e64cf012b7bf20b515b36a85ae70ba6d.ppt

- Количество слайдов: 24

MARPOL ANNEX VI AMENDMENTS AND THE PRACTICAL CONSEQUENCES INTERTANKO North American Panel October 14, 2008

MARPOL ANNEX VI AMENDMENTS AND THE PRACTICAL CONSEQUENCES INTERTANKO North American Panel October 14, 2008

AMENDMENTS • New regulation on SOx and PM • Primary compliance through fuel • Alternative methodologies (e. g. scrubbers) accepted as Equivalent Measures (first to be approved by Administrations) • Marine fuel oil quality to be further improved • No measures against ships that do not receive adequate supply • If BDN data is challenged by PSC or test results - Guidelines how to assess compliance • NOx Tier I on large engines from the 1990 s • NOx Tier II and Tier III on new engines

AMENDMENTS • New regulation on SOx and PM • Primary compliance through fuel • Alternative methodologies (e. g. scrubbers) accepted as Equivalent Measures (first to be approved by Administrations) • Marine fuel oil quality to be further improved • No measures against ships that do not receive adequate supply • If BDN data is challenged by PSC or test results - Guidelines how to assess compliance • NOx Tier I on large engines from the 1990 s • NOx Tier II and Tier III on new engines

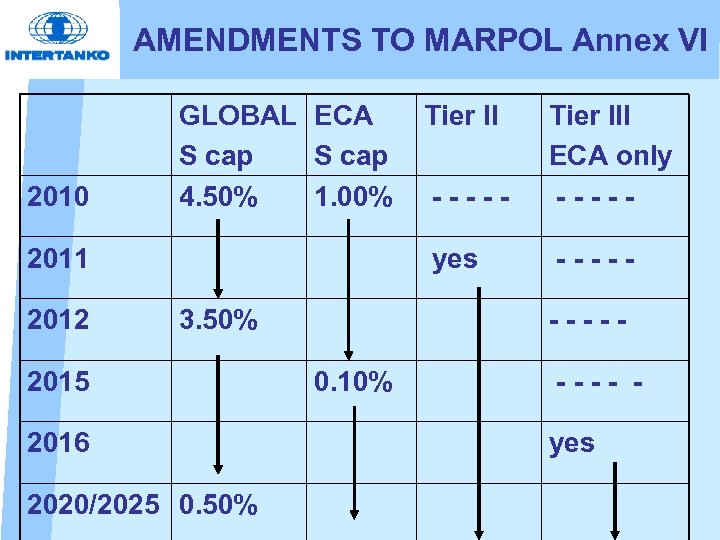

AMENDMENTS TO MARPOL Annex VI 2010 GLOBAL ECA S cap 4. 50% 1. 00% 2012 3. 50% 2015 2016 2020/2025 0. 50% - - - Tier III ECA only - - - yes 2011 Tier II - - - - - 0. 10% - - yes

AMENDMENTS TO MARPOL Annex VI 2010 GLOBAL ECA S cap 4. 50% 1. 00% 2012 3. 50% 2015 2016 2020/2025 0. 50% - - - Tier III ECA only - - - yes 2011 Tier II - - - - - 0. 10% - - yes

GENERAL ASSESSMENT OF THE AMENDMENTS • Positive but not perfect • Positive: – contributes to a long-term and predictable global regulatory regime – ensures a solid platform of requirements – is realistic and feasible – achieves a global, long-term and positive reduction of air emissions from ships • BUT practical consequences need to be carefully assessed

GENERAL ASSESSMENT OF THE AMENDMENTS • Positive but not perfect • Positive: – contributes to a long-term and predictable global regulatory regime – ensures a solid platform of requirements – is realistic and feasible – achieves a global, long-term and positive reduction of air emissions from ships • BUT practical consequences need to be carefully assessed

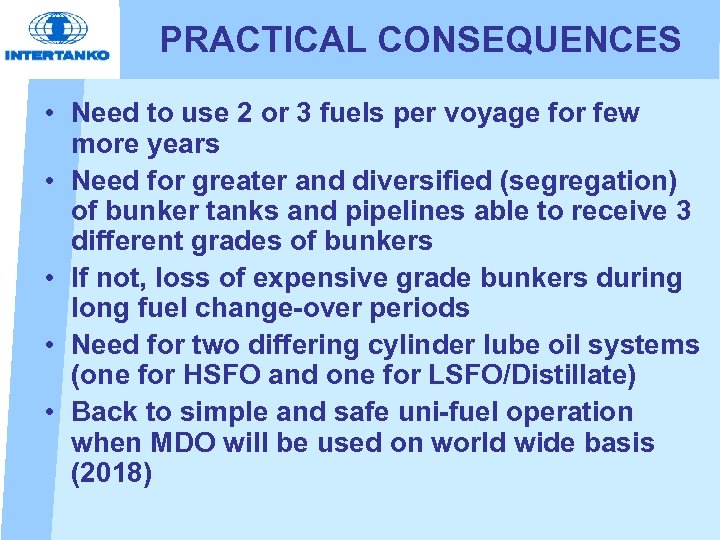

PRACTICAL CONSEQUENCES • Need to use 2 or 3 fuels per voyage for few more years • Need for greater and diversified (segregation) of bunker tanks and pipelines able to receive 3 different grades of bunkers • If not, loss of expensive grade bunkers during long fuel change-over periods • Need for two differing cylinder lube oil systems (one for HSFO and one for LSFO/Distillate) • Back to simple and safe uni-fuel operation when MDO will be used on world wide basis (2018)

