04539281c5c05a099a08a0f69d15357b.ppt

- Количество слайдов: 63

Mars or Bust Management Briefing Subsystem Update 11/19/03

Current Status - all Subsystems • Revised Systems Requirements Document • Block diagrams indicating inputs/outputs • Requests for Information (RFI’s) written and responded • Iterating technology equipment lists with mass, power and volume estimates

Environment Control and Life Support System (ECLSS)

Current Status • All technologies selected with optimum mass, power, volume considerations • Functional diagrams completed: – – Atmosphere Water Waste Food • Human Consumables estimates completed: – – Air Water Waste Food

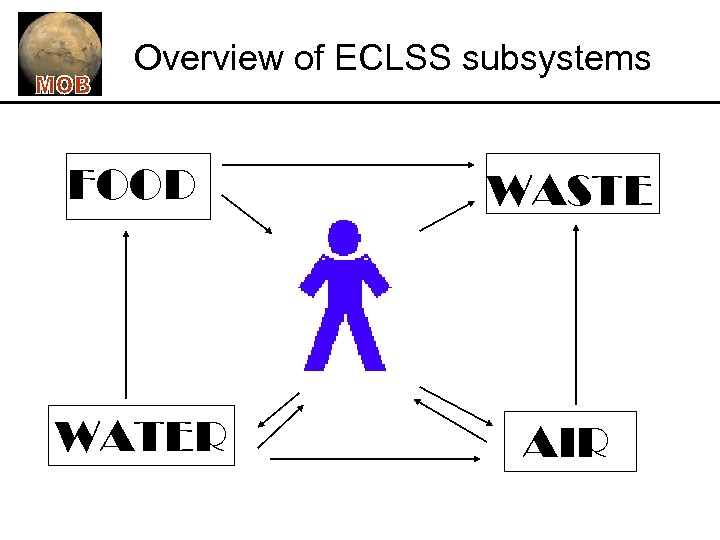

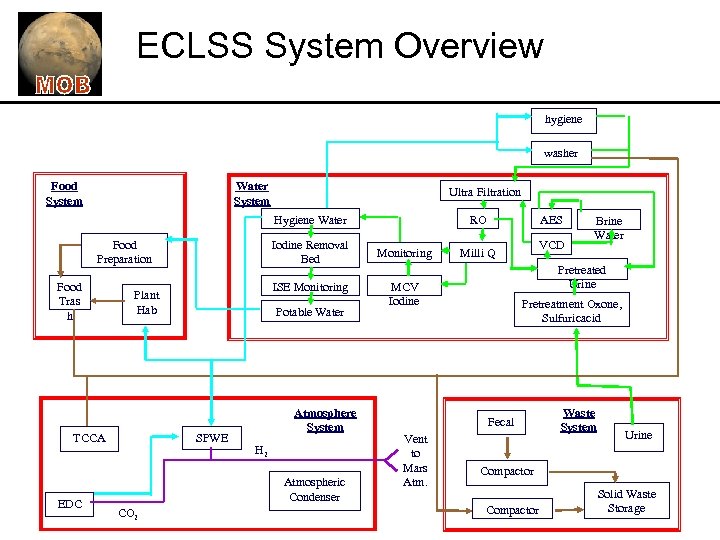

Overview of ECLSS subsystems FOOD WASTE WATER AIR

ECLSS System Overview hygiene washer Food System Water System Ultra Filtration Hygiene Water Iodine Removal Bed Food Preparation Food Tras h TCCA EDC ISE Monitoring Plant Hab Potable Water SPWE Atmosphere System H 2 Atmospheric Condenser CO 2 RO Monitoring AES VCD Milli Q Pretreated Urine MCV Iodine Pretreatment Oxone, Sulfuricacid Fecal Vent to Mars Atm. Brine Water Waste System Urine Compactor Solid Waste Storage

![Human Consumables • Atmosphere – O 2 consumption: 0. 85 kg/man-day [Eckart, 1996] – Human Consumables • Atmosphere – O 2 consumption: 0. 85 kg/man-day [Eckart, 1996] –](https://present5.com/presentation/04539281c5c05a099a08a0f69d15357b/image-7.jpg)

Human Consumables • Atmosphere – O 2 consumption: 0. 85 kg/man-day [Eckart, 1996] – CO 2 production: 1. 0 kg/man-day [Eckart, 1996] – Leakage (14. 7 psi): 0. 11 kg. N 2/day & 0. 03 kg. O 2/day • Water – Potable 3 L/person/day [Larson, 1997] • 1. 86 Food Preparation • 1. 14 Drink – Hygiene 18. 5 L/person/day [Larson, 1997] • 5. 5 Personal Hygiene • 12. 5 Laundry • 0. 5 Toilet Flush

![Human Consumables • Waste – Urine: 9. 36 kg/day [Eckart, 1996] – Feces: 0. Human Consumables • Waste – Urine: 9. 36 kg/day [Eckart, 1996] – Feces: 0.](https://present5.com/presentation/04539281c5c05a099a08a0f69d15357b/image-8.jpg)

Human Consumables • Waste – Urine: 9. 36 kg/day [Eckart, 1996] – Feces: 0. 72 kg/day [Eckart, 1996] – Technology & Biomass 1. 012 kg/day [Eckart, 1996] • Food – ~ 2, 000 k. Cal person per day [Miller, 1994]

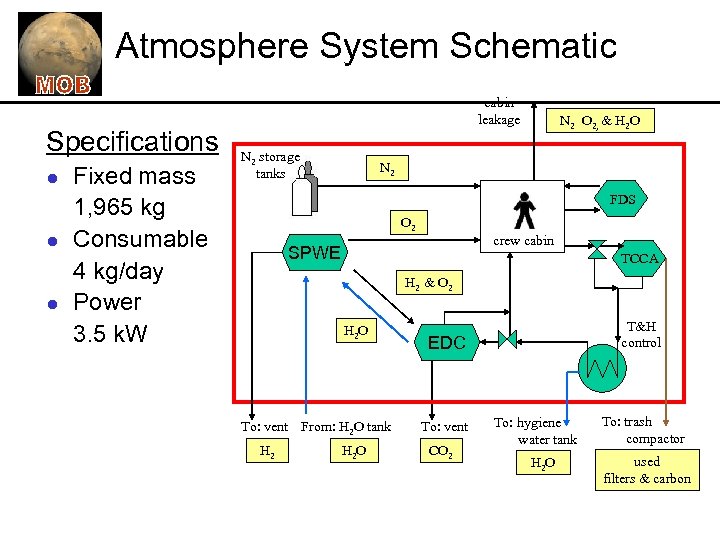

Atmosphere System Schematic Specifications l l l Fixed mass 1, 965 kg Consumable 4 kg/day Power 3. 5 k. W cabin leakage N 2 storage tanks N 2 O 2, & H 2 O N 2 FDS O 2 crew cabin SPWE TCCA H 2 & O 2 H 2 O To: vent From: H 2 O tank H 2 O T&H control EDC To: vent CO 2 To: hygiene water tank H 2 O To: trash compactor used filters & carbon

