9e8343436eacc918d9490012223237ca.ppt

- Количество слайдов: 40

Managing Quality Chapter 5

5 Chapter Objectives Be able to: § Discuss the various definitions and dimensions of quality and why quality is important to operations and supply chains. § Describe the different costs of quality, including internal and external failure, appraisal, and prevention costs. § Describe what TQM is, along with its seven core principles. § Calculate process capability ratios and indices and set up control charts for monitoring continuous variables and attributes. § Describe the key issues associated with acceptance sampling, as well as the use of OC curves. § Distinguish between Taguchi’s quality loss function and the traditional view of quality. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 -2

5 Quality Defined § Quality – The characteristics of a product or service that bear on its ability to satisfy stated or implied needs; a product or service that is free of deficiencies. § Value perspective – A quality perspective that holds that quality must be judged, in part, by how well the characteristics of a particular product or service align with the needs of a specific user. § Conformance perspective – A quality perspective focused on whether or not a product was made or a service was performed as intended. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 -3

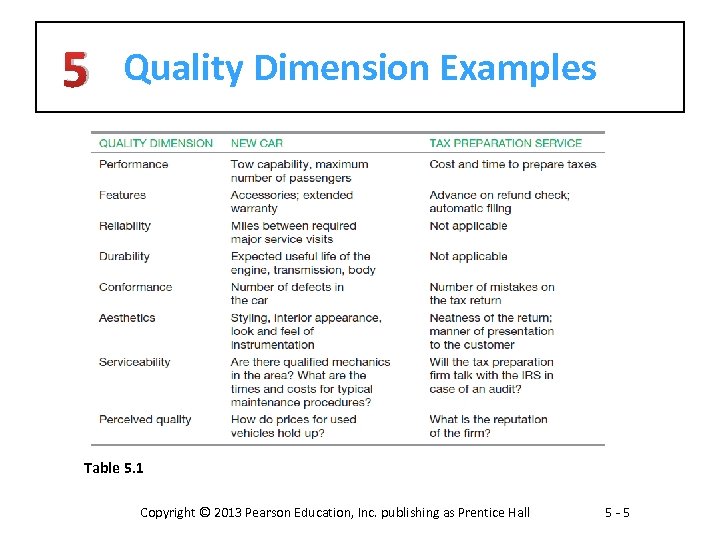

5 § § § § Eight Dimensions of Quality Performance Features Reliability Durability Conformance Aesthetics Serviceability Perceived Quality Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 -4

5 Quality Dimension Examples Table 5. 1 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 -5

5 Total Cost of Quality § Prevention costs – Costs an organization incurs to actually prevent defects from occurring to begin with. § Appraisal costs – Costs a company incurs for assessing its quality levels. § Internal failure costs – Costs caused by defects that occur prior to delivery to the customer. § External failure costs – Costs incurred by defects that are not detected until a product or service reaches the customer. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 -6

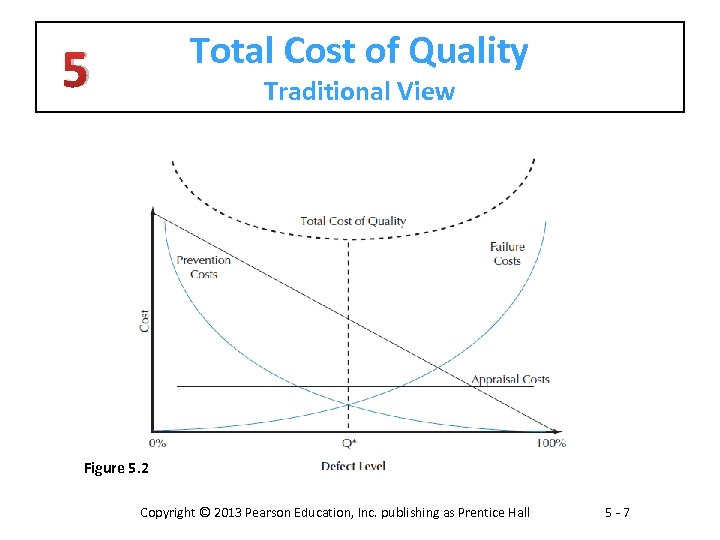

Total Cost of Quality 5 Traditional View Figure 5. 2 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 -7

