fd07409a9ac1b87543cf60e32e2522ba.ppt

- Количество слайдов: 27

Marine Current Modelling For Energy Production Group 4 – Marine Energy James Glynn Kirsten Hamilton Tom Mc. Combes Malcolm Mac. Donald

Marine Current Modelling For Energy Production Group 4 – Marine Energy James Glynn Kirsten Hamilton Tom Mc. Combes Malcolm Mac. Donald

Project Definition • Investigate the characteristics of the tidal resources in Scotland demonstrate how to match those resources with the appropriate Marine current technology

Project Definition • Investigate the characteristics of the tidal resources in Scotland demonstrate how to match those resources with the appropriate Marine current technology

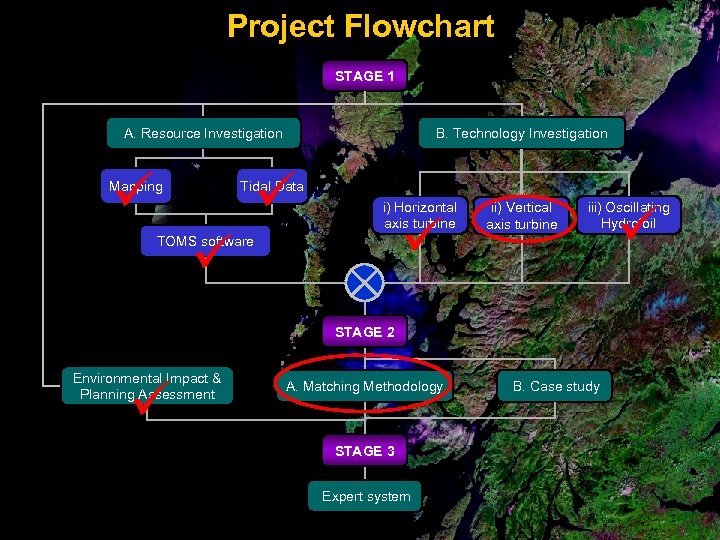

Project Flowchart STAGE 1 A. Resource Investigation B. Technology Investigation Mapping Tidal Data i) Horizontal axis turbine TOMS software ii) Vertical axis turbine STAGE 2 Environmental Impact & Planning Assessment A. Matching Methodology STAGE 3 Expert system iii) Oscillating Hydrofoil B. Case study

Project Flowchart STAGE 1 A. Resource Investigation B. Technology Investigation Mapping Tidal Data i) Horizontal axis turbine TOMS software ii) Vertical axis turbine STAGE 2 Environmental Impact & Planning Assessment A. Matching Methodology STAGE 3 Expert system iii) Oscillating Hydrofoil B. Case study

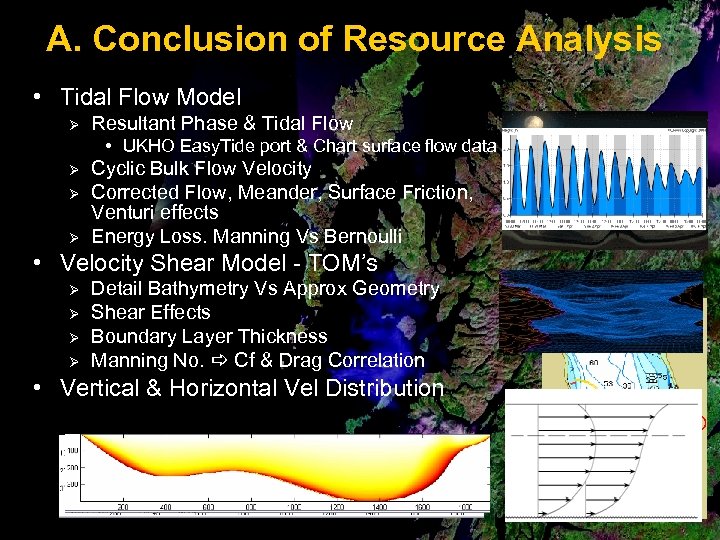

A. Conclusion of Resource Analysis • Tidal Flow Model Ø Resultant Phase & Tidal Flow • UKHO Easy. Tide port & Chart surface flow data Ø Ø Ø Cyclic Bulk Flow Velocity Corrected Flow, Meander, Surface Friction, Venturi effects Energy Loss. Manning Vs Bernoulli • Velocity Shear Model - TOM’s Ø Ø Detail Bathymetry Vs Approx Geometry Shear Effects Boundary Layer Thickness Manning No. a Cf & Drag Correlation • Vertical & Horizontal Vel Distribution

