2 MES is the mayor challenge to integrate the shop floor and the ERP systems The functionality of MES systems may very according to the supplier The interfaces are the most complicated structures and should be provided by the supplier of the MES systems The functionality must be selectable according to the users demand Literature 1. Stadtler, Kilger – Supply chain management and advanced planning, Springer Verlag, Berlin Heidelberg, 2000 2. Dangelmaier, Busch (Hrsg. ) – (in german) Integriertes Supply Chain Management, Gabler Verlag, Wiesbaden, 5/2004 h_DA WS 2011 Logistical applications and optimizations 45

Matthias Mekschrat Thank you very much for your participation …… and see you on Friday, 16 th of December h_DA WS 2011 Logistical applications and optimizations 46

Matthias Mekschrat Thank you very much for your participation …… and see you on Friday, 16 th of December h_DA WS 2011 Logistical applications and optimizations 46