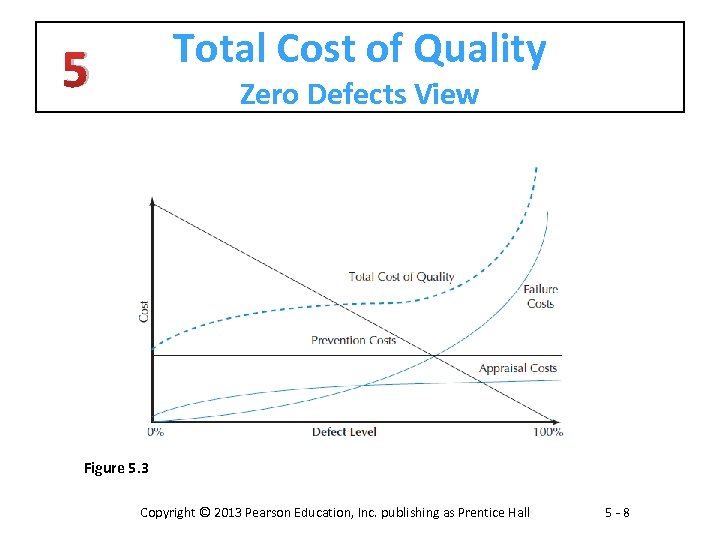

Total Cost of Quality 5 Zero Defects View Figure 5. 3 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 -8

5 Total Quality Management - A managerial approach in which an organization is managed so that it excels in all quality dimensions that are important to customers. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 -9

5 Total Quality Management § § § § Customer focus Leadership involvement Continuous improvement Employee empowerment Quality assurance Strategic partnerships Strategic quality plan Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 10

5 Total Quality Management § Customer focus § Each employee has a customer whether internal or external to the company. § Leadership involvement § Must be ‘top’ down, throughout the company. § If not, major cause of TQM failures. § Continuous improvement § There is always room for improvement. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 11

5 Total Quality Management § Employee empowerment § Giving employees the responsibility for managing quality. § Quality assurance § Quality Function Deployment (QFD) discussed in Chapter 15 § Statistical quality control (SQC), also called statistical process control (SPC) Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 12

5 Total Quality Management § Supplier Partnerships § The commitment between firms and supply chain partners must be the same. § Strategic Quality Plan § Sets a broad set of objectives. § Should establish measurable goals for the shortterm. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 13

5 Process Capability Answers the Question: Can the process provide acceptable quality consistently? Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 14

