ba06c31cc2b2db5e59ea29d5eef978d7.ppt

- Количество слайдов: 36

Marco La Valle Conferenza. GNL - ROMA 11/06/2015 LNG carriers and bunkering vessels M. E. S. MARINE ENGINEERING SERVICES

Marco La Valle Conferenza. GNL - ROMA 11/06/2015 LNG carriers and bunkering vessels M. E. S. MARINE ENGINEERING SERVICES

Introduction ESTABLISHMENT INTRODUCTION M. E. S. – Marine Engineering Services S. r. l. 1986 SPECIALIZED Ø Established on 1986 by Ing Giorgio La Valle (40 years experience in gas carriers design) Ø Specialized in gas carriers, chemical tankers and bitumen carriers Ø About 100 ships built with MES design Ø Market: worldwide Ø Headquarters: Trieste (Italy) Gas Carriers Chemical Tankers Bitumen Carriers MARKET Italy Turkey Vietnam China Korea Indonesia Poland The Netherlands Finland

Introduction ESTABLISHMENT INTRODUCTION M. E. S. – Marine Engineering Services S. r. l. 1986 SPECIALIZED Ø Established on 1986 by Ing Giorgio La Valle (40 years experience in gas carriers design) Ø Specialized in gas carriers, chemical tankers and bitumen carriers Ø About 100 ships built with MES design Ø Market: worldwide Ø Headquarters: Trieste (Italy) Gas Carriers Chemical Tankers Bitumen Carriers MARKET Italy Turkey Vietnam China Korea Indonesia Poland The Netherlands Finland

Head office HEAD OFFICE COMPANY PROFILE Trieste (ITALY) • 500 m 2 • Abt. 30 workstations Head Office – TRIESTE 500 m 2 – abt. 30 workstations See VIDEO See some Picture

Head office HEAD OFFICE COMPANY PROFILE Trieste (ITALY) • 500 m 2 • Abt. 30 workstations Head Office – TRIESTE 500 m 2 – abt. 30 workstations See VIDEO See some Picture

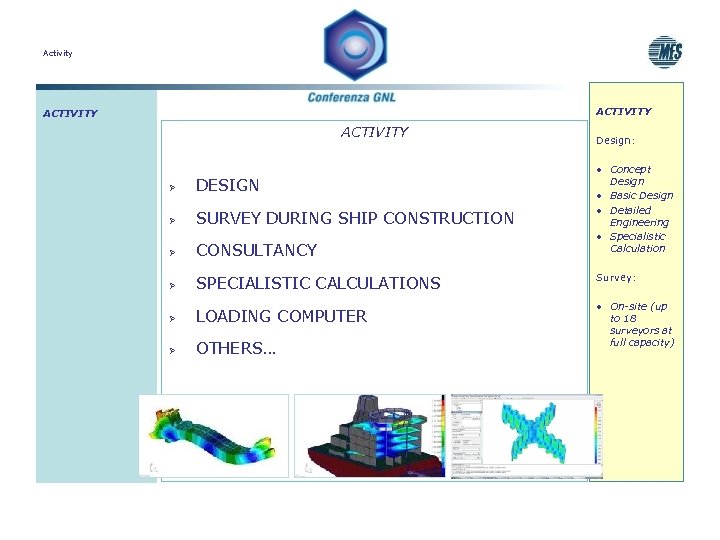

Activity ACTIVITY Ø DESIGN Ø SURVEY DURING SHIP CONSTRUCTION Ø CONSULTANCY Ø SPECIALISTIC CALCULATIONS Ø LOADING COMPUTER Ø OTHERS… Design: • Concept Design • Basic Design • Detailed Engineering • Specialistic Calculation Survey: • On-site (up to 18 surveyors at full capacity)

Activity ACTIVITY Ø DESIGN Ø SURVEY DURING SHIP CONSTRUCTION Ø CONSULTANCY Ø SPECIALISTIC CALCULATIONS Ø LOADING COMPUTER Ø OTHERS… Design: • Concept Design • Basic Design • Detailed Engineering • Specialistic Calculation Survey: • On-site (up to 18 surveyors at full capacity)

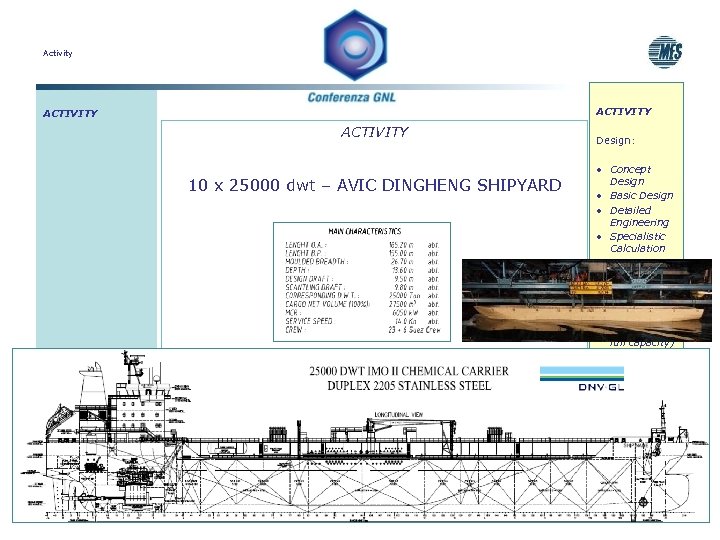

Activity ACTIVITY 10 x 25000 dwt – AVIC DINGHENG SHIPYARD Design: • Concept Design • Basic Design • Detailed Engineering • Specialistic Calculation Survey: • On-site (up to 18 surveyors at full capacity)

Activity ACTIVITY 10 x 25000 dwt – AVIC DINGHENG SHIPYARD Design: • Concept Design • Basic Design • Detailed Engineering • Specialistic Calculation Survey: • On-site (up to 18 surveyors at full capacity)

