m a n a g e m e n t 2 e Hitt/Black/Porter Chapter 13: Operations Management Power. Point slides by Susan A. Peterson, Scottsdale Community College #

m a n a g e m e n t 2 e Hitt/Black/Porter Chapter 13: Operations Management Power. Point slides by Susan A. Peterson, Scottsdale Community College #

Learning Objectives After studying this chapter, you should be able to: Define operations management and explain its importance within service and manufacturing firms Describe key techniques and tools for enhancing product and service quality Explain common means of ensuring appropriate product quantity Discuss tools for managing the appropriate timing of inventory and finished product © 2008 Prentice-Hall Business Publishing 2

Learning Objectives After studying this chapter, you should be able to: Define operations management and explain its importance within service and manufacturing firms Describe key techniques and tools for enhancing product and service quality Explain common means of ensuring appropriate product quantity Discuss tools for managing the appropriate timing of inventory and finished product © 2008 Prentice-Hall Business Publishing 2

Learning Objectives Describe methods for enhancing productivity and efficiency Explain the principle roles of effective supply chain management in the operations of organizations © 2008 Prentice-Hall Business Publishing 3

Learning Objectives Describe methods for enhancing productivity and efficiency Explain the principle roles of effective supply chain management in the operations of organizations © 2008 Prentice-Hall Business Publishing 3

Operations Management Operations management: focuses on the conversion of resources into products and services Old term: products and operations management (POM) Modern term: operations management (OM) © 2008 Prentice-Hall Business Publishing 4

Operations Management Operations management: focuses on the conversion of resources into products and services Old term: products and operations management (POM) Modern term: operations management (OM) © 2008 Prentice-Hall Business Publishing 4

Objectives of Operations Management Managing product/service quality Planning quantity and capacity Timing product and services Achieving the best possible cost © 2008 Prentice-Hall Business Publishing 5

Objectives of Operations Management Managing product/service quality Planning quantity and capacity Timing product and services Achieving the best possible cost © 2008 Prentice-Hall Business Publishing 5

Managing Quality: a measure of how well a product or service performs its intended purpose, including: How reliable it is How easy it is to service or repair when it does break down © 2008 Prentice-Hall Business Publishing 6

Managing Quality: a measure of how well a product or service performs its intended purpose, including: How reliable it is How easy it is to service or repair when it does break down © 2008 Prentice-Hall Business Publishing 6

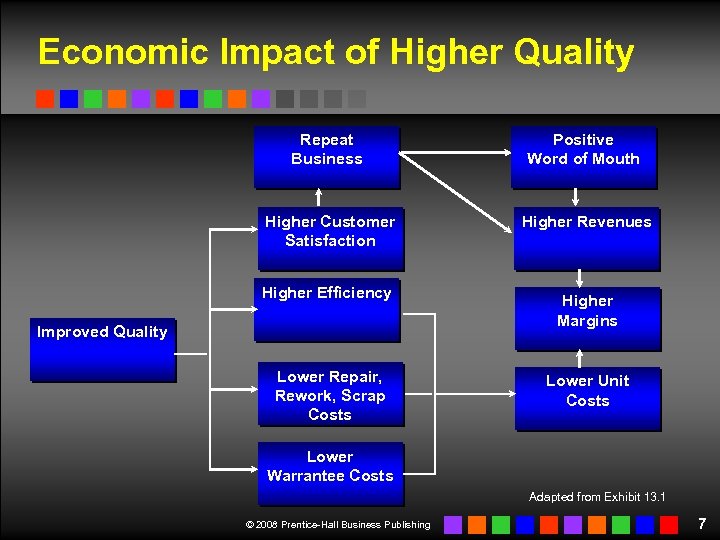

Economic Impact of Higher Quality Repeat Business Positive Word of Mouth Higher Customer Satisfaction Higher Revenues Higher Efficiency Improved Quality Lower Repair, Rework, Scrap Costs Higher Margins Lower Unit Costs Lower Warrantee Costs Adapted from Exhibit 13. 1 © 2008 Prentice-Hall Business Publishing 7

Economic Impact of Higher Quality Repeat Business Positive Word of Mouth Higher Customer Satisfaction Higher Revenues Higher Efficiency Improved Quality Lower Repair, Rework, Scrap Costs Higher Margins Lower Unit Costs Lower Warrantee Costs Adapted from Exhibit 13. 1 © 2008 Prentice-Hall Business Publishing 7

Total Quality Management (TQM) TQM: a management philosophy that: Focuses on continual improvement Emphasizes quality inspection at all stages of the production or service output Encompasses a commitment from employees at all levels © 2008 Prentice-Hall Business Publishing 8

Total Quality Management (TQM) TQM: a management philosophy that: Focuses on continual improvement Emphasizes quality inspection at all stages of the production or service output Encompasses a commitment from employees at all levels © 2008 Prentice-Hall Business Publishing 8

Total Quality Management (TQM) Important TQM concepts: Statistical Process Control (SPC) Continuous Process Improvement Six Sigma Employee Empowerment © 2008 Prentice-Hall Business Publishing 9

