581558de4ac8934b905177e45655f359.ppt

- Количество слайдов: 162

MAINTENANCE MANAGEMENT MSGT ABBOTT

OVERVIEW To provide you with the knowledge and skills necessary to supervise MIMMS-AIS and an Engineer Supply Support system

MAINTENANCE MANAGEMENT Ø TERMINAL LEARNING OBJECTIVE Ø ENABLING LEARNING OBJECTIVES

MEDIA This period of instruction will be taught by the lecture method, aided by detailed outline, student outlines, computer generated slides, demonstrations and practical applications.

EVALUATION There will be written and performance examinations at the times indicated on your schedule.

TURN TO DPR “B” IN THE MIMMS REPORTS BINDER

DPR UM-4790 -5 CHAPTER 17. PG. 17 -19

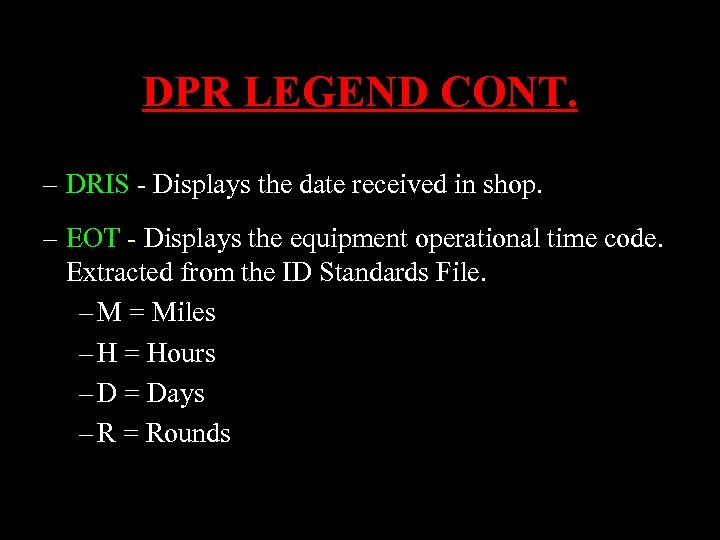

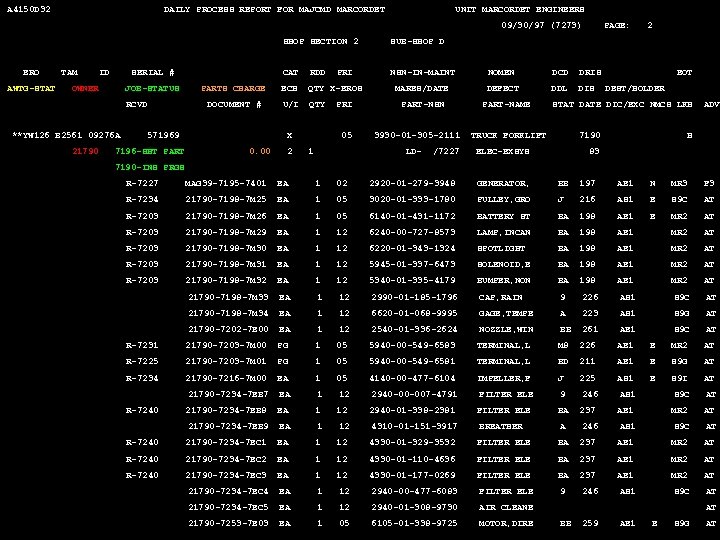

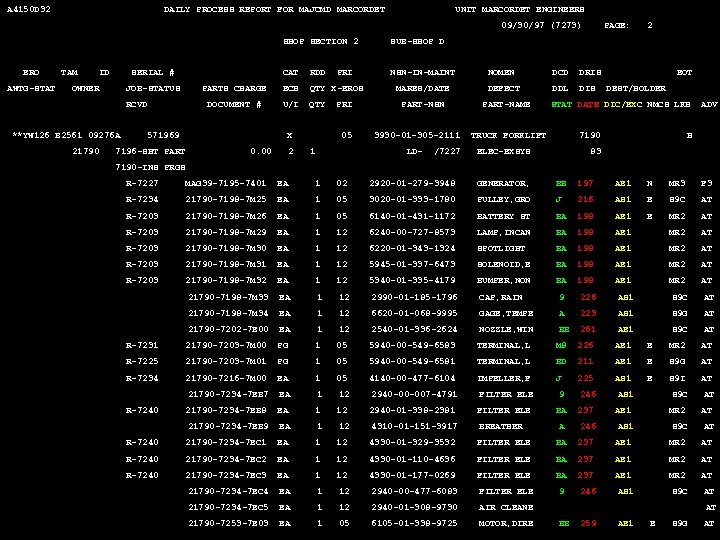

DAILY PROCESS REPORT Description. This daily report lists active Equipment Repair Orders (EROs) by shop for maintenance managers at all levels. (UM 4790 -5 Fig. 17 -5 Page 17 -28) Ø EROs which have had action taken will be indicated by two asterisks (**) to the left of the ERO number. Ø The Job Status field is capable of presenting up to ten history entries. Quantity over ten will cause the oldest one to fall off the record.

DAILY PROCESS REPORT Ø 9 TRANSACTION: (Closing out the ERO) Will print the following data: üClosed Date üJob Status üCiv. Labor Charge üMilitary Labor üParts Charge

DAILY PROCESS REPORT Ø Supply Status. üNormally entered automatically by: § SASSY: Supported Activities Supply Support System § MILSTRIP: Military Standard Requisitioning And Issue Procedures üUse of a “ 7 Transaction” will manually enter status.

DAILY PROCESS REPORT USE. The information on this report provides the complete history of an item in the maintenance cycle. Ø Distribution of this report should be at the shop section and Unit MMO. Ø Each open ERO is presented in shop section/ERO sequence. ü First two lines present basic identification data and current maintenance status. ü Third line for each ERO is a listing of repair parts requirements and the supply action to date on these requirements.

DAILY PROCESS REPORT Ø Spot situations where maintenance has added on parts which may indicate faulty initial inspection. Ø Identify repeat parts which may indicate: ü Parts previously RCVD were applied elsewhere ü Initial inspection was faulty ü Parts previously RCVD were faulty or damaged ü Mechanic lost the part

DAILY PROCESS REPORT Ø Identify misuse of category codes, priorities, and NMCS/NMCM. Ø MMO can identify parts which have long lead times based on its current status. Ø Is a tool to reconcile with SASSY. ü Information concerning reconciliation refer to current editions of MCO P 4790 -2 and UM 4400 -124.

DAILY PROCESS REPORT Ø Via a T-Transaction the MMO can identify the parts on order at a different echelon of maintenance. Ø Shows labor and material resources expended for a given ERO upon being closed.

REVIEW Ø We have discussed DPR: ü Description ü Use QUESTIONS?

BREAK!!!

DPR LEGEND 1 FIRST LINE. – ERO - Displays the equipment repair order number. (UM 4790 -5, pg. 21 -3) – TAM - Displays the table of authorized material control number of the equip. undergoing maintenance. – ID - Displays the identification number of the equip. undergoing maintenance.

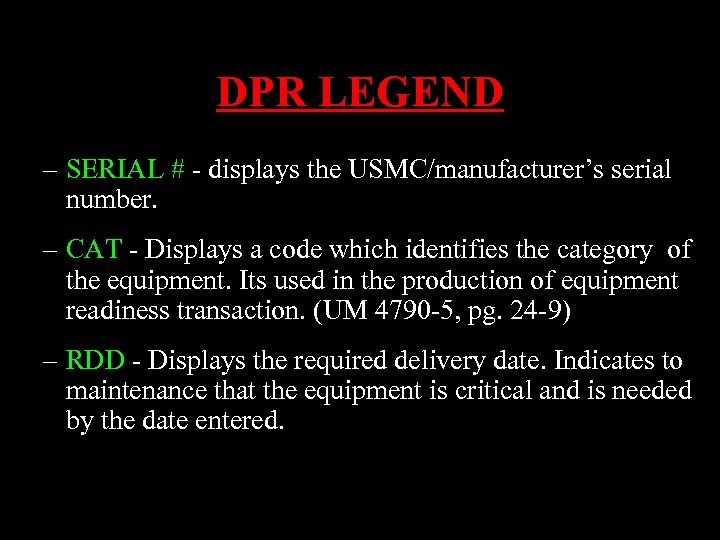

DPR LEGEND – SERIAL # - displays the USMC/manufacturer’s serial number. – CAT - Displays a code which identifies the category of the equipment. Its used in the production of equipment readiness transaction. (UM 4790 -5, pg. 24 -9) – RDD - Displays the required delivery date. Indicates to maintenance that the equipment is critical and is needed by the date entered.

