4393c7d70621c0d601ace6a70a835d29.ppt

- Количество слайдов: 50

Managing for Quality in the Electronics Industry Sean Kelly Motorola Inc. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Managing for Quality in the Electronics Industry Sean Kelly Motorola Inc. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Greetings from Arizona Grand Canyon Saguaro Cactus Motorola Computer Group Tempe, Arizona, USA SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Greetings from Arizona Grand Canyon Saguaro Cactus Motorola Computer Group Tempe, Arizona, USA SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

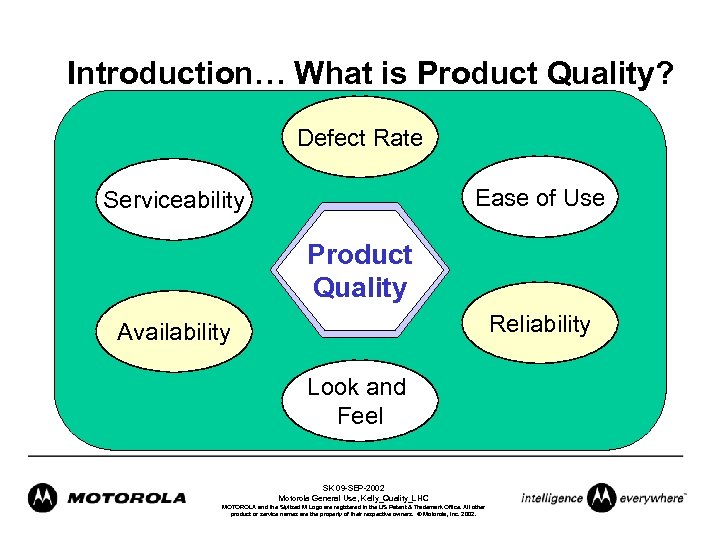

Introduction… What is Product Quality? Defect Rate Ease of Use Serviceability Product Quality Reliability Availability Look and Feel SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Introduction… What is Product Quality? Defect Rate Ease of Use Serviceability Product Quality Reliability Availability Look and Feel SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

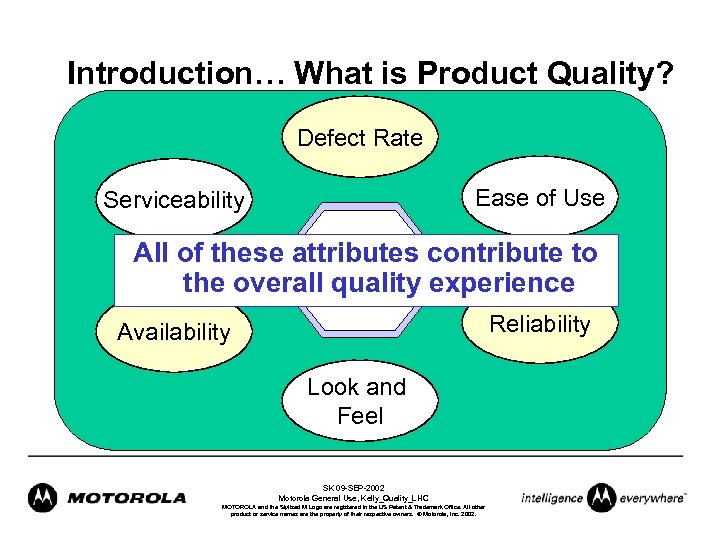

Introduction… What is Product Quality? Defect Rate Ease of Use Serviceability All of these attributes contribute to Product the overall quality experience Quality Reliability Availability Look and Feel SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Introduction… What is Product Quality? Defect Rate Ease of Use Serviceability All of these attributes contribute to Product the overall quality experience Quality Reliability Availability Look and Feel SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Introduction • This presentation will explore the reliability, availability and defect rate attributes of product quality – What the attributes mean – How they are measured – How they impact the product performance and the customer SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Introduction • This presentation will explore the reliability, availability and defect rate attributes of product quality – What the attributes mean – How they are measured – How they impact the product performance and the customer SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Introduction • This presentation will also cover some of the methods and tools that product developers and manufacturers use to ensure desirable quality results. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Introduction • This presentation will also cover some of the methods and tools that product developers and manufacturers use to ensure desirable quality results. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

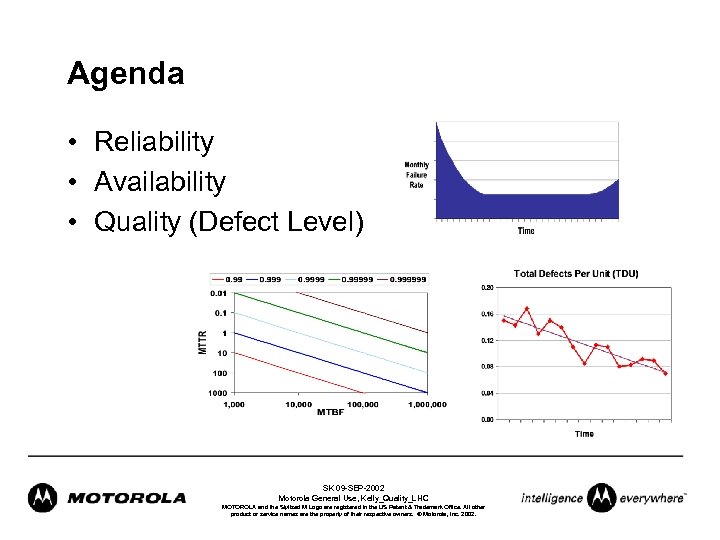

Agenda • Reliability • Availability • Quality (Defect Level) SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Agenda • Reliability • Availability • Quality (Defect Level) SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

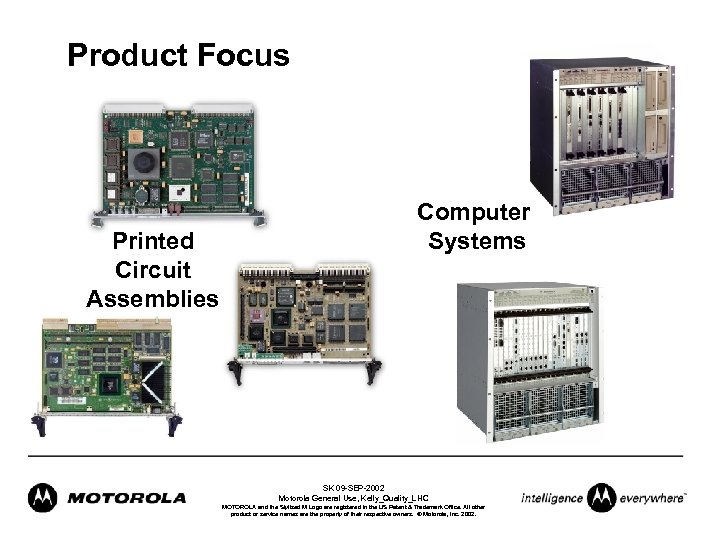

Product Focus Printed Circuit Assemblies Computer Systems SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Focus Printed Circuit Assemblies Computer Systems SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

