c3783514b7b45805db631fb5e98839e8.ppt

- Количество слайдов: 39

“Materials’ Issues and Research Needs for Electricity Generating Light Water Reactor Sustainability : An Industrial Perspective” Mike Burke Manager Materials Center of Excellence Westinghouse Electric Company Do. E BES Advisory Committee July 9 th 2009 N. Bethesda Md. 1

“Materials’ Issues and Research Needs for Electricity Generating Light Water Reactor Sustainability : An Industrial Perspective” Mike Burke Manager Materials Center of Excellence Westinghouse Electric Company Do. E BES Advisory Committee July 9 th 2009 N. Bethesda Md. 1

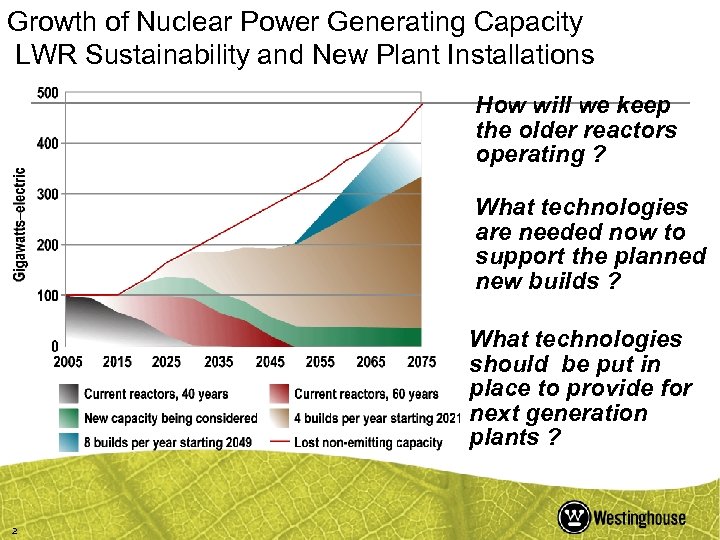

Growth of Nuclear Power Generating Capacity LWR Sustainability and New Plant Installations How will we keep the older reactors operating ? What technologies are needed now to support the planned new builds ? What technologies should be put in place to provide for next generation plants ? 2

Growth of Nuclear Power Generating Capacity LWR Sustainability and New Plant Installations How will we keep the older reactors operating ? What technologies are needed now to support the planned new builds ? What technologies should be put in place to provide for next generation plants ? 2

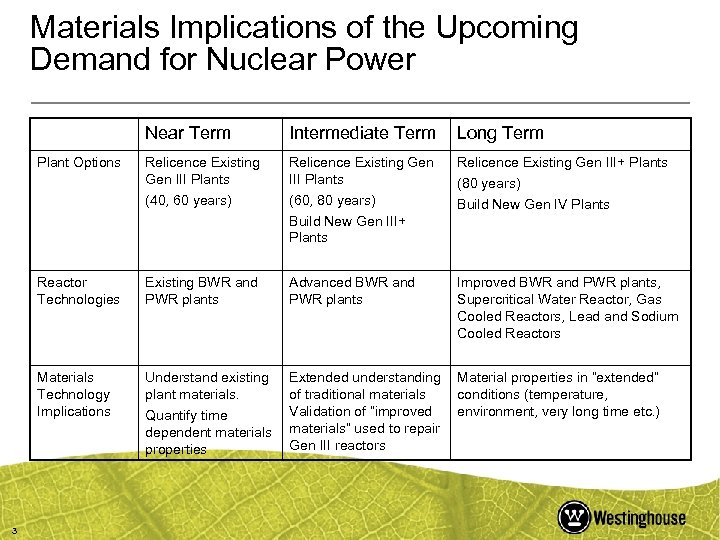

Materials Implications of the Upcoming Demand for Nuclear Power Near Term Long Term Plant Options Relicence Existing Gen III Plants (40, 60 years) Relicence Existing Gen III Plants (60, 80 years) Build New Gen III+ Plants Relicence Existing Gen III+ Plants (80 years) Build New Gen IV Plants Reactor Technologies Existing BWR and PWR plants Advanced BWR and PWR plants Improved BWR and PWR plants, Supercritical Water Reactor, Gas Cooled Reactors, Lead and Sodium Cooled Reactors Materials Technology Implications 3 Intermediate Term Understand existing plant materials. Quantify time dependent materials properties Extended understanding of traditional materials Validation of “improved materials” used to repair Gen III reactors Material properties in “extended” conditions (temperature, environment, very long time etc. )

Materials Implications of the Upcoming Demand for Nuclear Power Near Term Long Term Plant Options Relicence Existing Gen III Plants (40, 60 years) Relicence Existing Gen III Plants (60, 80 years) Build New Gen III+ Plants Relicence Existing Gen III+ Plants (80 years) Build New Gen IV Plants Reactor Technologies Existing BWR and PWR plants Advanced BWR and PWR plants Improved BWR and PWR plants, Supercritical Water Reactor, Gas Cooled Reactors, Lead and Sodium Cooled Reactors Materials Technology Implications 3 Intermediate Term Understand existing plant materials. Quantify time dependent materials properties Extended understanding of traditional materials Validation of “improved materials” used to repair Gen III reactors Material properties in “extended” conditions (temperature, environment, very long time etc. )

Issues for Materials Usage in Operating and New Plants ● ● Plants are designed for long lives No material is “Impervium” Degradation mechanisms are generally known Materials response must be predictable ● Quantitative precise prediction of materials’ response to service is needed linear models ● Discrimination between material variants is needed need to quantitatively understand the effects of the major variables ● Technologies for inspection, monitoring and repair will always be required 4

Issues for Materials Usage in Operating and New Plants ● ● Plants are designed for long lives No material is “Impervium” Degradation mechanisms are generally known Materials response must be predictable ● Quantitative precise prediction of materials’ response to service is needed linear models ● Discrimination between material variants is needed need to quantitatively understand the effects of the major variables ● Technologies for inspection, monitoring and repair will always be required 4

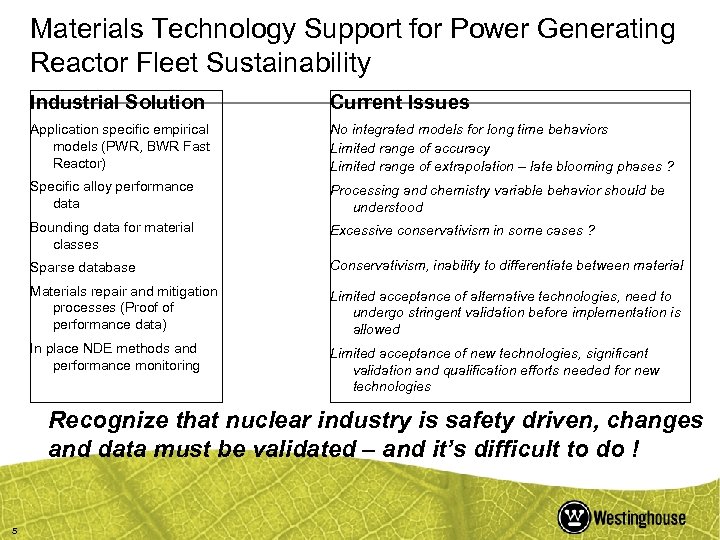

Materials Technology Support for Power Generating Reactor Fleet Sustainability Industrial Solution Current Issues Application specific empirical models (PWR, BWR Fast Reactor) No integrated models for long time behaviors Limited range of accuracy Limited range of extrapolation – late blooming phases ? Specific alloy performance data Processing and chemistry variable behavior should be understood Bounding data for material classes Excessive conservativism in some cases ? Sparse database Conservativism, inability to differentiate between material Materials repair and mitigation processes (Proof of performance data) Limited acceptance of alternative technologies, need to undergo stringent validation before implementation is allowed In place NDE methods and performance monitoring Limited acceptance of new technologies, significant validation and qualification efforts needed for new technologies Recognize that nuclear industry is safety driven, changes and data must be validated – and it’s difficult to do ! 5

Materials Technology Support for Power Generating Reactor Fleet Sustainability Industrial Solution Current Issues Application specific empirical models (PWR, BWR Fast Reactor) No integrated models for long time behaviors Limited range of accuracy Limited range of extrapolation – late blooming phases ? Specific alloy performance data Processing and chemistry variable behavior should be understood Bounding data for material classes Excessive conservativism in some cases ? Sparse database Conservativism, inability to differentiate between material Materials repair and mitigation processes (Proof of performance data) Limited acceptance of alternative technologies, need to undergo stringent validation before implementation is allowed In place NDE methods and performance monitoring Limited acceptance of new technologies, significant validation and qualification efforts needed for new technologies Recognize that nuclear industry is safety driven, changes and data must be validated – and it’s difficult to do ! 5

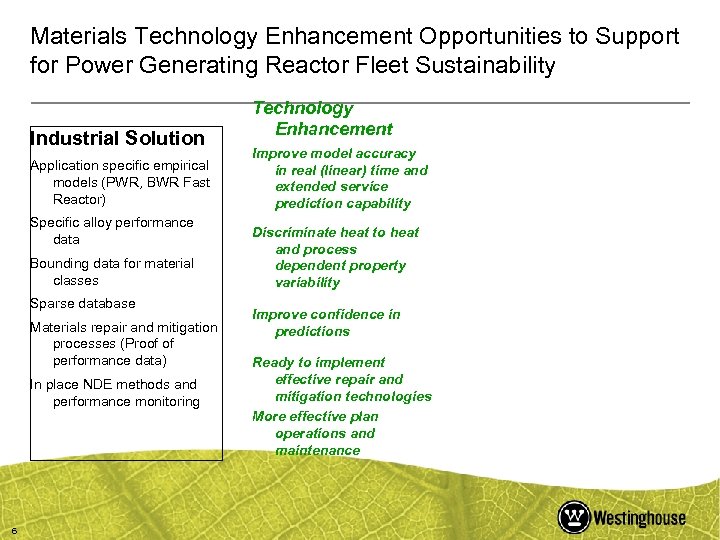

Materials Technology Enhancement Opportunities to Support for Power Generating Reactor Fleet Sustainability Industrial Solution Application specific empirical models (PWR, BWR Fast Reactor) Specific alloy performance data Bounding data for material classes Sparse database Materials repair and mitigation processes (Proof of performance data) In place NDE methods and performance monitoring 6 Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Discriminate heat to heat and process dependent property variability Improve confidence in predictions Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance

Materials Technology Enhancement Opportunities to Support for Power Generating Reactor Fleet Sustainability Industrial Solution Application specific empirical models (PWR, BWR Fast Reactor) Specific alloy performance data Bounding data for material classes Sparse database Materials repair and mitigation processes (Proof of performance data) In place NDE methods and performance monitoring 6 Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Discriminate heat to heat and process dependent property variability Improve confidence in predictions Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance

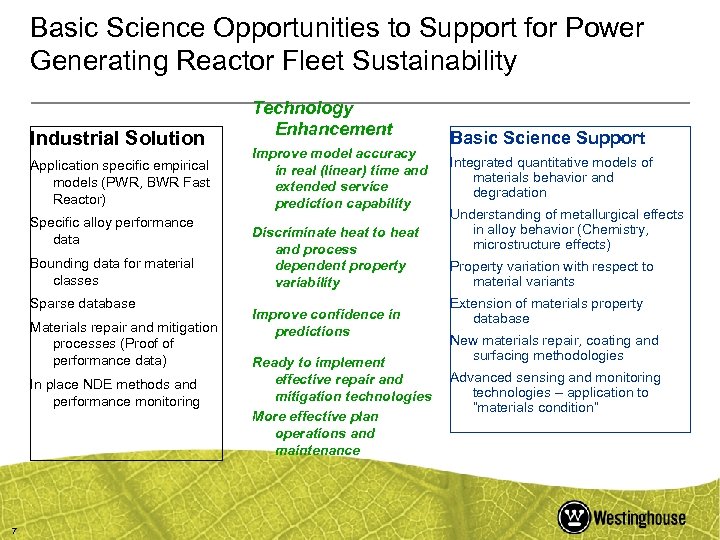

Basic Science Opportunities to Support for Power Generating Reactor Fleet Sustainability Industrial Solution Application specific empirical models (PWR, BWR Fast Reactor) Specific alloy performance data Bounding data for material classes Sparse database Materials repair and mitigation processes (Proof of performance data) In place NDE methods and performance monitoring 7 Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Discriminate heat to heat and process dependent property variability Improve confidence in predictions Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance Basic Science Support Integrated quantitative models of materials behavior and degradation Understanding of metallurgical effects in alloy behavior (Chemistry, microstructure effects) Property variation with respect to material variants Extension of materials property database New materials repair, coating and surfacing methodologies Advanced sensing and monitoring technologies – application to “materials condition”

Basic Science Opportunities to Support for Power Generating Reactor Fleet Sustainability Industrial Solution Application specific empirical models (PWR, BWR Fast Reactor) Specific alloy performance data Bounding data for material classes Sparse database Materials repair and mitigation processes (Proof of performance data) In place NDE methods and performance monitoring 7 Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Discriminate heat to heat and process dependent property variability Improve confidence in predictions Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance Basic Science Support Integrated quantitative models of materials behavior and degradation Understanding of metallurgical effects in alloy behavior (Chemistry, microstructure effects) Property variation with respect to material variants Extension of materials property database New materials repair, coating and surfacing methodologies Advanced sensing and monitoring technologies – application to “materials condition”

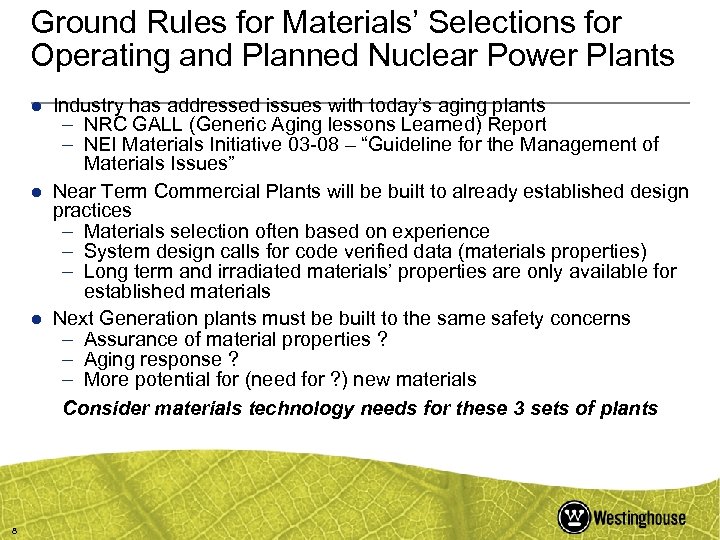

Ground Rules for Materials’ Selections for Operating and Planned Nuclear Power Plants ● Industry has addressed issues with today’s aging plants – NRC GALL (Generic Aging lessons Learned) Report – NEI Materials Initiative 03 -08 – “Guideline for the Management of Materials Issues” ● Near Term Commercial Plants will be built to already established design practices – Materials selection often based on experience – System design calls for code verified data (materials properties) – Long term and irradiated materials’ properties are only available for established materials ● Next Generation plants must be built to the same safety concerns – Assurance of material properties ? – Aging response ? – More potential for (need for ? ) new materials Consider materials technology needs for these 3 sets of plants 8

Ground Rules for Materials’ Selections for Operating and Planned Nuclear Power Plants ● Industry has addressed issues with today’s aging plants – NRC GALL (Generic Aging lessons Learned) Report – NEI Materials Initiative 03 -08 – “Guideline for the Management of Materials Issues” ● Near Term Commercial Plants will be built to already established design practices – Materials selection often based on experience – System design calls for code verified data (materials properties) – Long term and irradiated materials’ properties are only available for established materials ● Next Generation plants must be built to the same safety concerns – Assurance of material properties ? – Aging response ? – More potential for (need for ? ) new materials Consider materials technology needs for these 3 sets of plants 8

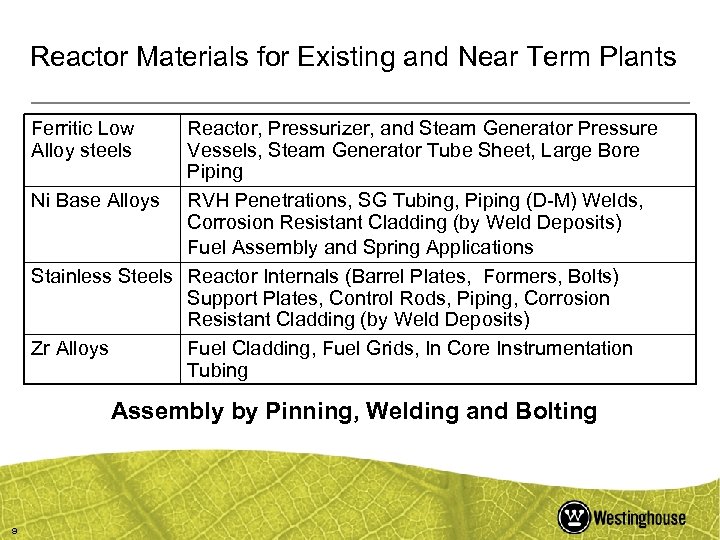

Reactor Materials for Existing and Near Term Plants Ferritic Low Alloy steels Reactor, Pressurizer, and Steam Generator Pressure Vessels, Steam Generator Tube Sheet, Large Bore Piping Ni Base Alloys RVH Penetrations, SG Tubing, Piping (D-M) Welds, Corrosion Resistant Cladding (by Weld Deposits) Fuel Assembly and Spring Applications Stainless Steels Reactor Internals (Barrel Plates, Formers, Bolts) Support Plates, Control Rods, Piping, Corrosion Resistant Cladding (by Weld Deposits) Zr Alloys Fuel Cladding, Fuel Grids, In Core Instrumentation Tubing Assembly by Pinning, Welding and Bolting 9

Reactor Materials for Existing and Near Term Plants Ferritic Low Alloy steels Reactor, Pressurizer, and Steam Generator Pressure Vessels, Steam Generator Tube Sheet, Large Bore Piping Ni Base Alloys RVH Penetrations, SG Tubing, Piping (D-M) Welds, Corrosion Resistant Cladding (by Weld Deposits) Fuel Assembly and Spring Applications Stainless Steels Reactor Internals (Barrel Plates, Formers, Bolts) Support Plates, Control Rods, Piping, Corrosion Resistant Cladding (by Weld Deposits) Zr Alloys Fuel Cladding, Fuel Grids, In Core Instrumentation Tubing Assembly by Pinning, Welding and Bolting 9

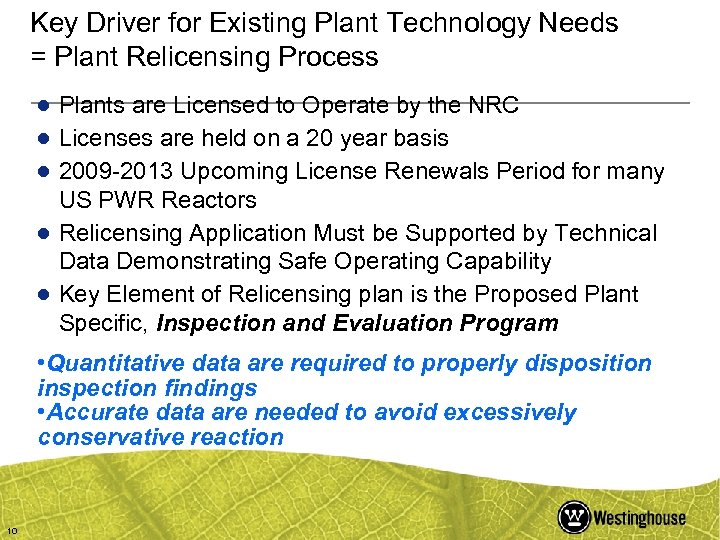

Key Driver for Existing Plant Technology Needs = Plant Relicensing Process ● Plants are Licensed to Operate by the NRC ● Licenses are held on a 20 year basis ● 2009 -2013 Upcoming License Renewals Period for many US PWR Reactors ● Relicensing Application Must be Supported by Technical Data Demonstrating Safe Operating Capability ● Key Element of Relicensing plan is the Proposed Plant Specific, Inspection and Evaluation Program • Quantitative data are required to properly disposition inspection findings • Accurate data are needed to avoid excessively conservative reaction 10

Key Driver for Existing Plant Technology Needs = Plant Relicensing Process ● Plants are Licensed to Operate by the NRC ● Licenses are held on a 20 year basis ● 2009 -2013 Upcoming License Renewals Period for many US PWR Reactors ● Relicensing Application Must be Supported by Technical Data Demonstrating Safe Operating Capability ● Key Element of Relicensing plan is the Proposed Plant Specific, Inspection and Evaluation Program • Quantitative data are required to properly disposition inspection findings • Accurate data are needed to avoid excessively conservative reaction 10