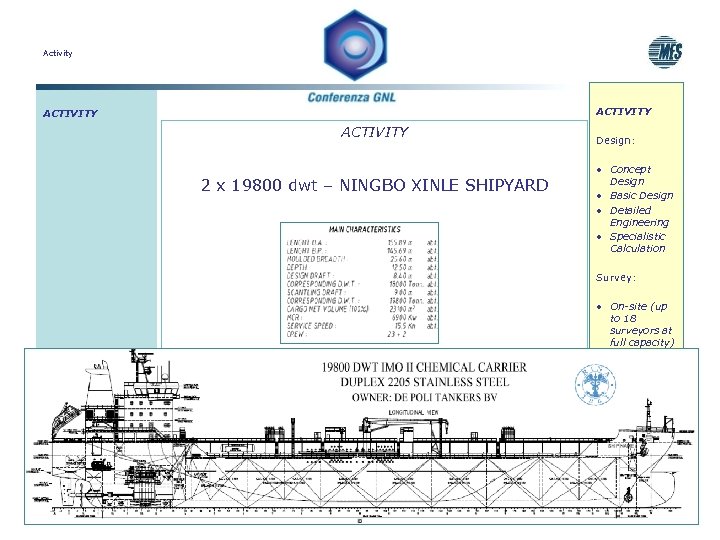

Activity ACTIVITY 2 x 19800 dwt – NINGBO XINLE SHIPYARD Design: • Concept Design • Basic Design • Detailed Engineering • Specialistic Calculation Survey: • On-site (up to 18 surveyors at full capacity)

Activity ACTIVITY 2 x 19800 dwt – NINGBO XINLE SHIPYARD Design: • Concept Design • Basic Design • Detailed Engineering • Specialistic Calculation Survey: • On-site (up to 18 surveyors at full capacity)

Key points KEY POINTS Ø HIGH PERFORMANCES Ø Ø Ø speed-power ratio (low consumptions, up to 25÷ 30%less than competitors) main dimensions optimization (reduce total ship cost) QUALITY Ø Ø Details Ø Support / Assistance Ø Ø Drawings / Documentation ISO 9001 CONTINUOUS FEEDBACK Ø Ø Production (Survey activity) Ø During ship’s life (Shipowners) Ø G&H production Ø Ø Production (Shipyard) Assistance for equipment tenders (Shipyard/Shipowner) EXPERIENCE Ø Ø 40 years in ship design Gas carriers Management Survey Innovation • HIGH PERFORMANCE • QUALITY • CONTINUOUS FEEDBACK • EXPERIENCE

Key points KEY POINTS Ø HIGH PERFORMANCES Ø Ø Ø speed-power ratio (low consumptions, up to 25÷ 30%less than competitors) main dimensions optimization (reduce total ship cost) QUALITY Ø Ø Details Ø Support / Assistance Ø Ø Drawings / Documentation ISO 9001 CONTINUOUS FEEDBACK Ø Ø Production (Survey activity) Ø During ship’s life (Shipowners) Ø G&H production Ø Ø Production (Shipyard) Assistance for equipment tenders (Shipyard/Shipowner) EXPERIENCE Ø Ø 40 years in ship design Gas carriers Management Survey Innovation • HIGH PERFORMANCE • QUALITY • CONTINUOUS FEEDBACK • EXPERIENCE

Products PRODUCTS see the complete REFERENCE LIST on our web page: www. mes. it/home. html Ø Chemical tankers: from 5500 dwt up to 40000 dwt Ø Gas carriers: from 2500 cbm up to 12000 cbm 40000 cbm Ø Bitumen carriers: from 6000 dwt up to 7000 dwt Ø LNG bunkering vessels • Gas carriers • Chemical tankers • Bitumen carriers • Ro-Ro • Ferry • Various

Products PRODUCTS see the complete REFERENCE LIST on our web page: www. mes. it/home. html Ø Chemical tankers: from 5500 dwt up to 40000 dwt Ø Gas carriers: from 2500 cbm up to 12000 cbm 40000 cbm Ø Bitumen carriers: from 6000 dwt up to 7000 dwt Ø LNG bunkering vessels • Gas carriers • Chemical tankers • Bitumen carriers • Ro-Ro • Ferry • Various

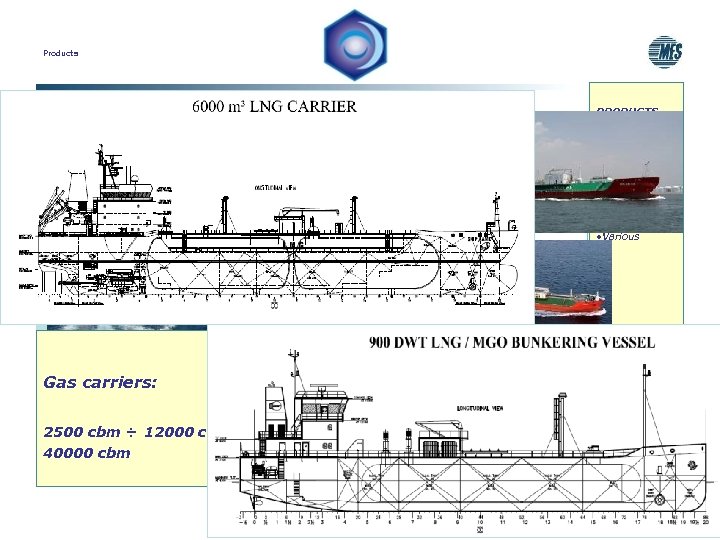

Products PRODUCTS see the complete REFERENCE LIST on our web page: www. mes. it/home. html Gas carriers: 2500 cbm ÷ 12000 cbm 40000 cbm Bunkering vessels: 600 cbm ÷ 40000 cbm • Gas carriers • Chemical tankers • Bitumen carriers • Ro-Ro • Ferry • Various

Products PRODUCTS see the complete REFERENCE LIST on our web page: www. mes. it/home. html Gas carriers: 2500 cbm ÷ 12000 cbm 40000 cbm Bunkering vessels: 600 cbm ÷ 40000 cbm • Gas carriers • Chemical tankers • Bitumen carriers • Ro-Ro • Ferry • Various