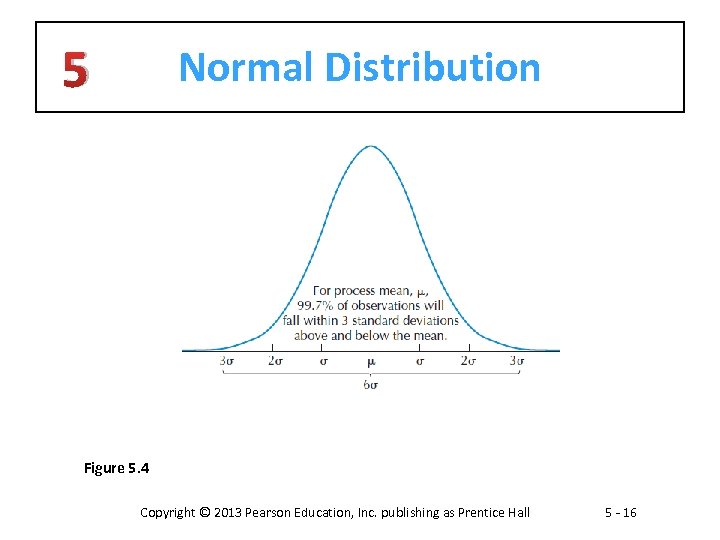

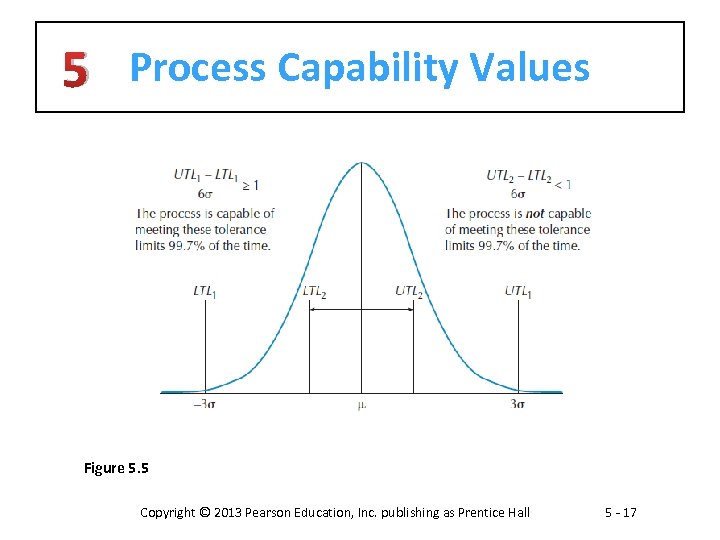

5 Process Capability Ratio (Cp) – Measures whether or not a process is potentially capable of meeting certain quality standards Cp = Upper Tolerance Limit – Lower Tolerance Limit 6σ Where σ is the estimated standard deviation for the individual observations Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 15

5 Normal Distribution Figure 5. 4 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 16

5 Process Capability Values Figure 5. 5 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 17

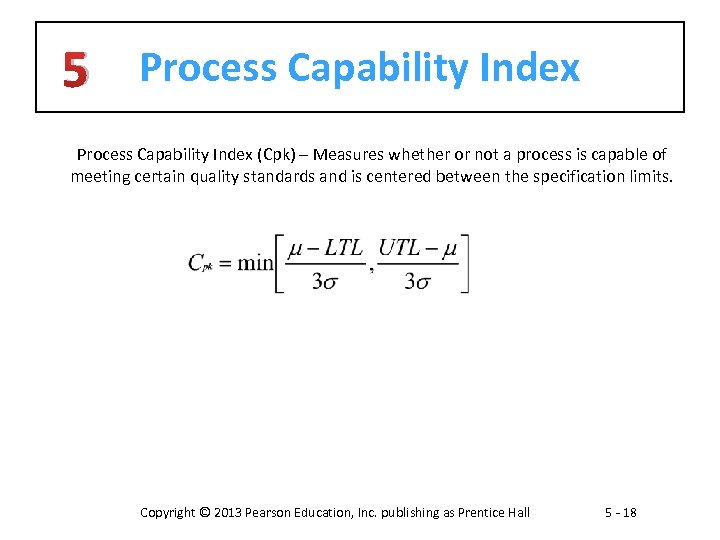

5 Process Capability Index (Cpk) – Measures whether or not a process is capable of meeting certain quality standards and is centered between the specification limits. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 18

