6c1e264ea7db4901a40e16aa0e12b794.ppt

- Количество слайдов: 42

Machine Design & Cost Reduction Activities Marc Ross Nick Walker Akira Yamamoto 1 st PAC Meeting 19 th October, 2008 1

Machine Design & Cost Reduction Activities Marc Ross Nick Walker Akira Yamamoto 1 st PAC Meeting 19 th October, 2008 1

Content • Brief (and superficial) introduction to RDR baseline. • The RDR cost estimate • Technical Design Phase cost-reduction strategy – the Minimum Machine 2

Content • Brief (and superficial) introduction to RDR baseline. • The RDR cost estimate • Technical Design Phase cost-reduction strategy – the Minimum Machine 2

ILC Requirements • Ecm adjustable from 200 – 500 Ge. V • Luminosity: ∫Ldt = 500 fb-1 in 4 years – Peak at max. energy of 2× 1034 cm-2 s-1 – Assume 1/g L scaling for <500 Ge. V • • ILCSC Parameters group Energy stability and precision below 0. 1% Electron polarization of at least 80% The machine must be upgradeable to 1 Te. V Two detectors – Single IR in push-pull configuration – Detector change-over in not more than 1 week 3

ILC Requirements • Ecm adjustable from 200 – 500 Ge. V • Luminosity: ∫Ldt = 500 fb-1 in 4 years – Peak at max. energy of 2× 1034 cm-2 s-1 – Assume 1/g L scaling for <500 Ge. V • • ILCSC Parameters group Energy stability and precision below 0. 1% Electron polarization of at least 80% The machine must be upgradeable to 1 Te. V Two detectors – Single IR in push-pull configuration – Detector change-over in not more than 1 week 3

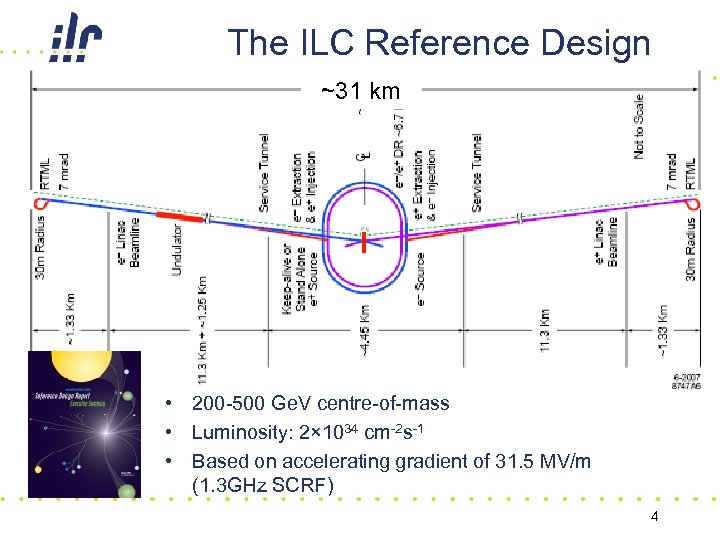

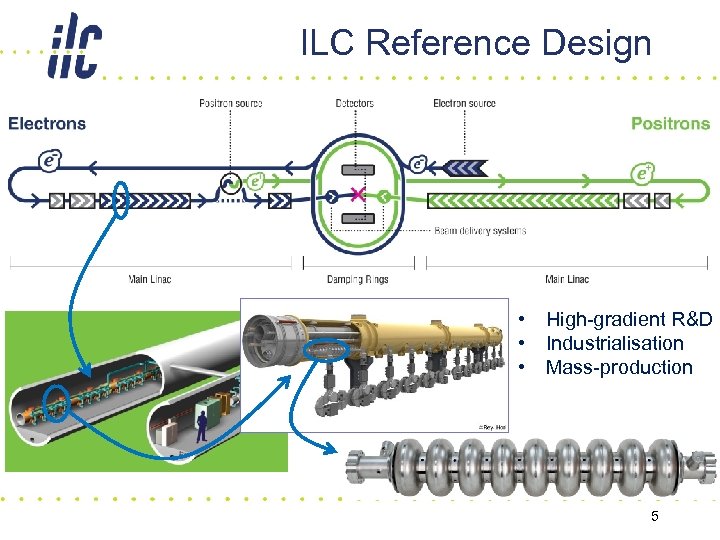

The ILC Reference Design ~31 km • 200 -500 Ge. V centre-of-mass • Luminosity: 2× 1034 cm-2 s-1 • Based on accelerating gradient of 31. 5 MV/m (1. 3 GHz SCRF) 4

The ILC Reference Design ~31 km • 200 -500 Ge. V centre-of-mass • Luminosity: 2× 1034 cm-2 s-1 • Based on accelerating gradient of 31. 5 MV/m (1. 3 GHz SCRF) 4

ILC Reference Design • • • High-gradient R&D Industrialisation Mass-production 5

ILC Reference Design • • • High-gradient R&D Industrialisation Mass-production 5

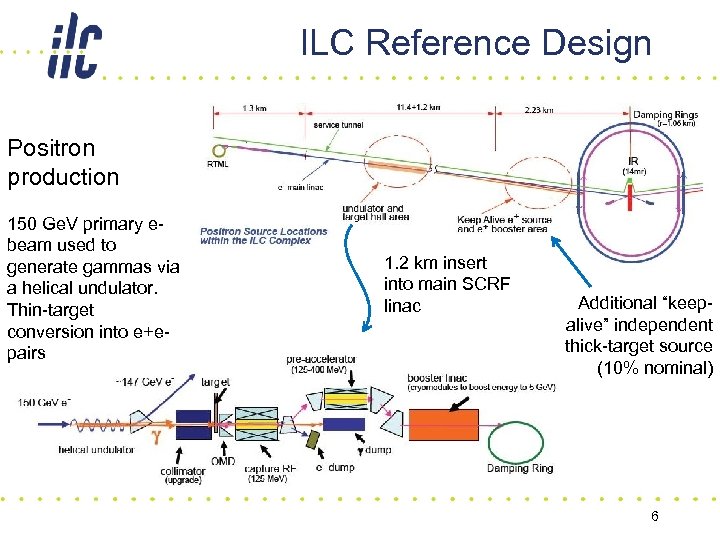

ILC Reference Design Positron production 150 Ge. V primary ebeam used to generate gammas via a helical undulator. Thin-target conversion into e+epairs 1. 2 km insert into main SCRF linac Additional “keepalive” independent thick-target source (10% nominal) 6

ILC Reference Design Positron production 150 Ge. V primary ebeam used to generate gammas via a helical undulator. Thin-target conversion into e+epairs 1. 2 km insert into main SCRF linac Additional “keepalive” independent thick-target source (10% nominal) 6