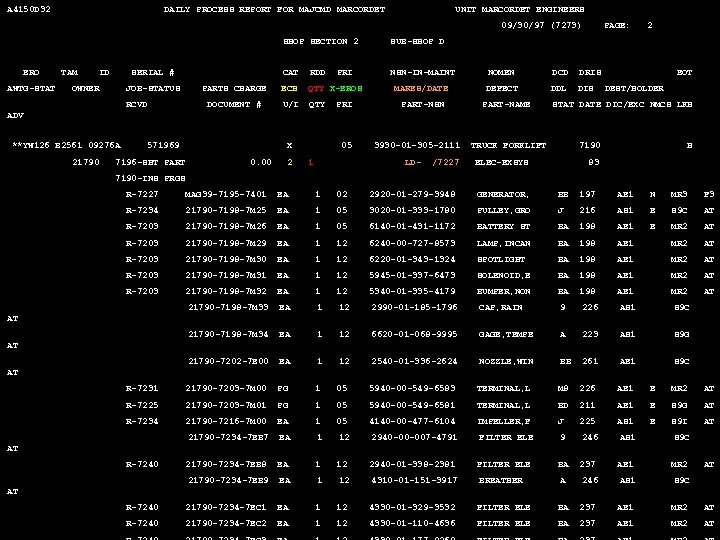

A 4150 D 32 DAILY PROCESS REPORT FOR MAJCMD MARCORDET UNIT MARCORDET ENGINEERS 9/30/97 (7273) PAGE: 2 0 SHOP SECTION 2 SUB-SHOP D ERO TAM ID SERIAL # CAT RDD PRI NSN-IN-MAINT NOMEN DCD DRIS EOT AWTG-STAT OWNER JOB-STATUS PARTS CHARGE ECH QTY X-EROS MARES/DATE DEFECT DDL DIS DEST/HOLDER RCVD DOCUMENT # U/I QTY PRI PART-NSN PART-NAME STAT DATE DIC/EXC NMCS LKH ADV **YW 126 B 2561 09276 A 571969 X 05 3930 -01 -305 -2111 TRUCK FORKLIFT 7190 H 21790 7196 -SHT PART 0. 00 2 1 LD- /7227 ELEC-EXSYS 83 7190 -INS PRGS R-7227 MAG 39 -7195 -7401 EA 1 02 2920 -01 -279 -3948 GENERATOR, BB 197 AE 1 N MR 3 F 3 R-7234 21790 -7198 -7 M 25 EA 1 05 3020 -01 -333 -1780 PULLEY, GRO J 216 AS 1 E S 9 C AT R-7203 21790 -7198 -7 M 26 EA 1 05 6140 -01 -431 -1172 BATTERY ST BA 198 AE 1 E MR 2 AT R-7203 21790 -7198 -7 M 29 EA 1 12 6240 -00 -727 -8573 LAMP, INCAN BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 30 EA 1 12 6220 -01 -343 -1324 SPOTLIGHT BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 31 EA 1 12 5945 -01 -337 -6473 SOLENOID, E BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 32 EA 1 12 5340 -01 -335 -4179 BUMPER, NON BA 198 AE 1 MR 2 AT 21790 -7198 -7 M 33 EA 1 12 2990 -01 -185 -1796 CAP, RAIN 9 226 AS 1 S 9 C AT 21790 -7198 -7 M 34 EA 1 12 6620 -01 -068 -9995 GAGE, TEMPE A 223 AS 1 S 9 G AT 21790 -7202 -7 E 00 EA 1 12 2540 -01 -336 -2624 NOZZLE, WIN BB 261 AE 1 S 9 C AT R-7231 21790 -7203 -7 M 00 PG 1 05 5940 -00 -549 -6583 TERMINAL, L M 8 226 AE 1 E MR 2 AT R-7225 21790 -7203 -7 M 01 PG 1 05 5940 -00 -549 -6581 TERMINAL, L BD 211 AE 1 E S 9 G AT R-7234 21790 -7216 -7 M 00 EA 1 05 4140 -00 -477 -6104 IMPELLER, F J 225 AS 1 E S 9 I AT 21790 -7234 -7 EB 7 EA 1 12 2940 -00 -007 -4791 FILTER ELE 9 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EB 8 EA 1 12 2940 -01 -338 -2381 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EB 9 EA 1 12 4310 -01 -151 -3917 BREATHER A 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EC 1 EA 1 12 4330 -01 -329 -3532 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 2 EA 1 12 4330 -01 -110 -4636 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 3 EA 1 12 4330 -01 -177 -0269 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EC 4 EA 1 12 2940 -00 -477 -6083 FILTER ELE 9 246 AS 1 S 9 C AT 21790 -7234 -7 EC 5 EA 1 12 2940 -01 -308 -9730 AIR CLEANE AT 21790 -7253 -7 E 03 EA 1 05 6105 -01 -338 -9725 MOTOR, DIRE BB 259 AE 1 E S 9 G AT

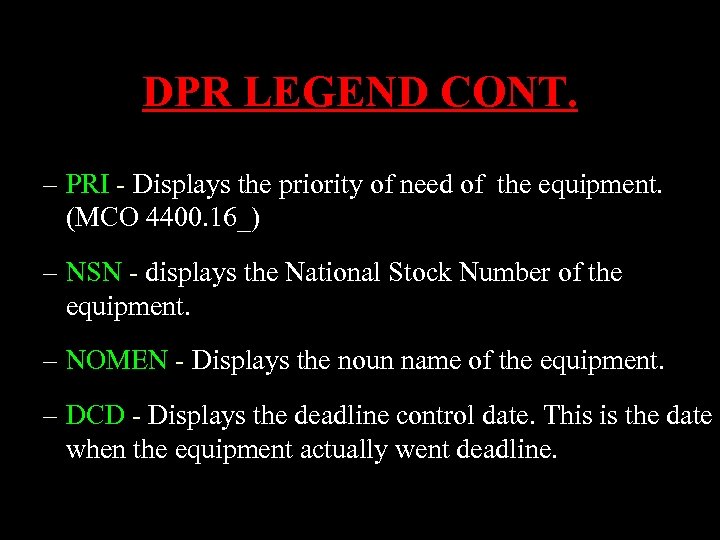

DPR LEGEND CONT. – PRI - Displays the priority of need of the equipment. (MCO 4400. 16_) – NSN - displays the National Stock Number of the equipment. – NOMEN - Displays the noun name of the equipment. – DCD - Displays the deadline control date. This is the date when the equipment actually went deadline.

DPR LEGEND CONT. – DRIS - Displays the date received in shop. – EOT - Displays the equipment operational time code. Extracted from the ID Standards File. – M = Miles – H = Hours – D = Days – R = Rounds

A 4150 D 32 DAILY PROCESS REPORT FOR MAJCMD MARCORDET UNIT MARCORDET ENGINEERS 9/30/97 (7273) PAGE: 2 0 SHOP SECTION 2 SUB-SHOP D ERO TAM ID SERIAL # CAT RDD PRI NSN-IN-MAINT NOMEN DCD DRIS EOT AWTG-STAT OWNER JOB-STATUS PARTS CHARGE ECH QTY X-EROS MARES/DATE DEFECT DDL DIS DEST/HOLDER RCVD DOCUMENT # U/I QTY PRI PART-NSN PART-NAME STAT DATE DIC/EXC NMCS LKH ADV **YW 126 B 2561 09276 A 571969 X 05 3930 -01 -305 -2111 TRUCK FORKLIFT 7190 H 21790 7196 -SHT PART 0. 00 2 1 LD- /7227 ELEC-EXSYS 83 7190 -INS PRGS R-7227 MAG 39 -7195 -7401 EA 1 02 2920 -01 -279 -3948 GENERATOR, BB 197 AE 1 N MR 3 F 3 R-7234 21790 -7198 -7 M 25 EA 1 05 3020 -01 -333 -1780 PULLEY, GRO J 216 AS 1 E S 9 C AT R-7203 21790 -7198 -7 M 26 EA 1 05 6140 -01 -431 -1172 BATTERY ST BA 198 AE 1 E MR 2 AT R-7203 21790 -7198 -7 M 29 EA 1 12 6240 -00 -727 -8573 LAMP, INCAN BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 30 EA 1 12 6220 -01 -343 -1324 SPOTLIGHT BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 31 EA 1 12 5945 -01 -337 -6473 SOLENOID, E BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 32 EA 1 12 5340 -01 -335 -4179 BUMPER, NON BA 198 AE 1 MR 2 AT 21790 -7198 -7 M 33 EA 1 12 2990 -01 -185 -1796 CAP, RAIN 9 226 AS 1 S 9 C AT 21790 -7198 -7 M 34 EA 1 12 6620 -01 -068 -9995 GAGE, TEMPE A 223 AS 1 S 9 G AT 21790 -7202 -7 E 00 EA 1 12 2540 -01 -336 -2624 NOZZLE, WIN BB 261 AE 1 S 9 C AT R-7231 21790 -7203 -7 M 00 PG 1 05 5940 -00 -549 -6583 TERMINAL, L M 8 226 AE 1 E MR 2 AT R-7225 21790 -7203 -7 M 01 PG 1 05 5940 -00 -549 -6581 TERMINAL, L BD 211 AE 1 E S 9 G AT R-7234 21790 -7216 -7 M 00 EA 1 05 4140 -00 -477 -6104 IMPELLER, F J 225 AS 1 E S 9 I AT 21790 -7234 -7 EB 7 EA 1 12 2940 -00 -007 -4791 FILTER ELE 9 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EB 8 EA 1 12 2940 -01 -338 -2381 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EB 9 EA 1 12 4310 -01 -151 -3917 BREATHER A 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EC 1 EA 1 12 4330 -01 -329 -3532 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 2 EA 1 12 4330 -01 -110 -4636 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 3 EA 1 12 4330 -01 -177 -0269 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EC 4 EA 1 12 2940 -00 -477 -6083 FILTER ELE 9 246 AS 1 S 9 C AT 21790 -7234 -7 EC 5 EA 1 12 2940 -01 -308 -9730 AIR CLEANE AT 21790 -7253 -7 E 03 EA 1 05 6105 -01 -338 -9725 MOTOR, DIRE BB 259 AE 1 E S 9 G AT

REVIEW We have discussed the first line of the DPR.

QUESTIONS!? !

QUESTIONS TO YOU!!! Q. In what sequence is the DPR arranged? A. Shop Section / ERO Number Matrix Q. What does the first line of information on the DPR pertain to? A. Basic identification data and current maintenance status.

BREAK!!!

DPR LEGEND CONT. 2 SECOND LINE. – AWTG-STAT - Indicates the status of equip. prior to being inducted into the maint. Cycle or once maint. Has been completed. – OWNER - Displays the activity address code of the unit which owns the equipment.

DPR LEGEND CONT. – JOB STATUS - Reflects the actions which have occurred on the equip. and the date action was initiated. (Refer to UM 4790 -5 Chapter 24 page 24 -5) – PARTS CHARGE - Displays the accumulated parts charge for those parts that have been obtained.

A 4150 D 32 DAILY PROCESS REPORT FOR MAJCMD MARCORDET UNIT MARCORDET ENGINEERS 9/30/97 (7273) PAGE: 2 0 SHOP SECTION 2 SUB-SHOP D ERO TAM ID SERIAL # CAT RDD PRI NSN-IN-MAINT NOMEN DCD DRIS EOT AWTG-STAT OWNER JOB-STATUS PARTS CHARGE ECH QTY X-EROS MARES/DATE DEFECT DDL DIS DEST/HOLDER RCVD DOCUMENT # U/I QTY PRI PART-NSN PART-NAME STAT DATE DIC/EXC NMCS LKH ADV **YW 126 B 2561 09276 A 571969 X 05 3930 -01 -305 -2111 TRUCK FORKLIFT 7190 H 21790 7196 -SHT PART 0. 00 2 1 LD- /7227 ELEC-EXSYS 83 7190 -INS PRGS R-7227 MAG 39 -7195 -7401 EA 1 02 2920 -01 -279 -3948 GENERATOR, BB 197 AE 1 N MR 3 F 3 R-7234 21790 -7198 -7 M 25 EA 1 05 3020 -01 -333 -1780 PULLEY, GRO J 216 AS 1 E S 9 C AT R-7203 21790 -7198 -7 M 26 EA 1 05 6140 -01 -431 -1172 BATTERY ST BA 198 AE 1 E MR 2 AT R-7203 21790 -7198 -7 M 29 EA 1 12 6240 -00 -727 -8573 LAMP, INCAN BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 30 EA 1 12 6220 -01 -343 -1324 SPOTLIGHT BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 31 EA 1 12 5945 -01 -337 -6473 SOLENOID, E BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 32 EA 1 12 5340 -01 -335 -4179 BUMPER, NON BA 198 AE 1 MR 2 AT 21790 -7198 -7 M 33 EA 1 12 2990 -01 -185 -1796 CAP, RAIN 9 226 AS 1 S 9 C AT 21790 -7198 -7 M 34 EA 1 12 6620 -01 -068 -9995 GAGE, TEMPE A 223 AS 1 S 9 G AT 21790 -7202 -7 E 00 EA 1 12 2540 -01 -336 -2624 NOZZLE, WIN BB 261 AE 1 S 9 C AT R-7231 21790 -7203 -7 M 00 PG 1 05 5940 -00 -549 -6583 TERMINAL, L M 8 226 AE 1 E MR 2 AT R-7225 21790 -7203 -7 M 01 PG 1 05 5940 -00 -549 -6581 TERMINAL, L BD 211 AE 1 E S 9 G AT R-7234 21790 -7216 -7 M 00 EA 1 05 4140 -00 -477 -6104 IMPELLER, F J 225 AS 1 E S 9 I AT 21790 -7234 -7 EB 7 EA 1 12 2940 -00 -007 -4791 FILTER ELE 9 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EB 8 EA 1 12 2940 -01 -338 -2381 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EB 9 EA 1 12 4310 -01 -151 -3917 BREATHER A 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EC 1 EA 1 12 4330 -01 -329 -3532 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 2 EA 1 12 4330 -01 -110 -4636 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 3 EA 1 12 4330 -01 -177 -0269 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EC 4 EA 1 12 2940 -00 -477 -6083 FILTER ELE 9 246 AS 1 S 9 C AT 21790 -7234 -7 EC 5 EA 1 12 2940 -01 -308 -9730 AIR CLEANE AT 21790 -7253 -7 E 03 EA 1 05 6105 -01 -338 -9725 MOTOR, DIRE BB 259 AE 1 E S 9 G AT

DPR LEGEND CONT. – ECH - Displays the echelon of maintenance. 1 or 2 (organic), 3 or 4 (intermediate). – QTY - Displays the quantity of equip. undergoing maintenance. – X-EROS - Displays the up to two inter-shop/interechelon EROs for an item of equipment. – MARES/DATE – Displays the MARES logistics readiness indicator. Identifies the type of LM 2 readiness transaction that has been prepared for an ERO and the date of that transaction.

