375c6e3662a7b31fdd7caa512a73be9e.ppt

- Количество слайдов: 53

Low voltage assemblies x. Energy Design-verified switchboard system for Infrastructure up to 5000 A January, 2012 © 2011 Eaton Corporation. All rights reserved.

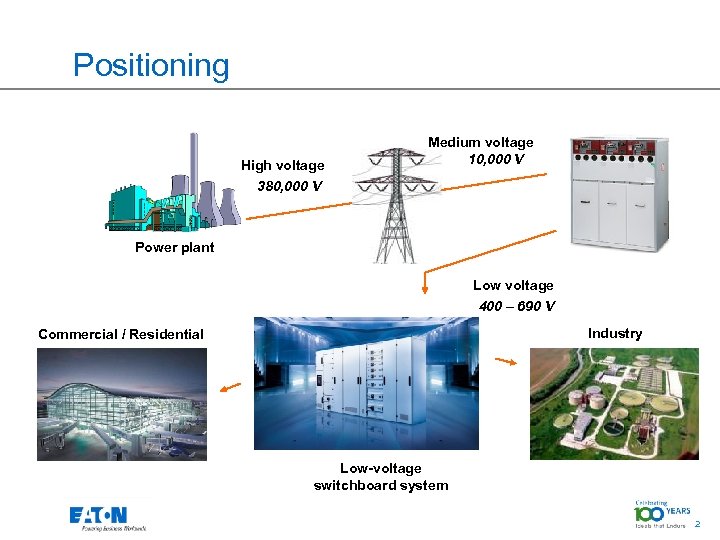

Positioning High voltage 380, 000 V Medium voltage 10, 000 V Power plant Low voltage 400 – 690 V Industry Commercial / Residential Low-voltage switchboard system 2

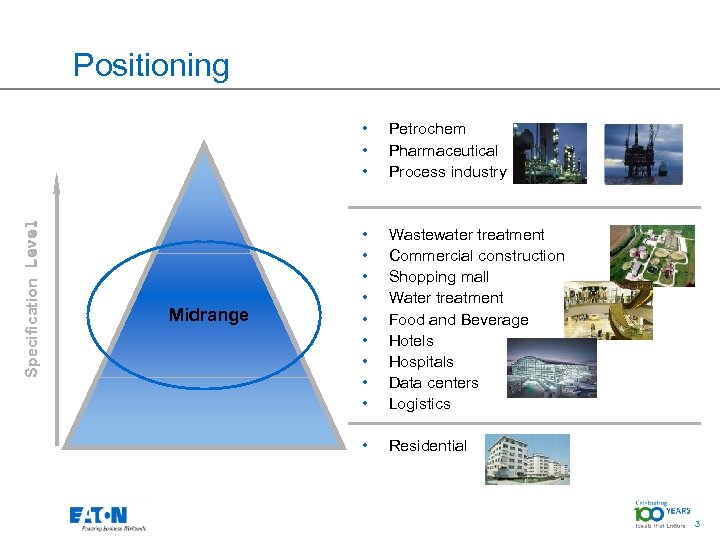

Positioning Specification Level • • • Midrange Petrochem Pharmaceutical Process industry • • • Wastewater treatment Commercial construction Shopping mall Water treatment Food and Beverage Hotels Hospitals Data centers Logistics • Residential 3

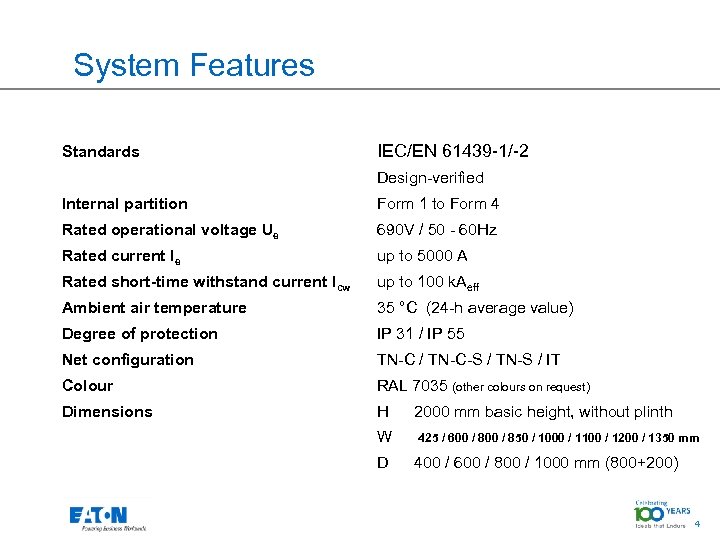

System Features Standards IEC/EN 61439 -1/-2 Design-verified Internal partition Form 1 to Form 4 Rated operational voltage Ue 690 V / 50 - 60 Hz Rated current Ie up to 5000 A Rated short-time withstand current Icw up to 100 k. Aeff Ambient air temperature 35 °C (24 -h average value) Degree of protection IP 31 / IP 55 Net configuration TN-C / TN-C-S / TN-S / IT Colour RAL 7035 (other colours on request) Dimensions H W D 2000 mm basic height, without plinth 425 / 600 / 850 / 1000 / 1100 / 1200 / 1350 mm 400 / 600 / 800 / 1000 mm (800+200) 4

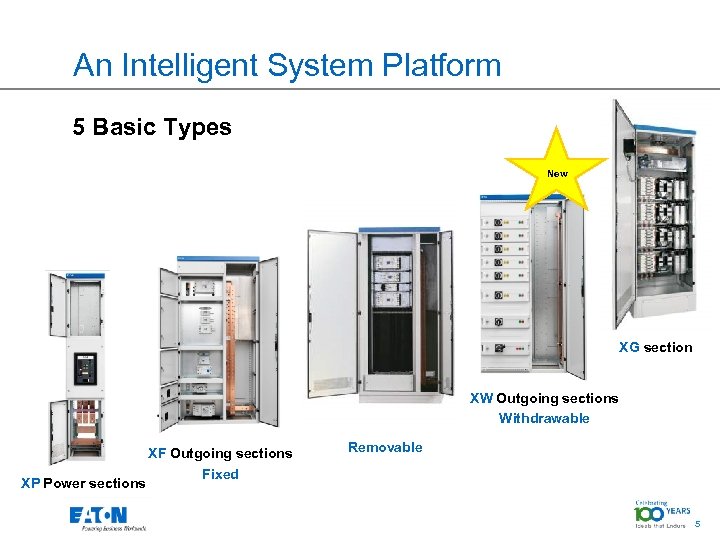

An Intelligent System Platform 5 Basic Types New XG section XP Power sections XF Outgoing sections Fixed XR Outgoing sections Removable XW Outgoing sections Withdrawable 5

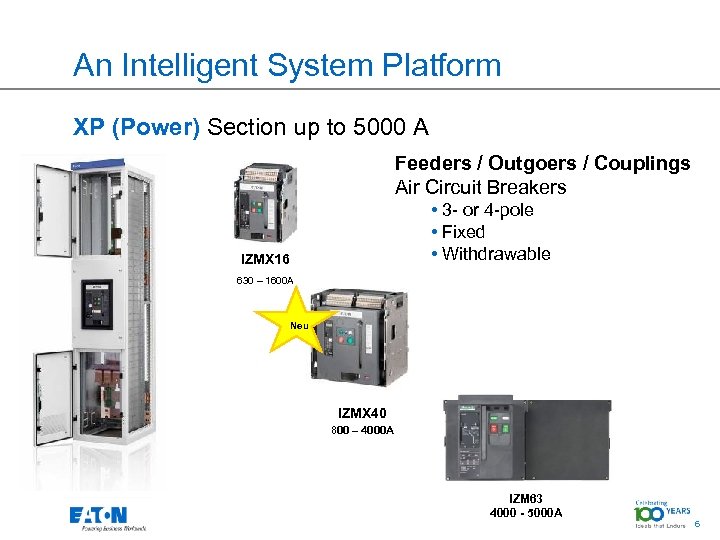

An Intelligent System Platform XP (Power) Section up to 5000 A Feeders / Outgoers / Couplings Air Circuit Breakers • 3 - or 4 -pole • Fixed • Withdrawable IZMX 16 630 – 1600 A Neu IZMX 40 800 – 4000 A IZM 63 4000 - 5000 A 6

