57b469b6cc2e5ebe6434616a8482fea7.ppt

- Количество слайдов: 18

machine design product development added resource and expertise Solid. Works Large Assembly Techniques Using Solid. Works to Design Buses for Designline Taking the Stress out of Engineering Your Vision!

machine design product development added resource and expertise Solid. Works Large Assembly Techniques Using Solid. Works to Design Buses for Designline Taking the Stress out of Engineering Your Vision!

Canterbury Solid. Works User Group CANSWUG About Me – Karl Celeste • Design Engineer for Motovated 1. 5 years • Worked on Designline projects both offsite and in-house • Solid. Works advocate

Canterbury Solid. Works User Group CANSWUG About Me – Karl Celeste • Design Engineer for Motovated 1. 5 years • Worked on Designline projects both offsite and in-house • Solid. Works advocate

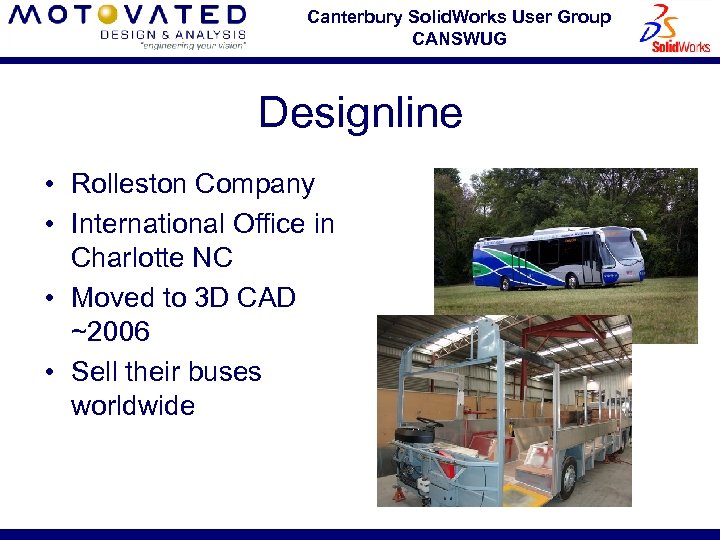

Canterbury Solid. Works User Group CANSWUG Designline • Rolleston Company • International Office in Charlotte NC • Moved to 3 D CAD ~2006 • Sell their buses worldwide

Canterbury Solid. Works User Group CANSWUG Designline • Rolleston Company • International Office in Charlotte NC • Moved to 3 D CAD ~2006 • Sell their buses worldwide

Canterbury Solid. Works User Group CANSWUG Motovated Design & Analysis • Christchurch based • Advanced Mechanical Engineering and Analysis via CAD • Helped Designline in transition to 3 D CAD • Continued on to US Hybrid Design/Modeling

Canterbury Solid. Works User Group CANSWUG Motovated Design & Analysis • Christchurch based • Advanced Mechanical Engineering and Analysis via CAD • Helped Designline in transition to 3 D CAD • Continued on to US Hybrid Design/Modeling

Canterbury Solid. Works User Group CANSWUG Challenges with Large Assemblies • Load time • File size • Even larger drw (x 10 not uncommon) • Write Access • Position Accuracy • Safeguarding modification • Robust mates, stability etc. over time

Canterbury Solid. Works User Group CANSWUG Challenges with Large Assemblies • Load time • File size • Even larger drw (x 10 not uncommon) • Write Access • Position Accuracy • Safeguarding modification • Robust mates, stability etc. over time

Canterbury Solid. Works User Group CANSWUG Client Needs • • • Flexibility Common & differential parts SW 2007 Multi-user environment without PDM Clear & easy to understand model structure Drawings mainly for BOM & general location

Canterbury Solid. Works User Group CANSWUG Client Needs • • • Flexibility Common & differential parts SW 2007 Multi-user environment without PDM Clear & easy to understand model structure Drawings mainly for BOM & general location