Total Quality Management (TQM) Important TQM concepts: Statistical Process Control (SPC) Continuous Process Improvement Six Sigma Employee Empowerment © 2008 Prentice-Hall Business Publishing 9

TQM Concepts: Continuous Process Improvement Continuous process improvement: refers to both incremental and breakthrough improvements in the way an organization does business Four key elements: - Objective - Design - Capabilities - Metrics © 2008 Prentice-Hall Business Publishing 10

TQM Concepts: Continuous Process Improvement Continuous process improvement: refers to both incremental and breakthrough improvements in the way an organization does business Four key elements: - Objective - Design - Capabilities - Metrics © 2008 Prentice-Hall Business Publishing 10

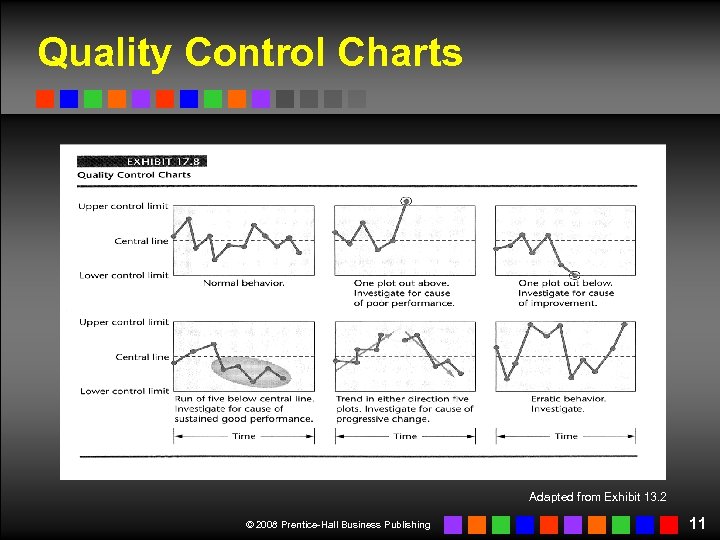

Quality Control Charts Adapted from Exhibit 13. 2 © 2008 Prentice-Hall Business Publishing 11

Quality Control Charts Adapted from Exhibit 13. 2 © 2008 Prentice-Hall Business Publishing 11

TQM Concepts: Six Sigma: a disciplined, data-driven approach for eliminating defects and enhancing quality with an orientation toward the impact such improvements will have on the customer Quality is improved two ways: - DMAIC process (define, measure, analyze, improve, control) - DMADV process (define, measure, analyze, design, verify) © 2008 Prentice-Hall Business Publishing 12

TQM Concepts: Six Sigma: a disciplined, data-driven approach for eliminating defects and enhancing quality with an orientation toward the impact such improvements will have on the customer Quality is improved two ways: - DMAIC process (define, measure, analyze, improve, control) - DMADV process (define, measure, analyze, design, verify) © 2008 Prentice-Hall Business Publishing 12

TQM Concepts: Employee Empowerment By empowering employees, organizations will: Engage the expertise of employees Allow them to feel responsible for quality Allow managers to understand communicate the TQM vision © 2008 Prentice-Hall Business Publishing 13

TQM Concepts: Employee Empowerment By empowering employees, organizations will: Engage the expertise of employees Allow them to feel responsible for quality Allow managers to understand communicate the TQM vision © 2008 Prentice-Hall Business Publishing 13

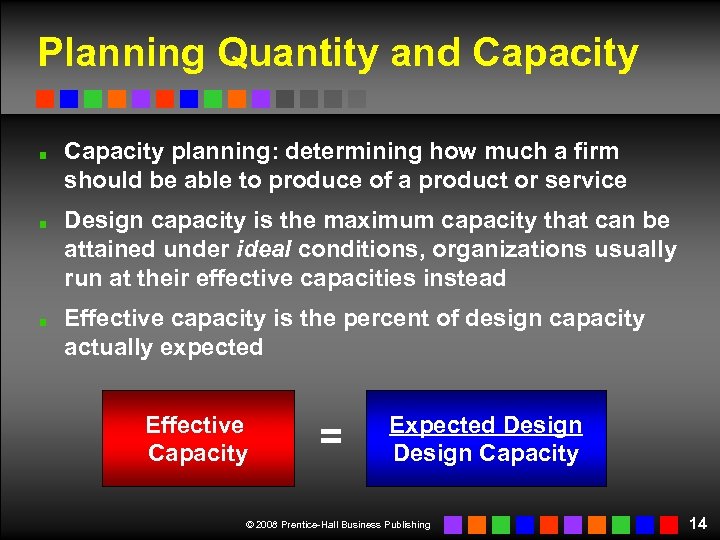

Planning Quantity and Capacity planning: determining how much a firm should be able to produce of a product or service Design capacity is the maximum capacity that can be attained under ideal conditions, organizations usually run at their effective capacities instead Effective capacity is the percent of design capacity actually expected Effective Capacity = Expected Design Capacity © 2008 Prentice-Hall Business Publishing 14