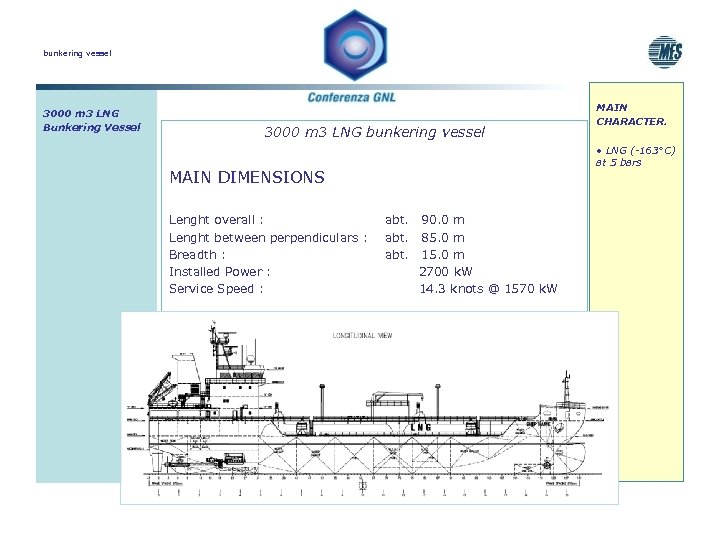

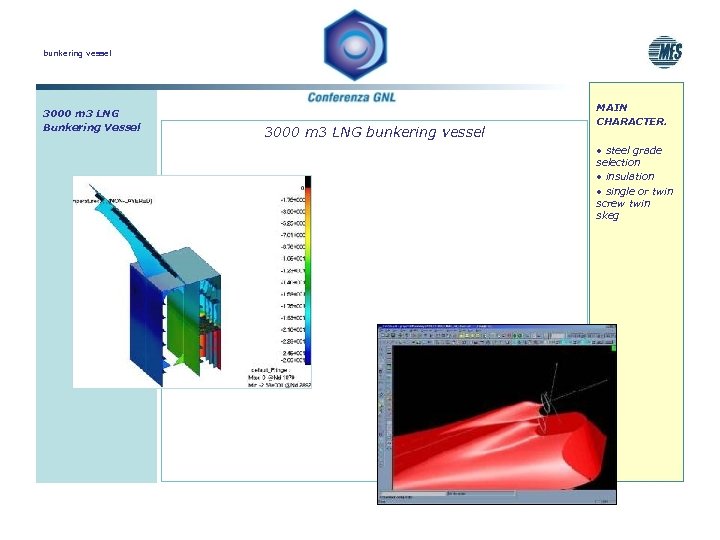

bunkering vessel 3000 m 3 LNG Bunkering Vessel 3000 m 3 LNG bunkering vessel • LNG (-163°C) at 5 bars MAIN DIMENSIONS Lenght overall : Lenght between perpendiculars : Breadth : Installed Power : Service Speed : MAIN CHARACTER. abt. 90. 0 m 85. 0 m 15. 0 m 2700 k. W 14. 3 knots @ 1570 k. W

bunkering vessel 3000 m 3 LNG Bunkering Vessel 3000 m 3 LNG bunkering vessel • LNG (-163°C) at 5 bars MAIN DIMENSIONS Lenght overall : Lenght between perpendiculars : Breadth : Installed Power : Service Speed : MAIN CHARACTER. abt. 90. 0 m 85. 0 m 15. 0 m 2700 k. W 14. 3 knots @ 1570 k. W

bunkering vessel 3000 m 3 LNG Bunkering Vessel 3000 m 3 LNG bunkering vessel MAIN CHARACTER. • steel grade selection • insulation • single or twin screw twin skeg

bunkering vessel 3000 m 3 LNG Bunkering Vessel 3000 m 3 LNG bunkering vessel MAIN CHARACTER. • steel grade selection • insulation • single or twin screw twin skeg

bunkering vessel REFERENCES 3000 m 3 LNG Bunkering Vessel 3000 m 3 LNG bunkering vessel • 8 sisterships already built (3300 cbm LPG)

bunkering vessel REFERENCES 3000 m 3 LNG Bunkering Vessel 3000 m 3 LNG bunkering vessel • 8 sisterships already built (3300 cbm LPG)

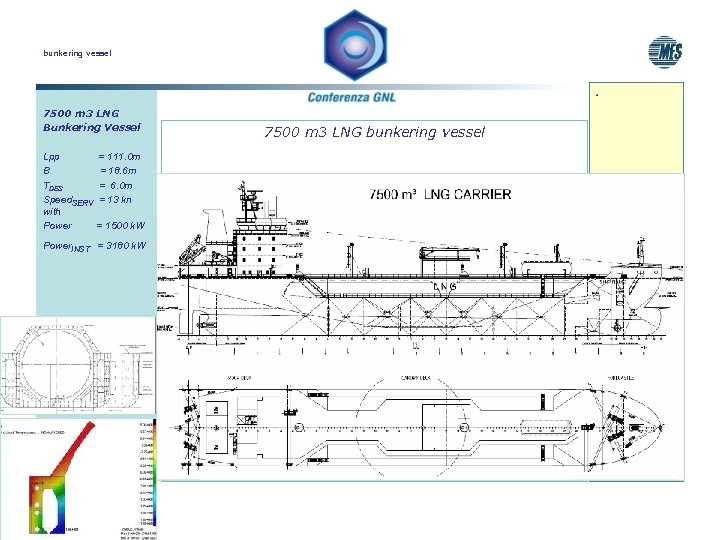

bunkering vessel . 7500 m 3 LNG Bunkering Vessel Lpp B TDES Speed. SERV with Power = 111. 0 m = 18. 6 m = 6. 0 m = 13 kn = 1500 k. W Power. INST = 3180 k. W 7500 m 3 LNG bunkering vessel

bunkering vessel . 7500 m 3 LNG Bunkering Vessel Lpp B TDES Speed. SERV with Power = 111. 0 m = 18. 6 m = 6. 0 m = 13 kn = 1500 k. W Power. INST = 3180 k. W 7500 m 3 LNG bunkering vessel

