263e053857ba08e1253da6a87e7af92d.ppt

- Количество слайдов: 17

Low AC and DC Resistance Inductor Technology n Weyman Lundquist – President and CEO n West Coast Magnetics n April 4, 2007 n International Patent # WO 2005/09630

Low AC and DC Resistance Inductor Technology n Weyman Lundquist – President and CEO n West Coast Magnetics n April 4, 2007 n International Patent # WO 2005/09630

Patented Inductor Technology n Very Low DCR, High Window Utilization n n Foil winding AND Low AC Resistance n AC loss reduction comparable to litz wire n SIGNIFICANTLY LOWER TOTAL LOSSES n Applies to: n n Gapped core structures Idc > 10 amps Ripple > 5% Inductors (Chokes)

Patented Inductor Technology n Very Low DCR, High Window Utilization n n Foil winding AND Low AC Resistance n AC loss reduction comparable to litz wire n SIGNIFICANTLY LOWER TOTAL LOSSES n Applies to: n n Gapped core structures Idc > 10 amps Ripple > 5% Inductors (Chokes)

West Coast Magnetics is: n A Manufacturing Driven Organization n n A Customer Driven Organization n Lean since 2005 100% on-time delivery 100% defect free product Service Engineering Support A Technology Innovator

West Coast Magnetics is: n A Manufacturing Driven Organization n n A Customer Driven Organization n Lean since 2005 100% on-time delivery 100% defect free product Service Engineering Support A Technology Innovator

West Coast Magnetics Company History n Founded in 1976 in Silicon Valley n Present Ownership 1993 n Open Stockton facility in 1996 n Acquired Mexico Facility in 1999 n New Inductor Technology 2003

West Coast Magnetics Company History n Founded in 1976 in Silicon Valley n Present Ownership 1993 n Open Stockton facility in 1996 n Acquired Mexico Facility in 1999 n New Inductor Technology 2003

Company Overview n Stockton, CA • Corporate Headquarters and Manufacturing Facility n Tecate, MX • Production Facility n Custom and Standard Products • • • Power Transformers: 50/60 Hz to 13. 56 MHz Power Transformers: 1 Watt to 15 k. W Power Inductors to 200 amps Common Mode Chokes to 200 amps Current Sense Transformers 60 Hz to 13. 56 MHz RF Inductors to 100 MHz

Company Overview n Stockton, CA • Corporate Headquarters and Manufacturing Facility n Tecate, MX • Production Facility n Custom and Standard Products • • • Power Transformers: 50/60 Hz to 13. 56 MHz Power Transformers: 1 Watt to 15 k. W Power Inductors to 200 amps Common Mode Chokes to 200 amps Current Sense Transformers 60 Hz to 13. 56 MHz RF Inductors to 100 MHz

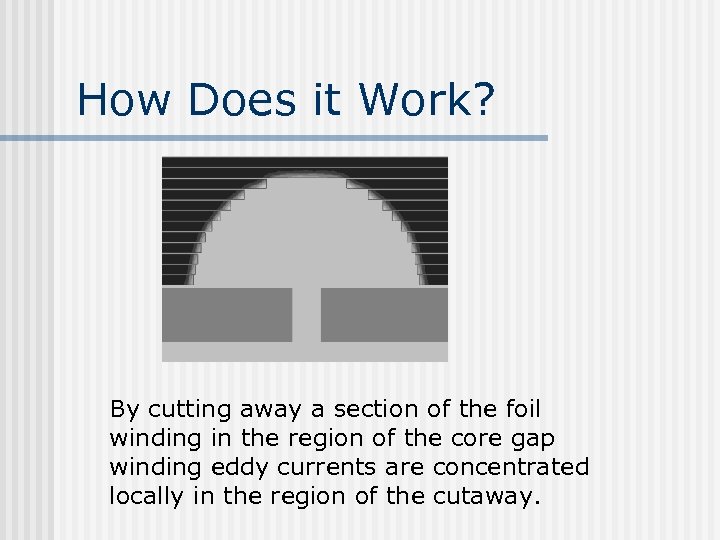

How Does it Work? By cutting away a section of the foil winding in the region of the core gap winding eddy currents are concentrated locally in the region of the cutaway.

How Does it Work? By cutting away a section of the foil winding in the region of the core gap winding eddy currents are concentrated locally in the region of the cutaway.

