64aaf2f05b5a6a0b631958e07d5d6aa4.ppt

- Количество слайдов: 30

Manufacturing Capabilities and Competitive Advantage Dr. Jesus A. Ponce-de-Leon January 2002 JPde. L and Associates, 2001, 2002, copyright 2001 1 Jump to first page

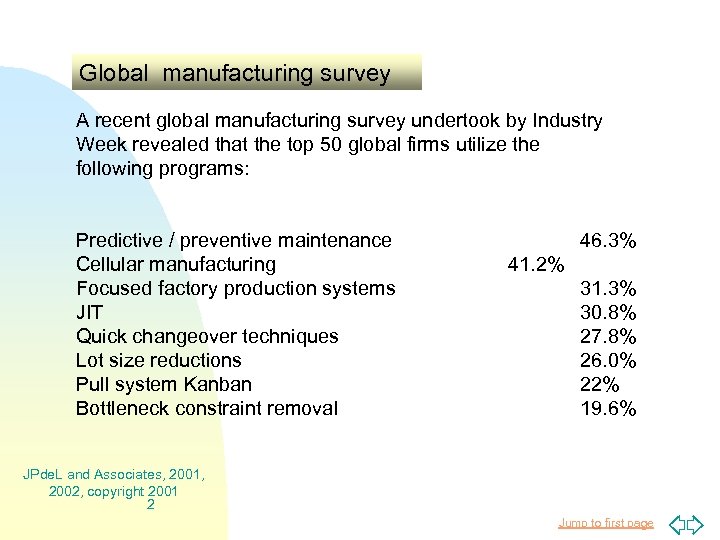

Global manufacturing survey A recent global manufacturing survey undertook by Industry Week revealed that the top 50 global firms utilize the following programs: Predictive / preventive maintenance Cellular manufacturing Focused factory production systems JIT Quick changeover techniques Lot size reductions Pull system Kanban Bottleneck constraint removal 46. 3% 41. 2% 31. 3% 30. 8% 27. 8% 26. 0% 22% 19. 6% JPde. L and Associates, 2001, 2002, copyright 2001 2 Jump to first page

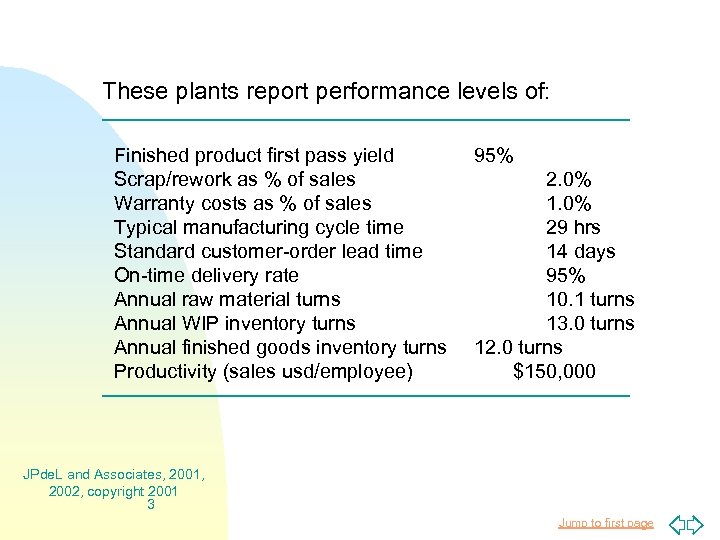

These plants report performance levels of: Finished product first pass yield Scrap/rework as % of sales Warranty costs as % of sales Typical manufacturing cycle time Standard customer-order lead time On-time delivery rate Annual raw material turns Annual WIP inventory turns Annual finished goods inventory turns Productivity (sales usd/employee) 95% 2. 0% 1. 0% 29 hrs 14 days 95% 10. 1 turns 13. 0 turns 12. 0 turns $150, 000 JPde. L and Associates, 2001, 2002, copyright 2001 3 Jump to first page

Situation • Your business has already tried the fancy programs: reengineering manufacturing cells JIT TQM subcontracting continuous improvements lean manufacturing ERP (such as SAP software) JPde. L and Associates, 2001, 2002, copyright 2001 4 Jump to first page