MARES/DATE Ø Contains codes, abbreviations and description of the Maint. Status on MARES Reportable Equip. üCat. Code of “M” generates this entry automatically. üJob Status Code generates the ML-IND, which describes the type of action taken. üGenerates an entry on the LM-2 and TAM Report

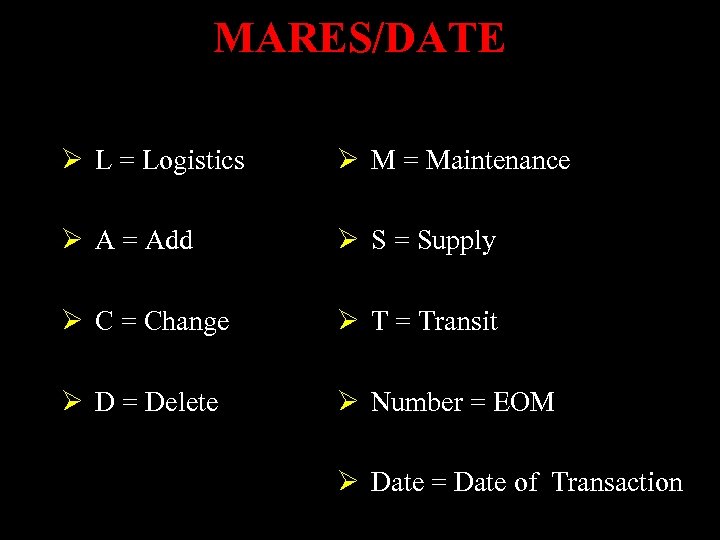

MARES/DATE Ø L = Logistics Ø M = Maintenance Ø A = Add Ø S = Supply Ø C = Change Ø T = Transit Ø D = Delete Ø Number = EOM Ø Date = Date of Transaction

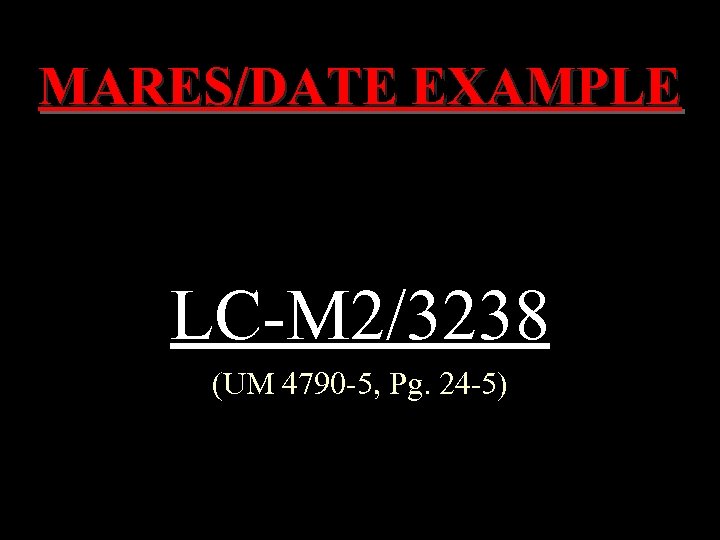

MARES/DATE EXAMPLE LC-M 2/3238 (UM 4790 -5, Pg. 24 -5)

A 4150 D 32 DAILY PROCESS REPORT FOR MAJCMD MARCORDET UNIT MARCORDET ENGINEERS 9/30/97 (7273) PAGE: 2 0 SHOP SECTION 2 SUB-SHOP D ERO TAM ID SERIAL # CAT RDD PRI NSN-IN-MAINT NOMEN DCD DRIS EOT AWTG-STAT OWNER JOB-STATUS PARTS CHARGE ECH QTY X-EROS MARES/DATE DEFECT DDL DIS DEST/HOLDER RCVD DOCUMENT # U/I QTY PRI PART-NSN PART-NAME STAT DATE DIC/EXC NMCS LKH ADV **YW 126 B 2561 09276 A 571969 X 05 3930 -01 -305 -2111 TRUCK FORKLIFT 7190 H 21790 7196 -SHT PART 0. 00 2 1 LD- /7227 ELEC-EXSYS 83 7190 -INS PRGS R-7227 MAG 39 -7195 -7401 EA 1 02 2920 -01 -279 -3948 GENERATOR, BB 197 AE 1 N MR 3 F 3 R-7234 21790 -7198 -7 M 25 EA 1 05 3020 -01 -333 -1780 PULLEY, GRO J 216 AS 1 E S 9 C AT R-7203 21790 -7198 -7 M 26 EA 1 05 6140 -01 -431 -1172 BATTERY ST BA 198 AE 1 E MR 2 AT R-7203 21790 -7198 -7 M 29 EA 1 12 6240 -00 -727 -8573 LAMP, INCAN BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 30 EA 1 12 6220 -01 -343 -1324 SPOTLIGHT BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 31 EA 1 12 5945 -01 -337 -6473 SOLENOID, E BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 32 EA 1 12 5340 -01 -335 -4179 BUMPER, NON BA 198 AE 1 MR 2 AT 21790 -7198 -7 M 33 EA 1 12 2990 -01 -185 -1796 CAP, RAIN 9 226 AS 1 S 9 C AT 21790 -7198 -7 M 34 EA 1 12 6620 -01 -068 -9995 GAGE, TEMPE A 223 AS 1 S 9 G AT 21790 -7202 -7 E 00 EA 1 12 2540 -01 -336 -2624 NOZZLE, WIN BB 261 AE 1 S 9 C AT R-7231 21790 -7203 -7 M 00 PG 1 05 5940 -00 -549 -6583 TERMINAL, L M 8 226 AE 1 E MR 2 AT R-7225 21790 -7203 -7 M 01 PG 1 05 5940 -00 -549 -6581 TERMINAL, L BD 211 AE 1 E S 9 G AT R-7234 21790 -7216 -7 M 00 EA 1 05 4140 -00 -477 -6104 IMPELLER, F J 225 AS 1 E S 9 I AT 21790 -7234 -7 EB 7 EA 1 12 2940 -00 -007 -4791 FILTER ELE 9 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EB 8 EA 1 12 2940 -01 -338 -2381 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EB 9 EA 1 12 4310 -01 -151 -3917 BREATHER A 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EC 1 EA 1 12 4330 -01 -329 -3532 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 2 EA 1 12 4330 -01 -110 -4636 FILTER ELE BA 237 AE 1 MR 2 AT

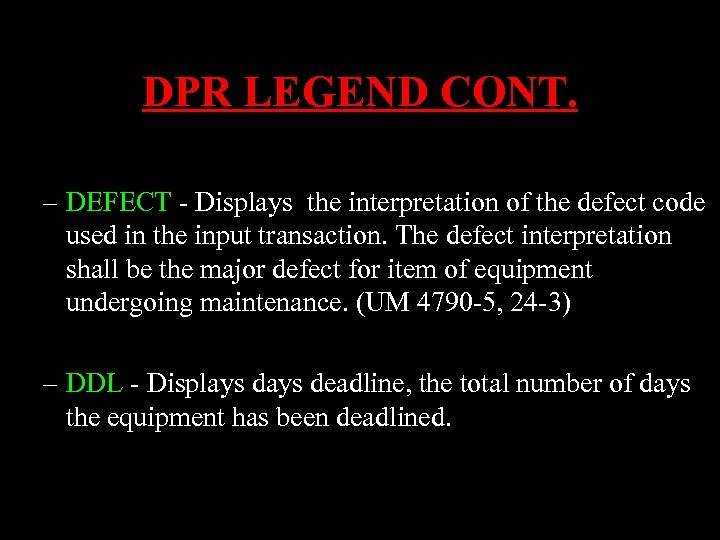

DPR LEGEND CONT. – DEFECT - Displays the interpretation of the defect code used in the input transaction. The defect interpretation shall be the major defect for item of equipment undergoing maintenance. (UM 4790 -5, 24 -3) – DDL - Displays deadline, the total number of days the equipment has been deadlined.

DPR LEGEND CONT. – DIS - Displays days in shop. This is the sum of the current processing date minus the DRIS. – DEST-HOLDER - Displays the destination ACC to which the equipment is being evacuated for repairs.