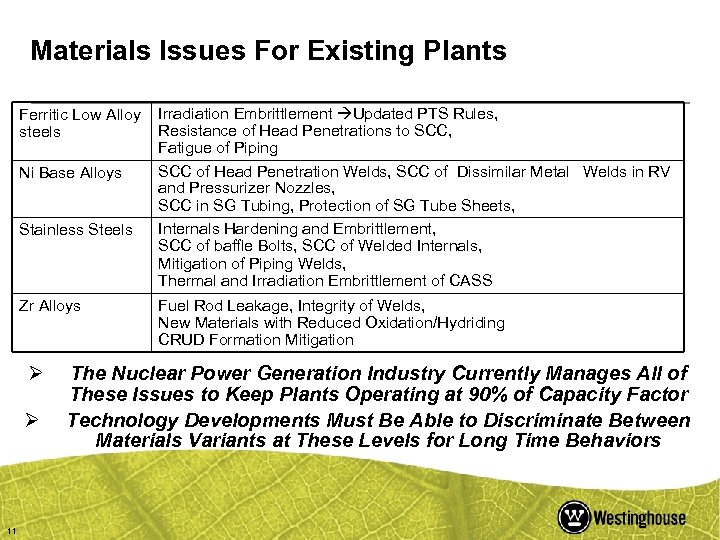

Materials Issues For Existing Plants Ferritic Low Alloy steels Ni Base Alloys Stainless Steels Zr Alloys Ø Ø 11 Irradiation Embrittlement Updated PTS Rules, Resistance of Head Penetrations to SCC, Fatigue of Piping SCC of Head Penetration Welds, SCC of Dissimilar Metal Welds in RV and Pressurizer Nozzles, SCC in SG Tubing, Protection of SG Tube Sheets, Internals Hardening and Embrittlement, SCC of baffle Bolts, SCC of Welded Internals, Mitigation of Piping Welds, Thermal and Irradiation Embrittlement of CASS Fuel Rod Leakage, Integrity of Welds, New Materials with Reduced Oxidation/Hydriding CRUD Formation Mitigation The Nuclear Power Generation Industry Currently Manages All of These Issues to Keep Plants Operating at 90% of Capacity Factor Technology Developments Must Be Able to Discriminate Between Materials Variants at These Levels for Long Time Behaviors

Materials Issues For Existing Plants Ferritic Low Alloy steels Ni Base Alloys Stainless Steels Zr Alloys Ø Ø 11 Irradiation Embrittlement Updated PTS Rules, Resistance of Head Penetrations to SCC, Fatigue of Piping SCC of Head Penetration Welds, SCC of Dissimilar Metal Welds in RV and Pressurizer Nozzles, SCC in SG Tubing, Protection of SG Tube Sheets, Internals Hardening and Embrittlement, SCC of baffle Bolts, SCC of Welded Internals, Mitigation of Piping Welds, Thermal and Irradiation Embrittlement of CASS Fuel Rod Leakage, Integrity of Welds, New Materials with Reduced Oxidation/Hydriding CRUD Formation Mitigation The Nuclear Power Generation Industry Currently Manages All of These Issues to Keep Plants Operating at 90% of Capacity Factor Technology Developments Must Be Able to Discriminate Between Materials Variants at These Levels for Long Time Behaviors

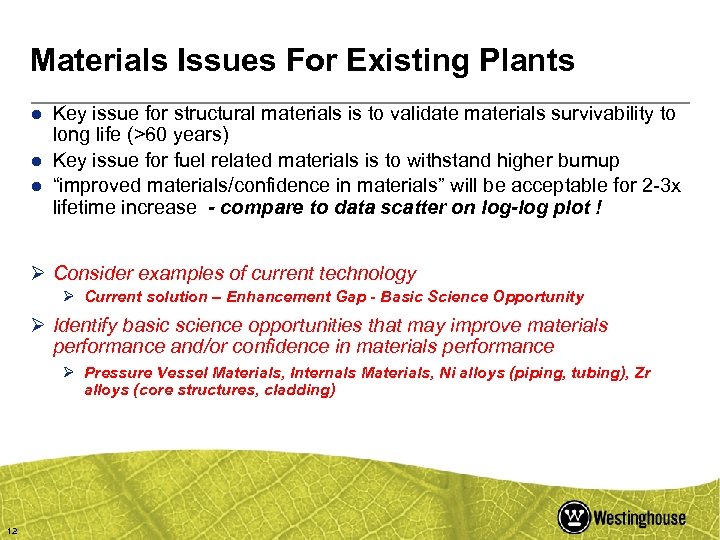

Materials Issues For Existing Plants ● Key issue for structural materials is to validate materials survivability to long life (>60 years) ● Key issue for fuel related materials is to withstand higher burnup ● “improved materials/confidence in materials” will be acceptable for 2 -3 x lifetime increase - compare to data scatter on log-log plot ! Ø Consider examples of current technology Ø Current solution – Enhancement Gap - Basic Science Opportunity Ø Identify basic science opportunities that may improve materials performance and/or confidence in materials performance Ø Pressure Vessel Materials, Internals Materials, Ni alloys (piping, tubing), Zr alloys (core structures, cladding) 12

Materials Issues For Existing Plants ● Key issue for structural materials is to validate materials survivability to long life (>60 years) ● Key issue for fuel related materials is to withstand higher burnup ● “improved materials/confidence in materials” will be acceptable for 2 -3 x lifetime increase - compare to data scatter on log-log plot ! Ø Consider examples of current technology Ø Current solution – Enhancement Gap - Basic Science Opportunity Ø Identify basic science opportunities that may improve materials performance and/or confidence in materials performance Ø Pressure Vessel Materials, Internals Materials, Ni alloys (piping, tubing), Zr alloys (core structures, cladding) 12

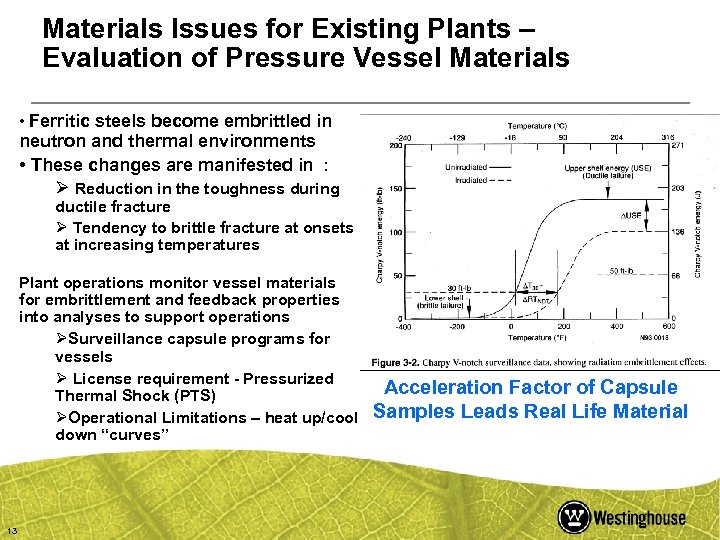

Materials Issues for Existing Plants – Evaluation of Pressure Vessel Materials • Ferritic steels become embrittled in neutron and thermal environments • These changes are manifested in : Ø Reduction in the toughness during ductile fracture Ø Tendency to brittle fracture at onsets at increasing temperatures Plant operations monitor vessel materials for embrittlement and feedback properties into analyses to support operations ØSurveillance capsule programs for vessels Ø License requirement - Pressurized Thermal Shock (PTS) ØOperational Limitations – heat up/cool down “curves” 13 Acceleration Factor of Capsule Samples Leads Real Life Material

Materials Issues for Existing Plants – Evaluation of Pressure Vessel Materials • Ferritic steels become embrittled in neutron and thermal environments • These changes are manifested in : Ø Reduction in the toughness during ductile fracture Ø Tendency to brittle fracture at onsets at increasing temperatures Plant operations monitor vessel materials for embrittlement and feedback properties into analyses to support operations ØSurveillance capsule programs for vessels Ø License requirement - Pressurized Thermal Shock (PTS) ØOperational Limitations – heat up/cool down “curves” 13 Acceleration Factor of Capsule Samples Leads Real Life Material

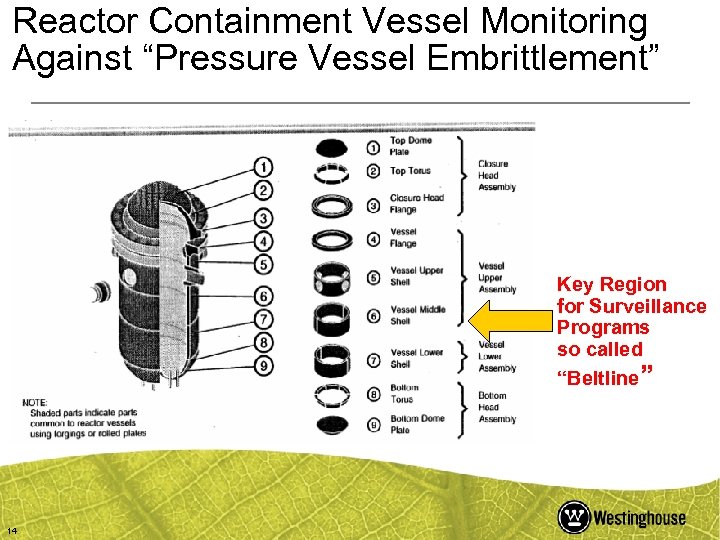

Reactor Containment Vessel Monitoring Against “Pressure Vessel Embrittlement” Key Region for Surveillance Programs so called “Beltline” 14

Reactor Containment Vessel Monitoring Against “Pressure Vessel Embrittlement” Key Region for Surveillance Programs so called “Beltline” 14

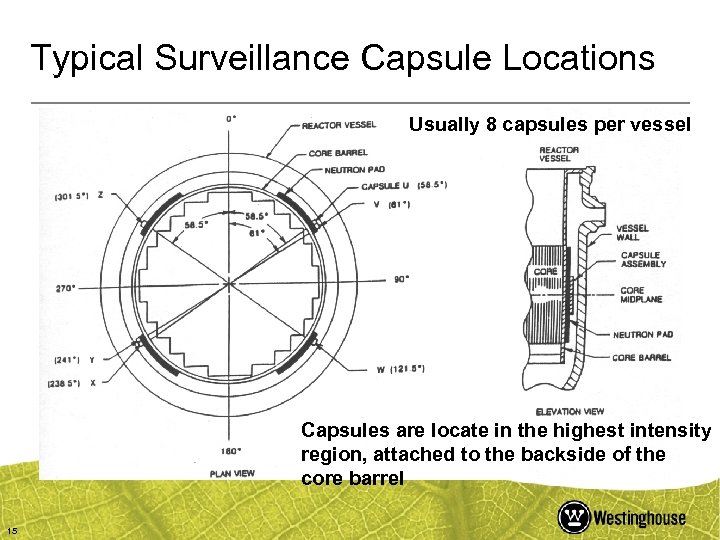

Typical Surveillance Capsule Locations Usually 8 capsules per vessel Capsules are locate in the highest intensity region, attached to the backside of the core barrel 15

Typical Surveillance Capsule Locations Usually 8 capsules per vessel Capsules are locate in the highest intensity region, attached to the backside of the core barrel 15