A. Conclusion of Resource Analysis • Tidal Flow Model Ø Resultant Phase & Tidal Flow • UKHO Easy. Tide port & Chart surface flow data Ø Ø Ø Cyclic Bulk Flow Velocity Corrected Flow, Meander, Surface Friction, Venturi effects Energy Loss. Manning Vs Bernoulli • Velocity Shear Model - TOM’s Ø Ø Detail Bathymetry Vs Approx Geometry Shear Effects Boundary Layer Thickness Manning No. a Cf & Drag Correlation • Vertical & Horizontal Vel Distribution

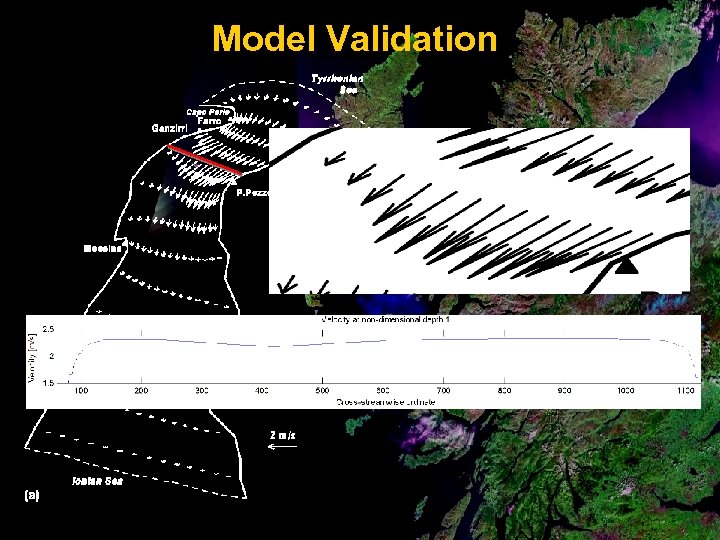

Model Validation The Strait of Messina

Model Validation The Strait of Messina

Model Validation The Strait of Messina

Model Validation The Strait of Messina

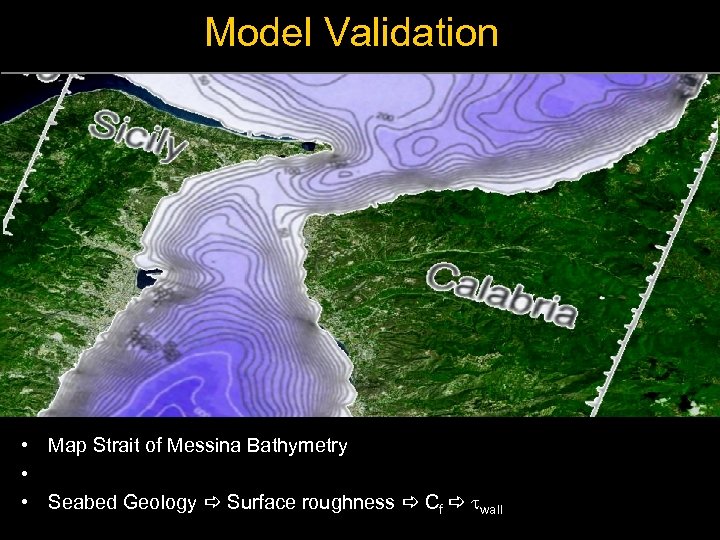

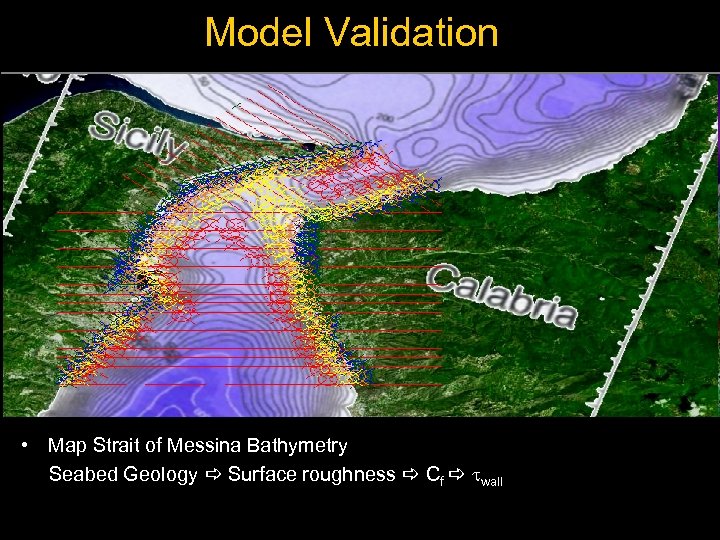

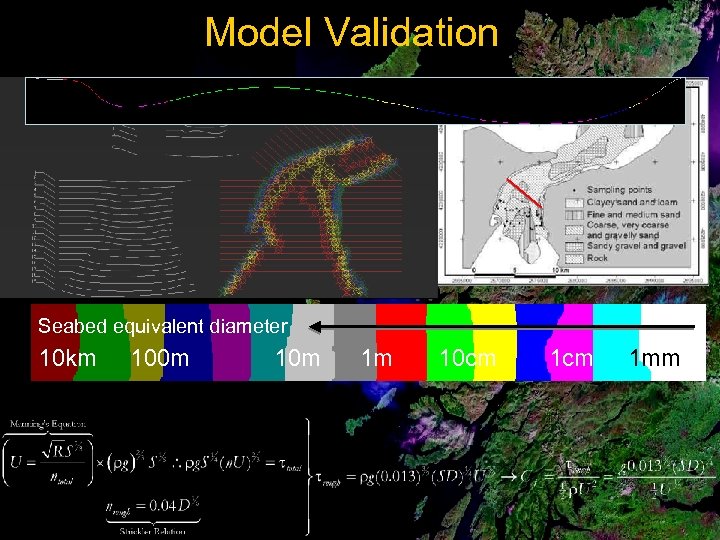

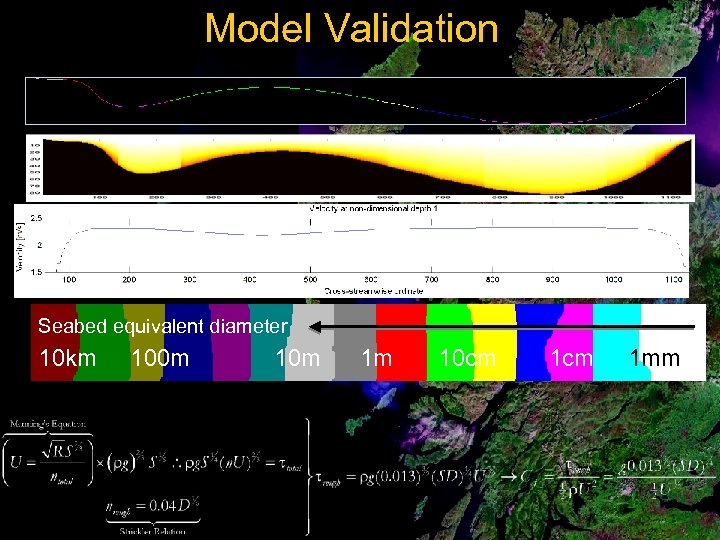

Model Validation • Map Strait of Messina Bathymetry • • Seabed Geology a Surface roughness a Cf a twall

