039bb0142a7b0e4f326efbaa1bfb5b34.ppt

- Количество слайдов: 19

Management of resources Producing and Using system data for mission planning and mission status Staffan Martinsen Systems Engineering Manager PM Office Indirect Firing Systems

Management of resources Producing and Using system data for mission planning and mission status Staffan Martinsen Systems Engineering Manager PM Office Indirect Firing Systems

Indirect Fire Systems Artillery systems Mortar systems Ammunition and sensors

Indirect Fire Systems Artillery systems Mortar systems Ammunition and sensors

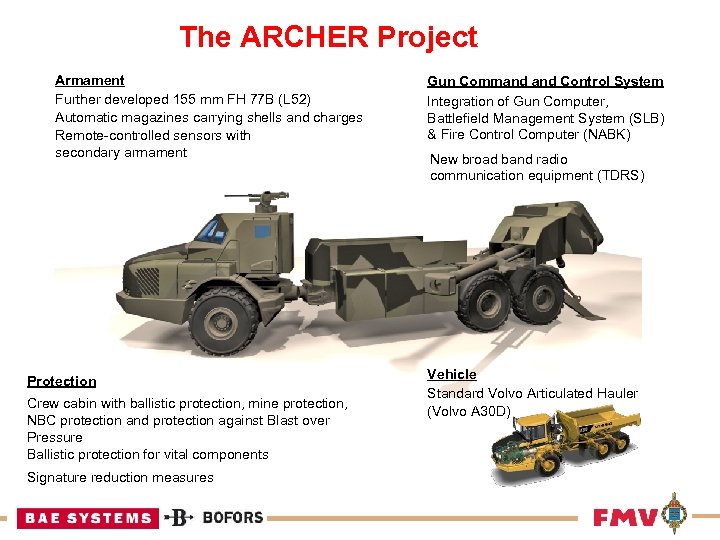

The ARCHER Project Armament Further developed 155 mm FH 77 B (L 52) Automatic magazines carrying shells and charges Remote-controlled sensors with secondary armament Protection Crew cabin with ballistic protection, mine protection, NBC protection and protection against Blast over Pressure Ballistic protection for vital components Signature reduction measures Gun Command Control System Integration of Gun Computer, Battlefield Management System (SLB) & Fire Control Computer (NABK) New broad band radio communication equipment (TDRS) Vehicle Standard Volvo Articulated Hauler (Volvo A 30 D)

The ARCHER Project Armament Further developed 155 mm FH 77 B (L 52) Automatic magazines carrying shells and charges Remote-controlled sensors with secondary armament Protection Crew cabin with ballistic protection, mine protection, NBC protection and protection against Blast over Pressure Ballistic protection for vital components Signature reduction measures Gun Command Control System Integration of Gun Computer, Battlefield Management System (SLB) & Fire Control Computer (NABK) New broad band radio communication equipment (TDRS) Vehicle Standard Volvo Articulated Hauler (Volvo A 30 D)

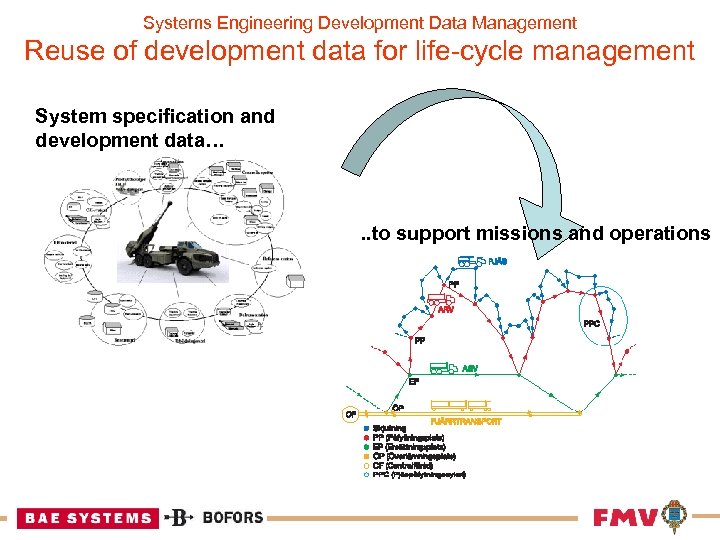

Systems Engineering Development Data Management Reuse of development data for life-cycle management System specification and development data… . . to support missions and operations

Systems Engineering Development Data Management Reuse of development data for life-cycle management System specification and development data… . . to support missions and operations

