20dd6a09f460e31628278001c1368f39.ppt

- Количество слайдов: 49

Making Green Jobs Safe Jobs: A case study – the safe use of Spray Polyurethane Foam (SPF) Janet Carter Sr. Health Scientist Directorate of Standards and Guidance Good Jobs Green Jobs Conference 4 May 2010

The Federal Spray Polyurethane Foam Workgroup • • • EPA OSHA NIOSH CPSC FTC

Discussion Outline • Background information – “Green” Jobs • Making “Green” jobs SAFE jobs • Case Study Presentation • • • Preplanning Hazard ID Hazard Communication Training Other considerations

Background Information: Green Jobs • American Resource and Recovery Act (ARRA) of 2009 is investing billions of dollars to promote green jobs & energy efficiency • “Green” jobs are not necessarily new jobs • Hazards may not be new either

Green Jobs “Green” Jobs

Weatherization • Green building practices – Various types of weatherization products • • Fiberglass Cellulose Spray styrofoam Spray polyurethane foam • All have potential benefits • All have potential hazards – Any chemical can be hazardous if used improperly – Most chemicals can be handled safely

Effective Green Building Practices Green Building Goal- “To facilitate the mainstream adoption of effective green building practices” Why Spray Polyurethane Foam is valuable – An important tool to help achieve energy efficiency – Numerous performance attributes • • • 3 -6 x R-value of other insulation Vapor barrier Moisture barrier (closed cell) Structural strengthener (closed cell) Fills all gaps and crevices – Stops air infiltration • Thermal break • Reduces noise – Can be made, in part, from sustainable resources (e. g. soy polyols)

Effective Green Building Practices • Use of SPF has increased 60% in the last five years • Superior insulating properties • More uniform insulation • With widespread use of SPF to retrofit buildings for energy conservation, the ENTIRE industry needs to ensure SPF installation is carried out in a safe manner to protect workers, helpers, building occupants, and consumers

Types of SPF Insulation/Sealants • Two-Component: > over 80 million lbs. sold in a year* - Professional – (high pressure SPF) 55 gal. drums - Do-It-Yourself – (low pressure SPF) large quantities also • Retail, hardware, internet purchase • One Component: > Over 50 mil. lbs. sold in a year* (or over 60 mil. cans) – fills, seals, and insulates gaps - Consumer (DIY) • 12 oz. can (market leader); also 16 oz. , 20 oz. • Plastic straw applicator included - Professional • 20 oz. , 24 oz. , 26 oz. , 30 oz. , 33 oz. • Typically gun delivery or applicator tool for precise control, sold separately * Data Courtesy CPI

Background information: Spray Polyurethane Foam

The Federal SPF Workgroup • • • EPA OSHA NIOSH CPSC FTC

The Industry Workgroup • American Chemistry Council (ACC) – Center For Polyurethane Industries (CPI) • Spray Polyurethane Foam Alliance (SPFA)

Advertising and Marketing Claims Examples: • • • “No off-gassing”, “non-toxic”, “safe”…foam “green” and “environmentally friendly” “…is plant-based”, “Made from soy beans” Principles of Sound Marketing: – – – FTC Act / FTC “Green Guides” Substantiate “Green” claims Deception occurs when there is a representation, omission or practice that is likely to mislead the consumer

Federal Workgroup and Industry Efforts • Ensuring the entire value chain is informed regarding benefits and hazards – Informative and accurate marketing – Consistent hazard communication • Ensuring health and safety best practices are incorporated with installation best practices

SPF and Isocyanates • SPF contains Isocyanates (MDI and p. MDI), polyol, amines, blow agents, flame retardants, surfactants • Isocyanates have been reported to be the leading attributable chemical cause of work-related asthma (WRA) – Causal-link for developing occupational asthma – Exacerbates existing asthma conditions – Other health effects attributed to isocyanate exposure • Amines have been reported to cause inhalation irritation and can cause temporary blurry vision (halo effect) • Hazard information not reaching all users across the entire value chain • Inconsistent worker protection