Limits to Improvements? Worldwide we are observing that leading edge manufacturing firms are reaching apparent limits to improvements from lean manufacturing techniques. These observations suggest a life cycle for lean manufacturing has been reached. That suggests a start up (up-hill stage), a growth and diffusion stage, a maturity stage and then an apparent decreasing benefits stage. JPde. L and Associates, 2001, 2002, copyright 2001 5 Jump to first page

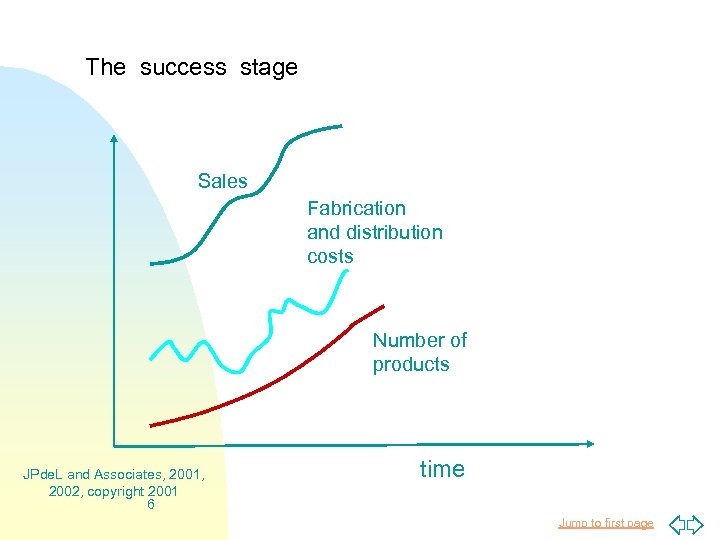

The success stage Sales Fabrication and distribution costs Number of products JPde. L and Associates, 2001, 2002, copyright 2001 6 time Jump to first page

Situation Today • Sales have stopped growing. • Your costs do not seem to improve anymore. • Your products do not seem to be leading edge in the market anymore. • Your organization is having difficulty coordinating among marketing and production and research & development. JPde. L and Associates, 2001, 2002, copyright 2001 7 Jump to first page

WHY? • So, you ask, why is that my operations do not seem to improve? • Why my costs do not seem to fall? • Why my improvement programs do not produce anymore dramatic results? • Why in spite of the marketing and sales efforts our profits do not seem to get any better? JPde. L and Associates, 2001, 2002, copyright 2001 8 Jump to first page

Before we proceed to answer these questions we need to make a short conceptual trip. 1. Let us first understand how some manufacturing global success came about. 2. And then look at why these manufacturing strategies seemed to have reached their limits for improvements. JPde. L and Associates, 2001, 2002, copyright 2001 9 Jump to first page

Part I How some manufacturing firms Succeeded in global markets JPde. L and Associates, 2001, 2002, copyright 2001 10 Jump to first page

DEVELOPING MANUFACTURING CAPABILITIES • FOR DECADES MANUFACTURING WAS NOT SEEN AS STRATEGIC. • EARLY 80 s MANUFACTURING AS A COMPETITIVE WEAPON (SKINNER, 1985) • RESEARCH BY FERDOWS ET AL; HALL-NAKANE; WHYBARK AND OTHERS FOUND JAPANESE SEEMED TO HAVE FOLLOWED A MANUFACTURING MODEL THAT IS SOLID AND LASTING. JPde. L and Associates, 2001, 2002, copyright 2001 11 Jump to first page

TWO DIFFERENT STARTING POINTS FOR MANUFACTURING PARADIGMS n n JAPANESE SAW QUALITY AS CRITICAL TO BE AN INTERNATIONAL PLAYER. AMERICANS SOUGHT ECONOMIES OF SCALE , SCOPE AND EXPERIENCE EFFECTS. THESE DIFFERENT VIEWS STEERED THEM IN TWO DIFFERENT MANUFACTURING PATHS JPde. L and Associates, 2001, 2002, copyright 2001 12 Jump to first page