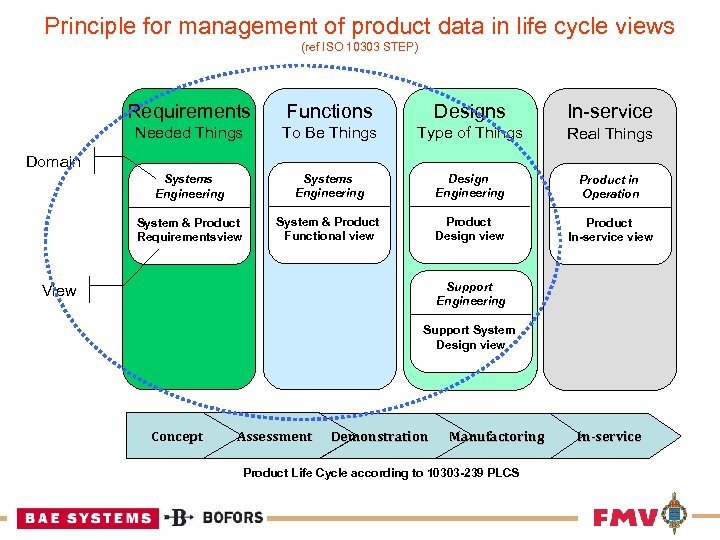

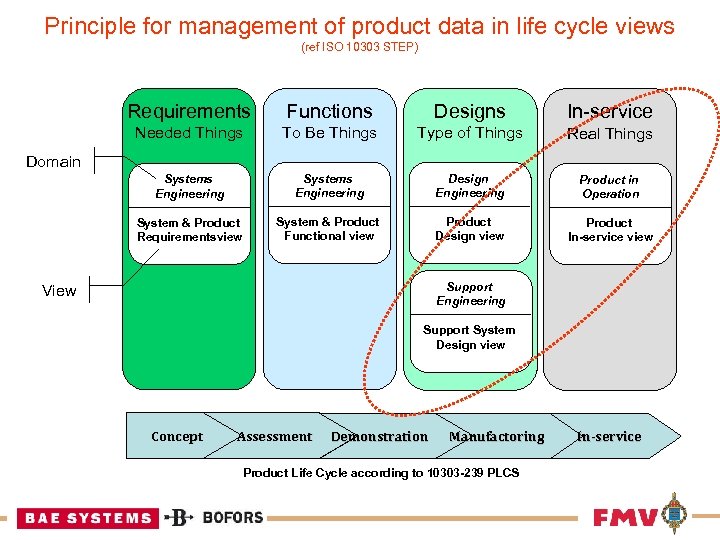

Principle for management of product data in life cycle views (ref ISO 10303 STEP) Requirements Functions Designs In-service Needed Things To Be Things Type of Things Real Things Systems Engineering Design Engineering Product in Operation System & Product Requirementsview System & Product Functional view Product Design view Product In-service view Domain Support Engineering View Support System Design view Concept Assessment Demonstration Manufactoring Product Life Cycle according to 10303 -239 PLCS In-service

Principle for management of product data in life cycle views (ref ISO 10303 STEP) Requirements Functions Designs In-service Needed Things To Be Things Type of Things Real Things Systems Engineering Design Engineering Product in Operation System & Product Requirementsview System & Product Functional view Product Design view Product In-service view Domain Support Engineering View Support System Design view Concept Assessment Demonstration Manufactoring Product Life Cycle according to 10303 -239 PLCS In-service

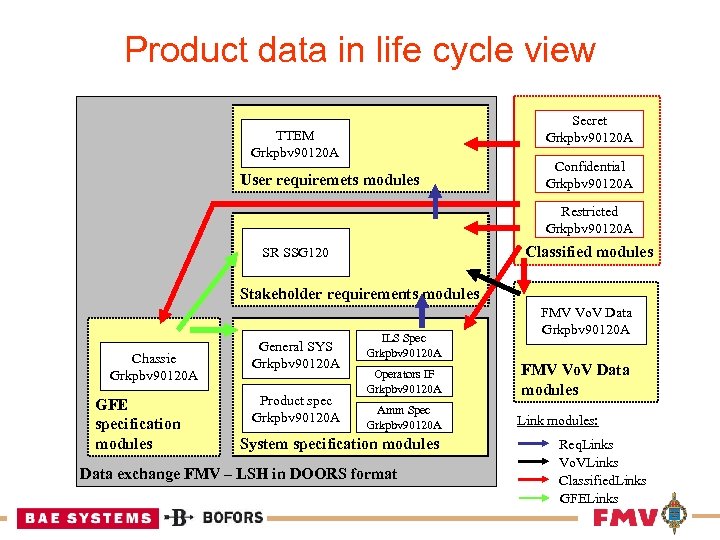

Product data in life cycle view Secret Grkpbv 90120 A TTEM Grkpbv 90120 A User requiremets modules Confidential Grkpbv 90120 A Restricted Grkpbv 90120 A Classified modules SR SSG 120 Stakeholder requirements modules Chassie Grkpbv 90120 A GFE specification modules General SYS Grkpbv 90120 A Product spec Grkpbv 90120 A ILS Spec Grkpbv 90120 A Operators IF Grkpbv 90120 A Amm Spec Grkpbv 90120 A System specification modules Data exchange FMV – LSH in DOORS format FMV Vo. V Data Grkpbv 90120 A FMV Vo. V Data modules Link modules: Req. Links Vo. VLinks Classified. Links GFELinks

Product data in life cycle view Secret Grkpbv 90120 A TTEM Grkpbv 90120 A User requiremets modules Confidential Grkpbv 90120 A Restricted Grkpbv 90120 A Classified modules SR SSG 120 Stakeholder requirements modules Chassie Grkpbv 90120 A GFE specification modules General SYS Grkpbv 90120 A Product spec Grkpbv 90120 A ILS Spec Grkpbv 90120 A Operators IF Grkpbv 90120 A Amm Spec Grkpbv 90120 A System specification modules Data exchange FMV – LSH in DOORS format FMV Vo. V Data Grkpbv 90120 A FMV Vo. V Data modules Link modules: Req. Links Vo. VLinks Classified. Links GFELinks

Principle for management of product data in life cycle views (ref ISO 10303 STEP) Requirements Functions Designs In-service Needed Things To Be Things Type of Things Real Things Systems Engineering Design Engineering Product in Operation System & Product Requirementsview System & Product Functional view Product Design view Product In-service view Domain Support Engineering View Support System Design view Concept Assessment Demonstration Manufactoring Product Life Cycle according to 10303 -239 PLCS In-service

