001b962054f05d10093a9ef7c2349052.ppt

- Количество слайдов: 16

MAKE OR BUY DECESION FOR FILM COATING MATERIAL

1. Consistency In Colour a. Advanced colour matching system. Once a shade is produced It is stored in the system for reproducibility. b. Over 30 years experience in colour producing and matching. c. Jet Milled Colours. Offering uniform particle size & even distribution of colour. In uniformity of film thickness a. Better homogenization of all the constituents of b. The film coating systems. c. b. Optimised concentration of Polymers & Plasticiser

2. Problems in preparation at your shop floor a. To many ingredients to be dispensed especially if the product is coated in different lots. b. Colour uniformity has to be constantly monitored. c. Colloid milling is a must so as to avoid colour variation. d. Skilled workers are always required to be present during all the steps of the coating operation. e. Prepared coating suspensions once stored beyond 36 hours have to be colloid milled again before use, could f. lead to shade variation.

3. Saving in Time In Production a. Higher Reconstitution level up to 20% b. Coating solution preparation is single step stirring process. In faster introduction of new products a. Samples of the Coating material and Coated tablets in various shades are made available immediately on request, thereby eliminating the need of spending your R&D time. b. Your product range can have various colours for brand identification.

4. Multiple sources vs. single source of supply a. As against different sources for supply of different ingredients of Film Coating material there is a single source offering many advantages.

5. Fixing Responsibility for quality of Raw materials • Multiple suppliers are involved and responsibility for bad quality cannot be pinpointed. • Being our own formula we take the complete responsibility for your product problems due to bad coating. • We give technical backup unlike suppliers involved in multiple sourcing

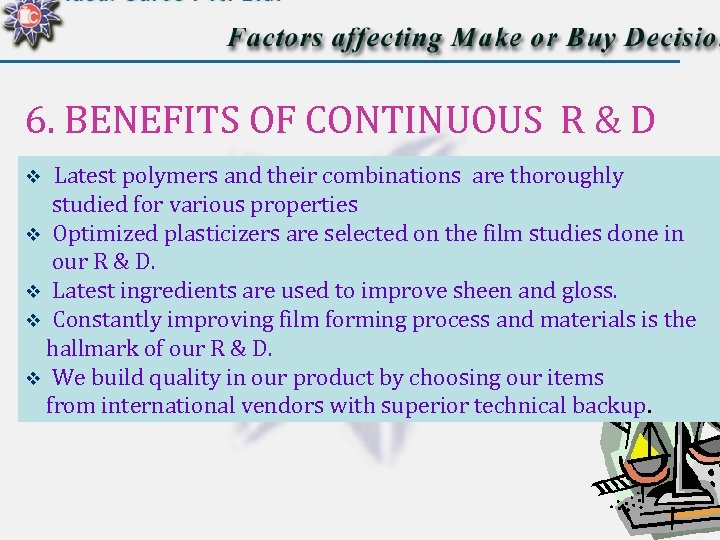

6. BENEFITS OF CONTINUOUS R & D Latest polymers and their combinations are thoroughly studied for various properties v Optimized plasticizers are selected on the film studies done in our R & D. v Latest ingredients are used to improve sheen and gloss. v Constantly improving film forming process and materials is the hallmark of our R & D. v We build quality in our product by choosing our items from international vendors with superior technical backup. v