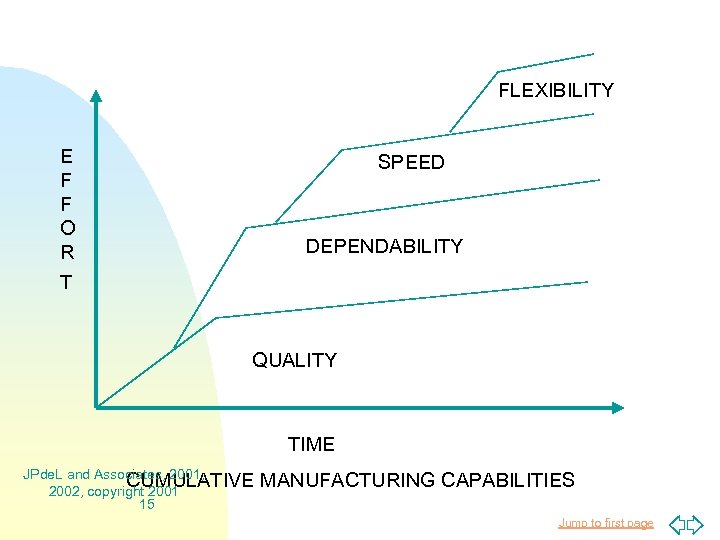

Two worldwide studies of global companies by academics and consulting firms found that the most successful path has been a build up of one competency on top of another in a Logical and predefined sequence. This is known as the cumulative capabilities model. JPde. L and Associates, 2001, 2002, copyright 2001 13 Jump to first page

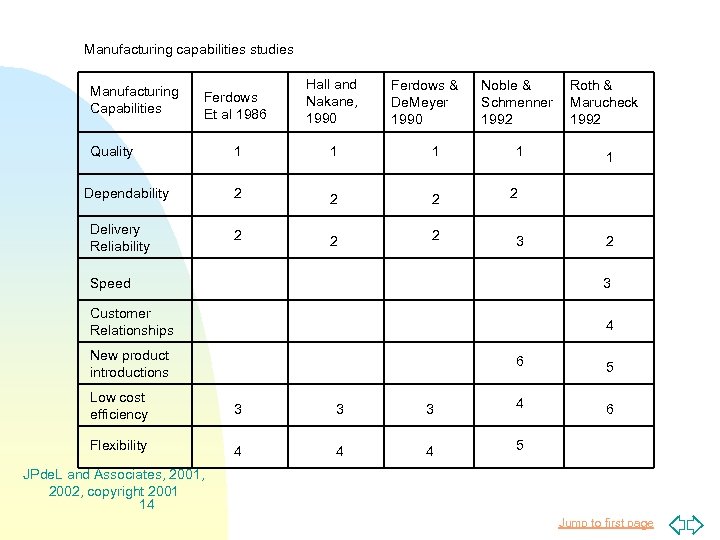

Manufacturing capabilities studies Manufacturing Capabilities Ferdows Et al 1986 Hall and Nakane, 1990 1 1 1 2 2 2 Quality Dependability Delivery Reliability Ferdows & De. Meyer 1990 Noble & Schmenner 1992 1 Roth & Marucheck 1992 1 2 3 2 Speed 3 Customer Relationships 4 New product introductions 6 5 6 Low cost efficiency 3 3 3 4 Flexibility 4 4 4 5 JPde. L and Associates, 2001, 2002, copyright 2001 14 Jump to first page

FLEXIBILITY E F F O R T SPEED DEPENDABILITY QUALITY TIME JPde. L and Associates, 2001, CUMULATIVE 2002, copyright 2001 15 MANUFACTURING CAPABILITIES Jump to first page