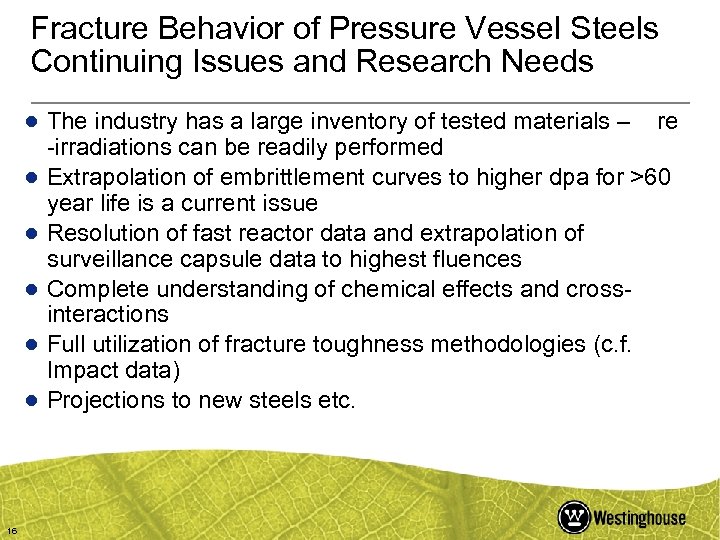

Fracture Behavior of Pressure Vessel Steels Continuing Issues and Research Needs ● The industry has a large inventory of tested materials – re -irradiations can be readily performed ● Extrapolation of embrittlement curves to higher dpa for >60 year life is a current issue ● Resolution of fast reactor data and extrapolation of surveillance capsule data to highest fluences ● Complete understanding of chemical effects and crossinteractions ● Full utilization of fracture toughness methodologies (c. f. Impact data) ● Projections to new steels etc. 16

Fracture Behavior of Pressure Vessel Steels Continuing Issues and Research Needs ● The industry has a large inventory of tested materials – re -irradiations can be readily performed ● Extrapolation of embrittlement curves to higher dpa for >60 year life is a current issue ● Resolution of fast reactor data and extrapolation of surveillance capsule data to highest fluences ● Complete understanding of chemical effects and crossinteractions ● Full utilization of fracture toughness methodologies (c. f. Impact data) ● Projections to new steels etc. 16

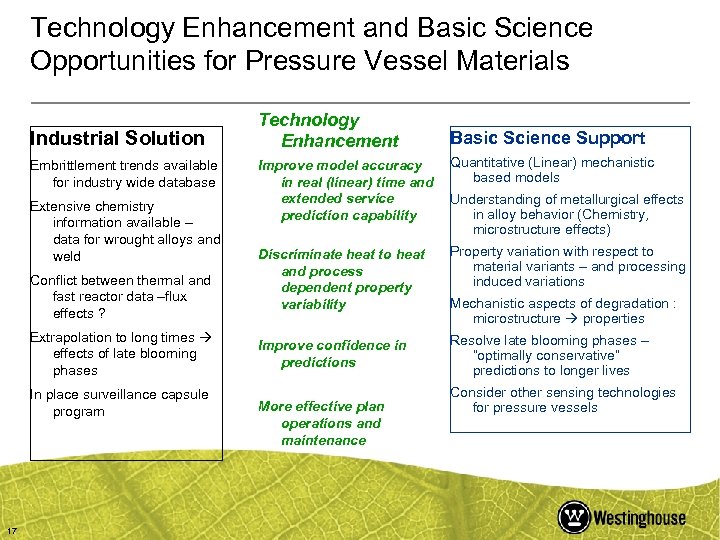

Technology Enhancement and Basic Science Opportunities for Pressure Vessel Materials Industrial Solution Embrittlement trends available for industry wide database Extensive chemistry information available – data for wrought alloys and weld Conflict between thermal and fast reactor data –flux effects ? Extrapolation to long times effects of late blooming phases In place surveillance capsule program 17 Technology Enhancement Basic Science Support Improve model accuracy in real (linear) time and extended service prediction capability Quantitative (Linear) mechanistic based models Discriminate heat to heat and process dependent property variability Property variation with respect to material variants – and processing induced variations Improve confidence in predictions Resolve late blooming phases – “optimally conservative” predictions to longer lives More effective plan operations and maintenance Understanding of metallurgical effects in alloy behavior (Chemistry, microstructure effects) Mechanistic aspects of degradation : microstructure properties Consider other sensing technologies for pressure vessels

Technology Enhancement and Basic Science Opportunities for Pressure Vessel Materials Industrial Solution Embrittlement trends available for industry wide database Extensive chemistry information available – data for wrought alloys and weld Conflict between thermal and fast reactor data –flux effects ? Extrapolation to long times effects of late blooming phases In place surveillance capsule program 17 Technology Enhancement Basic Science Support Improve model accuracy in real (linear) time and extended service prediction capability Quantitative (Linear) mechanistic based models Discriminate heat to heat and process dependent property variability Property variation with respect to material variants – and processing induced variations Improve confidence in predictions Resolve late blooming phases – “optimally conservative” predictions to longer lives More effective plan operations and maintenance Understanding of metallurgical effects in alloy behavior (Chemistry, microstructure effects) Mechanistic aspects of degradation : microstructure properties Consider other sensing technologies for pressure vessels

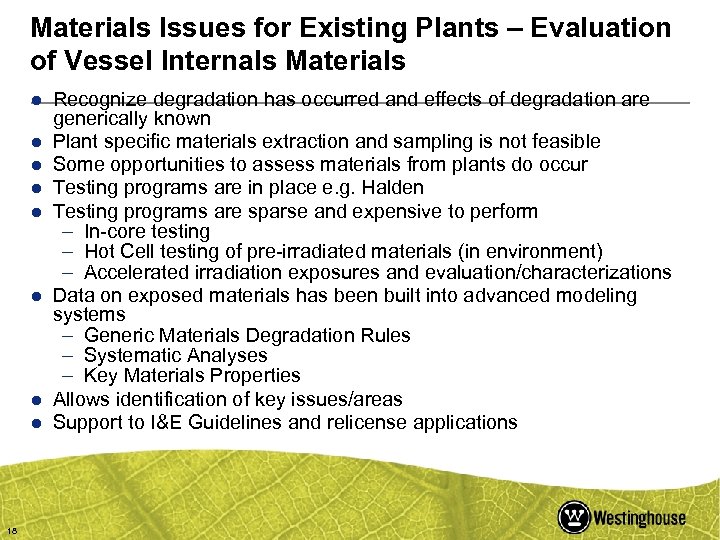

Materials Issues for Existing Plants – Evaluation of Vessel Internals Materials ● Recognize degradation has occurred and effects of degradation are generically known ● Plant specific materials extraction and sampling is not feasible ● Some opportunities to assess materials from plants do occur ● Testing programs are in place e. g. Halden ● Testing programs are sparse and expensive to perform – In-core testing – Hot Cell testing of pre-irradiated materials (in environment) – Accelerated irradiation exposures and evaluation/characterizations ● Data on exposed materials has been built into advanced modeling systems – Generic Materials Degradation Rules – Systematic Analyses – Key Materials Properties ● Allows identification of key issues/areas ● Support to I&E Guidelines and relicense applications 18

Materials Issues for Existing Plants – Evaluation of Vessel Internals Materials ● Recognize degradation has occurred and effects of degradation are generically known ● Plant specific materials extraction and sampling is not feasible ● Some opportunities to assess materials from plants do occur ● Testing programs are in place e. g. Halden ● Testing programs are sparse and expensive to perform – In-core testing – Hot Cell testing of pre-irradiated materials (in environment) – Accelerated irradiation exposures and evaluation/characterizations ● Data on exposed materials has been built into advanced modeling systems – Generic Materials Degradation Rules – Systematic Analyses – Key Materials Properties ● Allows identification of key issues/areas ● Support to I&E Guidelines and relicense applications 18

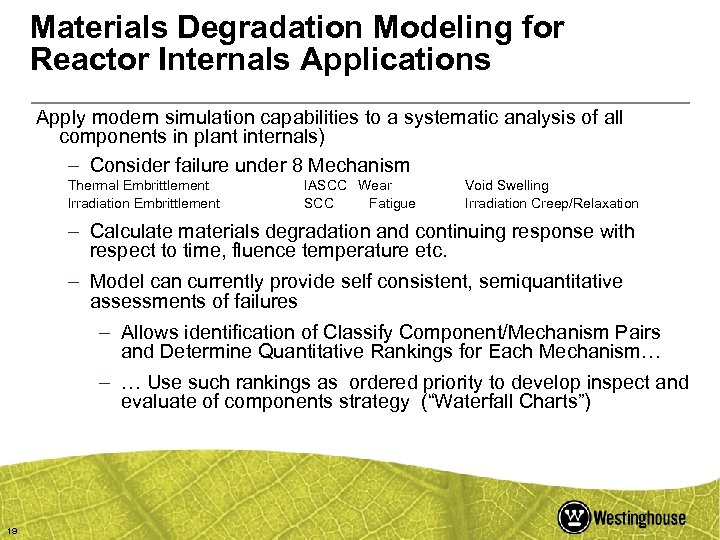

Materials Degradation Modeling for Reactor Internals Applications Apply modern simulation capabilities to a systematic analysis of all components in plant internals) – Consider failure under 8 Mechanism Thermal Embrittlement Irradiation Embrittlement IASCC Wear SCC Fatigue Void Swelling Irradiation Creep/Relaxation – Calculate materials degradation and continuing response with respect to time, fluence temperature etc. – Model can currently provide self consistent, semiquantitative assessments of failures – Allows identification of Classify Component/Mechanism Pairs and Determine Quantitative Rankings for Each Mechanism… – … Use such rankings as ordered priority to develop inspect and evaluate of components strategy (“Waterfall Charts”) 19

Materials Degradation Modeling for Reactor Internals Applications Apply modern simulation capabilities to a systematic analysis of all components in plant internals) – Consider failure under 8 Mechanism Thermal Embrittlement Irradiation Embrittlement IASCC Wear SCC Fatigue Void Swelling Irradiation Creep/Relaxation – Calculate materials degradation and continuing response with respect to time, fluence temperature etc. – Model can currently provide self consistent, semiquantitative assessments of failures – Allows identification of Classify Component/Mechanism Pairs and Determine Quantitative Rankings for Each Mechanism… – … Use such rankings as ordered priority to develop inspect and evaluate of components strategy (“Waterfall Charts”) 19