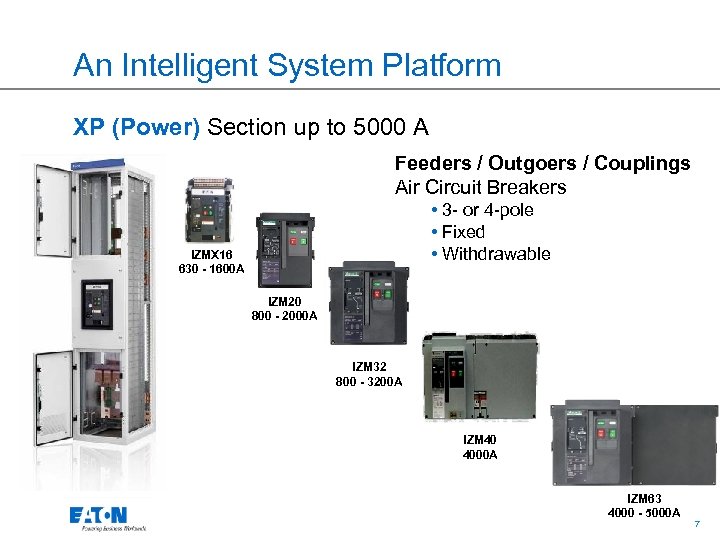

An Intelligent System Platform XP (Power) Section up to 5000 A Feeders / Outgoers / Couplings Air Circuit Breakers • 3 - or 4 -pole • Fixed • Withdrawable IZMX 16 630 - 1600 A IZM 20 800 - 2000 A IZM 32 800 - 3200 A IZM 40 4000 A IZM 63 4000 - 5000 A 7

An Intelligent System Platform XP (Power) Section up to 1600 A Feeders / Outgoers / Connections Compact Circuit Breaker • 3 or 4 -pole • Fixed • Withdrawable NZM 3 125 - 630 A NZM 4 315 - 1600 A 8

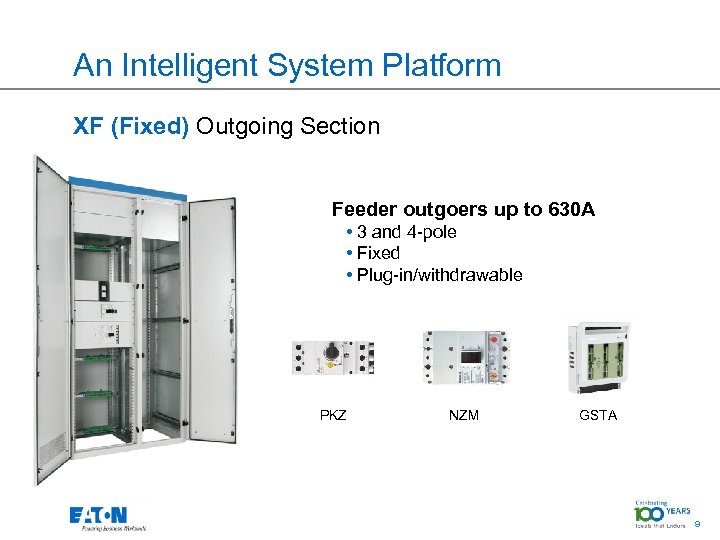

An Intelligent System Platform XF (Fixed) Outgoing Section Feeder outgoers up to 630 A • 3 and 4 -pole • Fixed • Plug-in/withdrawable PKZ NZM GSTA 9

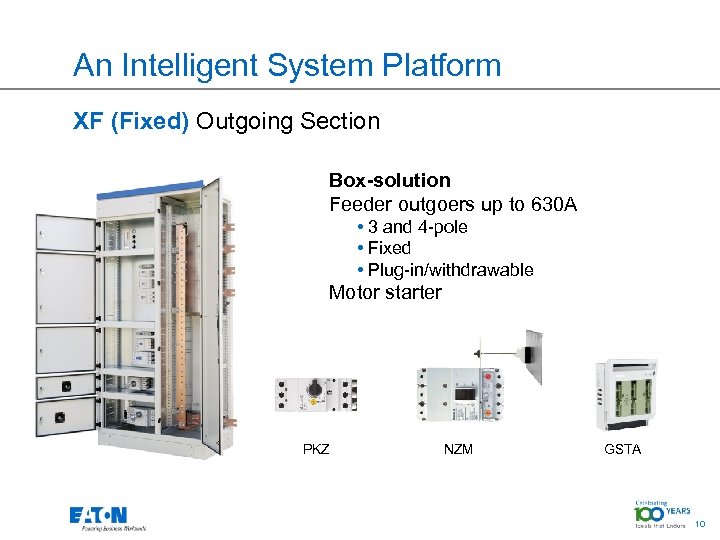

An Intelligent System Platform XF (Fixed) Outgoing Section Box-solution Feeder outgoers up to 630 A • 3 and 4 -pole • Fixed • Plug-in/withdrawable Motor starter PKZ NZM GSTA 10

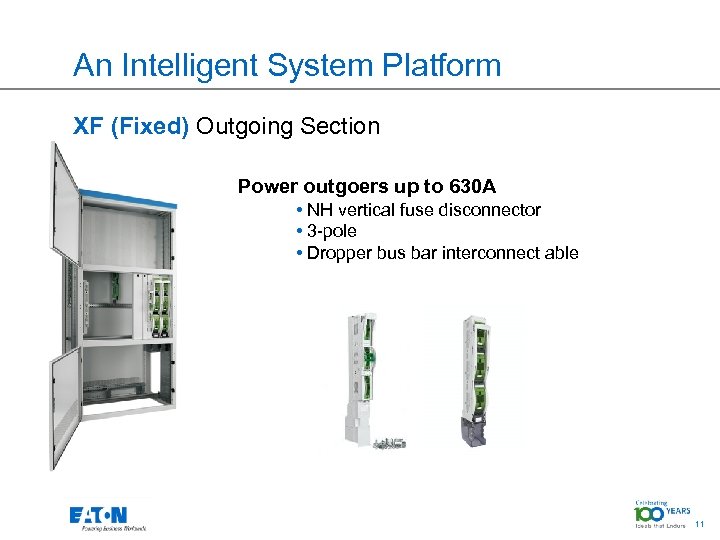

An Intelligent System Platform XF (Fixed) Outgoing Section Power outgoers up to 630 A • NH vertical fuse disconnector • 3 -pole • Dropper bus bar interconnect able 11

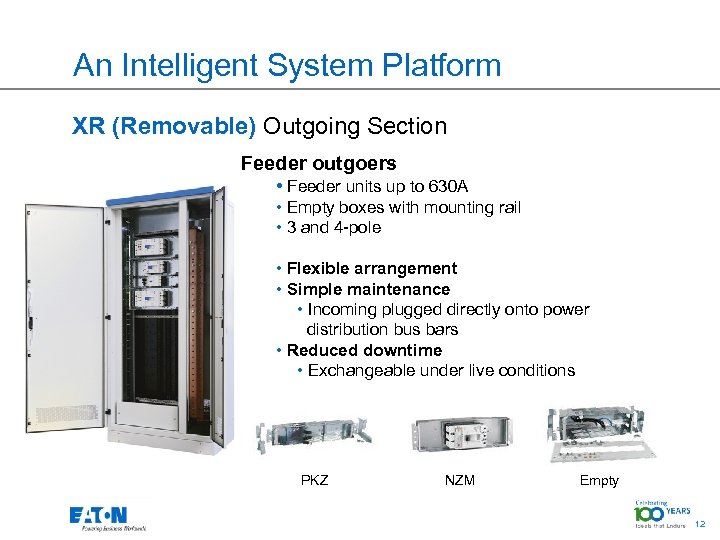

An Intelligent System Platform XR (Removable) Outgoing Section Feeder outgoers • Feeder units up to 630 A • Empty boxes with mounting rail • 3 and 4 -pole • Flexible arrangement • Simple maintenance • Incoming plugged directly onto power distribution bus bars • Reduced downtime • Exchangeable under live conditions PKZ NZM Empty 12