Model Validation • Map Strait of Messina Bathymetry • • Seabed Geology a Surface roughness a Cf a twall

Model Validation • Map Strait of Messina Bathymetry Seabed Geology a Surface roughness a Cf a twall

Model Validation • Map Strait of Messina Bathymetry Seabed Geology a Surface roughness a Cf a twall

Model Validation Seabed equivalent diameter 10 km 100 m 1 m 10 cm 1 mm

Model Validation Seabed equivalent diameter 10 km 100 m 1 m 10 cm 1 mm

Model Validation Seabed equivalent diameter 10 km 100 m 1 m 10 cm 1 mm

Model Validation Seabed equivalent diameter 10 km 100 m 1 m 10 cm 1 mm

Model Validation

Model Validation

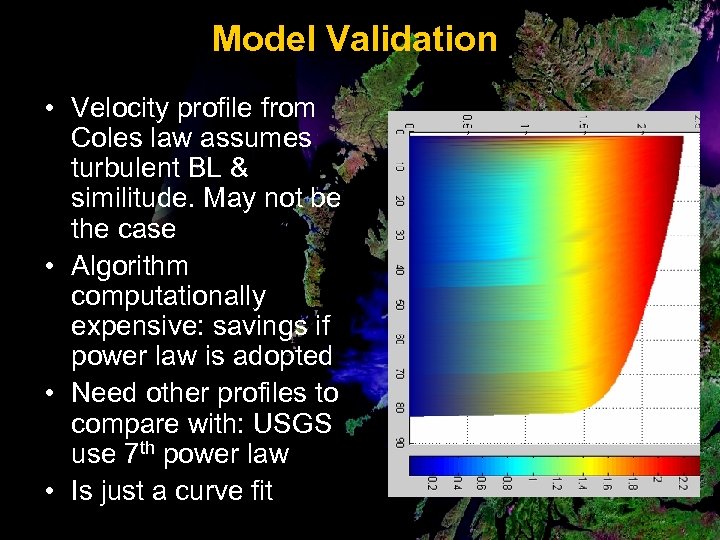

Model Validation • Velocity profile from Coles law assumes turbulent BL & similitude. May not be the case • Algorithm computationally expensive: savings if power law is adopted • Need other profiles to compare with: USGS use 7 th power law • Is just a curve fit