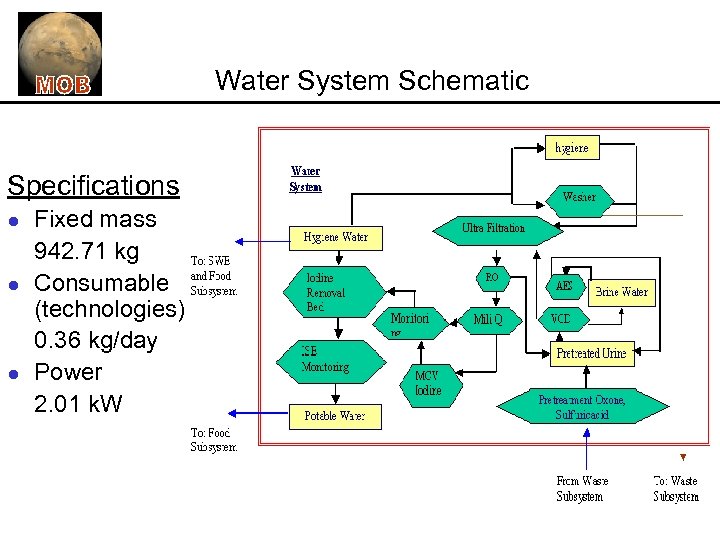

Water System Schematic Specifications l l l Fixed mass 942. 71 kg Consumable (technologies) 0. 36 kg/day Power 2. 01 k. W

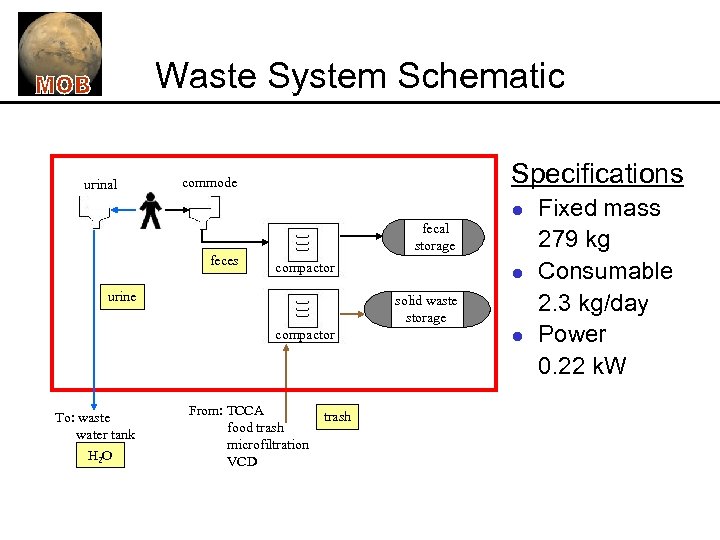

Waste System Schematic urinal Specifications commode l feces fecal storage compactor urine solid waste storage compactor To: waste water tank H 2 O l From: TCCA food trash microfiltration VCD trash l Fixed mass 279 kg Consumable 2. 3 kg/day Power 0. 22 k. W

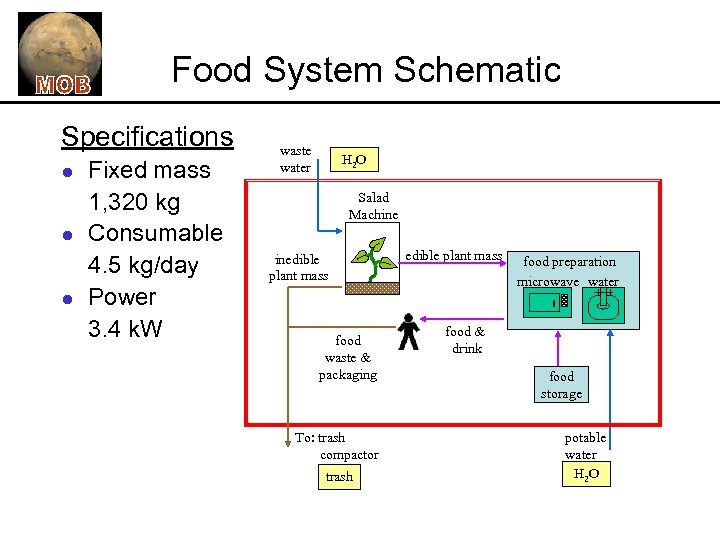

Food System Schematic Specifications l l l Fixed mass 1, 320 kg Consumable 4. 5 kg/day Power 3. 4 k. W waste water H 2 O Salad Machine inedible plant mass food waste & packaging To: trash compactor trash edible plant mass food preparation microwave water food & drink food storage potable water H 2 O