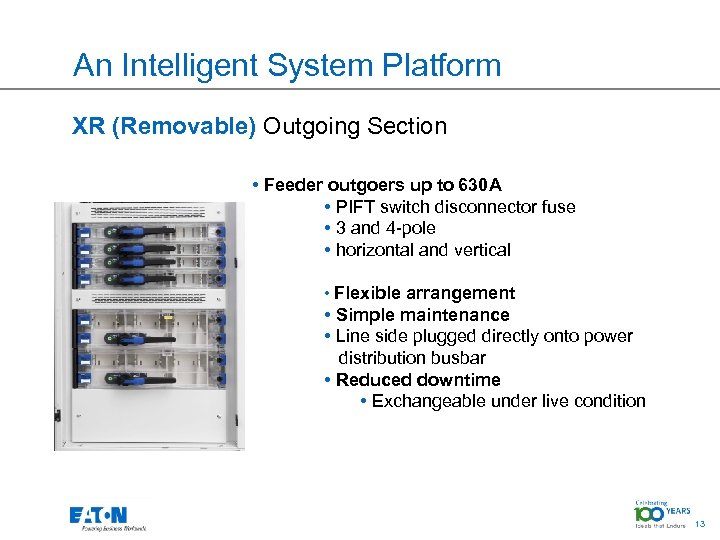

An Intelligent System Platform XR (Removable) Outgoing Section • Feeder outgoers up to 630 A • PIFT switch disconnector fuse • 3 and 4 -pole • horizontal and vertical • Flexible arrangement • Simple maintenance • Line side plugged directly onto power distribution busbar • Reduced downtime • Exchangeable under live condition 13

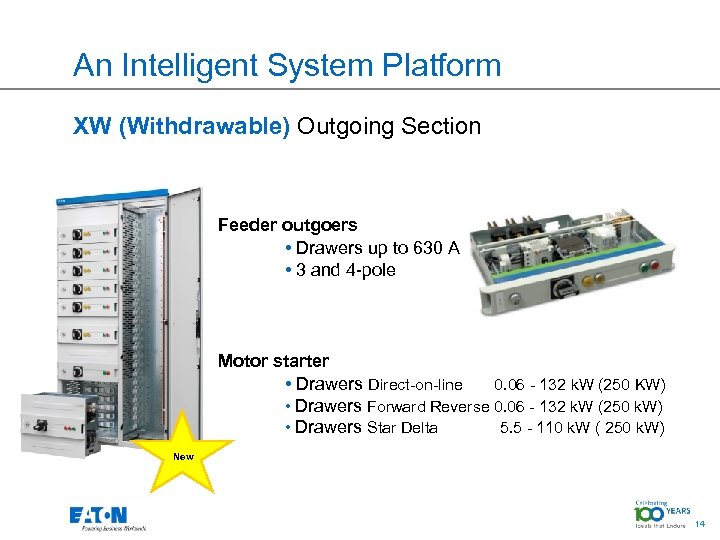

An Intelligent System Platform XW (Withdrawable) Outgoing Section Feeder outgoers • Drawers up to 630 A • 3 and 4 -pole Motor starter • Drawers Direct-on-line 0. 06 - 132 k. W (250 KW) • Drawers Forward Reverse 0. 06 - 132 k. W (250 k. W) • Drawers Star Delta 5. 5 - 110 k. W ( 250 k. W) New 14

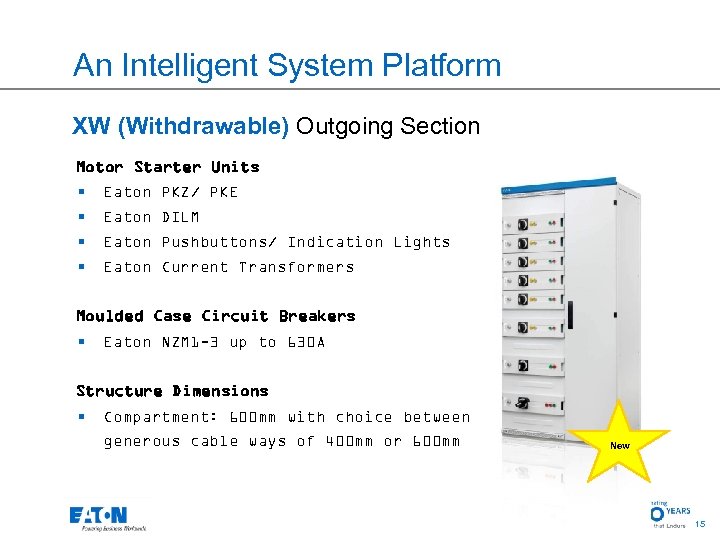

An Intelligent System Platform XW (Withdrawable) Outgoing Section Motor Starter Units • Eaton PKZ/ PKE • Eaton DILM • Eaton Pushbuttons/ Indication Lights • Eaton Current Transformers Moulded Case Circuit Breakers • Eaton NZM 1 -3 up to 630 A Structure Dimensions • Compartment: 600 mm with choice between generous cable ways of 400 mm or 600 mm New 15

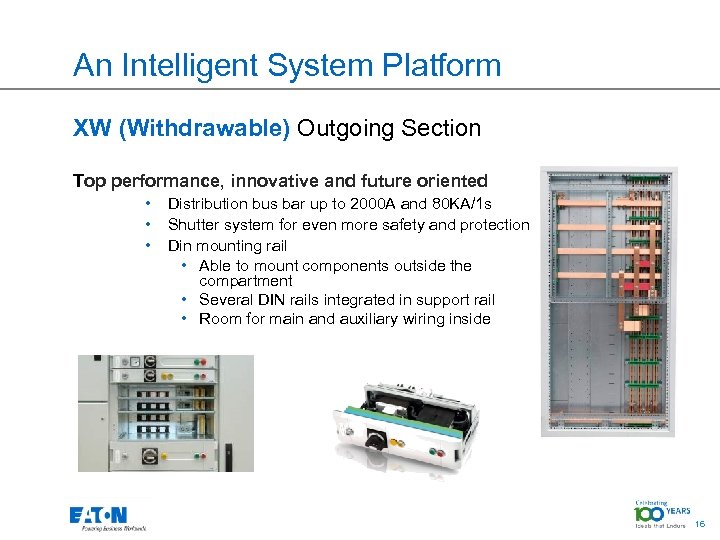

An Intelligent System Platform XW (Withdrawable) Outgoing Section Top performance, innovative and future oriented • • • Distribution bus bar up to 2000 A and 80 KA/1 s Shutter system for even more safety and protection Din mounting rail • Able to mount components outside the compartment • Several DIN rails integrated in support rail • Room for main and auxiliary wiring inside 16

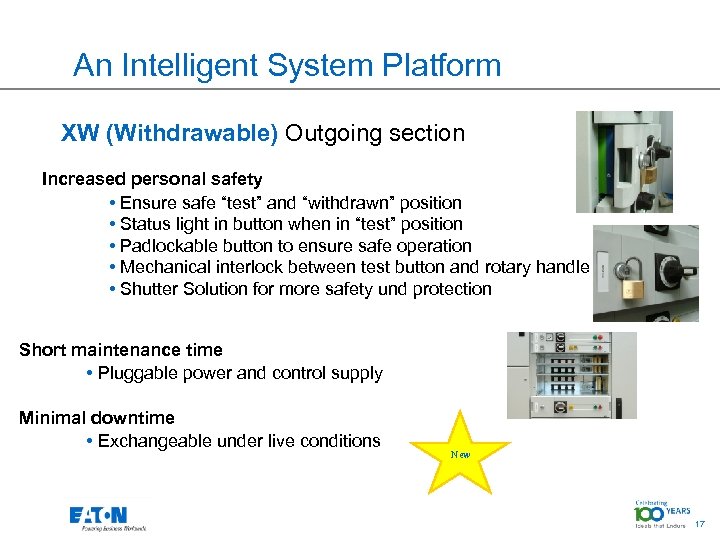

An Intelligent System Platform XW (Withdrawable) Outgoing section Increased personal safety • Ensure safe “test” and “withdrawn” position • Status light in button when in “test” position • Padlockable button to ensure safe operation • Mechanical interlock between test button and rotary handle • Shutter Solution for more safety und protection Short maintenance time • Pluggable power and control supply Minimal downtime • Exchangeable under live conditions New 17