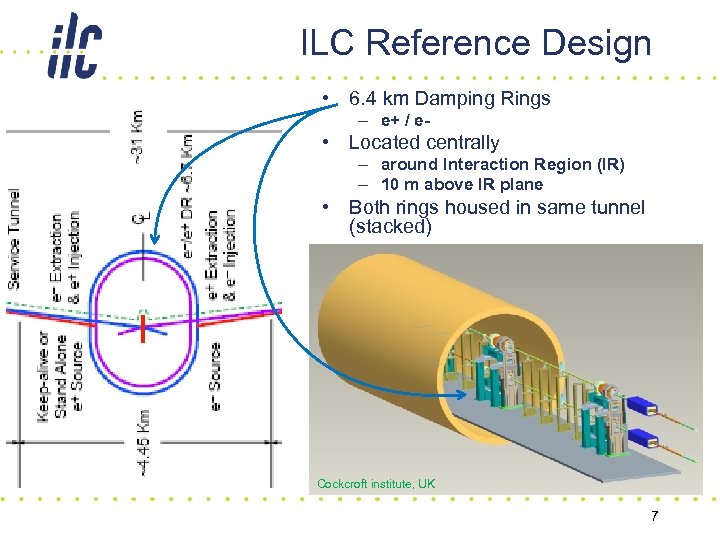

ILC Reference Design • 6. 4 km Damping Rings – e+ / e- • Located centrally – around Interaction Region (IR) – 10 m above IR plane • Both rings housed in same tunnel (stacked) Cockcroft institute, UK 7

ILC Reference Design • 6. 4 km Damping Rings – e+ / e- • Located centrally – around Interaction Region (IR) – 10 m above IR plane • Both rings housed in same tunnel (stacked) Cockcroft institute, UK 7

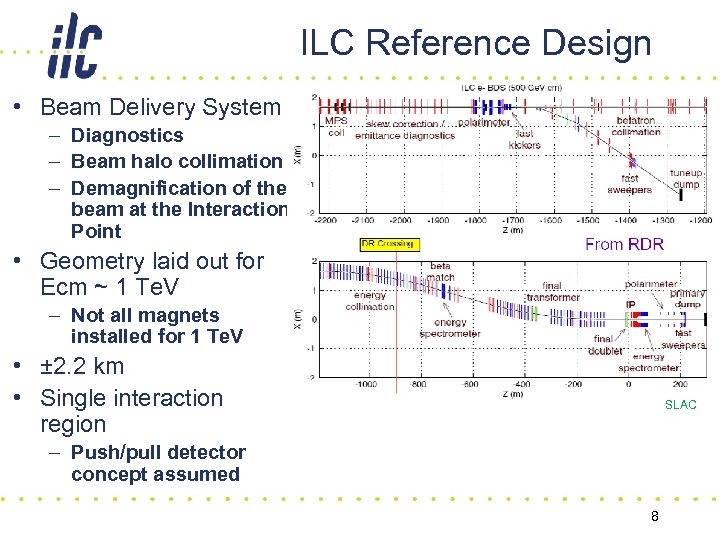

ILC Reference Design • Beam Delivery System – Diagnostics – Beam halo collimation – Demagnification of the beam at the Interaction Point • Geometry laid out for Ecm ~ 1 Te. V – Not all magnets installed for 1 Te. V • ± 2. 2 km • Single interaction region SLAC – Push/pull detector concept assumed 8

ILC Reference Design • Beam Delivery System – Diagnostics – Beam halo collimation – Demagnification of the beam at the Interaction Point • Geometry laid out for Ecm ~ 1 Te. V – Not all magnets installed for 1 Te. V • ± 2. 2 km • Single interaction region SLAC – Push/pull detector concept assumed 8

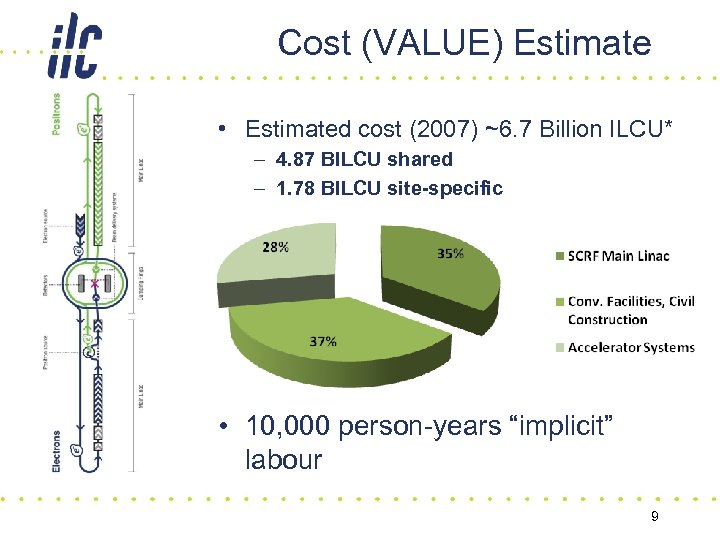

Cost (VALUE) Estimate • Estimated cost (2007) ~6. 7 Billion ILCU* – 4. 87 BILCU shared – 1. 78 BILCU site-specific • 10, 000 person-years “implicit” labour 9

Cost (VALUE) Estimate • Estimated cost (2007) ~6. 7 Billion ILCU* – 4. 87 BILCU shared – 1. 78 BILCU site-specific • 10, 000 person-years “implicit” labour 9

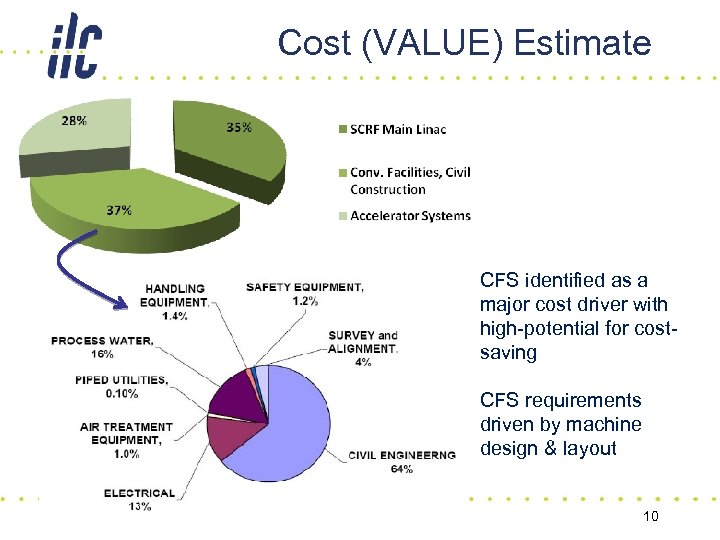

Cost (VALUE) Estimate CFS identified as a major cost driver with high-potential for costsaving CFS requirements driven by machine design & layout 10

Cost (VALUE) Estimate CFS identified as a major cost driver with high-potential for costsaving CFS requirements driven by machine design & layout 10