Principle for management of product data in life cycle views (ref ISO 10303 STEP) Requirements Functions Designs In-service Needed Things To Be Things Type of Things Real Things Systems Engineering Design Engineering Product in Operation System & Product Requirementsview System & Product Functional view Product Design view Product In-service view Domain Support Engineering View Support System Design view Concept Assessment Demonstration Manufactoring Product Life Cycle according to 10303 -239 PLCS In-service

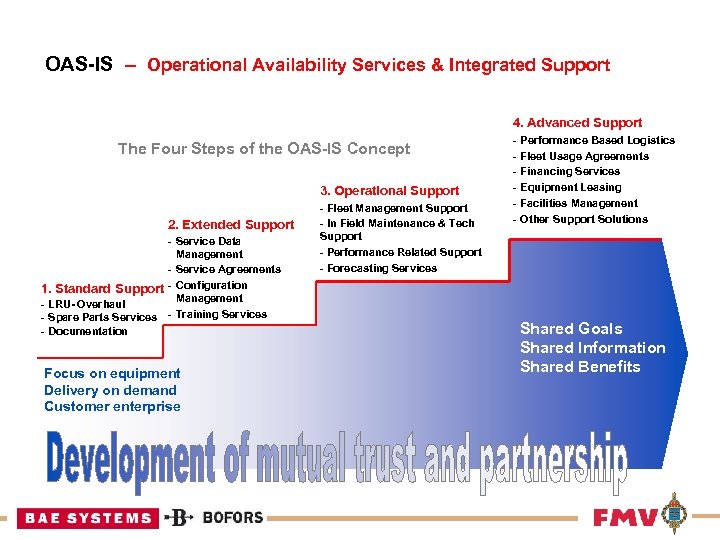

OAS-IS – Operational Availability Services & Integrated Support 4. Advanced Support The Four Steps of the OAS-IS Concept 3. Operational Support 2. Extended Support - Service Data Management - Service Agreements 1. Standard Support - Configuration Management - LRU- Overhaul - Spare Parts Services - Training Services - Documentation Focus on equipment Delivery on demand Customer enterprise - Fleet Management Support - In Field Maintenance & Tech Support - Performance Related Support - Forecasting Services - Performance Based Logistics Fleet Usage Agreements Financing Services Equipment Leasing Facilities Management Other Support Solutions Shared Goals Shared Information Shared Benefits

OAS-IS – Operational Availability Services & Integrated Support 4. Advanced Support The Four Steps of the OAS-IS Concept 3. Operational Support 2. Extended Support - Service Data Management - Service Agreements 1. Standard Support - Configuration Management - LRU- Overhaul - Spare Parts Services - Training Services - Documentation Focus on equipment Delivery on demand Customer enterprise - Fleet Management Support - In Field Maintenance & Tech Support - Performance Related Support - Forecasting Services - Performance Based Logistics Fleet Usage Agreements Financing Services Equipment Leasing Facilities Management Other Support Solutions Shared Goals Shared Information Shared Benefits

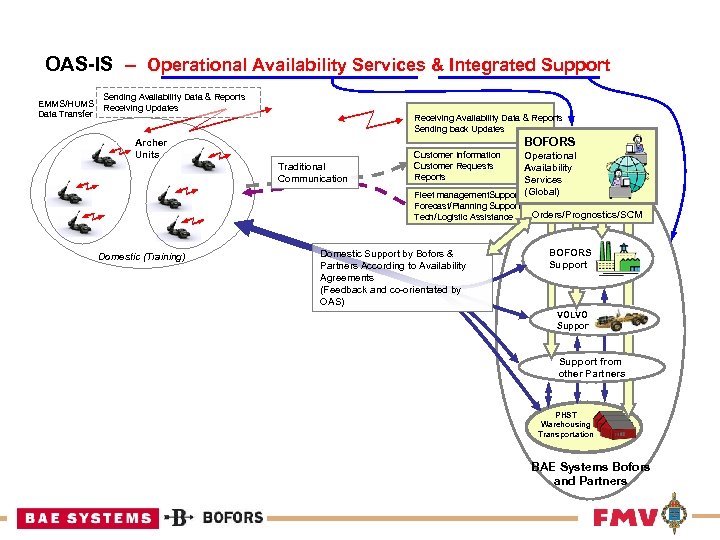

OAS-IS – Operational Availability Services & Integrated Support EMMS/HUMS Data Transfer Sending Availability Data & Reports Receiving Updates Receiving Availability Data & Reports Sending back Updates BOFORS Archer Units Traditional Communication Operational Availability Services Fleet management. Support (Global) Customer Information Customer Requests Reports Forecast/Planning Support Tech/Logistic Assistance Domestic (Training) Domestic Support by Bofors & Partners According to Availability Agreements (Feedback and co-orientated by OAS) Orders/Prognostics/SCM BOFORS Support VOLVO Support from other Partners PHST Warehousing Transportation BAE Systems Bofors and Partners

OAS-IS – Operational Availability Services & Integrated Support EMMS/HUMS Data Transfer Sending Availability Data & Reports Receiving Updates Receiving Availability Data & Reports Sending back Updates BOFORS Archer Units Traditional Communication Operational Availability Services Fleet management. Support (Global) Customer Information Customer Requests Reports Forecast/Planning Support Tech/Logistic Assistance Domestic (Training) Domestic Support by Bofors & Partners According to Availability Agreements (Feedback and co-orientated by OAS) Orders/Prognostics/SCM BOFORS Support VOLVO Support from other Partners PHST Warehousing Transportation BAE Systems Bofors and Partners