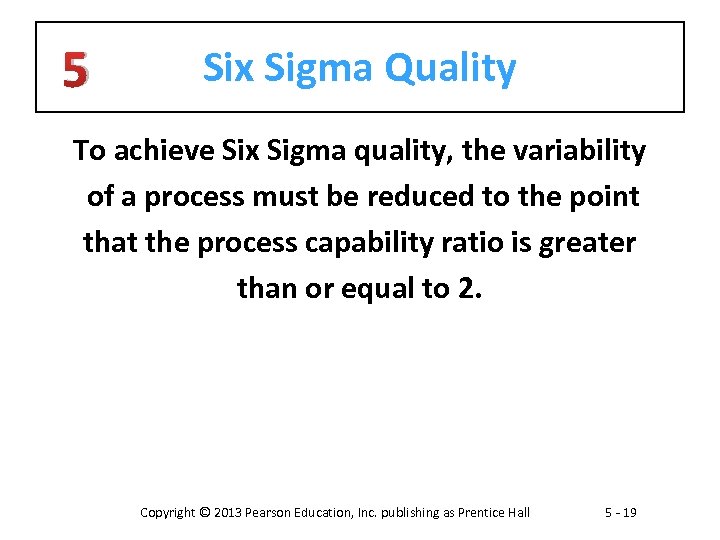

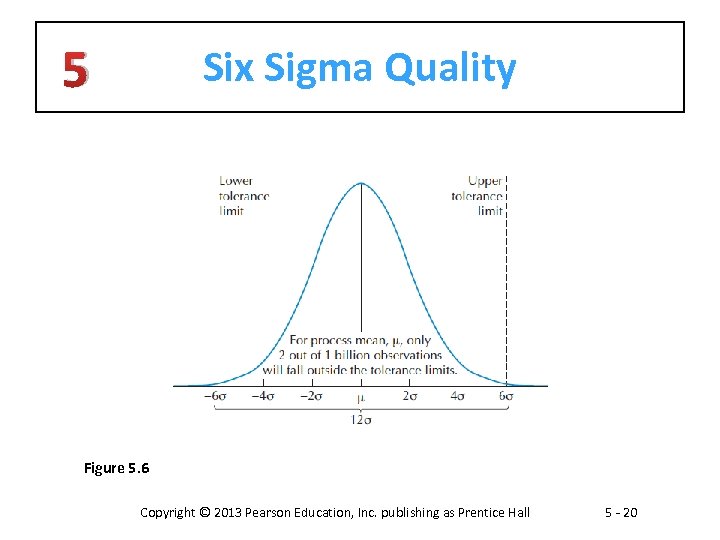

5 Six Sigma Quality To achieve Six Sigma quality, the variability of a process must be reduced to the point that the process capability ratio is greater than or equal to 2. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 19

5 Six Sigma Quality Figure 5. 6 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 20

5 Control Charts § Control Chart – A specialized run chart that helps an organization track changes in key measures over time. § Continuous variable – A variable that can be measured along a continuous scale. § Attribute – The presence or absence of a particular characteristic. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 21

5 Sampling § Sampling – Using carefully selected samples to get a fairly good idea of how well a process is working. § Good sample: § Every outcome has an equal chance of being selected into the sample. § The sample size is large enough to not be swayed by any single observation. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 22

5 Continuous Variable Measurements § Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 23

5 Control Charts § X chart - A specific type of control chart for a continuous variable that is used to track the average value for future samples. § R chart – A specific type of control chart for a continuous variable that is used to track how much the individual observations within each sample vary. § p chart – A specific type of control chart for attributes that is used to track sample proportions. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 24

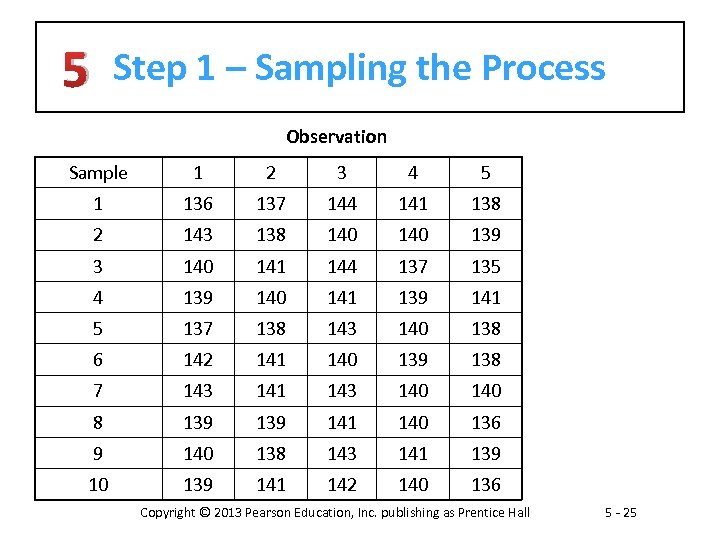

5 Step 1 – Sampling the Process Observation Sample 1 2 3 4 5 1 136 137 144 141 138 2 143 138 140 139 3 140 141 144 137 135 4 139 140 141 139 141 5 137 138 143 140 138 6 142 141 140 139 138 7 143 141 143 140 8 139 141 140 136 9 140 138 143 141 139 10 139 141 142 140 136 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 25

