4592d7be7b5b4bab0ddc9c86de1135e8.ppt

- Количество слайдов: 34

MASDAR International Consultants 2001: AFDB/MOFA Agro Industry Study 2001 2003: Technoserve Ghana Cashew Processing Aquaculture 0

So Cashew: Where does it all start? 1

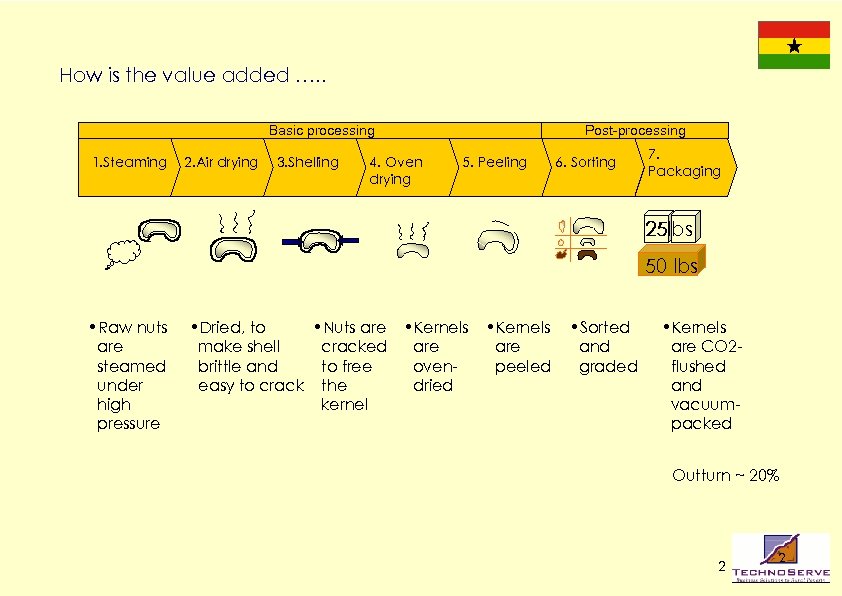

How is the value added …. . Basic processing 1. Steaming 2. Air drying 3. Shelling Post-processing 4. Oven drying 5. Peeling 6. Sorting 7. Packaging 25 lbs 25 50 lbs • Raw nuts are steamed under high pressure • Dried, to • Nuts are make shell cracked brittle and to free easy to crack the kernel • Kernels are ovendried • Kernels are peeled • Sorted and graded • Kernels are CO 2 flushed and vacuumpacked Outturn ~ 20% 2 2