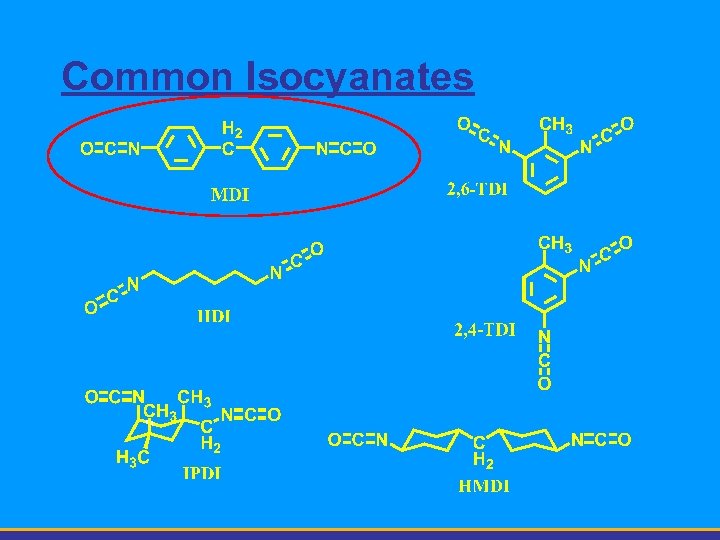

Common Isocyanates

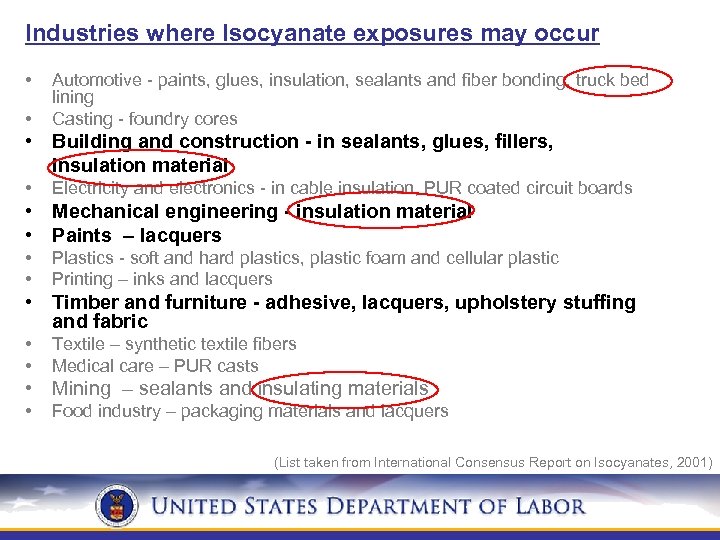

Industries where Isocyanate exposures may occur • • Automotive - paints, glues, insulation, sealants and fiber bonding, truck bed lining Casting - foundry cores • Building and construction - in sealants, glues, fillers, insulation material • Electricity and electronics - in cable insulation, PUR coated circuit boards • Mechanical engineering - insulation material • Paints – lacquers • • Plastics - soft and hard plastics, plastic foam and cellular plastic Printing – inks and lacquers • Timber and furniture - adhesive, lacquers, upholstery stuffing and fabric • • Textile – synthetic textile fibers Medical care – PUR casts • Mining – sealants and insulating materials • Food industry – packaging materials and lacquers (List taken from International Consensus Report on Isocyanates, 2001)

OSHA Responsibilities

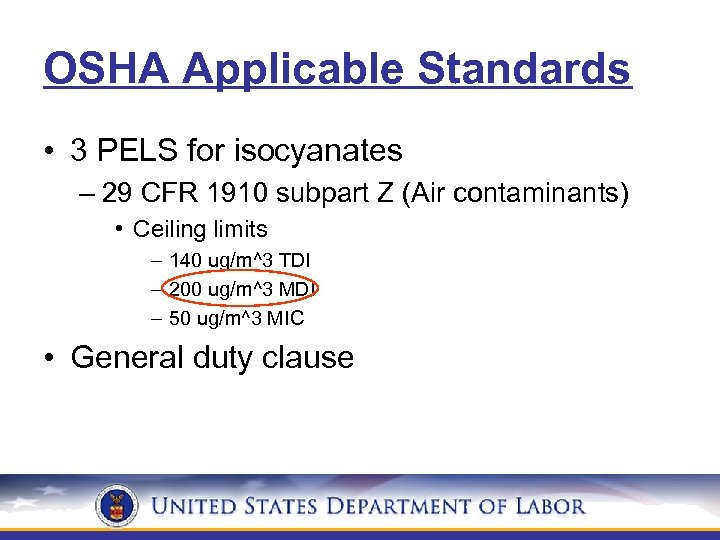

OSHA Applicable Standards • 3 PELS for isocyanates – 29 CFR 1910 subpart Z (Air contaminants) • Ceiling limits – 140 ug/m^3 TDI – 200 ug/m^3 MDI – 50 ug/m^3 MIC • General duty clause

