M 915 - Palletized Loading System Demonstrator 11 June 2003 Mr. Jeffrey Kozierowski National Automotive Center Tank-Automotive Research, Development & Engineering Center Committed to Excellence

M 915 - Palletized Loading System Demonstrator 11 June 2003 Mr. Jeffrey Kozierowski National Automotive Center Tank-Automotive Research, Development & Engineering Center Committed to Excellence

Outline • The 915 Family of Vehicles • New Technologies • Permo-Drive RDS • Questions

Outline • The 915 Family of Vehicles • New Technologies • Permo-Drive RDS • Questions

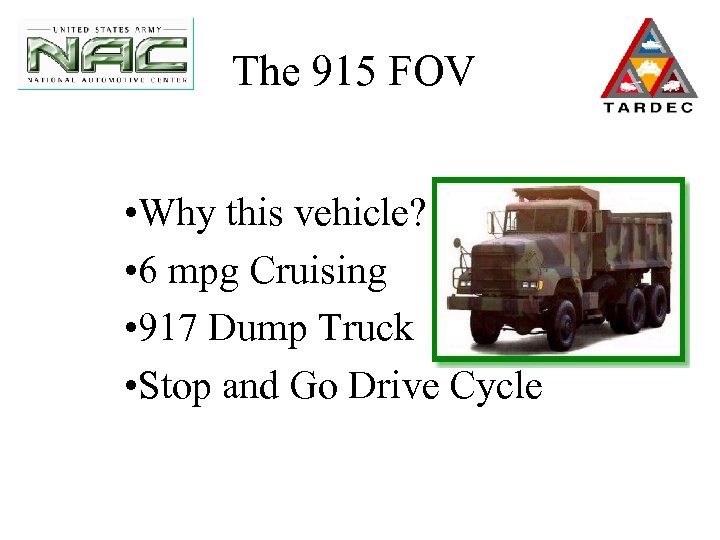

The 915 FOV • Why this vehicle? • 6 mpg Cruising • 917 Dump Truck • Stop and Go Drive Cycle

The 915 FOV • Why this vehicle? • 6 mpg Cruising • 917 Dump Truck • Stop and Go Drive Cycle

New Technologies • • • Electronic Braking System (EBS) Air Dryer LED Headlights/Taillights Steerable Rear Axles Exhaust Vibration Balancer

New Technologies • • • Electronic Braking System (EBS) Air Dryer LED Headlights/Taillights Steerable Rear Axles Exhaust Vibration Balancer

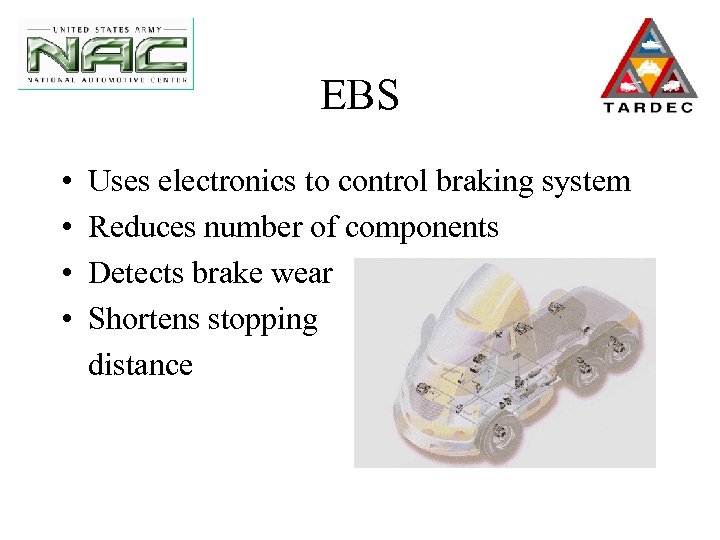

EBS • • Uses electronics to control braking system Reduces number of components Detects brake wear Shortens stopping distance

EBS • • Uses electronics to control braking system Reduces number of components Detects brake wear Shortens stopping distance

Air Dryer • Protects braking system from moisture and contamination • Weighs 11 pounds • Water absorption • High reliability

Air Dryer • Protects braking system from moisture and contamination • Weighs 11 pounds • Water absorption • High reliability