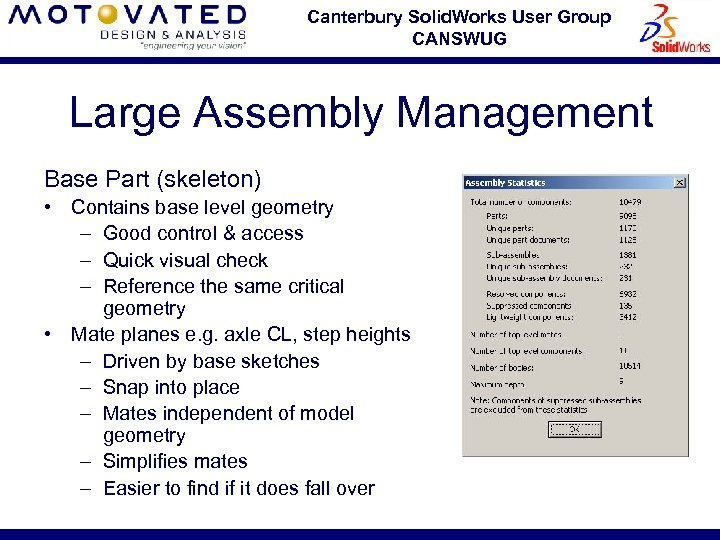

Canterbury Solid. Works User Group CANSWUG Large Assembly Management Base Part (skeleton) • Contains base level geometry – Good control & access – Quick visual check – Reference the same critical geometry • Mate planes e. g. axle CL, step heights – Driven by base sketches – Snap into place – Mates independent of model geometry – Simplifies mates – Easier to find if it does fall over

Canterbury Solid. Works User Group CANSWUG Large Assembly Management Base Part (skeleton) • Contains base level geometry – Good control & access – Quick visual check – Reference the same critical geometry • Mate planes e. g. axle CL, step heights – Driven by base sketches – Snap into place – Mates independent of model geometry – Simplifies mates – Easier to find if it does fall over