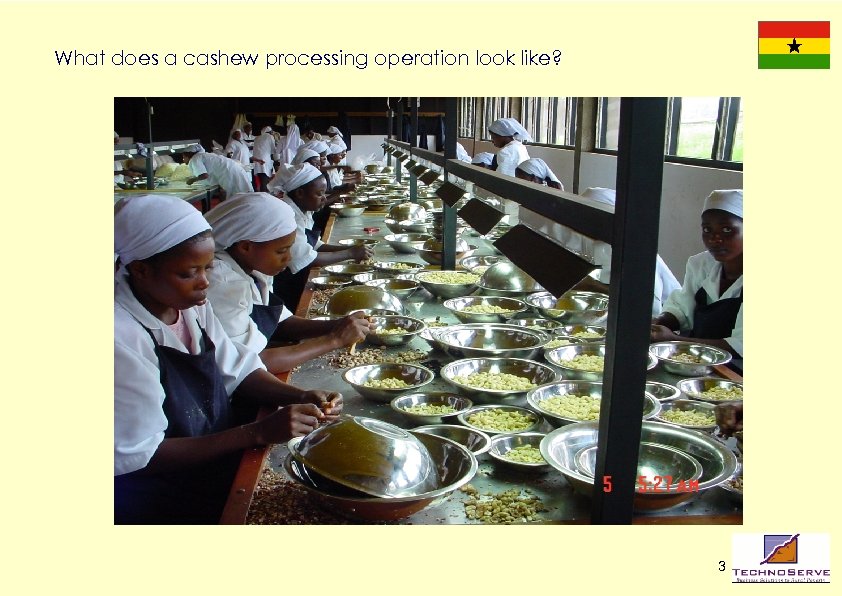

What does a cashew processing operation look like? 3

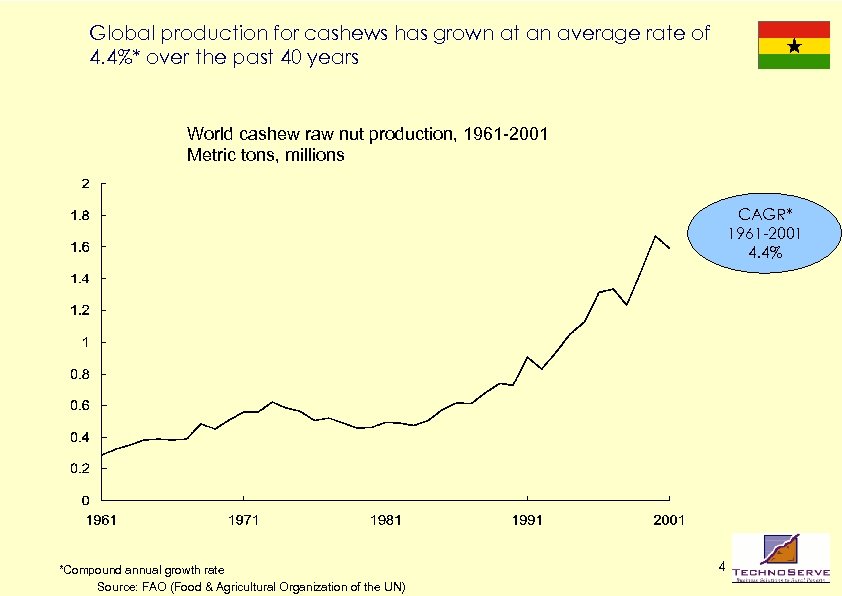

Global production for cashews has grown at an average rate of 4. 4%* over the past 40 years World cashew raw nut production, 1961 -2001 Metric tons, millions CAGR* 1961 -2001 4. 4% *Compound annual growth rate Source: FAO (Food & Agricultural Organization of the UN) 4

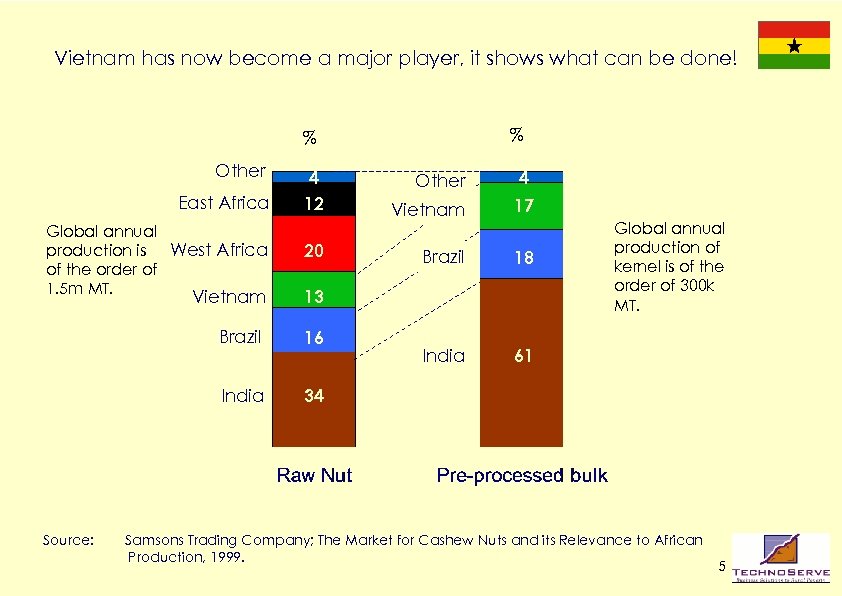

Vietnam has now become a major player, it shows what can be done! % % Other East Africa Global annual production is West Africa of the order of 1. 5 m MT. 4 12 20 Vietnam India Source: 16 4 Vietnam 17 Brazil 18 India 61 13 Brazil Other Global annual production of kernel is of the order of 300 k MT. 34 Samsons Trading Company; The Market for Cashew Nuts and its Relevance to African Production, 1999. 5

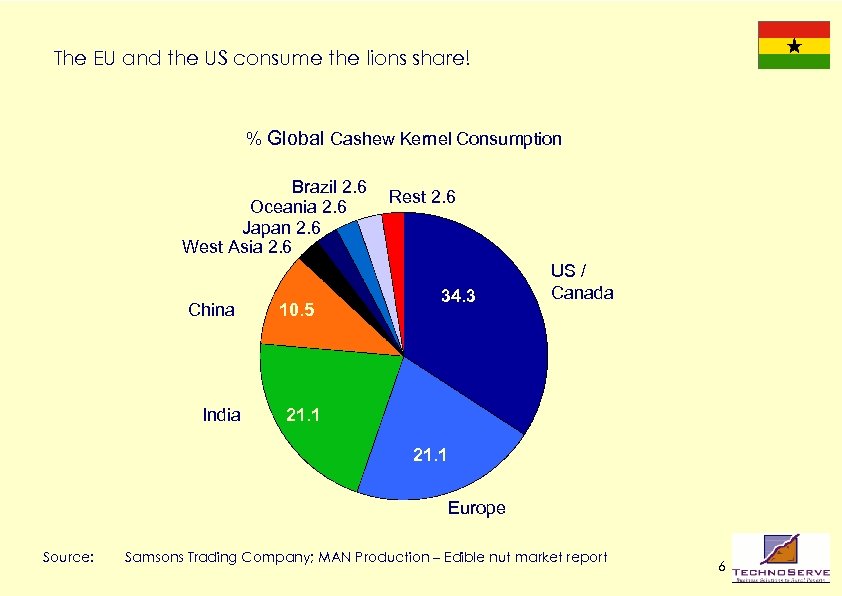

The EU and the US consume the lions share! % Global Cashew Kernel Consumption Brazil 2. 6 Oceania 2. 6 Japan 2. 6 West Asia 2. 6 China India 10. 5 Rest 2. 6 34. 3 US / Canada 21. 1 Europe Source: Samsons Trading Company; MAN Production – Edible nut market report 6

