9bd9a8c1a989f6311ff89d881358a2ab.ppt

- Количество слайдов: 22

Maintenance and Engineering Procedures and Tools at Soreq Applied Research Accelerator Facility I. Gertz, Y. Buzaglo, A. Grin, R. Michael, R. Raizman, L. Weissman, A. Nagler Soreq NRC, Yavne, Israel 26/9/2007 WAO 2007 September 26 th, 2007

Maintenance and Engineering Procedures and Tools at Soreq Applied Research Accelerator Facility I. Gertz, Y. Buzaglo, A. Grin, R. Michael, R. Raizman, L. Weissman, A. Nagler Soreq NRC, Yavne, Israel 26/9/2007 WAO 2007 September 26 th, 2007

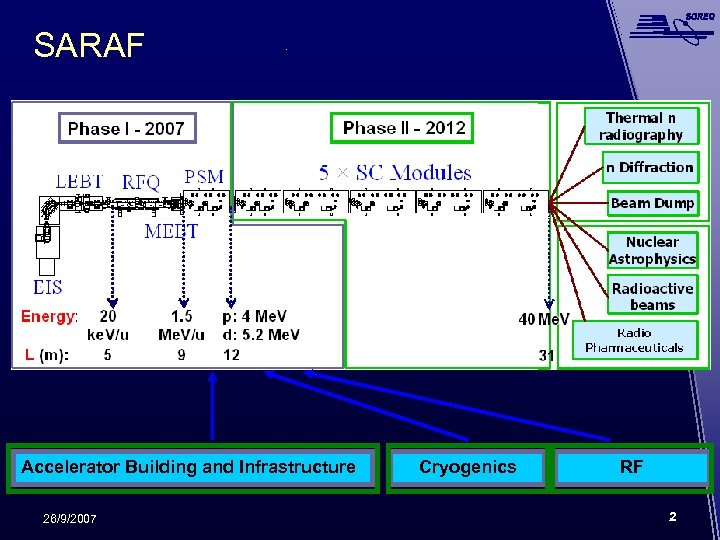

SARAF Accelerator Building and Infrastructure 26/9/2007 Cryogenics RF 2

SARAF Accelerator Building and Infrastructure 26/9/2007 Cryogenics RF 2

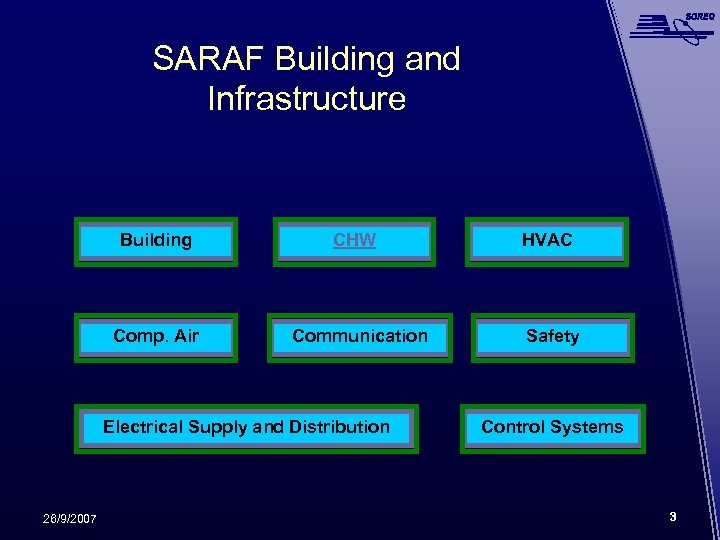

SARAF Building and Infrastructure Building Comp. Air CHW Communication Electrical Supply and Distribution 26/9/2007 HVAC Safety Control Systems 3

SARAF Building and Infrastructure Building Comp. Air CHW Communication Electrical Supply and Distribution 26/9/2007 HVAC Safety Control Systems 3