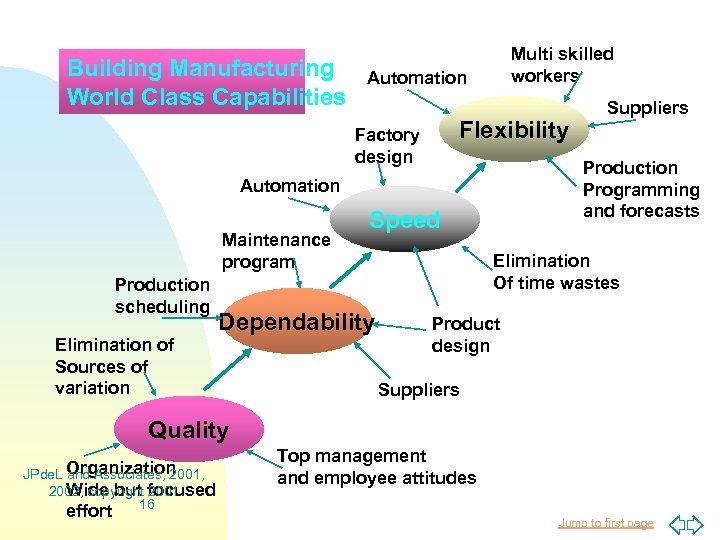

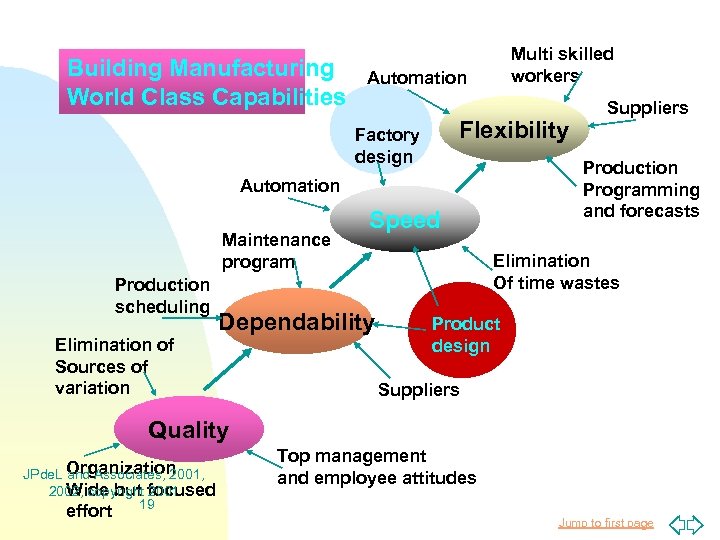

Building Manufacturing World Class Capabilities Multi skilled workers Automation Flexibility Factory design Production Programming and forecasts Automation Maintenance program Production scheduling Elimination of Sources of variation Speed Dependability Suppliers Elimination Of time wastes Product design Suppliers Quality JPde. L Organization and Associates, 2001, Wide but 2001 2002, copyright focused 16 effort Top management and employee attitudes Jump to first page

Part II Why world class programs reach apparent limits for improvement JPde. L and Associates, 2001, 2002, copyright 2001 17 Jump to first page

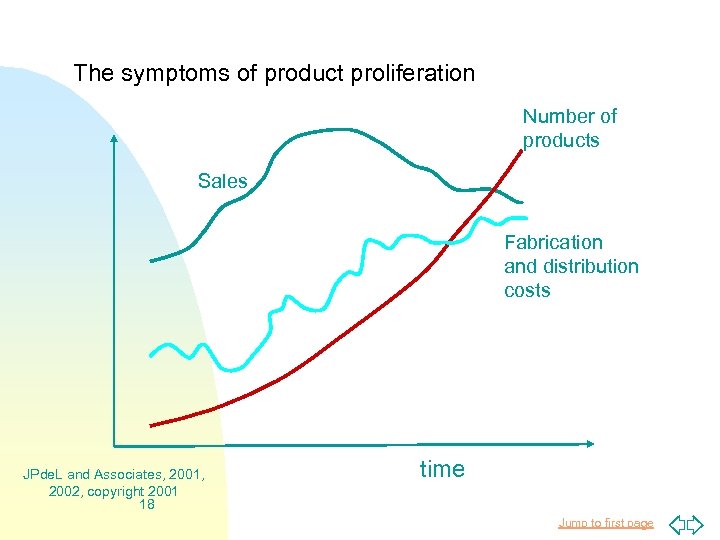

The symptoms of product proliferation Number of products Sales Fabrication and distribution costs JPde. L and Associates, 2001, 2002, copyright 2001 18 time Jump to first page

Building Manufacturing World Class Capabilities Multi skilled workers Automation Flexibility Factory design Production Programming and forecasts Automation Maintenance program Production scheduling Elimination of Sources of variation Speed Dependability Suppliers Elimination Of time wastes Product design Suppliers Quality JPde. L Organization and Associates, 2001, Wide but 2001 2002, copyright focused 19 effort Top management and employee attitudes Jump to first page