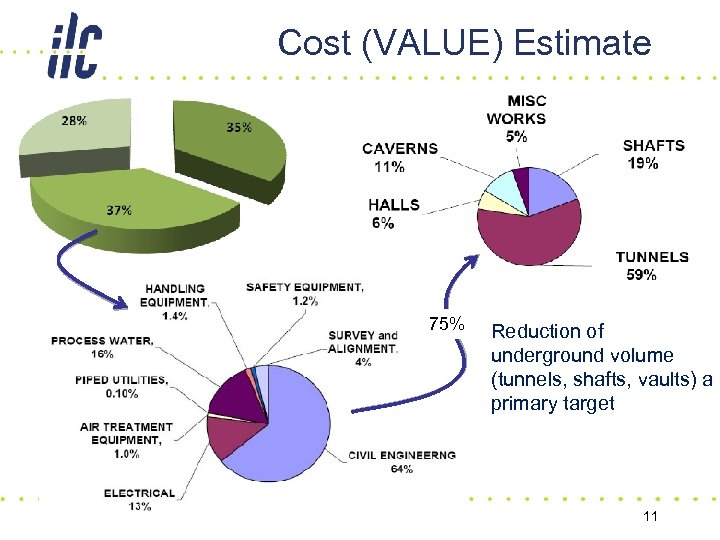

Cost (VALUE) Estimate 75% Reduction of underground volume (tunnels, shafts, vaults) a primary target 11

Cost (VALUE) Estimate 75% Reduction of underground volume (tunnels, shafts, vaults) a primary target 11

Stated TD Phase Goals (1/2) From the R&D Plan rel 2 (chapter 4) • Definition of the basic parameters and layout of a “minimum machine configuration”, as a basis for understand costincrements and cost-performance trade-offs (beginning 2009) • Cost-reduction and performance studies (parametric studies) of the minimum machine, leading to possible options for the rebaseline. Evaluation of estimated cost and performance risk impact (end 2009). • As part of the above, studies of a cost-optimised “shallow site” with a view to defining an optimum ‘reference site’ for further design studies (end 2009). 12

Stated TD Phase Goals (1/2) From the R&D Plan rel 2 (chapter 4) • Definition of the basic parameters and layout of a “minimum machine configuration”, as a basis for understand costincrements and cost-performance trade-offs (beginning 2009) • Cost-reduction and performance studies (parametric studies) of the minimum machine, leading to possible options for the rebaseline. Evaluation of estimated cost and performance risk impact (end 2009). • As part of the above, studies of a cost-optimised “shallow site” with a view to defining an optimum ‘reference site’ for further design studies (end 2009). 12

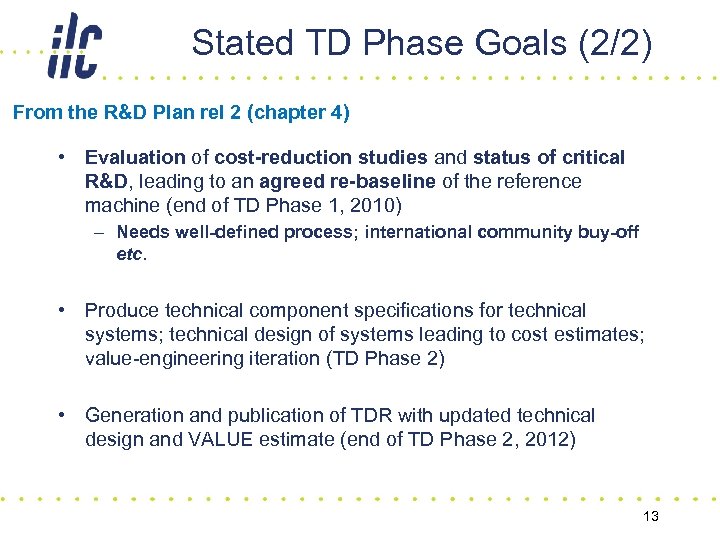

Stated TD Phase Goals (2/2) From the R&D Plan rel 2 (chapter 4) • Evaluation of cost-reduction studies and status of critical R&D, leading to an agreed re-baseline of the reference machine (end of TD Phase 1, 2010) – Needs well-defined process; international community buy-off etc. • Produce technical component specifications for technical systems; technical design of systems leading to cost estimates; value-engineering iteration (TD Phase 2) • Generation and publication of TDR with updated technical design and VALUE estimate (end of TD Phase 2, 2012) 13

Stated TD Phase Goals (2/2) From the R&D Plan rel 2 (chapter 4) • Evaluation of cost-reduction studies and status of critical R&D, leading to an agreed re-baseline of the reference machine (end of TD Phase 1, 2010) – Needs well-defined process; international community buy-off etc. • Produce technical component specifications for technical systems; technical design of systems leading to cost estimates; value-engineering iteration (TD Phase 2) • Generation and publication of TDR with updated technical design and VALUE estimate (end of TD Phase 2, 2012) 13

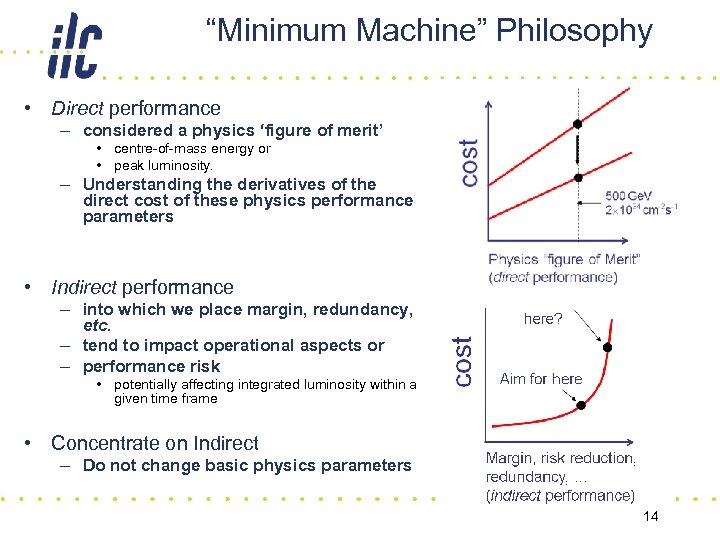

“Minimum Machine” Philosophy • Direct performance – considered a physics ‘figure of merit’ • centre-of-mass energy or • peak luminosity. – Understanding the derivatives of the direct cost of these physics performance parameters • Indirect performance – into which we place margin, redundancy, etc. – tend to impact operational aspects or – performance risk • potentially affecting integrated luminosity within a given time frame • Concentrate on Indirect – Do not change basic physics parameters 14

“Minimum Machine” Philosophy • Direct performance – considered a physics ‘figure of merit’ • centre-of-mass energy or • peak luminosity. – Understanding the derivatives of the direct cost of these physics performance parameters • Indirect performance – into which we place margin, redundancy, etc. – tend to impact operational aspects or – performance risk • potentially affecting integrated luminosity within a given time frame • Concentrate on Indirect – Do not change basic physics parameters 14