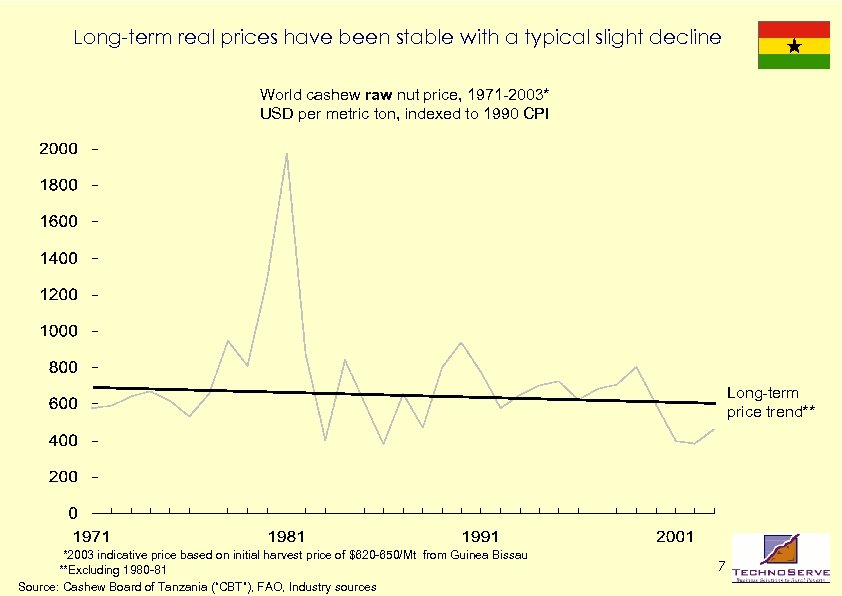

Long-term real prices have been stable with a typical slight decline World cashew raw nut price, 1971 -2003* USD per metric ton, indexed to 1990 CPI Long-term price trend** *2003 indicative price based on initial harvest price of $620 -650/Mt from Guinea Bissau **Excluding 1980 -81 Source: Cashew Board of Tanzania (“CBT”), FAO, Industry sources 7

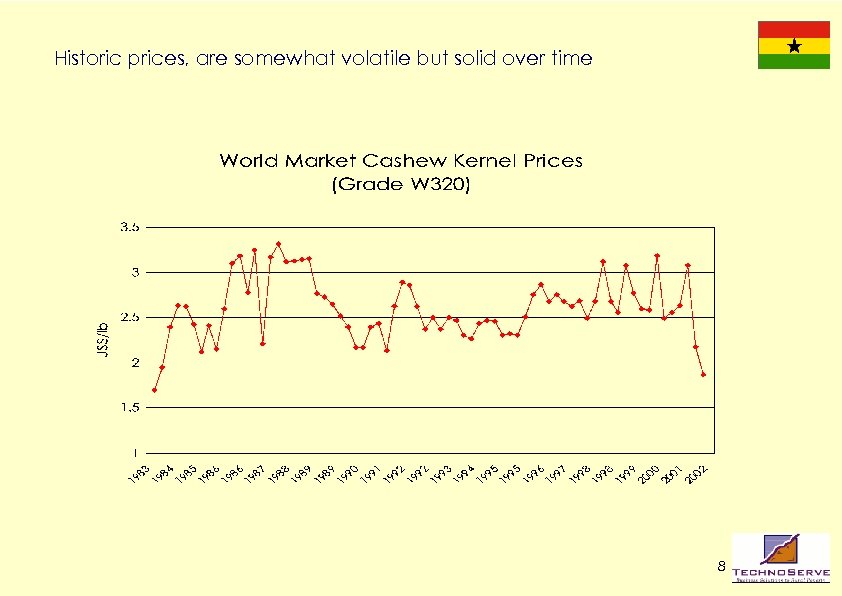

Historic prices, are somewhat volatile but solid over time 8

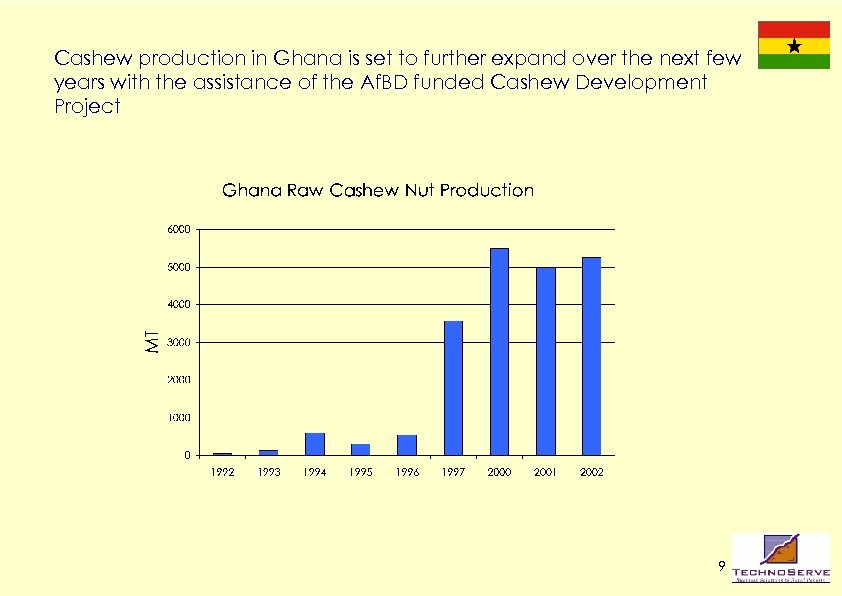

Cashew production in Ghana is set to further expand over the next few years with the assistance of the Af. BD funded Cashew Development Project 9