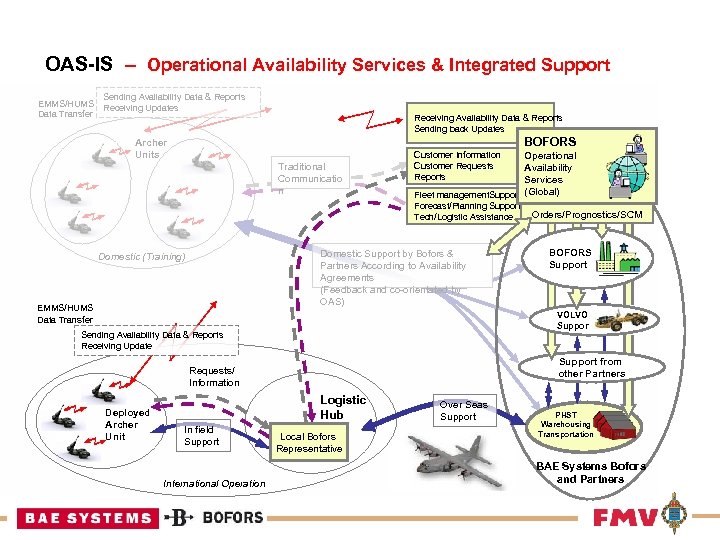

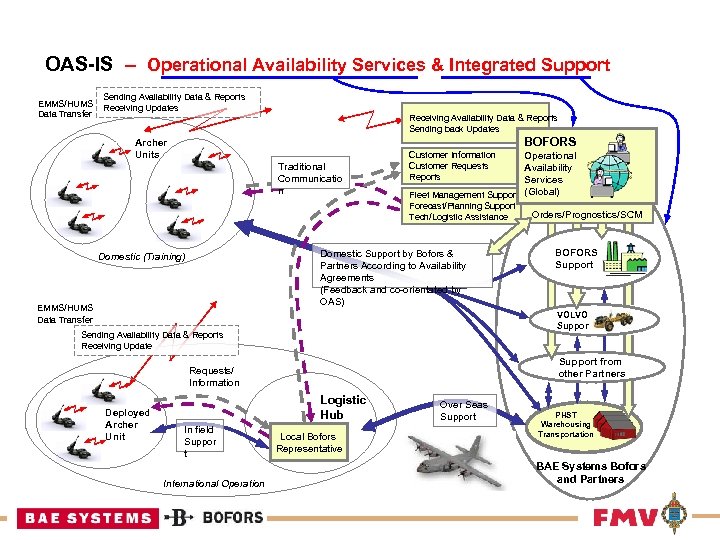

OAS-IS – Operational Availability Services & Integrated Support EMMS/HUMS Data Transfer Sending Availability Data & Reports Receiving Updates Receiving Availability Data & Reports Sending back Updates BOFORS Archer Units Traditional Communicatio n Operational Availability Services Fleet management. Support (Global) Customer Information Customer Requests Reports Forecast/Planning Support Tech/Logistic Assistance Domestic Support by Bofors & Partners According to Availability Agreements (Feedback and co-orientated by OAS) Domestic (Training) EMMS/HUMS Data Transfer Support from other Partners Requests/ Information Logistic Hub In field Support International Operation BOFORS Support VOLVO Support Sending Availability Data & Reports Receiving Update Deployed Archer Unit Orders/Prognostics/SCM Local Bofors Representative Over Seas Support PHST Warehousing Transportation BAE Systems Bofors and Partners

OAS-IS – Operational Availability Services & Integrated Support EMMS/HUMS Data Transfer Sending Availability Data & Reports Receiving Updates Receiving Availability Data & Reports Sending back Updates BOFORS Archer Units Traditional Communicatio n Operational Availability Services Fleet management. Support (Global) Customer Information Customer Requests Reports Forecast/Planning Support Tech/Logistic Assistance Domestic Support by Bofors & Partners According to Availability Agreements (Feedback and co-orientated by OAS) Domestic (Training) EMMS/HUMS Data Transfer Support from other Partners Requests/ Information Logistic Hub In field Support International Operation BOFORS Support VOLVO Support Sending Availability Data & Reports Receiving Update Deployed Archer Unit Orders/Prognostics/SCM Local Bofors Representative Over Seas Support PHST Warehousing Transportation BAE Systems Bofors and Partners