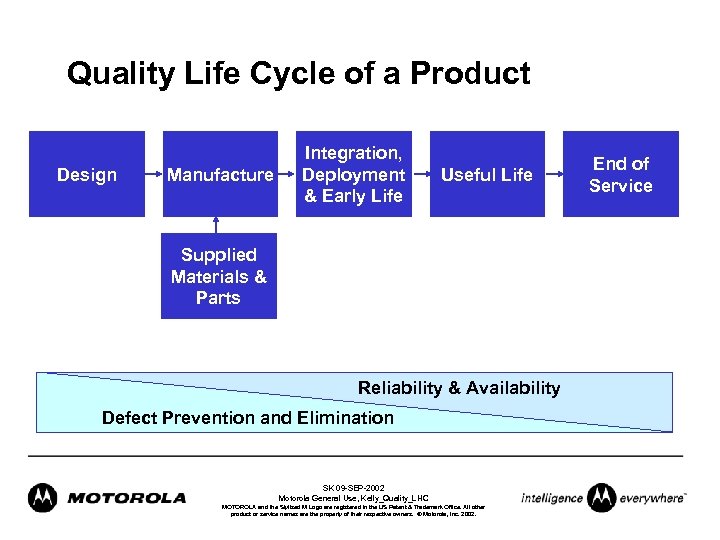

Quality Life Cycle of a Product Design Manufacture Integration, Deployment & Early Life Useful Life Supplied Materials & Parts Reliability & Availability Defect Prevention and Elimination SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002. End of Service

Quality Life Cycle of a Product Design Manufacture Integration, Deployment & Early Life Useful Life Supplied Materials & Parts Reliability & Availability Defect Prevention and Elimination SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002. End of Service

Product Reliability SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Reliability SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

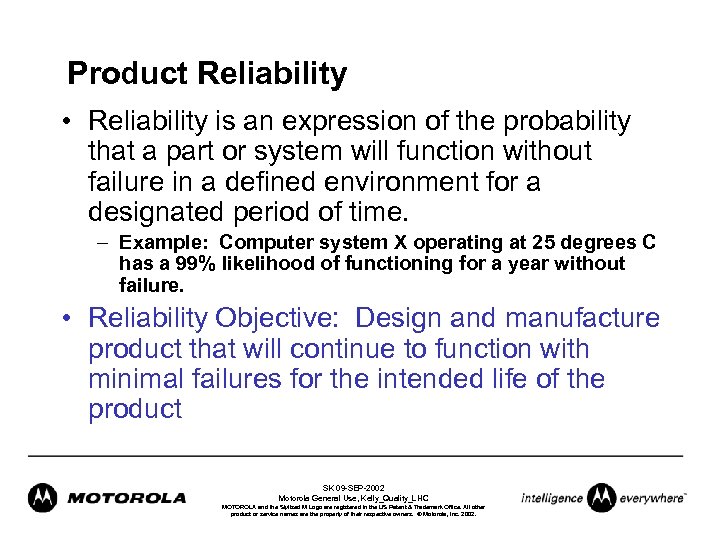

Product Reliability • Reliability is an expression of the probability that a part or system will function without failure in a defined environment for a designated period of time. – Example: Computer system X operating at 25 degrees C has a 99% likelihood of functioning for a year without failure. • Reliability Objective: Design and manufacture product that will continue to function with minimal failures for the intended life of the product SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Reliability • Reliability is an expression of the probability that a part or system will function without failure in a defined environment for a designated period of time. – Example: Computer system X operating at 25 degrees C has a 99% likelihood of functioning for a year without failure. • Reliability Objective: Design and manufacture product that will continue to function with minimal failures for the intended life of the product SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

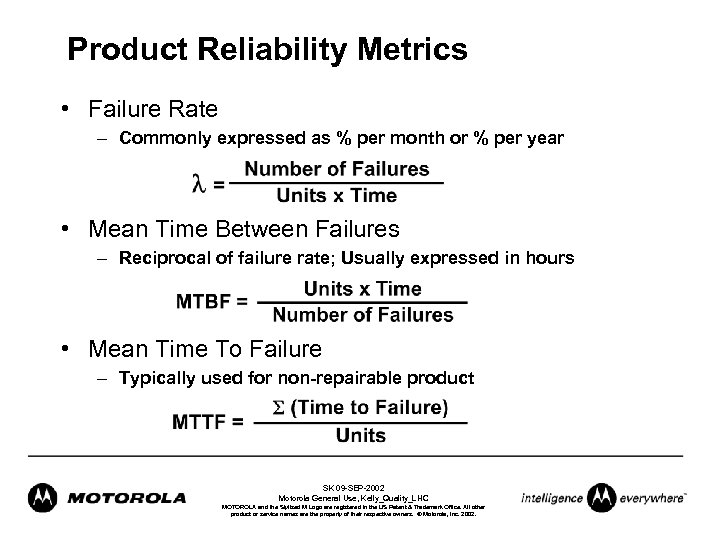

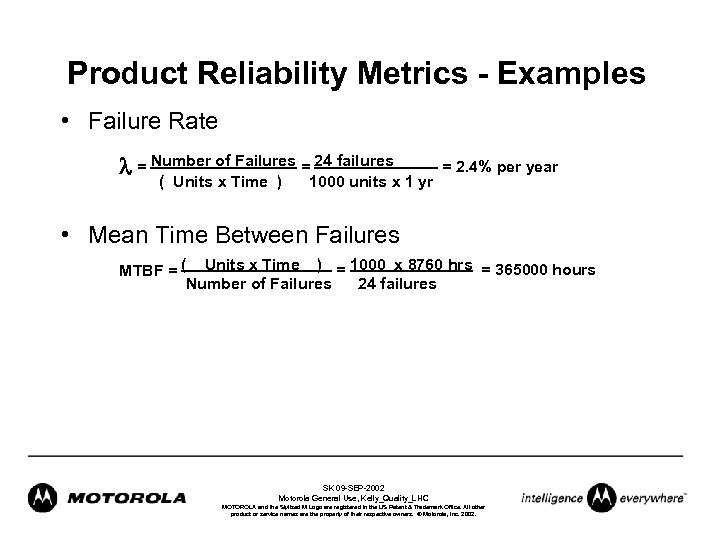

Product Reliability Metrics • Failure Rate – Commonly expressed as % per month or % per year • Mean Time Between Failures – Reciprocal of failure rate; Usually expressed in hours • Mean Time To Failure – Typically used for non-repairable product SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Reliability Metrics • Failure Rate – Commonly expressed as % per month or % per year • Mean Time Between Failures – Reciprocal of failure rate; Usually expressed in hours • Mean Time To Failure – Typically used for non-repairable product SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Reliability Metrics - Examples • Failure Rate l = Number of Failures = 24 failures ( Units x Time ) 1000 units x 1 yr = 2. 4% per year • Mean Time Between Failures MTBF = ( Units x Time ) = 1000 x 8760 hrs = 365000 hours Number of Failures 24 failures SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Reliability Metrics - Examples • Failure Rate l = Number of Failures = 24 failures ( Units x Time ) 1000 units x 1 yr = 2. 4% per year • Mean Time Between Failures MTBF = ( Units x Time ) = 1000 x 8760 hrs = 365000 hours Number of Failures 24 failures SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