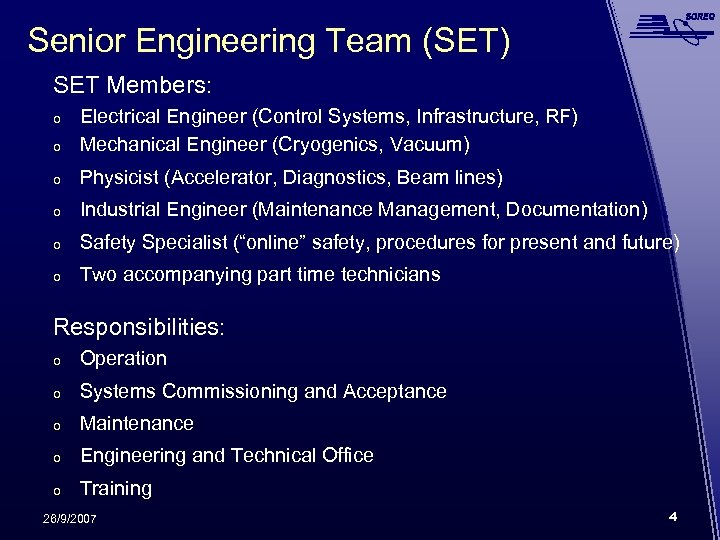

Senior Engineering Team (SET) SET Members: o Electrical Engineer (Control Systems, Infrastructure, RF) Mechanical Engineer (Cryogenics, Vacuum) o Physicist (Accelerator, Diagnostics, Beam lines) o Industrial Engineer (Maintenance Management, Documentation) o Safety Specialist (“online” safety, procedures for present and future) o Two accompanying part time technicians o Responsibilities: o Operation o Systems Commissioning and Acceptance o Maintenance o Engineering and Technical Office o Training 26/9/2007 4

Senior Engineering Team (SET) SET Members: o Electrical Engineer (Control Systems, Infrastructure, RF) Mechanical Engineer (Cryogenics, Vacuum) o Physicist (Accelerator, Diagnostics, Beam lines) o Industrial Engineer (Maintenance Management, Documentation) o Safety Specialist (“online” safety, procedures for present and future) o Two accompanying part time technicians o Responsibilities: o Operation o Systems Commissioning and Acceptance o Maintenance o Engineering and Technical Office o Training 26/9/2007 4

Operation Most infrastructure systems were accepted and serve accelerator installation and commissioning purposes SET members ware trained up to supervisor level to operate the infrastructure systems 26/9/2007 5

Operation Most infrastructure systems were accepted and serve accelerator installation and commissioning purposes SET members ware trained up to supervisor level to operate the infrastructure systems 26/9/2007 5

Accelerator Systems Commissioning and Acceptance (1) SET members are participating and assisting in accelerator installation, commissioning and acceptance tests Effort is lead by the accelerator contractor personnel and is under their responsibility 26/9/2007 6

Accelerator Systems Commissioning and Acceptance (1) SET members are participating and assisting in accelerator installation, commissioning and acceptance tests Effort is lead by the accelerator contractor personnel and is under their responsibility 26/9/2007 6

Accelerator Systems Commissioning and Acceptance (2) Emphasis is on thorough learning and understanding of all systems and components SET members spend about 40% of their time on these tasks 26/9/2007 7

Accelerator Systems Commissioning and Acceptance (2) Emphasis is on thorough learning and understanding of all systems and components SET members spend about 40% of their time on these tasks 26/9/2007 7

Engineering and Technical Office Engineering tasks and Technical Office responsibilities are entwined Engineering ð ð R&D of accelerator supplementary systems (Control, Diagnostics, infrastructure) Writing maintenance and operating procedures Technical Office ð Documentation of engineering tasks ð Updating of documentation and drawings ð Archiving of engineering data ð Maintenance schedule ð Coordination among SARAF and external contractors and suppliers ð Purchasing of spare parts and stock management 26/9/2007 8

Engineering and Technical Office Engineering tasks and Technical Office responsibilities are entwined Engineering ð ð R&D of accelerator supplementary systems (Control, Diagnostics, infrastructure) Writing maintenance and operating procedures Technical Office ð Documentation of engineering tasks ð Updating of documentation and drawings ð Archiving of engineering data ð Maintenance schedule ð Coordination among SARAF and external contractors and suppliers ð Purchasing of spare parts and stock management 26/9/2007 8

Maintenance procedures concern operational and mechanical systems conditions Currently, maintenance is mainly performed on The building ð Infrastructure systems ð Cryogenics ð Part of the accelerator vacuum and RF ð The maintenance works are divided into: Breakdown Maintenance (BM) ð Preventive Maintenance (PM) ð Predictive Maintenance (Pd. M) ð 26/9/2007 9

Maintenance procedures concern operational and mechanical systems conditions Currently, maintenance is mainly performed on The building ð Infrastructure systems ð Cryogenics ð Part of the accelerator vacuum and RF ð The maintenance works are divided into: Breakdown Maintenance (BM) ð Preventive Maintenance (PM) ð Predictive Maintenance (Pd. M) ð 26/9/2007 9