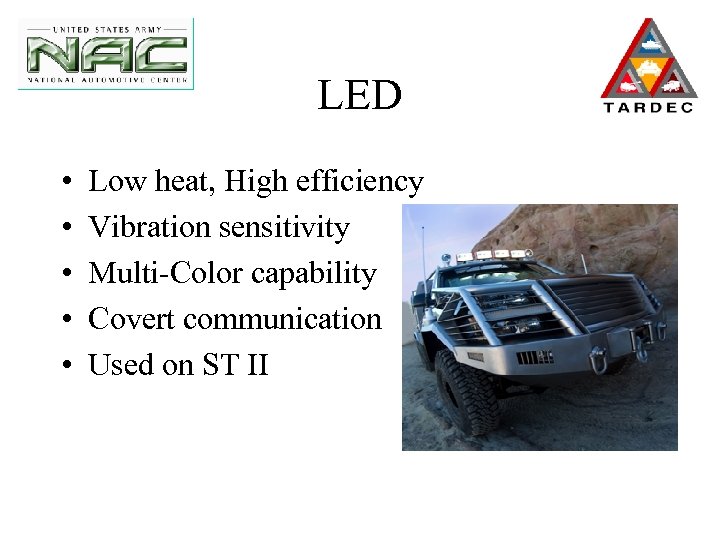

LED • • • Low heat, High efficiency Vibration sensitivity Multi-Color capability Covert communication Used on ST II

LED • • • Low heat, High efficiency Vibration sensitivity Multi-Color capability Covert communication Used on ST II

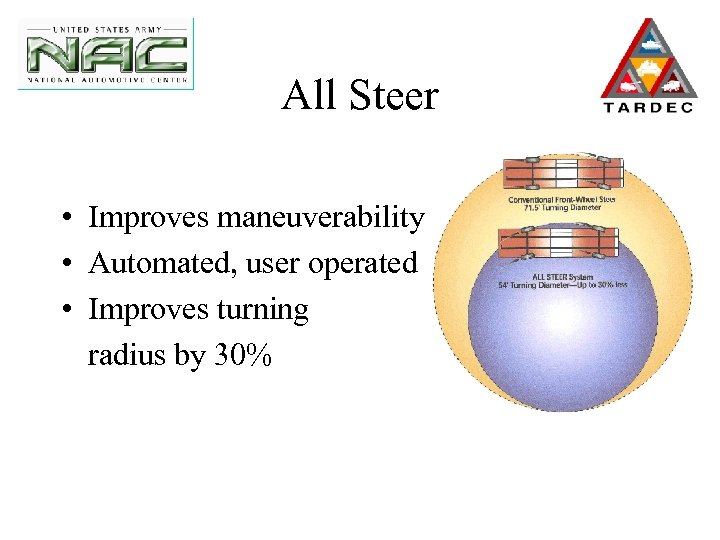

All Steer • Improves maneuverability • Automated, user operated • Improves turning radius by 30%

All Steer • Improves maneuverability • Automated, user operated • Improves turning radius by 30%

Exhaust Vibration Balancer • • Balances vibration, torque and road shock Reduces fuel consumption Reduces failure Increases durability

Exhaust Vibration Balancer • • Balances vibration, torque and road shock Reduces fuel consumption Reduces failure Increases durability