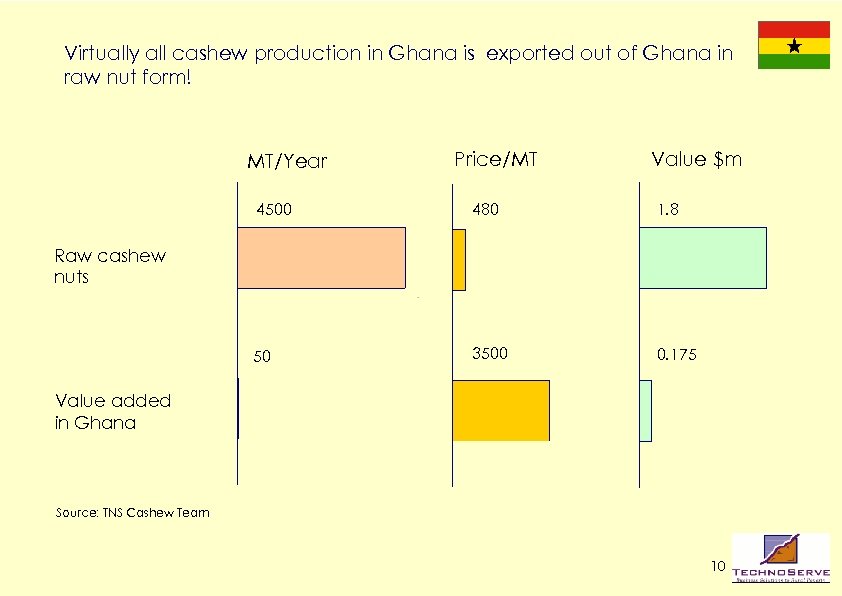

Virtually all cashew production in Ghana is exported out of Ghana in raw nut form! MT/Year Price/MT Value $m 4500 480 1. 8 50 3500 0. 175 Raw cashew nuts Value added in Ghana Source: TNS Cashew Team 10

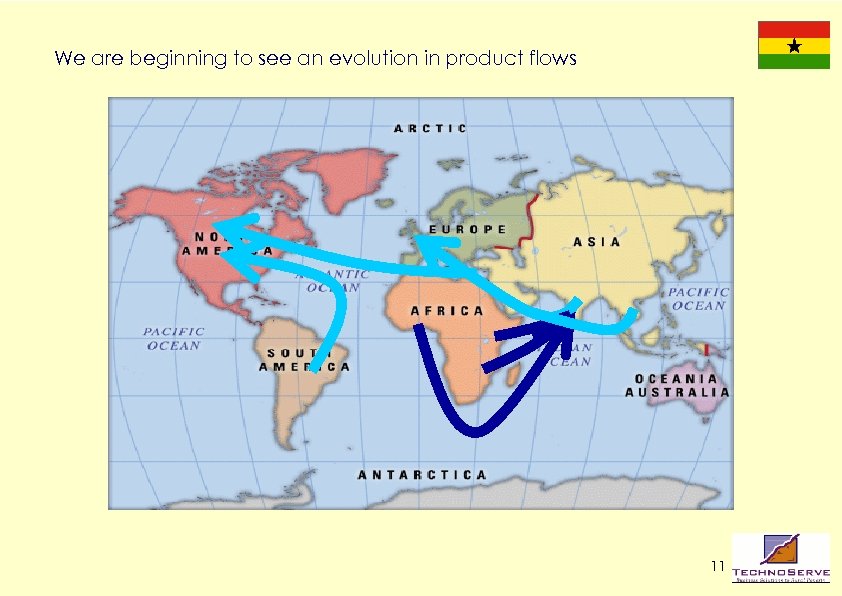

We are beginning to see an evolution in product flows 11

To: 12

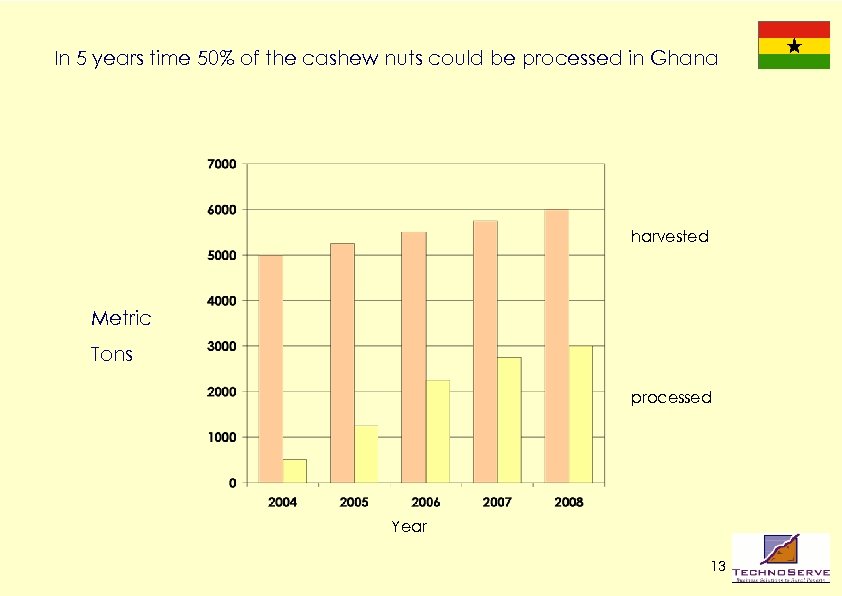

In 5 years time 50% of the cashew nuts could be processed in Ghana harvested Metric Tons processed Year 13