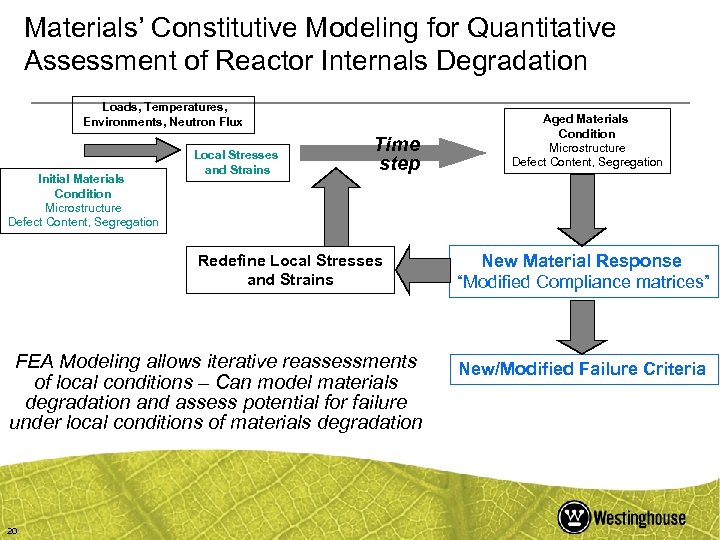

Materials’ Constitutive Modeling for Quantitative Assessment of Reactor Internals Degradation Loads, Temperatures, Environments, Neutron Flux Initial Materials Condition Microstructure Defect Content, Segregation Local Stresses and Strains Time step Redefine Local Stresses and Strains FEA Modeling allows iterative reassessments of local conditions – Can model materials degradation and assess potential for failure under local conditions of materials degradation 20 Aged Materials Condition Microstructure Defect Content, Segregation New Material Response “Modified Compliance matrices” New/Modified Failure Criteria

Materials’ Constitutive Modeling for Quantitative Assessment of Reactor Internals Degradation Loads, Temperatures, Environments, Neutron Flux Initial Materials Condition Microstructure Defect Content, Segregation Local Stresses and Strains Time step Redefine Local Stresses and Strains FEA Modeling allows iterative reassessments of local conditions – Can model materials degradation and assess potential for failure under local conditions of materials degradation 20 Aged Materials Condition Microstructure Defect Content, Segregation New Material Response “Modified Compliance matrices” New/Modified Failure Criteria

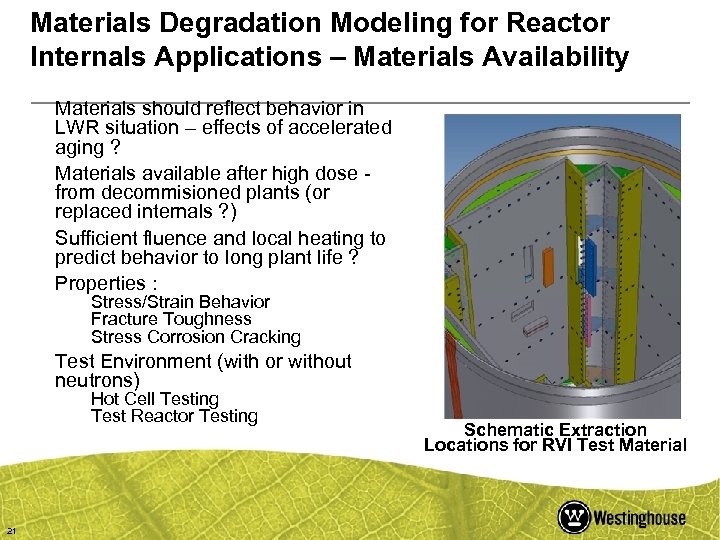

Materials Degradation Modeling for Reactor Internals Applications – Materials Availability Materials should reflect behavior in LWR situation – effects of accelerated aging ? Materials available after high dose from decommisioned plants (or replaced internals ? ) Sufficient fluence and local heating to predict behavior to long plant life ? Properties : Stress/Strain Behavior Fracture Toughness Stress Corrosion Cracking Test Environment (with or without neutrons) Hot Cell Testing Test Reactor Testing 21 Schematic Extraction Locations for RVI Test Material

Materials Degradation Modeling for Reactor Internals Applications – Materials Availability Materials should reflect behavior in LWR situation – effects of accelerated aging ? Materials available after high dose from decommisioned plants (or replaced internals ? ) Sufficient fluence and local heating to predict behavior to long plant life ? Properties : Stress/Strain Behavior Fracture Toughness Stress Corrosion Cracking Test Environment (with or without neutrons) Hot Cell Testing Test Reactor Testing 21 Schematic Extraction Locations for RVI Test Material

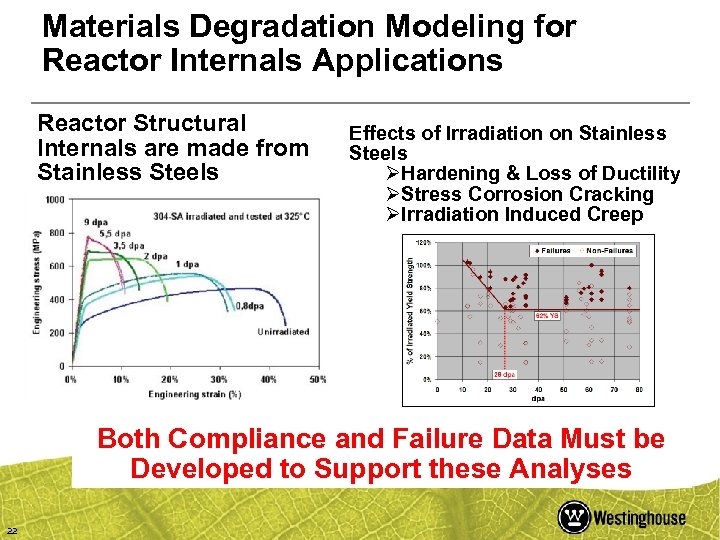

Materials Degradation Modeling for Reactor Internals Applications Reactor Structural Internals are made from Stainless Steels Effects of Irradiation on Stainless Steels ØHardening & Loss of Ductility ØStress Corrosion Cracking ØIrradiation Induced Creep Both Compliance and Failure Data Must be Developed to Support these Analyses 22

Materials Degradation Modeling for Reactor Internals Applications Reactor Structural Internals are made from Stainless Steels Effects of Irradiation on Stainless Steels ØHardening & Loss of Ductility ØStress Corrosion Cracking ØIrradiation Induced Creep Both Compliance and Failure Data Must be Developed to Support these Analyses 22

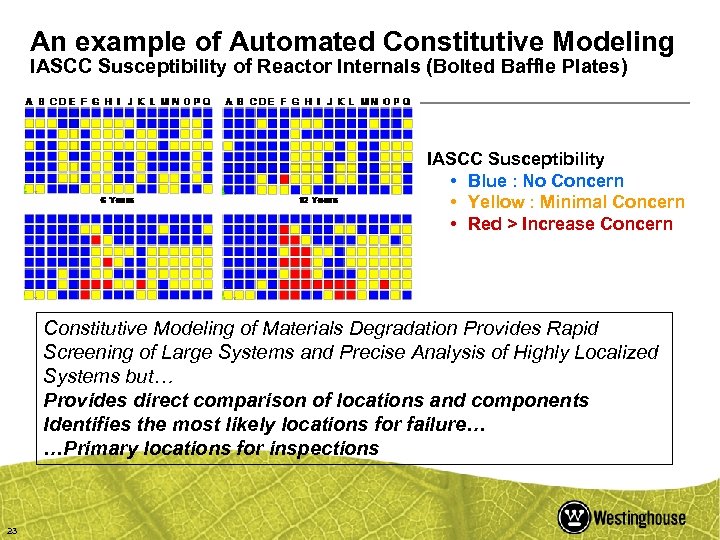

An example of Automated Constitutive Modeling IASCC Susceptibility of Reactor Internals (Bolted Baffle Plates) IASCC Susceptibility • Blue : No Concern • Yellow : Minimal Concern • Red > Increase Concern Constitutive Modeling of Materials Degradation Provides Rapid Screening of Large Systems and Precise Analysis of Highly Localized Systems but… Provides direct comparison of locations and components Identifies the most likely locations for failure… …Primary locations for inspections 23

An example of Automated Constitutive Modeling IASCC Susceptibility of Reactor Internals (Bolted Baffle Plates) IASCC Susceptibility • Blue : No Concern • Yellow : Minimal Concern • Red > Increase Concern Constitutive Modeling of Materials Degradation Provides Rapid Screening of Large Systems and Precise Analysis of Highly Localized Systems but… Provides direct comparison of locations and components Identifies the most likely locations for failure… …Primary locations for inspections 23

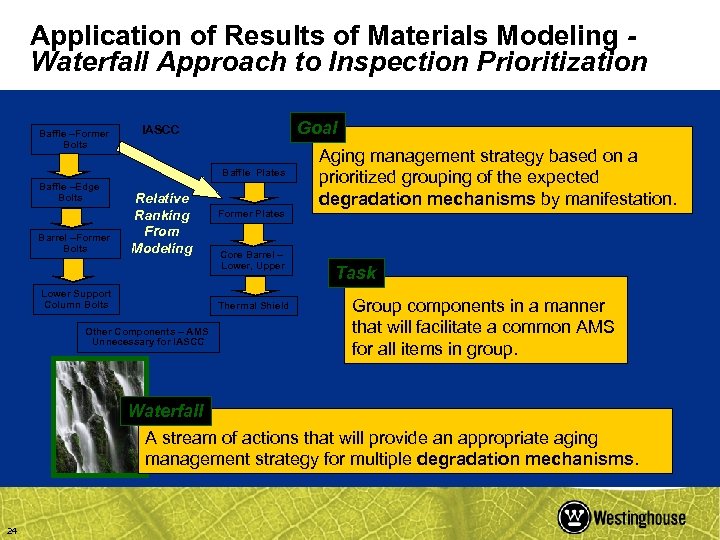

Application of Results of Materials Modeling Waterfall Approach to Inspection Prioritization Baffle –Former Bolts Goal IASCC Baffle Plates Baffle –Edge Bolts Barrel –Former Bolts Relative Ranking From Modeling Lower Support Column Bolts Former Plates Core Barrel – Lower, Upper Thermal Shield Other Components – AMS Unnecessary for IASCC Aging management strategy based on a prioritized grouping of the expected degradation mechanisms by manifestation. Task Group components in a manner that will facilitate a common AMS for all items in group. Waterfall A stream of actions that will provide an appropriate aging management strategy for multiple degradation mechanisms. 24

Application of Results of Materials Modeling Waterfall Approach to Inspection Prioritization Baffle –Former Bolts Goal IASCC Baffle Plates Baffle –Edge Bolts Barrel –Former Bolts Relative Ranking From Modeling Lower Support Column Bolts Former Plates Core Barrel – Lower, Upper Thermal Shield Other Components – AMS Unnecessary for IASCC Aging management strategy based on a prioritized grouping of the expected degradation mechanisms by manifestation. Task Group components in a manner that will facilitate a common AMS for all items in group. Waterfall A stream of actions that will provide an appropriate aging management strategy for multiple degradation mechanisms. 24