Planning Quantity and Capacity planning: determining how much a firm should be able to produce of a product or service Design capacity is the maximum capacity that can be attained under ideal conditions, organizations usually run at their effective capacities instead Effective capacity is the percent of design capacity actually expected Effective Capacity = Expected Design Capacity © 2008 Prentice-Hall Business Publishing 14

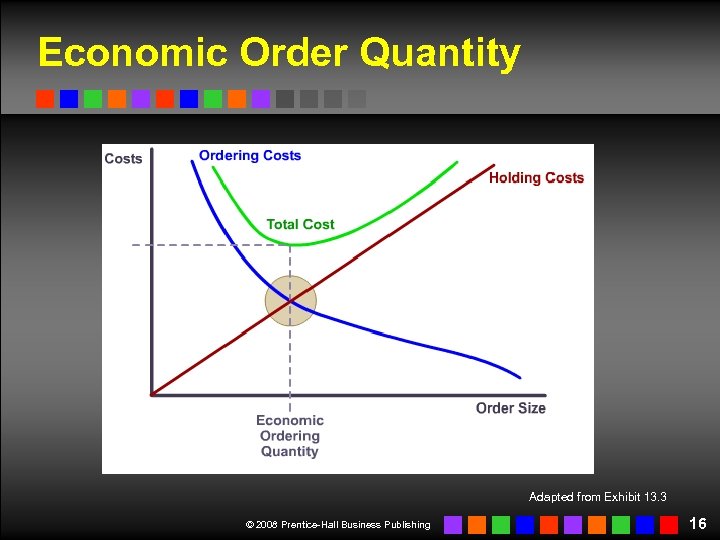

Planning Quantity and Capacity Other important concepts: Materials requirement planning (MRP): getting right materials to right place at right time Economic order quantity (EOQ): ordering economical quantity of product while minimizing costs ABC analysis: which inventory items require most attention © 2008 Prentice-Hall Business Publishing 15

Planning Quantity and Capacity Other important concepts: Materials requirement planning (MRP): getting right materials to right place at right time Economic order quantity (EOQ): ordering economical quantity of product while minimizing costs ABC analysis: which inventory items require most attention © 2008 Prentice-Hall Business Publishing 15

Economic Order Quantity Adapted from Exhibit 13. 3 © 2008 Prentice-Hall Business Publishing 16

Economic Order Quantity Adapted from Exhibit 13. 3 © 2008 Prentice-Hall Business Publishing 16

Timing Products and Services Delivery of products and services must be timed well to avoid both out-ofstocks and excess inventory Three important concepts: - Just-in-time (JIT) systems - Gantt charts - PERT and CPM charts © 2008 Prentice-Hall Business Publishing 17

Timing Products and Services Delivery of products and services must be timed well to avoid both out-ofstocks and excess inventory Three important concepts: - Just-in-time (JIT) systems - Gantt charts - PERT and CPM charts © 2008 Prentice-Hall Business Publishing 17

Timing Products and Services: Just-in-Time (JIT) System Objective: produce product or service only as needed with only the necessary materials, equipment, and employee time that will add value Benefits: - Reduces inventory levels (and lowers carrying cost of inventory) - Improves productivity - Increases customer satisfaction © 2008 Prentice-Hall Business Publishing 18

Timing Products and Services: Just-in-Time (JIT) System Objective: produce product or service only as needed with only the necessary materials, equipment, and employee time that will add value Benefits: - Reduces inventory levels (and lowers carrying cost of inventory) - Improves productivity - Increases customer satisfaction © 2008 Prentice-Hall Business Publishing 18

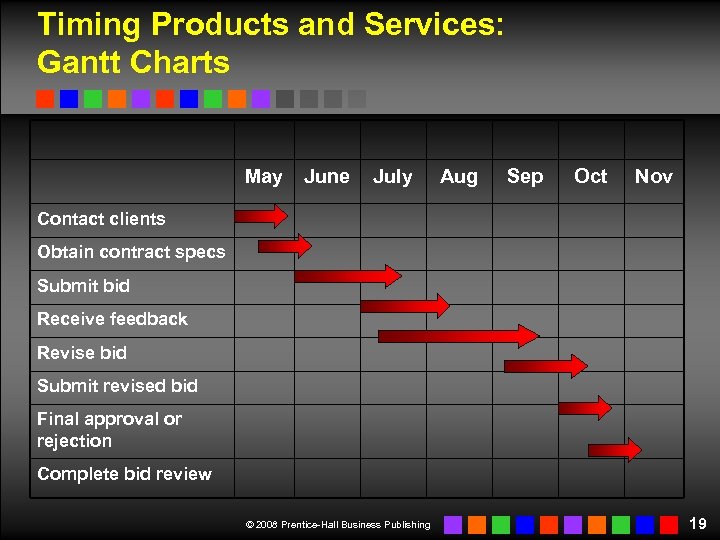

Timing Products and Services: Gantt Charts May June July Aug Sep Oct Nov Contact clients Obtain contract specs Submit bid Receive feedback Revise bid Submit revised bid Final approval or rejection Complete bid review © 2008 Prentice-Hall Business Publishing 19