PRACTICAL CONSEQUENCES • Need to use 2 or 3 fuels per voyage for few more years • Need for greater and diversified (segregation) of bunker tanks and pipelines able to receive 3 different grades of bunkers • If not, loss of expensive grade bunkers during long fuel change-over periods • Need for two differing cylinder lube oil systems (one for HSFO and one for LSFO/Distillate) • Back to simple and safe uni-fuel operation when MDO will be used on world wide basis (2018)

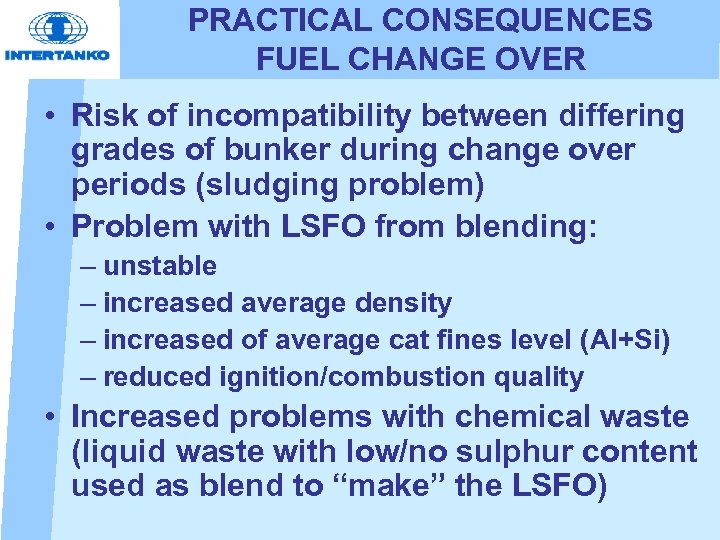

PRACTICAL CONSEQUENCES FUEL CHANGE OVER • Risk of incompatibility between differing grades of bunker during change over periods (sludging problem) • Problem with LSFO from blending: – unstable – increased average density – increased of average cat fines level (Al+Si) – reduced ignition/combustion quality • Increased problems with chemical waste (liquid waste with low/no sulphur content used as blend to “make” the LSFO)

PRACTICAL CONSEQUENCES FUEL CHANGE OVER • Risk of incompatibility between differing grades of bunker during change over periods (sludging problem) • Problem with LSFO from blending: – unstable – increased average density – increased of average cat fines level (Al+Si) – reduced ignition/combustion quality • Increased problems with chemical waste (liquid waste with low/no sulphur content used as blend to “make” the LSFO)

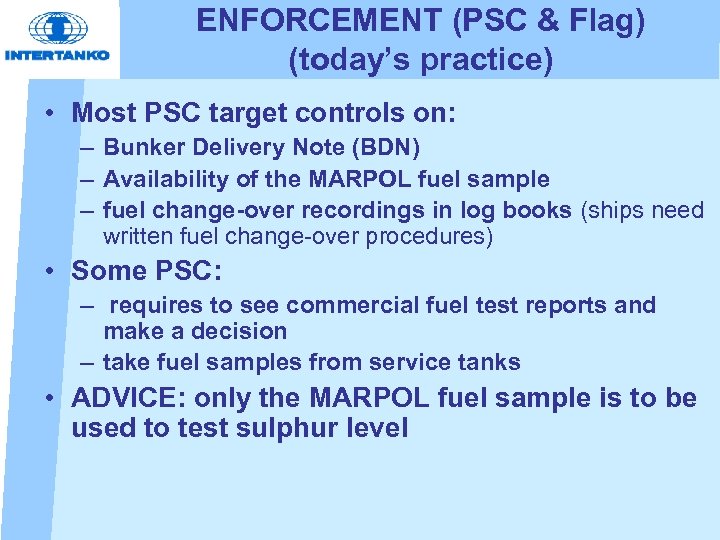

ENFORCEMENT (PSC & Flag) (today’s practice) • Most PSC target controls on: – Bunker Delivery Note (BDN) – Availability of the MARPOL fuel sample – fuel change-over recordings in log books (ships need written fuel change-over procedures) • Some PSC: – requires to see commercial fuel test reports and make a decision – take fuel samples from service tanks • ADVICE: only the MARPOL fuel sample is to be used to test sulphur level