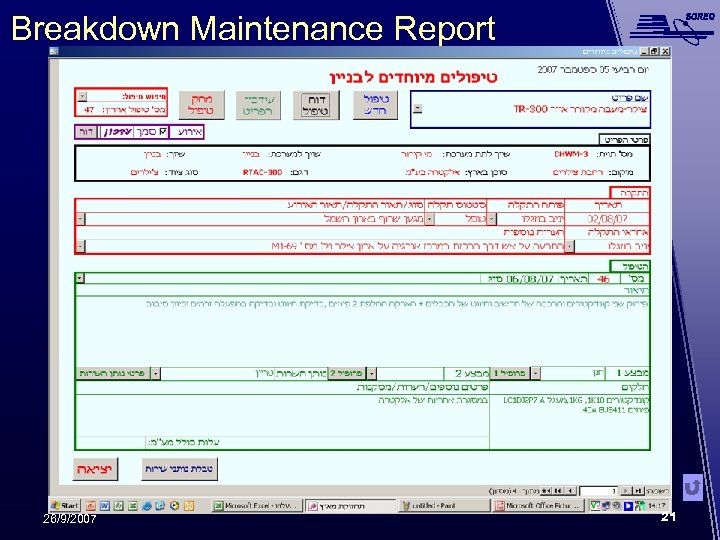

Breakdown Maintenance (BM) Most of the systems are still in their warranty periods, so they are usually repaired by the system contractor In urgent cases, breakdown maintenance is performed by SET members The procedure for BM is 1. 2. 3. 4. 5. 6. BM is requested in the commissioning logbook (if encountered during shifts) or in a PM form (if encountered during PM) The BM Request is accepted and checked by the relevant SET member A BM form is issued BM is performed according to the procedures A BM technical report is prepared The BM technical report is checked and approved by the SET head The data base of the Computerized Maintenance Management System (CMMS) is updated The approved report is logged and stored in the BM archive 26/9/2007 10

Breakdown Maintenance (BM) Most of the systems are still in their warranty periods, so they are usually repaired by the system contractor In urgent cases, breakdown maintenance is performed by SET members The procedure for BM is 1. 2. 3. 4. 5. 6. BM is requested in the commissioning logbook (if encountered during shifts) or in a PM form (if encountered during PM) The BM Request is accepted and checked by the relevant SET member A BM form is issued BM is performed according to the procedures A BM technical report is prepared The BM technical report is checked and approved by the SET head The data base of the Computerized Maintenance Management System (CMMS) is updated The approved report is logged and stored in the BM archive 26/9/2007 10

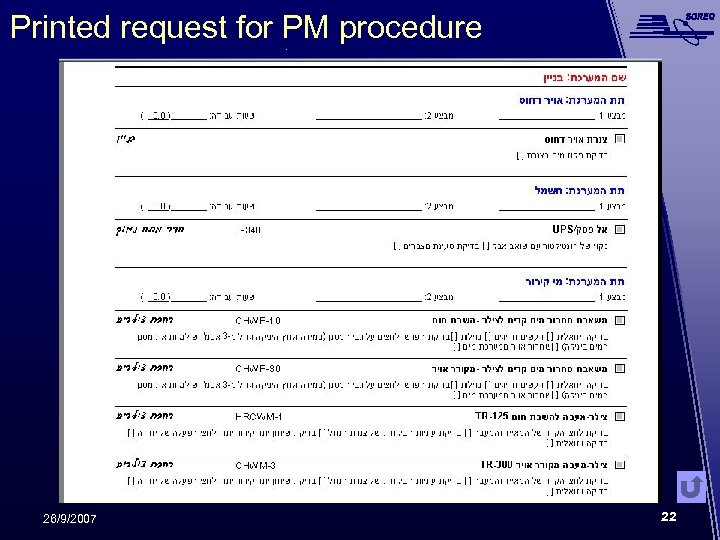

Preventive Maintenance (PM) For accepted systems PM procedures have been written and scheduled by the technical office The procedures are based on the system contractor requests and maintenance timetables (with small deviations) PM is performed either by SET members, the system contractor or other external contractors The procedure for PM is 1. 2. 3. 4. 5. 26/9/2007 A PM procedure form is issued by the technical office PM is performed and reported on the form The PM report is checked and approved by the SET head The data base of the CMMS is updated The approved report is logged and stored in the PM archive 11