Timing Products and Services: Gantt Charts May June July Aug Sep Oct Nov Contact clients Obtain contract specs Submit bid Receive feedback Revise bid Submit revised bid Final approval or rejection Complete bid review © 2008 Prentice-Hall Business Publishing 19

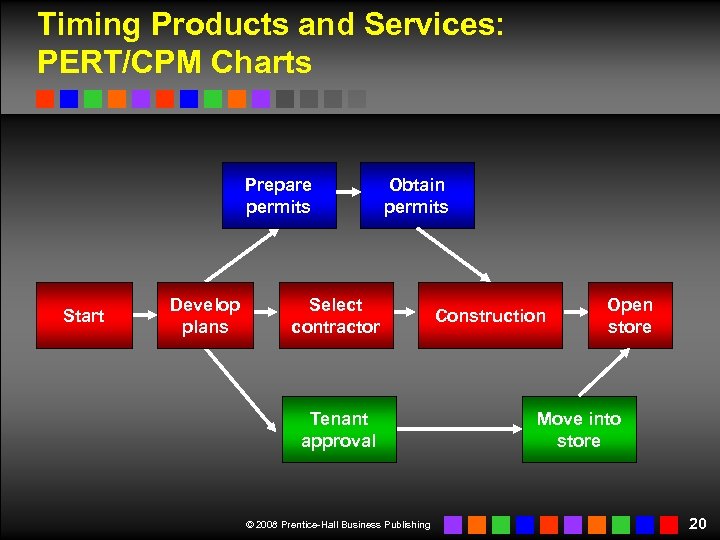

Timing Products and Services: PERT/CPM Charts Prepare permits Start Develop plans Obtain permits Select contractor Tenant approval © 2008 Prentice-Hall Business Publishing Construction Open store Move into store 20

Timing Products and Services: PERT/CPM Charts Prepare permits Start Develop plans Obtain permits Select contractor Tenant approval © 2008 Prentice-Hall Business Publishing Construction Open store Move into store 20

Achieving the Best Cost Productivity measures how well an organization is using its resources (inputs) to produce goods and services (outputs) Productivity = © 2008 Prentice-Hall Business Publishing Output Input 21

Achieving the Best Cost Productivity measures how well an organization is using its resources (inputs) to produce goods and services (outputs) Productivity = © 2008 Prentice-Hall Business Publishing Output Input 21

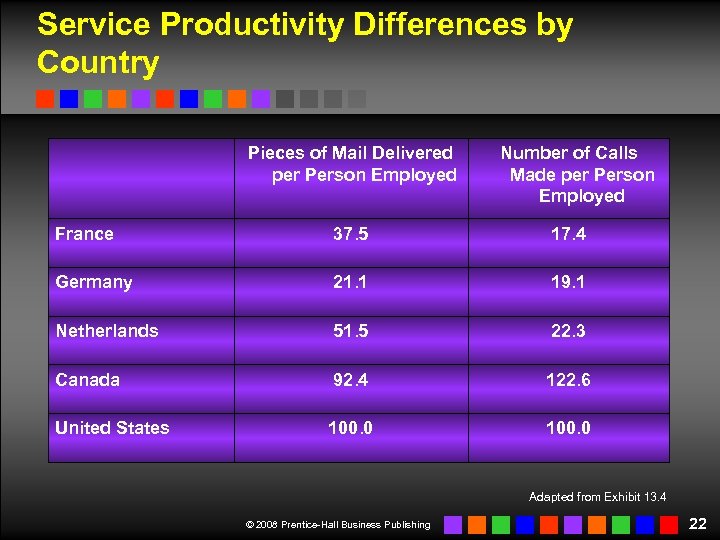

Service Productivity Differences by Country Pieces of Mail Delivered per Person Employed Number of Calls Made per Person Employed France 37. 5 17. 4 Germany 21. 1 19. 1 Netherlands 51. 5 22. 3 Canada 92. 4 122. 6 United States 100. 0 Adapted from Exhibit 13. 4 © 2008 Prentice-Hall Business Publishing 22

Service Productivity Differences by Country Pieces of Mail Delivered per Person Employed Number of Calls Made per Person Employed France 37. 5 17. 4 Germany 21. 1 19. 1 Netherlands 51. 5 22. 3 Canada 92. 4 122. 6 United States 100. 0 Adapted from Exhibit 13. 4 © 2008 Prentice-Hall Business Publishing 22

Achieving the Best Cost: Work Standard Work standard: amount of time it should take for a trained employee to complete a specific activity or process Two work measurement techniques: - Time and motion studies - Review each activity in detail so that unnecessary steps are eliminated - Work sampling - Take a sample of workers and calculate percentage of time spent on each activity during a working day or shift © 2008 Prentice-Hall Business Publishing 23