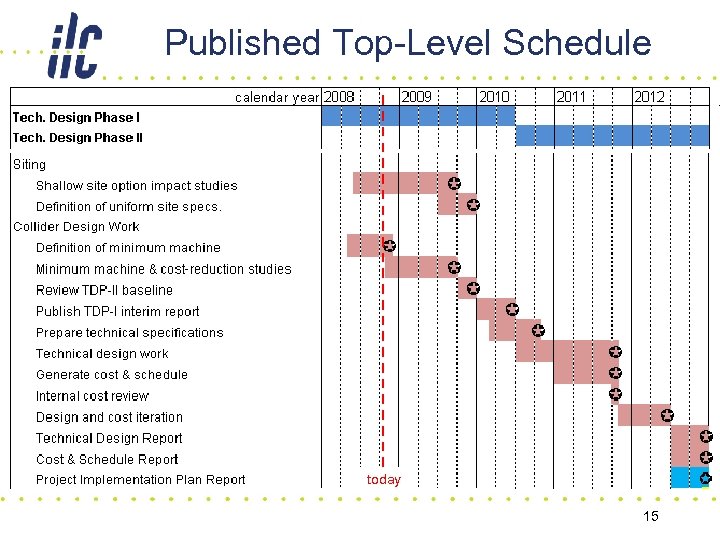

Published Top-Level Schedule today 15

Published Top-Level Schedule today 15

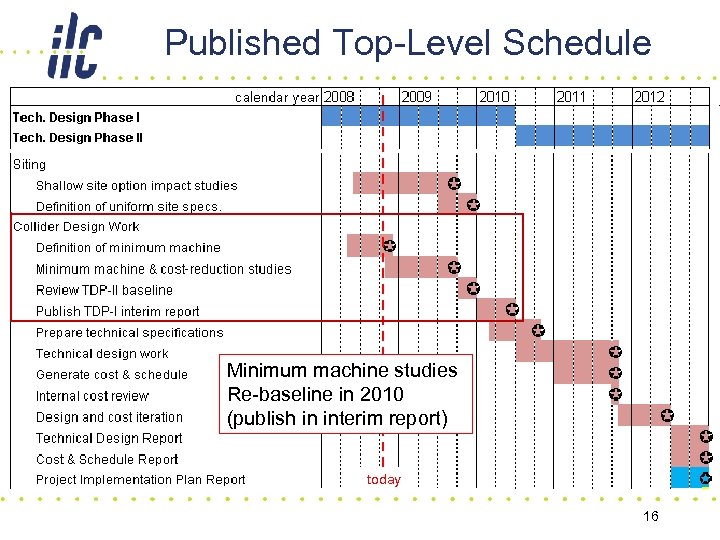

Published Top-Level Schedule Minimum machine studies Re-baseline in 2010 (publish in interim report) today 16

Published Top-Level Schedule Minimum machine studies Re-baseline in 2010 (publish in interim report) today 16

Minimum Machine: Current Definition • “Minimum Machine” now refers to a set of identified options (elements) which may prove cost-effective • Not a minimum in a definable sense – But a potential reduced-cost solutions… – with a potentially less margin (performance) • An alternative design for study purposes – Comparison with RDR baseline – Cost (not performance) driven – options which were not studied during RDR phase • Important to restrict options to manageable levels – available resources 17

Minimum Machine: Current Definition • “Minimum Machine” now refers to a set of identified options (elements) which may prove cost-effective • Not a minimum in a definable sense – But a potential reduced-cost solutions… – with a potentially less margin (performance) • An alternative design for study purposes – Comparison with RDR baseline – Cost (not performance) driven – options which were not studied during RDR phase • Important to restrict options to manageable levels – available resources 17

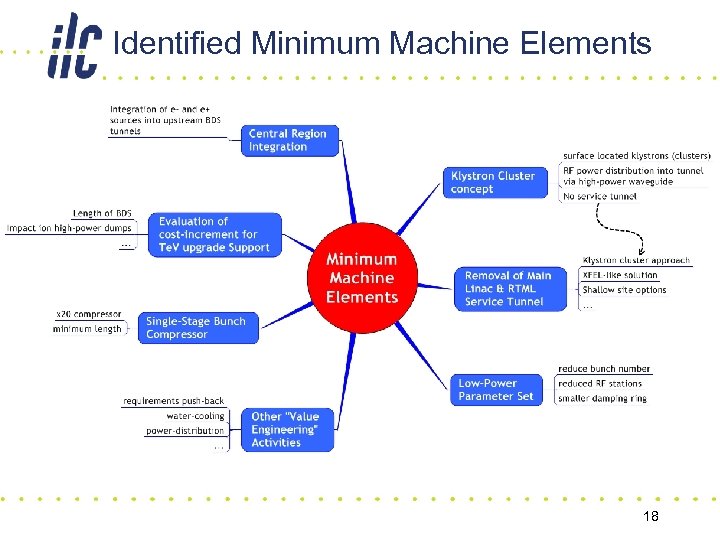

Identified Minimum Machine Elements 18

Identified Minimum Machine Elements 18

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 19

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 19

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 20

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 20

Main Linac Specific • Removal of support tunnel (single tunnel) – klystron cluster – XFEL-like – shallow site (JINR/Dubna) alternative options • Klystron Cluster (HLRF) – 30 klystrons located in localised surface buildings – ~300 MW RF power distributed in beam tunnel via overmoded waveguide – effectively ~1 km RF unit • Marx modulator – ongoing SLAC prototype • Reduced cost solution for process-water cooling – Higher DT specification (e. g. klystron cooling) 21

Main Linac Specific • Removal of support tunnel (single tunnel) – klystron cluster – XFEL-like – shallow site (JINR/Dubna) alternative options • Klystron Cluster (HLRF) – 30 klystrons located in localised surface buildings – ~300 MW RF power distributed in beam tunnel via overmoded waveguide – effectively ~1 km RF unit • Marx modulator – ongoing SLAC prototype • Reduced cost solution for process-water cooling – Higher DT specification (e. g. klystron cooling) 21

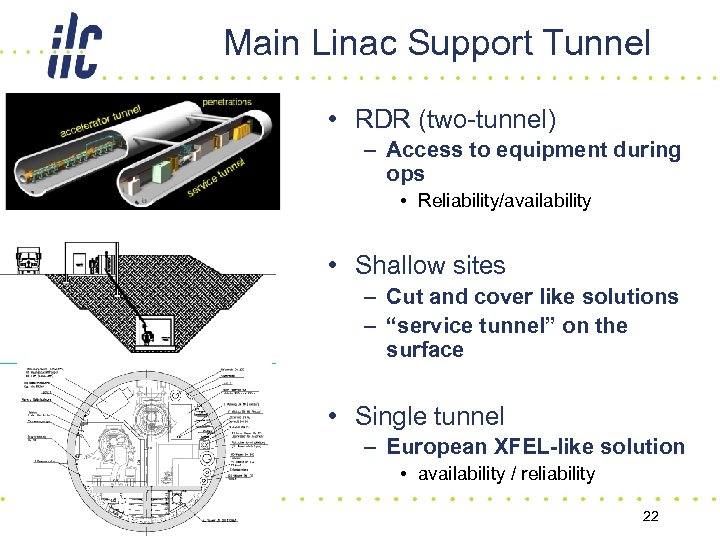

Main Linac Support Tunnel • RDR (two-tunnel) – Access to equipment during ops • Reliability/availability • Shallow sites – Cut and cover like solutions – “service tunnel” on the surface • Single tunnel – European XFEL-like solution • availability / reliability 22