OSHA Applicable Standards • Hazard Communication - 29 CFR 1910. 1200; 1915. 1200; 1917. 28; 1918. 90; and 1926. 59 • Respiratory Protection - 29 CFR 1910. 134 • Personal Protective Equipment - 29 CFR 1910 Part I, 1926. 95 • Ventilation - 29 CFR 1910. 94; 1915. 51; 1918. 94; 1926. 57

OSHA Applicable Standards • • • Confined space Electrical Falls Fire/explosion Flammable liquids Medical and First Aid

Employer Responsibilities • Full Hazard Communication • Provide worker training • Appropriate Exposure Control System – Appropriate PPE for ALL exposed workers – Adequate and appropriate containment and/or ventilation

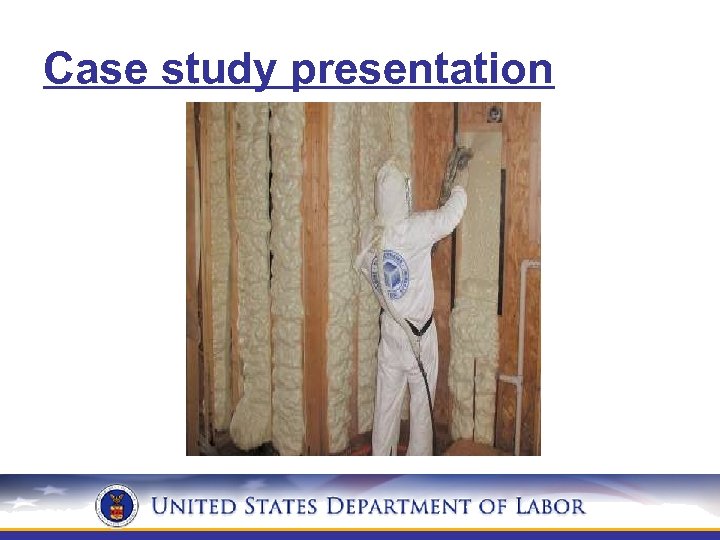

Case study presentation INTERIOR WALLS courtesy Icynene

Pre-planning the Job • Develop a check list – Before starting the job – Setting up the job site – The job – Post job wrap up – Clean-up

Before starting the job • Develop checklist • Train workers • Communication plan • Set up control measures • Plan for emergencies

Hazard Communication • Communicate all hazards via: – MSDS – Labeling of all hazardous substances – Warning signs

Hazard Communication - MSDS • Material Safety Data Sheets – Integral part of communication strategy – Must be readily available to all affected workers – Must be comprehensive

Hazard Communication - MSDS should contain the following: – Identify known hazards and exposure routes • Includes skin and other relevant health effects beyond asthma – Identify appropriate first-aid and medical measures – Identify appropriate exposure controls and PPE (skin and respiratory) – Address need for adequate containment and ventilation • Includes use of filters (bed-liner guidance) • Generation of dust – may contain isocyanates (ongoing research area)

Hazard Communication – New Communication Rule • Current - Hazard Communication – 29 CFR 1910. 1200 (general industry) – Others apply for construction; maritime; long shore • New - Global Harmonization System (GHS) – Proposed rulemaking • For MSDS – ANSI 400 standard – 16 Section format » Already in use with current standard – Comment period has ended – Public hearings ongoing

Training • Employers need to train workers on: – Hazards associated with use of ALL hazardous chemicals including Isocyanates and other SPF ingredients – Proper control measures – Proper use of PPE – Protecting those in adjacent areas – Appropriate ventilation

Training • Training should be available to all appropriate workers • Training material is available on web: – OSHA – NIOSH – ACC/Polyurethane Industry

Setting up the Jobsite • Exposure control measures – Worker protection – Safety considerations • Staging the equipment to reduce safety hazards

Staging the jobsite • Place air movers and supplied air sources (if used) out of source of contaminant • Eliminate trip hazards • Reduce or eliminate fire hazards

Staging the Jobsite • Make certain all equipment is in good working order

The Job

Exposures – Spray Application • Vapor, mist, particulates (isocyanates, amines) can migrate to other rooms or floors

