8b6f4f90d58ce8d1b875a861d7cc09cb.ppt

- Количество слайдов: 11

Magnesium Research Joe Robson University of Manchester joseph. robson@manchester. ac. uk

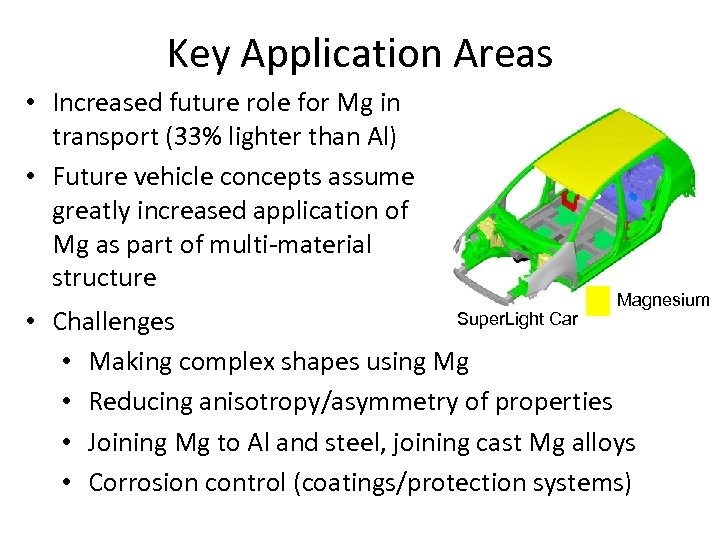

Key Application Areas • Increased future role for Mg in transport (33% lighter than Al) • Future vehicle concepts assume greatly increased application of Mg as part of multi-material structure Magnesium Super. Light Car • Challenges • Making complex shapes using Mg • Reducing anisotropy/asymmetry of properties • Joining Mg to Al and steel, joining cast Mg alloys • Corrosion control (coatings/protection systems)

Mg Research – Current Hot Topics • Based on a survey of recent conference proceedings, top research areas for Mg are – Improving low temperature formability (texture control, rare-earth additions etc. ) – Alternative production routes (e. g. twin roll casting, advanced casting processes) – Bio-resorbable magnesium alloys for implants – Corrosion control (alloy design and coatings) – Improving strengthening response (improving precipitation hardening. . . )

International Picture • China, Germany, Canada, Australia and US all have major Mg research activities • China – National Engineering Research Centre for Magnesium Alloys, Chongqing ~80 academics • Germany – Magnesium Innovation Centre (Mag. IC) ~50 scientists • Canada – Mag. NET. 20 academics from 5 partner universities

UK Picture • UK Mg research activity is comparatively small (handful of academics “part time” on Mg) but maintains wide coverage and internationally recognized position • Mg research in UK receives ~ 5% of light metals funding • Significant Mg activity within: – LATEST 2 programme – Towards Affordable, Closed-Loop Recyclable Future Low Carbon Vehicle Structures (TARF-LCV) – Centre for Innovative Manufacture in Liquid Metal Engineering (Li. ME) – Doctoral Training Centre in Advanced Metallic Systems (DTC) • Most UK Mg research involves collaboration with industry - Magnesium Elektron