Main Linac Support Tunnel • RDR (two-tunnel) – Access to equipment during ops • Reliability/availability • Shallow sites – Cut and cover like solutions – “service tunnel” on the surface • Single tunnel – European XFEL-like solution • availability / reliability 22

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 23

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 23

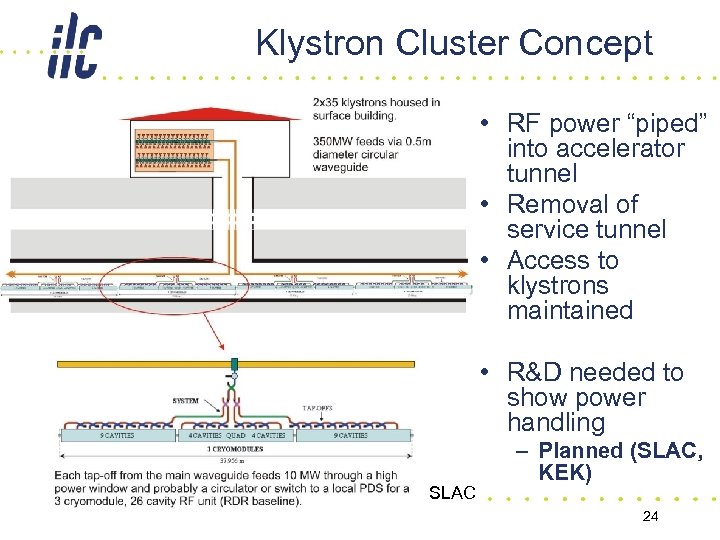

Klystron Cluster Concept • RF power “piped” into accelerator tunnel • Removal of service tunnel • Access to klystrons maintained • R&D needed to show power handling SLAC – Planned (SLAC, KEK) 24

Klystron Cluster Concept • RF power “piped” into accelerator tunnel • Removal of service tunnel • Access to klystrons maintained • R&D needed to show power handling SLAC – Planned (SLAC, KEK) 24

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 25

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 25

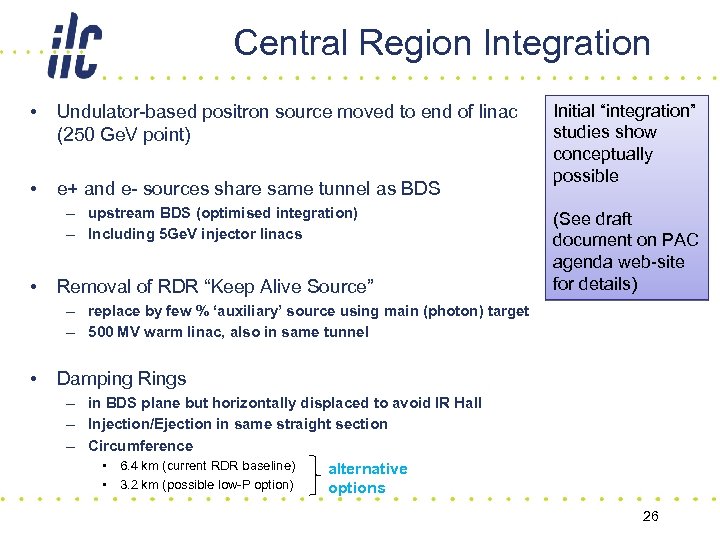

Central Region Integration • Undulator-based positron source moved to end of linac (250 Ge. V point) • e+ and e- sources share same tunnel as BDS – upstream BDS (optimised integration) – Including 5 Ge. V injector linacs • Removal of RDR “Keep Alive Source” Initial “integration” studies show conceptually possible (See draft document on PAC agenda web-site for details) – replace by few % ‘auxiliary’ source using main (photon) target – 500 MV warm linac, also in same tunnel • Damping Rings – in BDS plane but horizontally displaced to avoid IR Hall – Injection/Ejection in same straight section – Circumference • 6. 4 km (current RDR baseline) alternative • 3. 2 km (possible low-P option) options 26

Central Region Integration • Undulator-based positron source moved to end of linac (250 Ge. V point) • e+ and e- sources share same tunnel as BDS – upstream BDS (optimised integration) – Including 5 Ge. V injector linacs • Removal of RDR “Keep Alive Source” Initial “integration” studies show conceptually possible (See draft document on PAC agenda web-site for details) – replace by few % ‘auxiliary’ source using main (photon) target – 500 MV warm linac, also in same tunnel • Damping Rings – in BDS plane but horizontally displaced to avoid IR Hall – Injection/Ejection in same straight section – Circumference • 6. 4 km (current RDR baseline) alternative • 3. 2 km (possible low-P option) options 26

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 27

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 27

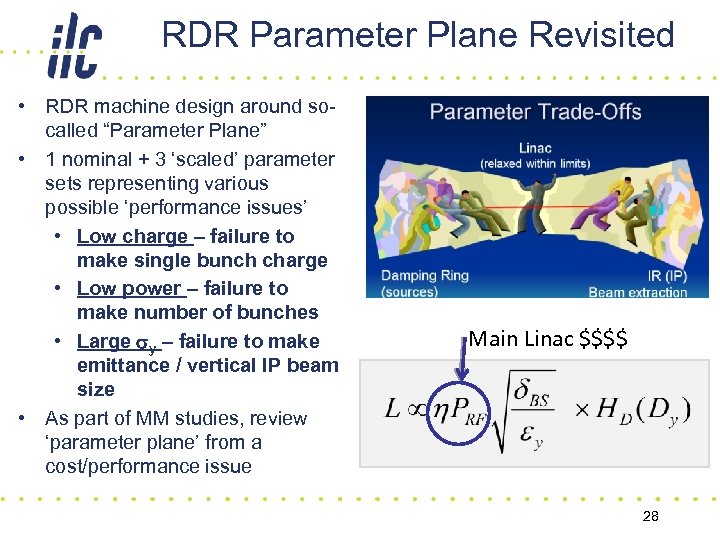

RDR Parameter Plane Revisited • RDR machine design around socalled “Parameter Plane” • 1 nominal + 3 ‘scaled’ parameter sets representing various possible ‘performance issues’ • Low charge – failure to make single bunch charge • Low power – failure to make number of bunches • Large sy – failure to make emittance / vertical IP beam size • As part of MM studies, review ‘parameter plane’ from a cost/performance issue Main Linac $$$$ 28

RDR Parameter Plane Revisited • RDR machine design around socalled “Parameter Plane” • 1 nominal + 3 ‘scaled’ parameter sets representing various possible ‘performance issues’ • Low charge – failure to make single bunch charge • Low power – failure to make number of bunches • Large sy – failure to make emittance / vertical IP beam size • As part of MM studies, review ‘parameter plane’ from a cost/performance issue Main Linac $$$$ 28