A 4150 D 32 DAILY PROCESS REPORT FOR MAJCMD MARCORDET UNIT MARCORDET ENGINEERS 9/30/97 (7273) PAGE: 2 0 SHOP SECTION 2 SUB-SHOP D ERO TAM ID SERIAL # CAT RDD PRI NSN-IN-MAINT NOMEN DCD DRIS EOT AWTG-STAT OWNER JOB-STATUS PARTS CHARGE ECH QTY X-EROS MARES/DATE DEFECT DDL DIS DEST/HOLDER RCVD DOCUMENT # U/I QTY PRI PART-NSN PART-NAME STAT DATE DIC/EXC NMCS LKH ADV **YW 126 B 2561 09276 A 571969 X 05 3930 -01 -305 -2111 TRUCK FORKLIFT 7190 H 21790 7196 -SHT PART 0. 00 2 1 LD- /7227 ELEC-EXSYS 83 7190 -INS PRGS R-7227 MAG 39 -7195 -7401 EA 1 02 2920 -01 -279 -3948 GENERATOR, BB 197 AE 1 N MR 3 F 3 R-7234 21790 -7198 -7 M 25 EA 1 05 3020 -01 -333 -1780 PULLEY, GRO J 216 AS 1 E S 9 C AT R-7203 21790 -7198 -7 M 26 EA 1 05 6140 -01 -431 -1172 BATTERY ST BA 198 AE 1 E MR 2 AT R-7203 21790 -7198 -7 M 29 EA 1 12 6240 -00 -727 -8573 LAMP, INCAN BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 30 EA 1 12 6220 -01 -343 -1324 SPOTLIGHT BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 31 EA 1 12 5945 -01 -337 -6473 SOLENOID, E BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 32 EA 1 12 5340 -01 -335 -4179 BUMPER, NON BA 198 AE 1 MR 2 AT 21790 -7198 -7 M 33 EA 1 12 2990 -01 -185 -1796 CAP, RAIN 9 226 AS 1 S 9 C AT 21790 -7198 -7 M 34 EA 1 12 6620 -01 -068 -9995 GAGE, TEMPE A 223 AS 1 S 9 G AT 21790 -7202 -7 E 00 EA 1 12 2540 -01 -336 -2624 NOZZLE, WIN BB 261 AE 1 S 9 C AT R-7231 21790 -7203 -7 M 00 PG 1 05 5940 -00 -549 -6583 TERMINAL, L M 8 226 AE 1 E MR 2 AT R-7225 21790 -7203 -7 M 01 PG 1 05 5940 -00 -549 -6581 TERMINAL, L BD 211 AE 1 E S 9 G AT R-7234 21790 -7216 -7 M 00 EA 1 05 4140 -00 -477 -6104 IMPELLER, F J 225 AS 1 E S 9 I AT 21790 -7234 -7 EB 7 EA 1 12 2940 -00 -007 -4791 FILTER ELE 9 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EB 8 EA 1 12 2940 -01 -338 -2381 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EB 9 EA 1 12 4310 -01 -151 -3917 BREATHER A 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EC 1 EA 1 12 4330 -01 -329 -3532 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 2 EA 1 12 4330 -01 -110 -4636 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 3 EA 1 12 4330 -01 -177 -0269 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EC 4 EA 1 12 2940 -00 -477 -6083 FILTER ELE 9 246 AS 1 S 9 C AT 21790 -7234 -7 EC 5 EA 1 12 2940 -01 -308 -9730 AIR CLEANE AT 21790 -7253 -7 E 03 EA 1 05 6105 -01 -338 -9725 MOTOR, DIRE BB 259 AE 1 E S 9 G AT

REVIEW Ø We discussed the second line of the DPR. QUESTIONS?

QUESTIONS TO YOU!!! Q. What does the second line of information on the DPR pertain to? A. Basic identification data and current maintenance status. Q. What does each element of the MARES Logistics Indicator LA-M 2/1059 mean? A. Logistics, Add, Maintenance, 2 nd EOM on 1059.

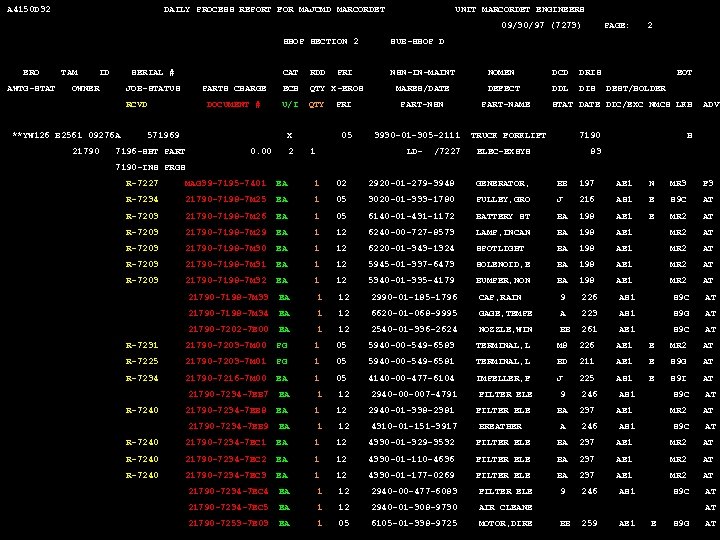

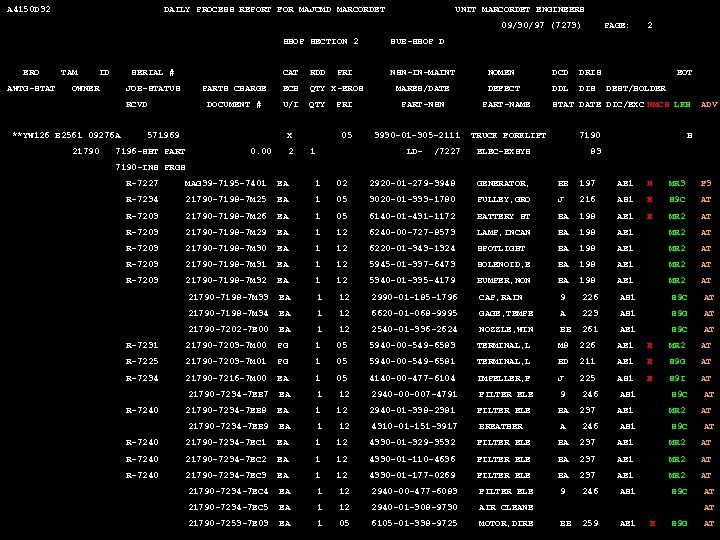

DPR LEGEND CONT. 3 THIRD LINE. – RCVD - This column serves two purposes. • First. When a part has been received and the receipt processed, an “R” and the Julian date of the receipt will appear. • Second. When a cancellation request has been inducted, a C and the Julian date will be posted. • If blank, it indicates the parts record is still open.

DPR LEGEND CONT. – DOCUMENT # - Displays the unit document number used for repair parts requisitioned or the maintenance float activity DOC number. – U/I - Displays the unit of issue of the item requested. – QTY - Displays the quantity of material requisitioned.

A 4150 D 32 DAILY PROCESS REPORT FOR MAJCMD MARCORDET UNIT MARCORDET ENGINEERS 9/30/97 (7273) PAGE: 2 0 SHOP SECTION 2 SUB-SHOP D ERO TAM ID SERIAL # CAT RDD PRI NSN-IN-MAINT NOMEN DCD DRIS EOT AWTG-STAT OWNER JOB-STATUS PARTS CHARGE ECH QTY X-EROS MARES/DATE DEFECT DDL DIS DEST/HOLDER RCVD DOCUMENT # U/I QTY PRI PART-NSN PART-NAME STAT DATE DIC/EXC NMCS LKH ADV **YW 126 B 2561 09276 A 571969 X 05 3930 -01 -305 -2111 TRUCK FORKLIFT 7190 H 21790 7196 -SHT PART 0. 00 2 1 LD- /7227 ELEC-EXSYS 83 7190 -INS PRGS R-7227 MAG 39 -7195 -7401 EA 1 02 2920 -01 -279 -3948 GENERATOR, BB 197 AE 1 N MR 3 F 3 R-7234 21790 -7198 -7 M 25 EA 1 05 3020 -01 -333 -1780 PULLEY, GRO J 216 AS 1 E S 9 C AT R-7203 21790 -7198 -7 M 26 EA 1 05 6140 -01 -431 -1172 BATTERY ST BA 198 AE 1 E MR 2 AT R-7203 21790 -7198 -7 M 29 EA 1 12 6240 -00 -727 -8573 LAMP, INCAN BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 30 EA 1 12 6220 -01 -343 -1324 SPOTLIGHT BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 31 EA 1 12 5945 -01 -337 -6473 SOLENOID, E BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 32 EA 1 12 5340 -01 -335 -4179 BUMPER, NON BA 198 AE 1 MR 2 AT 21790 -7198 -7 M 33 EA 1 12 2990 -01 -185 -1796 CAP, RAIN 9 226 AS 1 S 9 C AT 21790 -7198 -7 M 34 EA 1 12 6620 -01 -068 -9995 GAGE, TEMPE A 223 AS 1 S 9 G AT 21790 -7202 -7 E 00 EA 1 12 2540 -01 -336 -2624 NOZZLE, WIN BB 261 AE 1 S 9 C AT R-7231 21790 -7203 -7 M 00 PG 1 05 5940 -00 -549 -6583 TERMINAL, L M 8 226 AE 1 E MR 2 AT R-7225 21790 -7203 -7 M 01 PG 1 05 5940 -00 -549 -6581 TERMINAL, L BD 211 AE 1 E S 9 G AT R-7234 21790 -7216 -7 M 00 EA 1 05 4140 -00 -477 -6104 IMPELLER, F J 225 AS 1 E S 9 I AT 21790 -7234 -7 EB 7 EA 1 12 2940 -00 -007 -4791 FILTER ELE 9 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EB 8 EA 1 12 2940 -01 -338 -2381 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EB 9 EA 1 12 4310 -01 -151 -3917 BREATHER A 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EC 1 EA 1 12 4330 -01 -329 -3532 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 2 EA 1 12 4330 -01 -110 -4636 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 3 EA 1 12 4330 -01 -177 -0269 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EC 4 EA 1 12 2940 -00 -477 -6083 FILTER ELE 9 246 AS 1 S 9 C AT 21790 -7234 -7 EC 5 EA 1 12 2940 -01 -308 -9730 AIR CLEANE AT 21790 -7253 -7 E 03 EA 1 05 6105 -01 -338 -9725 MOTOR, DIRE BB 259 AE 1 E S 9 G AT

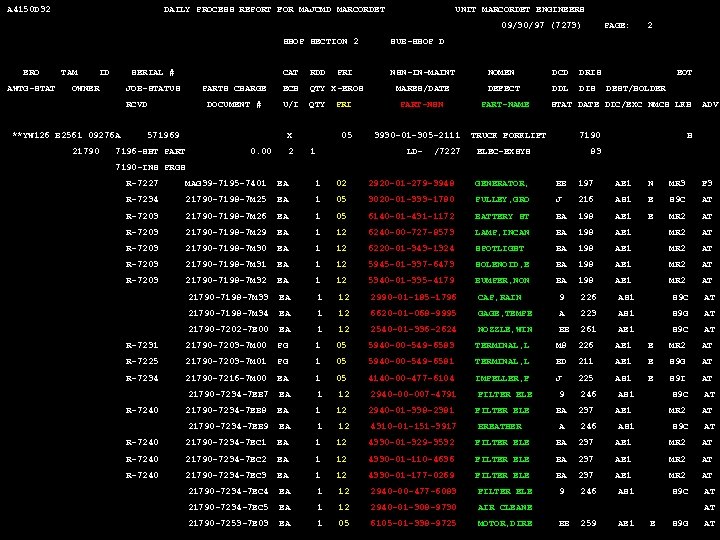

DPR LEGEND CONT. – PRI - Displays the priority of the requisition. Priority of the requisition may not exceed the priority of the ERO. – PART-NSN - Displays the national stock number or local stock number of the part. – PART-NAME - Displays the nomenclature of the part.