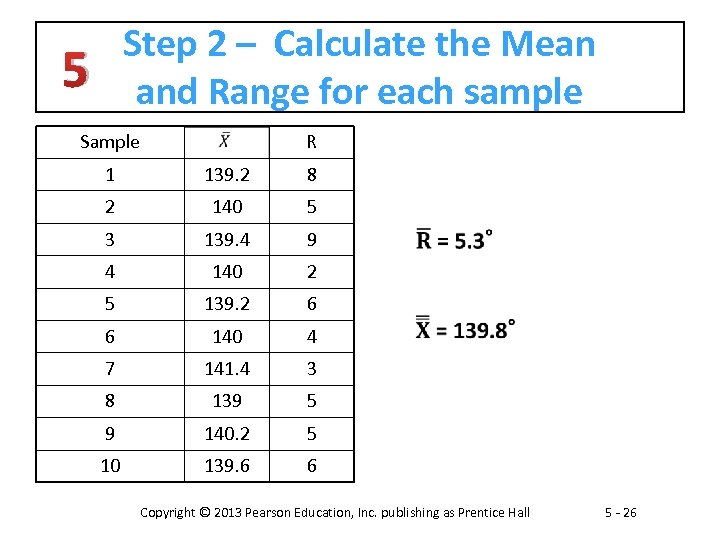

Step 2 – Calculate the Mean and Range for each sample 5 Sample R 1 139. 2 8 2 140 5 3 139. 4 9 4 140 2 5 139. 2 6 6 140 4 7 141. 4 3 8 139 5 9 140. 2 5 10 139. 6 6 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 26

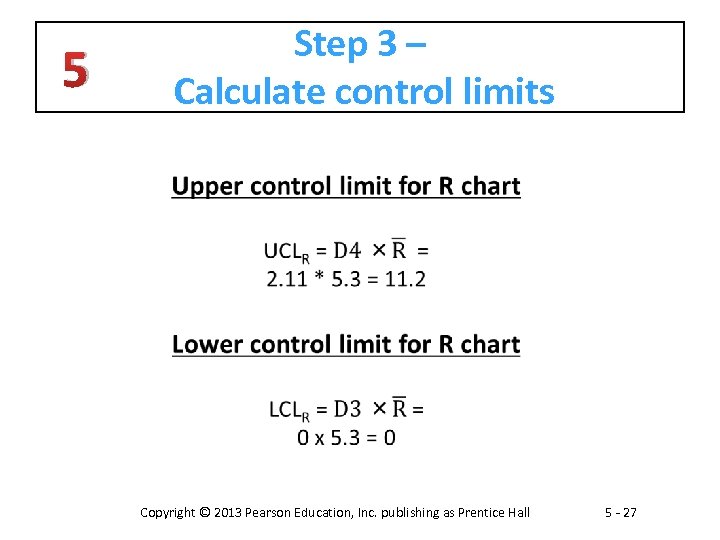

Step 3 – Calculate control limits 5 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 27

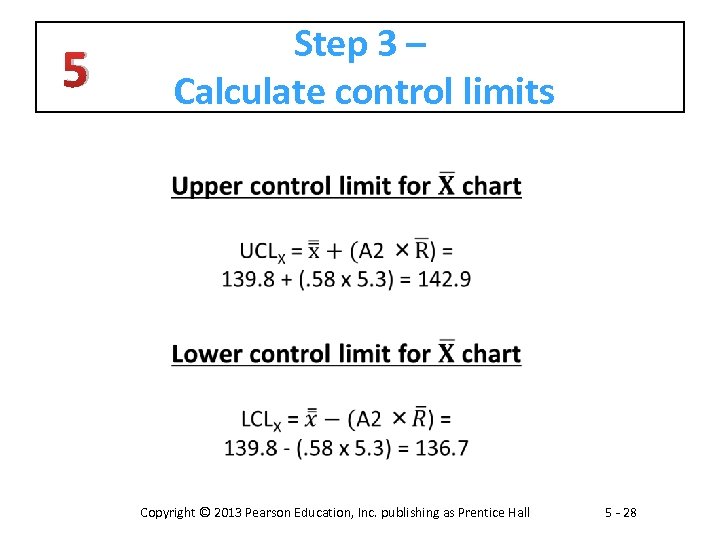

Step 3 – Calculate control limits 5 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 28