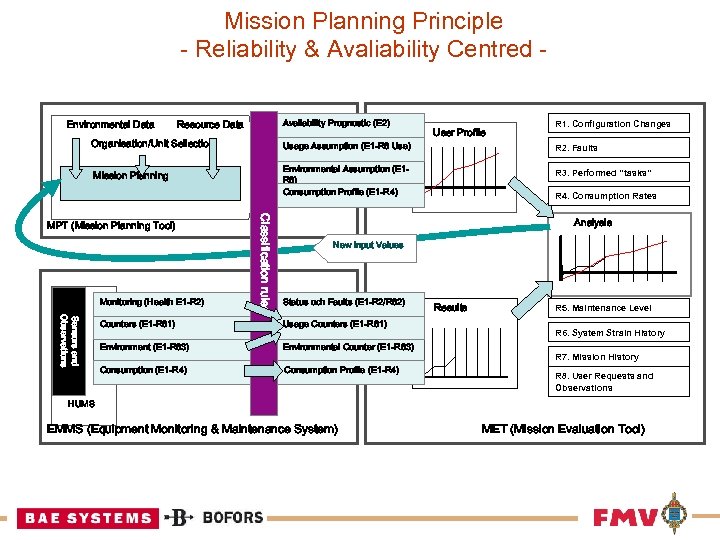

Mission Planning Principle - Reliability & Avaliability Centred Environmental Data Availability Prognostic (E 2) Resource Data Organisation/Unit Sellection R 2. Faults Environmental Assumption (E 1 R 6) Consumption Profile (E 1 -R 4) Classification rules Monitoring (Health E 1 -R 2) R 1. Configuration Changes Usage Assumption (E 1 -R 6 Use) Mission Planning MPT (Mission Planning Tool) User Profile R 3. Performed ”tasks” R 4. Consumption Rates Analysis New Input Values Status och Faults (E 1 -R 2/R 62) Sensors and Observations Counters (E 1 -R 61) Usage Counters (E 1 -R 61) Environment (E 1 -R 63) Environmental Counter (E 1 -R 63) Consumption (E 1 -R 4) Consumption Profile (E 1 -R 4) Results R 5. Maintenance Level R 6. System Strain History R 7. Mission History R 8. User Requests and Observations HUMS EMMS (Equipment Monitoring & Maintenance System) MET (Mission Evaluation Tool)

Mission Planning Principle - Reliability & Avaliability Centred Environmental Data Availability Prognostic (E 2) Resource Data Organisation/Unit Sellection R 2. Faults Environmental Assumption (E 1 R 6) Consumption Profile (E 1 -R 4) Classification rules Monitoring (Health E 1 -R 2) R 1. Configuration Changes Usage Assumption (E 1 -R 6 Use) Mission Planning MPT (Mission Planning Tool) User Profile R 3. Performed ”tasks” R 4. Consumption Rates Analysis New Input Values Status och Faults (E 1 -R 2/R 62) Sensors and Observations Counters (E 1 -R 61) Usage Counters (E 1 -R 61) Environment (E 1 -R 63) Environmental Counter (E 1 -R 63) Consumption (E 1 -R 4) Consumption Profile (E 1 -R 4) Results R 5. Maintenance Level R 6. System Strain History R 7. Mission History R 8. User Requests and Observations HUMS EMMS (Equipment Monitoring & Maintenance System) MET (Mission Evaluation Tool)

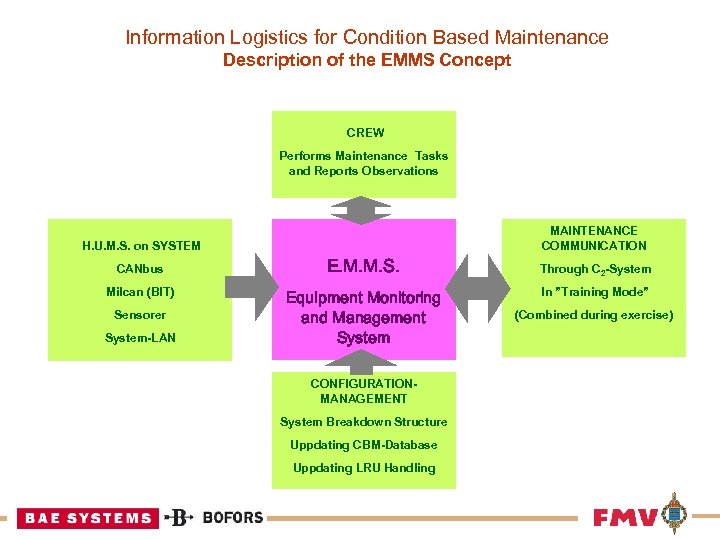

Information Logistics for Condition Based Maintenance Description of the EMMS Concept CREW Performs Maintenance Tasks and Reports Observations MAINTENANCE COMMUNICATION H. U. M. S. on SYSTEM CANbus Milcan (BIT) Sensorer System-LAN E. M. M. S. Equipment Monitoring and Management System CONFIGURATIONMANAGEMENT System Breakdown Structure Uppdating CBM-Database Uppdating LRU Handling Through C 2 -System In ”Training Mode” (Combined during exercise)

Information Logistics for Condition Based Maintenance Description of the EMMS Concept CREW Performs Maintenance Tasks and Reports Observations MAINTENANCE COMMUNICATION H. U. M. S. on SYSTEM CANbus Milcan (BIT) Sensorer System-LAN E. M. M. S. Equipment Monitoring and Management System CONFIGURATIONMANAGEMENT System Breakdown Structure Uppdating CBM-Database Uppdating LRU Handling Through C 2 -System In ”Training Mode” (Combined during exercise)