ENFORCEMENT (PSC & Flag) (today’s practice) • Most PSC target controls on: – Bunker Delivery Note (BDN) – Availability of the MARPOL fuel sample – fuel change-over recordings in log books (ships need written fuel change-over procedures) • Some PSC: – requires to see commercial fuel test reports and make a decision – take fuel samples from service tanks • ADVICE: only the MARPOL fuel sample is to be used to test sulphur level

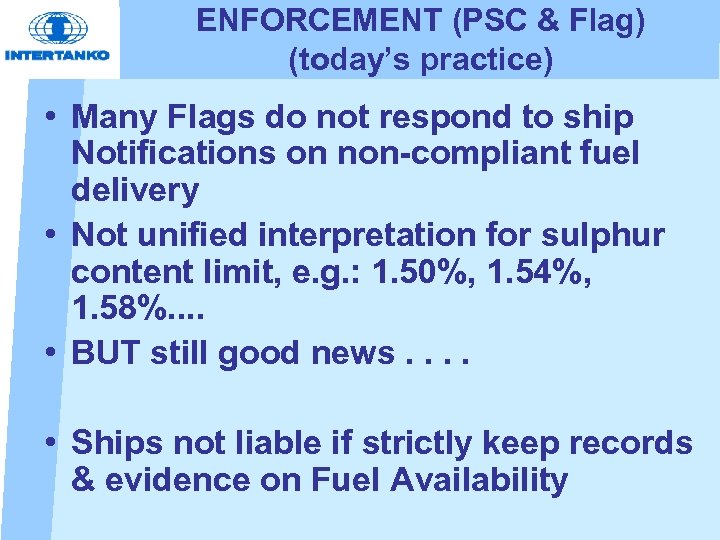

ENFORCEMENT (PSC & Flag) (today’s practice) • Many Flags do not respond to ship Notifications on non-compliant fuel delivery • Not unified interpretation for sulphur content limit, e. g. : 1. 50%, 1. 54%, 1. 58%. . • BUT still good news. . • Ships not liable if strictly keep records & evidence on Fuel Availability

ENFORCEMENT (PSC & Flag) (today’s practice) • Many Flags do not respond to ship Notifications on non-compliant fuel delivery • Not unified interpretation for sulphur content limit, e. g. : 1. 50%, 1. 54%, 1. 58%. . • BUT still good news. . • Ships not liable if strictly keep records & evidence on Fuel Availability

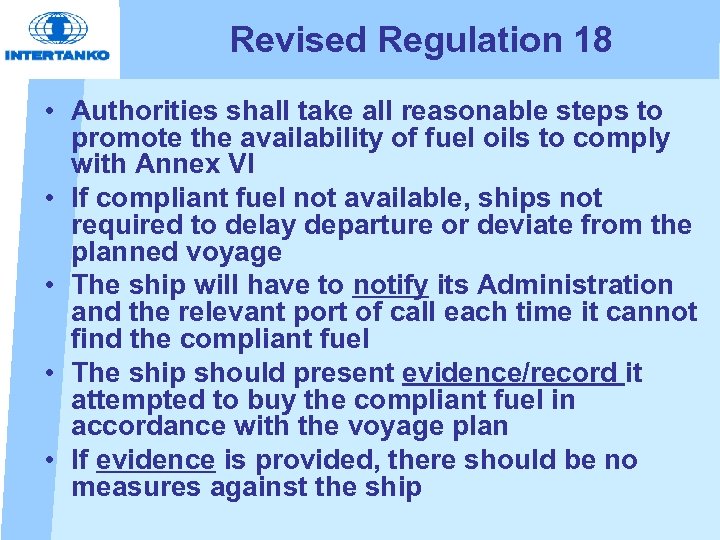

Revised Regulation 18 • Authorities shall take all reasonable steps to promote the availability of fuel oils to comply with Annex VI • If compliant fuel not available, ships not required to delay departure or deviate from the planned voyage • The ship will have to notify its Administration and the relevant port of call each time it cannot find the compliant fuel • The ship should present evidence/record it attempted to buy the compliant fuel in accordance with the voyage plan • If evidence is provided, there should be no measures against the ship

Revised Regulation 18 • Authorities shall take all reasonable steps to promote the availability of fuel oils to comply with Annex VI • If compliant fuel not available, ships not required to delay departure or deviate from the planned voyage • The ship will have to notify its Administration and the relevant port of call each time it cannot find the compliant fuel • The ship should present evidence/record it attempted to buy the compliant fuel in accordance with the voyage plan • If evidence is provided, there should be no measures against the ship

