41287439e44f3b7d09268d7229935616.ppt

- Количество слайдов: 26

Marine. LINE (Siloxirane) Coating for Ships Engaged in the Carriage of Edible Oils and Chemicals Presented to FOSFA International August 10, 2004 By Donald J. Keehan

Marine. LINE (Siloxirane) Coating for Ships Engaged in the Carriage of Edible Oils and Chemicals Presented to FOSFA International August 10, 2004 By Donald J. Keehan

Marine. LINE u u u Cargo Versatility - Can Carry Virtually All IMO Cargoes Carry More Cargoes than Stainless Steel Clean Tanks Faster than Stainless Steel Tanks or Other types of Coated Tanks

Marine. LINE u u u Cargo Versatility - Can Carry Virtually All IMO Cargoes Carry More Cargoes than Stainless Steel Clean Tanks Faster than Stainless Steel Tanks or Other types of Coated Tanks

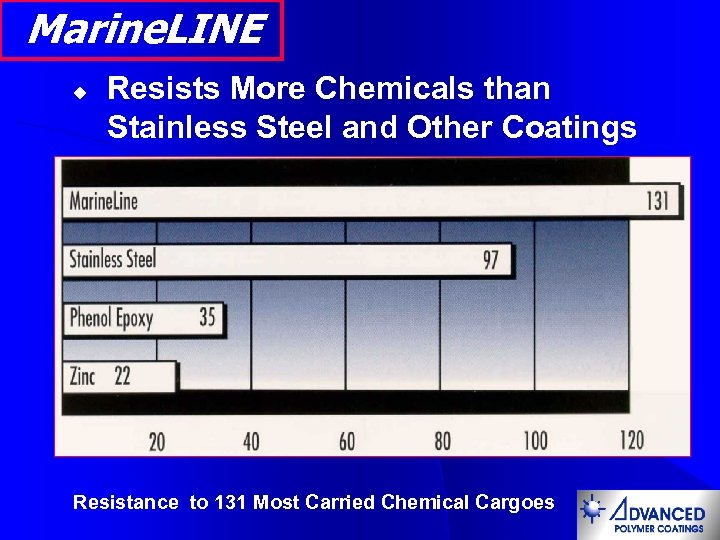

Marine. LINE u Resists More Chemicals than Stainless Steel and Other Coatings Resistance to 131 Most Carried Chemical Cargoes

Marine. LINE u Resists More Chemicals than Stainless Steel and Other Coatings Resistance to 131 Most Carried Chemical Cargoes

Marine. LINE Market Limitations Prior to Marine. Line Problems with Zinc Silicate Coatings • Absorbs Cargo Quickly • Retains Oil Like Cargoes • Subsequent Cargo Contamination • Limit Back Hauling Capability Not Resistant to Acids, Caustics, and Acid Containing Oils and Urea

Marine. LINE Market Limitations Prior to Marine. Line Problems with Zinc Silicate Coatings • Absorbs Cargo Quickly • Retains Oil Like Cargoes • Subsequent Cargo Contamination • Limit Back Hauling Capability Not Resistant to Acids, Caustics, and Acid Containing Oils and Urea

Marine. LINE Market Limitations Prior to Marine. Line Problems with Phenolic Epoxy Coating • Absorbs Cargoes to High Levels (depending on cargo) • Absorbs Cargo Relatively Slowly • Releases Absorbed Cargo Very Slowly • Small Traces May be Retained • Subsequent Cargo Contamination

Marine. LINE Market Limitations Prior to Marine. Line Problems with Phenolic Epoxy Coating • Absorbs Cargoes to High Levels (depending on cargo) • Absorbs Cargo Relatively Slowly • Releases Absorbed Cargo Very Slowly • Small Traces May be Retained • Subsequent Cargo Contamination