Achieving the Best Cost: Work Standard Work standard: amount of time it should take for a trained employee to complete a specific activity or process Two work measurement techniques: - Time and motion studies - Review each activity in detail so that unnecessary steps are eliminated - Work sampling - Take a sample of workers and calculate percentage of time spent on each activity during a working day or shift © 2008 Prentice-Hall Business Publishing 23

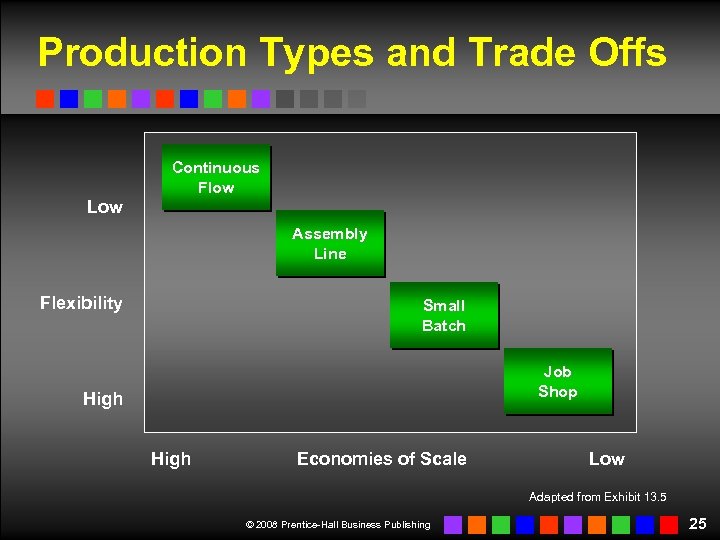

Achieving the Best Cost: Production Processes Four different production processes: Continuous flow production Assembly-line processes Small batch processes Job shops © 2008 Prentice-Hall Business Publishing 24

Achieving the Best Cost: Production Processes Four different production processes: Continuous flow production Assembly-line processes Small batch processes Job shops © 2008 Prentice-Hall Business Publishing 24

Production Types and Trade Offs Continuous Flow Low Assembly Line Flexibility Small Batch Job Shop High Economies of Scale Low Adapted from Exhibit 13. 5 © 2008 Prentice-Hall Business Publishing 25

Production Types and Trade Offs Continuous Flow Low Assembly Line Flexibility Small Batch Job Shop High Economies of Scale Low Adapted from Exhibit 13. 5 © 2008 Prentice-Hall Business Publishing 25

Achieving the Best Cost: Technology Computer-aided design (CAD) and computer-aided engineering (CAE) Rapid prototyping Computer-aided manufacturing (CAM) Designing for manufacturing (DFM) © 2008 Prentice-Hall Business Publishing 26

Achieving the Best Cost: Technology Computer-aided design (CAD) and computer-aided engineering (CAE) Rapid prototyping Computer-aided manufacturing (CAM) Designing for manufacturing (DFM) © 2008 Prentice-Hall Business Publishing 26

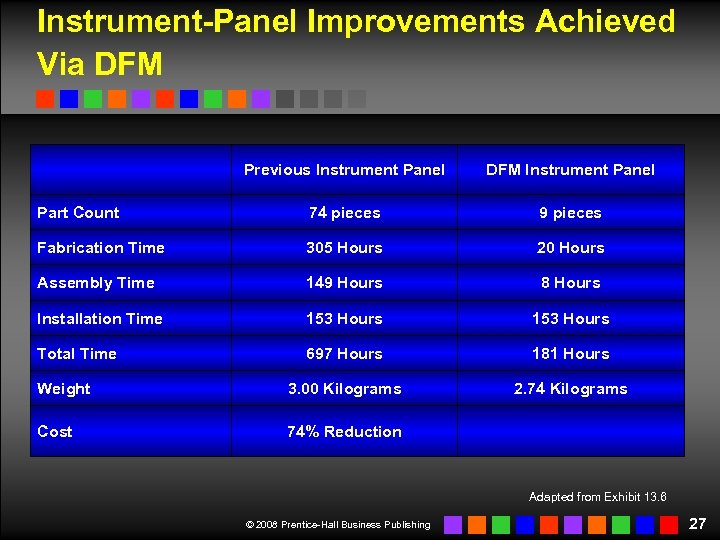

Instrument-Panel Improvements Achieved Via DFM Previous Instrument Panel DFM Instrument Panel Part Count 74 pieces 9 pieces Fabrication Time 305 Hours 20 Hours Assembly Time 149 Hours 8 Hours Installation Time 153 Hours Total Time 697 Hours 181 Hours Weight 3. 00 Kilograms 2. 74 Kilograms Cost 74% Reduction Adapted from Exhibit 13. 6 © 2008 Prentice-Hall Business Publishing 27