Model Validation • Velocity profile from Coles law assumes turbulent BL & similitude. May not be the case • Algorithm computationally expensive: savings if power law is adopted • Need other profiles to compare with: USGS use 7 th power law • Is just a curve fit

B. Conclusion of Technology Investigation • 3 Main Generic Technology Types Horizontal Axis Turbine, Oscillating Hydrofoil. Ø Quasi-Dynamic Modelling, BEM, Yaw Correction, Time Step Ø Flow conditions & Model Geometry Ø System Loads a Torque a Power Ø

B. Conclusion of Technology Investigation • 3 Main Generic Technology Types Horizontal Axis Turbine, Oscillating Hydrofoil. Ø Quasi-Dynamic Modelling, BEM, Yaw Correction, Time Step Ø Flow conditions & Model Geometry Ø System Loads a Torque a Power Ø

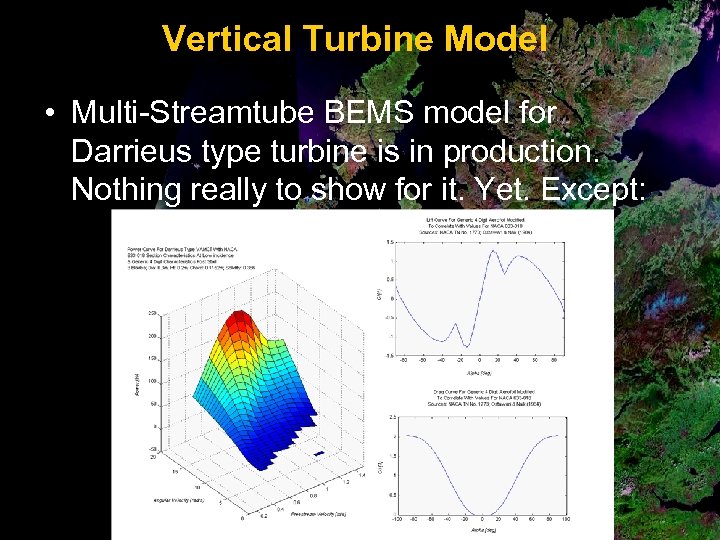

Vertical Turbine Model • Multi-Streamtube BEMS model for Darrieus type turbine is in production. Nothing really to show for it. Yet. Except:

Vertical Turbine Model • Multi-Streamtube BEMS model for Darrieus type turbine is in production. Nothing really to show for it. Yet. Except:

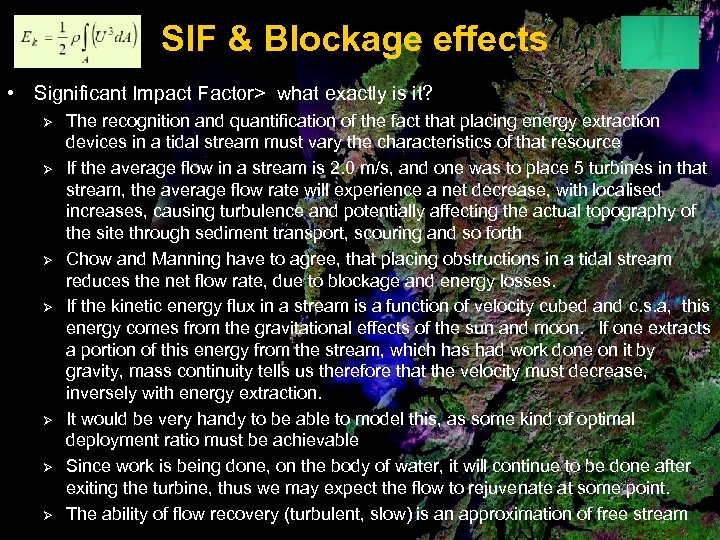

SIF & Blockage effects • Significant Impact Factor> what exactly is it? Ø Ø Ø Ø The recognition and quantification of the fact that placing energy extraction devices in a tidal stream must vary the characteristics of that resource If the average flow in a stream is 2. 0 m/s, and one was to place 5 turbines in that stream, the average flow rate will experience a net decrease, with localised increases, causing turbulence and potentially affecting the actual topography of the site through sediment transport, scouring and so forth Chow and Manning have to agree, that placing obstructions in a tidal stream reduces the net flow rate, due to blockage and energy losses. If the kinetic energy flux in a stream is a function of velocity cubed and c. s. a, this energy comes from the gravitational effects of the sun and moon. If one extracts a portion of this energy from the stream, which has had work done on it by gravity, mass continuity tells us therefore that the velocity must decrease, inversely with energy extraction. It would be very handy to be able to model this, as some kind of optimal deployment ratio must be achievable Since work is being done, on the body of water, it will continue to be done after exiting the turbine, thus we may expect the flow to rejuvenate at some point. The ability of flow recovery (turbulent, slow) is an approximation of free stream

SIF & Blockage effects • Significant Impact Factor> what exactly is it? Ø Ø Ø Ø The recognition and quantification of the fact that placing energy extraction devices in a tidal stream must vary the characteristics of that resource If the average flow in a stream is 2. 0 m/s, and one was to place 5 turbines in that stream, the average flow rate will experience a net decrease, with localised increases, causing turbulence and potentially affecting the actual topography of the site through sediment transport, scouring and so forth Chow and Manning have to agree, that placing obstructions in a tidal stream reduces the net flow rate, due to blockage and energy losses. If the kinetic energy flux in a stream is a function of velocity cubed and c. s. a, this energy comes from the gravitational effects of the sun and moon. If one extracts a portion of this energy from the stream, which has had work done on it by gravity, mass continuity tells us therefore that the velocity must decrease, inversely with energy extraction. It would be very handy to be able to model this, as some kind of optimal deployment ratio must be achievable Since work is being done, on the body of water, it will continue to be done after exiting the turbine, thus we may expect the flow to rejuvenate at some point. The ability of flow recovery (turbulent, slow) is an approximation of free stream

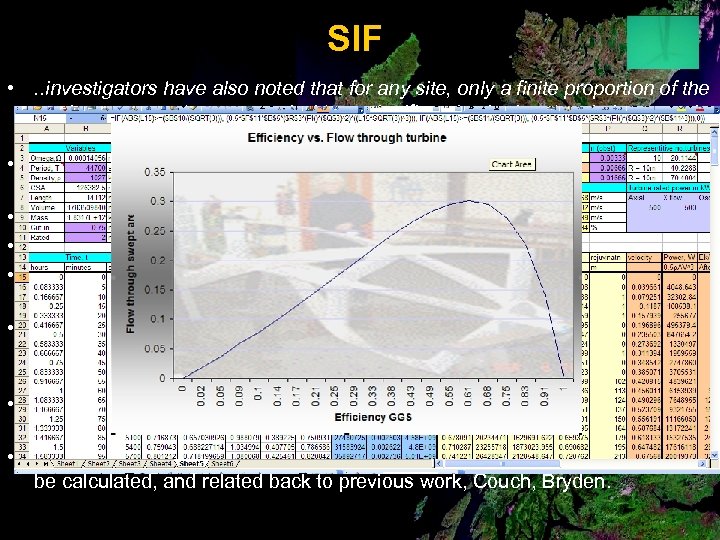

SIF • . . investigators have also noted that for any site, only a finite proportion of the total energy can be extracted without significantly altering the site’s general flow speed, which could have economic and environmental consequences. . • The SIF is unique to particular sites and may vary between 10% and 50% of the energy in the flow Carbon Trust 2005 • RGU’s envir impact suggest 10% max flow reduction ~ could be more • Packing densities suggested at 60 m lateral and 250 m longitudinal • Based on Chow’s Open Channel Hydraulics obstruction correction factors can be applied to a case study, with sensitivity analysis, to see effects • Flow velocity is not constant, but varies with the sine of the period, at the specified instant, as does time-step acceleration, work done and force, if desired • Further, flow passes through the swept area in a quantity depending on efficiency and pitch angle (axial predominantly). • Using these parameters, Chow’s correction factors and sensitivity SIF can be calculated, and related back to previous work, Couch, Bryden.

SIF • . . investigators have also noted that for any site, only a finite proportion of the total energy can be extracted without significantly altering the site’s general flow speed, which could have economic and environmental consequences. . • The SIF is unique to particular sites and may vary between 10% and 50% of the energy in the flow Carbon Trust 2005 • RGU’s envir impact suggest 10% max flow reduction ~ could be more • Packing densities suggested at 60 m lateral and 250 m longitudinal • Based on Chow’s Open Channel Hydraulics obstruction correction factors can be applied to a case study, with sensitivity analysis, to see effects • Flow velocity is not constant, but varies with the sine of the period, at the specified instant, as does time-step acceleration, work done and force, if desired • Further, flow passes through the swept area in a quantity depending on efficiency and pitch angle (axial predominantly). • Using these parameters, Chow’s correction factors and sensitivity SIF can be calculated, and related back to previous work, Couch, Bryden.