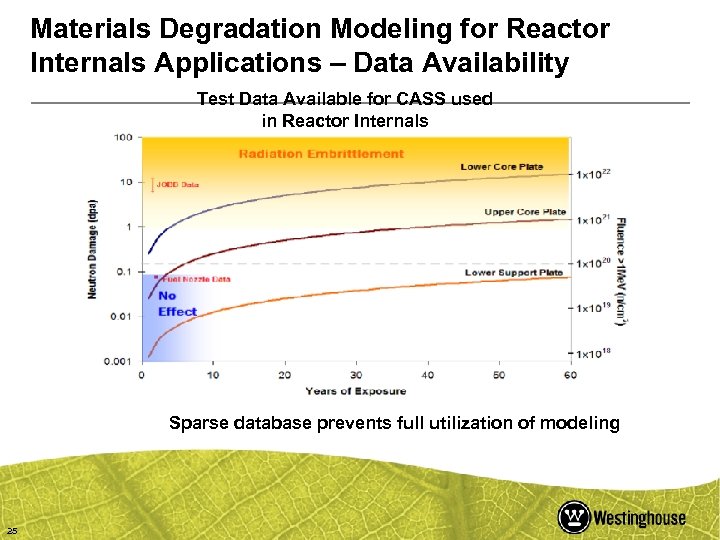

Materials Degradation Modeling for Reactor Internals Applications – Data Availability Test Data Available for CASS used in Reactor Internals Sparse database prevents full utilization of modeling 25

Materials Degradation Modeling for Reactor Internals Applications – Data Availability Test Data Available for CASS used in Reactor Internals Sparse database prevents full utilization of modeling 25

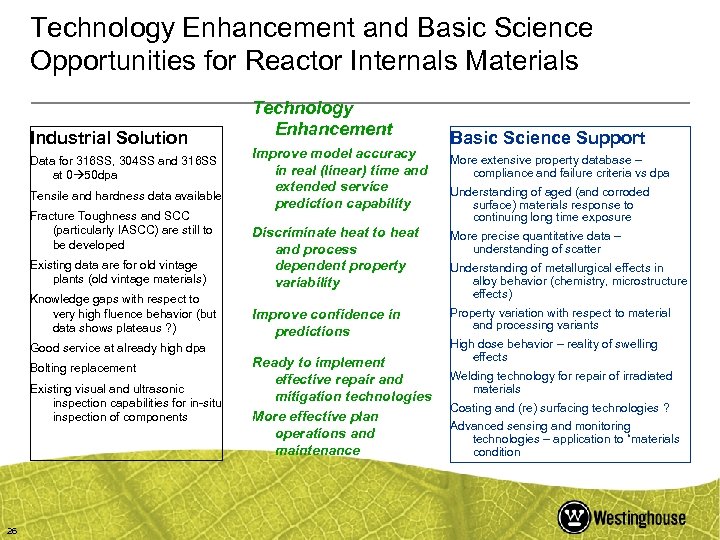

Technology Enhancement and Basic Science Opportunities for Reactor Internals Materials Industrial Solution Data for 316 SS, 304 SS and 316 SS at 0 50 dpa Tensile and hardness data available Fracture Toughness and SCC (particularly IASCC) are still to be developed Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Basic Science Support More extensive property database – compliance and failure criteria vs dpa Understanding of aged (and corroded surface) materials response to continuing long time exposure More precise quantitative data – understanding of scatter Existing data are for old vintage plants (old vintage materials) Discriminate heat to heat and process dependent property variability Knowledge gaps with respect to very high fluence behavior (but data shows plateaus ? ) Improve confidence in predictions Property variation with respect to material and processing variants Good service at already high dpa Bolting replacement Existing visual and ultrasonic inspection capabilities for in-situ inspection of components 26 Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance Understanding of metallurgical effects in alloy behavior (chemistry, microstructure effects) High dose behavior – reality of swelling effects Welding technology for repair of irradiated materials Coating and (re) surfacing technologies ? Advanced sensing and monitoring technologies – application to “materials condition

Technology Enhancement and Basic Science Opportunities for Reactor Internals Materials Industrial Solution Data for 316 SS, 304 SS and 316 SS at 0 50 dpa Tensile and hardness data available Fracture Toughness and SCC (particularly IASCC) are still to be developed Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Basic Science Support More extensive property database – compliance and failure criteria vs dpa Understanding of aged (and corroded surface) materials response to continuing long time exposure More precise quantitative data – understanding of scatter Existing data are for old vintage plants (old vintage materials) Discriminate heat to heat and process dependent property variability Knowledge gaps with respect to very high fluence behavior (but data shows plateaus ? ) Improve confidence in predictions Property variation with respect to material and processing variants Good service at already high dpa Bolting replacement Existing visual and ultrasonic inspection capabilities for in-situ inspection of components 26 Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance Understanding of metallurgical effects in alloy behavior (chemistry, microstructure effects) High dose behavior – reality of swelling effects Welding technology for repair of irradiated materials Coating and (re) surfacing technologies ? Advanced sensing and monitoring technologies – application to “materials condition

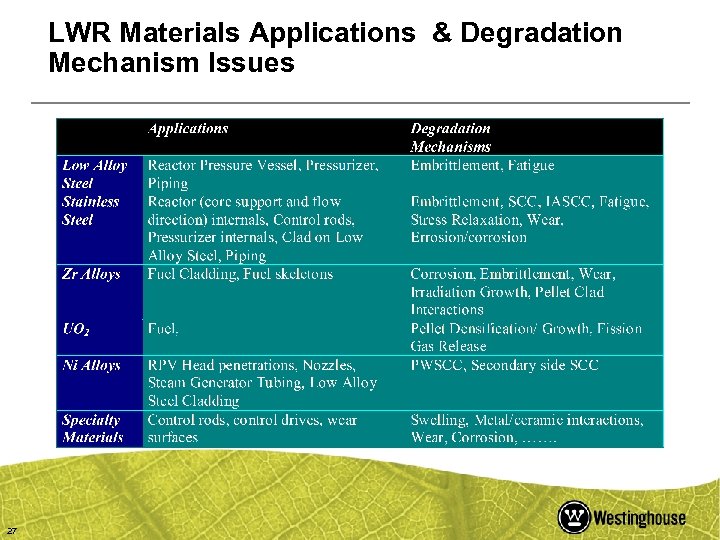

LWR Materials Applications & Degradation Mechanism Issues 27

LWR Materials Applications & Degradation Mechanism Issues 27

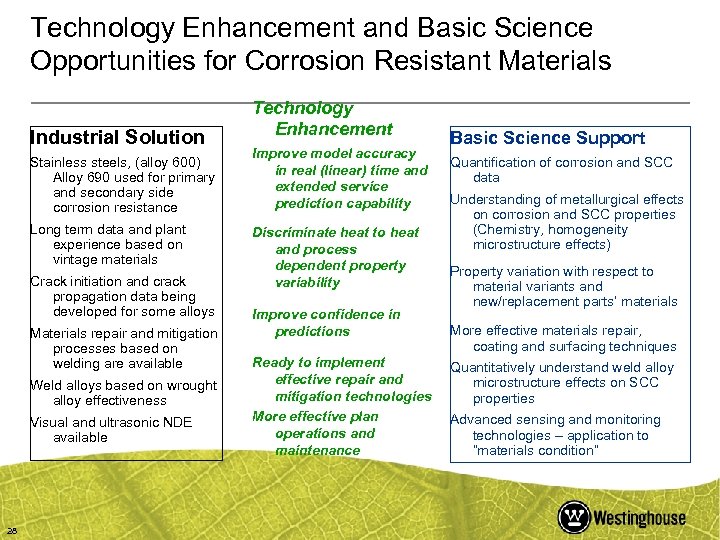

Technology Enhancement and Basic Science Opportunities for Corrosion Resistant Materials Industrial Solution Stainless steels, (alloy 600) Alloy 690 used for primary and secondary side corrosion resistance Long term data and plant experience based on vintage materials Crack initiation and crack propagation data being developed for some alloys Materials repair and mitigation processes based on welding are available Weld alloys based on wrought alloy effectiveness Visual and ultrasonic NDE available 28 Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Discriminate heat to heat and process dependent property variability Improve confidence in predictions Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance Basic Science Support Quantification of corrosion and SCC data Understanding of metallurgical effects on corrosion and SCC properties (Chemistry, homogeneity microstructure effects) Property variation with respect to material variants and new/replacement parts’ materials More effective materials repair, coating and surfacing techniques Quantitatively understand weld alloy microstructure effects on SCC properties Advanced sensing and monitoring technologies – application to “materials condition”

Technology Enhancement and Basic Science Opportunities for Corrosion Resistant Materials Industrial Solution Stainless steels, (alloy 600) Alloy 690 used for primary and secondary side corrosion resistance Long term data and plant experience based on vintage materials Crack initiation and crack propagation data being developed for some alloys Materials repair and mitigation processes based on welding are available Weld alloys based on wrought alloy effectiveness Visual and ultrasonic NDE available 28 Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Discriminate heat to heat and process dependent property variability Improve confidence in predictions Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance Basic Science Support Quantification of corrosion and SCC data Understanding of metallurgical effects on corrosion and SCC properties (Chemistry, homogeneity microstructure effects) Property variation with respect to material variants and new/replacement parts’ materials More effective materials repair, coating and surfacing techniques Quantitatively understand weld alloy microstructure effects on SCC properties Advanced sensing and monitoring technologies – application to “materials condition”

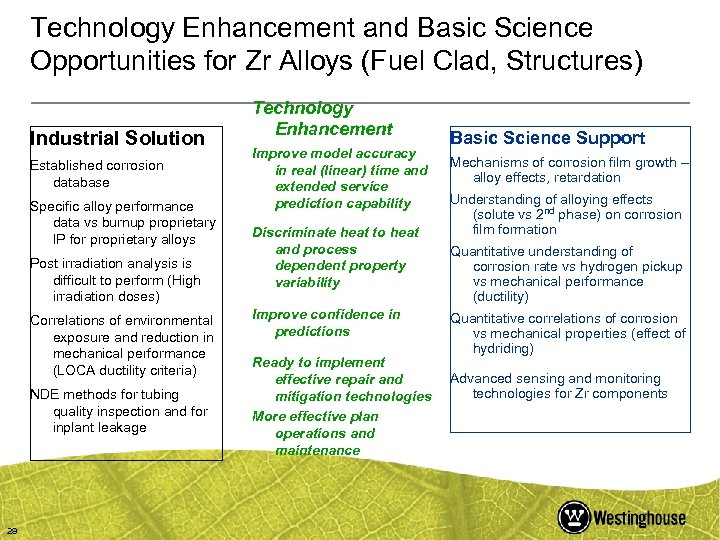

Technology Enhancement and Basic Science Opportunities for Zr Alloys (Fuel Clad, Structures) Industrial Solution Established corrosion database Specific alloy performance data vs burnup proprietary IP for proprietary alloys Post irradiation analysis is difficult to perform (High irradiation doses) Correlations of environmental exposure and reduction in mechanical performance (LOCA ductility criteria) NDE methods for tubing quality inspection and for inplant leakage 29 Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Discriminate heat to heat and process dependent property variability Improve confidence in predictions Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance Basic Science Support Mechanisms of corrosion film growth – alloy effects, retardation Understanding of alloying effects (solute vs 2 nd phase) on corrosion film formation Quantitative understanding of corrosion rate vs hydrogen pickup vs mechanical performance (ductility) Quantitative correlations of corrosion vs mechanical properties (effect of hydriding) Advanced sensing and monitoring technologies for Zr components