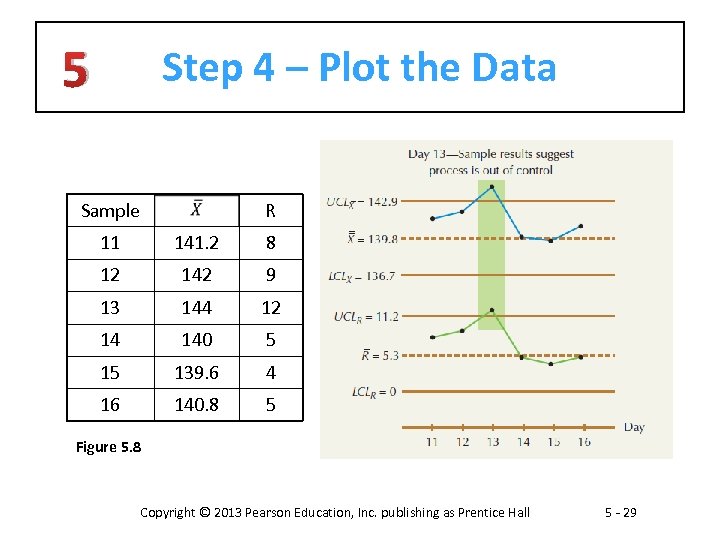

5 Step 4 – Plot the Data Sample R 11 141. 2 8 12 142 9 13 144 12 14 140 5 15 139. 6 4 16 140. 8 5 Figure 5. 8 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 29

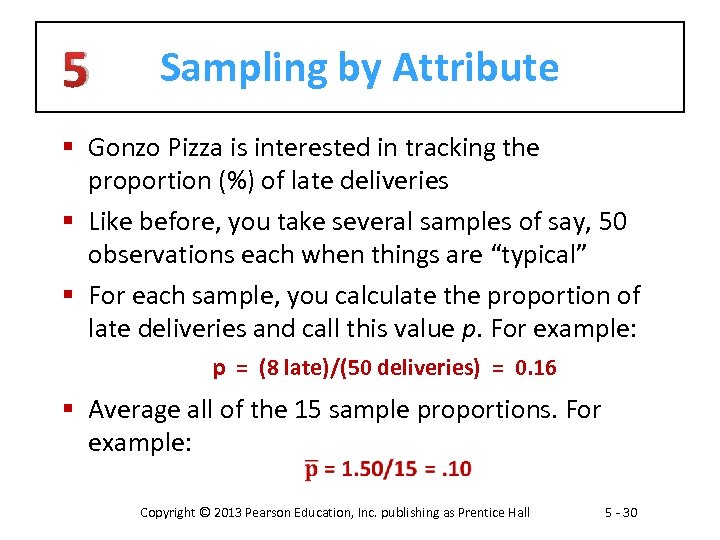

5 Sampling by Attribute § Gonzo Pizza is interested in tracking the proportion (%) of late deliveries § Like before, you take several samples of say, 50 observations each when things are “typical” § For each sample, you calculate the proportion of late deliveries and call this value p. For example: p = (8 late)/(50 deliveries) = 0. 16 § Average all of the 15 sample proportions. For example: Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 30