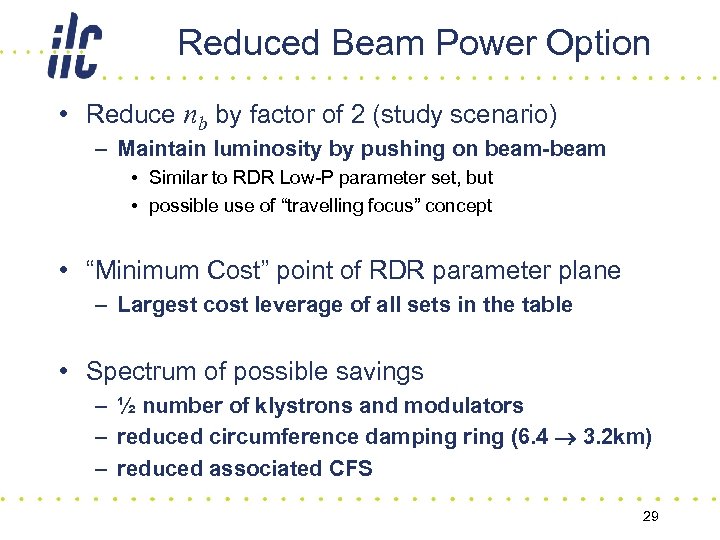

Reduced Beam Power Option • Reduce nb by factor of 2 (study scenario) – Maintain luminosity by pushing on beam-beam • Similar to RDR Low-P parameter set, but • possible use of “travelling focus” concept • “Minimum Cost” point of RDR parameter plane – Largest cost leverage of all sets in the table • Spectrum of possible savings – ½ number of klystrons and modulators – reduced circumference damping ring (6. 4 3. 2 km) – reduced associated CFS 29

Reduced Beam Power Option • Reduce nb by factor of 2 (study scenario) – Maintain luminosity by pushing on beam-beam • Similar to RDR Low-P parameter set, but • possible use of “travelling focus” concept • “Minimum Cost” point of RDR parameter plane – Largest cost leverage of all sets in the table • Spectrum of possible savings – ½ number of klystrons and modulators – reduced circumference damping ring (6. 4 3. 2 km) – reduced associated CFS 29

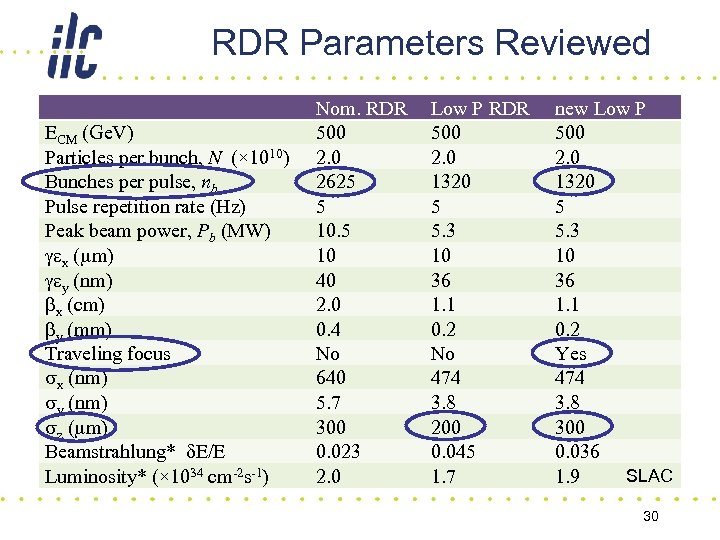

RDR Parameters Reviewed ECM (Ge. V) Particles per bunch, N (× 1010) Bunches per pulse, nb Pulse repetition rate (Hz) Peak beam power, Pb (MW) gex (mm) gey (nm) bx (cm) by (mm) Traveling focus sx (nm) sy (nm) sz (mm) Beamstrahlung* d. E/E Luminosity* (× 1034 cm-2 s-1) Nom. RDR 500 2. 0 2625 5 10 40 2. 0 0. 4 No 640 5. 7 300 0. 023 2. 0 Low P RDR 500 2. 0 1320 5 5. 3 10 36 1. 1 0. 2 No 474 3. 8 200 0. 045 1. 7 new Low P 500 2. 0 1320 5 5. 3 10 36 1. 1 0. 2 Yes 474 3. 8 300 0. 036 SLAC 1. 9 30

RDR Parameters Reviewed ECM (Ge. V) Particles per bunch, N (× 1010) Bunches per pulse, nb Pulse repetition rate (Hz) Peak beam power, Pb (MW) gex (mm) gey (nm) bx (cm) by (mm) Traveling focus sx (nm) sy (nm) sz (mm) Beamstrahlung* d. E/E Luminosity* (× 1034 cm-2 s-1) Nom. RDR 500 2. 0 2625 5 10 40 2. 0 0. 4 No 640 5. 7 300 0. 023 2. 0 Low P RDR 500 2. 0 1320 5 5. 3 10 36 1. 1 0. 2 No 474 3. 8 200 0. 045 1. 7 new Low P 500 2. 0 1320 5 5. 3 10 36 1. 1 0. 2 Yes 474 3. 8 300 0. 036 SLAC 1. 9 30

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 31

Minimum Machine Elements 1. Single-tunnel solution(s) 2. Klystron Cluster concept 3. Central region integration 4. Low beam power option 5. Single-stage compressor 6. Quantify cost of Te. V upgrade support 7. “Value engineering” 31

Remaining MM Study Elements • Single-stage compressor – Factor 20 bunch compression (sz 300 mm @IP) – (RDR two-stage compressor with factor 45) • Quantify cost of Te. V upgrade support in RDR – Minimum length 500 Ge. V Ecm BDS – (High-power dumps? ) Encouraged activities • Other “VALUE Engineering” – – Water cooling Vacuum solutions Magnets & Power supplies … Considered parallel (ongoing) to main ‘layout’ discussions (not primary cost drivers) 32

Remaining MM Study Elements • Single-stage compressor – Factor 20 bunch compression (sz 300 mm @IP) – (RDR two-stage compressor with factor 45) • Quantify cost of Te. V upgrade support in RDR – Minimum length 500 Ge. V Ecm BDS – (High-power dumps? ) Encouraged activities • Other “VALUE Engineering” – – Water cooling Vacuum solutions Magnets & Power supplies … Considered parallel (ongoing) to main ‘layout’ discussions (not primary cost drivers) 32