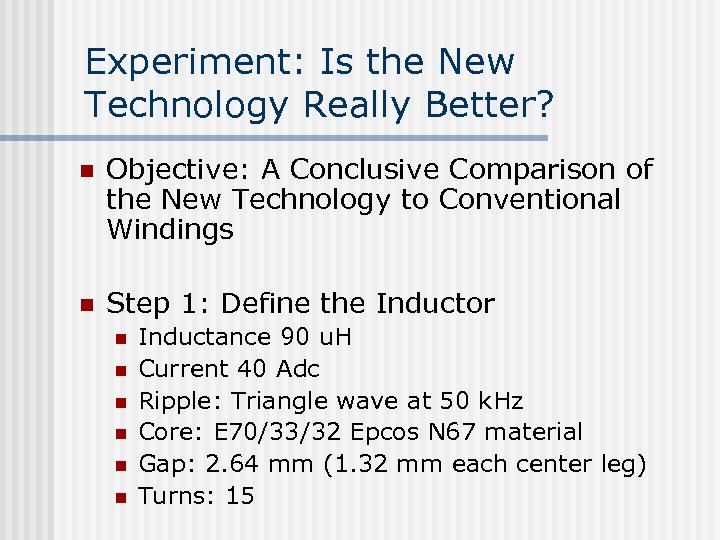

Experiment: Is the New Technology Really Better? n Objective: A Conclusive Comparison of the New Technology to Conventional Windings n Step 1: Define the Inductor n n n Inductance 90 u. H Current 40 Adc Ripple: Triangle wave at 50 k. Hz Core: E 70/33/32 Epcos N 67 material Gap: 2. 64 mm (1. 32 mm each center leg) Turns: 15

Experiment: Is the New Technology Really Better? n Objective: A Conclusive Comparison of the New Technology to Conventional Windings n Step 1: Define the Inductor n n n Inductance 90 u. H Current 40 Adc Ripple: Triangle wave at 50 k. Hz Core: E 70/33/32 Epcos N 67 material Gap: 2. 64 mm (1. 32 mm each center leg) Turns: 15

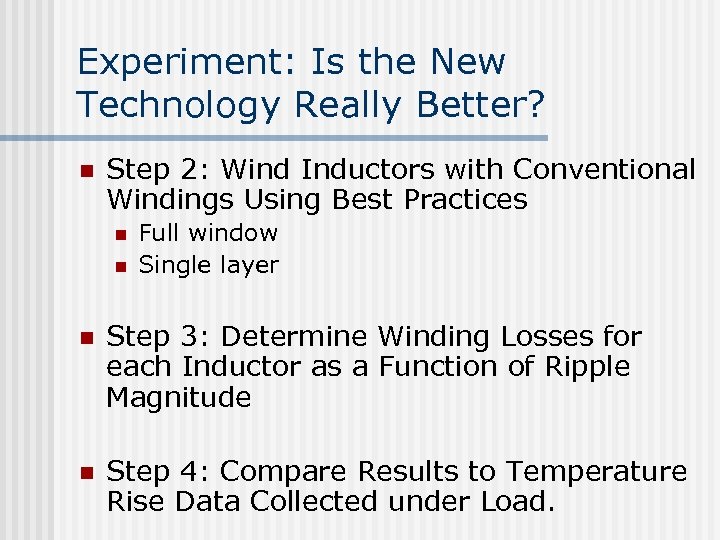

Experiment: Is the New Technology Really Better? n Step 2: Wind Inductors with Conventional Windings Using Best Practices n n Full window Single layer n Step 3: Determine Winding Losses for each Inductor as a Function of Ripple Magnitude n Step 4: Compare Results to Temperature Rise Data Collected under Load.

Experiment: Is the New Technology Really Better? n Step 2: Wind Inductors with Conventional Windings Using Best Practices n n Full window Single layer n Step 3: Determine Winding Losses for each Inductor as a Function of Ripple Magnitude n Step 4: Compare Results to Temperature Rise Data Collected under Load.