Preventive Maintenance (PM) For accepted systems PM procedures have been written and scheduled by the technical office The procedures are based on the system contractor requests and maintenance timetables (with small deviations) PM is performed either by SET members, the system contractor or other external contractors The procedure for PM is 1. 2. 3. 4. 5. 26/9/2007 A PM procedure form is issued by the technical office PM is performed and reported on the form The PM report is checked and approved by the SET head The data base of the CMMS is updated The approved report is logged and stored in the PM archive 11

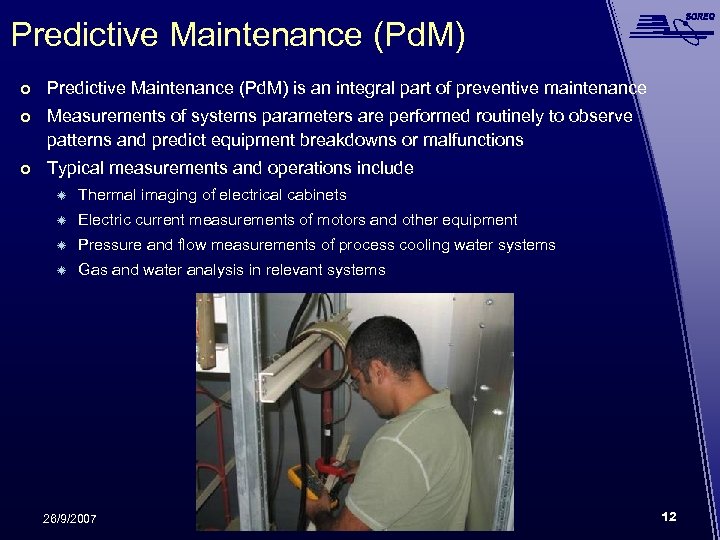

Predictive Maintenance (Pd. M) is an integral part of preventive maintenance Measurements of systems parameters are performed routinely to observe patterns and predict equipment breakdowns or malfunctions Typical measurements and operations include ð Thermal imaging of electrical cabinets ð Electric current measurements of motors and other equipment ð Pressure and flow measurements of process cooling water systems ð Gas and water analysis in relevant systems 26/9/2007 12

Predictive Maintenance (Pd. M) is an integral part of preventive maintenance Measurements of systems parameters are performed routinely to observe patterns and predict equipment breakdowns or malfunctions Typical measurements and operations include ð Thermal imaging of electrical cabinets ð Electric current measurements of motors and other equipment ð Pressure and flow measurements of process cooling water systems ð Gas and water analysis in relevant systems 26/9/2007 12

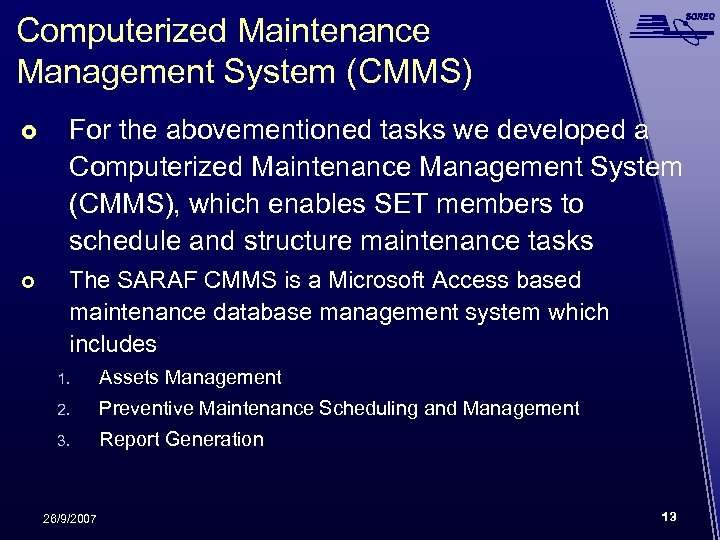

Computerized Maintenance Management System (CMMS) For the abovementioned tasks we developed a Computerized Maintenance Management System (CMMS), which enables SET members to schedule and structure maintenance tasks The SARAF CMMS is a Microsoft Access based maintenance database management system which includes 1. Assets Management 2. Preventive Maintenance Scheduling and Management 3. Report Generation 26/9/2007 13