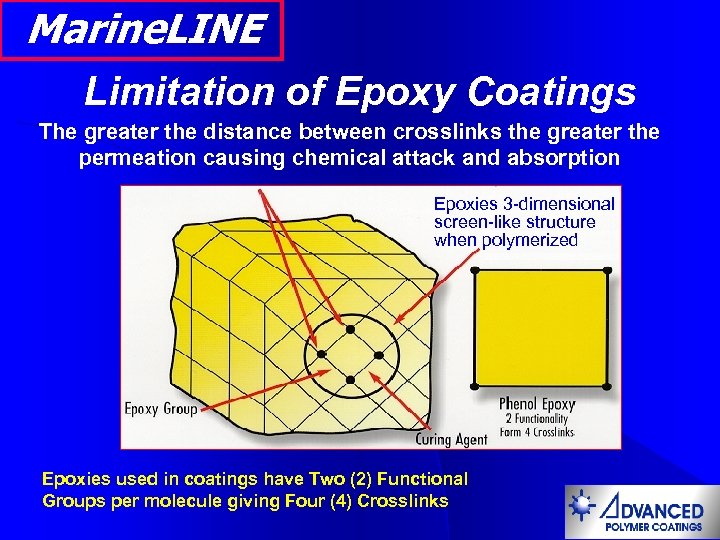

Marine. LINE Limitation of Epoxy Coatings The greater the distance between crosslinks the greater the permeation causing chemical attack and absorption Epoxies 3 -dimensional screen-like structure when polymerized Epoxies used in coatings have Two (2) Functional Groups per molecule giving Four (4) Crosslinks

Marine. LINE Limitation of Epoxy Coatings The greater the distance between crosslinks the greater the permeation causing chemical attack and absorption Epoxies 3 -dimensional screen-like structure when polymerized Epoxies used in coatings have Two (2) Functional Groups per molecule giving Four (4) Crosslinks

Marine. LINE Higher Functionality Produces Higher Crosslink Density. . . Giving: Ø Higher Chemical Resistance Ø Higher Temperature Resistance Ø Resistance to Permeation (absorption) 28 Functionality vs. Epoxy 2 Functionality in same area: 784 crosslinks vs. 4 crosslinks

Marine. LINE Higher Functionality Produces Higher Crosslink Density. . . Giving: Ø Higher Chemical Resistance Ø Higher Temperature Resistance Ø Resistance to Permeation (absorption) 28 Functionality vs. Epoxy 2 Functionality in same area: 784 crosslinks vs. 4 crosslinks

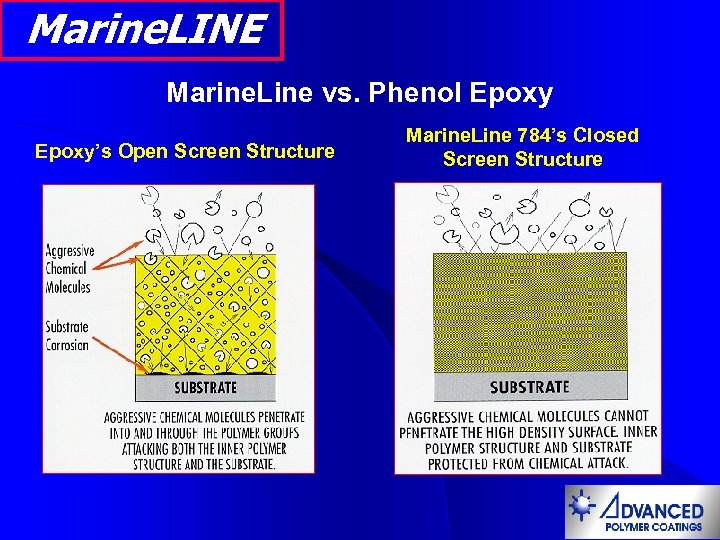

Marine. LINE Marine. Line vs. Phenol Epoxy’s Open Screen Structure Marine. Line 784’s Closed Screen Structure

Marine. LINE Marine. Line vs. Phenol Epoxy’s Open Screen Structure Marine. Line 784’s Closed Screen Structure

