b7e215bc7fb6df2777c407bd7376c82e.ppt

- Количество слайдов: 1

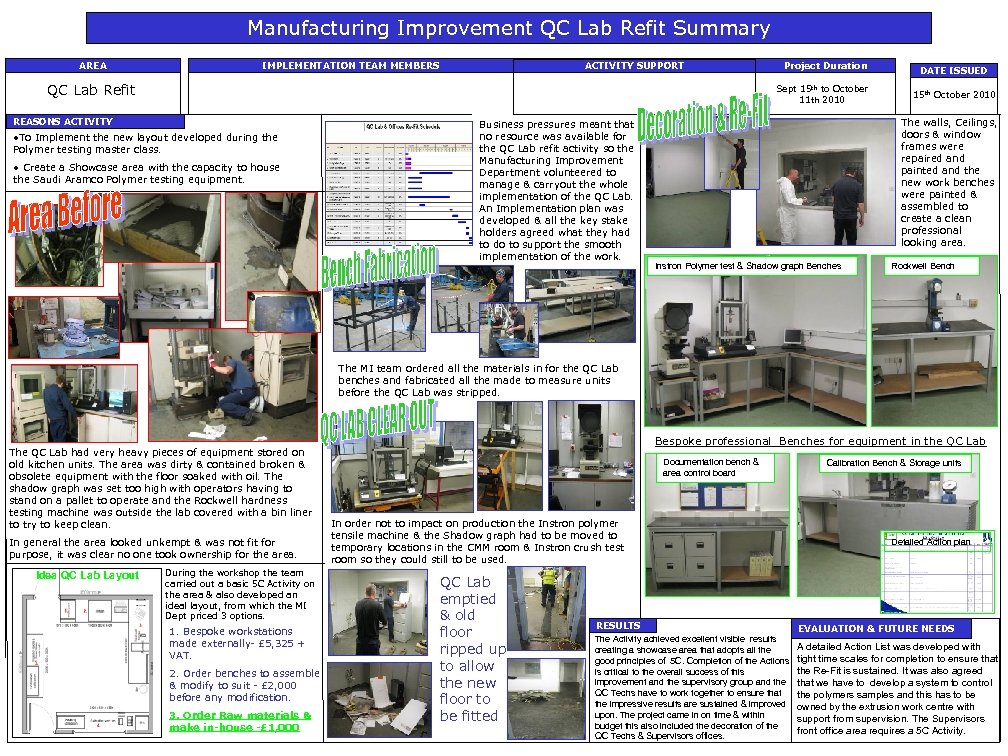

Manufacturing Improvement QC Lab Refit Summary AREA IMPLEMENTATION TEAM MEMBERS ACTIVITY SUPPORT QC Lab Refit Project Duration Sept 15 th to October 11 th 2010 REASONS ACTIVITY • To Implement the new layout developed during the Polymer testing master class. • Create a Showcase area with the capacity to house the Saudi Aramco Polymer testing equipment. Business pressures meant that no resource was available for the QC Lab refit activity so the Manufacturing Improvement Department volunteered to manage & carryout the whole implementation of the QC Lab. An Implementation plan was developed & all the key stake holders agreed what they had to do to support the smooth implementation of the work. DATE ISSUED 15 th October 2010 The walls, Ceilings, doors & window frames were repaired and painted and the new work benches were painted & assembled to create a clean professional looking area. Instron Polymer test & Shadow graph Benches Rockwell Bench The MI team ordered all the materials in for the QC Lab benches and fabricated all the made to measure units before the QC Lab was stripped. The QC Lab had very heavy pieces of equipment stored on old kitchen units. The area was dirty & contained broken & obsolete equipment with the floor soaked with oil. The shadow graph was set too high with operators having to stand on a pallet to operate and the Rockwell hardness testing machine was outside the lab covered with a bin liner to try to keep clean. In general the area looked unkempt & was not fit for purpose, it was clear no one took ownership for the area. Idea QC Lab Layout During the workshop the team carried out a basic 5 C Activity on the area & also developed an ideal layout, from which the MI Dept priced 3 options. 1. Bespoke workstations made externally- £ 5, 325 + VAT. 2. Order benches to assemble & modify to suit - £ 2, 000 before any modification. 3. Order Raw materials & make in-house -£ 1, 000 Bespoke professional Benches for equipment in the QC Lab Documentation bench & area control board In order not to impact on production the Instron polymer tensile machine & the Shadow graph had to be moved to temporary locations in the CMM room & Instron crush test room so they could still to be used. QC Lab emptied & old floor ripped up to allow the new floor to be fitted RESULTS The Activity achieved excellent visible results creating a showcase area that adopts all the good principles of 5 C. Completion of the Actions is critical to the overall success of this improvement and the supervisory group and the QC Techs have to work together to ensure that the impressive results are sustained & improved upon. The project came in on time & within budget this also included the decoration of the QC Techs & Supervisors offices. Calibration Bench & Storage units Detailed Action plan EVALUATION & FUTURE NEEDS A detailed Action List was developed with tight time scales for completion to ensure that the Re-Fit is sustained. It was also agreed that we have to develop a system to control the polymers samples and this has to be owned by the extrusion work centre with support from supervision. The Supervisors front office area requires a 5 C Activity.

b7e215bc7fb6df2777c407bd7376c82e.ppt