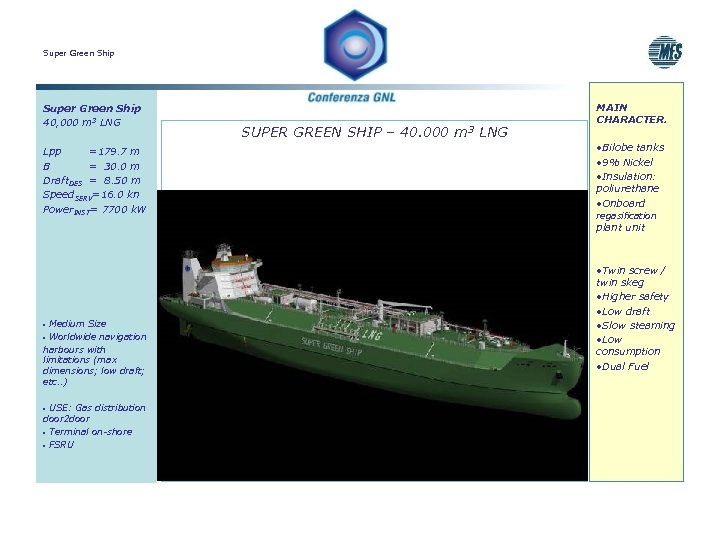

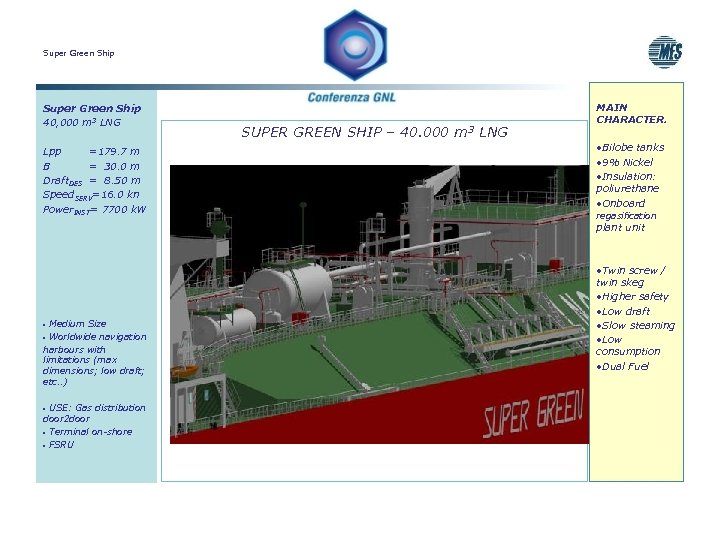

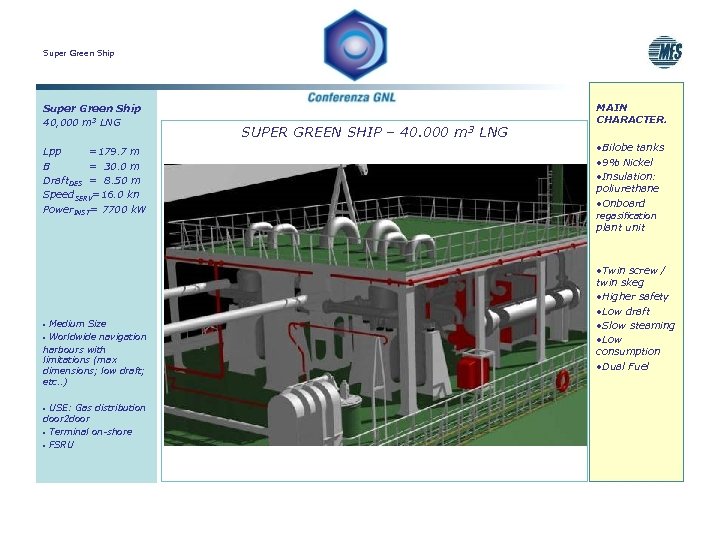

Super Green Ship 40, 000 m 3 LNG Lpp =179. 7 m B = 30. 0 m Draft. DES = 8. 50 m Speed. SERV=16. 0 kn Power. INST= 7700 k. W SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit Medium Size Worldwide navigation harbours with limitations (max dimensions; low draft; etc. . ) • • USE: Gas distribution door 2 door • Terminal on-shore • FSRU • • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

Super Green Ship 40, 000 m 3 LNG Lpp =179. 7 m B = 30. 0 m Draft. DES = 8. 50 m Speed. SERV=16. 0 kn Power. INST= 7700 k. W SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit Medium Size Worldwide navigation harbours with limitations (max dimensions; low draft; etc. . ) • • USE: Gas distribution door 2 door • Terminal on-shore • FSRU • • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

Super Green Ship 40, 000 m 3 LNG Lpp =179. 7 m B = 30. 0 m Draft. DES = 8. 50 m Speed. SERV=16. 0 kn Power. INST= 7700 k. W SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit Medium Size Worldwide navigation harbours with limitations (max dimensions; low draft; etc. . ) • • USE: Gas distribution door 2 door • Terminal on-shore • FSRU • • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

Super Green Ship 40, 000 m 3 LNG Lpp =179. 7 m B = 30. 0 m Draft. DES = 8. 50 m Speed. SERV=16. 0 kn Power. INST= 7700 k. W SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit Medium Size Worldwide navigation harbours with limitations (max dimensions; low draft; etc. . ) • • USE: Gas distribution door 2 door • Terminal on-shore • FSRU • • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

Super Green Ship 40, 000 m 3 LNG Lpp =179. 7 m B = 30. 0 m Draft. DES = 8. 50 m Speed. SERV=16. 0 kn Power. INST= 7700 k. W SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit Medium Size Worldwide navigation harbours with limitations (max dimensions; low draft; etc. . ) • • USE: Gas distribution door 2 door • Terminal on-shore • FSRU • • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

Super Green Ship 40, 000 m 3 LNG Lpp =179. 7 m B = 30. 0 m Draft. DES = 8. 50 m Speed. SERV=16. 0 kn Power. INST= 7700 k. W SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit Medium Size Worldwide navigation harbours with limitations (max dimensions; low draft; etc. . ) • • USE: Gas distribution door 2 door • Terminal on-shore • FSRU • • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

Super Green Ship 40, 000 m 3 LNG Lpp =179. 7 m B = 30. 0 m Draft. DES = 8. 50 m Speed. SERV=16. 0 kn Power. INST= 7700 k. W SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit Medium Size Worldwide navigation harbours with limitations (max dimensions; low draft; etc. . ) • • USE: Gas distribution door 2 door • Terminal on-shore • FSRU • • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

Super Green Ship 40, 000 m 3 LNG Lpp =179. 7 m B = 30. 0 m Draft. DES = 8. 50 m Speed. SERV=16. 0 kn Power. INST= 7700 k. W SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit Medium Size Worldwide navigation harbours with limitations (max dimensions; low draft; etc. . ) • • USE: Gas distribution door 2 door • Terminal on-shore • FSRU • • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

Super Green Ship 40, 000 m 3 LNG SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTERISTICS Ø Ø Ø Ø Ø Bilobe Tanks 9% Nickel Insulation: poliurethane Onboard regasification plant unit Twin screw / twin skeg Higher safety Low draft Slow steaming Low consumption Dual Fuel MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

Super Green Ship 40, 000 m 3 LNG SUPER GREEN SHIP – 40. 000 m 3 LNG MAIN CHARACTERISTICS Ø Ø Ø Ø Ø Bilobe Tanks 9% Nickel Insulation: poliurethane Onboard regasification plant unit Twin screw / twin skeg Higher safety Low draft Slow steaming Low consumption Dual Fuel MAIN CHARACTER. • Bilobe tanks • 9% Nickel • Insulation: poliurethane • Onboard regasification plant unit • Twin screw / twin skeg • Higher safety • Low draft • Slow steaming • Low consumption • Dual Fuel