A 4150 D 32 DAILY PROCESS REPORT FOR MAJCMD MARCORDET UNIT MARCORDET ENGINEERS 9/30/97 (7273) PAGE: 2 0 SHOP SECTION 2 SUB-SHOP D ERO TAM ID SERIAL # CAT RDD PRI NSN-IN-MAINT NOMEN DCD DRIS EOT AWTG-STAT OWNER JOB-STATUS PARTS CHARGE ECH QTY X-EROS MARES/DATE DEFECT DDL DIS DEST/HOLDER RCVD DOCUMENT # U/I QTY PRI PART-NSN PART-NAME STAT DATE DIC/EXC NMCS LKH ADV **YW 126 B 2561 09276 A 571969 X 05 3930 -01 -305 -2111 TRUCK FORKLIFT 7190 H 21790 7196 -SHT PART 0. 00 2 1 LD- /7227 ELEC-EXSYS 83 7190 -INS PRGS R-7227 MAG 39 -7195 -7401 EA 1 02 2920 -01 -279 -3948 GENERATOR, BB 197 AE 1 N MR 3 F 3 R-7234 21790 -7198 -7 M 25 EA 1 05 3020 -01 -333 -1780 PULLEY, GRO J 216 AS 1 E S 9 C AT R-7203 21790 -7198 -7 M 26 EA 1 05 6140 -01 -431 -1172 BATTERY ST BA 198 AE 1 E MR 2 AT R-7203 21790 -7198 -7 M 29 EA 1 12 6240 -00 -727 -8573 LAMP, INCAN BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 30 EA 1 12 6220 -01 -343 -1324 SPOTLIGHT BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 31 EA 1 12 5945 -01 -337 -6473 SOLENOID, E BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 32 EA 1 12 5340 -01 -335 -4179 BUMPER, NON BA 198 AE 1 MR 2 AT 21790 -7198 -7 M 33 EA 1 12 2990 -01 -185 -1796 CAP, RAIN 9 226 AS 1 S 9 C AT 21790 -7198 -7 M 34 EA 1 12 6620 -01 -068 -9995 GAGE, TEMPE A 223 AS 1 S 9 G AT 21790 -7202 -7 E 00 EA 1 12 2540 -01 -336 -2624 NOZZLE, WIN BB 261 AE 1 S 9 C AT R-7231 21790 -7203 -7 M 00 PG 1 05 5940 -00 -549 -6583 TERMINAL, L M 8 226 AE 1 E MR 2 AT R-7225 21790 -7203 -7 M 01 PG 1 05 5940 -00 -549 -6581 TERMINAL, L BD 211 AE 1 E S 9 G AT R-7234 21790 -7216 -7 M 00 EA 1 05 4140 -00 -477 -6104 IMPELLER, F J 225 AS 1 E S 9 I AT 21790 -7234 -7 EB 7 EA 1 12 2940 -00 -007 -4791 FILTER ELE 9 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EB 8 EA 1 12 2940 -01 -338 -2381 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EB 9 EA 1 12 4310 -01 -151 -3917 BREATHER A 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EC 1 EA 1 12 4330 -01 -329 -3532 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 2 EA 1 12 4330 -01 -110 -4636 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 3 EA 1 12 4330 -01 -177 -0269 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EC 4 EA 1 12 2940 -00 -477 -6083 FILTER ELE 9 246 AS 1 S 9 C AT 21790 -7234 -7 EC 5 EA 1 12 2940 -01 -308 -9730 AIR CLEANE AT 21790 -7253 -7 E 03 EA 1 05 6105 -01 -338 -9725 MOTOR, DIRE BB 259 AE 1 E S 9 G AT

DPR LEGEND CONT. – STAT - Displays the current status on the part. This code is a two digit code, it indicates the status of the part at the source of supply. A single digit code indicates a mode of shipment. (UM 4400 -124 and Defense Logistics Agency handbook) – DATE - Displays the date the part went into its current status.

DPR LEGEND CONT. – DIC/EXC - Displays the type of status being provided. – Document Identifier Code (DIC) in the AE series identify a automatic supply status. DICs in the AS series identify a automatic shipment status. – SASSY Exception Codes (EXC) These will appear in a B series. ** DICs and Exception codes are located in the UM 4400 -124.

A 4150 D 32 DAILY PROCESS REPORT FOR MAJCMD MARCORDET UNIT MARCORDET ENGINEERS 9/30/97 (7273) PAGE: 2 0 SHOP SECTION 2 SUB-SHOP D ERO TAM ID SERIAL # CAT RDD PRI NSN-IN-MAINT NOMEN DCD DRIS EOT AWTG-STAT OWNER JOB-STATUS PARTS CHARGE ECH QTY X-EROS MARES/DATE DEFECT DDL DIS DEST/HOLDER RCVD DOCUMENT # U/I QTY PRI PART-NSN PART-NAME STAT DATE DIC/EXC NMCS LKH ADV **YW 126 B 2561 09276 A 571969 X 05 3930 -01 -305 -2111 TRUCK FORKLIFT 7190 H 21790 7196 -SHT PART 0. 00 2 1 LD- /7227 ELEC-EXSYS 83 7190 -INS PRGS R-7227 MAG 39 -7195 -7401 EA 1 02 2920 -01 -279 -3948 GENERATOR, BB 197 AE 1 N MR 3 F 3 R-7234 21790 -7198 -7 M 25 EA 1 05 3020 -01 -333 -1780 PULLEY, GRO J 216 AS 1 E S 9 C AT R-7203 21790 -7198 -7 M 26 EA 1 05 6140 -01 -431 -1172 BATTERY ST BA 198 AE 1 E MR 2 AT R-7203 21790 -7198 -7 M 29 EA 1 12 6240 -00 -727 -8573 LAMP, INCAN BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 30 EA 1 12 6220 -01 -343 -1324 SPOTLIGHT BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 31 EA 1 12 5945 -01 -337 -6473 SOLENOID, E BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 32 EA 1 12 5340 -01 -335 -4179 BUMPER, NON BA 198 AE 1 MR 2 AT 21790 -7198 -7 M 33 EA 1 12 2990 -01 -185 -1796 CAP, RAIN 9 226 AS 1 S 9 C AT 21790 -7198 -7 M 34 EA 1 12 6620 -01 -068 -9995 GAGE, TEMPE A 223 AS 1 S 9 G AT 21790 -7202 -7 E 00 EA 1 12 2540 -01 -336 -2624 NOZZLE, WIN BB 261 AE 1 S 9 C AT R-7231 21790 -7203 -7 M 00 PG 1 05 5940 -00 -549 -6583 TERMINAL, L M 8 226 AE 1 E MR 2 AT R-7225 21790 -7203 -7 M 01 PG 1 05 5940 -00 -549 -6581 TERMINAL, L BD 211 AE 1 E S 9 G AT R-7234 21790 -7216 -7 M 00 EA 1 05 4140 -00 -477 -6104 IMPELLER, F J 225 AS 1 E S 9 I AT 21790 -7234 -7 EB 7 EA 1 12 2940 -00 -007 -4791 FILTER ELE 9 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EB 8 EA 1 12 2940 -01 -338 -2381 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EB 9 EA 1 12 4310 -01 -151 -3917 BREATHER A 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EC 1 EA 1 12 4330 -01 -329 -3532 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 2 EA 1 12 4330 -01 -110 -4636 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 3 EA 1 12 4330 -01 -177 -0269 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EC 4 EA 1 12 2940 -00 -477 -6083 FILTER ELE 9 246 AS 1 S 9 C AT 21790 -7234 -7 EC 5 EA 1 12 2940 -01 -308 -9730 AIR CLEANE AT 21790 -7253 -7 E 03 EA 1 05 6105 -01 -338 -9725 MOTOR, DIRE BB 259 AE 1 E S 9 G AT

DPR LEGEND CONT. – NMCS - Displays the not mission capable supply indicator. – N = indicates NMCS (deadline) – E = indicates anticipated NMCS (degraded) – 9 = indicates items requiring expedited handling – These indicators can be located in the TM 4700 -15/1 H page 2 -3 -7. – LKH - Identifies the Last Known Holder of the transaction. (UM 4400 -71) – A LKH of FLT indicates maintenance float is the supply source.

DPR LEGEND CONT. – ADV - Displays the Advice Codes. MIMMS Advice Codes identify information relative to the processing of the requisition and are not input into the supply system. ** MIMMS Advice Codes are located in the legend for the 4 (parts) transaction in the UM 4790 -5 Chapter 6 and Chapter 24 page 24 -35. Additional advice codes can be located in the UM 4400 -124.

A 4150 D 32 DAILY PROCESS REPORT FOR MAJCMD MARCORDET UNIT MARCORDET ENGINEERS 9/30/97 (7273) PAGE: 2 0 SHOP SECTION 2 SUB-SHOP D ERO TAM ID SERIAL # CAT RDD PRI NSN-IN-MAINT NOMEN DCD DRIS EOT AWTG-STAT OWNER JOB-STATUS PARTS CHARGE ECH QTY X-EROS MARES/DATE DEFECT DDL DIS DEST/HOLDER RCVD DOCUMENT # U/I QTY PRI PART-NSN PART-NAME STAT DATE DIC/EXC NMCS LKH ADV **YW 126 B 2561 09276 A 571969 X 05 3930 -01 -305 -2111 TRUCK FORKLIFT 7190 H 21790 7196 -SHT PART 0. 00 2 1 LD- /7227 ELEC-EXSYS 83 7190 -INS PRGS R-7227 MAG 39 -7195 -7401 EA 1 02 2920 -01 -279 -3948 GENERATOR, BB 197 AE 1 N MR 3 F 3 R-7234 21790 -7198 -7 M 25 EA 1 05 3020 -01 -333 -1780 PULLEY, GRO J 216 AS 1 E S 9 C AT R-7203 21790 -7198 -7 M 26 EA 1 05 6140 -01 -431 -1172 BATTERY ST BA 198 AE 1 E MR 2 AT R-7203 21790 -7198 -7 M 29 EA 1 12 6240 -00 -727 -8573 LAMP, INCAN BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 30 EA 1 12 6220 -01 -343 -1324 SPOTLIGHT BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 31 EA 1 12 5945 -01 -337 -6473 SOLENOID, E BA 198 AE 1 MR 2 AT R-7203 21790 -7198 -7 M 32 EA 1 12 5340 -01 -335 -4179 BUMPER, NON BA 198 AE 1 MR 2 AT 21790 -7198 -7 M 33 EA 1 12 2990 -01 -185 -1796 CAP, RAIN 9 226 AS 1 S 9 C AT 21790 -7198 -7 M 34 EA 1 12 6620 -01 -068 -9995 GAGE, TEMPE A 223 AS 1 S 9 G AT 21790 -7202 -7 E 00 EA 1 12 2540 -01 -336 -2624 NOZZLE, WIN BB 261 AE 1 S 9 C AT R-7231 21790 -7203 -7 M 00 PG 1 05 5940 -00 -549 -6583 TERMINAL, L M 8 226 AE 1 E MR 2 AT R-7225 21790 -7203 -7 M 01 PG 1 05 5940 -00 -549 -6581 TERMINAL, L BD 211 AE 1 E S 9 G AT R-7234 21790 -7216 -7 M 00 EA 1 05 4140 -00 -477 -6104 IMPELLER, F J 225 AS 1 E S 9 I AT 21790 -7234 -7 EB 7 EA 1 12 2940 -00 -007 -4791 FILTER ELE 9 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EB 8 EA 1 12 2940 -01 -338 -2381 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EB 9 EA 1 12 4310 -01 -151 -3917 BREATHER A 246 AS 1 S 9 C AT R-7240 21790 -7234 -7 EC 1 EA 1 12 4330 -01 -329 -3532 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 2 EA 1 12 4330 -01 -110 -4636 FILTER ELE BA 237 AE 1 MR 2 AT R-7240 21790 -7234 -7 EC 3 EA 1 12 4330 -01 -177 -0269 FILTER ELE BA 237 AE 1 MR 2 AT 21790 -7234 -7 EC 4 EA 1 12 2940 -00 -477 -6083 FILTER ELE 9 246 AS 1 S 9 C AT 21790 -7234 -7 EC 5 EA 1 12 2940 -01 -308 -9730 AIR CLEANE AT 21790 -7253 -7 E 03 EA 1 05 6105 -01 -338 -9725 MOTOR, DIRE BB 259 AE 1 E S 9 G AT

REVIEW Ø We discussed the third line of the DPR. QUESTIONS?