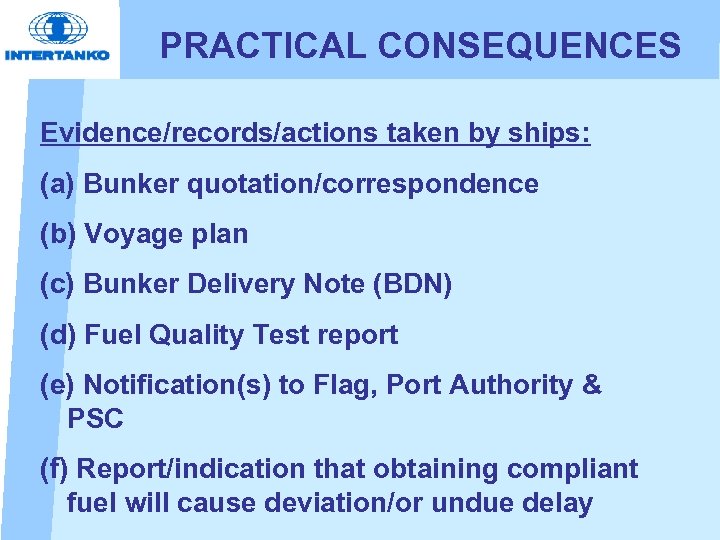

PRACTICAL CONSEQUENCES Evidence/records/actions taken by ships: (a) Bunker quotation/correspondence (b) Voyage plan (c) Bunker Delivery Note (BDN) (d) Fuel Quality Test report (e) Notification(s) to Flag, Port Authority & PSC (f) Report/indication that obtaining compliant fuel will cause deviation/or undue delay

PRACTICAL CONSEQUENCES Evidence/records/actions taken by ships: (a) Bunker quotation/correspondence (b) Voyage plan (c) Bunker Delivery Note (BDN) (d) Fuel Quality Test report (e) Notification(s) to Flag, Port Authority & PSC (f) Report/indication that obtaining compliant fuel will cause deviation/or undue delay

FUEL OIL QUALITY • IMO Secretariat invited ISO to consider a revision of a marine fuel oil specification (ISO 8217) addressing : -air quality, -ship safety, -engine performance, -crew health with recommendations for future consideration by the IMO

FUEL OIL QUALITY • IMO Secretariat invited ISO to consider a revision of a marine fuel oil specification (ISO 8217) addressing : -air quality, -ship safety, -engine performance, -crew health with recommendations for future consideration by the IMO

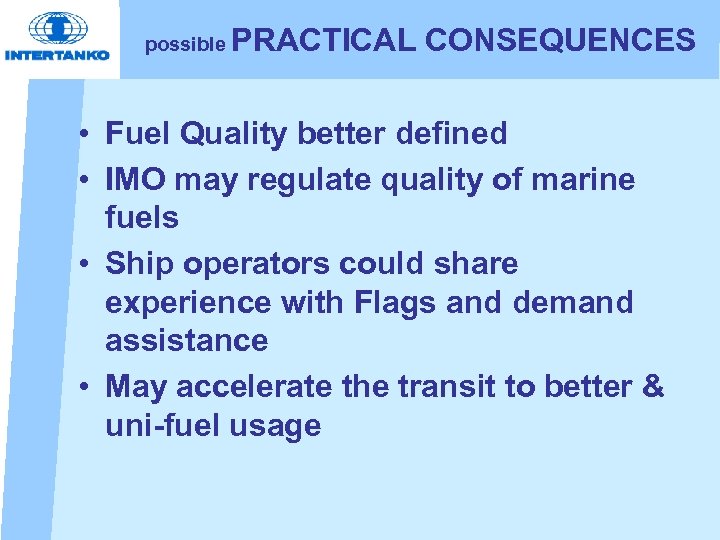

possible PRACTICAL CONSEQUENCES • Fuel Quality better defined • IMO may regulate quality of marine fuels • Ship operators could share experience with Flags and demand assistance • May accelerate the transit to better & uni-fuel usage

possible PRACTICAL CONSEQUENCES • Fuel Quality better defined • IMO may regulate quality of marine fuels • Ship operators could share experience with Flags and demand assistance • May accelerate the transit to better & uni-fuel usage