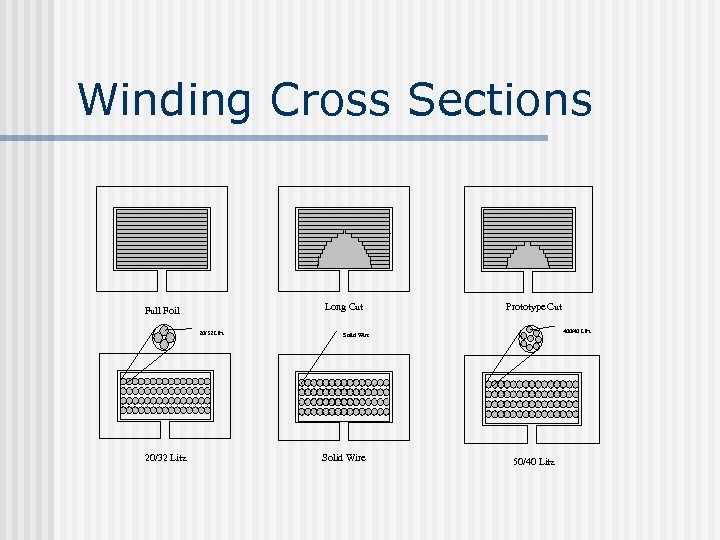

Winding Cross Sections Long Cut Full Foil 20/32 Litz Prototype Cut 400/40 Litz Solid Wire 50/40 Litz

Winding Cross Sections Long Cut Full Foil 20/32 Litz Prototype Cut 400/40 Litz Solid Wire 50/40 Litz

Method of Estimating Losses n n n DCR – Measure voltage drop under 5 Amp DC load. Core Losses: Derived from Epcos loss curves. AC resistance – Sweep from 10 k. Hz to 200 k. Hz with Agilent 4294 A network analyzer n Use Fourier decomposition to translate sinusoidal sweep data to triangular waveform

Method of Estimating Losses n n n DCR – Measure voltage drop under 5 Amp DC load. Core Losses: Derived from Epcos loss curves. AC resistance – Sweep from 10 k. Hz to 200 k. Hz with Agilent 4294 A network analyzer n Use Fourier decomposition to translate sinusoidal sweep data to triangular waveform

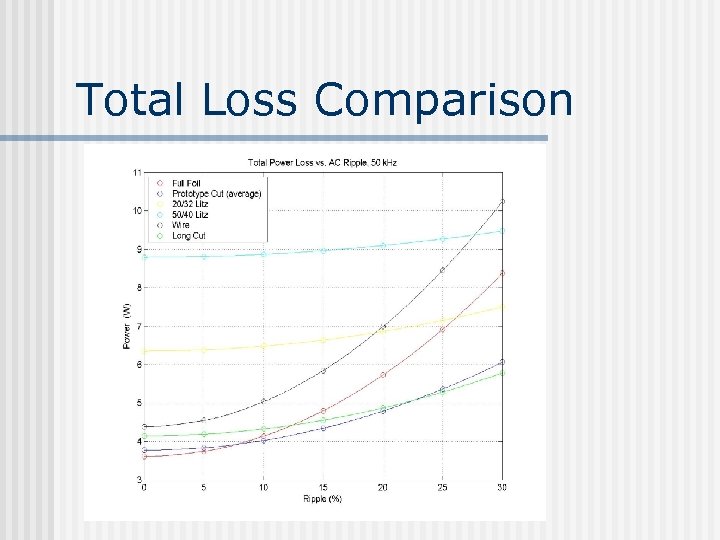

Total Loss Comparison

Total Loss Comparison

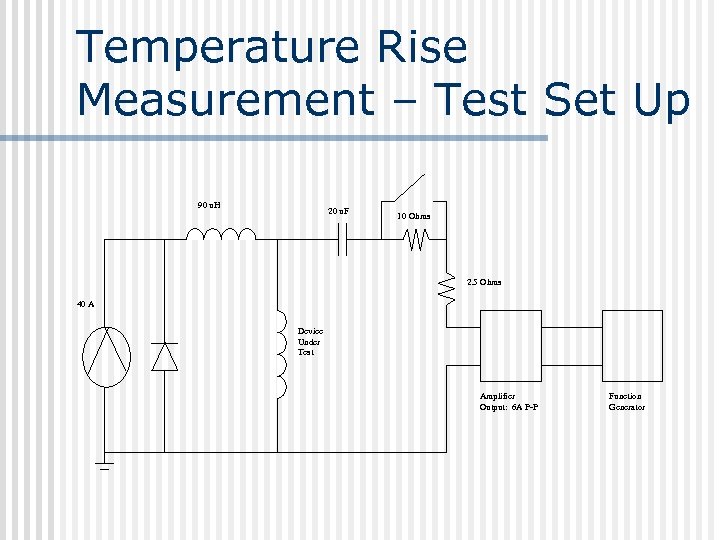

Temperature Rise Measurement – Test Set Up 90 u. H 20 u. F 10 Ohms 2. 5 Ohms 40 A Device Under Test Amplifier Output: 6 A P-P Function Generator