QUESTIONS TO YOU!!! Q. What does the third line of information of the DPR pertain to? A. Repair part requirements and the supply action to date on these requirements. Q. Which entry indicates whether the part deadlines equipment, degrades equipment, or is a non-critical repair part? A. NMCS

BREAK!!!

DEMONSTRATION

BREAK!!!

PRACTICAL APPLICATION

REVIEW Ø You researched information presented on the Daily Process Report. QUESTIONS?

REVIEW Ø During this period we have: ü Discussed the DPR ü Observed a demonstration ü Researched information QUESTIONS?

QUESTIONS TO YOU!!! Q. The DPR provides maintenance managers at all levels visibility of what in their shops? A. All active EROs.

TURN TO DTL “B” IN THE MIMMS REPORTS BINDER

DAILY TRANSACTION LISTING UM-4790 -5 CHAPTER 17, PG. 17 -7

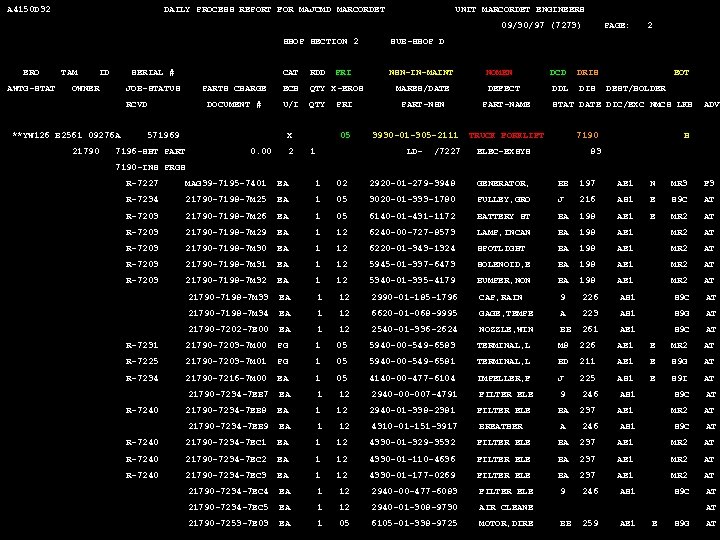

DAILY TRANSACTION LISTING Description. This report will provide visibility of input transactions which were accepted into the MIMMS daily cycle or rejected because of errors. Ø Transactions will be presented in the identical format they were entered. üDisplay transactions which were generated in response to other MIMMS or SASSY related input.

DAILY TRANSACTION LISTING CONT. Ø This report is divided into three sections: üTransactions processed with no errors. üTransactions processed with non-critical errors. üTransactions that did not process. Ø Transactions will appear in the applicable section.

DAILY TRANSACTION LISTING CONT. Ø Transactions with non-critical errors or did not process, an Error Code will be printed to the immediate right. ü This code indicates the type of error within that field. These Error Codes can be found in the UM 4790 -5 Chapter 24, page 24 -14. ü Any associated transaction submitted with an O, T, or O/T will be rejected if a fatal error appears on those transactions. ü A 4 transaction rejected for a Doc # or ERO # will cause rejections for the associated 5, 7, and/or 8 transactions.

REVIEW Ø During this period we have discussed: ü Description of the DTL QUESTIONS?

QUESTIONS TO YOU!!! Q. How many sections is the DTL divided into? A. Three.

BREAK!!!

DAILY TRANSACTION LISTING CONT. USE. The DTL is used to validate the Unit’s input to MIMMS. Ø This is accomplished by matching the previous day’s input data. Ø Unit MMO’s will monitor this report to ensure that prompt re-submissions of corrected transactions are accomplished either by Maintenance or Supply.

DAILY TRANSACTION LISTING CONT. Ø Transactions That Did Not Process must be corrected prior to them being entered into the system for that ERO. Ø MMO’s should look for common errors/rejects and conduct appropriate training. Ø Errors on the DTL should be corrected promptly with correct information on the next day’s cycle.

REVIEW Ø To this point we have discussed: ü Use of the DTL QUESTIONS?

QUESTIONS TO YOU!!! Q. What is the DTL used for? A. To validate the unit’s daily input into MIMMS.

BREAK!!!

DTL LEGEND The DTL contains each input transaction. Refer to Chapter 6 of the UM 4790 -5.

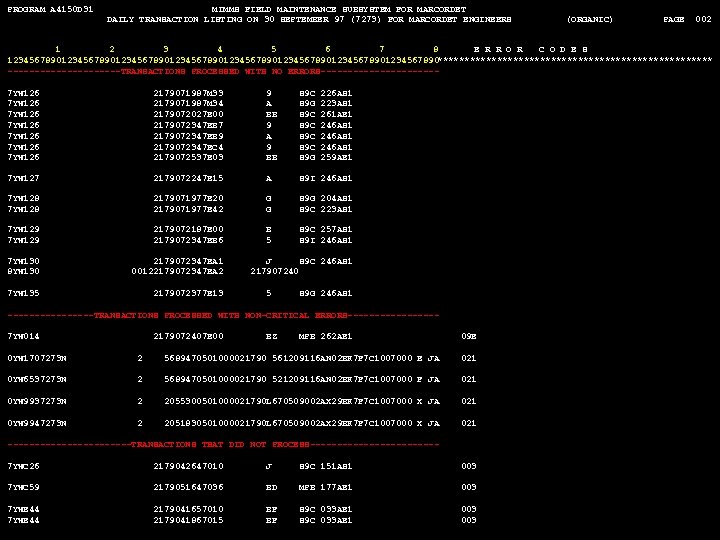

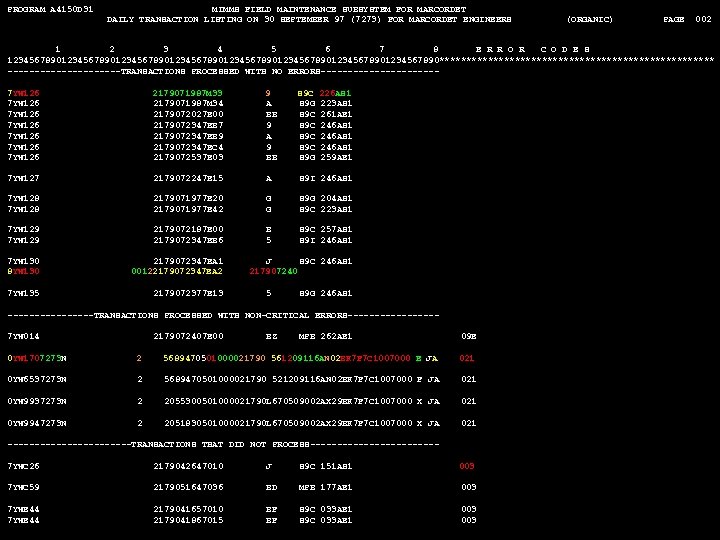

PROGRAM A 4150 D 31 MIMMS FIELD MAINTENANCE SUBSYSTEM FOR MARCORDET DAILY TRANSACTION LISTING ON 30 SEPTEMBER 97 (7273) FOR MARCORDET ENGINEERS (ORGANIC) PAGE 002 1 2 3 4 5 6 7 8 E R R O R C O D E S 1234567890123456789012345678901234567890 ************************** -----------TRANSACTIONS PROCESSED WITH NO ERRORS-----------7 YW 126 2179071987 M 33 9 S 9 C 226 AS 1 7 YW 126 2179071987 M 34 A S 9 G 223 AS 1 7 YW 126 2179072027 E 00 BB S 9 C 261 AE 1 7 YW 126 2179072347 EB 7 9 S 9 C 246 AS 1 7 YW 126 2179072347 EB 9 A S 9 C 246 AS 1 7 YW 126 2179072347 EC 4 9 S 9 C 246 AS 1 7 YW 126 2179072537 E 03 BB S 9 G 259 AE 1 7 YW 127 2179072247 E 15 A S 9 I 246 AS 1 7 YW 128 2179071977 E 20 G S 9 G 204 AS 1 7 YW 128 2179071977 E 42 G S 9 C 223 AS 1 7 YW 129 2179072187 E 00 B S 9 C 257 AS 1 7 YW 129 2179072347 EB 6 5 S 9 I 246 AS 1 7 YW 130 2179072347 EA 1 J S 9 C 246 AS 1 8 YW 130 00122179072347 EA 2 217907240 7 YW 135 2179072377 E 13 5 S 9 G 246 AS 1 --------TRANSACTIONS PROCESSED WITH NON-CRITICAL ERRORS--------7 YW 014 2179072407 E 00 BZ MPB 262 AE 1 09 E 0 YW 1707273 N 2 5689470501000021790 561209116 AN 02 BK 7 F 7 C 1007000 E JA 021 0 YW 6537273 N 2 5689470501000021790 521209116 AN 02 BK 7 F 7 C 1007000 F JA 021 0 YW 9937273 N 2 2055300501000021790 L 670509002 AX 29 BK 7 F 7 C 1007000 X JA 021 0 YW 9947273 N 2 2051830501000021790 L 670509002 AX 29 BK 7 F 7 C 1007000 X JA 021 ------------TRANSACTIONS THAT DID NOT PROCESS------------7 YWC 26 2179042647010 J S 9 C 151 AS 1 003 7 YWC 59 2179051647036 BD MPB 177 AE 1 003 7 YWE 44 2179041657010 BF S 9 C 033 AE 1 003 7 YWE 44 2179041867015 BF S 9 C 033 AE 1 003