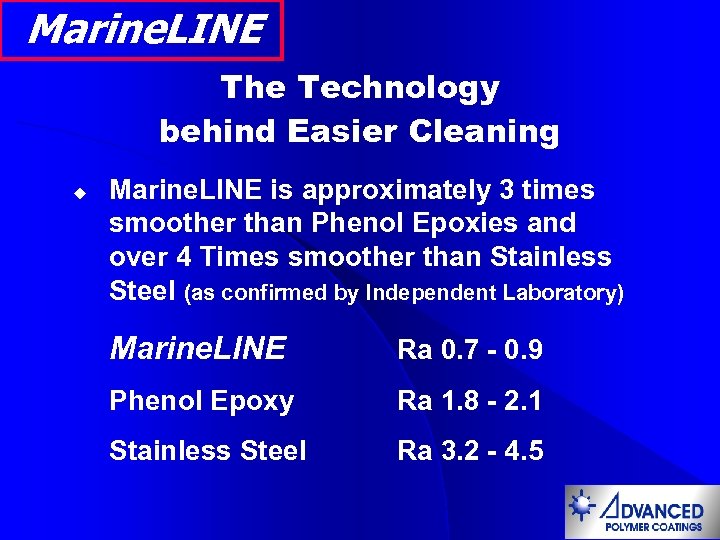

Marine. LINE The Technology behind Easier Cleaning u Marine. LINE is approximately 3 times smoother than Phenol Epoxies and over 4 Times smoother than Stainless Steel (as confirmed by Independent Laboratory) Marine. LINE Ra 0. 7 - 0. 9 Phenol Epoxy Ra 1. 8 - 2. 1 Stainless Steel Ra 3. 2 - 4. 5

Marine. LINE The Technology behind Easier Cleaning u Marine. LINE is approximately 3 times smoother than Phenol Epoxies and over 4 Times smoother than Stainless Steel (as confirmed by Independent Laboratory) Marine. LINE Ra 0. 7 - 0. 9 Phenol Epoxy Ra 1. 8 - 2. 1 Stainless Steel Ra 3. 2 - 4. 5

Marine. LINE The Technology Behind Easier Cleaning Surface Energy / Surface Tension Marine. LINE is Over 40 Times More Slippery than Stainless Steel and almost 5 times Slipperier than Phenol Epoxies Surface Energy is measured in Dynes/cm * Source: N. K. Adams The Physics and Chemistry of Surfaces

Marine. LINE The Technology Behind Easier Cleaning Surface Energy / Surface Tension Marine. LINE is Over 40 Times More Slippery than Stainless Steel and almost 5 times Slipperier than Phenol Epoxies Surface Energy is measured in Dynes/cm * Source: N. K. Adams The Physics and Chemistry of Surfaces

Marine. LINE u u Chemical Resistance Non Absorbent Qualities Verified Independent Test Certified by Members of International Association of Classification Societies (IACS)

Marine. LINE u u Chemical Resistance Non Absorbent Qualities Verified Independent Test Certified by Members of International Association of Classification Societies (IACS)