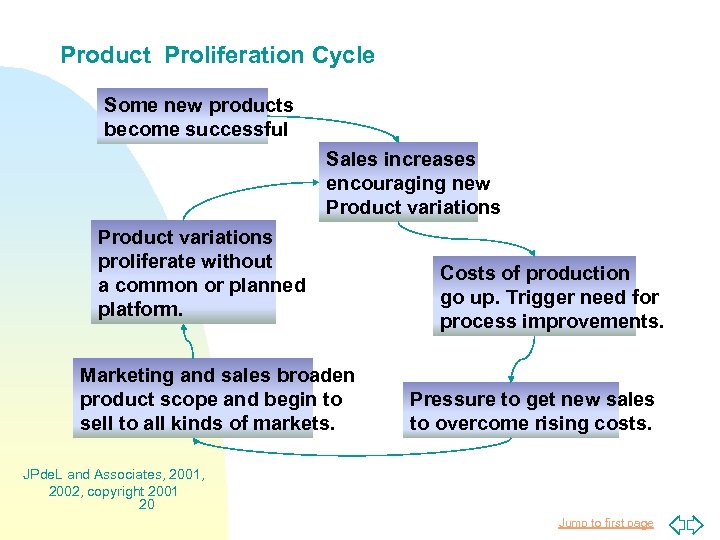

Product Proliferation Cycle Some new products become successful Sales increases encouraging new Product variations proliferate without a common or planned platform. Marketing and sales broaden product scope and begin to sell to all kinds of markets. Costs of production go up. Trigger need for process improvements. Pressure to get new sales to overcome rising costs. JPde. L and Associates, 2001, 2002, copyright 2001 20 Jump to first page

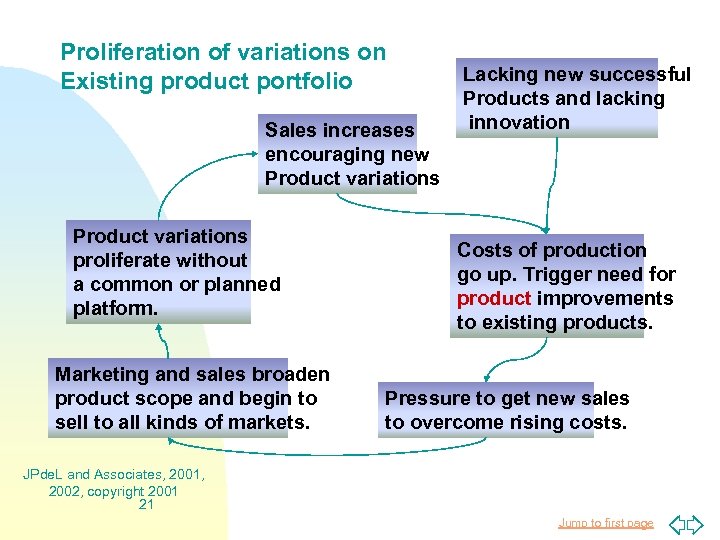

Proliferation of variations on Existing product portfolio Sales increases encouraging new Product variations proliferate without a common or planned platform. Marketing and sales broaden product scope and begin to sell to all kinds of markets. Lacking new successful Products and lacking innovation Costs of production go up. Trigger need for product improvements to existing products. Pressure to get new sales to overcome rising costs. JPde. L and Associates, 2001, 2002, copyright 2001 21 Jump to first page

• The world class programs have not failed. • What has failed is a business’s attention to the problems created by the growth and proliferation of products and product variations. • Product proliferation slowly but surely increases complexity in all manufacturing related functions. JPde. L and Associates, 2001, 2002, copyright 2001 22 Jump to first page

Complex Product Portfolio • Grows as a collection of uncoordinated designs, variations, materials used, processes, and manufacturing flow required to produce them. • Creating complexity in scheduling production planning and managing materials requirements. • Difficulty to plan and manage inventories in spite of JIT, cells, and lean stategies. JPde. L and Associates, 2001, 2002, copyright 2001 23 Jump to first page

Complex Product Portfolio • Slowly increases organizational complexity. • Difficult coordination between marketing and production and R&D. • Excessive product development programs. • Increasing difficulty to track real costs per product or product family due to product fragmentation. JPde. L and Associates, 2001, 2002, copyright 2001 24 Jump to first page

Part III Strategic Actions to Re-establish Manufacturing leadership JPde. L and Associates, 2001, 2002, copyright 2001 25 Jump to first page