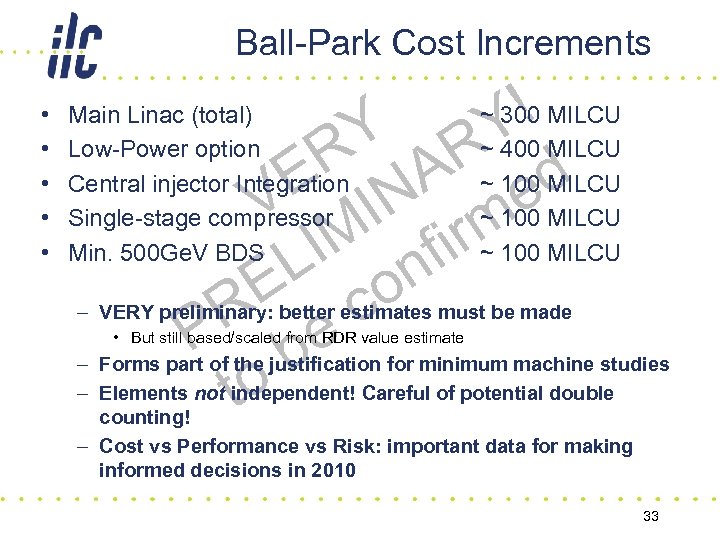

Ball-Park Cost Increments • • • ! Y Y R R A d E IN e V M firm I n L o E c R e P b to Main Linac (total) Low-Power option Central injector Integration Single-stage compressor Min. 500 Ge. V BDS ~ 300 MILCU ~ 400 MILCU ~ 100 MILCU – VERY preliminary: better estimates must be made • But still based/scaled from RDR value estimate – Forms part of the justification for minimum machine studies – Elements not independent! Careful of potential double counting! – Cost vs Performance vs Risk: important data for making informed decisions in 2010 33

Ball-Park Cost Increments • • • ! Y Y R R A d E IN e V M firm I n L o E c R e P b to Main Linac (total) Low-Power option Central injector Integration Single-stage compressor Min. 500 Ge. V BDS ~ 300 MILCU ~ 400 MILCU ~ 100 MILCU – VERY preliminary: better estimates must be made • But still based/scaled from RDR value estimate – Forms part of the justification for minimum machine studies – Elements not independent! Careful of potential double counting! – Cost vs Performance vs Risk: important data for making informed decisions in 2010 33

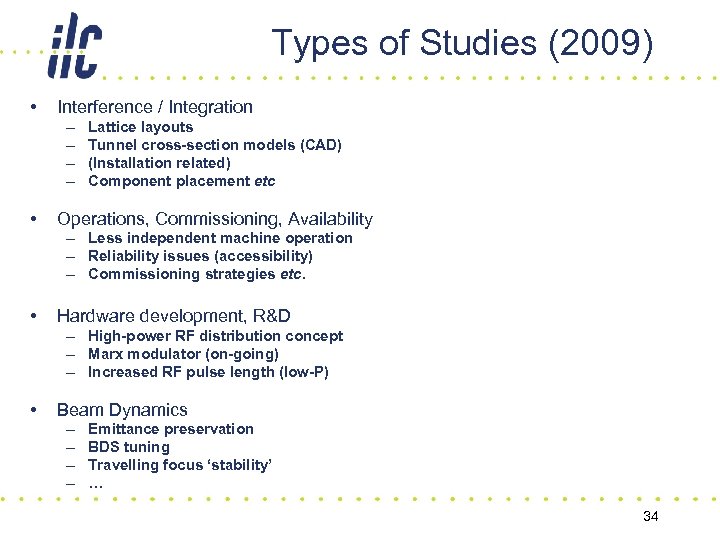

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – Emittance preservation BDS tuning Travelling focus ‘stability’ … 34

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – Emittance preservation BDS tuning Travelling focus ‘stability’ … 34

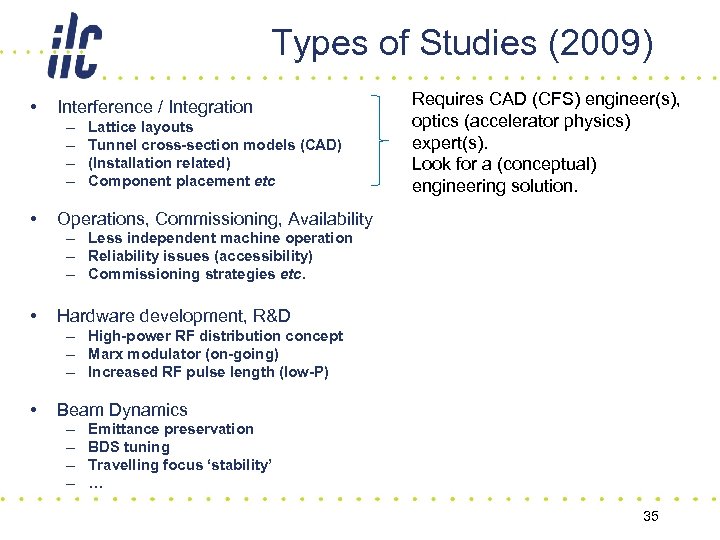

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Requires CAD (CFS) engineer(s), optics (accelerator physics) expert(s). Look for a (conceptual) engineering solution. Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – Emittance preservation BDS tuning Travelling focus ‘stability’ … 35

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Requires CAD (CFS) engineer(s), optics (accelerator physics) expert(s). Look for a (conceptual) engineering solution. Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – Emittance preservation BDS tuning Travelling focus ‘stability’ … 35

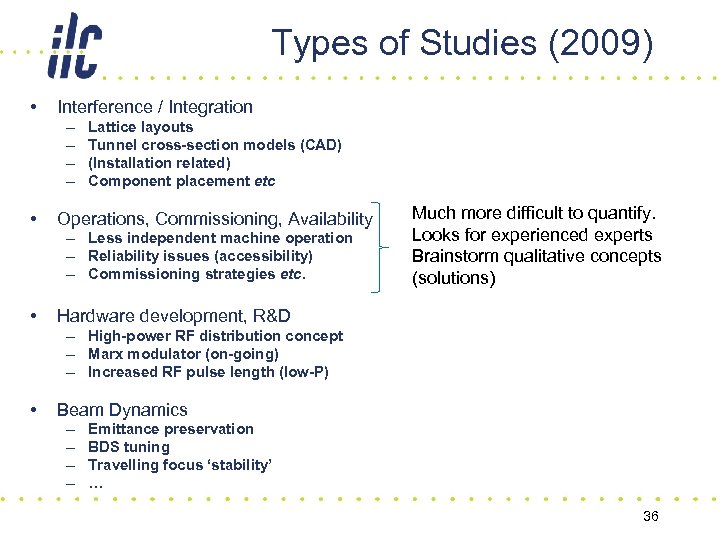

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Much more difficult to quantify. Looks for experienced experts Brainstorm qualitative concepts (solutions) Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – Emittance preservation BDS tuning Travelling focus ‘stability’ … 36

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Much more difficult to quantify. Looks for experienced experts Brainstorm qualitative concepts (solutions) Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – Emittance preservation BDS tuning Travelling focus ‘stability’ … 36

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – FTE and MS required. Well defined goals for R&D programme. Acceptance criteria of proposed solution. Emittance preservation BDS tuning Travelling focus ‘stability’ … 37

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – FTE and MS required. Well defined goals for R&D programme. Acceptance criteria of proposed solution. Emittance preservation BDS tuning Travelling focus ‘stability’ … 37

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – Emittance preservation BDS tuning Travelling focus ‘stability’ … Beam dynamics and simulation specialists (lc experts). (good coordination, well defined questions) 38