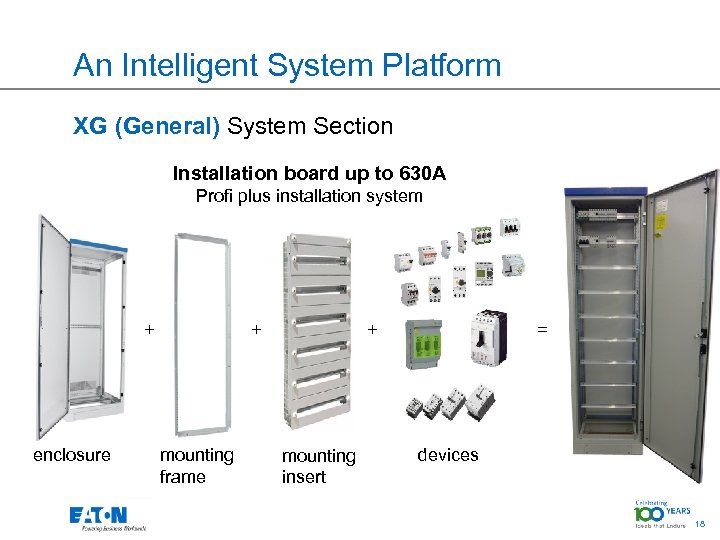

An Intelligent System Platform XG (General) System Section Installation board up to 630 A Profi plus installation system + + enclosure mounting frame + mounting insert = devices 18

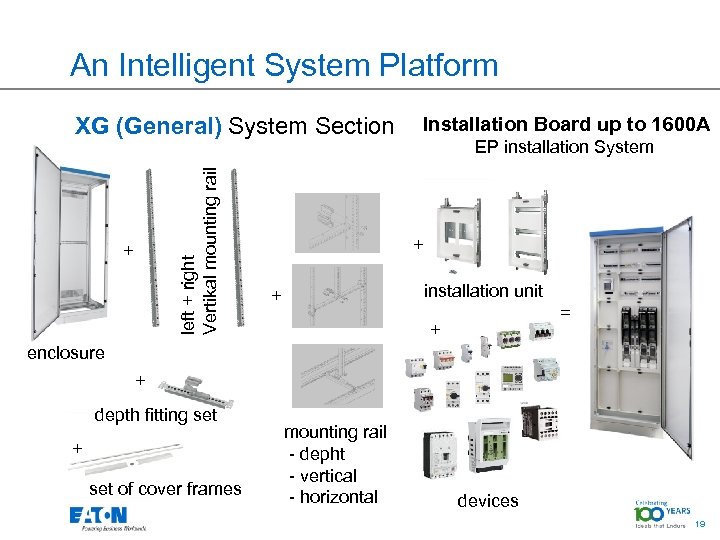

An Intelligent System Platform left + right Vertikal mounting rail XG (General) System Section + Installation Board up to 1600 A EP installation System + installation unit + = + enclosure + depth fitting set + set of cover frames mounting rail - depht - vertical - horizontal devices 19

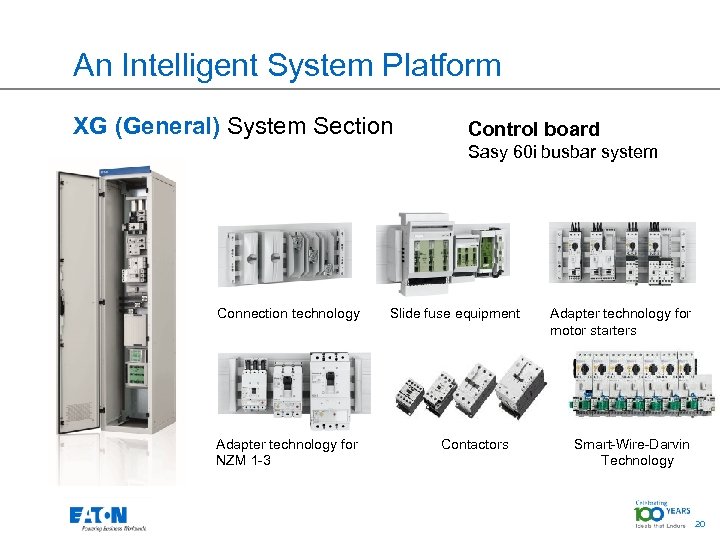

An Intelligent System Platform XG (General) System Section Control board Sasy 60 i busbar system Connection technology Adapter technology for NZM 1 -3 Slide fuse equipment Contactors Adapter technology for motor starters Smart-Wire-Darvin Technology 20

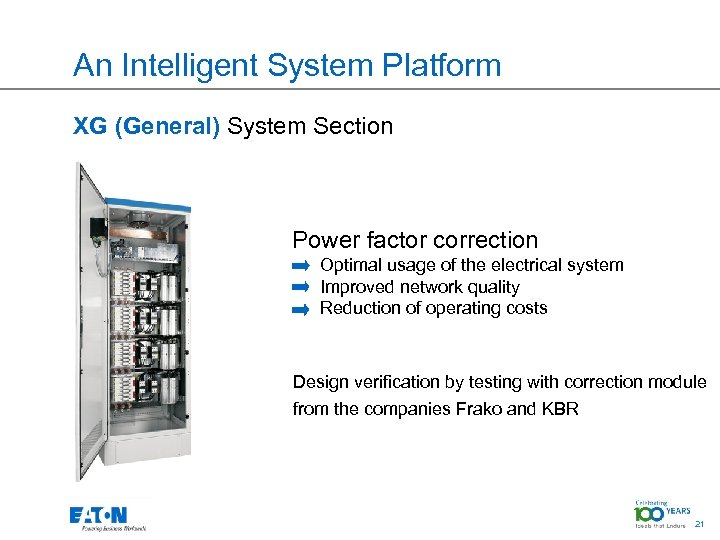

An Intelligent System Platform XG (General) System Section Power factor correction Optimal usage of the electrical system Improved network quality Reduction of operating costs Design verification by testing with correction module from the companies Frako and KBR 21

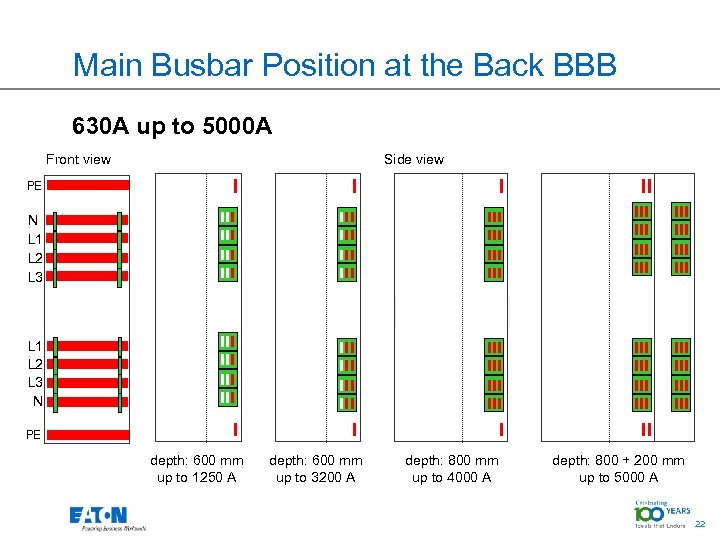

Main Busbar Position at the Back BBB 630 A up to 5000 A Side view Front view PE N L 1 L 2 L 3 N PE depth: 600 mm up to 1250 A depth: 600 mm up to 3200 A depth: 800 mm up to 4000 A depth: 800 + 200 mm up to 5000 A 22