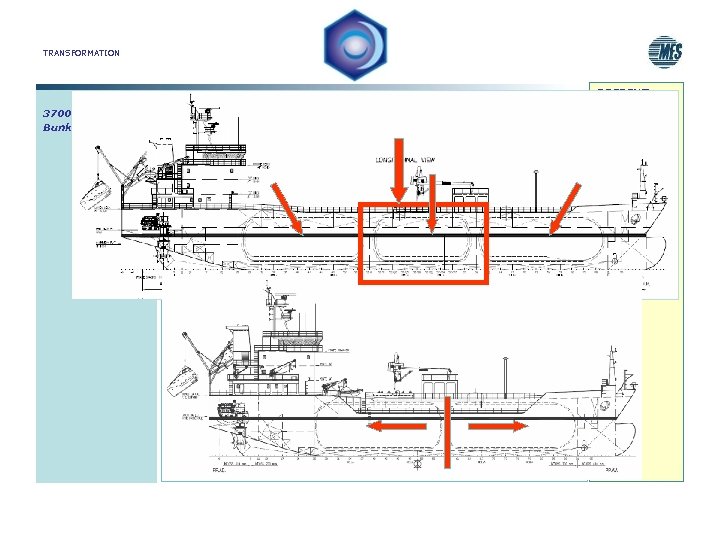

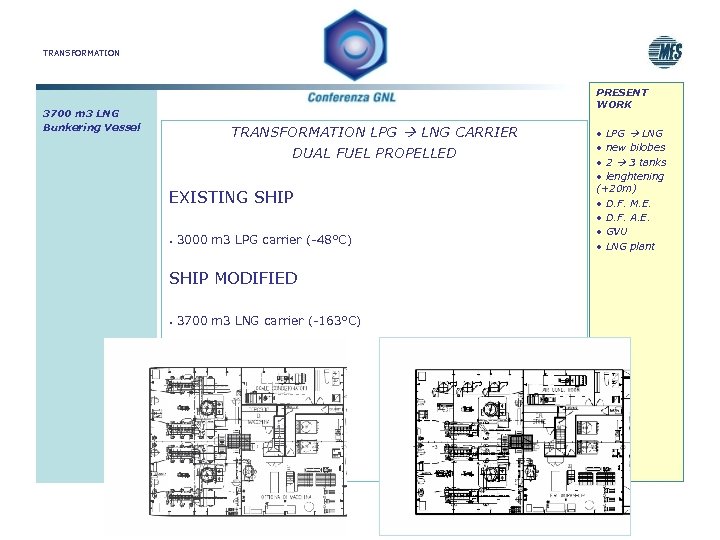

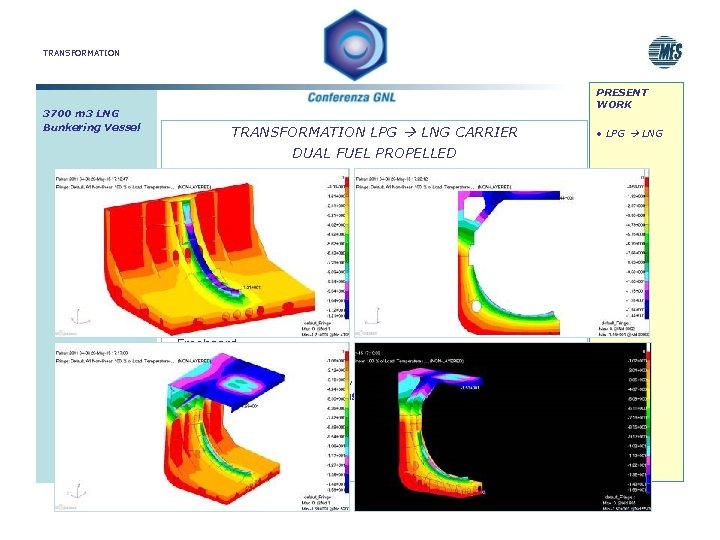

TRANSFORMATION PRESENT WORK 3700 m 3 LNG Bunkering Vessel TRANSFORMATION LPG LNG CARRIER DUAL FUEL PROPELLED EXISTING SHIP • 3000 m 3 LPG carrier (-48°C) SHIP MODIFIED • 3700 m 3 LNG carrier (-163°C) • LPG LNG • new bilobes 2 3 tanks • lenghtening (+20 m) • D. F. M. E. • D. F. A. E. • GVU • LNG plant

TRANSFORMATION PRESENT WORK 3700 m 3 LNG Bunkering Vessel TRANSFORMATION LPG LNG CARRIER DUAL FUEL PROPELLED EXISTING SHIP • 3000 m 3 LPG carrier (-48°C) SHIP MODIFIED • 3700 m 3 LNG carrier (-163°C) • LPG LNG • new bilobes 2 3 tanks • lenghtening (+20 m) • D. F. M. E. • D. F. A. E. • GVU • LNG plant

TRANSFORMATION PRESENT WORK 3700 m 3 LNG Bunkering Vessel TRANSFORMATION LPG LNG CARRIER DUAL FUEL PROPELLED EXISTING SHIP • 3000 m 3 LPG carrier (-48°C) SHIP MODIFIED • 3700 m 3 LNG carrier (-163°C) • LPG LNG • new bilobes • 2 3 tanks • lenghtening (+20 m) • D. F. M. E. • D. F. A. E. • GVU • LNG plant

TRANSFORMATION PRESENT WORK 3700 m 3 LNG Bunkering Vessel TRANSFORMATION LPG LNG CARRIER DUAL FUEL PROPELLED EXISTING SHIP • 3000 m 3 LPG carrier (-48°C) SHIP MODIFIED • 3700 m 3 LNG carrier (-163°C) • LPG LNG • new bilobes • 2 3 tanks • lenghtening (+20 m) • D. F. M. E. • D. F. A. E. • GVU • LNG plant