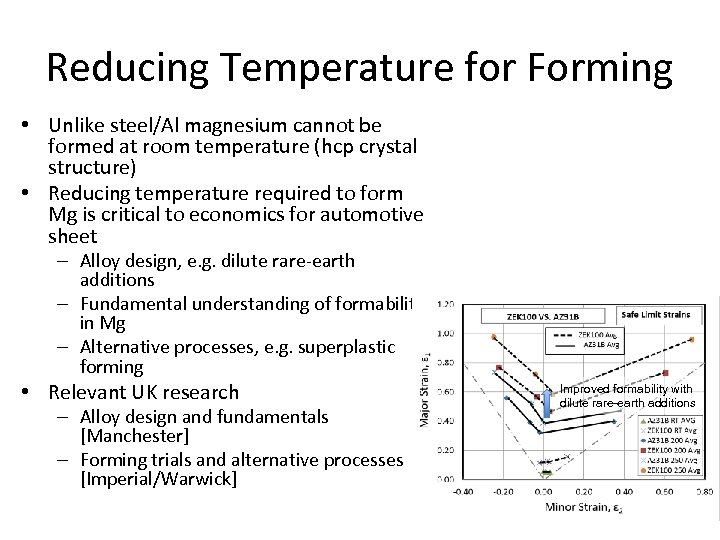

Reducing Temperature for Forming • Unlike steel/Al magnesium cannot be formed at room temperature (hcp crystal structure) • Reducing temperature required to form Mg is critical to economics for automotive sheet – Alloy design, e. g. dilute rare-earth additions – Fundamental understanding of formability in Mg – Alternative processes, e. g. superplastic forming • Relevant UK research – Alloy design and fundamentals [Manchester] – Forming trials and alternative processes [Imperial/Warwick] Improved formability with dilute rare-earth additions

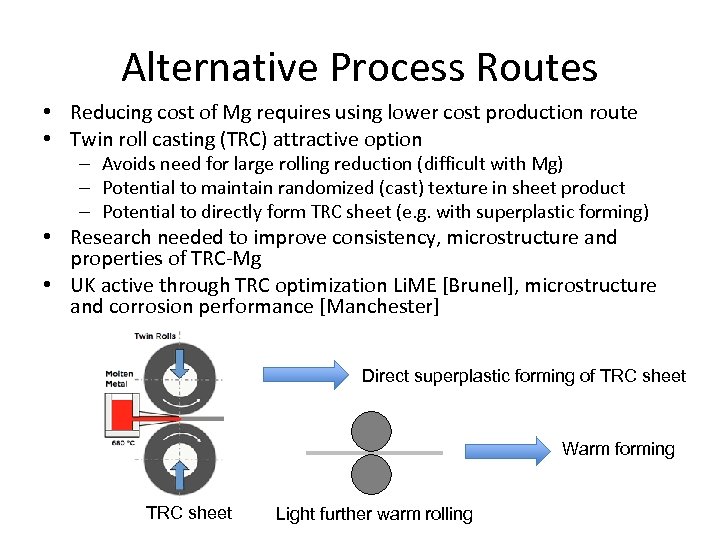

Alternative Process Routes • Reducing cost of Mg requires using lower cost production route • Twin roll casting (TRC) attractive option – Avoids need for large rolling reduction (difficult with Mg) – Potential to maintain randomized (cast) texture in sheet product – Potential to directly form TRC sheet (e. g. with superplastic forming) • Research needed to improve consistency, microstructure and properties of TRC-Mg • UK active through TRC optimization Li. ME [Brunel], microstructure and corrosion performance [Manchester] Direct superplastic forming of TRC sheet Warm forming TRC sheet Light further warm rolling

Bio-resorbable Mg Alloys • Potential of Mg for bio-resorbable implants has attracted massive new research interest in past ~10 years • Magnesium Elektron developed Synermag – first commercial Mg alloy designed for biological applications • UK research – Mg alloy optimization and biological performance [Manchester] – Magnesium Elektron in-house activities Magnesium alloy stent