Types of Studies (2009) • Interference / Integration – – • Lattice layouts Tunnel cross-section models (CAD) (Installation related) Component placement etc Operations, Commissioning, Availability – Less independent machine operation – Reliability issues (accessibility) – Commissioning strategies etc. • Hardware development, R&D – High-power RF distribution concept – Marx modulator (on-going) – Increased RF pulse length (low-P) • Beam Dynamics – – Emittance preservation BDS tuning Travelling focus ‘stability’ … Beam dynamics and simulation specialists (lc experts). (good coordination, well defined questions) 38

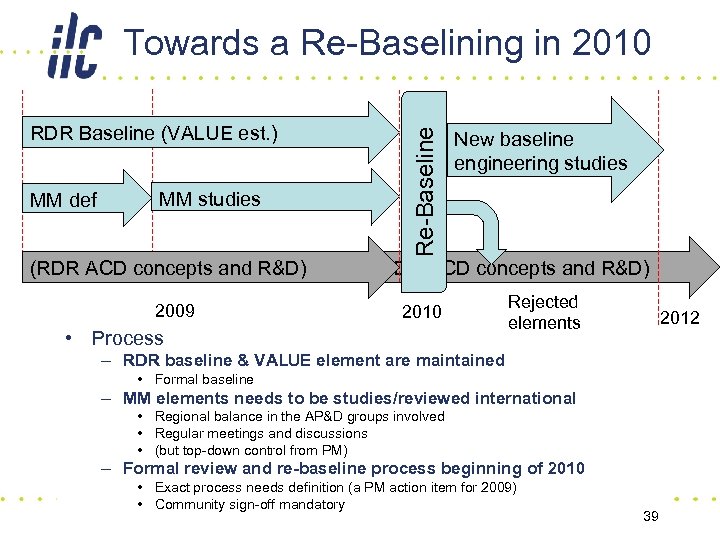

RDR Baseline (VALUE est. ) MM def MM studies (RDR ACD concepts and R&D) 2009 Re-Baseline Towards a Re-Baselining in 2010 New baseline engineering studies (RDR ACD concepts and R&D) 2010 • Process Rejected elements 2012 – RDR baseline & VALUE element are maintained • Formal baseline – MM elements needs to be studies/reviewed international • Regional balance in the AP&D groups involved • Regular meetings and discussions • (but top-down control from PM) – Formal review and re-baseline process beginning of 2010 • Exact process needs definition (a PM action item for 2009) • Community sign-off mandatory 39

RDR Baseline (VALUE est. ) MM def MM studies (RDR ACD concepts and R&D) 2009 Re-Baseline Towards a Re-Baselining in 2010 New baseline engineering studies (RDR ACD concepts and R&D) 2010 • Process Rejected elements 2012 – RDR baseline & VALUE element are maintained • Formal baseline – MM elements needs to be studies/reviewed international • Regional balance in the AP&D groups involved • Regular meetings and discussions • (but top-down control from PM) – Formal review and re-baseline process beginning of 2010 • Exact process needs definition (a PM action item for 2009) • Community sign-off mandatory 39

Minimum Machine Document in Preparation • Draft document is preparation • (draft available on PAC website) • (One) Focus of ILC 08 workshop – Study planning – Resources • Final publication end of year 40

Minimum Machine Document in Preparation • Draft document is preparation • (draft available on PAC website) • (One) Focus of ILC 08 workshop – Study planning – Resources • Final publication end of year 40

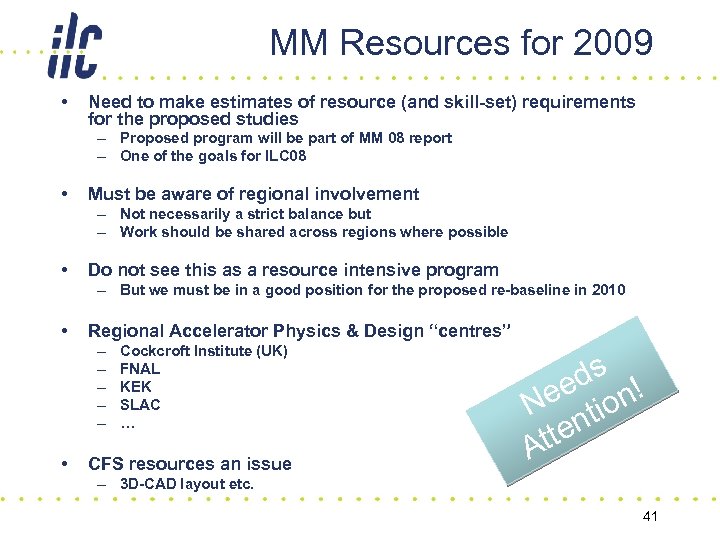

MM Resources for 2009 • Need to make estimates of resource (and skill-set) requirements for the proposed studies – Proposed program will be part of MM 08 report – One of the goals for ILC 08 • Must be aware of regional involvement – Not necessarily a strict balance but – Work should be shared across regions where possible • Do not see this as a resource intensive program – But we must be in a good position for the proposed re-baseline in 2010 • Regional Accelerator Physics & Design “centres” – – – • Cockcroft Institute (UK) FNAL KEK SLAC … CFS resources an issue ds ! ee ion N t ten At – 3 D-CAD layout etc. 41

MM Resources for 2009 • Need to make estimates of resource (and skill-set) requirements for the proposed studies – Proposed program will be part of MM 08 report – One of the goals for ILC 08 • Must be aware of regional involvement – Not necessarily a strict balance but – Work should be shared across regions where possible • Do not see this as a resource intensive program – But we must be in a good position for the proposed re-baseline in 2010 • Regional Accelerator Physics & Design “centres” – – – • Cockcroft Institute (UK) FNAL KEK SLAC … CFS resources an issue ds ! ee ion N t ten At – 3 D-CAD layout etc. 41

Summary • RDR design represents a solid and relative detailed baseline on which our current cost estimate is based • Assumption that design is ‘conservative – potential opportunities for significant cost reduction – Primary target for machine designers: reduction of underground volume! • Minimum machine accelerator physics/design activities for 2009 – Formal re-baseline in early 2010 for TD Phase 2 activities – Guesstimate ball-park savings ~1 BILCU – (In parallel with critical risk-mitigating R&D) • MM document defining scope and detailed 2009 study plans to be published after ILC 08 • 2009 resources are an issue and need close scrutiny 42

Summary • RDR design represents a solid and relative detailed baseline on which our current cost estimate is based • Assumption that design is ‘conservative – potential opportunities for significant cost reduction – Primary target for machine designers: reduction of underground volume! • Minimum machine accelerator physics/design activities for 2009 – Formal re-baseline in early 2010 for TD Phase 2 activities – Guesstimate ball-park savings ~1 BILCU – (In parallel with critical risk-mitigating R&D) • MM document defining scope and detailed 2009 study plans to be published after ILC 08 • 2009 resources are an issue and need close scrutiny 42