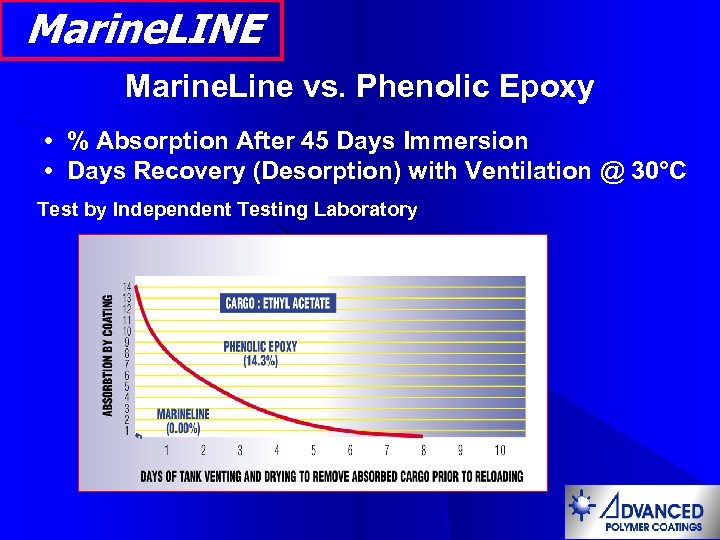

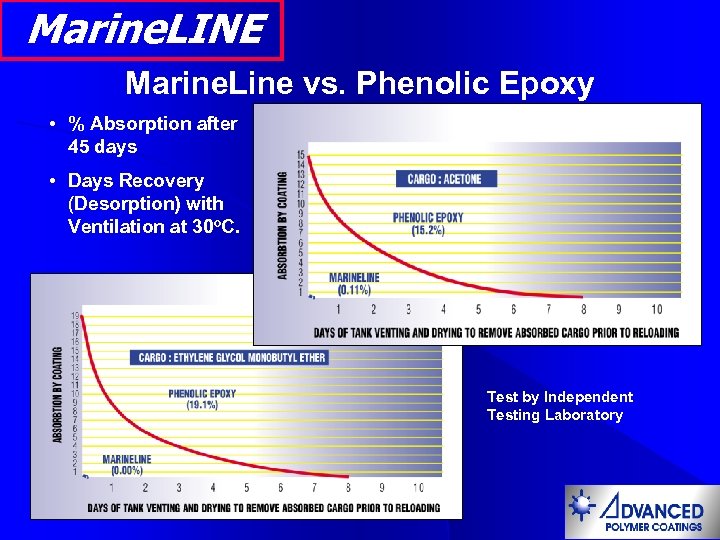

Marine. LINE Marine. Line vs. Phenolic Epoxy • % Absorption After 45 Days Immersion • Days Recovery (Desorption) with Ventilation @ 30°C Test by Independent Testing Laboratory

Marine. LINE Marine. Line vs. Phenolic Epoxy • % Absorption After 45 Days Immersion • Days Recovery (Desorption) with Ventilation @ 30°C Test by Independent Testing Laboratory

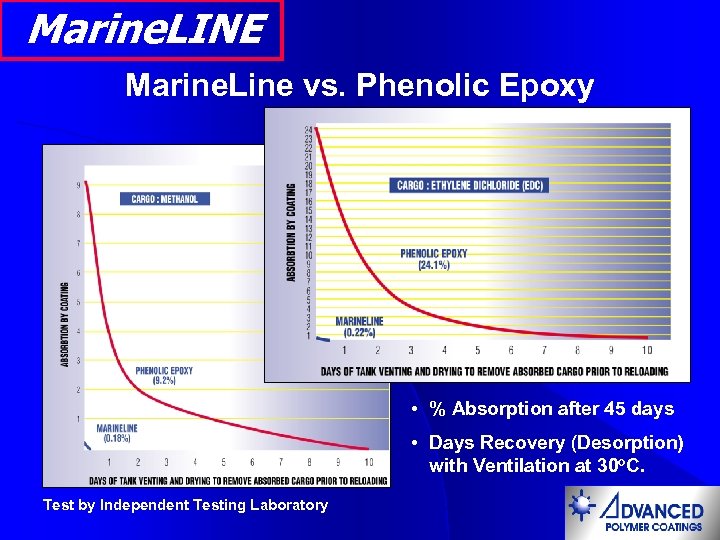

Marine. LINE Marine. Line vs. Phenolic Epoxy • % Absorption after 45 days • Days Recovery (Desorption) with Ventilation at 30 o. C. Test by Independent Testing Laboratory

Marine. LINE Marine. Line vs. Phenolic Epoxy • % Absorption after 45 days • Days Recovery (Desorption) with Ventilation at 30 o. C. Test by Independent Testing Laboratory

Marine. LINE Marine. Line vs. Phenolic Epoxy • % Absorption after 45 days • Days Recovery (Desorption) with Ventilation at 30 o. C. Test by Independent Testing Laboratory