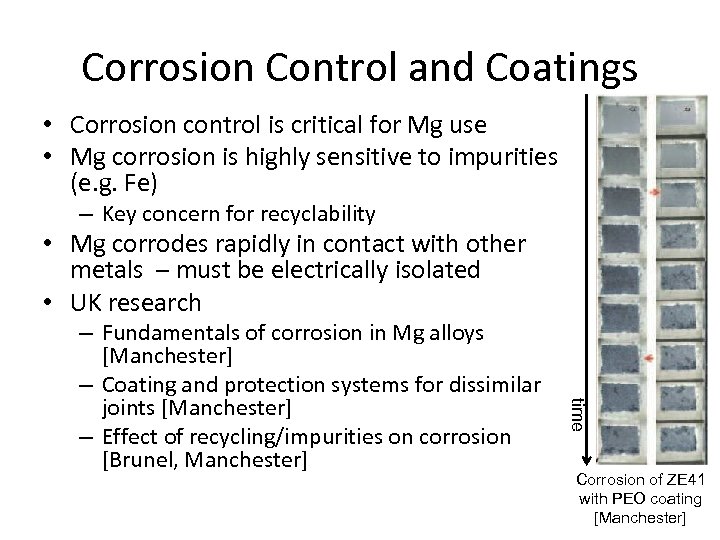

Corrosion Control and Coatings • Corrosion control is critical for Mg use • Mg corrosion is highly sensitive to impurities (e. g. Fe) – Key concern for recyclability • Mg corrodes rapidly in contact with other metals – must be electrically isolated • UK research time – Fundamentals of corrosion in Mg alloys [Manchester] – Coating and protection systems for dissimilar joints [Manchester] – Effect of recycling/impurities on corrosion [Brunel, Manchester] Corrosion of ZE 41 with PEO coating [Manchester]

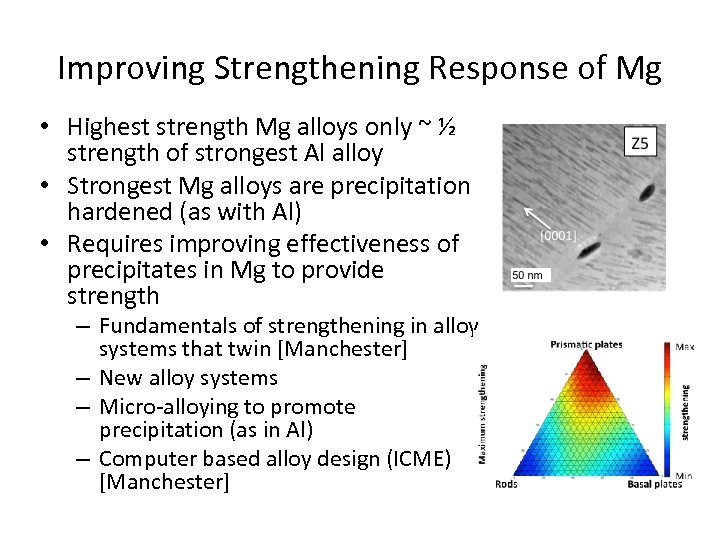

Improving Strengthening Response of Mg • Highest strength Mg alloys only ~ ½ strength of strongest Al alloy • Strongest Mg alloys are precipitation hardened (as with Al) • Requires improving effectiveness of precipitates in Mg to provide strength – Fundamentals of strengthening in alloy systems that twin [Manchester] – New alloy systems – Micro-alloying to promote precipitation (as in Al) – Computer based alloy design (ICME) [Manchester]

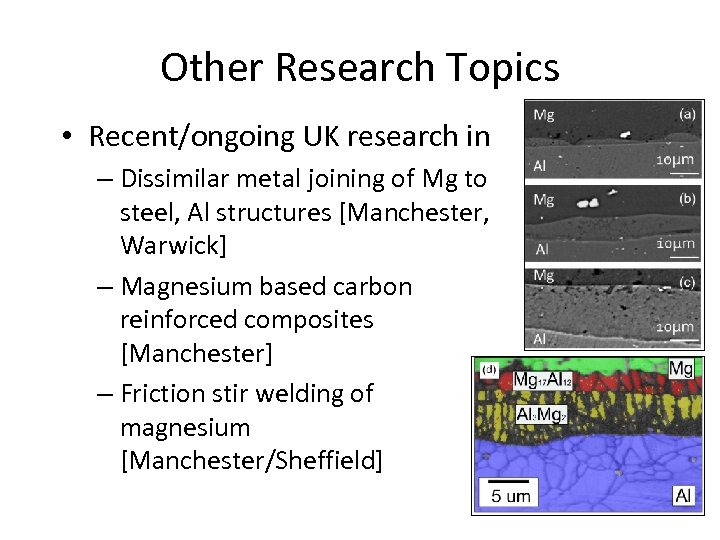

Other Research Topics • Recent/ongoing UK research in – Dissimilar metal joining of Mg to steel, Al structures [Manchester, Warwick] – Magnesium based carbon reinforced composites [Manchester] – Friction stir welding of magnesium [Manchester/Sheffield]

8b6f4f90d58ce8d1b875a861d7cc09cb.ppt