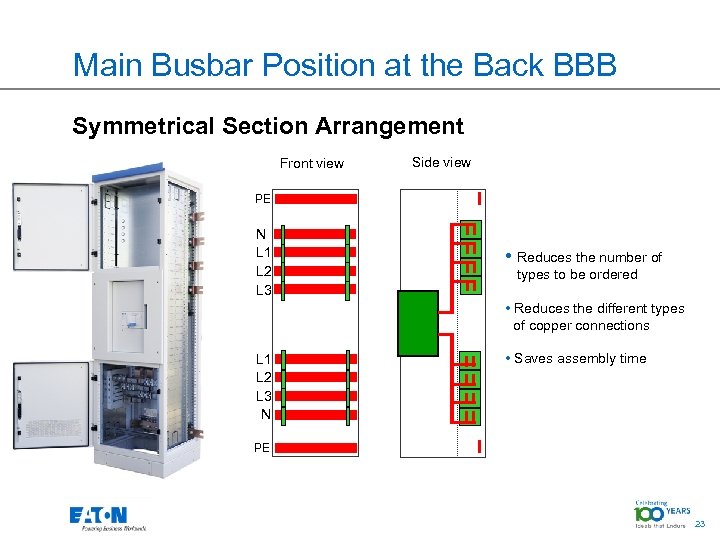

Main Busbar Position at the Back BBB Symmetrical Section Arrangement Front view Side view PE N L 1 L 2 L 3 • Reduces the number of types to be ordered • Reduces the different types of copper connections L 1 L 2 L 3 N • Saves assembly time PE 23

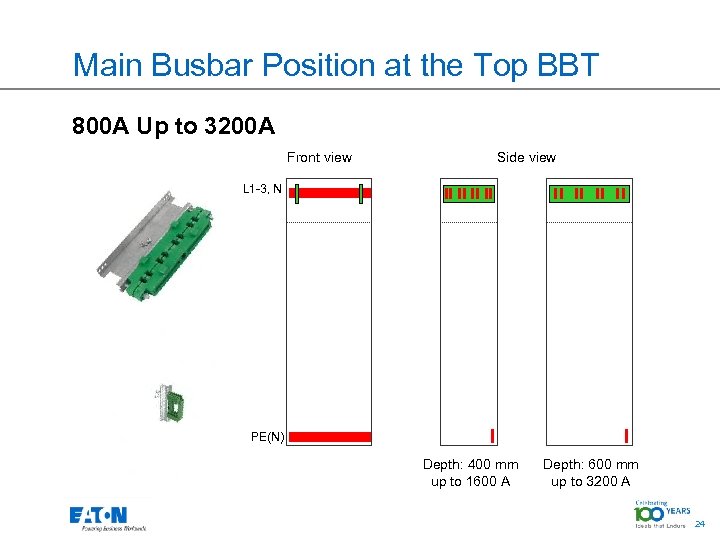

Main Busbar Position at the Top BBT 800 A Up to 3200 A Front view Side view L 1 -3, N PE(N) Depth: 400 mm up to 1600 A Depth: 600 mm up to 3200 A 24

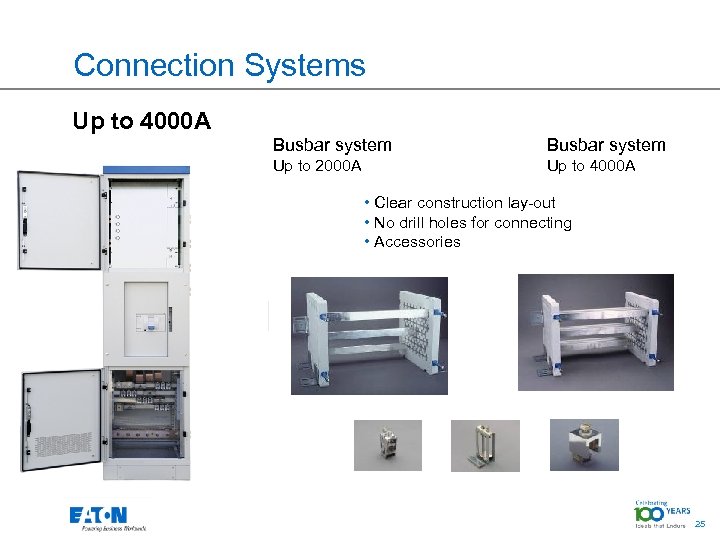

Connection Systems Up to 4000 A Busbar system Up to 2000 A Up to 4000 A • Clear construction lay-out • No drill holes for connecting • Accessories 25

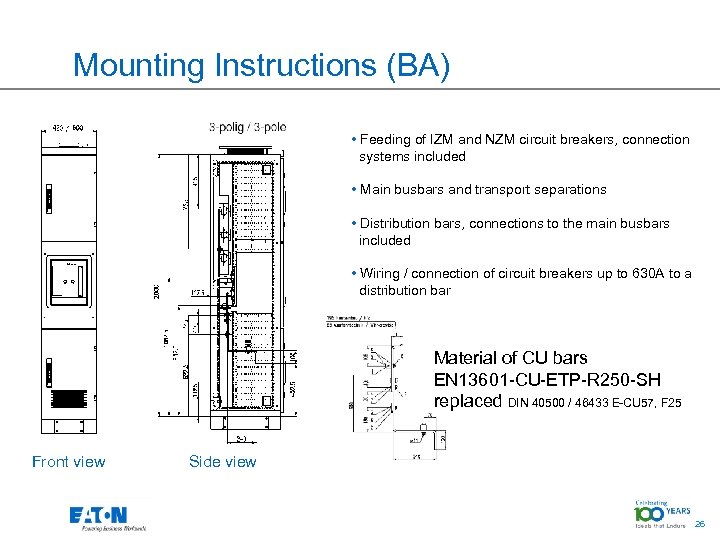

Mounting Instructions (BA) • Feeding of IZM and NZM circuit breakers, connection systems included • Main busbars and transport separations • Distribution bars, connections to the main busbars included • Wiring / connection of circuit breakers up to 630 A to a distribution bar Material of CU bars EN 13601 -CU-ETP-R 250 -SH replaced DIN 40500 / 46433 E-CU 57, F 25 Front view Side view 26

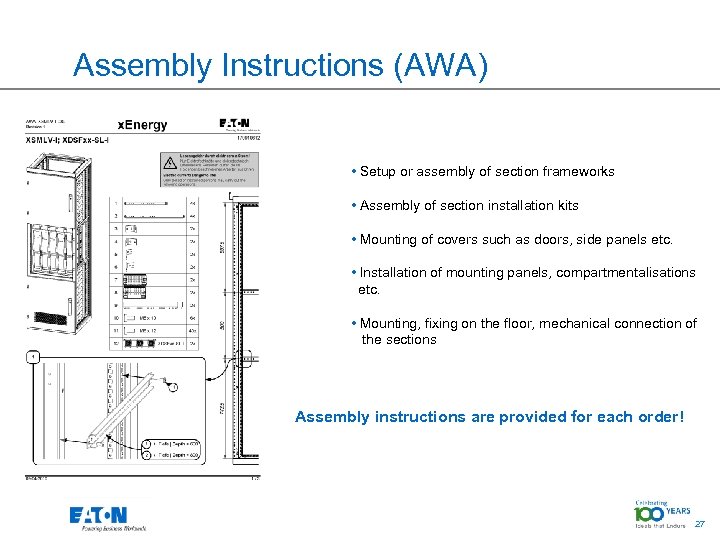

Assembly Instructions (AWA) • Setup or assembly of section frameworks • Assembly of section installation kits • Mounting of covers such as doors, side panels etc. • Installation of mounting panels, compartmentalisations etc. • Mounting, fixing on the floor, mechanical connection of the sections Assembly instructions are provided for each order! 27

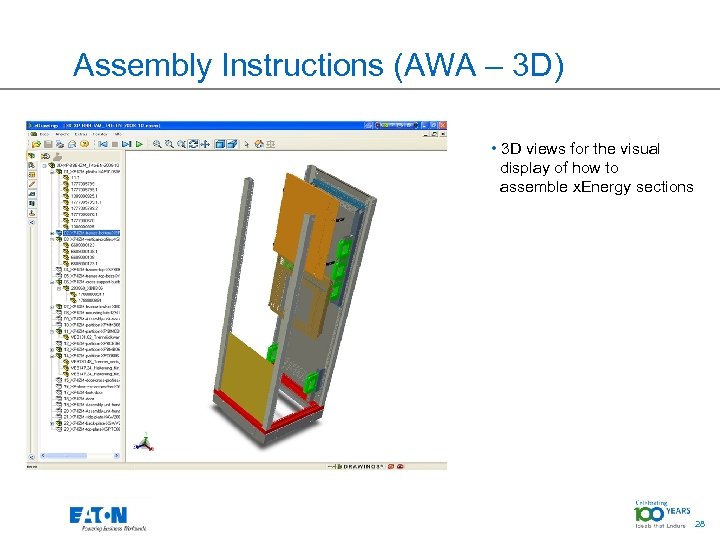

Assembly Instructions (AWA – 3 D) • 3 D views for the visual display of how to assemble x. Energy sections 28