Marine. LINE Marine. Line vs. Phenolic Epoxy • % Absorption after 45 days • Days Recovery (Desorption) with Ventilation at 30 o. C. Test by Independent Testing Laboratory

Marine. LINE Laboratorio Chimico Merceologico Genoa, Italy, Dr. R. Cosulich All Tests Witnessed and Certified by DNV Italy and RINA Test Protocol: 1) 3 Steel Boxes Coated With Marine. Line and Bottoms Reinforced With Fiberglass Impregnated With Marine. Line Resin - Boxes Blasted and Coated Inside Cargo Tanks of M/T Joran - Boxes Cured in Oven at 80°C for 6 Hours

Marine. LINE Laboratorio Chimico Merceologico Genoa, Italy, Dr. R. Cosulich All Tests Witnessed and Certified by DNV Italy and RINA Test Protocol: 1) 3 Steel Boxes Coated With Marine. Line and Bottoms Reinforced With Fiberglass Impregnated With Marine. Line Resin - Boxes Blasted and Coated Inside Cargo Tanks of M/T Joran - Boxes Cured in Oven at 80°C for 6 Hours

Marine. LINE Laboratorio Chimico Merceologico Genoa, Italy, Dr. R. Cosulich All Tests Witnessed and Certified by DNV Italy and RINA 2) Each Box Was Loaded With a Chemical for 30 Days. Chemicals Tested: • 80% Acetic Acid • Methanol • Ethylene Dichloride • Virgin Naphtha • 50% Phosphoric Acid • 96% Sulfuric Acid • Caustic Soda • Premium Gasoline

Marine. LINE Laboratorio Chimico Merceologico Genoa, Italy, Dr. R. Cosulich All Tests Witnessed and Certified by DNV Italy and RINA 2) Each Box Was Loaded With a Chemical for 30 Days. Chemicals Tested: • 80% Acetic Acid • Methanol • Ethylene Dichloride • Virgin Naphtha • 50% Phosphoric Acid • 96% Sulfuric Acid • Caustic Soda • Premium Gasoline

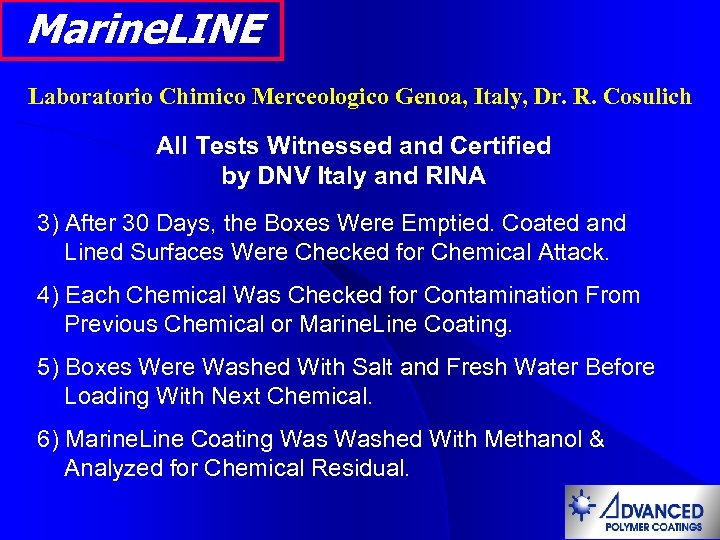

Marine. LINE Laboratorio Chimico Merceologico Genoa, Italy, Dr. R. Cosulich All Tests Witnessed and Certified by DNV Italy and RINA 3) After 30 Days, the Boxes Were Emptied. Coated and Lined Surfaces Were Checked for Chemical Attack. 4) Each Chemical Was Checked for Contamination From Previous Chemical or Marine. Line Coating. 5) Boxes Were Washed With Salt and Fresh Water Before Loading With Next Chemical. 6) Marine. Line Coating Washed With Methanol & Analyzed for Chemical Residual.