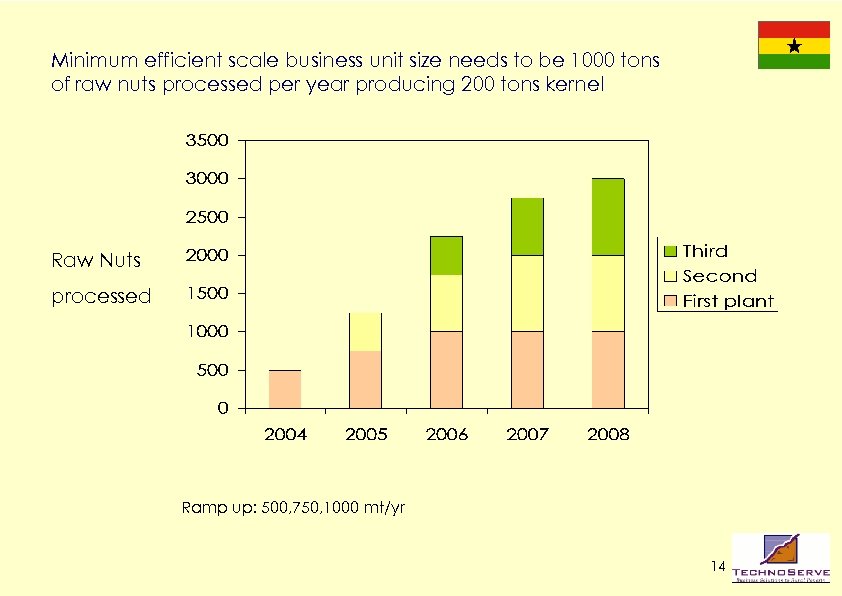

Minimum efficient scale business unit size needs to be 1000 tons of raw nuts processed per year producing 200 tons kernel Raw Nuts processed Ramp up: 500, 750, 1000 mt/yr 14

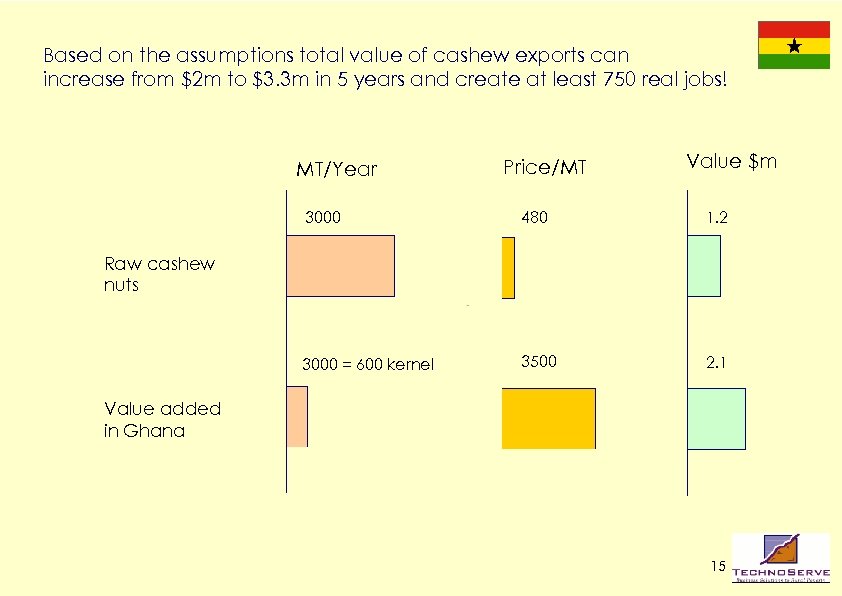

Based on the assumptions total value of cashew exports can increase from $2 m to $3. 3 m in 5 years and create at least 750 real jobs! MT/Year Price/MT Value $m 3000 480 1. 2 3000 = 600 kernel 3500 2. 1 Raw cashew nuts Value added in Ghana 15

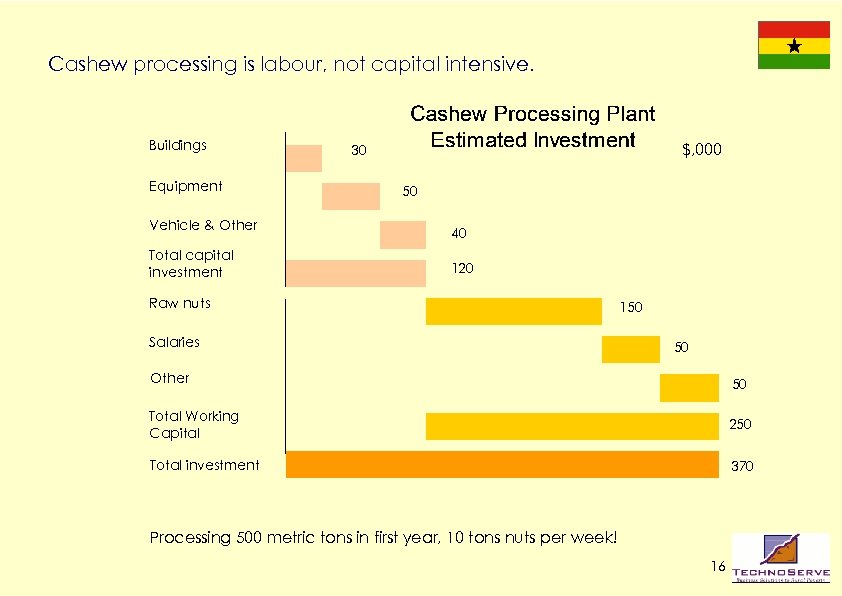

Cashew processing is labour, not capital intensive. Buildings Equipment Vehicle & Other Total capital investment $, 000 30 50 40 120 Raw nuts Salaries 150 50 Other 50 Total Working Capital 250 Total investment 370 Processing 500 metric tons in first year, 10 tons nuts per week! 16