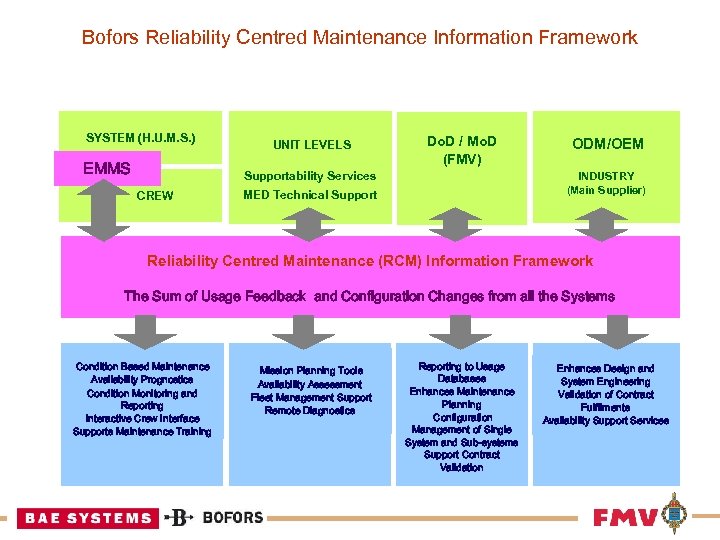

Bofors Reliability Centred Maintenance Information Framework SYSTEM (H. U. M. S. ) EMMS UNIT LEVELS Do. D / Mo. D (FMV) Supportability Services CREW ODM/OEM INDUSTRY (Main Supplier) MED Technical Support T. B. U. S. Reliability Centred Maintenance (RCM) Information Framework Stöd på systemet The Sum of Usage Feedback and Configuration Changes from all the Systems Condition Based Maintenance Availability Prognostics Condition Monitoring and Reporting Interactive Crew Interface Supports Maintenance Training Mission Planning Tools Availability Assessment Fleet Management Support Remote Diagnostics Reporting to Usage Databases Enhances Maintenance Planning Configuration Management of Single System and Sub-systems Support Contract Validation Enhances Design and System Engineering Validation of Contract Fulfilments Availability Support Services

Bofors Reliability Centred Maintenance Information Framework SYSTEM (H. U. M. S. ) EMMS UNIT LEVELS Do. D / Mo. D (FMV) Supportability Services CREW ODM/OEM INDUSTRY (Main Supplier) MED Technical Support T. B. U. S. Reliability Centred Maintenance (RCM) Information Framework Stöd på systemet The Sum of Usage Feedback and Configuration Changes from all the Systems Condition Based Maintenance Availability Prognostics Condition Monitoring and Reporting Interactive Crew Interface Supports Maintenance Training Mission Planning Tools Availability Assessment Fleet Management Support Remote Diagnostics Reporting to Usage Databases Enhances Maintenance Planning Configuration Management of Single System and Sub-systems Support Contract Validation Enhances Design and System Engineering Validation of Contract Fulfilments Availability Support Services

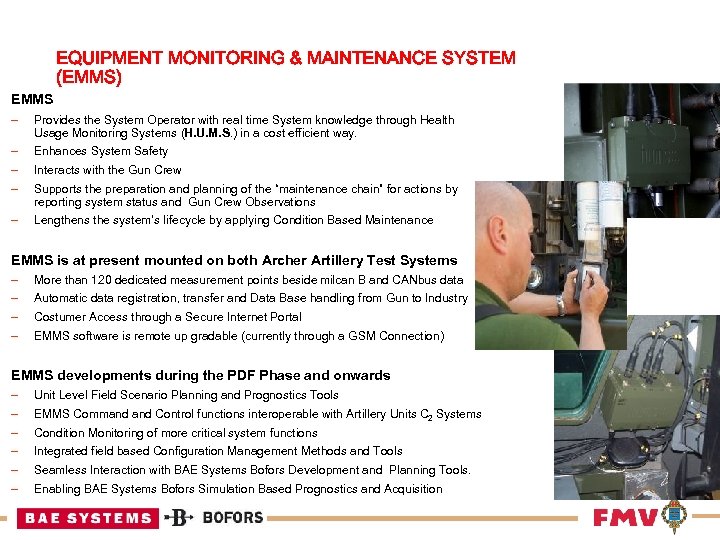

EQUIPMENT MONITORING & MAINTENANCE SYSTEM (EMMS) EMMS – Provides the System Operator with real time System knowledge through Health Usage Monitoring Systems (H. U. M. S. ) in a cost efficient way. – – – Enhances System Safety – Lengthens the system’s lifecycle by applying Condition Based Maintenance Interacts with the Gun Crew Supports the preparation and planning of the “maintenance chain” for actions by reporting system status and Gun Crew Observations EMMS is at present mounted on both Archer Artillery Test Systems – – More than 120 dedicated measurement points beside milcan B and CANbus data Automatic data registration, transfer and Data Base handling from Gun to Industry Costumer Access through a Secure Internet Portal EMMS software is remote up gradable (currently through a GSM Connection) EMMS developments during the PDF Phase and onwards – – – Unit Level Field Scenario Planning and Prognostics Tools EMMS Command Control functions interoperable with Artillery Units C 2 Systems Condition Monitoring of more critical system functions Integrated field based Configuration Management Methods and Tools Seamless Interaction with BAE Systems Bofors Development and Planning Tools. Enabling BAE Systems Bofors Simulation Based Prognostics and Acquisition

EQUIPMENT MONITORING & MAINTENANCE SYSTEM (EMMS) EMMS – Provides the System Operator with real time System knowledge through Health Usage Monitoring Systems (H. U. M. S. ) in a cost efficient way. – – – Enhances System Safety – Lengthens the system’s lifecycle by applying Condition Based Maintenance Interacts with the Gun Crew Supports the preparation and planning of the “maintenance chain” for actions by reporting system status and Gun Crew Observations EMMS is at present mounted on both Archer Artillery Test Systems – – More than 120 dedicated measurement points beside milcan B and CANbus data Automatic data registration, transfer and Data Base handling from Gun to Industry Costumer Access through a Secure Internet Portal EMMS software is remote up gradable (currently through a GSM Connection) EMMS developments during the PDF Phase and onwards – – – Unit Level Field Scenario Planning and Prognostics Tools EMMS Command Control functions interoperable with Artillery Units C 2 Systems Condition Monitoring of more critical system functions Integrated field based Configuration Management Methods and Tools Seamless Interaction with BAE Systems Bofors Development and Planning Tools. Enabling BAE Systems Bofors Simulation Based Prognostics and Acquisition