Computerized Maintenance Management System (CMMS) For the abovementioned tasks we developed a Computerized Maintenance Management System (CMMS), which enables SET members to schedule and structure maintenance tasks The SARAF CMMS is a Microsoft Access based maintenance database management system which includes 1. Assets Management 2. Preventive Maintenance Scheduling and Management 3. Report Generation 26/9/2007 13

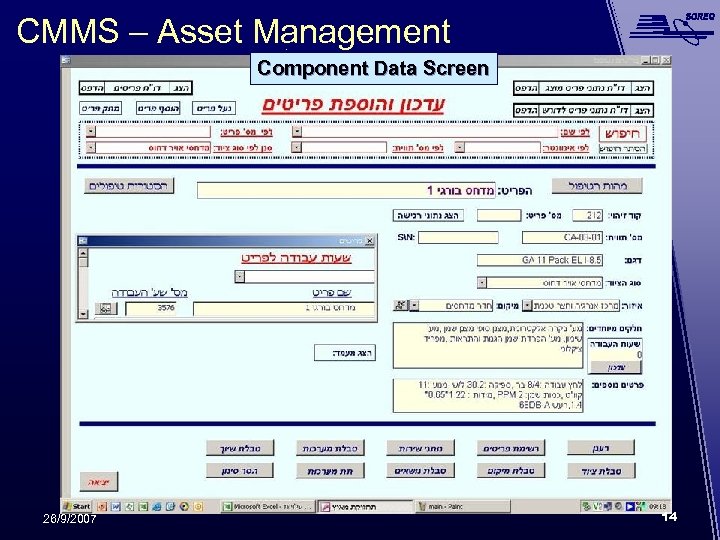

CMMS – Asset Management Component Data Screen 26/9/2007 14

CMMS – Asset Management Component Data Screen 26/9/2007 14

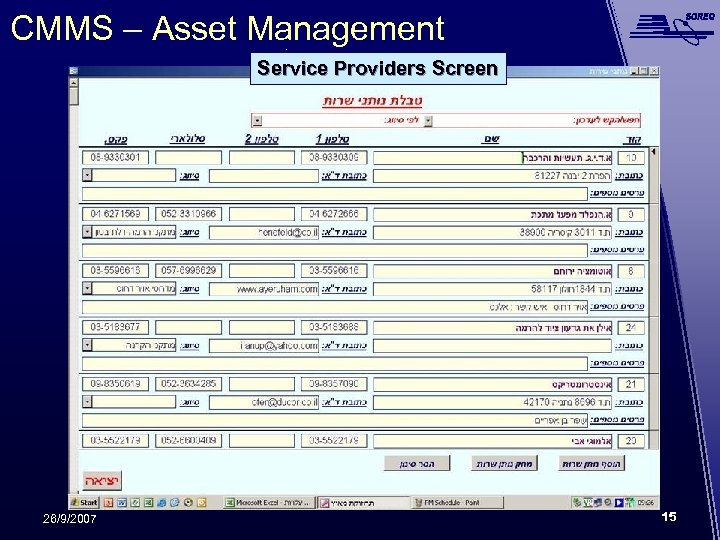

CMMS – Asset Management Service Providers Screen 26/9/2007 15

CMMS – Asset Management Service Providers Screen 26/9/2007 15

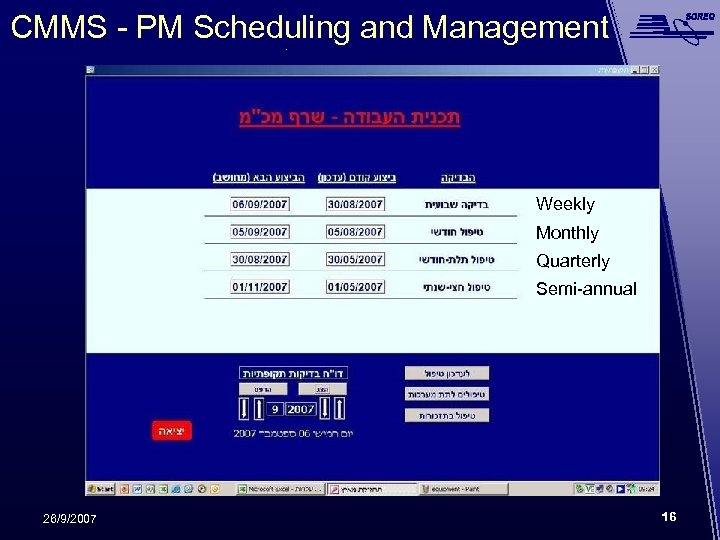

CMMS - PM Scheduling and Management Weekly Monthly Quarterly Semi-annual 26/9/2007 16