Strategic Manufacturing Actions: I. Time to redesign whole set of product lines and their variations. II. Identify new product platforms to simplify and rationalize entire product portfolio. III. Redesign plants moving freezing point in accordance to new product designs. IV. Take into account customer preferences and market trends. JPde. L and Associates, 2001, 2002, copyright 2001 26 Jump to first page

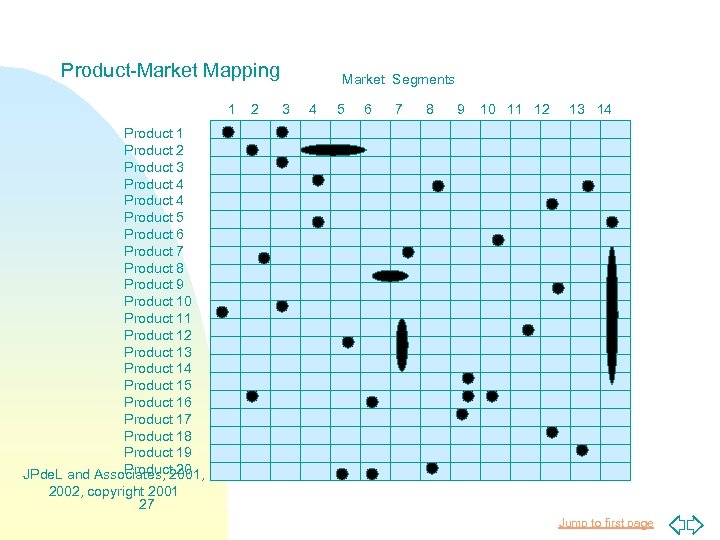

Product-Market Mapping 1 2 Market Segments 3 4 5 6 7 8 9 10 11 12 13 14 Product 1 Product 2 Product 3 Product 4 Product 5 Product 6 Product 7 Product 8 Product 9 Product 10 Product 11 Product 12 Product 13 Product 14 Product 15 Product 16 Product 17 Product 18 Product 19 Product 20 JPde. L and Associates, 2001, 2002, copyright 2001 27 Jump to first page

Product redesign strategies 1. 2. 3. 4. 5. 6. 7. 8. Tear apart to analyze each part and subsystem Eliminate parts or subsystems Simplify Combine Reconfigure Automate Reuse Substitute 9. Keep function and customer preferences in mind 10. To redesign and reconfigure. JPde. L and Associates, 2001, 2002, copyright 2001 28 Jump to first page

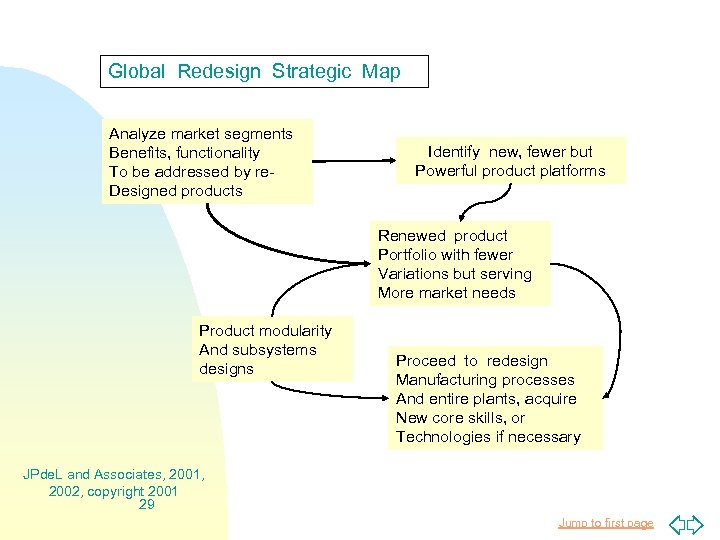

Global Redesign Strategic Map Analyze market segments Benefits, functionality To be addressed by re. Designed products Identify new, fewer but Powerful product platforms Renewed product Portfolio with fewer Variations but serving More market needs Product modularity And subsystems designs Proceed to redesign Manufacturing processes And entire plants, acquire New core skills, or Technologies if necessary JPde. L and Associates, 2001, 2002, copyright 2001 29 Jump to first page

End of Presentation January 2002 JPde. L and Associates, 2001, 2002, copyright 2001 30 Jump to first page

64aaf2f05b5a6a0b631958e07d5d6aa4.ppt