Instrument-Panel Improvements Achieved Via DFM Previous Instrument Panel DFM Instrument Panel Part Count 74 pieces 9 pieces Fabrication Time 305 Hours 20 Hours Assembly Time 149 Hours 8 Hours Installation Time 153 Hours Total Time 697 Hours 181 Hours Weight 3. 00 Kilograms 2. 74 Kilograms Cost 74% Reduction Adapted from Exhibit 13. 6 © 2008 Prentice-Hall Business Publishing 27

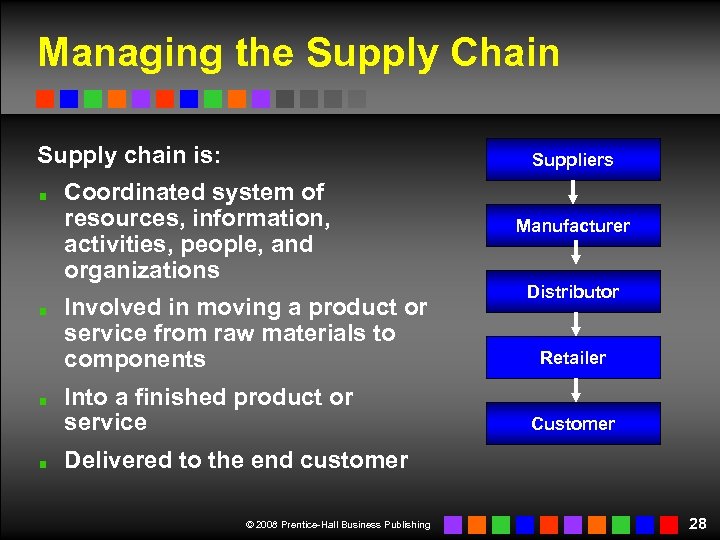

Managing the Supply Chain Supply chain is: Suppliers Coordinated system of resources, information, activities, people, and organizations Involved in moving a product or service from raw materials to components Into a finished product or service Manufacturer Distributor Retailer Customer Delivered to the end customer © 2008 Prentice-Hall Business Publishing 28

Managing the Supply Chain Supply chain is: Suppliers Coordinated system of resources, information, activities, people, and organizations Involved in moving a product or service from raw materials to components Into a finished product or service Manufacturer Distributor Retailer Customer Delivered to the end customer © 2008 Prentice-Hall Business Publishing 28

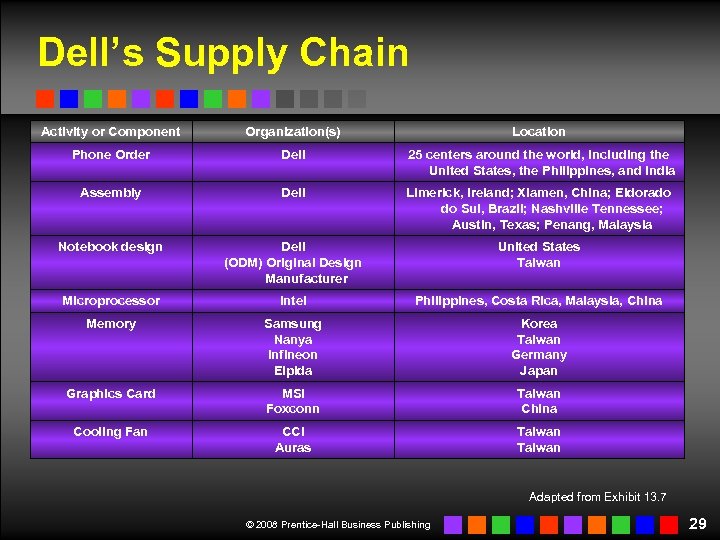

Dell’s Supply Chain Activity or Component Organization(s) Location Phone Order Dell 25 centers around the world, including the United States, the Philippines, and India Assembly Dell Limerick, Ireland; Xiamen, China; Eldorado do Sul, Brazil; Nashville Tennessee; Austin, Texas; Penang, Malaysia Notebook design Dell (ODM) Original Design Manufacturer United States Taiwan Microprocessor Intel Philippines, Costa Rica, Malaysia, China Memory Samsung Nanya Infineon Elpida Korea Taiwan Germany Japan Graphics Card MSI Foxconn Taiwan China Cooling Fan CCI Auras Taiwan Adapted from Exhibit 13. 7 © 2008 Prentice-Hall Business Publishing 29

Dell’s Supply Chain Activity or Component Organization(s) Location Phone Order Dell 25 centers around the world, including the United States, the Philippines, and India Assembly Dell Limerick, Ireland; Xiamen, China; Eldorado do Sul, Brazil; Nashville Tennessee; Austin, Texas; Penang, Malaysia Notebook design Dell (ODM) Original Design Manufacturer United States Taiwan Microprocessor Intel Philippines, Costa Rica, Malaysia, China Memory Samsung Nanya Infineon Elpida Korea Taiwan Germany Japan Graphics Card MSI Foxconn Taiwan China Cooling Fan CCI Auras Taiwan Adapted from Exhibit 13. 7 © 2008 Prentice-Hall Business Publishing 29