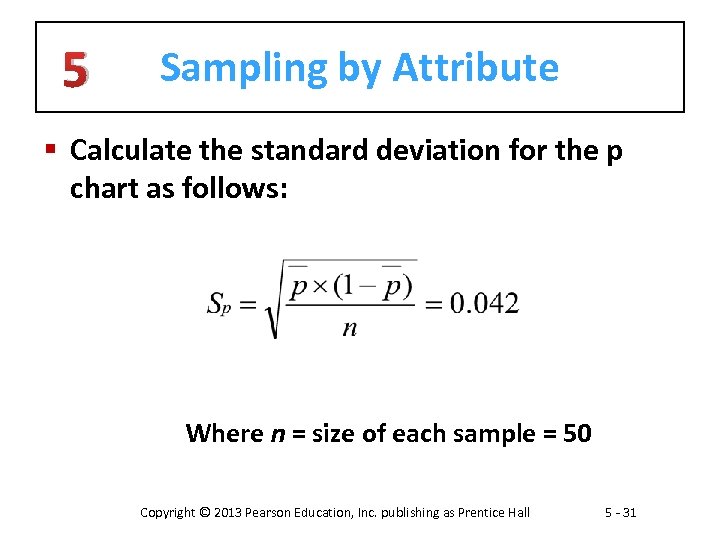

5 Sampling by Attribute § Calculate the standard deviation for the p chart as follows: Where n = size of each sample = 50 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 31

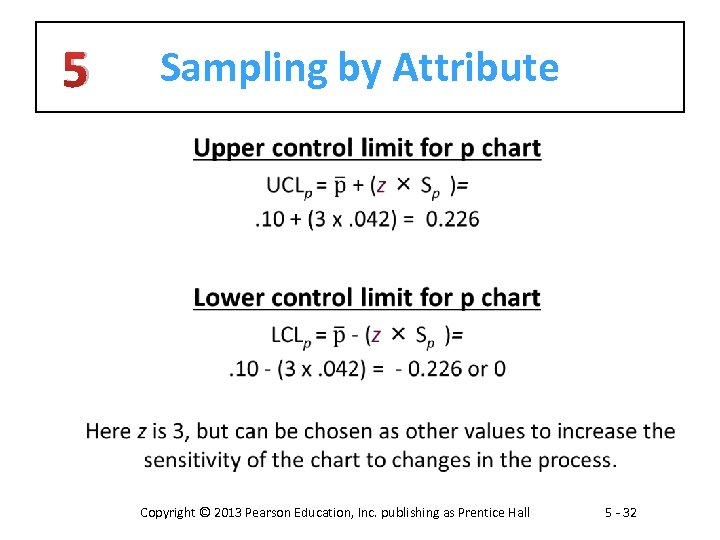

5 Sampling by Attribute Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 32

5 Sampling by Attribute § Although text says to go ahead with control charts, consider that it is probably too early to develop them since the process is not yet in control (i. e. , late deliveries are too high a percentage at present). § A more practical approach would be: § First, fix the more obvious problem(s) § Then take new samples § Then put in place control charts Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 33

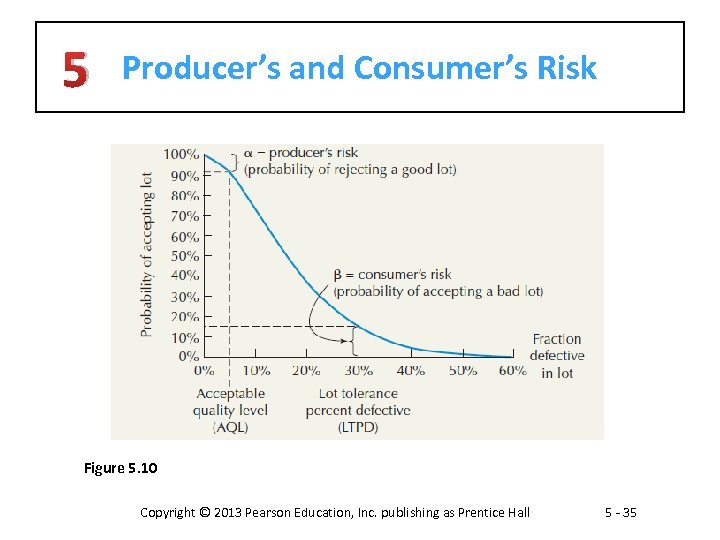

5 Acceptance Sampling Some definitions § Acceptable quality level (AQL) § Maximum defect level for 100% customer acceptance § Lot tolerance percent defective (LTPD) § Highest defect level customer will tolerate § Consumer’s risk § Probability of accepting a bad lot § Producer’s risk § Probability of rejecting a good lot § Operating characteristics (OC) curve § Probability of accepting a lot given the actual fraction defective in the entire lot and the sampling plan being used Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 34