Structures

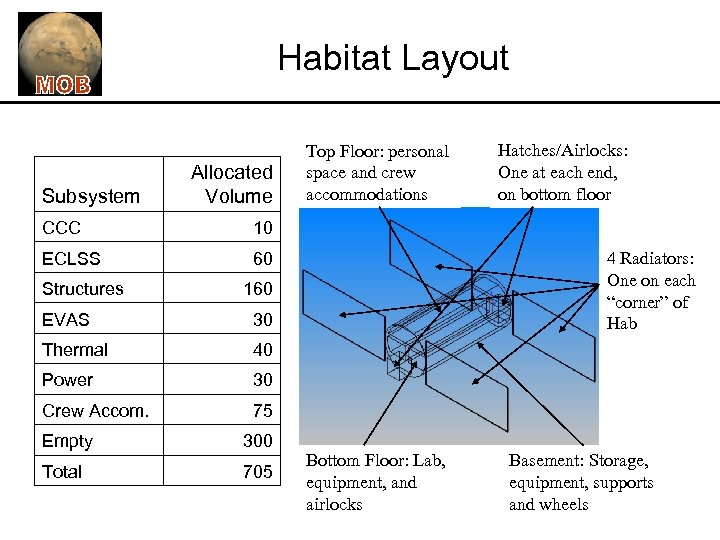

Habitat Layout Subsystem Allocated Volume CCC 60 Hatches/Airlocks: One at each end, on bottom floor 10 ECLSS Top Floor: personal space and crew accommodations Structures 4 Radiators: One on each “corner” of Hab 160 EVAS 30 Thermal 40 Power 30 Crew Accom. 75 Empty 300 Total 705 Bottom Floor: Lab, equipment, and airlocks Basement: Storage, equipment, supports and wheels

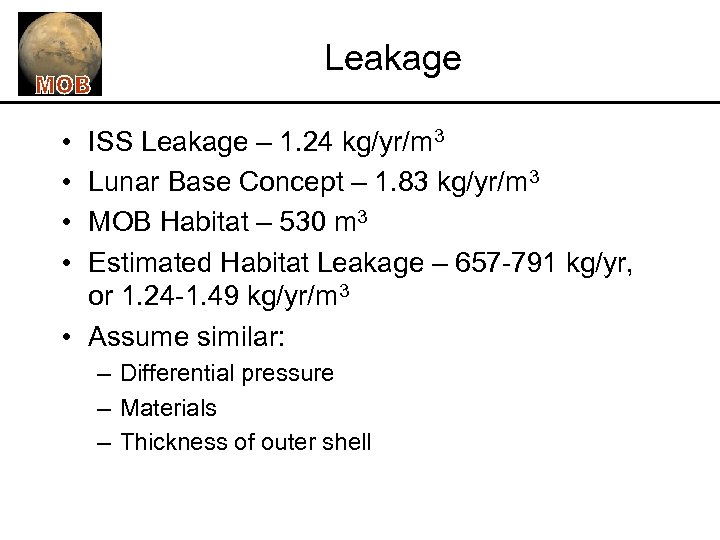

Leakage • • ISS Leakage – 1. 24 kg/yr/m 3 Lunar Base Concept – 1. 83 kg/yr/m 3 MOB Habitat – 530 m 3 Estimated Habitat Leakage – 657 -791 kg/yr, or 1. 24 -1. 49 kg/yr/m 3 • Assume similar: – Differential pressure – Materials – Thickness of outer shell

Future Tasks • • • Load analysis Insulation Shielding Layout – more detail Volume Allocation – more detail

Thermal Control

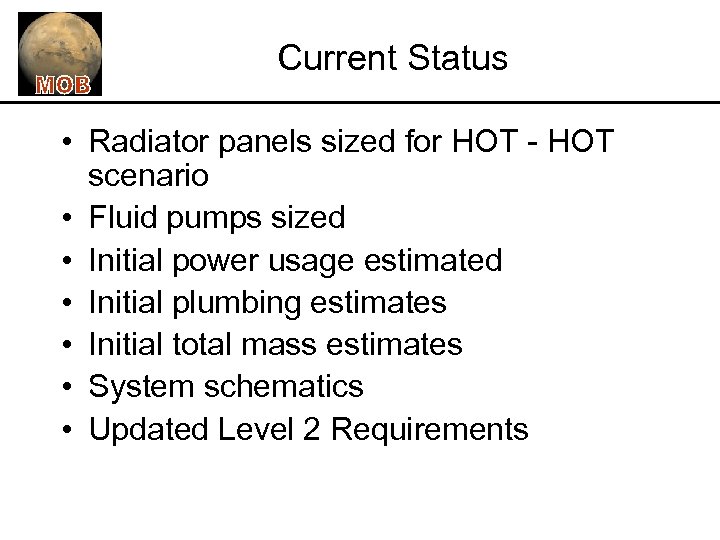

Current Status • Radiator panels sized for HOT - HOT scenario • Fluid pumps sized • Initial power usage estimated • Initial plumbing estimates • Initial total mass estimates • System schematics • Updated Level 2 Requirements

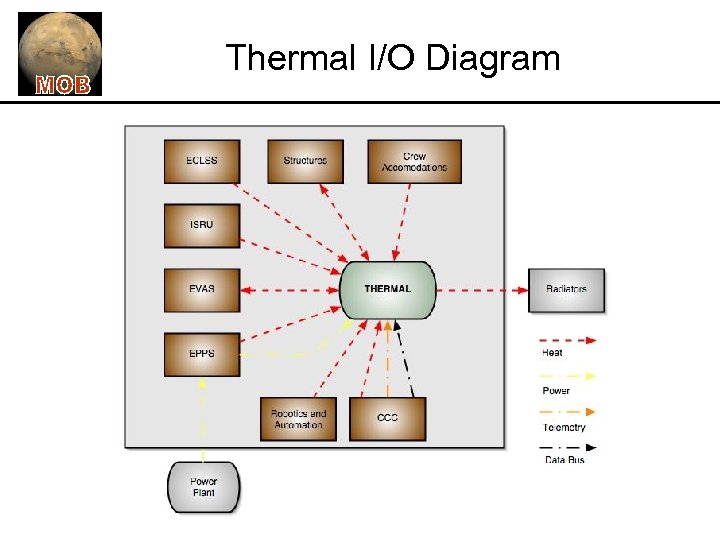

Thermal I/O Diagram

Thermal Schematic

Thermal System Overview • Requirement – Must reject 25 KW (from Power system) – Must cool each subsystem – Must use a non-toxic interior fluid loop – External fluid loop must not freeze – Accommodating transit to Mars • Design – Rejects up to 40 KW via radiator panels – Cold plates for heat collection from each subsystem – Internal water fluid loop – External TBD fluid loop – During transit heat exchangers will connect to the transfer vehicle’s thermal system