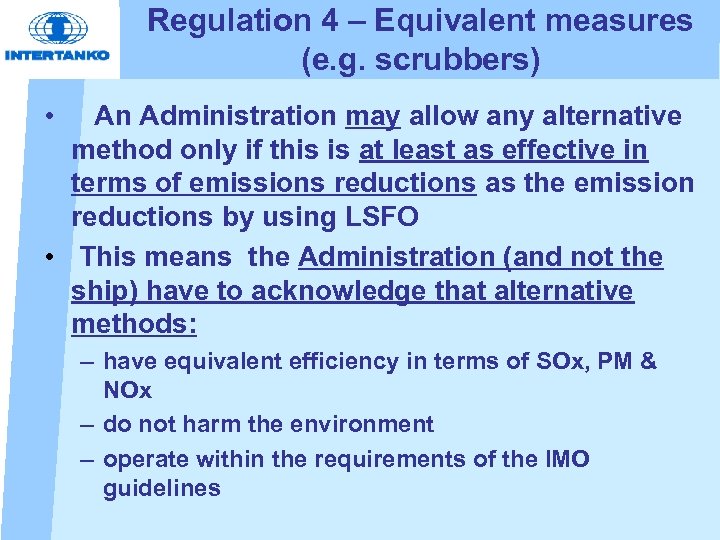

Regulation 4 – Equivalent measures (e. g. scrubbers) • An Administration may allow any alternative method only if this is at least as effective in terms of emissions reductions as the emission reductions by using LSFO • This means the Administration (and not the ship) have to acknowledge that alternative methods: – have equivalent efficiency in terms of SOx, PM & NOx – do not harm the environment – operate within the requirements of the IMO guidelines

Regulation 4 – Equivalent measures (e. g. scrubbers) • An Administration may allow any alternative method only if this is at least as effective in terms of emissions reductions as the emission reductions by using LSFO • This means the Administration (and not the ship) have to acknowledge that alternative methods: – have equivalent efficiency in terms of SOx, PM & NOx – do not harm the environment – operate within the requirements of the IMO guidelines

PRACTICAL CONSEQUENCES • Positive outcome for ship operators • Adminstrations and not ships responsible to asses the efficiency and the reliability of the alternative measures • Adminstrations and not the ships responsible that certified alternatives do not harm the environment

PRACTICAL CONSEQUENCES • Positive outcome for ship operators • Adminstrations and not ships responsible to asses the efficiency and the reliability of the alternative measures • Adminstrations and not the ships responsible that certified alternatives do not harm the environment

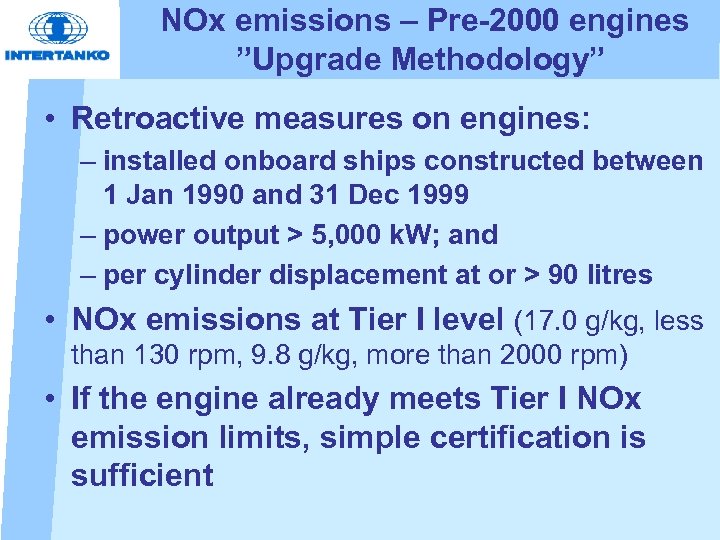

NOx emissions – Pre-2000 engines ”Upgrade Methodology” • Retroactive measures on engines: – installed onboard ships constructed between 1 Jan 1990 and 31 Dec 1999 – power output > 5, 000 k. W; and – per cylinder displacement at or > 90 litres • NOx emissions at Tier I level (17. 0 g/kg, less than 130 rpm, 9. 8 g/kg, more than 2000 rpm) • If the engine already meets Tier I NOx emission limits, simple certification is sufficient

NOx emissions – Pre-2000 engines ”Upgrade Methodology” • Retroactive measures on engines: – installed onboard ships constructed between 1 Jan 1990 and 31 Dec 1999 – power output > 5, 000 k. W; and – per cylinder displacement at or > 90 litres • NOx emissions at Tier I level (17. 0 g/kg, less than 130 rpm, 9. 8 g/kg, more than 2000 rpm) • If the engine already meets Tier I NOx emission limits, simple certification is sufficient