5 Producer’s and Consumer’s Risk Figure 5. 10 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 35

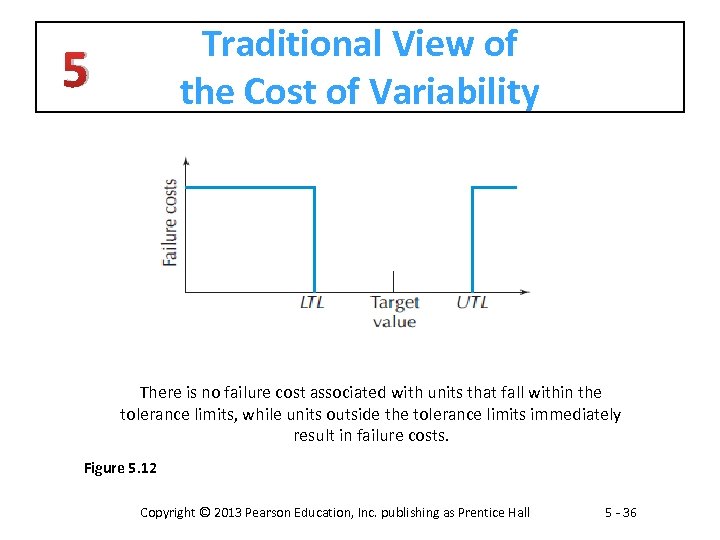

Traditional View of the Cost of Variability 5 There is no failure cost associated with units that fall within the tolerance limits, while units outside the tolerance limits immediately result in failure costs. Figure 5. 12 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 36

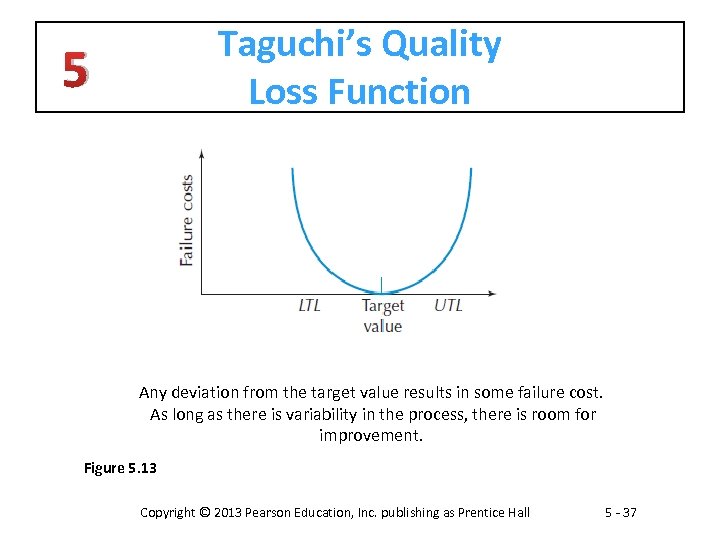

Taguchi’s Quality Loss Function 5 Any deviation from the target value results in some failure cost. As long as there is variability in the process, there is room for improvement. Figure 5. 13 Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 37

5 ISO 9000 Family § ISO 9000 - A family of standards supported by the International Organization for Standardization. § Goals: § Meet the customer’s quality requirements and applicable regulatory requirements. § Enhance customer satisfaction. § Achieve continual improvement of performance in pursuit of these objectives. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 38

Managing Quality Case Study Dittenhoefer’s Fine China Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 -

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of the publisher. Printed in the United States of America. Copyright © 2013 Pearson Education, Inc. publishing as Prentice Hall 5 - 40

9e8343436eacc918d9490012223237ca.ppt