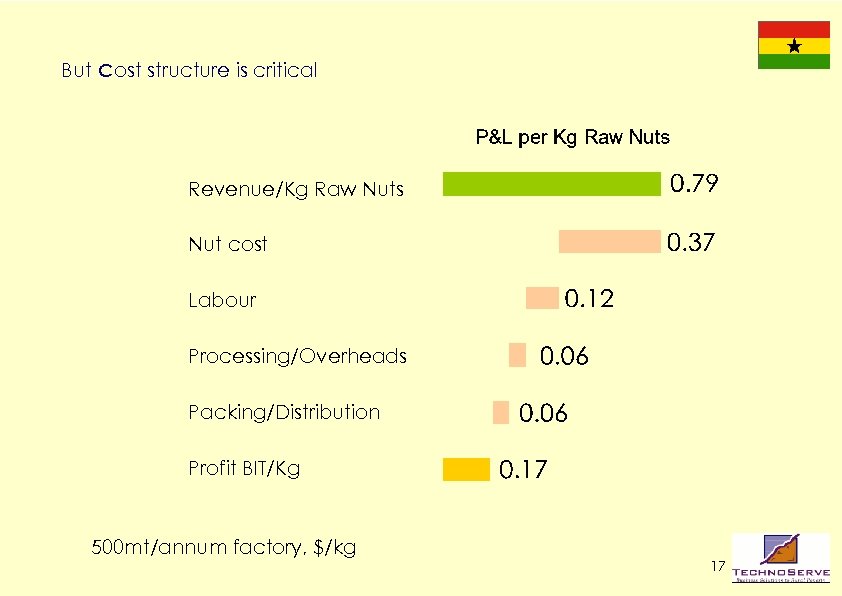

But cost structure is critical Revenue/Kg Raw Nuts Nut cost Labour Processing/Overheads Packing/Distribution Profit BIT/Kg 500 mt/annum factory, $/kg 17

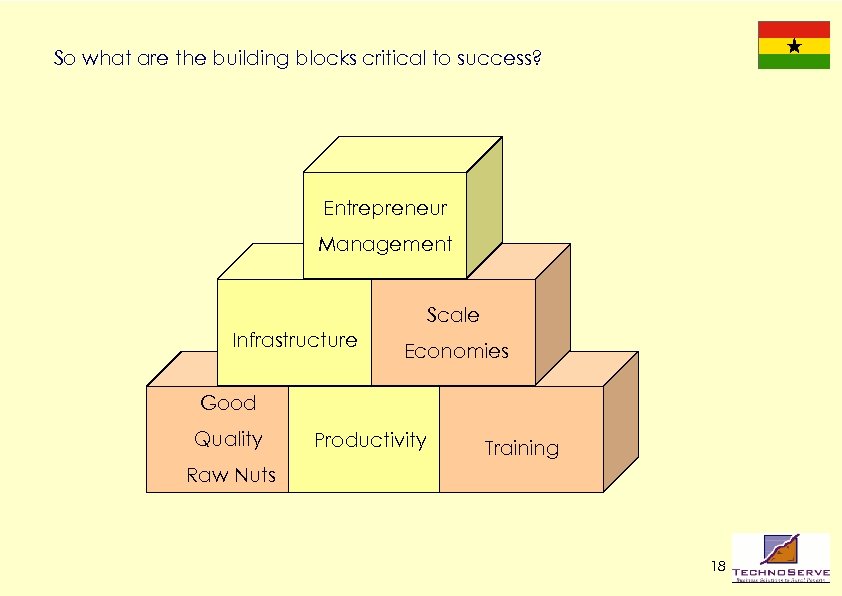

So what are the building blocks critical to success? Entrepreneur Management Scale Infrastructure Economies Good Quality Productivity Training Raw Nuts 18

Who can help develop my business idea? MOFA Cashew Development Project (launched April 2003)l • Increase cashew production and production in Ghana • $13 m provided by African Development Bank/GOG • $4. 8 m credit facilities available to private sector • 6 year implementation period, 5 regions. • Contact CDP on 021 662472 Technoserve Experience of cashew in Mozambique, Tanzania and Ghana Knowledge and Information of International Cashew Industry Market Linkages Business Development Skills Contact us on 021 763675 19