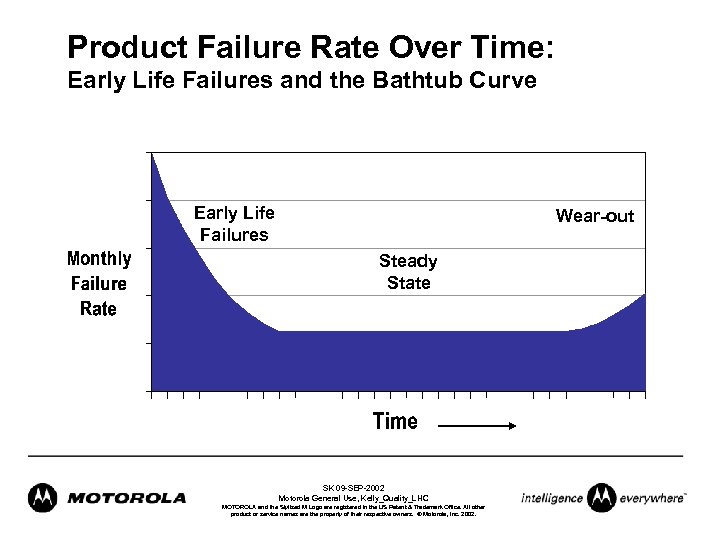

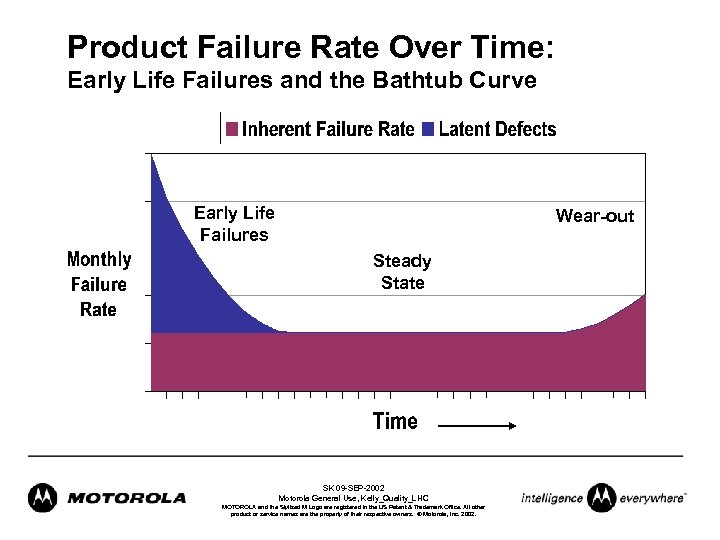

Product Failure Rate Over Time: Early Life Failures and the Bathtub Curve Early Life Failures Wear-out Steady State SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Failure Rate Over Time: Early Life Failures and the Bathtub Curve Early Life Failures Wear-out Steady State SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Failure Rate Over Time: Early Life Failures and the Bathtub Curve Early Life Failures Wear-out Steady State SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Failure Rate Over Time: Early Life Failures and the Bathtub Curve Early Life Failures Wear-out Steady State SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

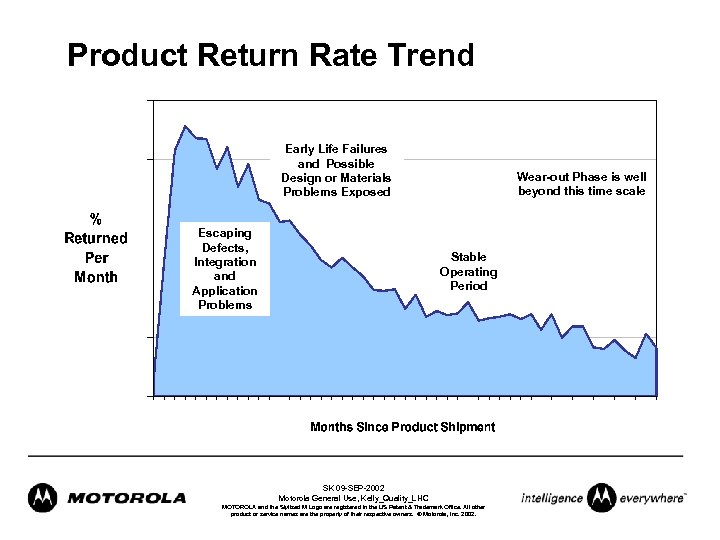

Product Return Rate Trend Early Life Failures and Possible Design or Materials Problems Exposed Escaping Defects, Integration and Application Problems Wear-out Phase is well beyond this time scale Stable Operating Period SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Return Rate Trend Early Life Failures and Possible Design or Materials Problems Exposed Escaping Defects, Integration and Application Problems Wear-out Phase is well beyond this time scale Stable Operating Period SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

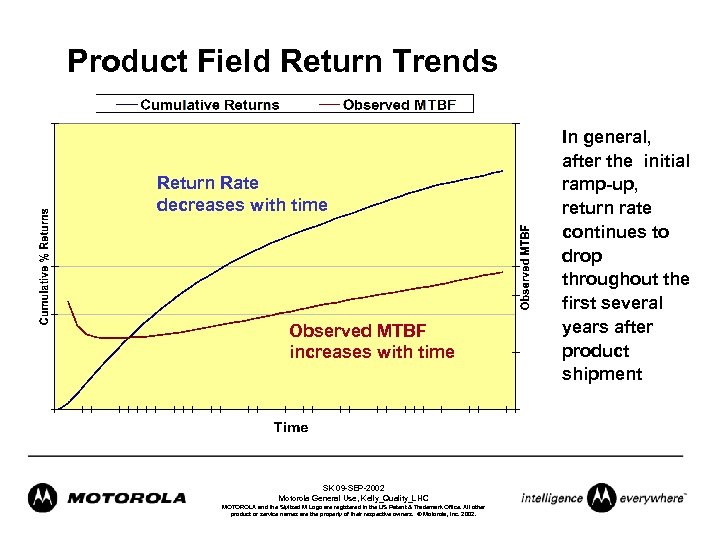

Product Field Return Trends Return Rate decreases with time Observed MTBF increases with time SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002. In general, after the initial ramp-up, return rate continues to drop throughout the first several years after product shipment

Product Field Return Trends Return Rate decreases with time Observed MTBF increases with time SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002. In general, after the initial ramp-up, return rate continues to drop throughout the first several years after product shipment

Predicting Product Reliability • Reliability Predicted using models – Based on expected reliability of the components used in the higher level product • Demonstrated via ALT (Accelerated Life Testing) – Stress test a sample of the product • Actual or Observed – Track field failure and returns data – Compare new designs to similar existing designs SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Predicting Product Reliability • Reliability Predicted using models – Based on expected reliability of the components used in the higher level product • Demonstrated via ALT (Accelerated Life Testing) – Stress test a sample of the product • Actual or Observed – Track field failure and returns data – Compare new designs to similar existing designs SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

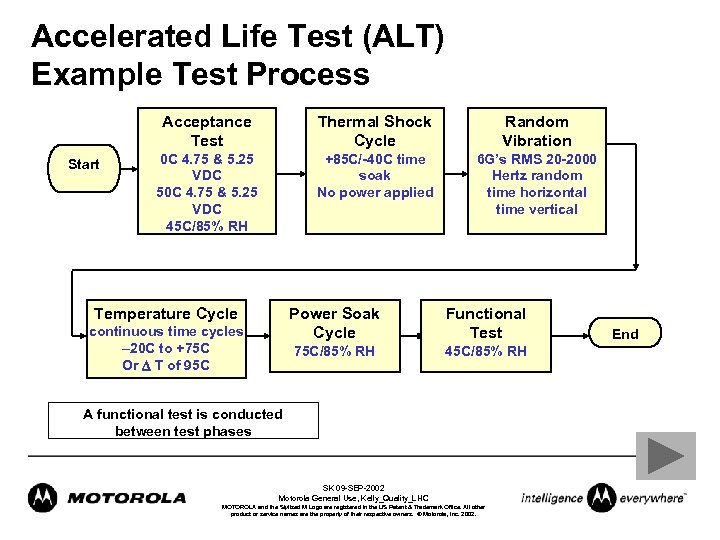

Accelerated Life Test (ALT) • ALT is a process by which products are subjected to increased stress factors for controlled time periods – – – Temperature Vibration Humidity Voltage Power, etc. • Multiple years of normal product life are compressed into a several week period. • ALT testing enables a product developer to simulate potential product field-failure modes. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Accelerated Life Test (ALT) • ALT is a process by which products are subjected to increased stress factors for controlled time periods – – – Temperature Vibration Humidity Voltage Power, etc. • Multiple years of normal product life are compressed into a several week period. • ALT testing enables a product developer to simulate potential product field-failure modes. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