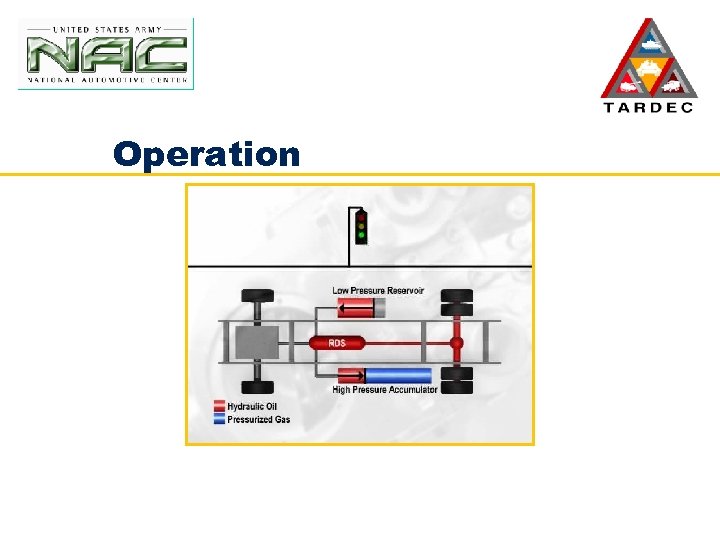

Operation

Operation

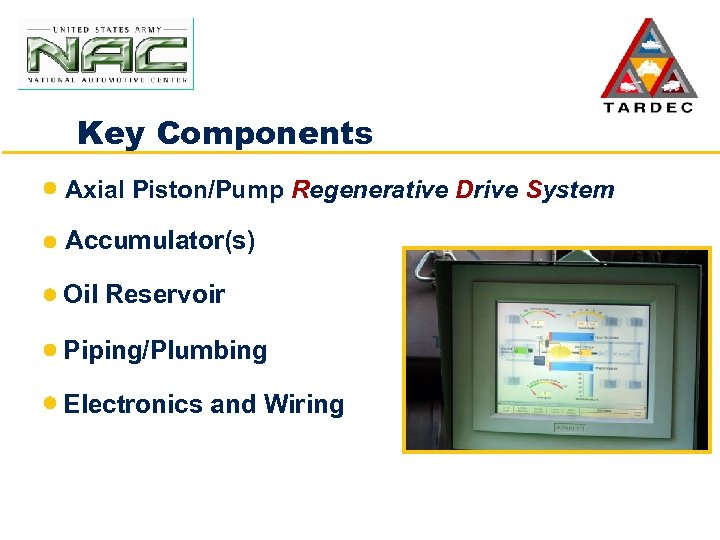

Key Components Axial Piston/Pump Regenerative Drive System Accumulator(s) Oil Reservoir Piping/Plumbing Electronics and Wiring

Key Components Axial Piston/Pump Regenerative Drive System Accumulator(s) Oil Reservoir Piping/Plumbing Electronics and Wiring

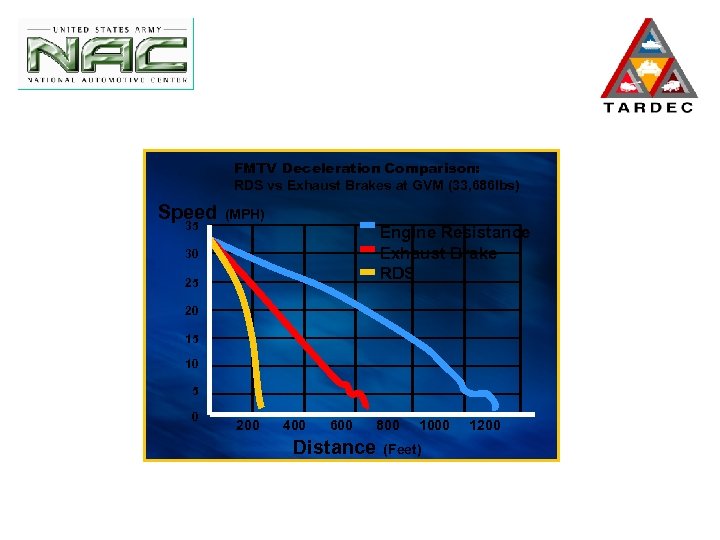

FMTV Deceleration Comparison: RDS vs Exhaust Brakes at GVM (33, 686 lbs) Speed 35 (MPH) Engine Resistance Exhaust Brake RDS 30 25 20 15 10 5 0 200 400 600 800 Distance 1000 (Feet) 1200

FMTV Deceleration Comparison: RDS vs Exhaust Brakes at GVM (33, 686 lbs) Speed 35 (MPH) Engine Resistance Exhaust Brake RDS 30 25 20 15 10 5 0 200 400 600 800 Distance 1000 (Feet) 1200

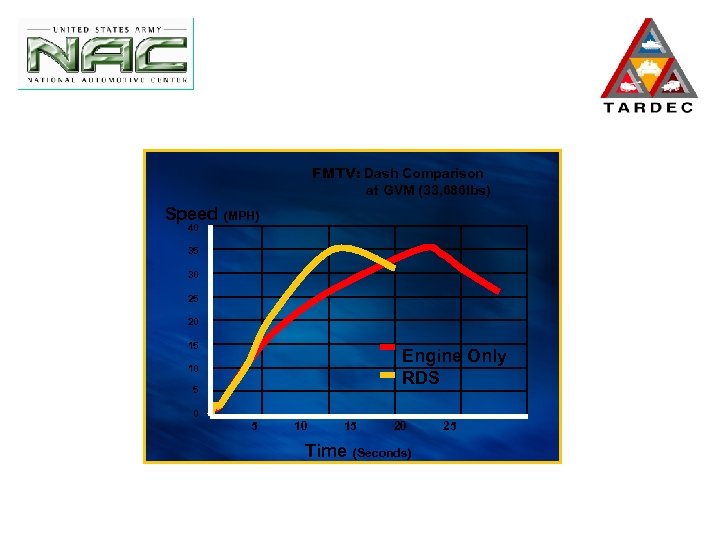

FMTV: Dash Comparison at GVM (33, 686 lbs) Speed 40 (MPH) 35 30 25 20 15 Engine Only RDS 10 5 10 15 Time 20 (Seconds) 25

FMTV: Dash Comparison at GVM (33, 686 lbs) Speed 40 (MPH) 35 30 25 20 15 Engine Only RDS 10 5 10 15 Time 20 (Seconds) 25