Technology Enhancement and Basic Science Opportunities for Zr Alloys (Fuel Clad, Structures) Industrial Solution Established corrosion database Specific alloy performance data vs burnup proprietary IP for proprietary alloys Post irradiation analysis is difficult to perform (High irradiation doses) Correlations of environmental exposure and reduction in mechanical performance (LOCA ductility criteria) NDE methods for tubing quality inspection and for inplant leakage 29 Technology Enhancement Improve model accuracy in real (linear) time and extended service prediction capability Discriminate heat to heat and process dependent property variability Improve confidence in predictions Ready to implement effective repair and mitigation technologies More effective plan operations and maintenance Basic Science Support Mechanisms of corrosion film growth – alloy effects, retardation Understanding of alloying effects (solute vs 2 nd phase) on corrosion film formation Quantitative understanding of corrosion rate vs hydrogen pickup vs mechanical performance (ductility) Quantitative correlations of corrosion vs mechanical properties (effect of hydriding) Advanced sensing and monitoring technologies for Zr components

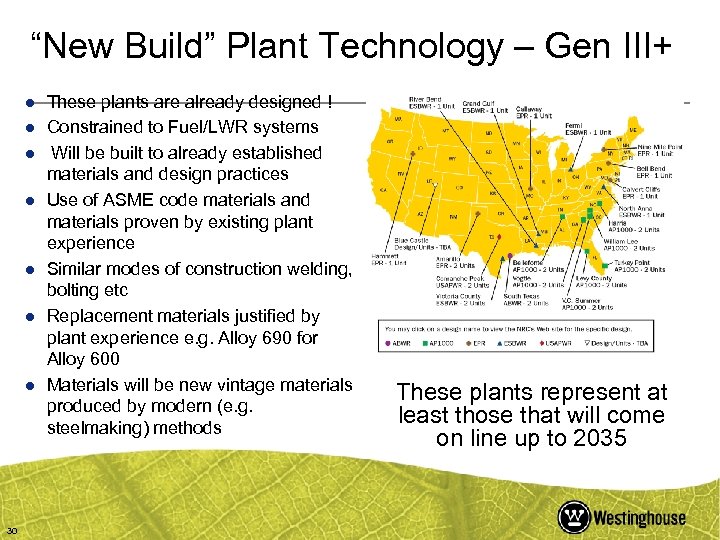

“New Build” Plant Technology – Gen III+ ● These plants are already designed ! ● Constrained to Fuel/LWR systems ● Will be built to already established materials and design practices ● Use of ASME code materials and materials proven by existing plant experience ● Similar modes of construction welding, bolting etc ● Replacement materials justified by plant experience e. g. Alloy 690 for Alloy 600 ● Materials will be new vintage materials produced by modern (e. g. steelmaking) methods 30 These plants represent at least those that will come on line up to 2035

“New Build” Plant Technology – Gen III+ ● These plants are already designed ! ● Constrained to Fuel/LWR systems ● Will be built to already established materials and design practices ● Use of ASME code materials and materials proven by existing plant experience ● Similar modes of construction welding, bolting etc ● Replacement materials justified by plant experience e. g. Alloy 690 for Alloy 600 ● Materials will be new vintage materials produced by modern (e. g. steelmaking) methods 30 These plants represent at least those that will come on line up to 2035

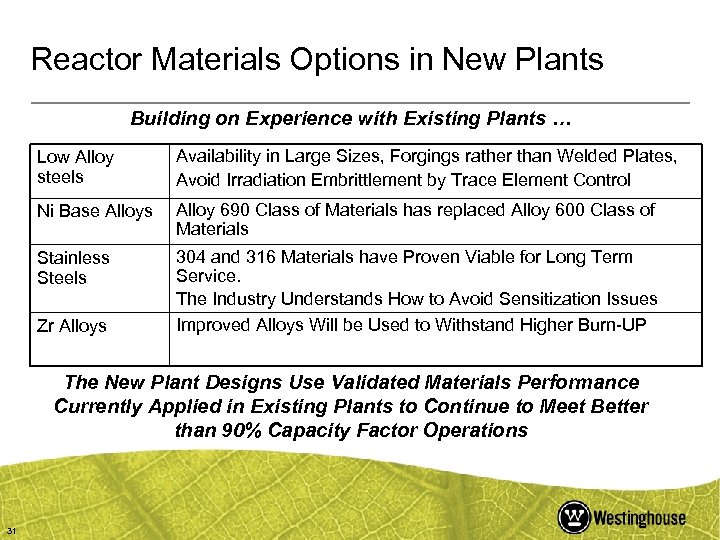

Reactor Materials Options in New Plants Building on Experience with Existing Plants … Low Alloy steels Availability in Large Sizes, Forgings rather than Welded Plates, Avoid Irradiation Embrittlement by Trace Element Control Ni Base Alloys Alloy 690 Class of Materials has replaced Alloy 600 Class of Materials Stainless Steels 304 and 316 Materials have Proven Viable for Long Term Service. The Industry Understands How to Avoid Sensitization Issues Improved Alloys Will be Used to Withstand Higher Burn-UP Zr Alloys The New Plant Designs Use Validated Materials Performance Currently Applied in Existing Plants to Continue to Meet Better than 90% Capacity Factor Operations 31

Reactor Materials Options in New Plants Building on Experience with Existing Plants … Low Alloy steels Availability in Large Sizes, Forgings rather than Welded Plates, Avoid Irradiation Embrittlement by Trace Element Control Ni Base Alloys Alloy 690 Class of Materials has replaced Alloy 600 Class of Materials Stainless Steels 304 and 316 Materials have Proven Viable for Long Term Service. The Industry Understands How to Avoid Sensitization Issues Improved Alloys Will be Used to Withstand Higher Burn-UP Zr Alloys The New Plant Designs Use Validated Materials Performance Currently Applied in Existing Plants to Continue to Meet Better than 90% Capacity Factor Operations 31

New Plant Materials Technology Issues • Manufacturing Issues • Product Validation • Degradation Mechanism Understanding • Operational Assessment Capability • Mitigation Approaches • Inspection & Evaluation Needs • Repair / Replacement Options • Regulatory Issues 32

New Plant Materials Technology Issues • Manufacturing Issues • Product Validation • Degradation Mechanism Understanding • Operational Assessment Capability • Mitigation Approaches • Inspection & Evaluation Needs • Repair / Replacement Options • Regulatory Issues 32

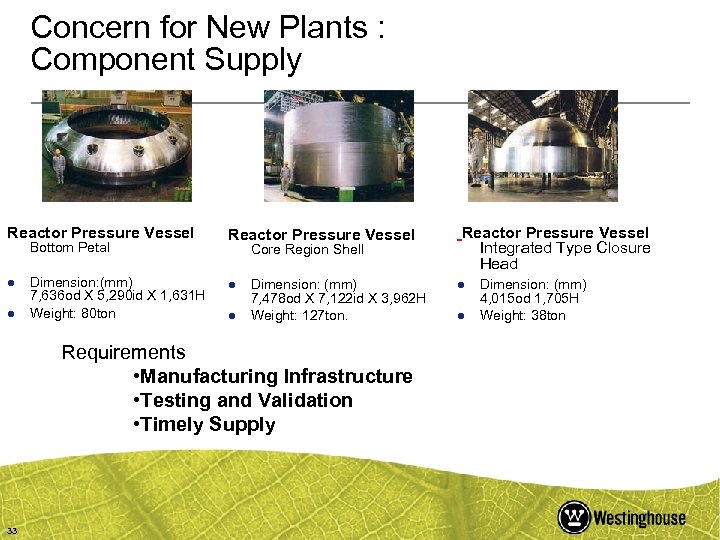

Concern for New Plants : Component Supply Reactor Pressure Vessel Bottom Petal ● Dimension: (mm) 7, 636 od X 5, 290 id X 1, 631 H ● Weight: 80 ton Reactor Pressure Vessel Core Region Shell ● Dimension: (mm) 7, 478 od X 7, 122 id X 3, 962 H ● Weight: 127 ton. Requirements • Manufacturing Infrastructure • Testing and Validation • Timely Supply 33 Reactor Pressure Vessel Integrated Type Closure Head ● Dimension: (mm) 4, 015 od 1, 705 H ● Weight: 38 ton

Concern for New Plants : Component Supply Reactor Pressure Vessel Bottom Petal ● Dimension: (mm) 7, 636 od X 5, 290 id X 1, 631 H ● Weight: 80 ton Reactor Pressure Vessel Core Region Shell ● Dimension: (mm) 7, 478 od X 7, 122 id X 3, 962 H ● Weight: 127 ton. Requirements • Manufacturing Infrastructure • Testing and Validation • Timely Supply 33 Reactor Pressure Vessel Integrated Type Closure Head ● Dimension: (mm) 4, 015 od 1, 705 H ● Weight: 38 ton

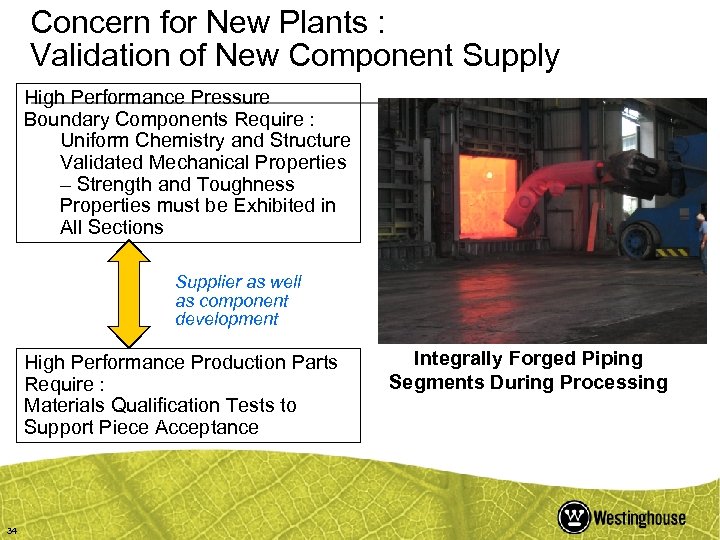

Concern for New Plants : Validation of New Component Supply High Performance Pressure Boundary Components Require : Uniform Chemistry and Structure Validated Mechanical Properties – Strength and Toughness Properties must be Exhibited in All Sections Supplier as well as component development High Performance Production Parts Require : Materials Qualification Tests to Support Piece Acceptance 34 Integrally Forged Piping Segments During Processing