CMMS - PM Scheduling and Management Weekly Monthly Quarterly Semi-annual 26/9/2007 16

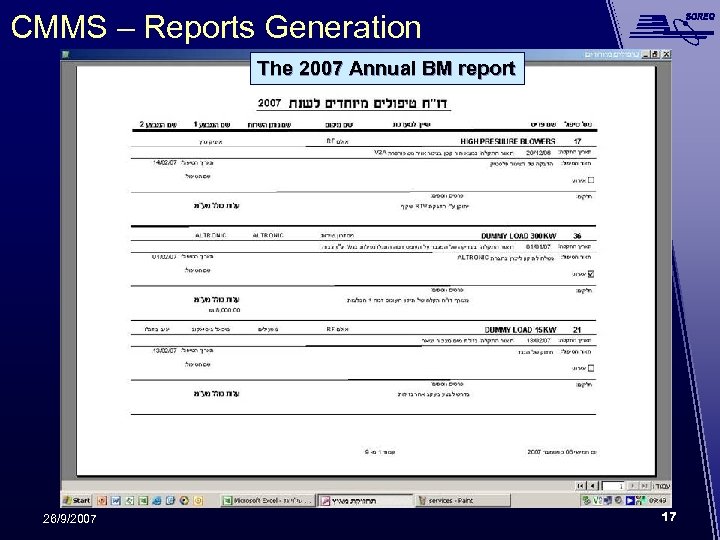

CMMS – Reports Generation The 2007 Annual BM report 26/9/2007 17

CMMS – Reports Generation The 2007 Annual BM report 26/9/2007 17

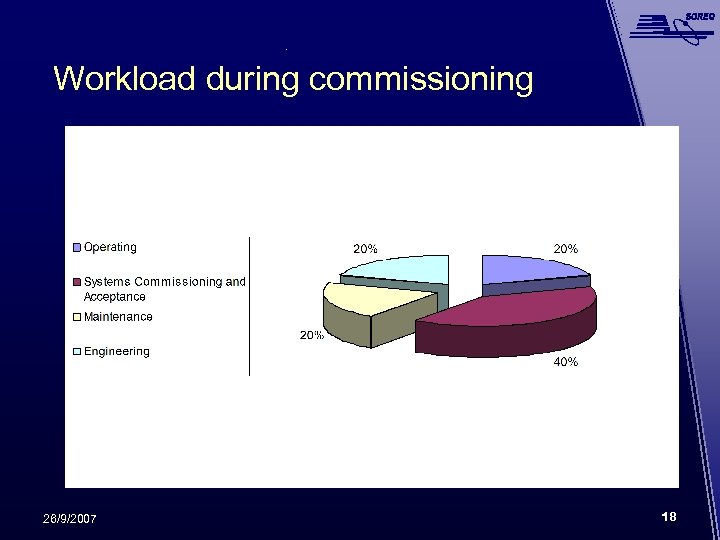

Workload during commissioning 26/9/2007 18

Workload during commissioning 26/9/2007 18

Conclusions Development and assimilation of maintenance and engineering systems during accelerator installation and commissioning presents a big challenge for SARAF Senior Engineering Team. Currently, the biggest effort is the accelerator installation and commissioning, so maintenance and engineering receive a smaller share of the workload It is unequivocal that after the accelerator systems will be accepted, the maintenance load will grow accordingly. Therefore major SET tasks are: Verified written procedures ð ð A CMMS including all of the accepted systems Appropriate training of SET members Development of a maintenance culture 26/9/2007 19

Conclusions Development and assimilation of maintenance and engineering systems during accelerator installation and commissioning presents a big challenge for SARAF Senior Engineering Team. Currently, the biggest effort is the accelerator installation and commissioning, so maintenance and engineering receive a smaller share of the workload It is unequivocal that after the accelerator systems will be accepted, the maintenance load will grow accordingly. Therefore major SET tasks are: Verified written procedures ð ð A CMMS including all of the accepted systems Appropriate training of SET members Development of a maintenance culture 26/9/2007 19

Thank You 26/9/2007

Thank You 26/9/2007

Breakdown Maintenance Report 26/9/2007 21

Breakdown Maintenance Report 26/9/2007 21

Printed request for PM procedure 26/9/2007 22

Printed request for PM procedure 26/9/2007 22