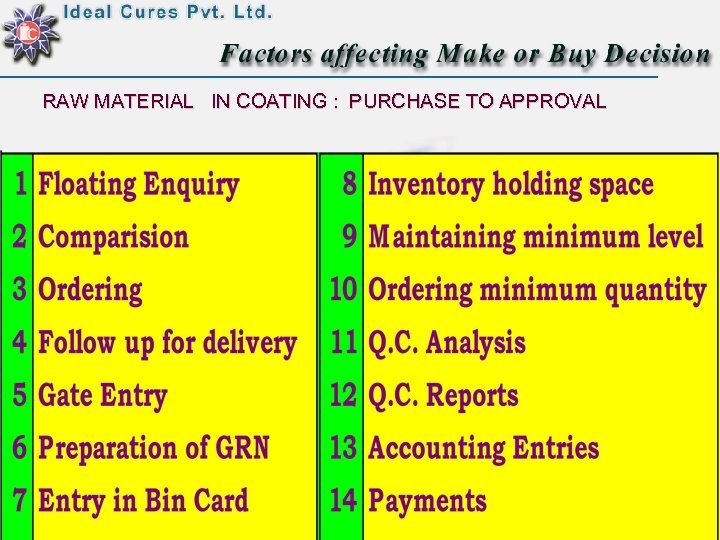

RAW MATERIAL IN COATING : PURCHASE TO APPROVAL

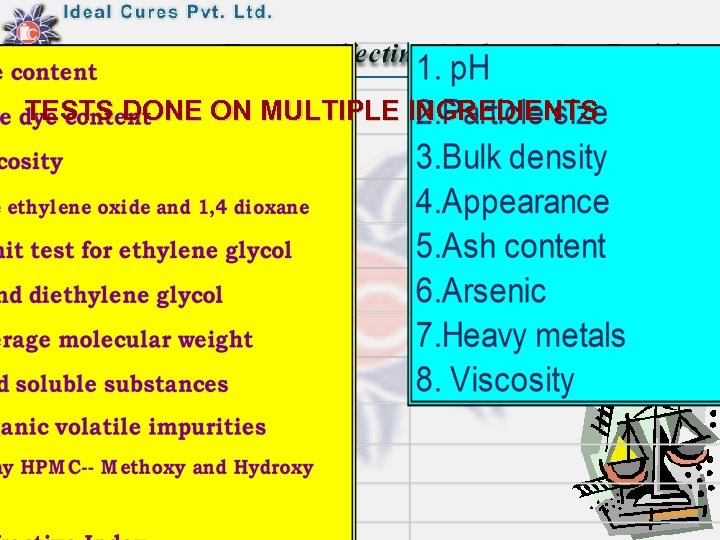

TESTS DONE ON MULTIPLE INGREDIENTS

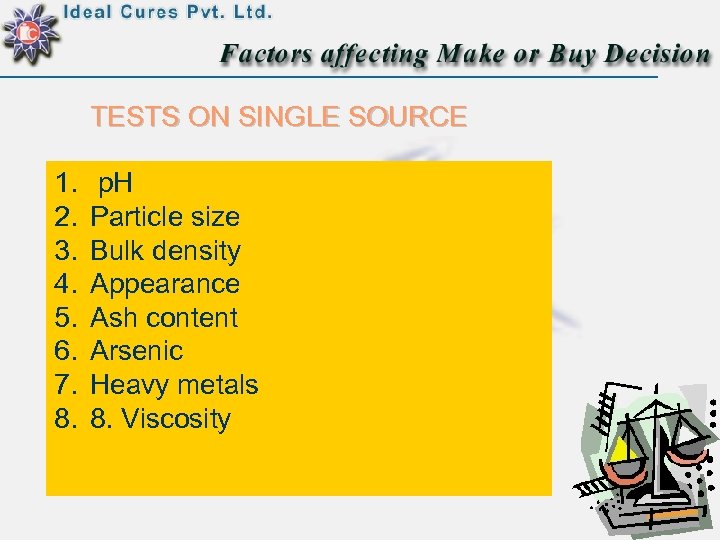

TESTS ON SINGLE SOURCE 1. 2. 3. 4. 5. 6. 7. 8. p. H Particle size Bulk density Appearance Ash content Arsenic Heavy metals 8. Viscosity

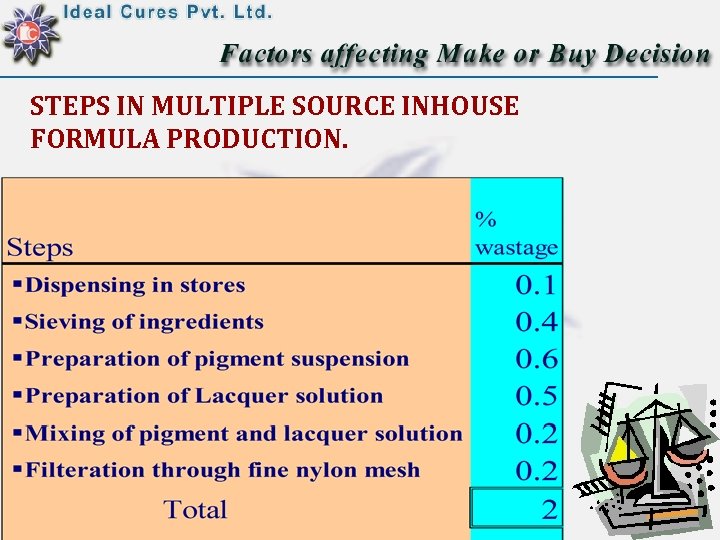

STEPS IN MULTIPLE SOURCE INHOUSE FORMULA PRODUCTION.