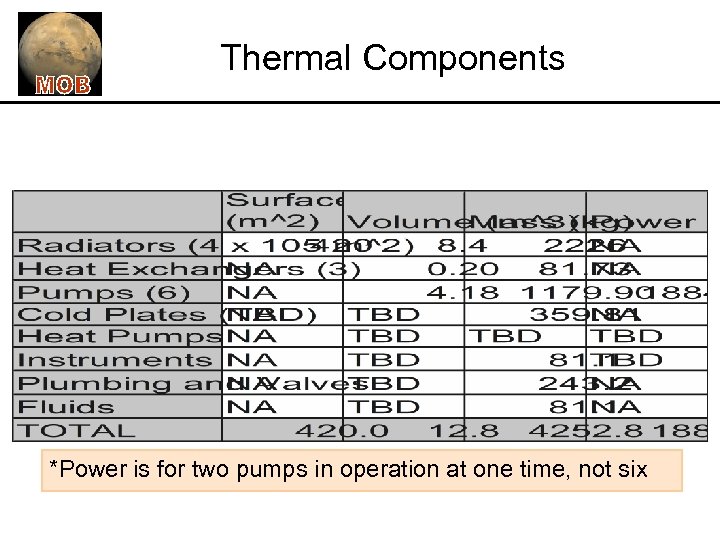

Thermal Components *Power is for two pumps in operation at one time, not six

Future Tasks • • • Cold plates and sizing External fluid loop Heat exchangers Radiator locations Fluid storage COLD - COLD scenario Sensors/Data/Command structure FMEA Report

Command, Control, Communication (C 3)

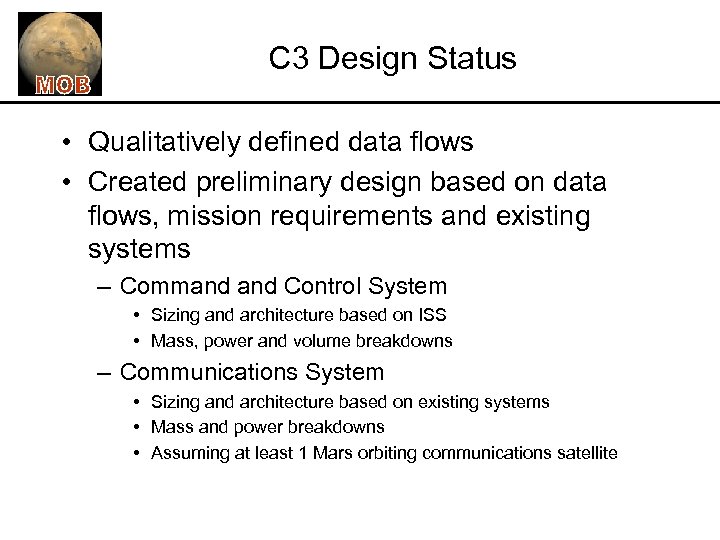

C 3 Design Status • Qualitatively defined data flows • Created preliminary design based on data flows, mission requirements and existing systems – Command Control System • Sizing and architecture based on ISS • Mass, power and volume breakdowns – Communications System • Sizing and architecture based on existing systems • Mass and power breakdowns • Assuming at least 1 Mars orbiting communications satellite

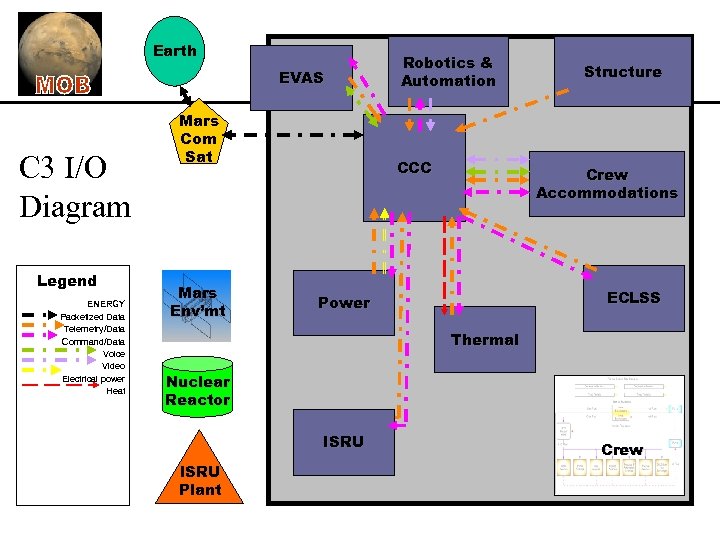

Earth EVAS C 3 I/O Diagram Legend ENERGY Packetized Data Telemetry/Data Command/Data Voice Video Electrical power Heat Mars Com Sat Mars Env’mt Robotics & Automation CCC Structure Crew Accommodations ECLSS Power Thermal Nuclear Reactor ISRU Plant Crew

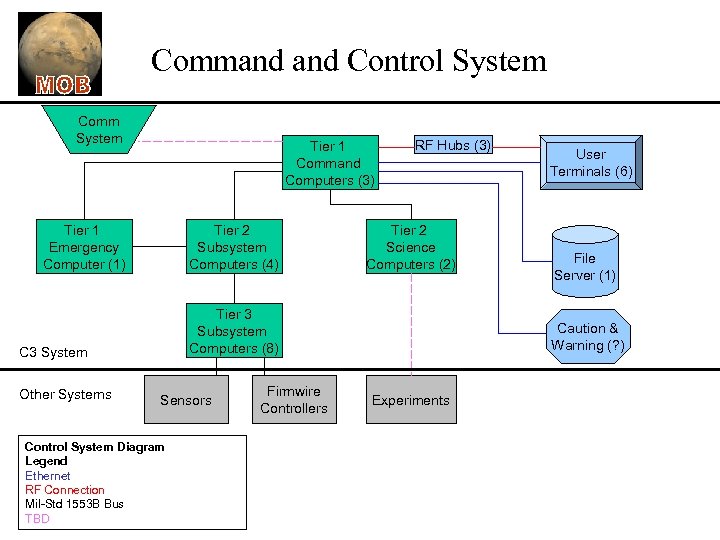

Command Control System Comm System Tier 1 Command Computers (3) Tier 1 Emergency Computer (1) Tier 2 Subsystem Computers (4) Tier 2 Science Computers (2) Tier 3 Subsystem Computers (8) C 3 System Other Systems RF Hubs (3) Sensors Control System Diagram Legend Ethernet RF Connection Mil-Std 1553 B Bus TBD Firmwire Controllers User Terminals (6) File Server (1) Caution & Warning (? ) Experiments