Marine. LINE Laboratorio Chimico Merceologico Genoa, Italy, Dr. R. Cosulich All Tests Witnessed and Certified by DNV Italy and RINA 3) After 30 Days, the Boxes Were Emptied. Coated and Lined Surfaces Were Checked for Chemical Attack. 4) Each Chemical Was Checked for Contamination From Previous Chemical or Marine. Line Coating. 5) Boxes Were Washed With Salt and Fresh Water Before Loading With Next Chemical. 6) Marine. Line Coating Washed With Methanol & Analyzed for Chemical Residual.

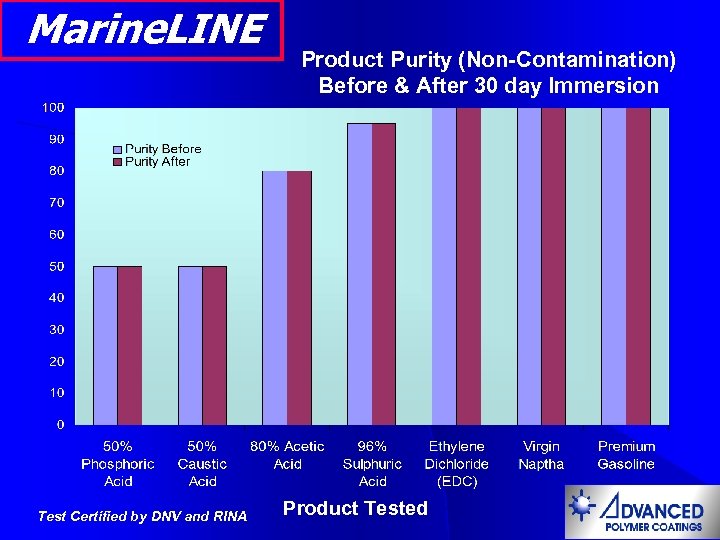

Marine. LINE Test Certified by DNV and RINA Product Purity (Non-Contamination) Before & After 30 day Immersion Product Tested

Marine. LINE Test Certified by DNV and RINA Product Purity (Non-Contamination) Before & After 30 day Immersion Product Tested

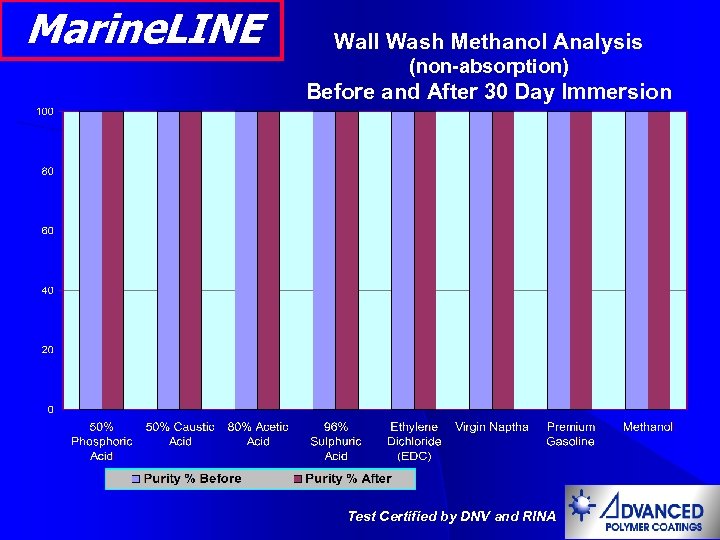

Marine. LINE Wall Wash Methanol Analysis (non-absorption) Before and After 30 Day Immersion Test Certified by DNV and RINA

Marine. LINE Wall Wash Methanol Analysis (non-absorption) Before and After 30 Day Immersion Test Certified by DNV and RINA