ALT • ALT may expose: – Hardware failures - True defects (repairable) – Design Failures - Failures due to design problems – Component Failures - Failures due to component deficiencies – Integration Failures - Failures resulting from integration with other products SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

ALT • ALT may expose: – Hardware failures - True defects (repairable) – Design Failures - Failures due to design problems – Component Failures - Failures due to component deficiencies – Integration Failures - Failures resulting from integration with other products SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Accelerated Life Test (ALT) Example Test Process Acceptance Test Start Thermal Shock Cycle Random Vibration 0 C 4. 75 & 5. 25 VDC 50 C 4. 75 & 5. 25 VDC 45 C/85% RH +85 C/-40 C time soak No power applied 6 G’s RMS 20 -2000 Hertz random time horizontal time vertical Temperature Cycle Power Soak Cycle 75 C/85% RH continuous time cycles – 20 C to +75 C Or T of 95 C Functional Test 45 C/85% RH A functional test is conducted between test phases SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002. End

Accelerated Life Test (ALT) Example Test Process Acceptance Test Start Thermal Shock Cycle Random Vibration 0 C 4. 75 & 5. 25 VDC 50 C 4. 75 & 5. 25 VDC 45 C/85% RH +85 C/-40 C time soak No power applied 6 G’s RMS 20 -2000 Hertz random time horizontal time vertical Temperature Cycle Power Soak Cycle 75 C/85% RH continuous time cycles – 20 C to +75 C Or T of 95 C Functional Test 45 C/85% RH A functional test is conducted between test phases SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002. End

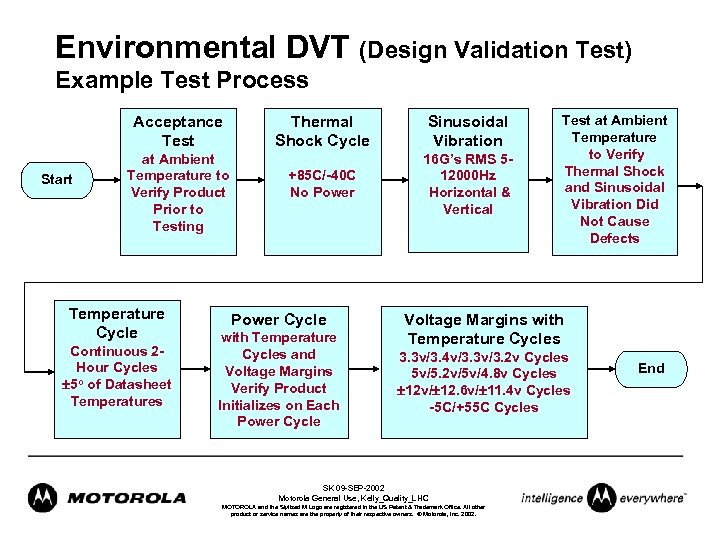

Environmental DVT (Design Validation Test) • The purpose of Environmental Design Validation Testing (DVT) is to validate the hardware design and manufacturing process by stressing the product in various environmental conditions. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Environmental DVT (Design Validation Test) • The purpose of Environmental Design Validation Testing (DVT) is to validate the hardware design and manufacturing process by stressing the product in various environmental conditions. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Environmental DVT (Design Validation Test) Example Test Process Acceptance Test Start at Ambient Temperature to Verify Product Prior to Testing Temperature Cycle Continuous 2 Hour Cycles 5 o of Datasheet Temperatures Thermal Shock Cycle Sinusoidal Vibration +85 C/-40 C No Power 16 G’s RMS 512000 Hz Horizontal & Vertical Power Cycle with Temperature Cycles and Voltage Margins Verify Product Initializes on Each Power Cycle Test at Ambient Temperature to Verify Thermal Shock and Sinusoidal Vibration Did Not Cause Defects Voltage Margins with Temperature Cycles 3. 3 v/3. 4 v/3. 3 v/3. 2 v Cycles 5 v/5. 2 v/5 v/4. 8 v Cycles 12 v/ 12. 6 v/ 11. 4 v Cycles -5 C/+55 C Cycles SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002. End

Environmental DVT (Design Validation Test) Example Test Process Acceptance Test Start at Ambient Temperature to Verify Product Prior to Testing Temperature Cycle Continuous 2 Hour Cycles 5 o of Datasheet Temperatures Thermal Shock Cycle Sinusoidal Vibration +85 C/-40 C No Power 16 G’s RMS 512000 Hz Horizontal & Vertical Power Cycle with Temperature Cycles and Voltage Margins Verify Product Initializes on Each Power Cycle Test at Ambient Temperature to Verify Thermal Shock and Sinusoidal Vibration Did Not Cause Defects Voltage Margins with Temperature Cycles 3. 3 v/3. 4 v/3. 3 v/3. 2 v Cycles 5 v/5. 2 v/5 v/4. 8 v Cycles 12 v/ 12. 6 v/ 11. 4 v Cycles -5 C/+55 C Cycles SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002. End

Other Tests: Compliance, Regulatory, Safety, Packaging, etc. • • • Drop Tests (Packaging) Radiated & Conducted Emissions Electrostatic Discharge Immunity (ESD) Surge Voltage Dips and Interruptions Safety SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Other Tests: Compliance, Regulatory, Safety, Packaging, etc. • • • Drop Tests (Packaging) Radiated & Conducted Emissions Electrostatic Discharge Immunity (ESD) Surge Voltage Dips and Interruptions Safety SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Availability • Probability that a product is operational at a given time High Availability Five 9’s 99. 999% SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Availability • Probability that a product is operational at a given time High Availability Five 9’s 99. 999% SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

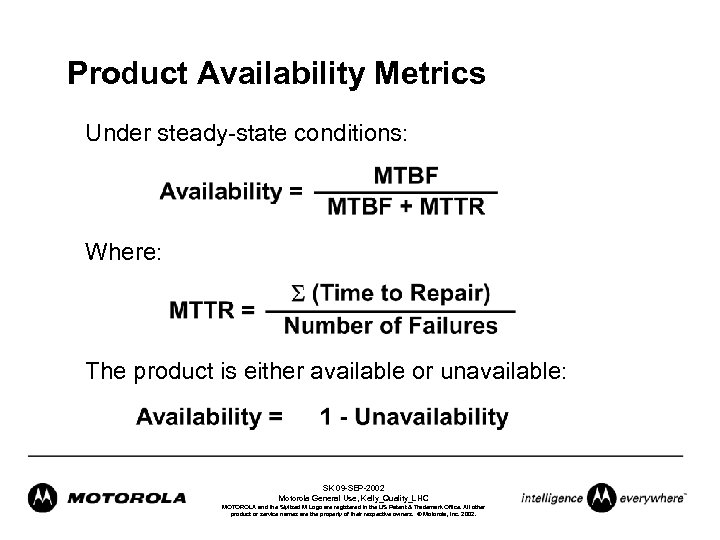

Product Availability Metrics Under steady-state conditions: Where: The product is either available or unavailable: SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Availability Metrics Under steady-state conditions: Where: The product is either available or unavailable: SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