PROGRAM A 4150 D 31 MIMMS FIELD MAINTENANCE SUBSYSTEM FOR MARCORDET DAILY TRANSACTION LISTING ON 30 SEPTEMBER 97 (7273) FOR MARCORDET ENGINEERS (ORGANIC) PAGE 002 1 2 3 4 5 6 7 8 E R R O R C O D E S 1234567890123456789012345678901234567890************************** -----------TRANSACTIONS PROCESSED WITH NO ERRORS-----------7 YW 126 2179071987 M 33 9 S 9 C 226 AS 1 7 YW 126 2179071987 M 34 A S 9 G 223 AS 1 7 YW 126 2179072027 E 00 BB S 9 C 261 AE 1 7 YW 126 2179072347 EB 7 9 S 9 C 246 AS 1 7 YW 126 2179072347 EB 9 A S 9 C 246 AS 1 7 YW 126 2179072347 EC 4 9 S 9 C 246 AS 1 7 YW 126 2179072537 E 03 BB S 9 G 259 AE 1 7 YW 127 2179072247 E 15 A S 9 I 246 AS 1 7 YW 128 2179071977 E 20 G S 9 G 204 AS 1 7 YW 128 2179071977 E 42 G S 9 C 223 AS 1 7 YW 129 2179072187 E 00 B S 9 C 257 AS 1 7 YW 129 2179072347 EB 6 5 S 9 I 246 AS 1 7 YW 130 2179072347 EA 1 J S 9 C 246 AS 1 8 YW 130 00122179072347 EA 2 217907240 7 YW 135 2179072377 E 13 5 S 9 G 246 AS 1 --------TRANSACTIONS PROCESSED WITH NON-CRITICAL ERRORS--------7 YW 014 2179072407 E 00 BZ MPB 262 AE 1 09 E 0 YW 1707273 N 2 5689470501000021790 561209116 AN 02 BK 7 F 7 C 1007000 E JA 021 0 YW 6537273 N 2 5689470501000021790 521209116 AN 02 BK 7 F 7 C 1007000 F JA 021 0 YW 9937273 N 2 2055300501000021790 L 670509002 AX 29 BK 7 F 7 C 1007000 X JA 021 0 YW 9947273 N 2 2051830501000021790 L 670509002 AX 29 BK 7 F 7 C 1007000 X JA 021 ------------TRANSACTIONS THAT DID NOT PROCESS------------7 YWC 26 2179042647010 J S 9 C 151 AS 1 003 7 YWC 59 2179051647036 BD MPB 177 AE 1 003 7 YWE 44 2179041657010 BF S 9 C 033 AE 1 003 7 YWE 44 2179041867015 BF S 9 C 033 AE 1 003

REVIEW We have discussed the DTL legend.

QUESTIONS!? !

QUESTIONS TO YOU!!! Q. What is the reference that provides an explanation of entries on the DTL? A. UM 4790 -5, CH. 6

BREAK!!!

DEMONSTRATION

REVIEW You have observed a demonstration of how to research information presented on a DTL.

QUESTIONS!? !

PRACTICAL APPLICATION

REVIEW Ø During this period you have researched information presented on a DTL. QUESTIONS?

BREAK!!!

REVIEW Ø During this period you have: ü Discussed the DTL ü Observed a demonstration ü Performed a practical application exercise QUESTIONS?

QUESTIONS TO YOU!!! Q. What are three sections of the DTL? A. Transactions processed with no errors, Transactions processed with non-critical errors, and Transactions that did not process.

PRE-EXPENDED BIN PURPOSE. Provide continuous availability of high usage, fast moving items. üCommon hardware items. üScheduled PMCS items. üItems that effect readiness of a unit.

PRE-EXPENDED BIN CONT. PRIMARY REASON. Is to enhance: üReadiness. üMaintenance operations. üEconomical management of low-cost, fast moving expendable items.

PRE-EXPENDED BIN CONT. ULTIMATE GOAL. Place fast moving, critical repair parts at the same location of the mechanics.

PRE-EXPENDED BIN CONT. Ø Stocking of these PEB items at the commodity enables units to return critical assets to an operational status sooner. Ø Commands must monitor PEB usage so that only required items are stocked. Ø PEB stockage should be minimal.

PRE-EXPENDED BIN CONT. Ø Items in PEB require planning and coordination of all authorized items that are fast moving among the following personnel: üMMO üMaintenance section üSupply officer

PRE-EXPENDED BIN CONT. Ø Proper planning and coordination results in items being available for across the counter issue. üThis ensures items are available instead of being place in a back-order status.

REVIEW Ø We discussed PEB: ü Purpose ü Primary reason ü Ultimate goal ü Stocking considerations QUESTIONS?

QUESTIONS TO YOU!!! Q. What is the purpose of maintaining a PEB? A. To provide continuous availability of high usage, fast moving items for mechanics and technicians. Q. What is the primary reason for maintaining a PEB? A. To enhance readiness, maintenance operations, and economical management of low cost, fast moving expendable items.

QUESTIONS TO YOU!!! Q. What is the ultimate goal of a PEB? A. To place fast moving, critical repair parts at the same location as the mechanic/technician who applies them.

BREAK!!!

PRE-EXPENDED BIN CONT. Ø When deciding to authorize a PEB, the CO must consider time and efforts of personnel to: üStore üStock üAccount for items ÜAlso, unit funds will be expended prior to usage.

PRE-EXPENDED BIN CONT. Ø When a PEB is determined to enhance the maintenance effort the unit commander will publish a letter authorizing specific items. It will contain, at a minimum: § Nomenclature § Unit Price (UP) § NSN / Part# § Extended Price § Max. Qty. authorized § Reorder Point § Unit of Issue (U/I)

PRE-EXPENDED BIN CONT. Ø Items procured and issued to the PEB require no further accounting. Ø Prudent management dictates that simple procedures are required for: üLocating/Identifying. üEstablish a time when to replenish.

PRE-EXPENDED BIN CONT. Ø Some examples of these procedures are as follows: üNeed to segregate the NSN’s. üEstablish a ROP in the authorization letter. § Requires periodic review. üPlace the ROP in a bag.

PRE-EXPENDED BIN CONT. Ø PEB procedures should ensure replenishment within limits of necessary control and accountability. Ø Should not be a substitute for normal supply procedures from other sources of supply.

PRE-EXPENDED BIN CONT. UNIT COMMANDERS: Ø Will review and approve PEB annually in writing. Ø May approve changes as required. Ø Will initial each page of enclosures if used. SUPPLY & MAINTENANCE PERSONNEL: Ø Will review and assist CO’s, as required, with establishing and maintaining PEB’s: üRange üDepth.

REVIEW Ø We discussed PEB authorization letter requirements. QUESTIONS?

QUESTIONS TO YOU!!! Q. What seven items must be included in the unit commander’s PEB authorization letter? A. Nomenclature, NSN/Part No. , Max Qty authorized, Unit of issue, Unit price, Extended price, and Reorder point. Q. What is used to determine when a PEB item is to be replenished? A. Reorder point.

BREAK!!!

PRE-EXPENDED BIN CONT. Ø MMSOP must include procedures for: üIdentifying. üLocating. üReordering PEB items.

STOCKAGE/USAGE CRITERIA Ø Based on the U/P and item Usage. Ø U/P criteria: üShall be < or = to $500. 00 per U/I. Ø Usage criteria: üItems applied or consumed as a Full U/I (EA, PR) it must have 6 hits in 12 months. üItems applied or consumed less than full U/I (RL, HD) it must have 1 hit 12 months.

PRE-EXPENDED BIN CONT. Ø Total dollar value of a PEB item that is applied is less than or equal to $50. 00, its not mandatory to show usage via a class I system using MIMMS. Ø Usage must be compiled using the most logical method deemed appropriate by the CO.

PRE-EXPENDED BIN CONT. Ø Consumables approved for the PEB will not exceed 30 days of supply, this is based on the previous 12 months. Ø Items having an average Qty. of more than onehalf over the previous 12 months are authorized a Qty. of one.

PRE-EXPENDED BIN CONT. Ø Items applied in qty’s of less than a full U/I may stock no more than 2 full U/I or 30 days of supply or whichever is greater.

BROKEN U/I’S Ø Broken U/I’s of common hardware costing less than or equal to $5. 00 per U/I that is ordered against a CM ERO and do not meet PEB criteria do not require further control or accounting once applied. üLeftover portion will be displayed in plain view of all personnel, and used until exhausted. üControl & accountability is not required. üEnsure all items are used prior to reordering.

BROKEN U/I’S CONT. Ø Broken U/I’s not considered common hardware or costing more than $5. 00 per U/I will be added to the PEB list or on a list of Broken U/I’s where PEB has not been established. üList must identify that: v. It is a Broken Unit of Issue. v. Date when it was added to the list. v. Retain until exhausted. Do not re-order.

REVIEW Ø We have discussed PEB: ü MMSOP requirements ü Stocking ü Broken units of issue QUESTIONS?

QUESTIONS TO YOU!!! Q. What is the Unit Price criterion for PEB stockage per Unit of Issue? A. Less than or equal to $500. Q. What is the Usage criterion for PEB stockage? A. Applied/consumed as full U/I = 6 hits in 12 months –--- Applied/consumed as less than full U/I = 1 hit in 12 months.

BREAK!!!!

PEB WAIVER Ø OIC, FSMAO-EAST ltr 4400 of 22 JUN 10. üProcedures and requirements. üHas been approved and will incorporated into the next revision or change to the MCO P 4400. 150_.

PEB CONT. Ø Usage criteria is to restrictive. Ø Does not allow the flexibility to stock PEB based on additional criteria such as: üFluctuating usage üExcessive lead-time associated to ordering slowmoving items or high impact items.

PEB CONT. Ø Difficulties in capturing usage data via MIMMSAIS has prevented units from accurately stocking PEB. Ø The new usage criteria is as follows: ü Only items for which there is a known or anticipated requirement.

PEB CONT. Ø Historical usage data from: üMIMMS-AIS üManual tracking records should be used to facilitate sound stocking decisions.

PEB CONT. Ø Advice code “PB” must be used accurately when an item is pulled from the PEB. üMIMMS-AIS does not capture data unless this is done. Ø Candidate for PEB’s should be continuous process at the unit level using the most logical method. Local databases & manual records. Ø Stockage decisions should include consideration of lead time and readiness impact.

PEB CONT. Ø Broken U/I’s is the same as previously discussed, except there is no dollar value.

PEB CONT. Ø CO’s will review no less than annually and document their approved items and associated quantities via official correspondence. Ø MMO & Sup. O will review after the initial 6 months and annually thereafter by the CO to ensure: üProper risk management üExpenditures of funds consistent w/needs of the unit. Ø Periodic reviews throughout the year will ensure a PEB’s appropriate range and depth.

REVIEW Ø We have discussed the Pre-expended Bin. QUESTIONS?

QUESTIONS TO YOU! Q. What PEB criterion does the PEB waiver letter affect? A. Usage.

QUESTIONS TO YOU! Q. How often must the PEB authorization letter be reviewed, and by whom? A. MMO and Supply Officer initially after the first six months, and annually thereafter by the CO.

ERO PARTS BIN (Layettes) PURPOSE A means of controlling and/or accounting for repair parts.

ERO PARTS BIN CONT. Ø Where parts ordered against an ERO are stored üCan be shelf, box, etc. Ø All parts for the same ERO Number will be stored together. üERO# normally indicates the location. üLarge items that will not fit in their bin will be stored separately, and must be marked with the applicable ERO#.

ERO PARTS BIN CONT. Ø Parts can be traced from requisition to receipt by the supply section through SASSY and MIMMS AIS. üOnce RCVD automated accounting stops. üShops will annotate the EROSL when received and issued with the date and quantity.

REVIEW Ø We have discussed ERO Parts Bin: ü Purpose ü Description QUESTIONS?

QUESTIONS TO YOU! Q. What is the purpose of the ERO Parts Bin? A. Means of controlling or accounting for repair parts.

BREAK!!!