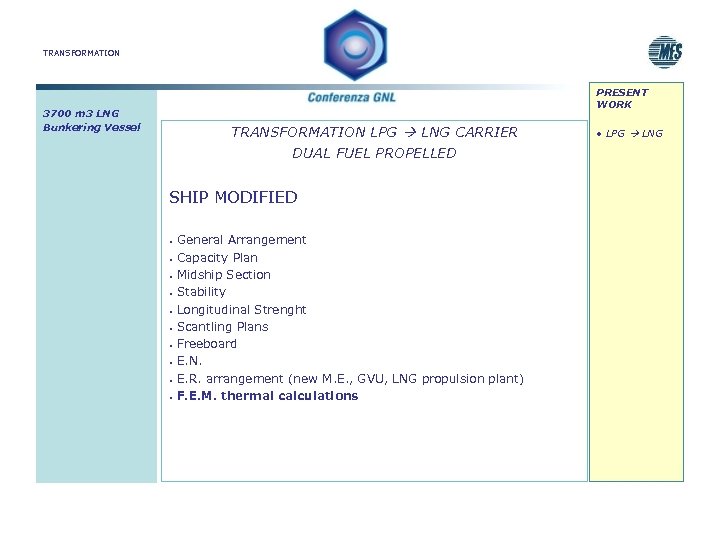

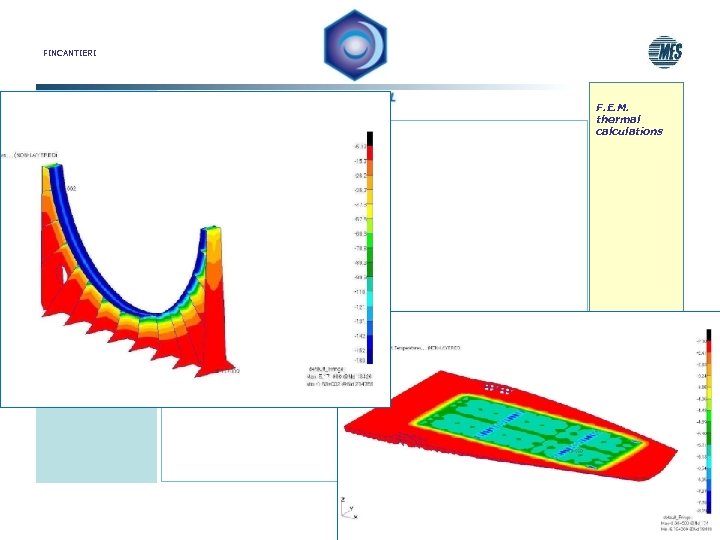

TRANSFORMATION PRESENT WORK 3700 m 3 LNG Bunkering Vessel TRANSFORMATION LPG LNG CARRIER DUAL FUEL PROPELLED SHIP MODIFIED • • • General Arrangement Capacity Plan Midship Section Stability Longitudinal Strenght Scantling Plans Freeboard E. N. E. R. arrangement (new M. E. , GVU, LNG propulsion plant) F. E. M. thermal calculations • LPG LNG

TRANSFORMATION PRESENT WORK 3700 m 3 LNG Bunkering Vessel TRANSFORMATION LPG LNG CARRIER DUAL FUEL PROPELLED SHIP MODIFIED • • • General Arrangement Capacity Plan Midship Section Stability Longitudinal Strenght Scantling Plans Freeboard E. N. E. R. arrangement (new M. E. , GVU, LNG propulsion plant) F. E. M. thermal calculations • LPG LNG

TRANSFORMATION PRESENT WORK 3700 m 3 LNG Bunkering Vessel TRANSFORMATION LPG LNG CARRIER DUAL FUEL PROPELLED SHIP MODIFIED • • • General Arrangement Capacity Plan Midship Section Stability Longitudinal Strenght Scantling Plans Freeboard E. N. E. R. arrangement (new M. E. , GVU, LNG propulsion plant) F. E. M. thermal calculations • LPG LNG

TRANSFORMATION PRESENT WORK 3700 m 3 LNG Bunkering Vessel TRANSFORMATION LPG LNG CARRIER DUAL FUEL PROPELLED SHIP MODIFIED • • • General Arrangement Capacity Plan Midship Section Stability Longitudinal Strenght Scantling Plans Freeboard E. N. E. R. arrangement (new M. E. , GVU, LNG propulsion plant) F. E. M. thermal calculations • LPG LNG

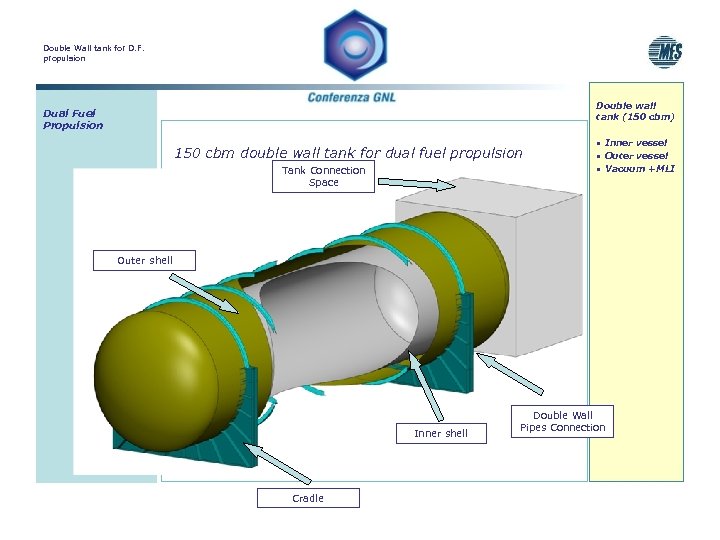

Double Wall tank for D. F. propulsion Double wall tank (150 cbm) Dual Fuel Propulsion 150 cbm double wall tank for dual fuel propulsion Tank Connection Space • Inner vessel • Outer vessel • Vacuum +MLI Outer shell Inner shell Cradle Double Wall Pipes Connection

Double Wall tank for D. F. propulsion Double wall tank (150 cbm) Dual Fuel Propulsion 150 cbm double wall tank for dual fuel propulsion Tank Connection Space • Inner vessel • Outer vessel • Vacuum +MLI Outer shell Inner shell Cradle Double Wall Pipes Connection

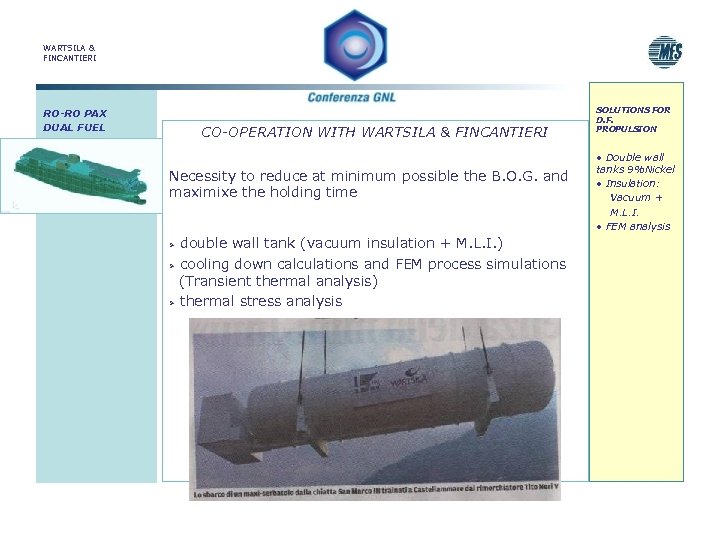

WARTSILA & FINCANTIERI RO-RO PAX DUAL FUEL CO-OPERATION WITH WARTSILA & FINCANTIERI Necessity to reduce at minimum possible the B. O. G. and maximixe the holding time Ø double wall tank (vacuum insulation + M. L. I. ) cooling down calculations and FEM process simulations (Transient thermal analysis) Ø thermal stress analysis Ø SOLUTIONS FOR D. F. PROPULSION • Double wall tanks 9%Nickel • Insulation: Vacuum + M. L. I. • FEM analysis