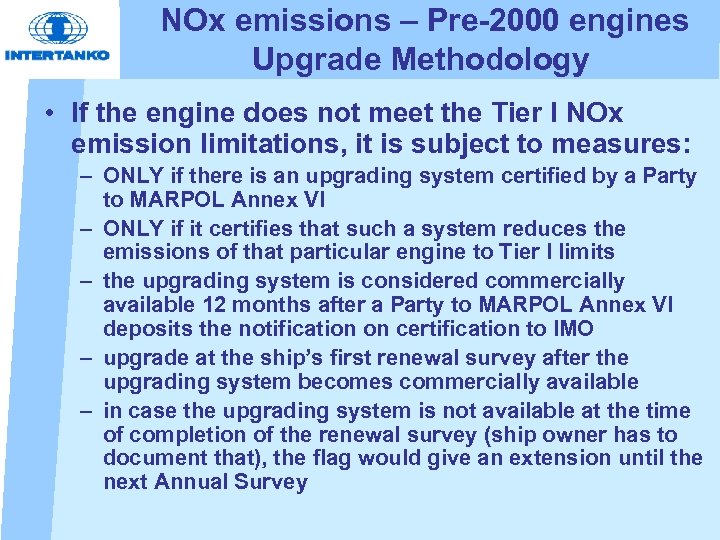

NOx emissions – Pre-2000 engines Upgrade Methodology • If the engine does not meet the Tier I NOx emission limitations, it is subject to measures: – ONLY if there is an upgrading system certified by a Party to MARPOL Annex VI – ONLY if it certifies that such a system reduces the emissions of that particular engine to Tier I limits – the upgrading system is considered commercially available 12 months after a Party to MARPOL Annex VI deposits the notification on certification to IMO – upgrade at the ship’s first renewal survey after the upgrading system becomes commercially available – in case the upgrading system is not available at the time of completion of the renewal survey (ship owner has to document that), the flag would give an extension until the next Annual Survey

NOx emissions – Pre-2000 engines Upgrade Methodology • If the engine does not meet the Tier I NOx emission limitations, it is subject to measures: – ONLY if there is an upgrading system certified by a Party to MARPOL Annex VI – ONLY if it certifies that such a system reduces the emissions of that particular engine to Tier I limits – the upgrading system is considered commercially available 12 months after a Party to MARPOL Annex VI deposits the notification on certification to IMO – upgrade at the ship’s first renewal survey after the upgrading system becomes commercially available – in case the upgrading system is not available at the time of completion of the renewal survey (ship owner has to document that), the flag would give an extension until the next Annual Survey

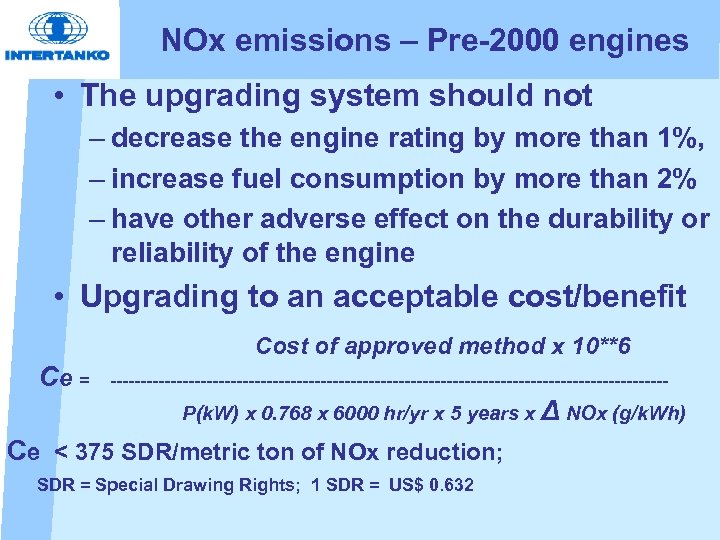

NOx emissions – Pre-2000 engines • The upgrading system should not – decrease the engine rating by more than 1%, – increase fuel consumption by more than 2% – have other adverse effect on the durability or reliability of the engine • Upgrading to an acceptable cost/benefit Cost of approved method x 10**6 Ce = P(k. W) x 0. 768 x 6000 hr/yr x 5 years x Δ NOx (g/k. Wh) Ce < 375 SDR/metric ton of NOx reduction; SDR = Special Drawing Rights; 1 SDR = US$ 0. 632

NOx emissions – Pre-2000 engines • The upgrading system should not – decrease the engine rating by more than 1%, – increase fuel consumption by more than 2% – have other adverse effect on the durability or reliability of the engine • Upgrading to an acceptable cost/benefit Cost of approved method x 10**6 Ce = P(k. W) x 0. 768 x 6000 hr/yr x 5 years x Δ NOx (g/k. Wh) Ce < 375 SDR/metric ton of NOx reduction; SDR = Special Drawing Rights; 1 SDR = US$ 0. 632

