5d98c774cd1227a9e0dc0bb534bdd0ac.ppt

- Количество слайдов: 24

Managing & Improving Your Boat Plant Safety Program Erik R. Wiborg Regulator Marine Inc. IBEX – September 29, 2010

Regulator Safety Program ► History – Past Safety Record ► OSHA Partnership § Carolina Star Program ►NCOSH – Management - Employees ► Regulator’s Path – 12 Steps to Safety

Regulator’s Safety Record Last Recordable: October 13, 2008

OSHA Partnership ►Who wants a SAFE work place? ►Are you SERIOUS about safety? ►Do you have anything to HIDE? ►Would YOU invite OSHA into your plant? OSHA Management Employees

OSHA Partnership ► OSHA Regulated by Federal Government ► Each State has a VPP ► Contact your OWN state’s OSHA office to see what Safety Improvement programs are available.

Carolina Star Goal ► North Carolina Department of Labor ► Out of 200, 000 North Carolina Businesses § ONLY 87 Carolina Star Sites ► Guidelines are available… NO COOKIE CUTTER APPROACH ► Not just a change of policy… It’s a change of CULTURE!

Changing Safety Culture ►Have to make SAFETY First! ►How DO you make Safety First? § We found 12 ways to make Safety First.

12 Steps to Improving Safety Step 1 ► Upper Management Support § Employees MUST know that ALL of management is in support of improving safety! ►Have a Plant Meeting! ►Owner’s & Manager’s must lead by EXAMPLE!

Upper Management Support ► Simple ways to LEAD BY EXAMPLE: Communicate Safety News & Info! …Keep it FRESH! Wear PPE in work areas!

12 Steps to Improving Safety Step 2 ► SQDIP – Morning Meeting with crews. ► Safety ► Quality ► Delivery ► Inventory ► Productivity Employees communication board!

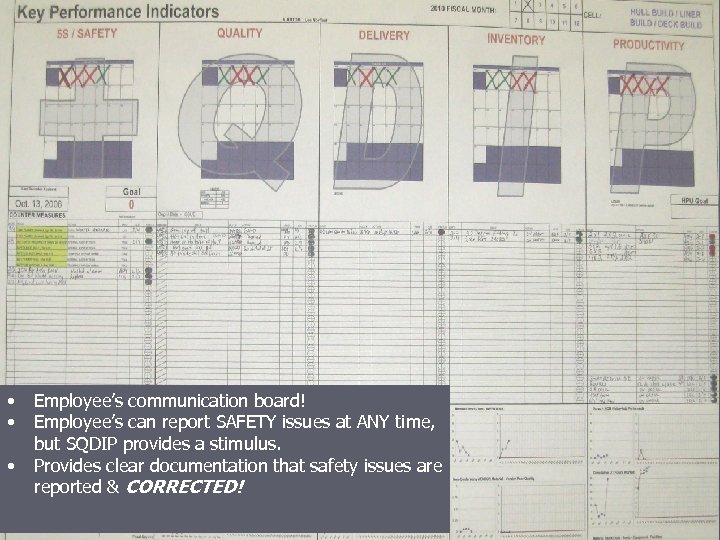

• Employee’s communication board! • Employee’s can report SAFETY issues at ANY time, but SQDIP provides a stimulus. • Provides clear documentation that safety issues are reported & CORRECTED!

12 Steps to Improving Safety Step 3 ► SPACER – Used to start meetings ► Safety – Safety issue or message! ► Purpose – What is this meeting about? ► Agenda – What will be covered? ► Code of Conduct – Any specific rules? ► Expectations – What should we learn? ► Roles – Who has specific tasks?

SPACER Example ►S – Know where the exits are located. ► P – Present our Safety Program ► A – Give Presentation & Take Questions ► C – Please ask questions! ► E – See the steps taken to develop a safety program that fulfills our needs. ► R – John Q. Boatbuilder - Presenter

12 Steps to Improving Safety Step 4 ► Daily Safety Walks § Select employees from different shops. § Daily Inspection for Safety Issues. § Daily reported findings to management.

12 Steps to Improving Safety Step 5 ► Weekly Safety Walks § Safety & Housekeeping inspection of shops. § Performed by management. § Report findings to shop supervisors.

12 Steps to Improving Safety MS Step 6 D ► 7 S – Minute Safety Trainer § Specific Topic Safety Worksheet. ►Ex: Use of Personal Protective Equipment - PPE § Performed at SQDIP meeting. Fi § Performed Bi-Monthly. r C al ic hem po Ex ure s e. P rev en tio n

12 Steps to Improving Safety Step 7 ► Policy Change Process – For Safety as Well! § Issue a bulletin with the change or update. § Management reviews & signs document. § ALL employees review & sign document. § ALL NEW HIRES – Review & Sign all SAFETY POLICY DOCUMENTS! Ignorance is NOT an EXCUSE!

12 Steps to Improving Safety Step 8 ► Spirit of Openness § Nothing is hidden from employees! § Nothing should be hidden from management! § Report ANYTHING – No repercussions!

12 Steps to Improving Safety Step 9 ► Continuous Improvement § Good is NEVER good enough! § Never let perfection stand in the way of getting better! § Always room to improve

12 Steps to Improving Safety Step 10 ► Measure Progress § You have to know where you ARE to know WHERE YOUR GOING! § Set your TARGET HIGH § Set mini Goals as steps toward target.

12 Steps to Improving Safety Step 11 ► Positive Reinforcement § Thank those that follow Safety policies! § Congratulate those that bring forth issues!

12 Steps to Improving Safety Step 12 ► Celebrate Achievements! § Celebrate the Goals that you meet! § Celebrate IMMEDIATELY or ASAP! ►Celebrations should reinforce specific goals!

► No Conclusion Cookie cutter approach. ► Continuously drive the message of Safety! ► Upper Management & Employee Buy In! ► Be persistent in improvements! ► Measure your performance! ► Set Achievable Goals! ► Celebrate Successes – QUICKLY!

THANK YOU!

5d98c774cd1227a9e0dc0bb534bdd0ac.ppt