Evidence of Exposures in Adjacent Areas Information from an industry research study: – Isocyanate vapors drifted throughout building after application of SPF w/i 20 minutes • Mostly lower floors – Exposure levels above the PEL in adjacent areas • More than 20 feet away from applicator – Also found in truck trailer

Exposures – Trimming Foam • Cutting, scraping foam generates dust

Appropriate Exposure Control • Exposures should be controlled whenever possible – PPE should be last resort • Use hierarchy of controls – Problems with compliance • Need for education and training • Develop best practices for work activities – Enclosures or partitions – Dust control measures – Proper air circulation and ventilation

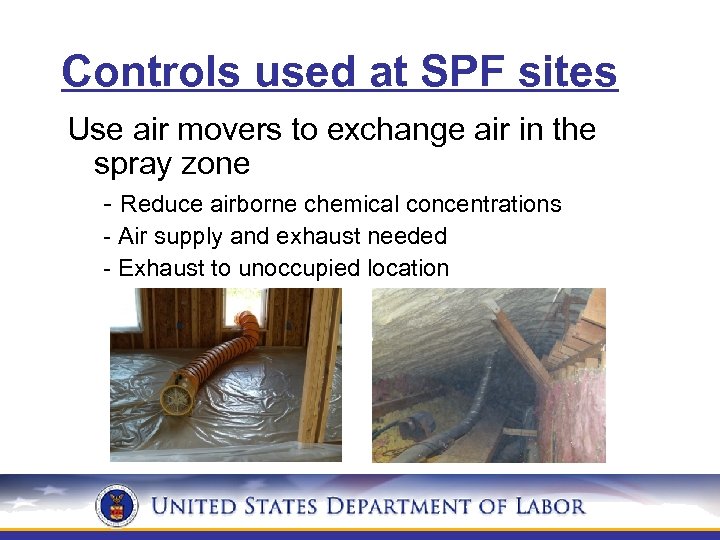

Controls used at SPF sites Use air movers to exchange air in the spray zone - Reduce airborne chemical concentrations - Air supply and exhaust needed - Exhaust to unoccupied location

Appropriate Exposure Control Ventilation Considerations • Ventilation crucial for worker safety – Especially in confined spaces where combustible gases can build up • Only vent to outside using EPA approved filter – Protect workers or passers-by outside – Similar methods can be adapted from measures used in truck bed-liner industry

Appropriate Exposure Control • Consider all phases of operation – Start to finish, including clean-up – Consider use of PPE for clean-up crew • May be same as operator/helper • Training is essential – Consider developing checklist to ensure compliance

Appropriate Exposure Control Proper Use of PPE • Primary worker (spray applicator): – Full chemical resistant body cover (no exposed skin) – Gloves, over-boots – Appropriate respirator with full face mask • Helpers (need to evaluate on case-by-case basis) – Full skin protection and gloves (no skin exposed) – Full face mask • Adjacent workers • Train ALL workers

Other Job site considerations • Confined spaces • Emergency and medical planning – Monitoring employees health

Cleanup • Make certain workers handling contaminated surfaces use appropriate PPE • Dispose of all hazardous materials properly

Other Considerations Long term stability of SPF: – Fully cured polyurethane foam is not considered a problem at this time – Ongoing research area – Heating, welding, or grinding may generate isocyanates and other hazards – Fires and thermal degradation can generate and release hydrogen cyanide, carbon monoxide, amines, and isocyanates

Summary/Concluding Remarks • Communication and training is key to safe use and handling of SPF • Employers should develop a workplace strategy for jobsites prior to initiating work • OSHA is developing guidance material for work-place safety with SPF

Additional Information • OSHA assistance – OSHA has free consultation program • Small and medium sized businesses – All 50 states participate – “Full service consultation" • Covers all working conditions, includes assistance in establishing effective workplace safety and health programs, with emphasis on preventing worker injuries and illnesses. Assistance may also include training and education for the employer and his or her employees and supervisors as well. – “Limited service consultation” • Consultant focuses on more specific workplace problems or specific issues or hazardous processes relating to a particular business – Information available on website: www. osha. gov

Contact information: Janet Carter DOL/OSHA Directorate of Standards and Guidance 200 Constitution Ave, NW Room N 3718 Washington, DC 20210 (202) 693 -2282 carter. janet@dol. gov

20dd6a09f460e31628278001c1368f39.ppt