Results analysis • Study undertaken on two distinct sites • Some interesting relationships… Ø Further model input information perhaps Ø Suggested: “. . analysis suggests a non-linear relationship between energy extracted and velocity deficit. ” C&B Ø 10% extraction = 5 k rejuvenation/recovery distance • Results: Channel used displays venturi effects, RGU have square cross-section, and uniform length, but general accord with findings

Results analysis • Study undertaken on two distinct sites • Some interesting relationships… Ø Further model input information perhaps Ø Suggested: “. . analysis suggests a non-linear relationship between energy extracted and velocity deficit. ” C&B Ø 10% extraction = 5 k rejuvenation/recovery distance • Results: Channel used displays venturi effects, RGU have square cross-section, and uniform length, but general accord with findings

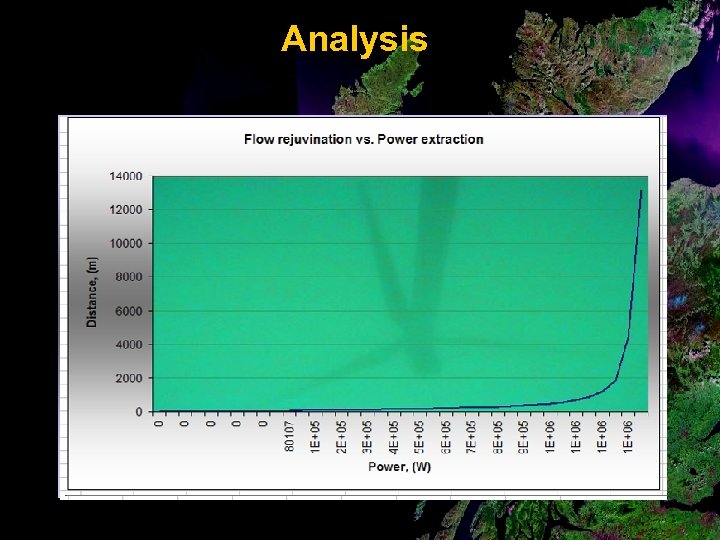

Analysis

Analysis

Technology Comparisons • Efficiency-Velocity-Area 3 D Curve Ø Ø Optimal site specific device characteristics Extractable energy • For each technology compare: Ø Ø Ø Size of inflow AREA Flow VELOCITY POWER output or EFFICIENCY • Allow tidal developer to immediately identify how the different technologies perform in respect to their size and the relationship to velocity and efficiency

Technology Comparisons • Efficiency-Velocity-Area 3 D Curve Ø Ø Optimal site specific device characteristics Extractable energy • For each technology compare: Ø Ø Ø Size of inflow AREA Flow VELOCITY POWER output or EFFICIENCY • Allow tidal developer to immediately identify how the different technologies perform in respect to their size and the relationship to velocity and efficiency

Proposed Methodology • Objective : To define rules to match the most appropriate technology to a particular resource site • A number of tools have been developed throughout the project for this purpose: Ø Ø Ø Surface Tidal Current Spreadsheet The influence of shear on the Velocity distribution for a profile 3 generic technology models • Performing analysis between different technologies and their power output and efficiency for varying flow

Proposed Methodology • Objective : To define rules to match the most appropriate technology to a particular resource site • A number of tools have been developed throughout the project for this purpose: Ø Ø Ø Surface Tidal Current Spreadsheet The influence of shear on the Velocity distribution for a profile 3 generic technology models • Performing analysis between different technologies and their power output and efficiency for varying flow