WARTSILA & FINCANTIERI RO-RO PAX DUAL FUEL CO-OPERATION WITH WARTSILA & FINCANTIERI Necessity to reduce at minimum possible the B. O. G. and maximixe the holding time Ø double wall tank (vacuum insulation + M. L. I. ) cooling down calculations and FEM process simulations (Transient thermal analysis) Ø thermal stress analysis Ø SOLUTIONS FOR D. F. PROPULSION • Double wall tanks 9%Nickel • Insulation: Vacuum + M. L. I. • FEM analysis

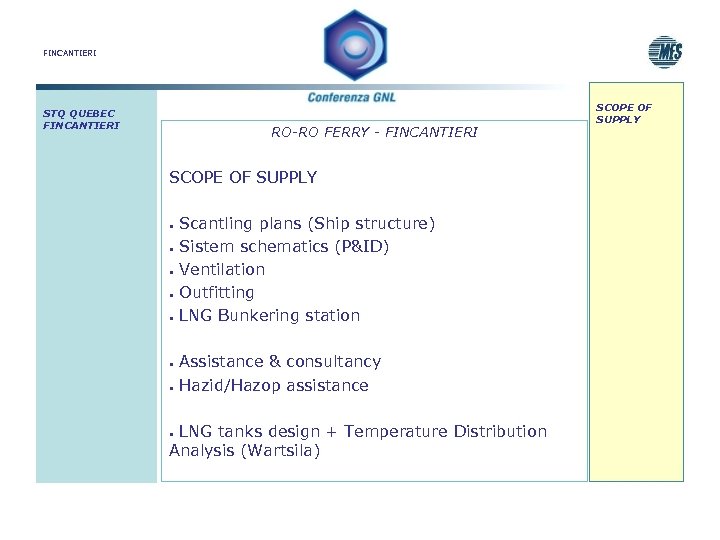

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI SCOPE OF SUPPLY • • Scantling plans (Ship structure) Sistem schematics (P&ID) Ventilation Outfitting LNG Bunkering station Assistance & consultancy Hazid/Hazop assistance LNG tanks design + Temperature Distribution Analysis (Wartsila) • SCOPE OF SUPPLY

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI SCOPE OF SUPPLY • • Scantling plans (Ship structure) Sistem schematics (P&ID) Ventilation Outfitting LNG Bunkering station Assistance & consultancy Hazid/Hazop assistance LNG tanks design + Temperature Distribution Analysis (Wartsila) • SCOPE OF SUPPLY

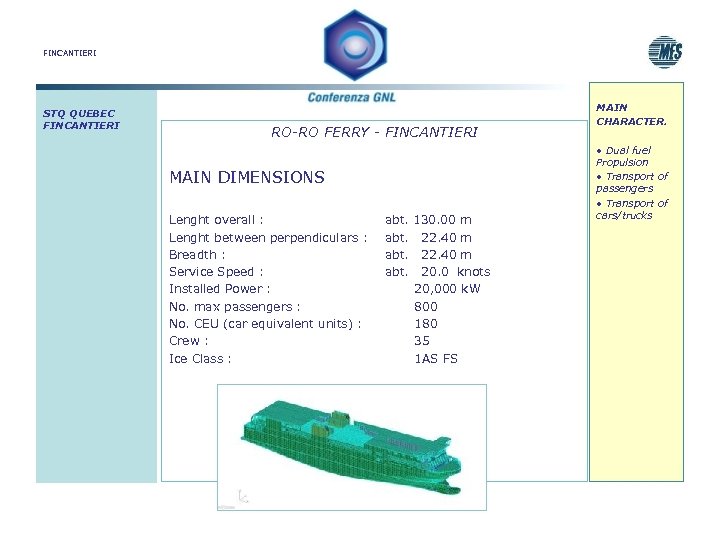

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI MAIN DIMENSIONS Lenght overall : Lenght between perpendiculars : Breadth : Service Speed : Installed Power : No. max passengers : No. CEU (car equivalent units) : Crew : Ice Class : abt. 130. 00 m abt. 22. 40 m abt. 20. 0 knots 20, 000 k. W 800 180 35 1 AS FS MAIN CHARACTER. • Dual fuel Propulsion • Transport of passengers • Transport of cars/trucks

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI MAIN DIMENSIONS Lenght overall : Lenght between perpendiculars : Breadth : Service Speed : Installed Power : No. max passengers : No. CEU (car equivalent units) : Crew : Ice Class : abt. 130. 00 m abt. 22. 40 m abt. 20. 0 knots 20, 000 k. W 800 180 35 1 AS FS MAIN CHARACTER. • Dual fuel Propulsion • Transport of passengers • Transport of cars/trucks

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI LNG TANKS Capacity : 2 x 280 m 3 Indipendent type IMO C Support cradles Max Pression : 9 bar Double Wall Insulation by vacuum in combination with M. L. I. Double wall pipes MAIN CHARACTER. • Dual fuel propulsion • Transport of passengers • Transport of cars/trucks

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI LNG TANKS Capacity : 2 x 280 m 3 Indipendent type IMO C Support cradles Max Pression : 9 bar Double Wall Insulation by vacuum in combination with M. L. I. Double wall pipes MAIN CHARACTER. • Dual fuel propulsion • Transport of passengers • Transport of cars/trucks

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI BUNKER STATION • • Bunkering by trucks Semi-enclosed space Airlock Hazardous Area Mechanical ventilation OCIMF Regulations Gas detection Dry Powder MAIN CHARACTER. • Dual fuel propulsion • Transport of passengers • Transport of cars/trucks