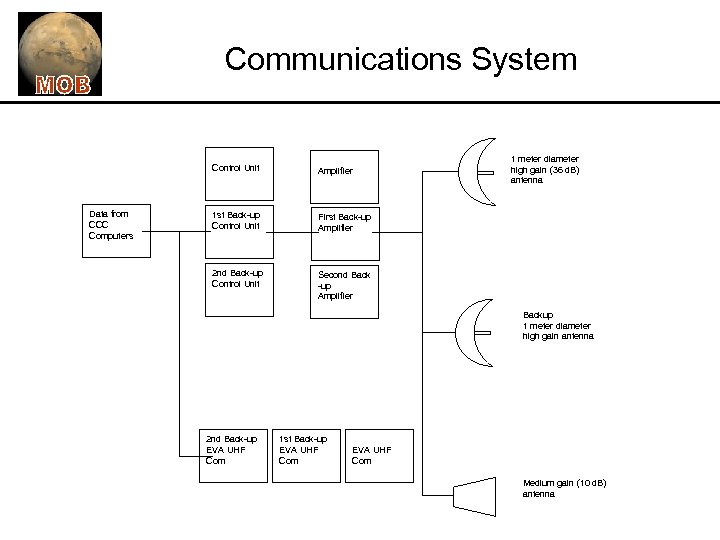

Communications System Control Unit Data from CCC Computers Amplifier 1 st Back-up Control Unit First Back-up Amplifier 2 nd Back-up Control Unit 1 meter diameter high gain (36 d. B) antenna Second Back -up Amplifier Backup 1 meter diameter high gain antenna 2 nd Back-up EVA UHF Com 1 st Back-up EVA UHF Com Medium gain (10 d. B) antenna

C 3 Future Tasks • Quantify data flows and adjust preliminary design • Determine spare parts needs • Estimate cabling mass • Address total system mass overrun • Define maintenance and operational requirements • FMEA • Report

Mission Operations and Crew Accommodations

Current Status – Completed initial Functional Diagram for Crew Accommodations – Iterating lists of operations received for each subsystem • Crew Operations • Automated Operations • Earth Controlled Operations – Giving input to subsystems • Based on human factors considerations • Incorporating MSIS, Larson and Pranke, experience – Iterating mass, power, & volume parameters