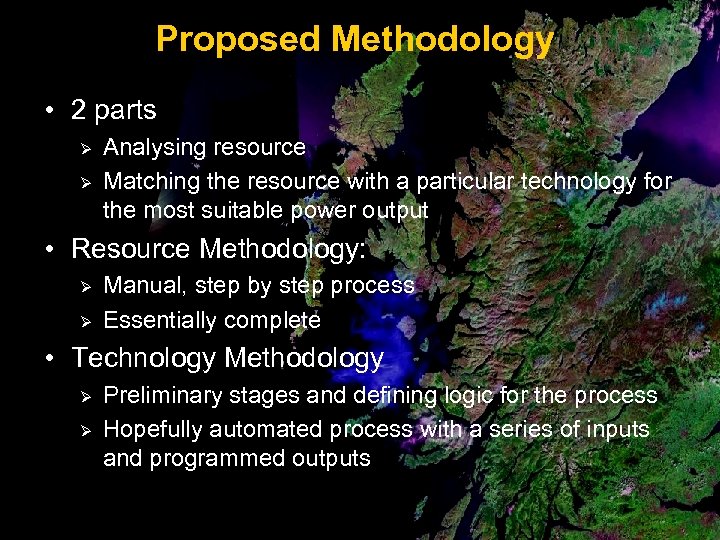

Proposed Methodology • 2 parts Ø Ø Analysing resource Matching the resource with a particular technology for the most suitable power output • Resource Methodology: Ø Ø Manual, step by step process Essentially complete • Technology Methodology Ø Ø Preliminary stages and defining logic for the process Hopefully automated process with a series of inputs and programmed outputs

Proposed Methodology • 2 parts Ø Ø Analysing resource Matching the resource with a particular technology for the most suitable power output • Resource Methodology: Ø Ø Manual, step by step process Essentially complete • Technology Methodology Ø Ø Preliminary stages and defining logic for the process Hopefully automated process with a series of inputs and programmed outputs