Temperature Rise Measurement – Test Set Up 90 u. H 20 u. F 10 Ohms 2. 5 Ohms 40 A Device Under Test Amplifier Output: 6 A P-P Function Generator

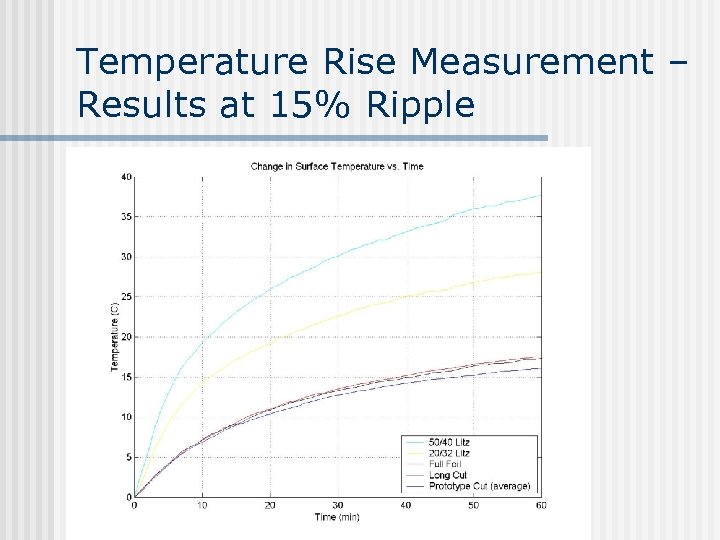

Temperature Rise Measurement – Results at 15% Ripple

Temperature Rise Measurement – Results at 15% Ripple

Global Market – High Growth Green Energy! n Distributed Power: Wind, Solar and FACTs n Estimated $4. 3 Billion in Power Electronic Equipment in 2007 n 15% plus forecasted growth n Hybrid Vehicles n Est. 600, 000 in 2007 n 50% plus forecasted growth n Uninterruptible Power Supplies n Estimated $4 Billion in Power Electronic Equipment > 1 k. W in 2007 n 7% plus forecasted growth

Global Market – High Growth Green Energy! n Distributed Power: Wind, Solar and FACTs n Estimated $4. 3 Billion in Power Electronic Equipment in 2007 n 15% plus forecasted growth n Hybrid Vehicles n Est. 600, 000 in 2007 n 50% plus forecasted growth n Uninterruptible Power Supplies n Estimated $4 Billion in Power Electronic Equipment > 1 k. W in 2007 n 7% plus forecasted growth

Design Tools n Code for Winding Loss Simulation n Code for Translation of Winding Cross Section into 2 D Foil Shape n Code for Prediction of H vs. L vs. Gap for any Inductor

Design Tools n Code for Winding Loss Simulation n Code for Translation of Winding Cross Section into 2 D Foil Shape n Code for Prediction of H vs. L vs. Gap for any Inductor

Licensing Opportunity n Objective: The widest possible application of the technology. n n n Develop tools for design support. Maintain license rate at a level which will lead to widespread use. Contact: Weyman Lundquist wlundquist@wcmagnetics. com n 800 -628 -1123

Licensing Opportunity n Objective: The widest possible application of the technology. n n n Develop tools for design support. Maintain license rate at a level which will lead to widespread use. Contact: Weyman Lundquist wlundquist@wcmagnetics. com n 800 -628 -1123

Thank you for your time Weyman Lundquist, President West Coast Magnetics 4848 Frontier Way, Ste 100 Stockton, CA 95215 www. wcmagnetics. com 800 -628 -1123

Thank you for your time Weyman Lundquist, President West Coast Magnetics 4848 Frontier Way, Ste 100 Stockton, CA 95215 www. wcmagnetics. com 800 -628 -1123