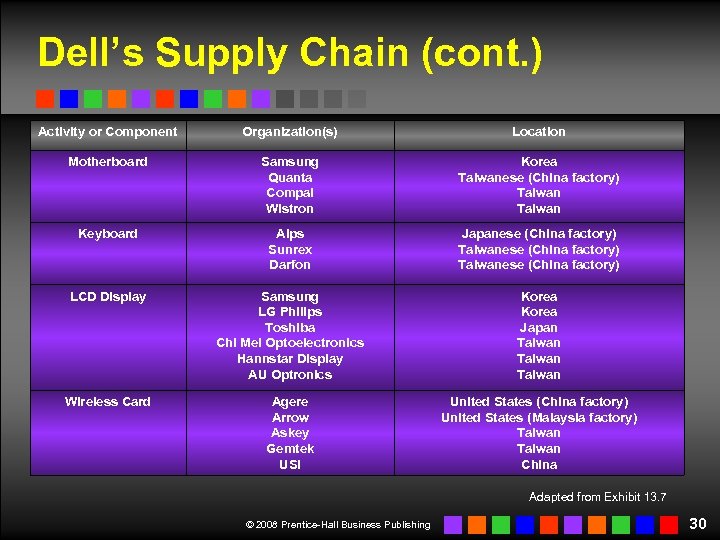

Dell’s Supply Chain (cont. ) Activity or Component Organization(s) Location Motherboard Samsung Quanta Compal Wistron Korea Taiwanese (China factory) Taiwan Keyboard Alps Sunrex Darfon Japanese (China factory) Taiwanese (China factory) LCD Display Samsung LG Philips Toshiba Chi Mei Optoelectronics Hannstar Display AU Optronics Korea Japan Taiwan Wireless Card Agere Arrow Askey Gemtek USI United States (China factory) United States (Malaysia factory) Taiwan China Adapted from Exhibit 13. 7 © 2008 Prentice-Hall Business Publishing 30

Dell’s Supply Chain (cont. ) Activity or Component Organization(s) Location Motherboard Samsung Quanta Compal Wistron Korea Taiwanese (China factory) Taiwan Keyboard Alps Sunrex Darfon Japanese (China factory) Taiwanese (China factory) LCD Display Samsung LG Philips Toshiba Chi Mei Optoelectronics Hannstar Display AU Optronics Korea Japan Taiwan Wireless Card Agere Arrow Askey Gemtek USI United States (China factory) United States (Malaysia factory) Taiwan China Adapted from Exhibit 13. 7 © 2008 Prentice-Hall Business Publishing 30

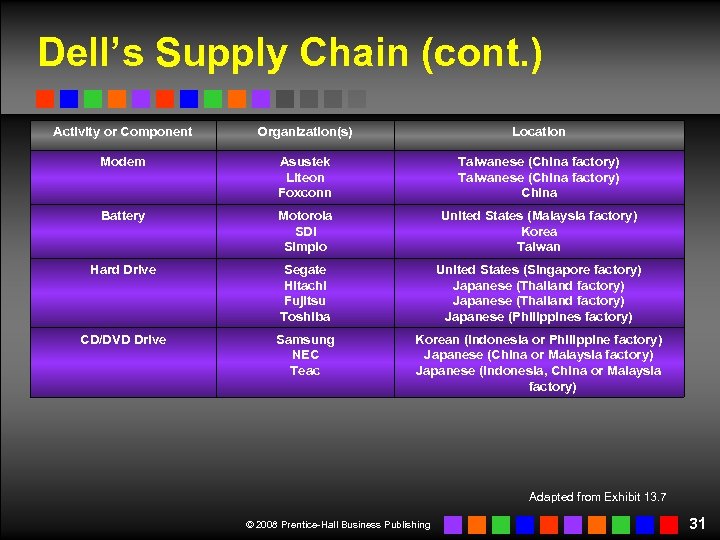

Dell’s Supply Chain (cont. ) Activity or Component Organization(s) Location Modem Asustek Liteon Foxconn Taiwanese (China factory) China Battery Motorola SDI Simplo United States (Malaysia factory) Korea Taiwan Hard Drive Segate Hitachi Fujitsu Toshiba United States (Singapore factory) Japanese (Thailand factory) Japanese (Philippines factory) CD/DVD Drive Samsung NEC Teac Korean (Indonesia or Philippine factory) Japanese (China or Malaysia factory) Japanese (Indonesia, China or Malaysia factory) Adapted from Exhibit 13. 7 © 2008 Prentice-Hall Business Publishing 31

Dell’s Supply Chain (cont. ) Activity or Component Organization(s) Location Modem Asustek Liteon Foxconn Taiwanese (China factory) China Battery Motorola SDI Simplo United States (Malaysia factory) Korea Taiwan Hard Drive Segate Hitachi Fujitsu Toshiba United States (Singapore factory) Japanese (Thailand factory) Japanese (Philippines factory) CD/DVD Drive Samsung NEC Teac Korean (Indonesia or Philippine factory) Japanese (China or Malaysia factory) Japanese (Indonesia, China or Malaysia factory) Adapted from Exhibit 13. 7 © 2008 Prentice-Hall Business Publishing 31