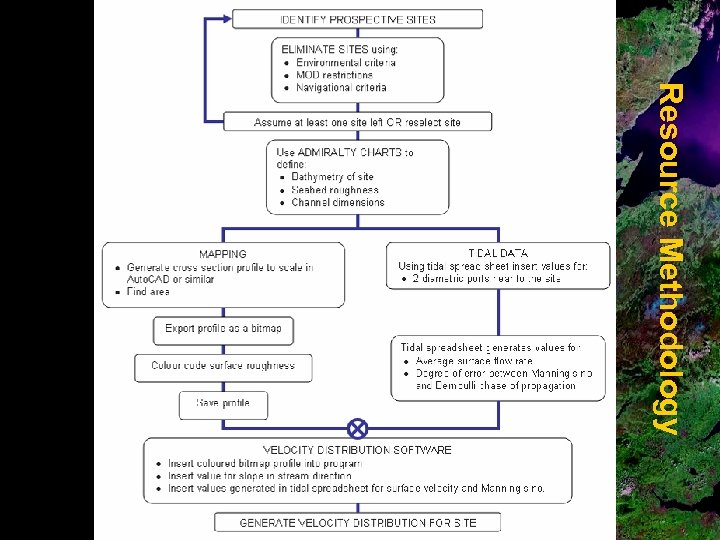

Resource Methodology

Resource Methodology

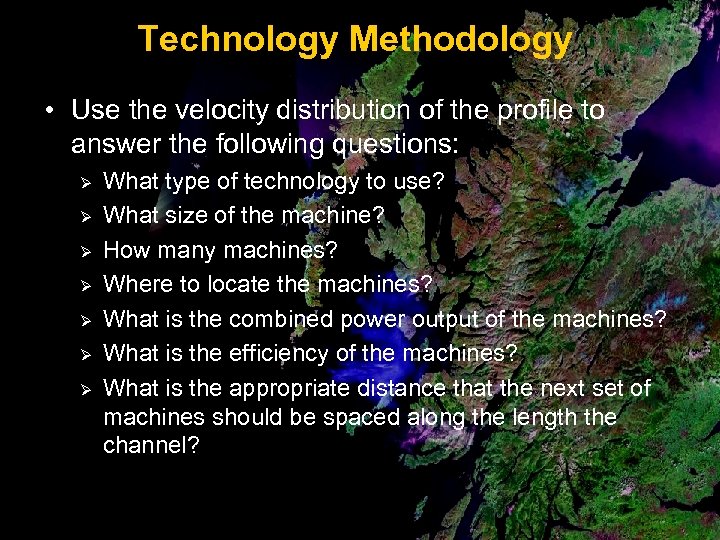

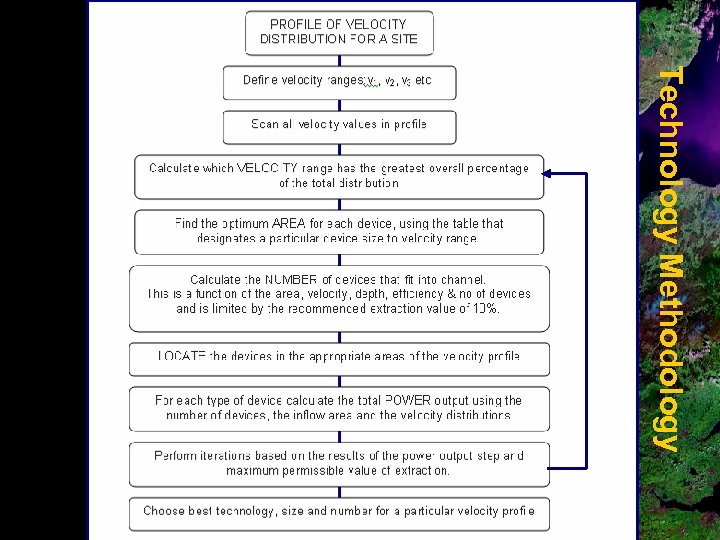

Technology Methodology • Use the velocity distribution of the profile to answer the following questions: Ø Ø Ø Ø What type of technology to use? What size of the machine? How many machines? Where to locate the machines? What is the combined power output of the machines? What is the efficiency of the machines? What is the appropriate distance that the next set of machines should be spaced along the length the channel?

Technology Methodology • Use the velocity distribution of the profile to answer the following questions: Ø Ø Ø Ø What type of technology to use? What size of the machine? How many machines? Where to locate the machines? What is the combined power output of the machines? What is the efficiency of the machines? What is the appropriate distance that the next set of machines should be spaced along the length the channel?

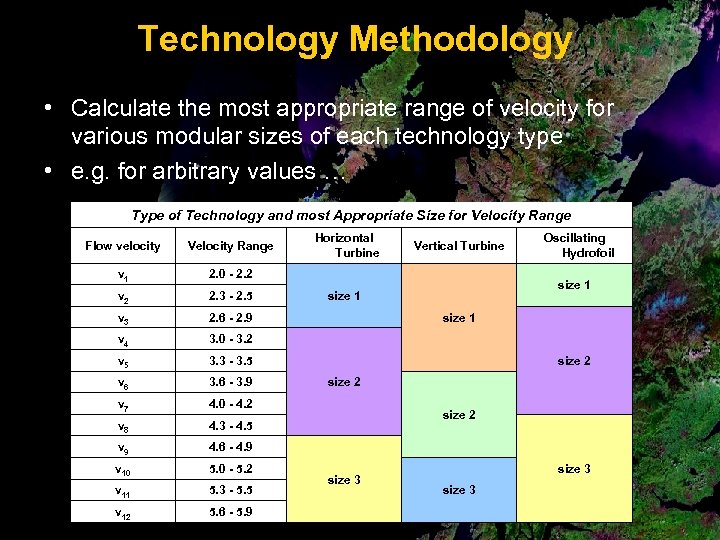

Technology Methodology • Calculate the most appropriate range of velocity for various modular sizes of each technology type • e. g. for arbitrary values … Type of Technology and most Appropriate Size for Velocity Range Flow velocity Velocity Range v 1 2. 0 - 2. 2 v 2 2. 3 - 2. 5 v 3 2. 6 - 2. 9 v 4 3. 3 - 3. 5 v 6 3. 6 - 3. 9 v 7 4. 0 - 4. 2 v 8 4. 3 - 4. 5 v 9 4. 6 - 4. 9 v 10 5. 0 - 5. 2 v 11 5. 3 - 5. 5 v 12 5. 6 - 5. 9 Vertical Turbine Oscillating Hydrofoil 3. 0 - 3. 2 v 5 Horizontal Turbine size 1 size 2 size 3

Technology Methodology • Calculate the most appropriate range of velocity for various modular sizes of each technology type • e. g. for arbitrary values … Type of Technology and most Appropriate Size for Velocity Range Flow velocity Velocity Range v 1 2. 0 - 2. 2 v 2 2. 3 - 2. 5 v 3 2. 6 - 2. 9 v 4 3. 3 - 3. 5 v 6 3. 6 - 3. 9 v 7 4. 0 - 4. 2 v 8 4. 3 - 4. 5 v 9 4. 6 - 4. 9 v 10 5. 0 - 5. 2 v 11 5. 3 - 5. 5 v 12 5. 6 - 5. 9 Vertical Turbine Oscillating Hydrofoil 3. 0 - 3. 2 v 5 Horizontal Turbine size 1 size 2 size 3

Technology Methodology

Technology Methodology

WIP: Website

WIP: Website

Next Steps: • Finish programming and calculations for the resource methodology & (quasirigorous) validation of all models • Complete case study on the Sound of Jura to prove robustness of work and further quantify methodology • Examine economic and cost issues for different technology types and resource characteristics • Complete website

Next Steps: • Finish programming and calculations for the resource methodology & (quasirigorous) validation of all models • Complete case study on the Sound of Jura to prove robustness of work and further quantify methodology • Examine economic and cost issues for different technology types and resource characteristics • Complete website