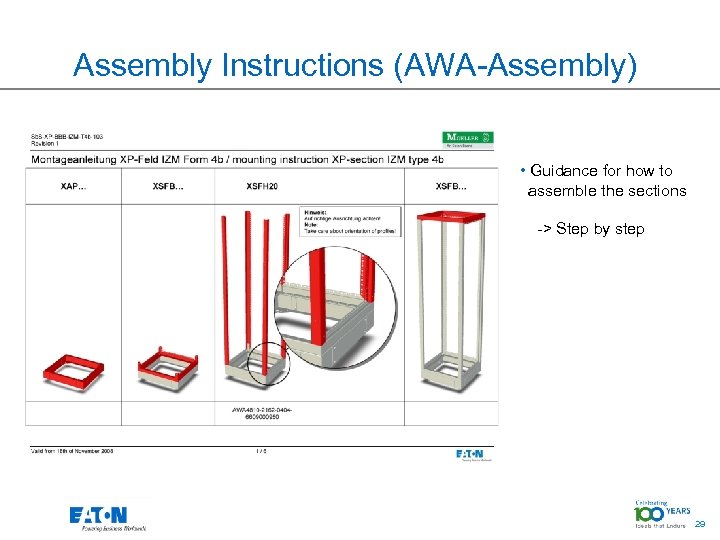

Assembly Instructions (AWA-Assembly) • Guidance for how to assemble the sections -> Step by step 29

Customer-specific Solution Special Paints Customer-specific solutions • Special dimensions • Cut-outs • Double-wing doors • Enquiries to Sonderblech. EGSchrems@eaton. net Special paints • RAL colours as customary in trade 30

Ordering Tool Catalogue for product range Allows quick and easy orders • Complete range of x. Energy products • User-friendly, solution-oriented presentation • Quick-selection fields • Application-oriented • Individual parts • Hints and tips for project design • Technical data 31

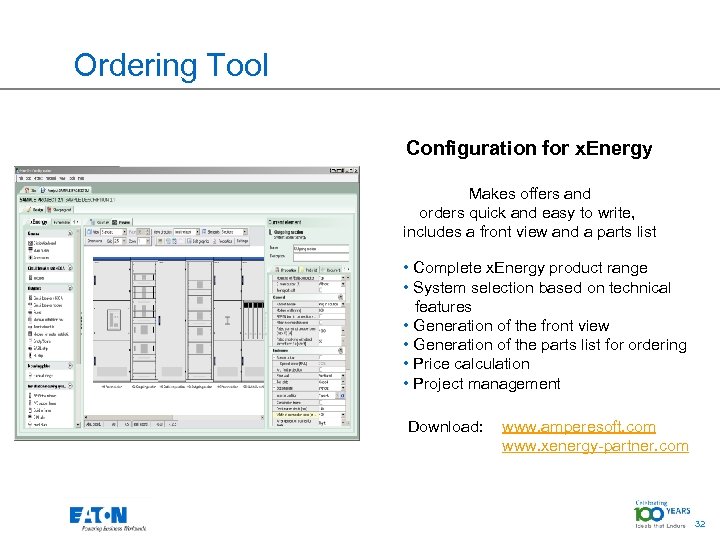

Ordering Tool Configuration for x. Energy Makes offers and orders quick and easy to write, includes a front view and a parts list • Complete x. Energy product range • System selection based on technical features • Generation of the front view • Generation of the parts list for ordering • Price calculation • Project management Download: www. amperesoft. com www. xenergy-partner. com 32

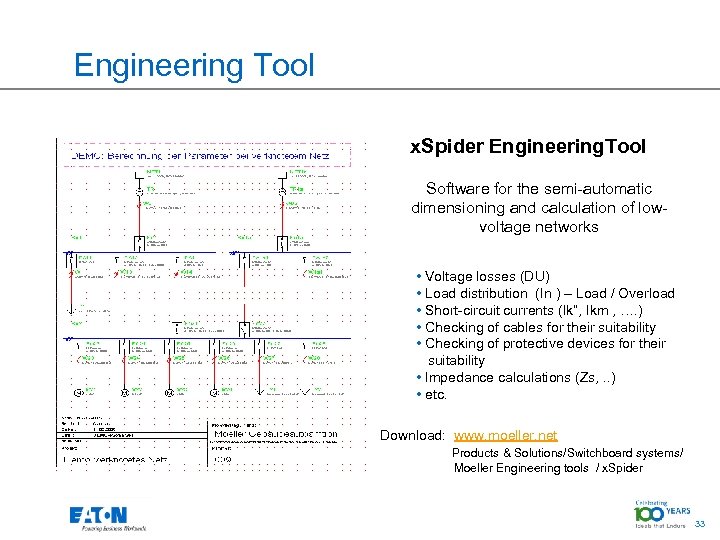

Engineering Tool x. Spider Engineering. Tool Software for the semi-automatic dimensioning and calculation of lowvoltage networks • Voltage losses (DU) • Load distribution (In ) – Load / Overload • Short-circuit currents (Ik“, Ikm , …. ) • Checking of cables for their suitability • Checking of protective devices for their suitability • Impedance calculations (Zs, . . ) • etc. Download: www. moeller. net Products & Solutions/Switchboard systems/ Moeller Engineering tools / x. Spider 33

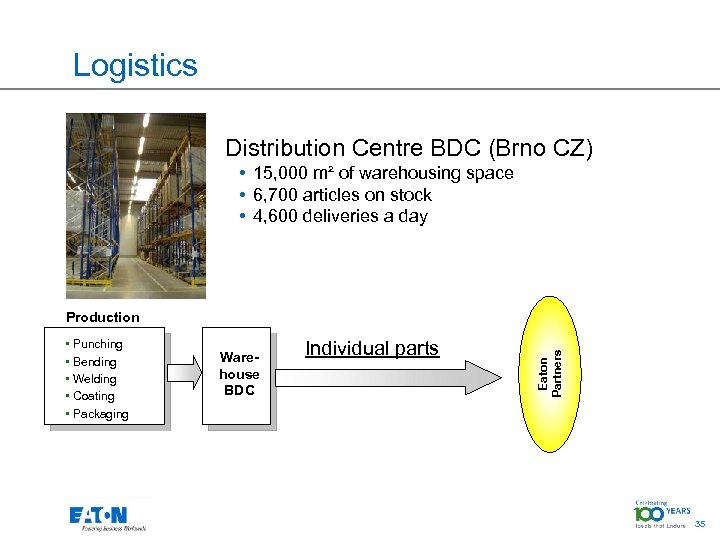

Logistics Distribution Centre BDC (Brno CZ) • 15, 000 m² of warehousing space • 6, 700 articles on stock • 4, 600 deliveries a day • Punching • Bending • Welding • Coating • Packaging Warehouse BDC Individual parts Eaton Partners Production 35

Marketing Image Movie Endcostumer Flyer Panel builder Flyer Technical book Tender 36

Support and Service • On-site service through staff of Eaton´s national sales subsidiaries • Worldwide spare-parts supply thanks to a global distribution network • Support team in Austria: Support. Distributionboard. Austria@eaton. com Mr. Herbert Roessler +43 2853 702 -1451 Mr. Martin Scherzer +43 2853 702 -1274 Mr. Gerald Deutsch +43 2853 702 -1336 Mr. Reinhard Zahrl +43 2853 702 -1296 • Marketing Caroline. Hala@eaton. com Ms. Caroline Hala +43 50868 3352 • Product management Johannes. Thaller@eaton. com Mr. Johannes Thaller +43 676 89952426 37

Type Tests Type tests are intended to verify compliance with the requirements of IEC 60439 -1 Type tests will be carried out on a sample of such an ASSEMBLY or on such parts of ASSEMBLIES manufactured to the same or a similar design. They shall be carried out on the initiative of the manufacturer. 1. Verification of the temperature-rise limits 2. Verification of dielectric properties 3. Verification of the short-circuit withstand strength 4. Verification of the effectiveness of the protective circuit 5. Verification of clearances and creepage distances 6. Verification of mechanical operation 7. Verification of degree of protection 38