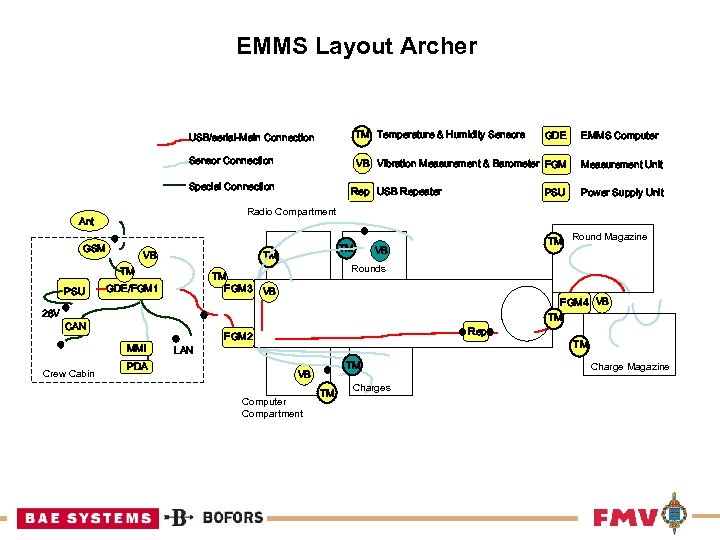

EMMS Layout Archer USB/serial-Main Connection TM Temperature & Humidity Sensors Sensor Connection VB Vibration Measurement & Barometer FGM Special Connection GSM VB TM FGM 3 GDE/FGM 1 CAN MMI Crew Cabin PDA TM TM TM 28 V PSU EMMS Computer Measurement Unit Power Supply Unit Radio Compartment Ant PSU Rep USB Repeater GDE TM VB Round Magazine Rounds VB FGM 4 VB TM Rep FGM 2 TM LAN TM VB Computer Compartment TM Charges Charge Magazine

EMMS Layout Archer USB/serial-Main Connection TM Temperature & Humidity Sensors Sensor Connection VB Vibration Measurement & Barometer FGM Special Connection GSM VB TM FGM 3 GDE/FGM 1 CAN MMI Crew Cabin PDA TM TM TM 28 V PSU EMMS Computer Measurement Unit Power Supply Unit Radio Compartment Ant PSU Rep USB Repeater GDE TM VB Round Magazine Rounds VB FGM 4 VB TM Rep FGM 2 TM LAN TM VB Computer Compartment TM Charges Charge Magazine

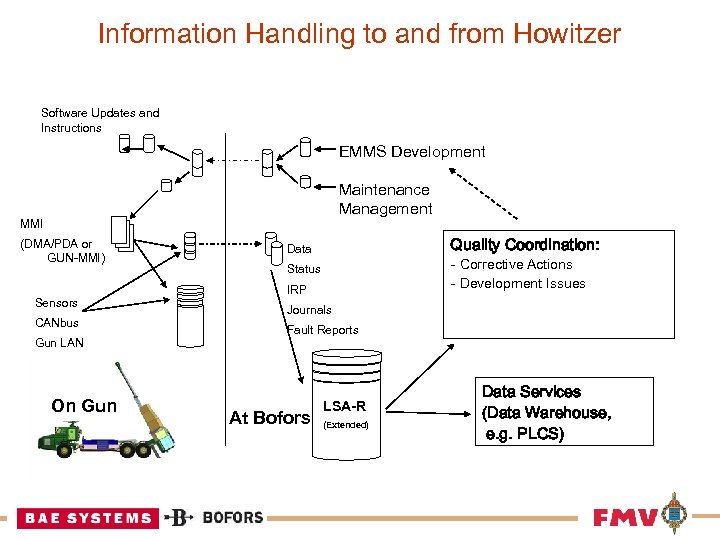

Information Handling to and from Howitzer Software Updates and Instructions EMMS Development Maintenance Management MMI (DMA/PDA or GUN-MMI) Quality Coordination: Data - Corrective Actions - Development Issues Status IRP Sensors CANbus Journals Fault Reports Gun LAN On Gun At Bofors LSA-R (Extended) Data Services (Data Warehouse, e. g. PLCS)

Information Handling to and from Howitzer Software Updates and Instructions EMMS Development Maintenance Management MMI (DMA/PDA or GUN-MMI) Quality Coordination: Data - Corrective Actions - Development Issues Status IRP Sensors CANbus Journals Fault Reports Gun LAN On Gun At Bofors LSA-R (Extended) Data Services (Data Warehouse, e. g. PLCS)