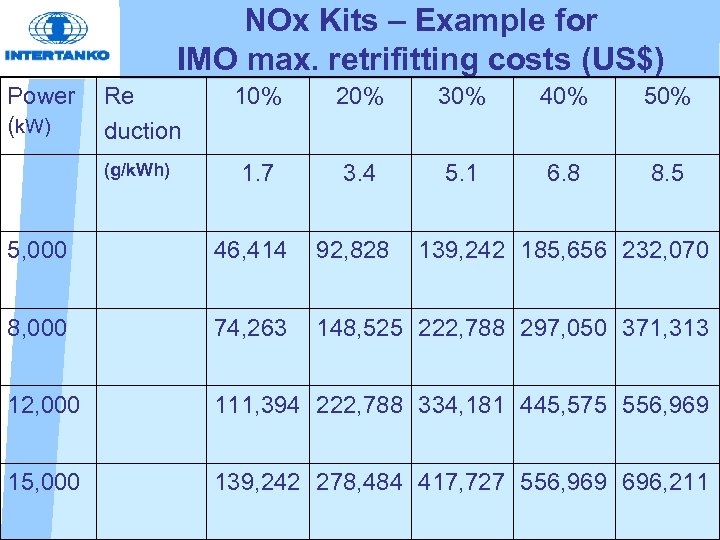

NOx Kits – Example for IMO max. retrifitting costs (US$) Power (k. W) Re duction 10% 20% 30% 40% 50% 1. 7 3. 4 5. 1 6. 8 8. 5 5, 000 46, 414 92, 828 8, 000 74, 263 148, 525 222, 788 297, 050 371, 313 12, 000 111, 394 222, 788 334, 181 445, 575 556, 969 15, 000 139, 242 278, 484 417, 727 556, 969 696, 211 (g/k. Wh) 139, 242 185, 656 232, 070

NOx Kits – Example for IMO max. retrifitting costs (US$) Power (k. W) Re duction 10% 20% 30% 40% 50% 1. 7 3. 4 5. 1 6. 8 8. 5 5, 000 46, 414 92, 828 8, 000 74, 263 148, 525 222, 788 297, 050 371, 313 12, 000 111, 394 222, 788 334, 181 445, 575 556, 969 15, 000 139, 242 278, 484 417, 727 556, 969 696, 211 (g/k. Wh) 139, 242 185, 656 232, 070

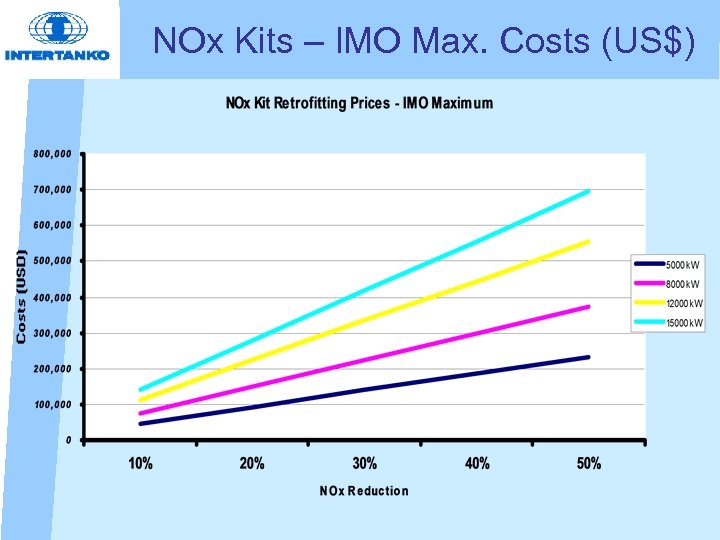

NOx Kits – IMO Max. Costs (US$)

NOx Kits – IMO Max. Costs (US$)

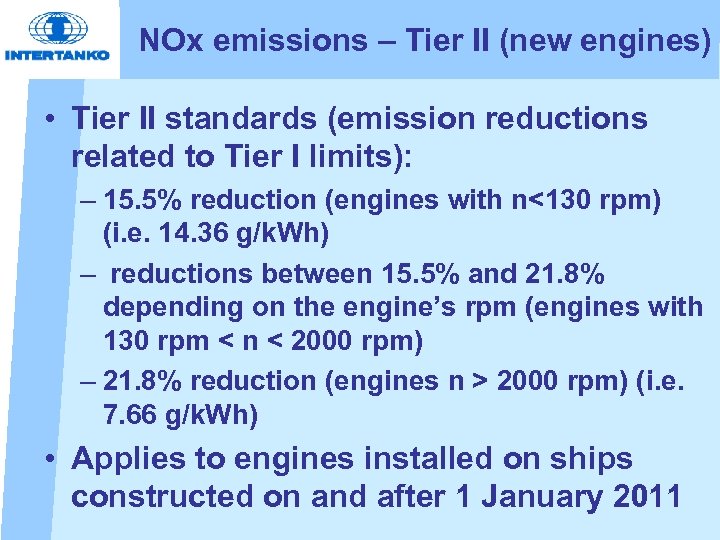

NOx emissions – Tier II (new engines) • Tier II standards (emission reductions related to Tier I limits): – 15. 5% reduction (engines with n<130 rpm) (i. e. 14. 36 g/k. Wh) – reductions between 15. 5% and 21. 8% depending on the engine’s rpm (engines with 130 rpm < n < 2000 rpm) – 21. 8% reduction (engines n > 2000 rpm) (i. e. 7. 66 g/k. Wh) • Applies to engines installed on ships constructed on and after 1 January 2011