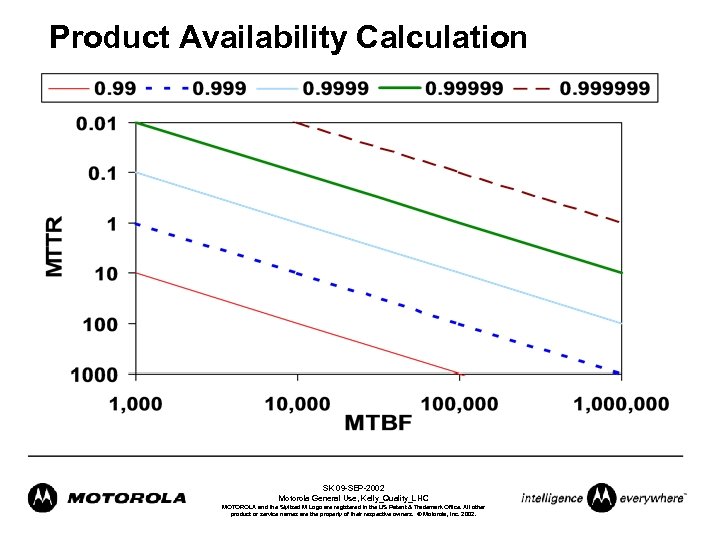

Product Availability Calculation SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Availability Calculation SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

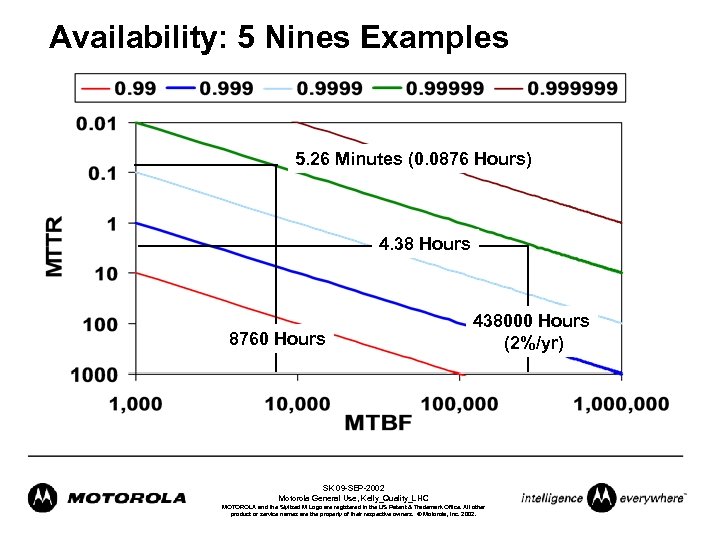

Availability: 5 Nines Examples 5. 26 Minutes (0. 0876 Hours) 4. 38 Hours 8760 Hours 438000 Hours (2%/yr) SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Availability: 5 Nines Examples 5. 26 Minutes (0. 0876 Hours) 4. 38 Hours 8760 Hours 438000 Hours (2%/yr) SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Availability From An End-User Perspective • Probability that a product is available for use when the user wants to use the product • Availability is often dependent on both the enduser product and the service provider – Example: Each of these factors contributes to cell phone availability from the end-user perspective • Cellular phone is functional Network • User has a charged battery • Network coverage exists • Network is functional SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Availability From An End-User Perspective • Probability that a product is available for use when the user wants to use the product • Availability is often dependent on both the enduser product and the service provider – Example: Each of these factors contributes to cell phone availability from the end-user perspective • Cellular phone is functional Network • User has a charged battery • Network coverage exists • Network is functional SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

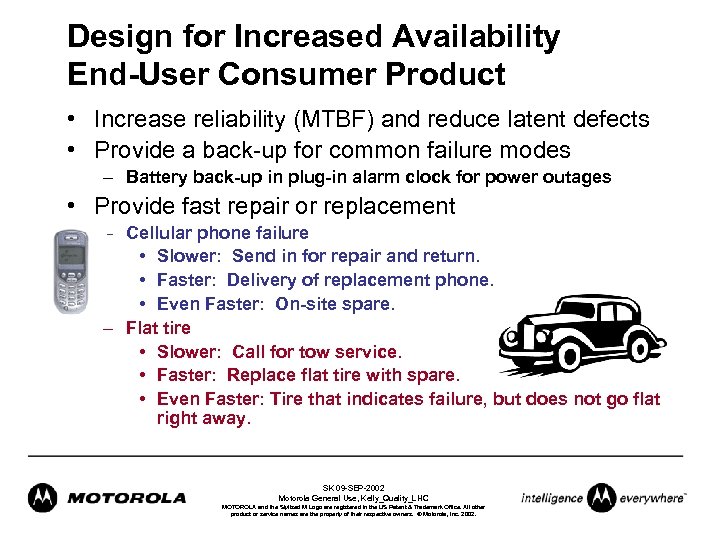

Design for Increased Availability End-User Consumer Product • Increase reliability (MTBF) and reduce latent defects • Provide a back-up for common failure modes – Battery back-up in plug-in alarm clock for power outages • Provide fast repair or replacement – Cellular phone failure • Slower: Send in for repair and return. • Faster: Delivery of replacement phone. • Even Faster: On-site spare. – Flat tire • Slower: Call for tow service. • Faster: Replace flat tire with spare. • Even Faster: Tire that indicates failure, but does not go flat right away. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Design for Increased Availability End-User Consumer Product • Increase reliability (MTBF) and reduce latent defects • Provide a back-up for common failure modes – Battery back-up in plug-in alarm clock for power outages • Provide fast repair or replacement – Cellular phone failure • Slower: Send in for repair and return. • Faster: Delivery of replacement phone. • Even Faster: On-site spare. – Flat tire • Slower: Call for tow service. • Faster: Replace flat tire with spare. • Even Faster: Tire that indicates failure, but does not go flat right away. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Availability From A System Perspective • Percentage of time a system is available for use • Key factors – Failure Rate of each system module – Impact of a module failure on the overall system • Single point of failure causes system level failure – Time to repair or replace faulty product determines downtime • Module failure causes loss of certain functions – May be able to continue to use • Module failure does not result in system level failure – Redundancy and fault resiliency – Time to Repair or Restore full system functionality SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Availability From A System Perspective • Percentage of time a system is available for use • Key factors – Failure Rate of each system module – Impact of a module failure on the overall system • Single point of failure causes system level failure – Time to repair or replace faulty product determines downtime • Module failure causes loss of certain functions – May be able to continue to use • Module failure does not result in system level failure – Redundancy and fault resiliency – Time to Repair or Restore full system functionality SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