• There is a future in farming fish! November 2003 20

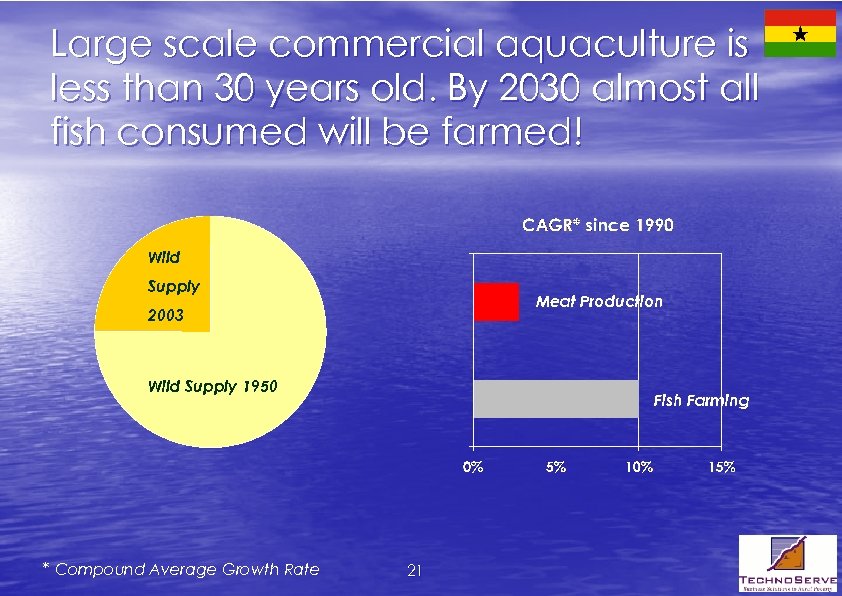

Large scale commercial aquaculture is less than 30 years old. By 2030 almost all fish consumed will be farmed! Wild Supply Meat Production 2003 Wild Supply 1950 * Compound Average Growth Rate Fish Farming 21

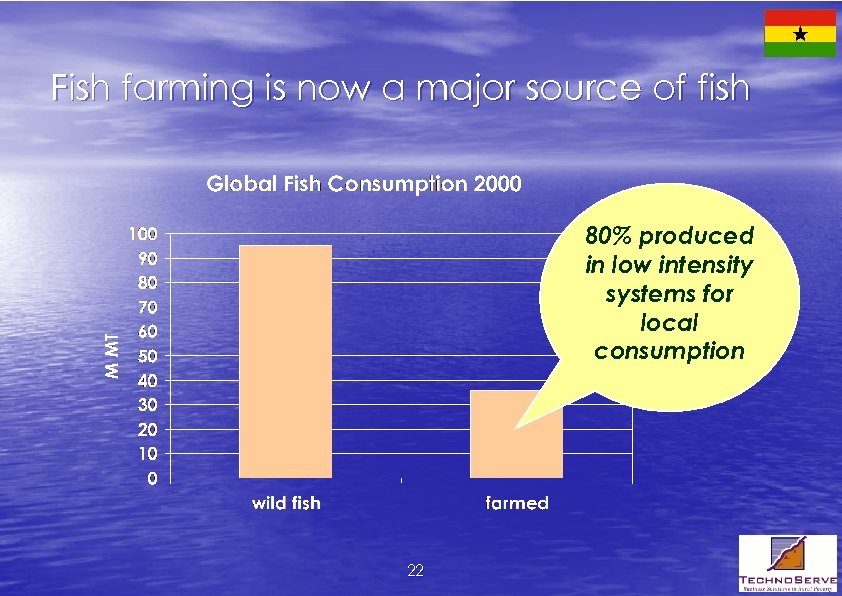

Fish farming is now a major source of fish 80% produced in low intensity systems for local consumption 22

the local pond • Current catch (350 MT) is at max. sustainable level • Fish imports in 2000 were estimated at $150 m • Fish represents 70% of animal protein consumed • Fish is the major source of protein in most dishes • Demand is growing with population increase 23

the EU fish supper • Technoserve Market Study 2003 looked at the opportunity to export tilapia from Ghana to EU – EU fish market huge and growing – Existing tilapia suppliers making slow inroads – Need to educate customers to potential – New suppliers should focus on fresh sector – Cost of product delivered critical (€ 6/Kg) – Regulations complex – Duty free access 24

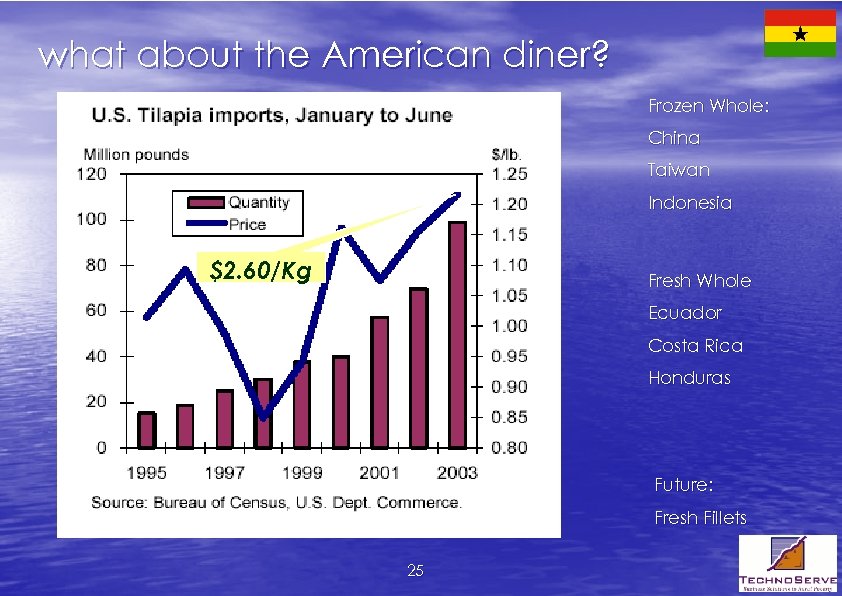

what about the American diner? Frozen Whole: China Taiwan Indonesia $2. 60/Kg Fresh Whole Ecuador Costa Rica Honduras Future: Fresh Fillets 25