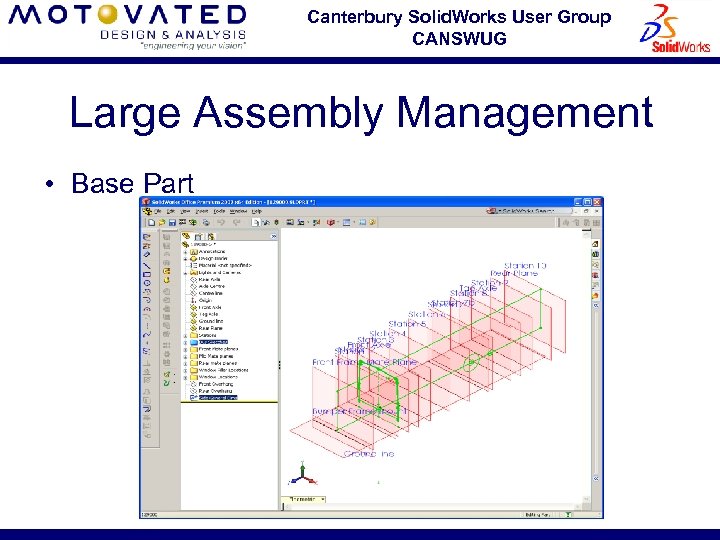

Canterbury Solid. Works User Group CANSWUG Large Assembly Management • Base Part

Canterbury Solid. Works User Group CANSWUG Large Assembly Management • Base Part

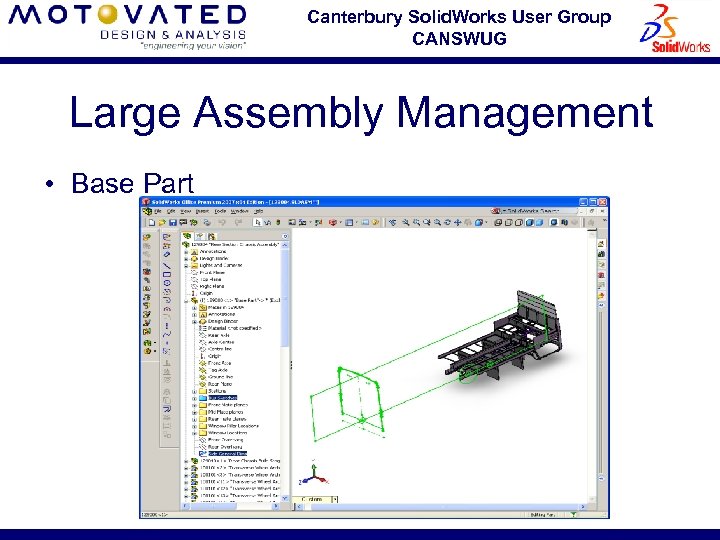

Canterbury Solid. Works User Group CANSWUG Large Assembly Management • Base Part

Canterbury Solid. Works User Group CANSWUG Large Assembly Management • Base Part

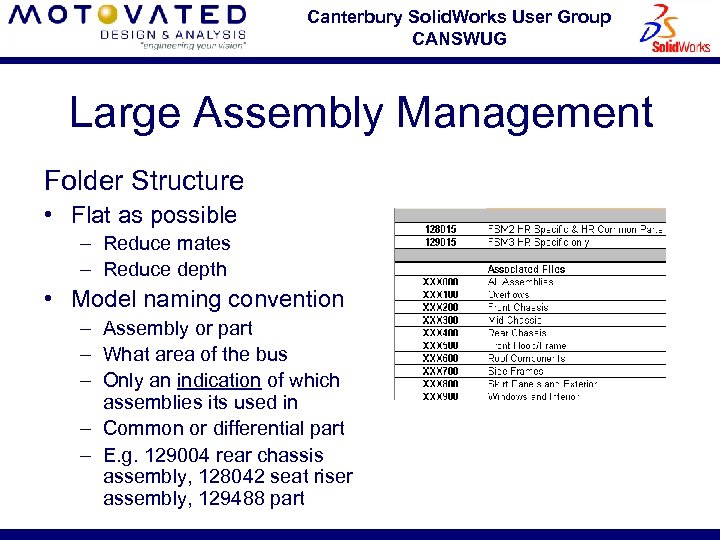

Canterbury Solid. Works User Group CANSWUG Large Assembly Management Folder Structure • Flat as possible – Reduce mates – Reduce depth • Model naming convention – Assembly or part – What area of the bus – Only an indication of which assemblies its used in – Common or differential part – E. g. 129004 rear chassis assembly, 128042 seat riser assembly, 129488 part

Canterbury Solid. Works User Group CANSWUG Large Assembly Management Folder Structure • Flat as possible – Reduce mates – Reduce depth • Model naming convention – Assembly or part – What area of the bus – Only an indication of which assemblies its used in – Common or differential part – E. g. 129004 rear chassis assembly, 128042 seat riser assembly, 129488 part

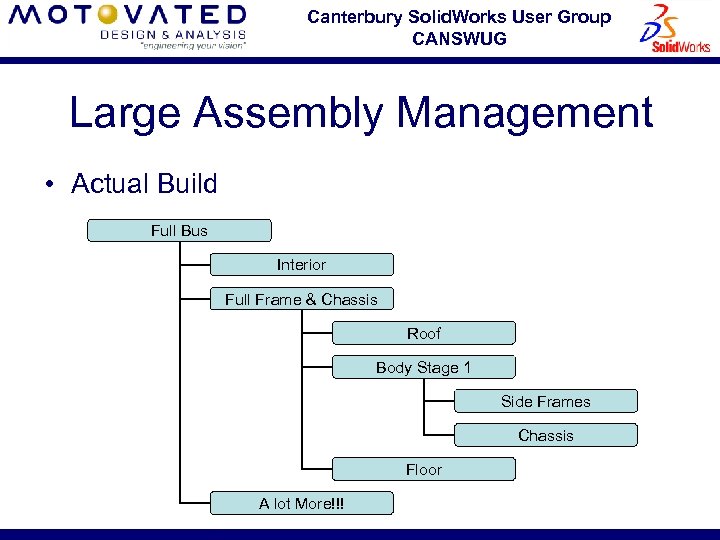

Canterbury Solid. Works User Group CANSWUG Large Assembly Management • Actual Build Full Bus Interior Full Frame & Chassis Roof Body Stage 1 Side Frames Chassis Floor A lot More!!!