Marine. LINE Siloxirane Coating Approved for Food and Potable Water

Marine. LINE Siloxirane Coating Approved for Food and Potable Water

Marine. LINE Siloxirane Coating

Marine. LINE Siloxirane Coating

Marine. LINE Tanker Operators Statements Aurora Tanker’s M/T “Selendang Sari” "It was found that conventional intensive cleaning methods used for Zinc and Epoxy coated tanks does not have much effect on Marine. Line coating. Marine. Line coated tanks can be cleaned quicker in the same way as cleaning stainless steel tanks. Rust remover and caustic based detergents used to spray and scrub were used to scrub and remove dried up patches of sulphur after Sulphured Gas Oil last cargo. After this simple cleaning the tank can be made ready for methanol and MEG (methanol wall wash standard) cargoes quickly. " Capt. Ramu Naidu

Marine. LINE Tanker Operators Statements Aurora Tanker’s M/T “Selendang Sari” "It was found that conventional intensive cleaning methods used for Zinc and Epoxy coated tanks does not have much effect on Marine. Line coating. Marine. Line coated tanks can be cleaned quicker in the same way as cleaning stainless steel tanks. Rust remover and caustic based detergents used to spray and scrub were used to scrub and remove dried up patches of sulphur after Sulphured Gas Oil last cargo. After this simple cleaning the tank can be made ready for methanol and MEG (methanol wall wash standard) cargoes quickly. " Capt. Ramu Naidu

Marine. LINE Tanker Operators Statements “M/T “Coralwater” changes cargoes on weekly basis. As an example ships 5 P/S had 7 different cargoes over 7 week period. Sequence of cargoes, spent caustic, nitrobenzene, epichlorohydrin, acryonitrile, EDC, analine, and formaldehyde. Prior to unloading sample of each cargo was taken for test and verification on non-contamination. After each unloading tanks were washed with hot salt water, followed by fresh water wash. Tanks were certified clean by methanol wall wash test prior to loading next cargo. Over 5 -year period M/T “Coralwater” has never had a cargo contamination claim. Ship has carried over 400 different cargoes. Our Marine. Line coated ships clean easier and faster than our older stainless steel ships. ” Mr. Jan Slooter, MD Clearwater Group

Marine. LINE Tanker Operators Statements “M/T “Coralwater” changes cargoes on weekly basis. As an example ships 5 P/S had 7 different cargoes over 7 week period. Sequence of cargoes, spent caustic, nitrobenzene, epichlorohydrin, acryonitrile, EDC, analine, and formaldehyde. Prior to unloading sample of each cargo was taken for test and verification on non-contamination. After each unloading tanks were washed with hot salt water, followed by fresh water wash. Tanks were certified clean by methanol wall wash test prior to loading next cargo. Over 5 -year period M/T “Coralwater” has never had a cargo contamination claim. Ship has carried over 400 different cargoes. Our Marine. Line coated ships clean easier and faster than our older stainless steel ships. ” Mr. Jan Slooter, MD Clearwater Group

Marine. LINE Herning’s Marine. Line coated M/T “Serra Theresa” is carrying French Cognac to Ukraine and Ethyl Alcohol on return voyages.

Marine. LINE Herning’s Marine. Line coated M/T “Serra Theresa” is carrying French Cognac to Ukraine and Ethyl Alcohol on return voyages.

Marine. LINE Over 50 Marine. Line coated ships operating since 1994 without a contamination claim Additional 60 tankers contracted for Marine. Line coating by 2007

Marine. LINE Over 50 Marine. Line coated ships operating since 1994 without a contamination claim Additional 60 tankers contracted for Marine. Line coating by 2007

Thank You. For Complete Chemical Listing see Marine. LINEResistance also on this CD (Excel ‘ 97 format) For Additional Information Please Contact: Advanced Polymer Coatings, LLC Avon, Ohio 44011 U. S. A. Phone: (+01) 440 -937 -6218 Fax: (+01) 440 -937 -5046 email: apc@adv-polymer. com

Thank You. For Complete Chemical Listing see Marine. LINEResistance also on this CD (Excel ‘ 97 format) For Additional Information Please Contact: Advanced Polymer Coatings, LLC Avon, Ohio 44011 U. S. A. Phone: (+01) 440 -937 -6218 Fax: (+01) 440 -937 -5046 email: apc@adv-polymer. com