NOx emissions – Tier II (new engines) • Tier II standards (emission reductions related to Tier I limits): – 15. 5% reduction (engines with n<130 rpm) (i. e. 14. 36 g/k. Wh) – reductions between 15. 5% and 21. 8% depending on the engine’s rpm (engines with 130 rpm < n < 2000 rpm) – 21. 8% reduction (engines n > 2000 rpm) (i. e. 7. 66 g/k. Wh) • Applies to engines installed on ships constructed on and after 1 January 2011

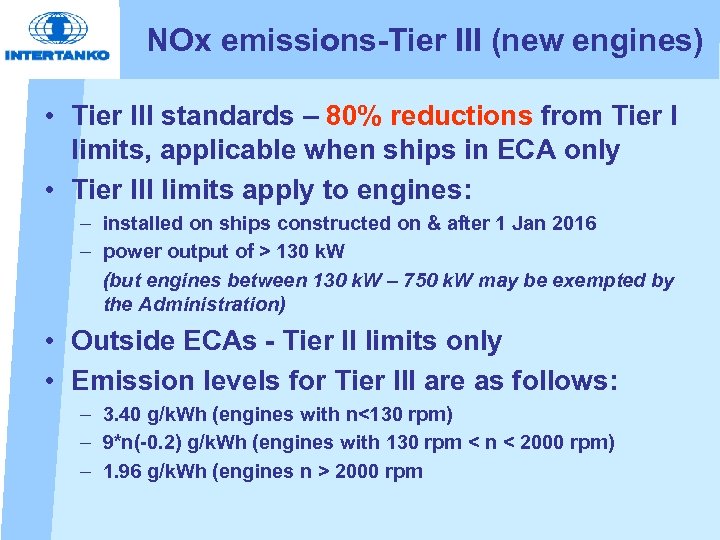

NOx emissions-Tier III (new engines) • Tier III standards – 80% reductions from Tier I limits, applicable when ships in ECA only • Tier III limits apply to engines: – installed on ships constructed on & after 1 Jan 2016 – power output of > 130 k. W (but engines between 130 k. W – 750 k. W may be exempted by the Administration) • Outside ECAs - Tier II limits only • Emission levels for Tier III are as follows: – 3. 40 g/k. Wh (engines with n<130 rpm) – 9*n(-0. 2) g/k. Wh (engines with 130 rpm < n < 2000 rpm) – 1. 96 g/k. Wh (engines n > 2000 rpm

NOx emissions-Tier III (new engines) • Tier III standards – 80% reductions from Tier I limits, applicable when ships in ECA only • Tier III limits apply to engines: – installed on ships constructed on & after 1 Jan 2016 – power output of > 130 k. W (but engines between 130 k. W – 750 k. W may be exempted by the Administration) • Outside ECAs - Tier II limits only • Emission levels for Tier III are as follows: – 3. 40 g/k. Wh (engines with n<130 rpm) – 9*n(-0. 2) g/k. Wh (engines with 130 rpm < n < 2000 rpm) – 1. 96 g/k. Wh (engines n > 2000 rpm

PRACTICAL CONSEQUENCES • Not a responsibility for ship operators • Tier III compliance with SCRs (latest news – possible solution through in engine technology) • If compliance through SCR only – existing SCR technology not efficient at low engine loads – compliance might not be achieved in ECAs (close to port, through estuaries and straits ships slow down) because the engine runs at a lowwe load • Engine manufacturers to demonstrate compliance • Class/Administration to certify • BUT, in the long run, how would be Tier II compliant ships (delivered between 2011 and 2016) be treated in ECAs? • Good advice: if possible, plan for Tier III compliant ships as from 2011

PRACTICAL CONSEQUENCES • Not a responsibility for ship operators • Tier III compliance with SCRs (latest news – possible solution through in engine technology) • If compliance through SCR only – existing SCR technology not efficient at low engine loads – compliance might not be achieved in ECAs (close to port, through estuaries and straits ships slow down) because the engine runs at a lowwe load • Engine manufacturers to demonstrate compliance • Class/Administration to certify • BUT, in the long run, how would be Tier II compliant ships (delivered between 2011 and 2016) be treated in ECAs? • Good advice: if possible, plan for Tier III compliant ships as from 2011

Regulation 15 Volatile Organic Compounds • All tankers carrying crude oil shall have on board an approved VOC-Management Plan describing all the procedures the ship is applying in order to minimize the emissions of VOC • Apart from that, there is no requirement for equipment or technical installations to limit the emissions • INTERTANKO works with DNV to a draft VOC Management Plan model to be submitted to IMO

Regulation 15 Volatile Organic Compounds • All tankers carrying crude oil shall have on board an approved VOC-Management Plan describing all the procedures the ship is applying in order to minimize the emissions of VOC • Apart from that, there is no requirement for equipment or technical installations to limit the emissions • INTERTANKO works with DNV to a draft VOC Management Plan model to be submitted to IMO

OUTCOME ON MARPOL ANNEX VI THANK YOU VERY MUCH

OUTCOME ON MARPOL ANNEX VI THANK YOU VERY MUCH