Crew Accommodations Functional Diagram

Crew Accommodations Equipment

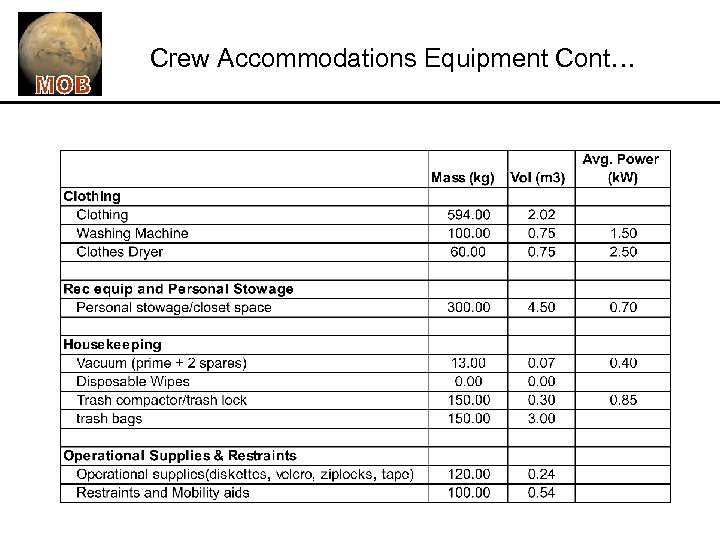

Crew Accommodations Equipment Cont…

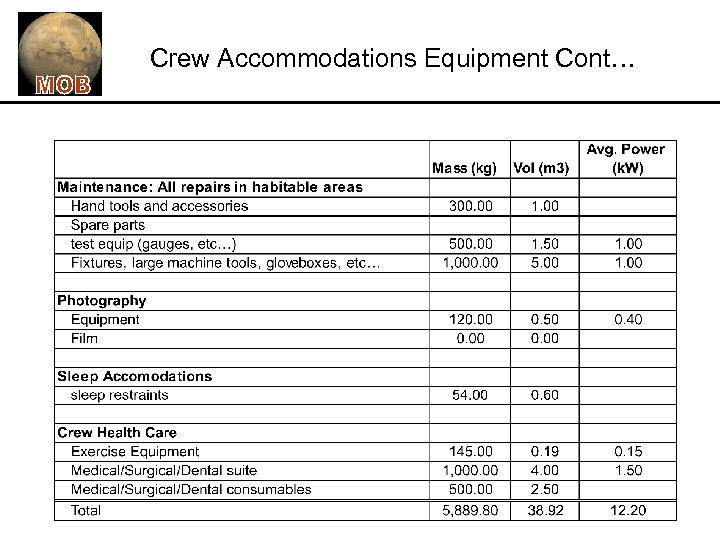

Crew Accommodations Equipment Cont…

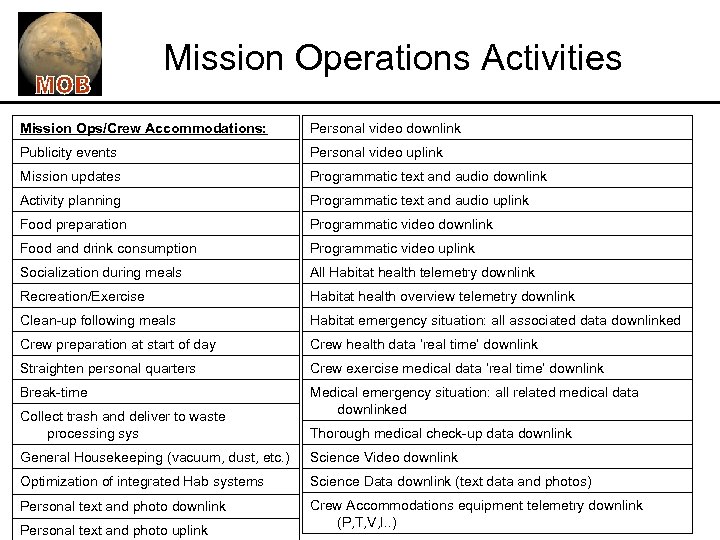

Mission Operations Activities Mission Ops/Crew Accommodations: Personal video downlink Publicity events Personal video uplink Mission updates Programmatic text and audio downlink Activity planning Programmatic text and audio uplink Food preparation Programmatic video downlink Food and drink consumption Programmatic video uplink Socialization during meals All Habitat health telemetry downlink Recreation/Exercise Habitat health overview telemetry downlink Clean-up following meals Habitat emergency situation: all associated data downlinked Crew preparation at start of day Crew health data ‘real time’ downlink Straighten personal quarters Crew exercise medical data ‘real time’ downlink Break-time Medical emergency situation: all related medical data downlinked Collect trash and deliver to waste processing sys Thorough medical check-up data downlink General Housekeeping (vacuum, dust, etc. ) Science Video downlink Optimization of integrated Hab systems Science Data downlink (text data and photos) Personal text and photo downlink Crew Accommodations equipment telemetry downlink (P, T, V, I. . ) Personal text and photo uplink

Future Tasks – Continue integration of human factors into subsystems – Create Data Flow Diagram – Create preliminary crew schedules • • • Equipment Maintenance Housekeeping Proficiency Training Scientific Tasks Programs/Paperwork Personal Time – Integration with subsystems regarding resulting schedules

Robotics and Automation

Robotics and Automation • Number/Functions of rovers – Three classes of rovers • Small rover for scientific exploration • Medium rover for local transportation • Large pressurized rover for long exploration and infrastructure inspection • Power/Mass specs on all rovers • Power specs on robotic arms

Robotics and Automation • Small Rover – Deploy scientific instruments for analysis and monitoring of Mars – Determine safe routes for crew travel – Collect and return samples –. 64 k. W power requirement • Calculated using data from Pathfinder • Solar arrays needed for power/recharging of batteries – Mass 440 kg

Robotics and Automation • Local unpressurized rover – Transport crew up to 100 km – Operate continuously for up to 10 hours – Must transport crew as well as EVA tools – 2. 8 k. W power requirement • 14 hours charge time using 2 k. W allocated power – Mass 4000 kg

Robotics and Automation • Large pressurized rover – Must deploy and inspect infrasturcture • Power station, antennas, solar arrays, etc. – Nominal crew of two but must be able to carry four – Support 16 person hours of EVA per day – Will operate 2 mechanical arms from workstation or telerobotically – Uses separate power source – Ten day max work time – 500 km range – 10 k. W power output – Mass 14000 kg

Automation items (in progress) • • • Automated doors in case of depressurization Deployment of habitat Connection to power plant Inspection of infrastructure Site preparation Communications hardware External monitoring equipment Deploy radiator panels Deployment/Movement of scientific equipment

Extra-Vehicular Activity Systems (EVAS)

External Vehicular Activity Systems • EVAS is primarily responsible for providing the ability for individual crew members to move around and conduct useful tasks outside the pressurized habitat • EVA tasks will consist of constructing and maintaining habitat, and scientific investigation • EVAS broken up into 3 systems – EVA suit – Airlock – Pressurized Rover

EVAS – EVA Suit • Critical functional elements: pressure shell, atmospheric and thermal control, communications, monitor and display, nourishment, and hygiene • Current suit is much too heavy and cumbersome to explore the Martian environment • ILC Dover is currently developing the I-Suit which is lighter, packable into a smaller volume, and has better mobility and dexterity

EVAS – EVA Suit • I-Suit specs: – – – – Soft upper-torso 3. 7 lbs/in 2 (suit pressure can be varied) Easier to tailor to each individual astronaut ~65 lbs Bearings at important rotational points Greater visibility Boots with tread for walking on Martian terrain Parts are easily interchangeable (decrease number of spare parts needed)

EVAS - Airlock • Independent element capable of being ‘plugged’ or relocated as mission requires • Airlock sized for three crew members with facilities for EVA suit maintenance and consumables servicing • There will be two airlocks each containing three EVA suits • Airlock will be a solid shell (opposed to inflatable) • The airlock will interface with the habitat through both an umbilical system and the hatch

EVAS – Umbilical System • Connections from the habitat to the airlock and rover will be identical • Inputs from habitat to airlock/rover (through umbilical system) – Water (potable and non-potable) – Oxygen/Nitrogen – Data – Power • Outputs from airlock/rover to habitat (through umbilical system) – Waste water – Air – Data

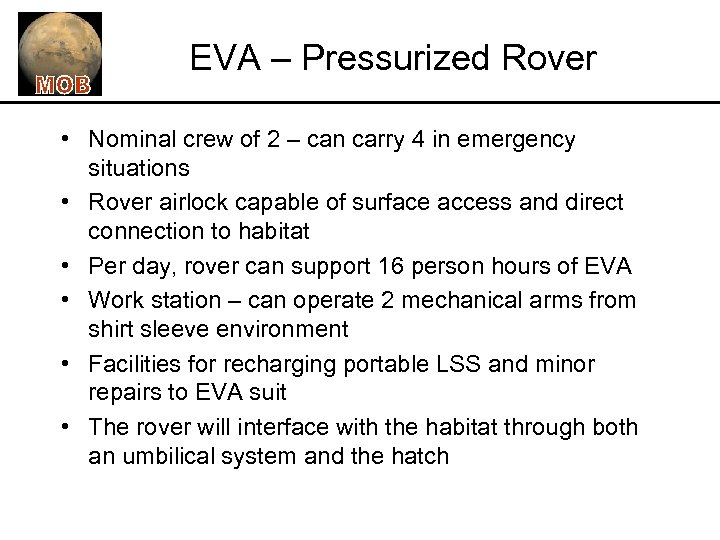

EVA – Pressurized Rover • Nominal crew of 2 – can carry 4 in emergency situations • Rover airlock capable of surface access and direct connection to habitat • Per day, rover can support 16 person hours of EVA • Work station – can operate 2 mechanical arms from shirt sleeve environment • Facilities for recharging portable LSS and minor repairs to EVA suit • The rover will interface with the habitat through both an umbilical system and the hatch