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI BUNKER STATION • • Bunkering by trucks Semi-enclosed space Airlock Hazardous Area Mechanical ventilation OCIMF Regulations Gas detection Dry Powder MAIN CHARACTER. • Dual fuel propulsion • Transport of passengers • Transport of cars/trucks

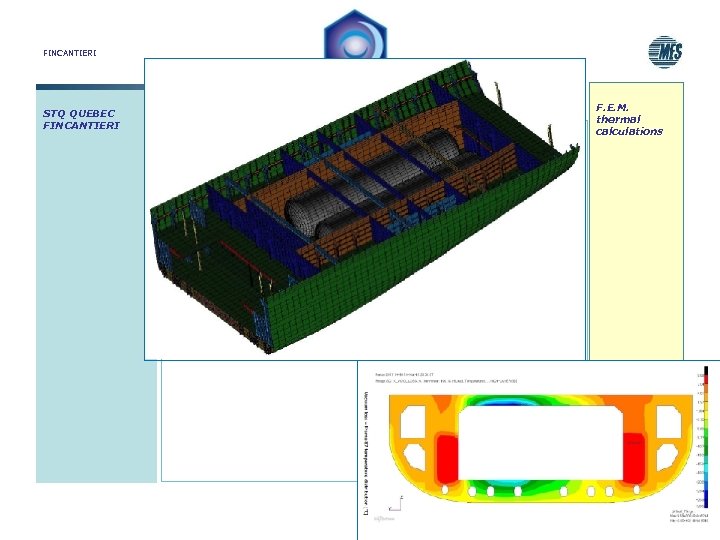

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI LNG TANKS Capacity : 2 x 280 m 3 Indipendent type IMO C Support cradles Max Pression : 9 bar F. E. M. thermal calculations

FINCANTIERI STQ QUEBEC FINCANTIERI RO-RO FERRY - FINCANTIERI LNG TANKS Capacity : 2 x 280 m 3 Indipendent type IMO C Support cradles Max Pression : 9 bar F. E. M. thermal calculations

FINCANTIERI F. E. M. thermal calculations STQ QUEBEC FINCANTIERI Double wall pipes

FINCANTIERI F. E. M. thermal calculations STQ QUEBEC FINCANTIERI Double wall pipes

FINCANTIERI STQ FERRY http: //www. rai. tv/dl/Rai. TV/programmi/media/Content. Item-bebacf 7 c-d 60 e-47 a 1 bd 9 c-fd 3 a 067 ca 7 d 4. html

FINCANTIERI STQ FERRY http: //www. rai. tv/dl/Rai. TV/programmi/media/Content. Item-bebacf 7 c-d 60 e-47 a 1 bd 9 c-fd 3 a 067 ca 7 d 4. html

FINCANTIERI STQ FERRY http: //www. rai. tv/dl/Rai. TV/programmi/media/Content. Item-bebacf 7 c-d 60 e-47 a 1 bd 9 c-fd 3 a 067 ca 7 d 4. html

FINCANTIERI STQ FERRY http: //www. rai. tv/dl/Rai. TV/programmi/media/Content. Item-bebacf 7 c-d 60 e-47 a 1 bd 9 c-fd 3 a 067 ca 7 d 4. html

FINCANTIERI STQ FERRY http: //www. rai. tv/dl/Rai. TV/programmi/media/Content. Item-bebacf 7 c-d 60 e-47 a 1 bd 9 c-fd 3 a 067 ca 7 d 4. html

FINCANTIERI STQ FERRY http: //www. rai. tv/dl/Rai. TV/programmi/media/Content. Item-bebacf 7 c-d 60 e-47 a 1 bd 9 c-fd 3 a 067 ca 7 d 4. html

FINCANTIERI STQ FERRY http: //www. rai. tv/dl/Rai. TV/programmi/media/Content. Item-bebacf 7 c-d 60 e-47 a 1 bd 9 c-fd 3 a 067 ca 7 d 4. html

FINCANTIERI STQ FERRY http: //www. rai. tv/dl/Rai. TV/programmi/media/Content. Item-bebacf 7 c-d 60 e-47 a 1 bd 9 c-fd 3 a 067 ca 7 d 4. html

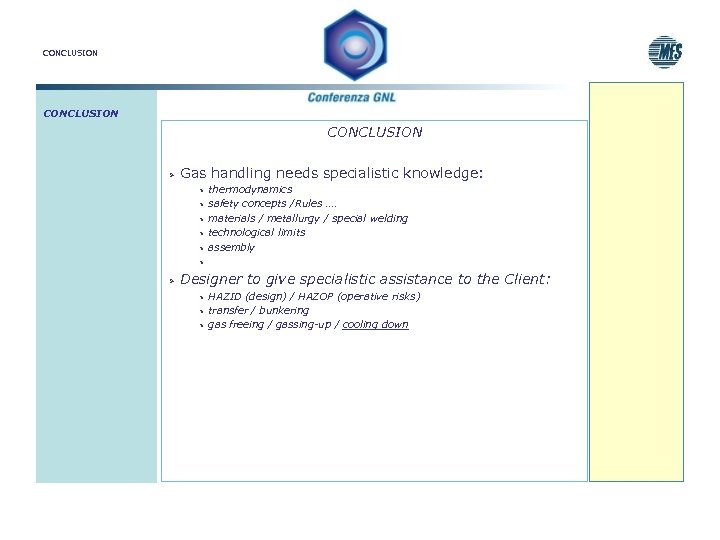

CONCLUSION Ø Gas handling needs specialistic knowledge: Ø Ø Ø thermodynamics safety concepts /Rules …. materials / metallurgy / special welding technological limits assembly Ø Ø Designer to give specialistic assistance to the Client: Ø Ø Ø HAZID (design) / HAZOP (operative risks) transfer / bunkering gas freeing / gassing-up / cooling down

CONCLUSION Ø Gas handling needs specialistic knowledge: Ø Ø Ø thermodynamics safety concepts /Rules …. materials / metallurgy / special welding technological limits assembly Ø Ø Designer to give specialistic assistance to the Client: Ø Ø Ø HAZID (design) / HAZOP (operative risks) transfer / bunkering gas freeing / gassing-up / cooling down

Contacts THANKS FOR THE ATTENTION Visit us on the web : www. mes. it Follow us on (Marine Engineering Services Srl) M. E. S. – Marine Engineering Services S. r. l. info@mes. it techdep@mes. it

Contacts THANKS FOR THE ATTENTION Visit us on the web : www. mes. it Follow us on (Marine Engineering Services Srl) M. E. S. – Marine Engineering Services S. r. l. info@mes. it techdep@mes. it