Type Test – Data Sheet / Certificate 39

Routine Tests Routine tests are intended to detect faults in materials and workmanship. They are carried out on every new ASSEMBLY after it has been assembled or on each transport unit. Another routine test at the place of installation is not required. Routine tests include: 1. Inspection of the ASSEMBLY including inspection of wiring and, if necessary, electrical operation test. 2. Dielectric test 3. Checking of protective measures and of the electrical continuity of the protective circuit 40

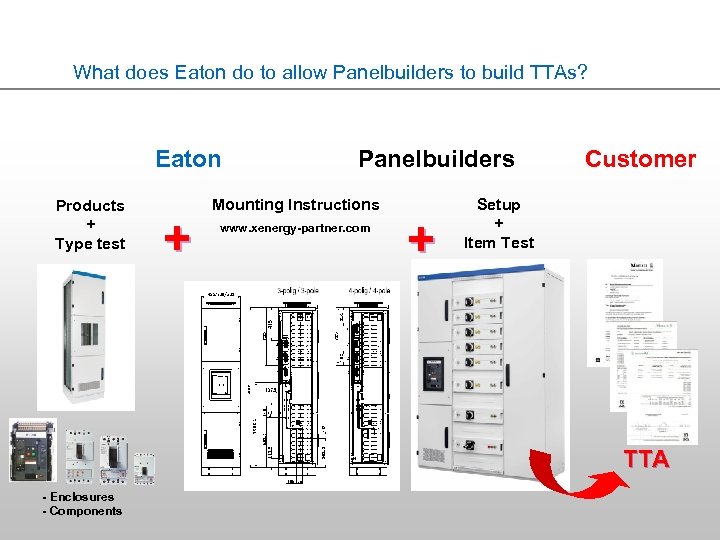

What does Eaton do to allow Panelbuilders to build TTAs? Eaton Products + Type test + Panelbuilders Mounting Instructions www. xenergy-partner. com + Customer Setup + Item Test TTA - Enclosures - Components 41

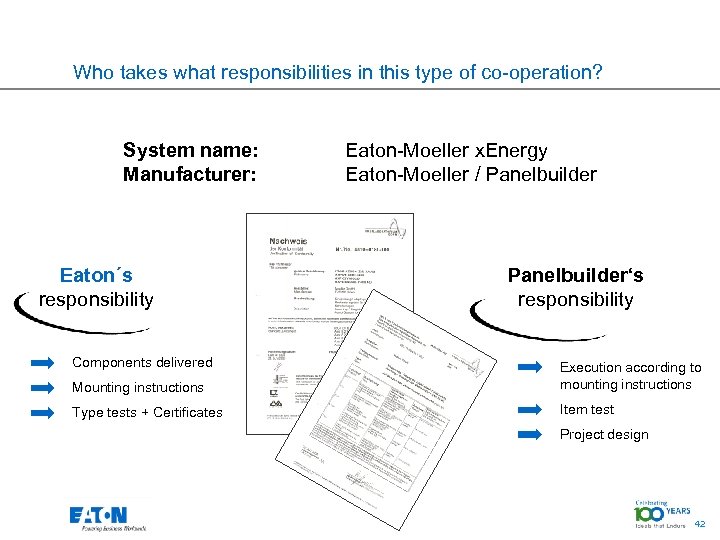

Who takes what responsibilities in this type of co-operation? System name: Manufacturer: Eaton´s responsibility Components delivered Eaton-Moeller x. Energy Eaton-Moeller / Panelbuilder‘s responsibility Mounting instructions Execution according to mounting instructions Type tests + Certificates Item test Project design 42

How do I get Access to the Mounting Instructions and Certificates? All mounting instructions and certificates are available for x. Energy partners on Eaton‘s web site. Every partner will receive an access code giving him access to the data bases. For more information visit us at: www. xenergy-partner. com 43

Benefits for Eaton‘s Partners • Eaton‘s technology has been tried and tested for more than 100 years • Optimal added value for the panel builder • Design verification by testing and prepared for the requirements of the future • Optimized system platform up to 5000 A • Reduced number of individual parts and modules • Suitable for universal use (DIN VDE, CEI, UNE, NF) • Flexible when it comes to combining • Worldwide service and support • Everything from a single source 44

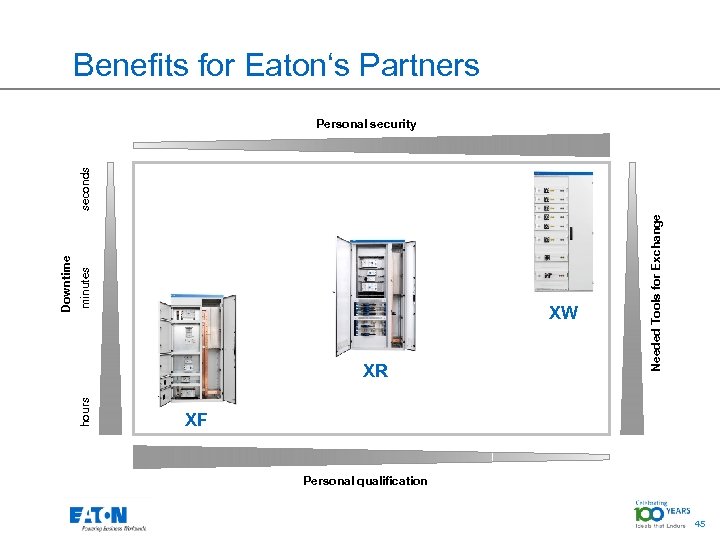

Benefits for Eaton‘s Partners Needed Tools for Exchange minutes XW XR hours Downtime seconds Personal security XF Personal qualification 45

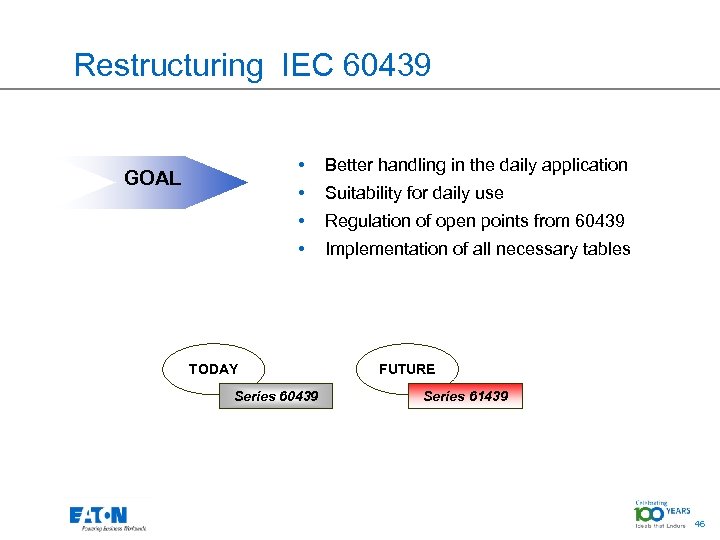

Restructuring IEC 60439 • • Suitability for daily use • Regulation of open points from 60439 • GOAL Better handling in the daily application Implementation of all necessary tables TODAY Series 60439 FUTURE Series 61439 46

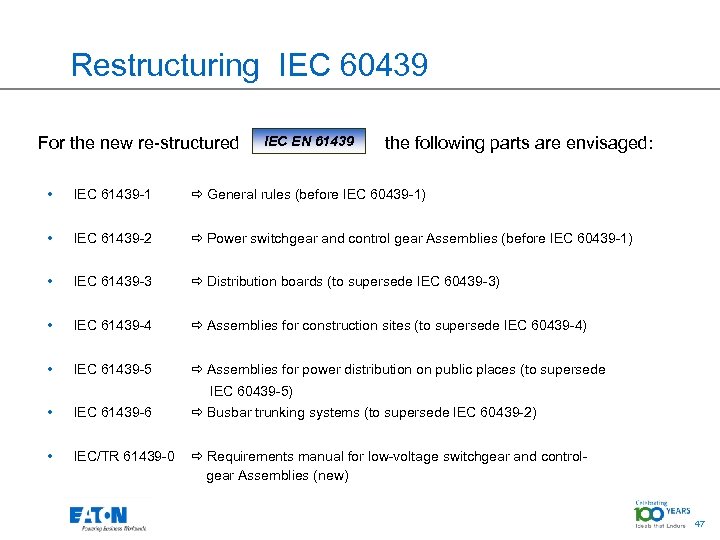

Restructuring IEC 60439 For the new re-structured IEC EN 61439 the following parts are envisaged: • IEC 61439 -1 General rules (before IEC 60439 -1) • IEC 61439 -2 Power switchgear and control gear Assemblies (before IEC 60439 -1) • IEC 61439 -3 Distribution boards (to supersede IEC 60439 -3) • IEC 61439 -4 Assemblies for construction sites (to supersede IEC 60439 -4) • IEC 61439 -5 Assemblies for power distribution on public places (to supersede IEC 60439 -5) • IEC 61439 -6 Busbar trunking systems (to supersede IEC 60439 -2) • IEC/TR 61439 -0 Requirements manual for low-voltage switchgear and controlgear Assemblies (new) 47