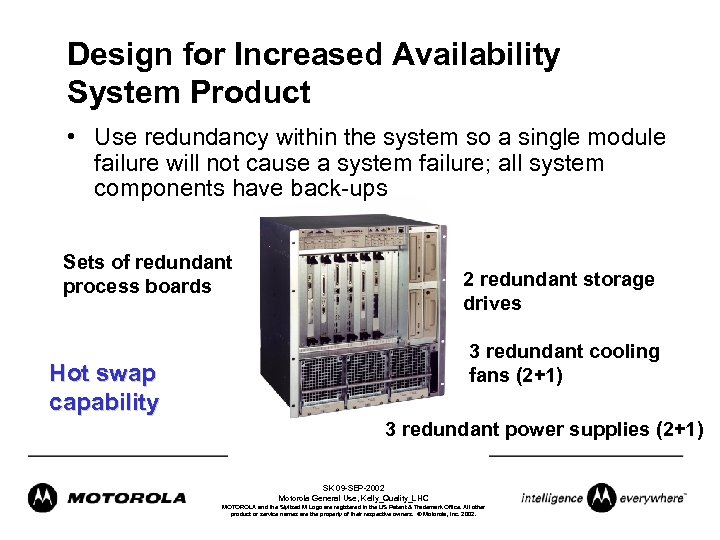

Design for Increased Availability System Product • Use redundancy within the system so a single module failure will not cause a system failure; all system components have back-ups Sets of redundant process boards 2 redundant storage drives 3 redundant cooling fans (2+1) Hot swap capability 3 redundant power supplies (2+1) SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Design for Increased Availability System Product • Use redundancy within the system so a single module failure will not cause a system failure; all system components have back-ups Sets of redundant process boards 2 redundant storage drives 3 redundant cooling fans (2+1) Hot swap capability 3 redundant power supplies (2+1) SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Design for Increased Availability System Product • Allow for very rapid return to service – Software fault management • Software manages system resources to work around faulty module and to restore operation to the replacement module – Hot swap replacement • System remains functional during replacement operation – Redundant system as standby • Hot standby with immediate switchover SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Design for Increased Availability System Product • Allow for very rapid return to service – Software fault management • Software manages system resources to work around faulty module and to restore operation to the replacement module – Hot swap replacement • System remains functional during replacement operation – Redundant system as standby • Hot standby with immediate switchover SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Selection For Availability • Determine application requirements – Impact of a failure during operation • Service options – Attended vs. remote site • For example, office vs. mountain top product location – Cost and time of service vs. cost of other designed in robustness options • Select products and suppliers that can hit the quality, reliability and availability requirements SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Selection For Availability • Determine application requirements – Impact of a failure during operation • Service options – Attended vs. remote site • For example, office vs. mountain top product location – Cost and time of service vs. cost of other designed in robustness options • Select products and suppliers that can hit the quality, reliability and availability requirements SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Quality • Objective: Design, manufacture and deliver defect free product that meets defined specifications and customer requirements SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Quality • Objective: Design, manufacture and deliver defect free product that meets defined specifications and customer requirements SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Manufacturing Quality Definitions • Unit – The item produced or processed. • CTQ (Critical To Quality) – Characteristics which are key to the customer’s perception of quality. • Defect – An unacceptable variation of a quality characteristic from its intended level. • Opportunity – Any action in which the product, service, or information is handled. – Any action performed or neglected during the creation of a unit of work. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Manufacturing Quality Definitions • Unit – The item produced or processed. • CTQ (Critical To Quality) – Characteristics which are key to the customer’s perception of quality. • Defect – An unacceptable variation of a quality characteristic from its intended level. • Opportunity – Any action in which the product, service, or information is handled. – Any action performed or neglected during the creation of a unit of work. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

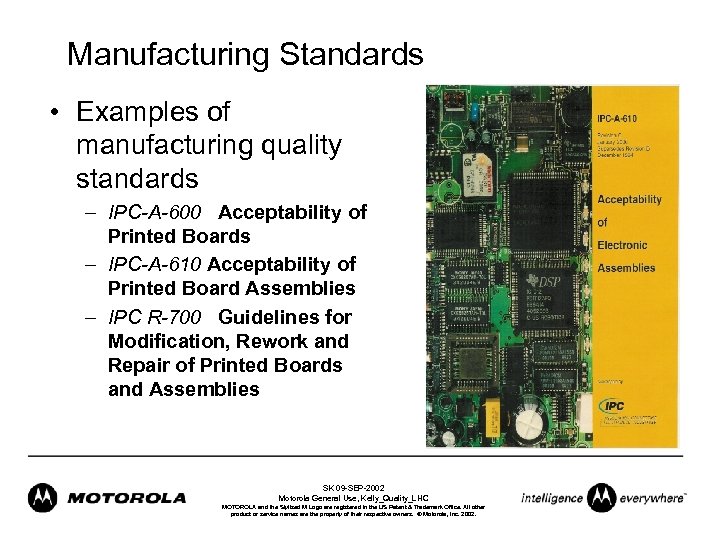

Manufacturing Standards • Examples of manufacturing quality standards – IPC-A-600 Acceptability of Printed Boards – IPC-A-610 Acceptability of Printed Board Assemblies – IPC R-700 Guidelines for Modification, Rework and Repair of Printed Boards and Assemblies SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Manufacturing Standards • Examples of manufacturing quality standards – IPC-A-600 Acceptability of Printed Boards – IPC-A-610 Acceptability of Printed Board Assemblies – IPC R-700 Guidelines for Modification, Rework and Repair of Printed Boards and Assemblies SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Manufacturing Testing Printed Circuit Board Example • In-Circuit Test (ICT), sometimes using a bed-of-nails fixture, tests the product for electrical properties. – Shorts, Opens, Parts, etc. • Functional Test is performed on the completed product assembly to verify the functional characteristics of the product. – Use on-board or external diagnostics and relevant operating systems. – Intent is to simulate actual customer operation of the product as closely as possible. • Automated Optical Inspection (AOI) is used to verify all parts are on the board in the correct position. – Supplements human inspection, which is not capable of detecting all defects SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Manufacturing Testing Printed Circuit Board Example • In-Circuit Test (ICT), sometimes using a bed-of-nails fixture, tests the product for electrical properties. – Shorts, Opens, Parts, etc. • Functional Test is performed on the completed product assembly to verify the functional characteristics of the product. – Use on-board or external diagnostics and relevant operating systems. – Intent is to simulate actual customer operation of the product as closely as possible. • Automated Optical Inspection (AOI) is used to verify all parts are on the board in the correct position. – Supplements human inspection, which is not capable of detecting all defects SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Manufacturing Process: Delivered Defects • No test or inspection is 100% effective in finding defects. – For example, a single visual inspection may only identify 70% of the actual defects • Multiple, successive visual inspections will find more defects, but this adds cost and time • Delivered defects escape the test and inspection processes within the factory. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Manufacturing Process: Delivered Defects • No test or inspection is 100% effective in finding defects. – For example, a single visual inspection may only identify 70% of the actual defects • Multiple, successive visual inspections will find more defects, but this adds cost and time • Delivered defects escape the test and inspection processes within the factory. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

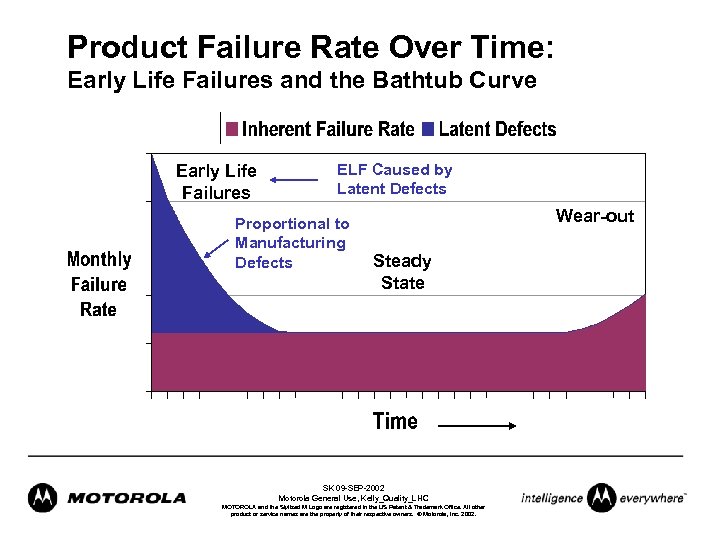

Product Failure Rate Over Time: Early Life Failures and the Bathtub Curve Early Life Failures ELF Caused by Latent Defects Proportional to Manufacturing Defects Wear-out Steady State SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Failure Rate Over Time: Early Life Failures and the Bathtub Curve Early Life Failures ELF Caused by Latent Defects Proportional to Manufacturing Defects Wear-out Steady State SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