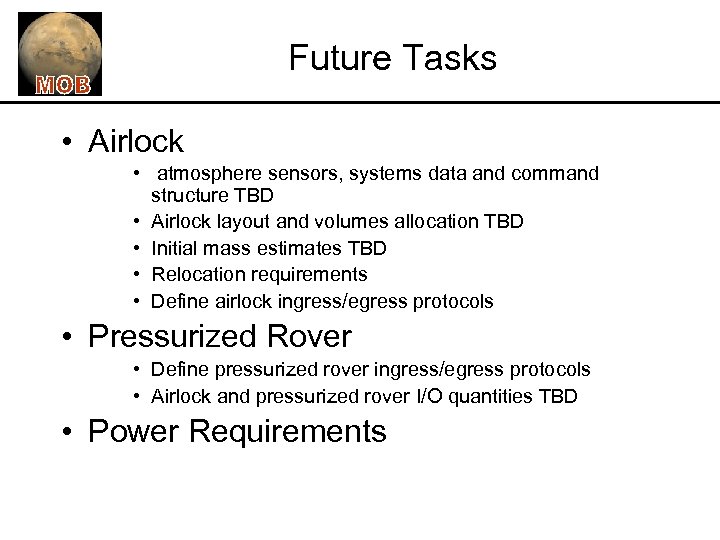

Future Tasks • Airlock • atmosphere sensors, systems data and command structure TBD • Airlock layout and volumes allocation TBD • Initial mass estimates TBD • Relocation requirements • Define airlock ingress/egress protocols • Pressurized Rover • Define pressurized rover ingress/egress protocols • Airlock and pressurized rover I/O quantities TBD • Power Requirements

In-situ Resource Utilization/Mars Environment (ISRU)

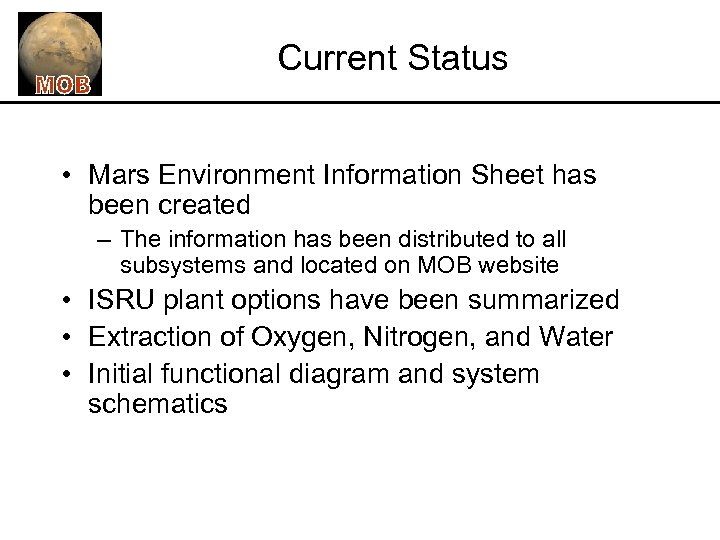

Current Status • Mars Environment Information Sheet has been created – The information has been distributed to all subsystems and located on MOB website • ISRU plant options have been summarized • Extraction of Oxygen, Nitrogen, and Water • Initial functional diagram and system schematics