Canterbury Solid. Works User Group CANSWUG Large Assembly Management • Actual Build Full Bus Interior Full Frame & Chassis Roof Body Stage 1 Side Frames Chassis Floor A lot More!!!

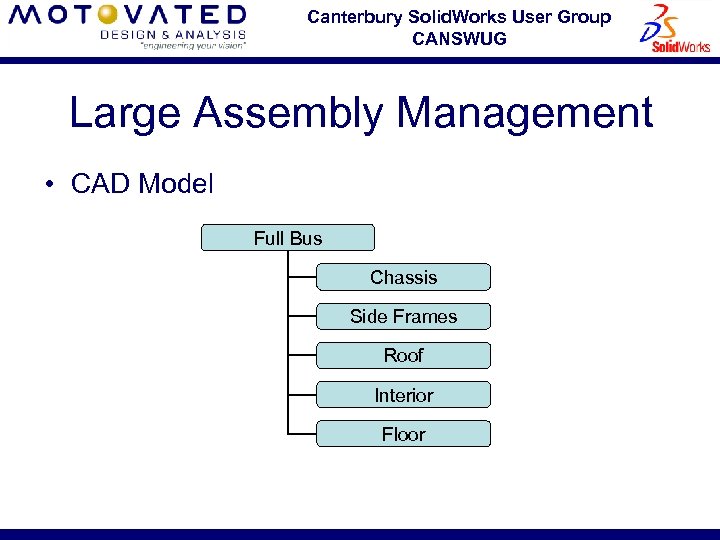

Canterbury Solid. Works User Group CANSWUG Large Assembly Management • CAD Model Full Bus Chassis Side Frames Roof Interior Floor

Canterbury Solid. Works User Group CANSWUG Large Assembly Management • CAD Model Full Bus Chassis Side Frames Roof Interior Floor

Canterbury Solid. Works User Group CANSWUG Large Assembly Management General • • Don’t model in context! Fully constrain sketches 1 drawing per model Display ‘shaded’ not ‘shaded with edges’ • Use supplier models or model over them

Canterbury Solid. Works User Group CANSWUG Large Assembly Management General • • Don’t model in context! Fully constrain sketches 1 drawing per model Display ‘shaded’ not ‘shaded with edges’ • Use supplier models or model over them

Canterbury Solid. Works User Group CANSWUG Large Assembly Management General • Remove all unnecessary info • Macros to speed up tedious processes e. g. re-use drawing, custom properties, pdf/dxf • Could use Speed Pak if using SW 2009+ • Avoid complexity

Canterbury Solid. Works User Group CANSWUG Large Assembly Management General • Remove all unnecessary info • Macros to speed up tedious processes e. g. re-use drawing, custom properties, pdf/dxf • Could use Speed Pak if using SW 2009+ • Avoid complexity