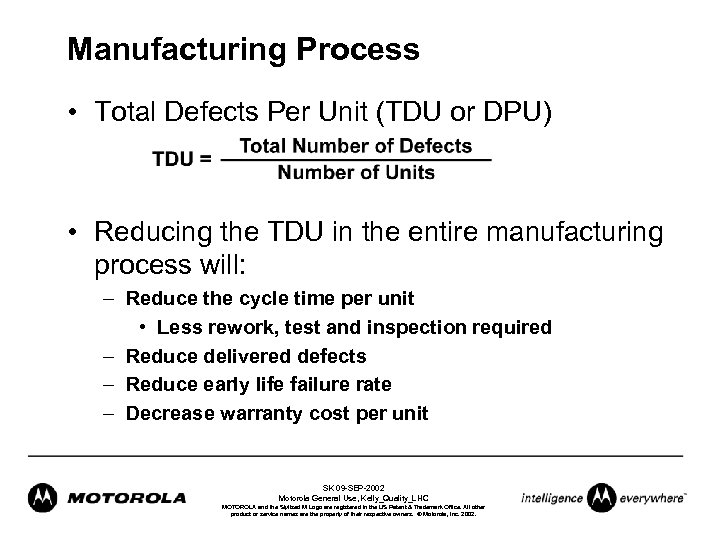

Manufacturing Process • Total Defects Per Unit (TDU or DPU) • Reducing the TDU in the entire manufacturing process will: – Reduce the cycle time per unit • Less rework, test and inspection required – Reduce delivered defects – Reduce early life failure rate – Decrease warranty cost per unit SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Manufacturing Process • Total Defects Per Unit (TDU or DPU) • Reducing the TDU in the entire manufacturing process will: – Reduce the cycle time per unit • Less rework, test and inspection required – Reduce delivered defects – Reduce early life failure rate – Decrease warranty cost per unit SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Design Process: Long-Term Reliability • The greater the design margin, the lower the inherent failure rate. • Electronic products, with superior design margin, built without defect, and operated within design limits… will operate without failure for many, many years SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Design Process: Long-Term Reliability • The greater the design margin, the lower the inherent failure rate. • Electronic products, with superior design margin, built without defect, and operated within design limits… will operate without failure for many, many years SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

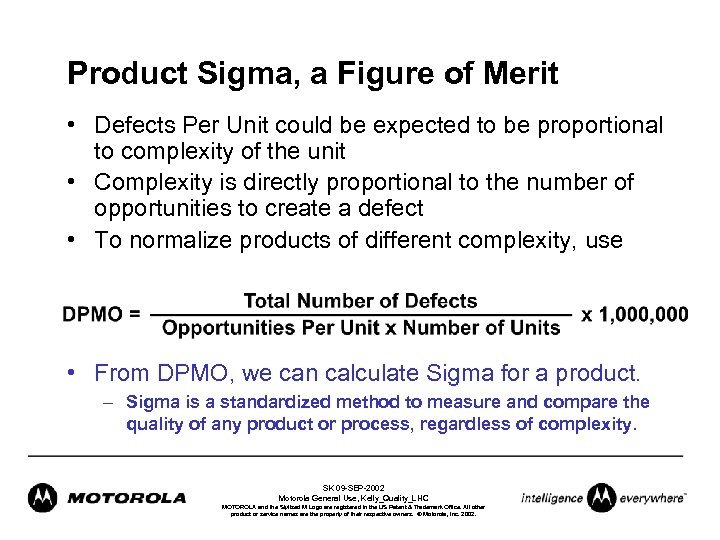

Product Sigma, a Figure of Merit • Defects Per Unit could be expected to be proportional to complexity of the unit • Complexity is directly proportional to the number of opportunities to create a defect • To normalize products of different complexity, use • From DPMO, we can calculate Sigma for a product. – Sigma is a standardized method to measure and compare the quality of any product or process, regardless of complexity. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Sigma, a Figure of Merit • Defects Per Unit could be expected to be proportional to complexity of the unit • Complexity is directly proportional to the number of opportunities to create a defect • To normalize products of different complexity, use • From DPMO, we can calculate Sigma for a product. – Sigma is a standardized method to measure and compare the quality of any product or process, regardless of complexity. SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

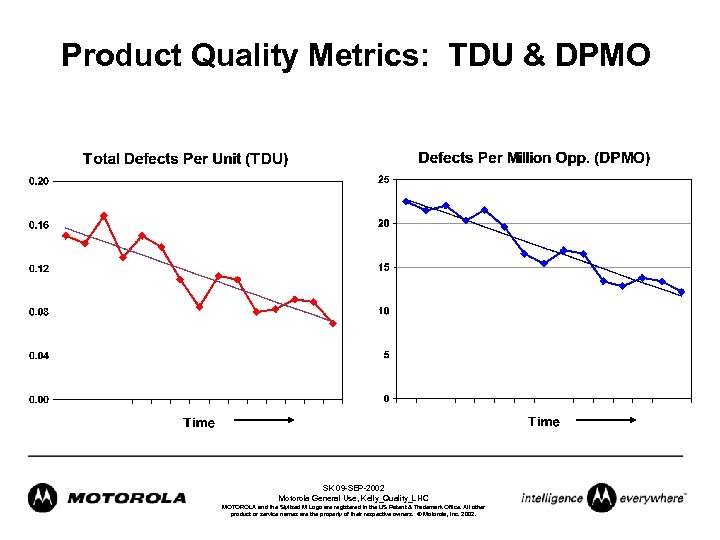

Product Quality Metrics: TDU & DPMO SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Product Quality Metrics: TDU & DPMO SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

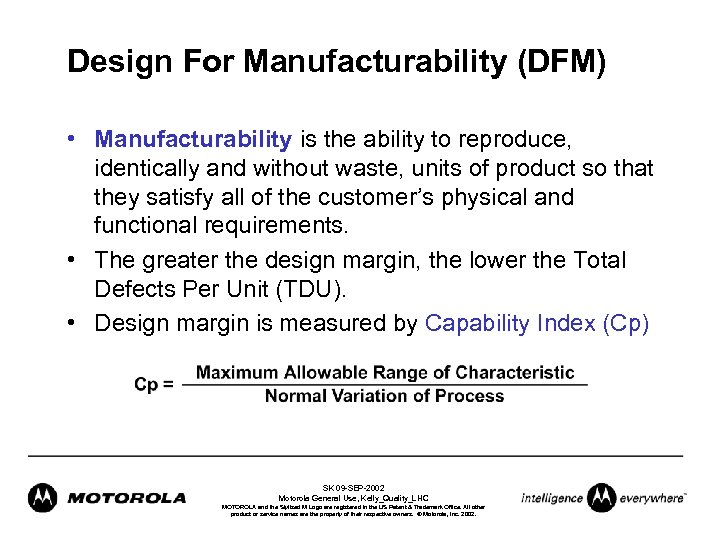

Design For Manufacturability (DFM) • Manufacturability is the ability to reproduce, identically and without waste, units of product so that they satisfy all of the customer’s physical and functional requirements. • The greater the design margin, the lower the Total Defects Per Unit (TDU). • Design margin is measured by Capability Index (Cp) SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Design For Manufacturability (DFM) • Manufacturability is the ability to reproduce, identically and without waste, units of product so that they satisfy all of the customer’s physical and functional requirements. • The greater the design margin, the lower the Total Defects Per Unit (TDU). • Design margin is measured by Capability Index (Cp) SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