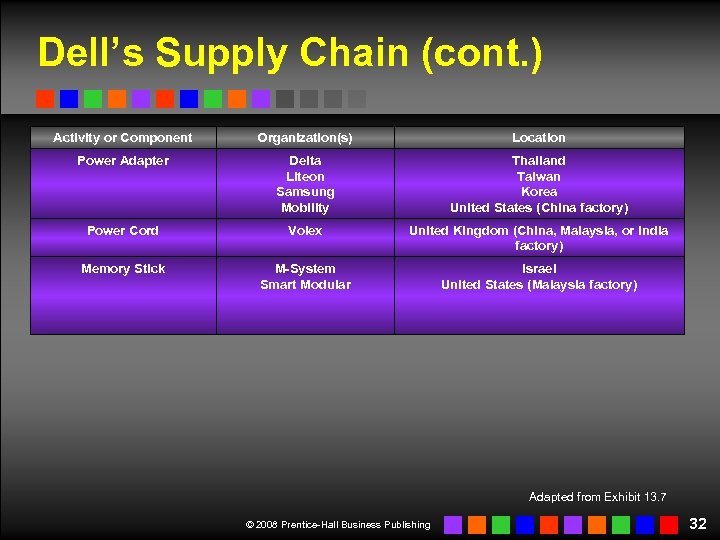

Dell’s Supply Chain (cont. ) Activity or Component Organization(s) Location Power Adapter Delta Liteon Samsung Mobility Thailand Taiwan Korea United States (China factory) Power Cord Volex United Kingdom (China, Malaysia, or India factory) Memory Stick M-System Smart Modular Israel United States (Malaysia factory) Adapted from Exhibit 13. 7 © 2008 Prentice-Hall Business Publishing 32

Dell’s Supply Chain (cont. ) Activity or Component Organization(s) Location Power Adapter Delta Liteon Samsung Mobility Thailand Taiwan Korea United States (China factory) Power Cord Volex United Kingdom (China, Malaysia, or India factory) Memory Stick M-System Smart Modular Israel United States (Malaysia factory) Adapted from Exhibit 13. 7 © 2008 Prentice-Hall Business Publishing 32

Managing the Supply Chain: Using Technology Electronic data interchange (EDI): the integration and real-time exchange of supply chain information that allows supply chain managers to manage complicated relationships and processes Web-based systems © 2008 Prentice-Hall Business Publishing 33

Managing the Supply Chain: Using Technology Electronic data interchange (EDI): the integration and real-time exchange of supply chain information that allows supply chain managers to manage complicated relationships and processes Web-based systems © 2008 Prentice-Hall Business Publishing 33

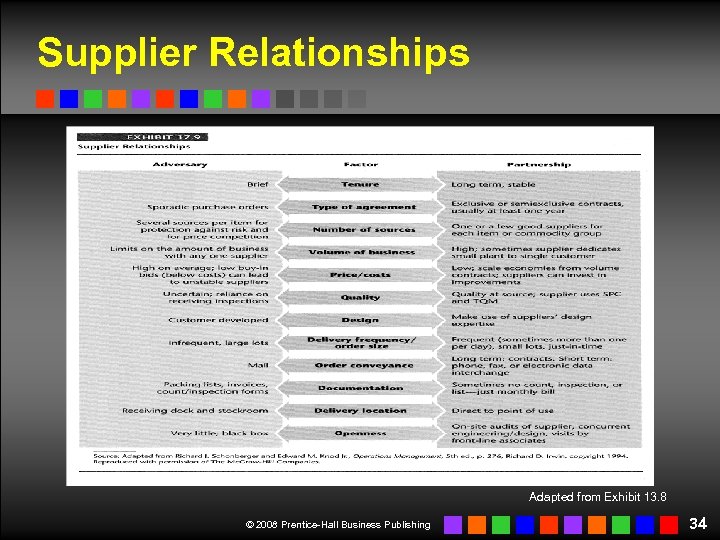

Supplier Relationships Adapted from Exhibit 13. 8 © 2008 Prentice-Hall Business Publishing 34

Supplier Relationships Adapted from Exhibit 13. 8 © 2008 Prentice-Hall Business Publishing 34

Managing the Supply Chain: Reverse Supply Chain Reverse supply chain: activities needed to retrieve a used product from a customer and either reuse it or dispose of it Activities include: Acquiring the used products Managing reverse logistics to get the products to the company Inspecting the product Determining the disposition (destruction or reuse) Distributing and selling refurbished products © 2008 Prentice-Hall Business Publishing 35

Managing the Supply Chain: Reverse Supply Chain Reverse supply chain: activities needed to retrieve a used product from a customer and either reuse it or dispose of it Activities include: Acquiring the used products Managing reverse logistics to get the products to the company Inspecting the product Determining the disposition (destruction or reuse) Distributing and selling refurbished products © 2008 Prentice-Hall Business Publishing 35