Concern for New Plants : Validation of New Component Supply High Performance Pressure Boundary Components Require : Uniform Chemistry and Structure Validated Mechanical Properties – Strength and Toughness Properties must be Exhibited in All Sections Supplier as well as component development High Performance Production Parts Require : Materials Qualification Tests to Support Piece Acceptance 34 Integrally Forged Piping Segments During Processing

Concern for New Plants : Component Fabrication Capability ● Large welded Structure need processes to minimize residual stresses etc. 35

Concern for New Plants : Component Fabrication Capability ● Large welded Structure need processes to minimize residual stresses etc. 35

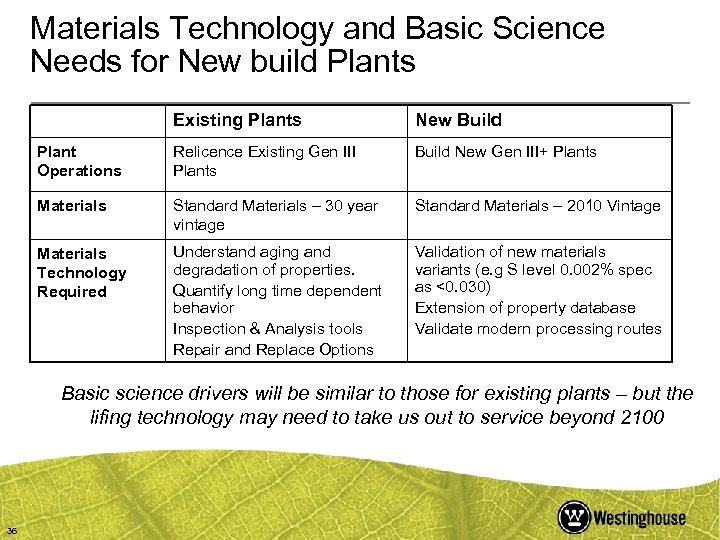

Materials Technology and Basic Science Needs for New build Plants Existing Plants New Build Plant Operations Relicence Existing Gen III Plants Build New Gen III+ Plants Materials Standard Materials – 30 year vintage Standard Materials – 2010 Vintage Materials Technology Required Understand aging and degradation of properties. Quantify long time dependent behavior Inspection & Analysis tools Repair and Replace Options Validation of new materials variants (e. g S level 0. 002% spec as <0. 030) Extension of property database Validate modern processing routes Basic science drivers will be similar to those for existing plants – but the lifing technology may need to take us out to service beyond 2100 36

Materials Technology and Basic Science Needs for New build Plants Existing Plants New Build Plant Operations Relicence Existing Gen III Plants Build New Gen III+ Plants Materials Standard Materials – 30 year vintage Standard Materials – 2010 Vintage Materials Technology Required Understand aging and degradation of properties. Quantify long time dependent behavior Inspection & Analysis tools Repair and Replace Options Validation of new materials variants (e. g S level 0. 002% spec as <0. 030) Extension of property database Validate modern processing routes Basic science drivers will be similar to those for existing plants – but the lifing technology may need to take us out to service beyond 2100 36

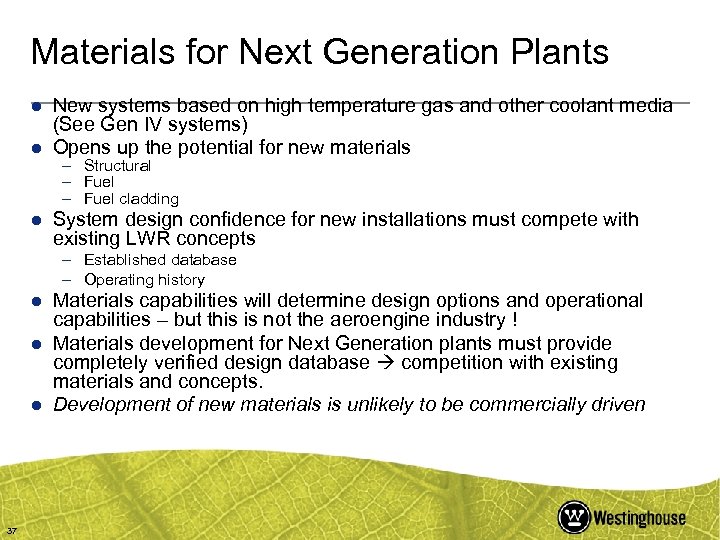

Materials for Next Generation Plants ● New systems based on high temperature gas and other coolant media (See Gen IV systems) ● Opens up the potential for new materials – Structural – Fuel cladding ● System design confidence for new installations must compete with existing LWR concepts – Established database – Operating history ● Materials capabilities will determine design options and operational capabilities – but this is not the aeroengine industry ! ● Materials development for Next Generation plants must provide completely verified design database competition with existing materials and concepts. ● Development of new materials is unlikely to be commercially driven 37

Materials for Next Generation Plants ● New systems based on high temperature gas and other coolant media (See Gen IV systems) ● Opens up the potential for new materials – Structural – Fuel cladding ● System design confidence for new installations must compete with existing LWR concepts – Established database – Operating history ● Materials capabilities will determine design options and operational capabilities – but this is not the aeroengine industry ! ● Materials development for Next Generation plants must provide completely verified design database competition with existing materials and concepts. ● Development of new materials is unlikely to be commercially driven 37

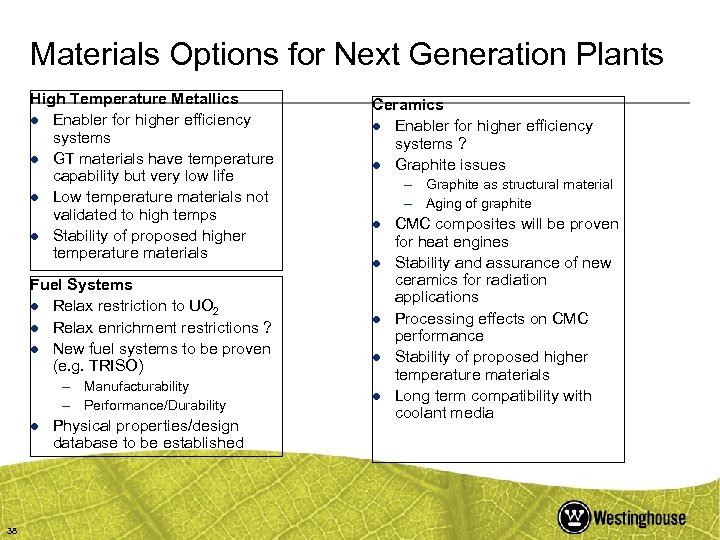

Materials Options for Next Generation Plants High Temperature Metallics ● Enabler for higher efficiency systems ● GT materials have temperature capability but very low life ● Low temperature materials not validated to high temps ● Stability of proposed higher temperature materials Fuel Systems ● Relax restriction to UO 2 ● Relax enrichment restrictions ? ● New fuel systems to be proven (e. g. TRISO) – Manufacturability – Performance/Durability ● Physical properties/design database to be established 38 Ceramics ● Enabler for higher efficiency systems ? ● Graphite issues – Graphite as structural material – Aging of graphite ● CMC composites will be proven for heat engines ● Stability and assurance of new ceramics for radiation applications ● Processing effects on CMC performance ● Stability of proposed higher temperature materials ● Long term compatibility with coolant media

Materials Options for Next Generation Plants High Temperature Metallics ● Enabler for higher efficiency systems ● GT materials have temperature capability but very low life ● Low temperature materials not validated to high temps ● Stability of proposed higher temperature materials Fuel Systems ● Relax restriction to UO 2 ● Relax enrichment restrictions ? ● New fuel systems to be proven (e. g. TRISO) – Manufacturability – Performance/Durability ● Physical properties/design database to be established 38 Ceramics ● Enabler for higher efficiency systems ? ● Graphite issues – Graphite as structural material – Aging of graphite ● CMC composites will be proven for heat engines ● Stability and assurance of new ceramics for radiation applications ● Processing effects on CMC performance ● Stability of proposed higher temperature materials ● Long term compatibility with coolant media

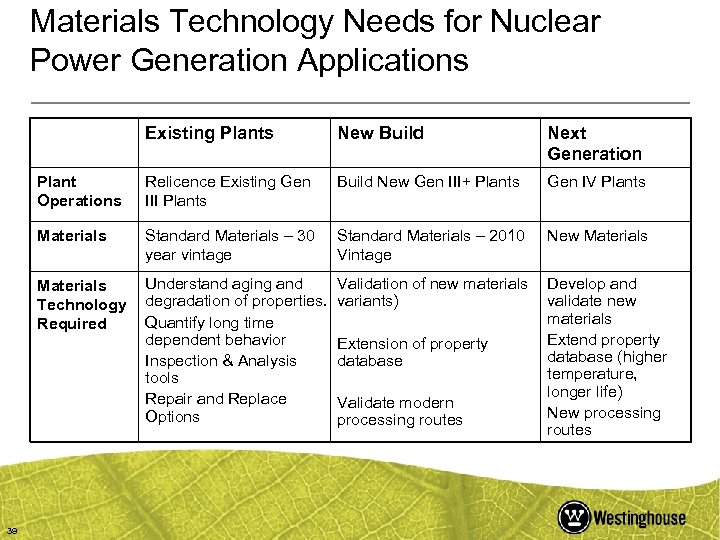

Materials Technology Needs for Nuclear Power Generation Applications Existing Plants Next Generation Plant Operations Relicence Existing Gen III Plants Build New Gen III+ Plants Gen IV Plants Materials Standard Materials – 30 year vintage Standard Materials – 2010 Vintage New Materials Technology Required 39 New Build Understand aging and degradation of properties. Quantify long time dependent behavior Inspection & Analysis tools Repair and Replace Options Validation of new materials variants) Develop and validate new materials Extend property database (higher temperature, longer life) New processing routes Extension of property database Validate modern processing routes

Materials Technology Needs for Nuclear Power Generation Applications Existing Plants Next Generation Plant Operations Relicence Existing Gen III Plants Build New Gen III+ Plants Gen IV Plants Materials Standard Materials – 30 year vintage Standard Materials – 2010 Vintage New Materials Technology Required 39 New Build Understand aging and degradation of properties. Quantify long time dependent behavior Inspection & Analysis tools Repair and Replace Options Validation of new materials variants) Develop and validate new materials Extend property database (higher temperature, longer life) New processing routes Extension of property database Validate modern processing routes