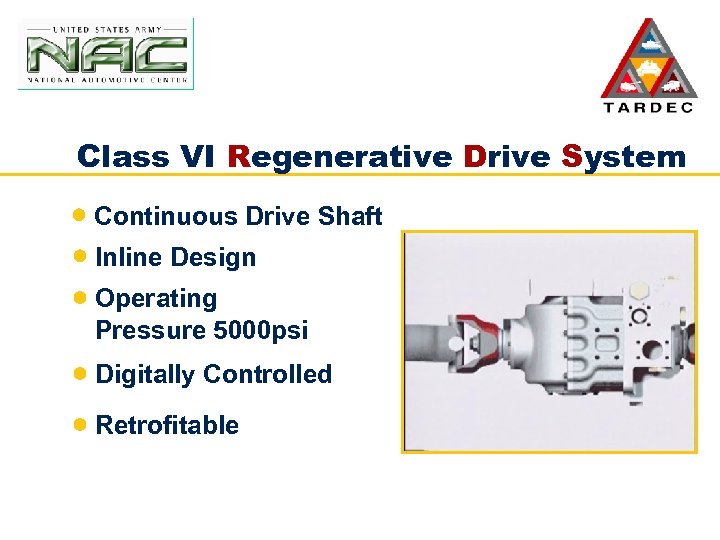

Class VI Regenerative Drive System Continuous Drive Shaft Inline Design Operating Pressure 5000 psi Digitally Controlled Retrofitable

Class VI Regenerative Drive System Continuous Drive Shaft Inline Design Operating Pressure 5000 psi Digitally Controlled Retrofitable

Why Hydraulic? High Power Density High Energy Flow – Not Temperature or Chemically Limited Efficient Charging & Discharging Reliable Performance Over a Wide Range of Operating & Climatic Conditions Minimal Routine Maintenance

Why Hydraulic? High Power Density High Energy Flow – Not Temperature or Chemically Limited Efficient Charging & Discharging Reliable Performance Over a Wide Range of Operating & Climatic Conditions Minimal Routine Maintenance

Why Hydraulic? Readily Available Spare Parts Hoses Oil Filters Fittings Robust Components Mature Technology Excellent ROI Retrofitable

Why Hydraulic? Readily Available Spare Parts Hoses Oil Filters Fittings Robust Components Mature Technology Excellent ROI Retrofitable

Braking Through the Barriers Introducing Regenerative Drive System Class VI

Braking Through the Barriers Introducing Regenerative Drive System Class VI

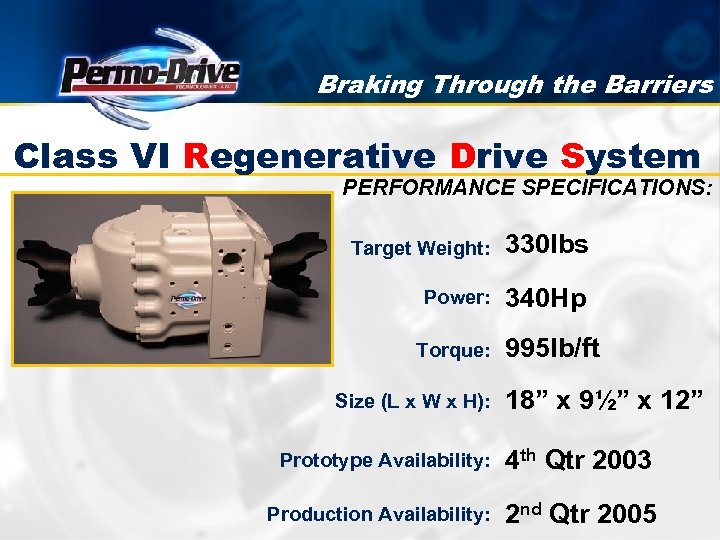

Braking Through the Barriers Class VI Regenerative Drive System PERFORMANCE SPECIFICATIONS: Target Weight: 330 lbs Power: 340 Hp Torque: Size (L x W x H): 995 lb/ft 18” x 9½” x 12” Prototype Availability: 4 th Qtr 2003 Production Availability: 2 nd Qtr 2005

Braking Through the Barriers Class VI Regenerative Drive System PERFORMANCE SPECIFICATIONS: Target Weight: 330 lbs Power: 340 Hp Torque: Size (L x W x H): 995 lb/ft 18” x 9½” x 12” Prototype Availability: 4 th Qtr 2003 Production Availability: 2 nd Qtr 2005

Braking Through the Barriers Summary Simple Design & Installation Robust Performance Available Technology Substantial ROI Better Fuel Economy Reduced Maintenance Retrofitable Lower Emissions

Braking Through the Barriers Summary Simple Design & Installation Robust Performance Available Technology Substantial ROI Better Fuel Economy Reduced Maintenance Retrofitable Lower Emissions

Braking Through the Barriers Special Thanks to: National Automotive Center

Braking Through the Barriers Special Thanks to: National Automotive Center