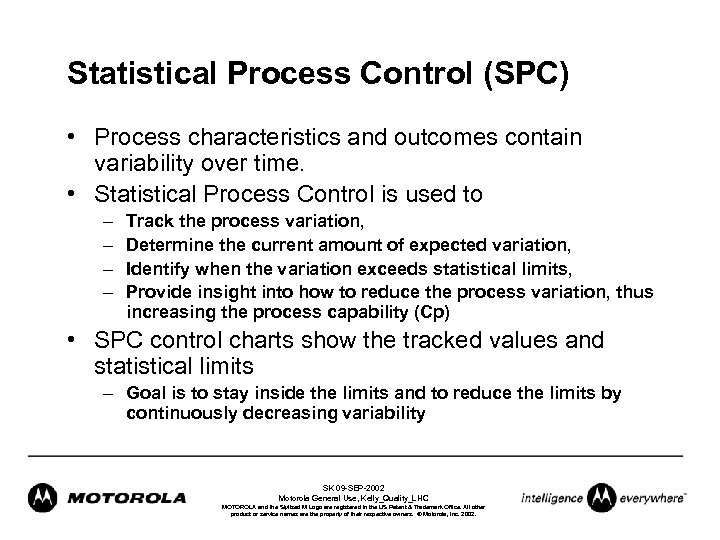

Statistical Process Control (SPC) • Process characteristics and outcomes contain variability over time. • Statistical Process Control is used to – – Track the process variation, Determine the current amount of expected variation, Identify when the variation exceeds statistical limits, Provide insight into how to reduce the process variation, thus increasing the process capability (Cp) • SPC control charts show the tracked values and statistical limits – Goal is to stay inside the limits and to reduce the limits by continuously decreasing variability SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Statistical Process Control (SPC) • Process characteristics and outcomes contain variability over time. • Statistical Process Control is used to – – Track the process variation, Determine the current amount of expected variation, Identify when the variation exceeds statistical limits, Provide insight into how to reduce the process variation, thus increasing the process capability (Cp) • SPC control charts show the tracked values and statistical limits – Goal is to stay inside the limits and to reduce the limits by continuously decreasing variability SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

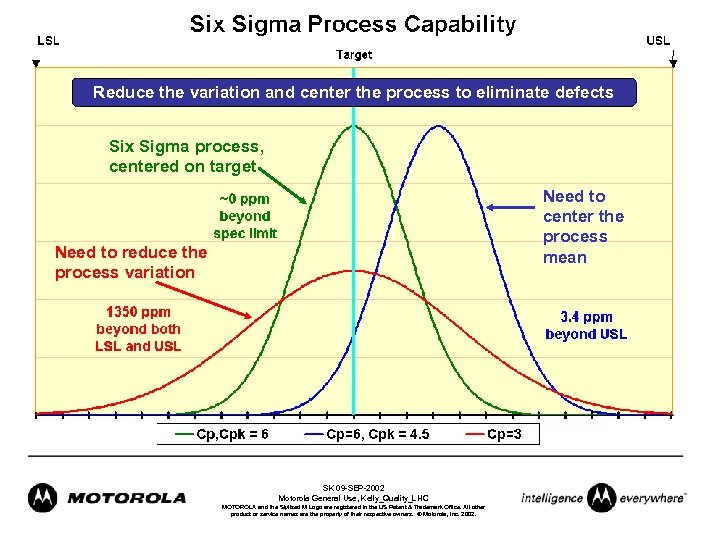

Reduce the variation and center the process to eliminate defects Six Sigma process, centered on target Need to center the process mean Need to reduce the process variation SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Reduce the variation and center the process to eliminate defects Six Sigma process, centered on target Need to center the process mean Need to reduce the process variation SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

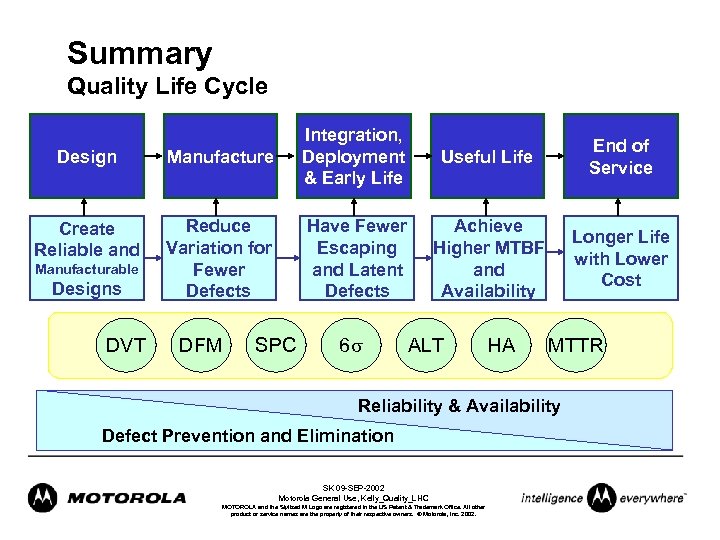

Summary Quality Life Cycle Design Manufacture Integration, Deployment & Early Life Create Reliable and Reduce Variation for Fewer Defects Have Fewer Escaping and Latent Defects Manufacturable Designs DVT DFM SPC 6 s Useful Life End of Service Achieve Higher MTBF and Availability Longer Life with Lower Cost ALT HA MTTR Reliability & Availability Defect Prevention and Elimination SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Summary Quality Life Cycle Design Manufacture Integration, Deployment & Early Life Create Reliable and Reduce Variation for Fewer Defects Have Fewer Escaping and Latent Defects Manufacturable Designs DVT DFM SPC 6 s Useful Life End of Service Achieve Higher MTBF and Availability Longer Life with Lower Cost ALT HA MTTR Reliability & Availability Defect Prevention and Elimination SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

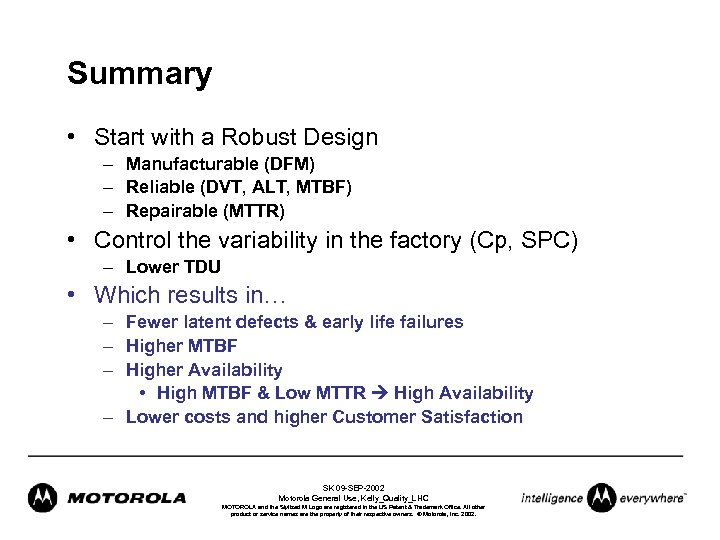

Summary • Start with a Robust Design – Manufacturable (DFM) – Reliable (DVT, ALT, MTBF) – Repairable (MTTR) • Control the variability in the factory (Cp, SPC) – Lower TDU • Which results in… – Fewer latent defects & early life failures – Higher MTBF – Higher Availability • High MTBF & Low MTTR High Availability – Lower costs and higher Customer Satisfaction SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

Summary • Start with a Robust Design – Manufacturable (DFM) – Reliable (DVT, ALT, MTBF) – Repairable (MTTR) • Control the variability in the factory (Cp, SPC) – Lower TDU • Which results in… – Fewer latent defects & early life failures – Higher MTBF – Higher Availability • High MTBF & Low MTTR High Availability – Lower costs and higher Customer Satisfaction SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.

SK 09 -SEP-2002 Motorola General Use, Kelly_Quality_LHC MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002.