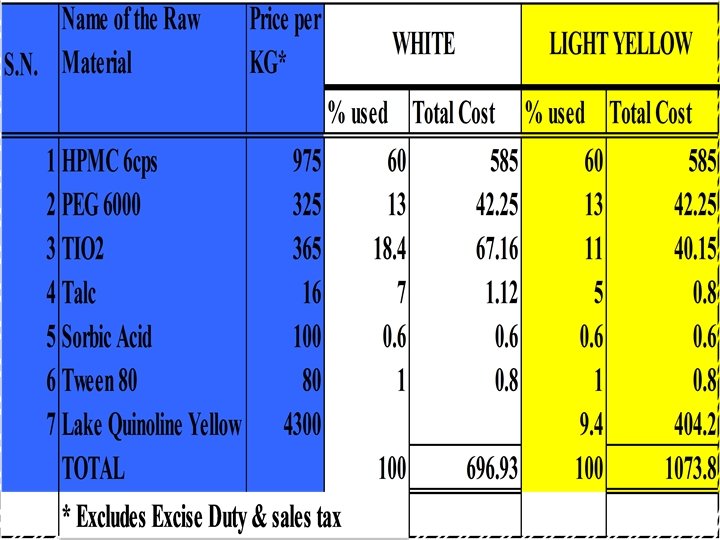

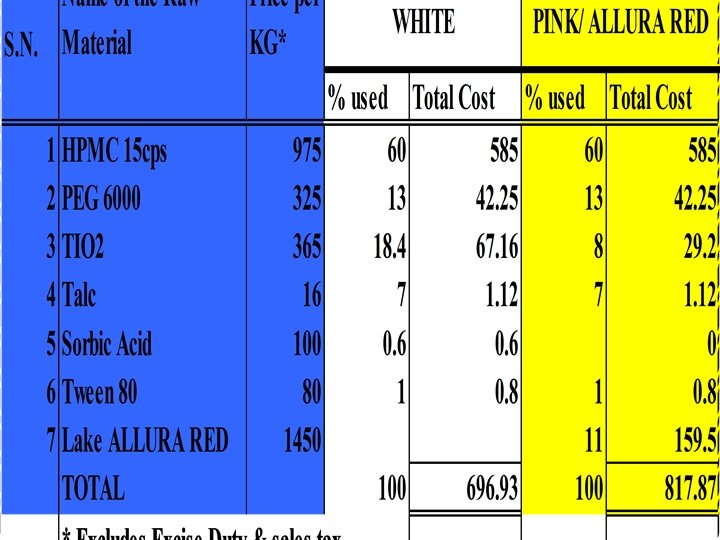

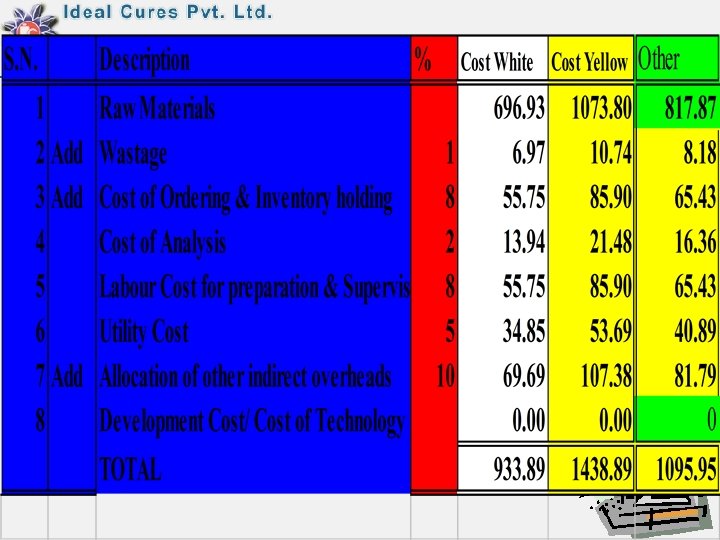

COST EFFECTIVENESS Raw Material DIRECT COST IN DIRECT COST Utilities Labour Cost of Order Processing & Inventory holding Cost of Analysis Cost of Rejections/ Rework

COST EFFECTIVENESS OTHER APPORTIONABLE COST Benefit of Continuous R&D Single source responsibility & Tech. Service Faster Introduction of Newer Products Avoidance of Problems in manufacturing & Preparation

001b962054f05d10093a9ef7c2349052.ppt