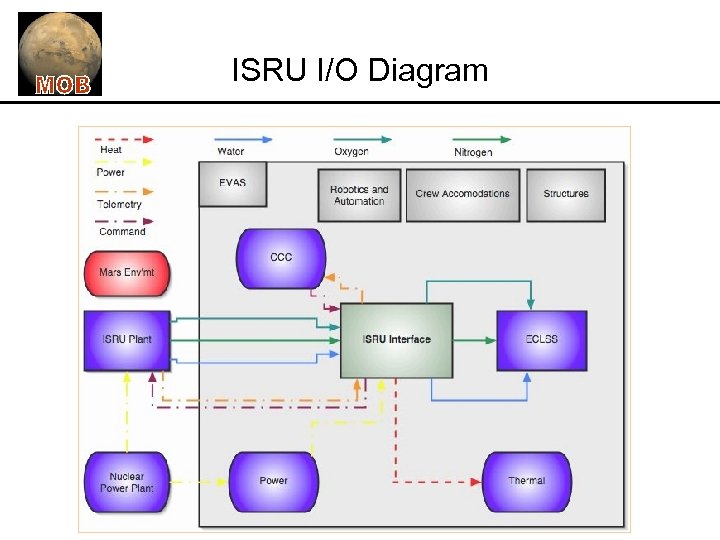

ISRU I/O Diagram

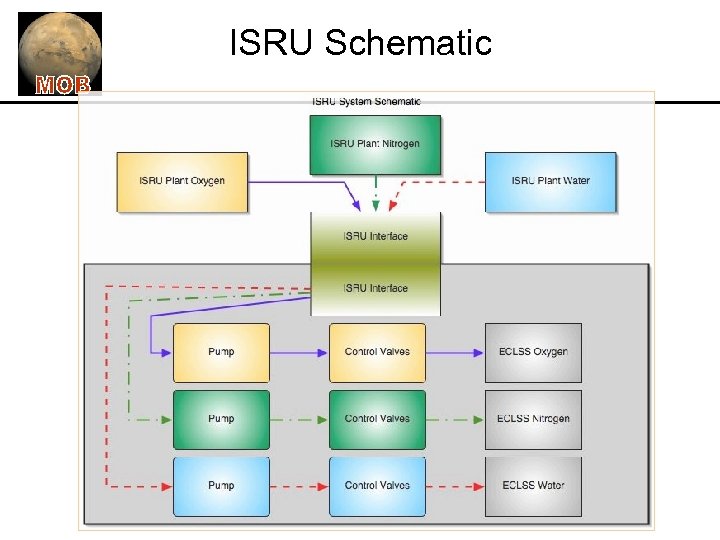

ISRU Schematic

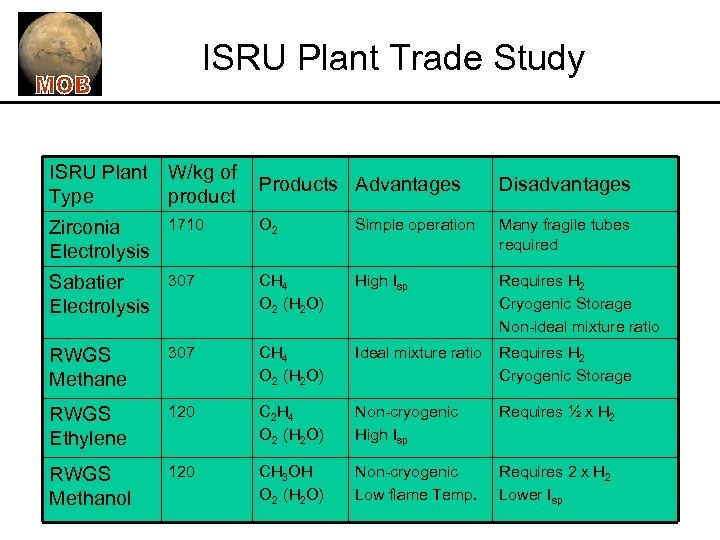

ISRU Plant Trade Study ISRU Plant Type W/kg of product Products Advantages Disadvantages Zirconia Electrolysis 1710 O 2 Simple operation Many fragile tubes required Sabatier Electrolysis 307 CH 4 O 2 (H 2 O) High Isp Requires H 2 Cryogenic Storage Non-ideal mixture ratio RWGS Methane 307 CH 4 O 2 (H 2 O) Ideal mixture ratio Requires H 2 Cryogenic Storage RWGS Ethylene 120 C 2 H 4 O 2 (H 2 O) Non-cryogenic High Isp Requires ½ x H 2 RWGS Methanol 120 CH 3 OH O 2 (H 2 O) Non-cryogenic Low flame Temp. Requires 2 x H 2 Lower Isp

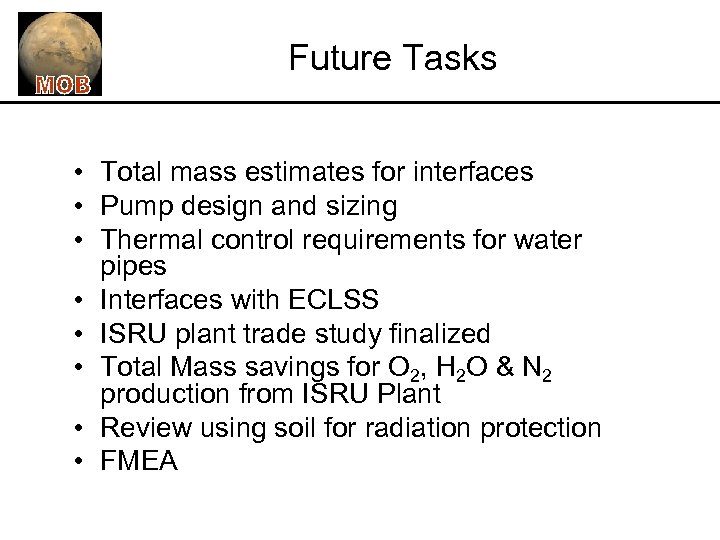

Future Tasks • Total mass estimates for interfaces • Pump design and sizing • Thermal control requirements for water pipes • Interfaces with ECLSS • ISRU plant trade study finalized • Total Mass savings for O 2, H 2 O & N 2 production from ISRU Plant • Review using soil for radiation protection • FMEA

Power Allocation and Distribution

Current Status – Researching hardware • Volume predictions dependant on hardware – Power circuit configuration – FMEA

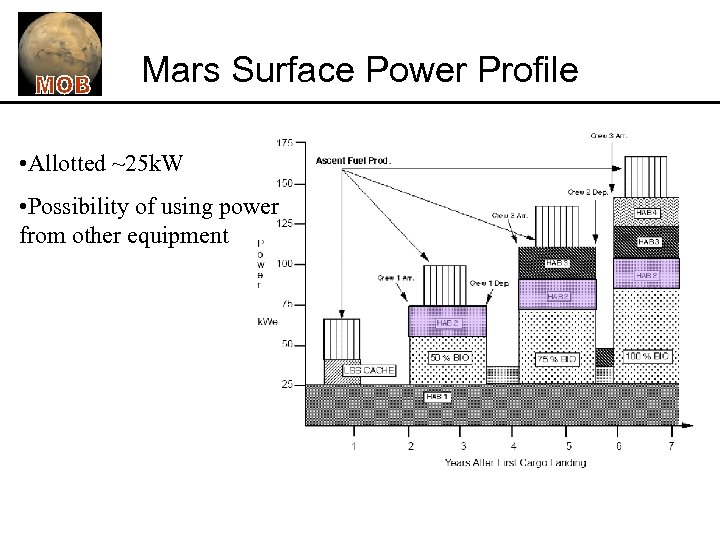

Mars Surface Power Profile • Allotted ~25 k. W • Possibility of using power from other equipment

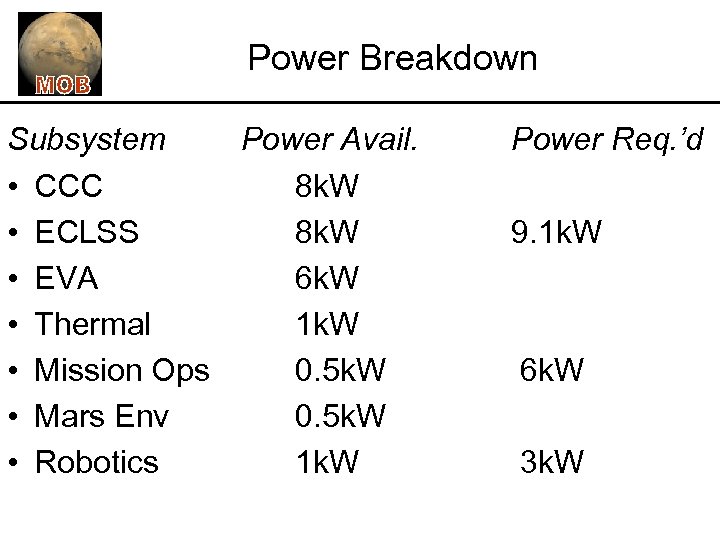

Power Breakdown Subsystem Power Avail. • CCC 8 k. W • ECLSS 8 k. W • EVA 6 k. W • Thermal 1 k. W • Mission Ops 0. 5 k. W • Mars Env 0. 5 k. W • Robotics 1 k. W Power Req. ’d 9. 1 k. W 6 k. W 3 k. W

Future Tasks – Finalize power profile

Questions/Comments?

04539281c5c05a099a08a0f69d15357b.ppt