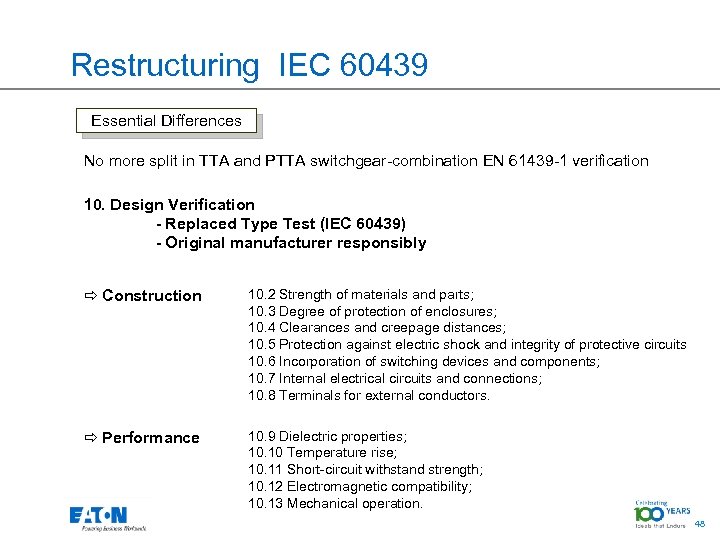

Restructuring IEC 60439 Essential Differences No more split in TTA and PTTA switchgear-combination EN 61439 -1 verification 10. Design Verification - Replaced Type Test (IEC 60439) - Original manufacturer responsibly Construction 10. 2 Strength of materials and parts; 10. 3 Degree of protection of enclosures; 10. 4 Clearances and creepage distances; 10. 5 Protection against electric shock and integrity of protective circuits 10. 6 Incorporation of switching devices and components; 10. 7 Internal electrical circuits and connections; 10. 8 Terminals for external conductors. Performance 10. 9 Dielectric properties; 10. 10 Temperature rise; 10. 11 Short-circuit withstand strength; 10. 12 Electromagnetic compatibility; 10. 13 Mechanical operation. 48

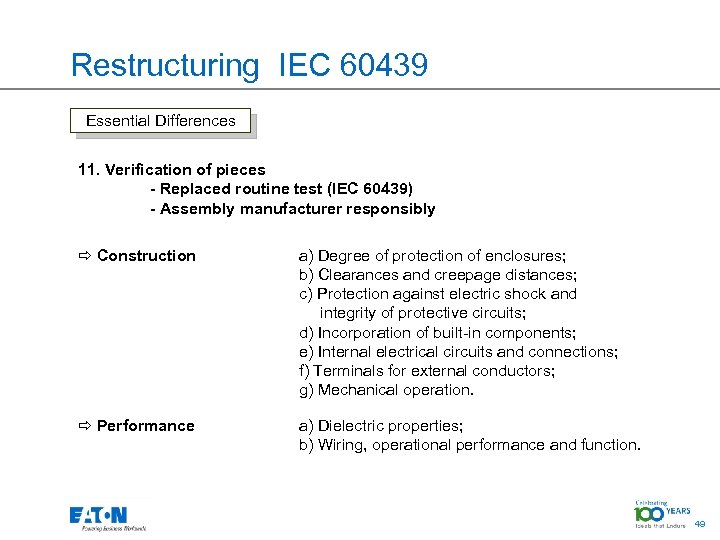

Restructuring IEC 60439 Essential Differences 11. Verification of pieces - Replaced routine test (IEC 60439) - Assembly manufacturer responsibly Construction a) Degree of protection of enclosures; b) Clearances and creepage distances; c) Protection against electric shock and integrity of protective circuits; d) Incorporation of built-in components; e) Internal electrical circuits and connections; f) Terminals for external conductors; g) Mechanical operation. Performance a) Dielectric properties; b) Wiring, operational performance and function. 49

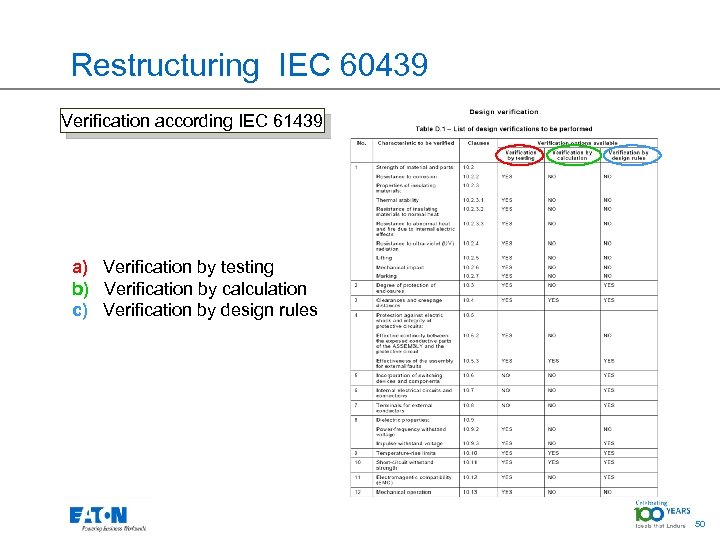

Restructuring IEC 60439 Verification according IEC 61439 a) Verification by testing b) Verification by calculation c) Verification by design rules 50

Restructuring IEC 60439 Status / Perspective • Where tests on the assembley have been contuced in accordance with the IEC 60439 series and the test results fulfill the requirements of the relevant part of IEC 61439, the verification of these reqirements need not repeated. • • The physics didn’t change, so all parameters which are coming out of type-tests are still valid. • For companies which work today with TTA-Systems we don’t see fundamental changes. • After a transitional period until 2015 approx. in the IEC 60439 cease to apply. 51

Reference Projects Planned, designed and built by Hollandia Offset Heerhugowaard Netherlands Low-voltage main distribution 2 x 1000 k. VA 52

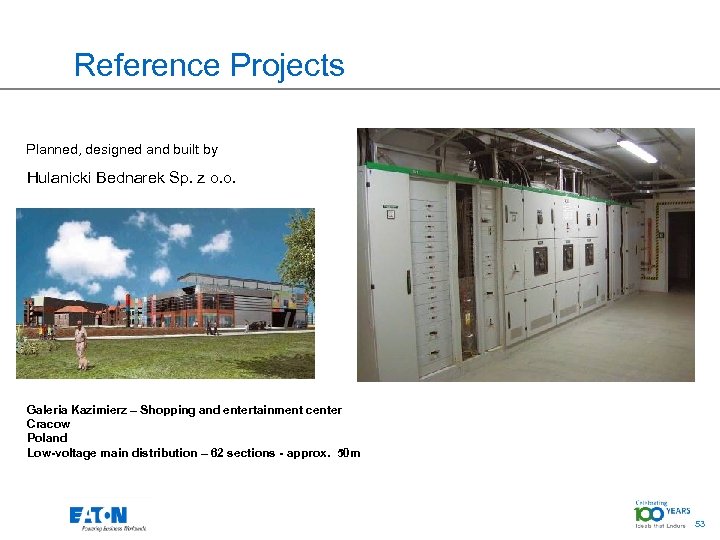

Reference Projects Planned, designed and built by Hulanicki Bednarek Sp. z o. o. Galeria Kazimierz – Shopping and entertainment center Cracow Poland Low-voltage main distribution – 62 sections - approx. 50 m 53

54

375c6e3662a7b31fdd7caa512a73be9e.ppt