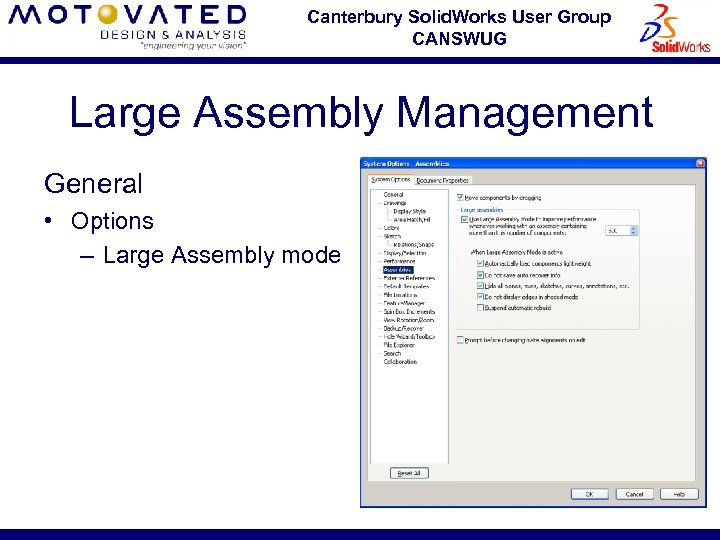

Canterbury Solid. Works User Group CANSWUG Large Assembly Management General • Options – Large Assembly mode

Canterbury Solid. Works User Group CANSWUG Large Assembly Management General • Options – Large Assembly mode

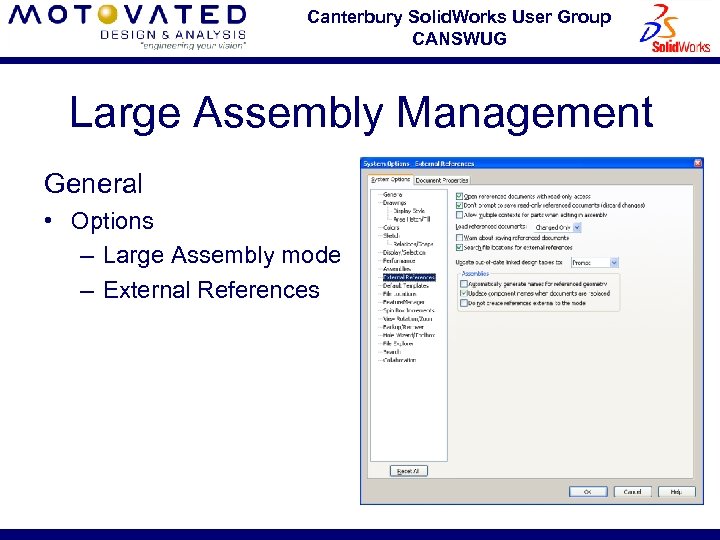

Canterbury Solid. Works User Group CANSWUG Large Assembly Management General • Options – Large Assembly mode – External References

Canterbury Solid. Works User Group CANSWUG Large Assembly Management General • Options – Large Assembly mode – External References

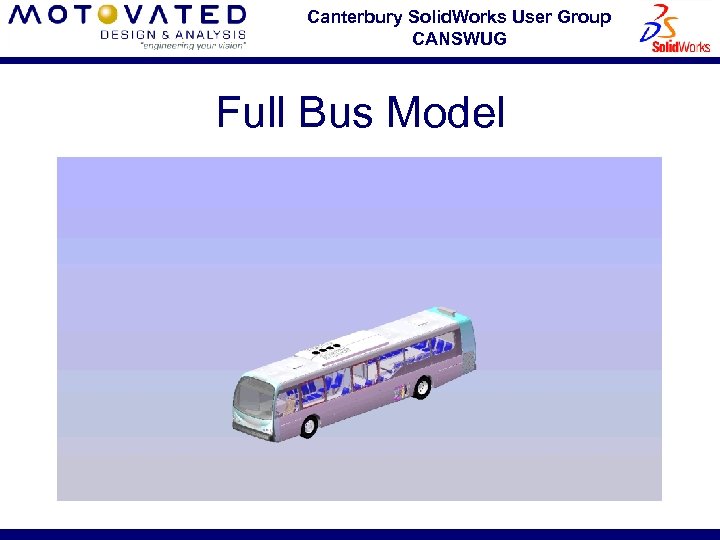

Canterbury Solid. Works User Group CANSWUG Full Bus Model

Canterbury Solid. Works User Group CANSWUG Full Bus Model

Canterbury Solid. Works User Group CANSWUG Questions?

Canterbury Solid. Works User Group CANSWUG Questions?