ERO PARTS BIN CONT. Ø ERO Parts Bins must be validated daily and biweekly. Ø Validation - Process used to confirm repair part requirements, which involves confirmation of: üItems that are still needed. üCancellations. üReceipts. üScrounges. üCurrent status

ERO PARTS BIN CONT. Ø When confirming needed items, you must ensure: üItems have been made known. üStill exist. üAre resident in the supply system.

VALIDATION PROCEDURES Ø Each day the MIMMS/Layettes Clerk will: üVerify the DTL. üEnsure ERO’s on the DPR reflect the correct Job Status. üERO’s in SHT PART w/ nothing on order, ensure EROSL’s have been prepared and submitted. v. Not submitted, submit ASAP. NCOM

VALIDATION PROCEDURES CONT. ü Check off parts on EROSL that have been submitted and appear on DPR. ü When all parts appear on DPR, file EROSL in Layette Bin. ü Any parts transactions on the EROSL, do not appear on DPR, check off those that do appear and file EROSL in a pending file. ü Always verify data for accuracy. NCOM

VALIDATION PROCEDURES CONT. Ø EROSL will have the following annotations: (Annotation procedures will be established in the MSCMMSOP) üQty. RCVD and date. üERO Bin location. If ERO# is used as location annotation is not required. üParts issued for installation. NCOM

VALIDATION PROCEDURES CONT. Ø Each day the shop/maintenance officer/chief will ensure: üCritical parts received Cat. Code “M, ” but noncritical parts are still outstanding: § Ensure Cat. Code “M” parts are installed as well as noncritical parts that practical to install. § Either downgrade or a new ERO will be opened. § If new ERO is opened ensure the following actions have been accomplished:

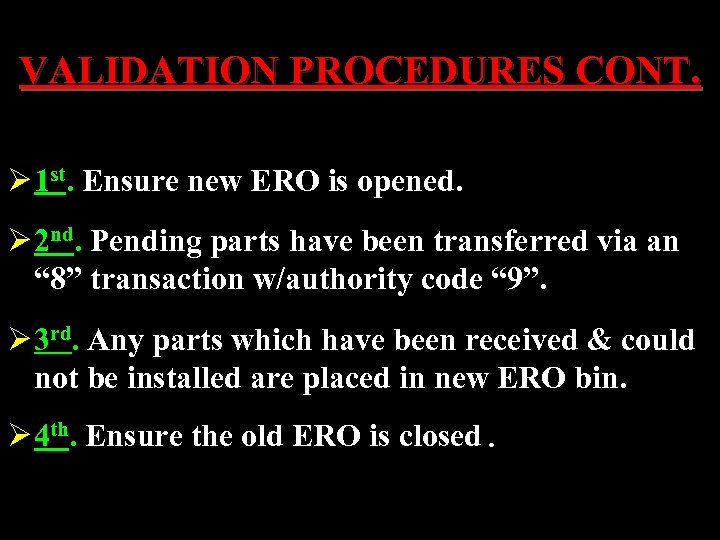

VALIDATION PROCEDURES CONT. Ø 1 st. Ensure new ERO is opened. Ø 2 nd. Pending parts have been transferred via an “ 8” transaction w/authority code “ 9”. Ø 3 rd. Any parts which have been received & could not be installed are placed in new ERO bin. Ø 4 th. Ensure the old ERO is closed.

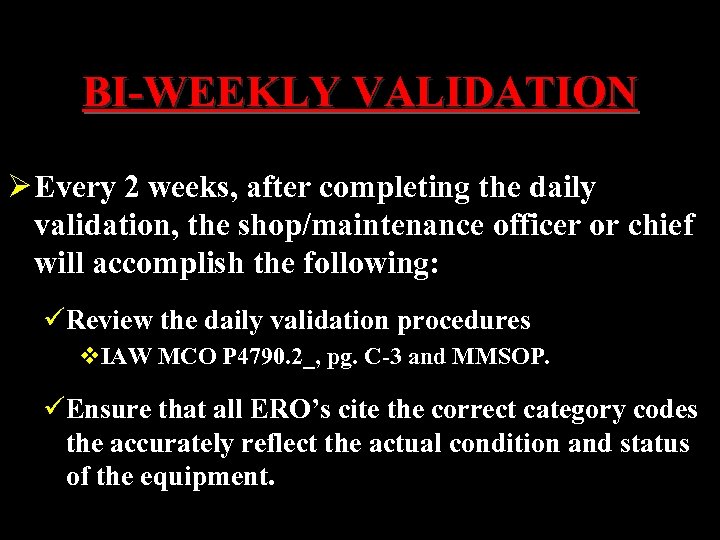

BI-WEEKLY VALIDATION Ø Every 2 weeks, after completing the daily validation, the shop/maintenance officer or chief will accomplish the following: üReview the daily validation procedures v. IAW MCO P 4790. 2_, pg. C-3 and MMSOP. üEnsure that all ERO’s cite the correct category codes the accurately reflect the actual condition and status of the equipment.

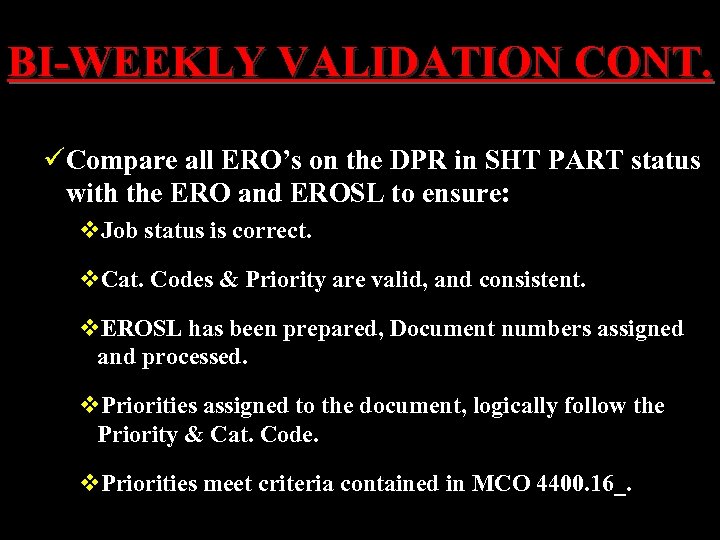

BI-WEEKLY VALIDATION CONT. üCompare all ERO’s on the DPR in SHT PART status with the ERO and EROSL to ensure: v. Job status is correct. v. Cat. Codes & Priority are valid, and consistent. v. EROSL has been prepared, Document numbers assigned and processed. v. Priorities assigned to the document, logically follow the Priority & Cat. Code. v. Priorities meet criteria contained in MCO 4400. 16_.

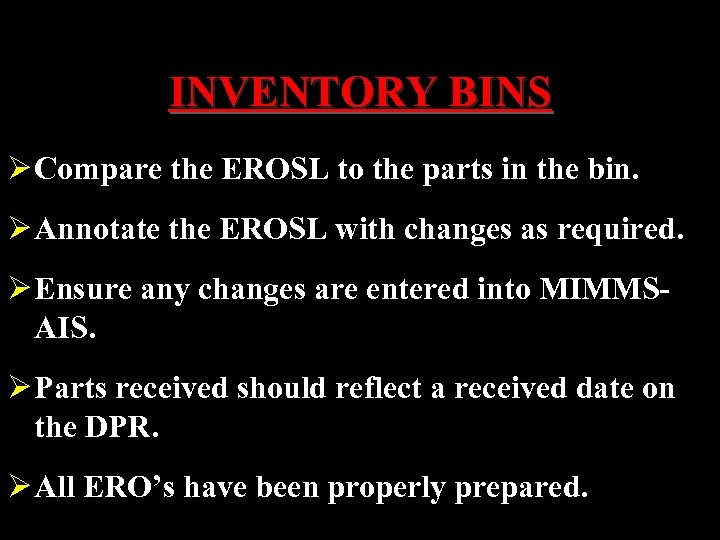

INVENTORY BINS Ø Compare the EROSL to the parts in the bin. Ø Annotate the EROSL with changes as required. Ø Ensure any changes are entered into MIMMSAIS. Ø Parts received should reflect a received date on the DPR. Ø All ERO’s have been properly prepared.

REVIEW Ø We have discussed validation of ERO Parts Bins. QUESTIONS?

QUESTIONS TO YOU! Q. How often must ERO Parts Bins (Layettes) be validated? A. Daily and Bi-weekly.

QUESTIONS TO YOU! Q. What is the definition of validation? A. The process used to confirm repair parts requirements.

BREAK!!!

RECONCILIATION PROCEDURES Ø Is the process used to ensure that validation requirements are properly logged within the MIMMS/SASSY (AIS) output reports. Ø Every 2 weeks, after completing validation, the shop/maintenance officer or chief will accomplish the following:

RECONCILIATION PROCEDURES CONT. üEROSL is annotated with all receipts, CANC’s and scrounges; and have been submitted & processed. üSupply status provided is: v. Current. v. Acceptable. v. Understood. üSupply section should clarify any status not understood, or does not respond according to the priority.

RECONCILIATION PROCEDURES CONT. üEnsure DPR is annotated with current and correct data and reconciled with supply. üPrepare and submit, required transactions to correct invalid data reflected on the DPR.

ERO PARTS BIN Ø Annotate the EROSL to indicate all parts received by the maintenance section from the supply section. üException to the rule is stated in paragraph “k”. Ø Annotate the EROSL when parts are removed from the layettes. üIf part is not applied, part should be returned to the layettes.

ERO PARTS BIN CONT. Ø Annotate EROSL when parts have been transferred from one ERO to another, when unit has already received the parts. üBefore receipt by supply, parts may be transferred by using MIMMS-AIS and the associated EROSL will be annotated.

REVIEW Ø We have discussed: ü Reconciliation procedures ü EROSL annotation QUESTIONS?

QUESTIONS TO YOU! Q. What is the definition of reconciliation? A. The process used to ensure that validation requirements are properly logged within the MIMMS/SASSY (AIS) output reports.

BREAK!!!!

ERO PARTS BIN CONT. Ø Parts applied, ensure ERO is annotated with maintenance action, including man hours. Ø Action is identified by the defect codes on the ERO. Ø Parts removed from the Layettes must be substantiated by maintenance action on the ERO.

ERO PARTS BIN CONT. Ø Annotation of the EROSL is not required if all parts are installed upon receipt from supply. Ø Annotation of the ERO is required.

ERO PARTS BIN CONT. Ø All parts held by the maintenance section must be on an EROSL and associated with an ERO or authorized PEB. Ø Parts that are not indicated on EROSL and ERO or in an authorized PEB will be reported to supply for disposition. Ø Same applies for Non-FMSS supported units.

REVIEW Ø We have discussed EROSL annotation procedures. QUESTIONS?

QUESTIONS TO YOU! Q. What is the difference between validation and reconciliation? A. Validation is confirmation of repair part requirements, and reconciliation is used to ensure validation requirements are properly logged within the MIMMS/SASSY (AIS) output reports.

SUMMARY Ø During this period of instruction we have discussed: ü Daily Process Report (DPR) ü Daily Transaction Listing (DTL) ü Pre-expended Bin requirements ü ERO Parts Bin (Layette) requirements

581558de4ac8934b905177e45655f359.ppt