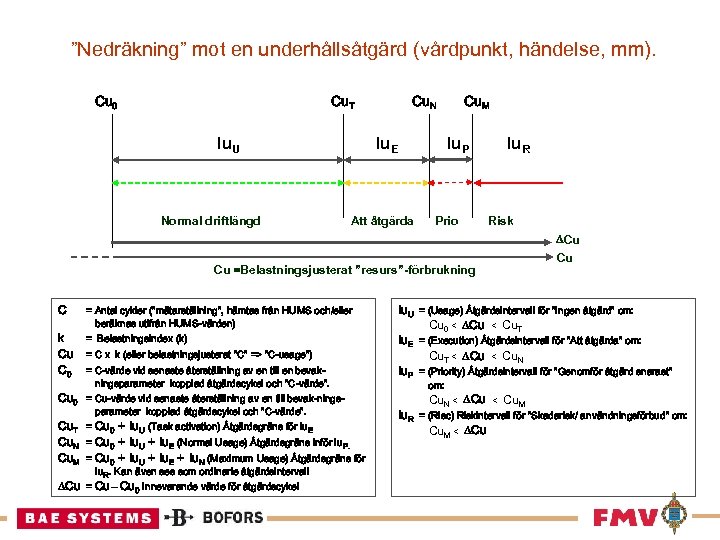

”Nedräkning” mot en underhållsåtgärd (vårdpunkt, händelse, mm). Cu 0 Cu. T Iu. U Normal driftlängd Cu. N Iu. E Cu. M Iu. P Att åtgärda Prio Iu. R Risk Cu Cu =Belastningsjusterat ”resurs”-förbrukning C k Cu C 0 = Antal cykler (”mätarställning”, hämtas från HUMS och/eller beräknas utifrån HUMS-värden) = Belastningsindex (k) = C x k (eller belastningsjusterat ”C” => ”C-usage”) = C-värde vid senaste återställning av en till en bevakningsparameter kopplad åtgärdscykel och ”C-värde”. Cu 0 = Cu-värde vid senaste återställning av en till bevak-ningsparameter kopplad åtgärdscykel och ”C-värde”. Cu. T = Cu 0 + Iu. U (Task activation) Åtgärdsgräns för Iu. E Cu. N = Cu 0 + Iu. U + Iu. E (Normal Usage) Åtgärdsgräns inför Iu. P. Cu. M = Cu 0 + Iu. U + Iu. E + Iu. N (Maximum Usage) Åtgärdsgräns för Iu. R. Kan även ses som ordinarie åtgärdsintervall Cu = Cu – Cu 0 Innevarande värde för åtgärdscykel Cu Iu. U = (Usage) Åtgärdsintervall för ”Ingen åtgärd” om: Cu 0 < Cu. T Iu. E = (Execution) Åtgärdsintervall för ”Att åtgärda” om: Cu. T < Cu. N Iu. P = (Priority) Åtgärdsintervall för ”Genomför åtgärd snarast” om: Cu. N < Cu. M Iu. R = (Risc) Riskintervall för ”Skadarisk/ användningsförbud” om: Cu. M < Cu

”Nedräkning” mot en underhållsåtgärd (vårdpunkt, händelse, mm). Cu 0 Cu. T Iu. U Normal driftlängd Cu. N Iu. E Cu. M Iu. P Att åtgärda Prio Iu. R Risk Cu Cu =Belastningsjusterat ”resurs”-förbrukning C k Cu C 0 = Antal cykler (”mätarställning”, hämtas från HUMS och/eller beräknas utifrån HUMS-värden) = Belastningsindex (k) = C x k (eller belastningsjusterat ”C” => ”C-usage”) = C-värde vid senaste återställning av en till en bevakningsparameter kopplad åtgärdscykel och ”C-värde”. Cu 0 = Cu-värde vid senaste återställning av en till bevak-ningsparameter kopplad åtgärdscykel och ”C-värde”. Cu. T = Cu 0 + Iu. U (Task activation) Åtgärdsgräns för Iu. E Cu. N = Cu 0 + Iu. U + Iu. E (Normal Usage) Åtgärdsgräns inför Iu. P. Cu. M = Cu 0 + Iu. U + Iu. E + Iu. N (Maximum Usage) Åtgärdsgräns för Iu. R. Kan även ses som ordinarie åtgärdsintervall Cu = Cu – Cu 0 Innevarande värde för åtgärdscykel Cu Iu. U = (Usage) Åtgärdsintervall för ”Ingen åtgärd” om: Cu 0 < Cu. T Iu. E = (Execution) Åtgärdsintervall för ”Att åtgärda” om: Cu. T < Cu. N Iu. P = (Priority) Åtgärdsintervall för ”Genomför åtgärd snarast” om: Cu. N < Cu. M Iu. R = (Risc) Riskintervall för ”Skadarisk/ användningsförbud” om: Cu. M < Cu

OAS-IS – Operational Availability Services & Integrated Support EMMS/HUMS Data Transfer Sending Availability Data & Reports Receiving Updates Receiving Availability Data & Reports Sending back Updates BOFORS Archer Units Traditional Communicatio n Operational Availability Services Fleet Management Support (Global) Customer Information Customer Requests Reports Forecast/Planning Support Tech/Logistic Assistance Domestic Support by Bofors & Partners According to Availability Agreements (Feedback and co-orientated by OAS) Domestic (Training) EMMS/HUMS Data Transfer Support from other Partners Requests/ Information Logistic Hub In field Suppor t International Operation BOFORS Support VOLVO Support Sending Availability Data & Reports Receiving Update Deployed Archer Unit Orders/Prognostics/SCM Local Bofors Representative Over Seas Support PHST Warehousing Transportation BAE Systems Bofors and Partners

OAS-IS – Operational Availability Services & Integrated Support EMMS/HUMS Data Transfer Sending Availability Data & Reports Receiving Updates Receiving Availability Data & Reports Sending back Updates BOFORS Archer Units Traditional Communicatio n Operational Availability Services Fleet Management Support (Global) Customer Information Customer Requests Reports Forecast/Planning Support Tech/Logistic Assistance Domestic Support by Bofors & Partners According to Availability Agreements (Feedback and co-orientated by OAS) Domestic (Training) EMMS/HUMS Data Transfer Support from other Partners Requests/ Information Logistic Hub In field Suppor t International Operation BOFORS Support VOLVO Support Sending Availability Data & Reports Receiving Update Deployed Archer Unit Orders/Prognostics/SCM Local Bofors Representative Over Seas Support PHST Warehousing Transportation BAE Systems Bofors and Partners

Increasing system performance by giving Artillery-soldiers a user-friendly home office… Questions ?

Increasing system performance by giving Artillery-soldiers a user-friendly home office… Questions ?