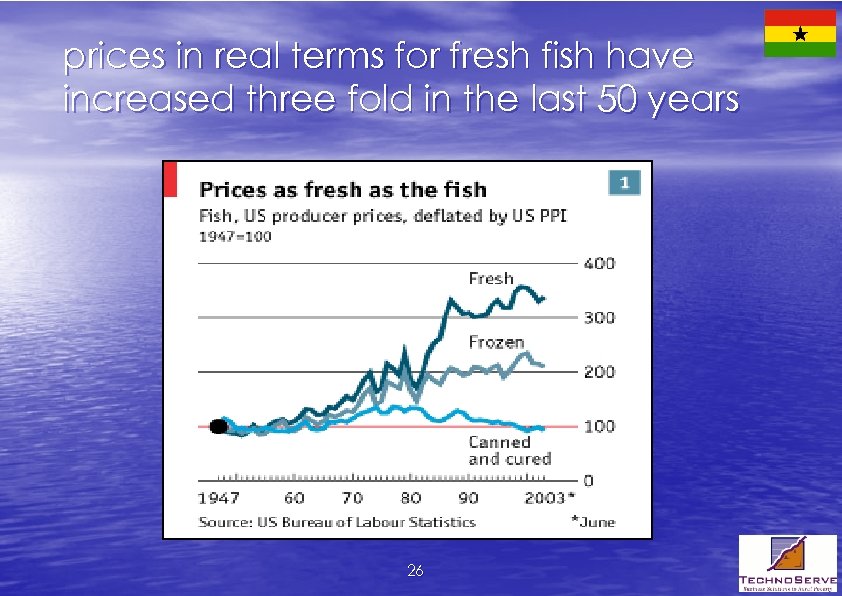

prices in real terms for fresh fish have increased three fold in the last 50 years 26

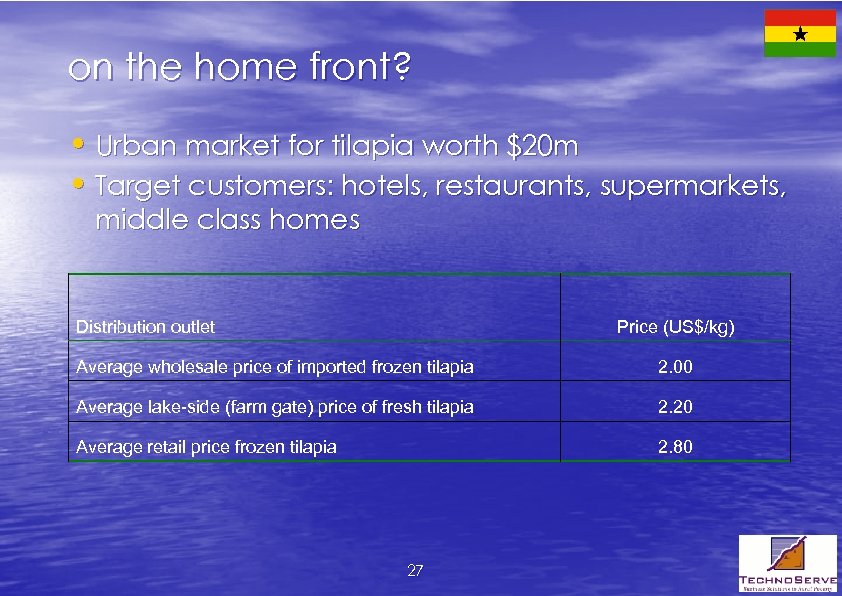

on the home front? • Urban market for tilapia worth $20 m • Target customers: hotels, restaurants, supermarkets, middle class homes Distribution outlet Price (US$/kg) Average wholesale price of imported frozen tilapia 2. 00 Average lake-side (farm gate) price of fresh tilapia 2. 20 Average retail price frozen tilapia 2. 80 27

the catch • Ponds: rejuvenation, improvements, new ponds • Inland water bodies, particularly Volta Lake • New Technology: Cages – Wide span of water surface – Gentle breeze and a gentle current – Water quality (p. H, temp, O 2, Ca) – Depth of water (6 -8 m) • Volta Lake has some ideal sites. 28

model cage farm • 1000 tons Tilapia annually • 180 days from hatching to harvesting • Production cycle to produce 20 tons a week • Consume 2, 500 tons extruded feed • Employ 40 full time staff • Analysis suggested this is an attractive investment 29

issues • Site location • Need stock with high genetic potential • High quality feed • Technical/management expertise • Environmental management plan • Security 30

conclusion • Strong local market for tilapia • Suitable natural resources • Technology proven • Financially viable • Management/Knowledge Critical 31

Give a man a fish and he will eat for a day Teach a man to fish and he will eat for life Help that man to build a fish farm then he can feed a nation! 32

Contact Details • Presentations: www. masdar. com • Internet: www. technoserve. org • Email : tns@tnsgh. org • Tel Accra 021 763675 • Tel Kumasi 051 60264 33

4592d7be7b5b4bab0ddc9c86de1135e8.ppt