LOGO Profile

LOGO Profile

History Indac International, Indonesia (Manufacturer of carbon electrodes) 1988 Incorporation 1989 Installation of Kiln #1 Start commercial production 1994 Acquisition by Daiichi Carbon. , Ltd. 1997 Installation of Kiln #2 2003 Installation of Kiln #3 (Relocation from Japan) Start production of gouging carbon (Relocation from Japan)

History Indac International, Indonesia (Manufacturer of carbon electrodes) 1988 Incorporation 1989 Installation of Kiln #1 Start commercial production 1994 Acquisition by Daiichi Carbon. , Ltd. 1997 Installation of Kiln #2 2003 Installation of Kiln #3 (Relocation from Japan) Start production of gouging carbon (Relocation from Japan)

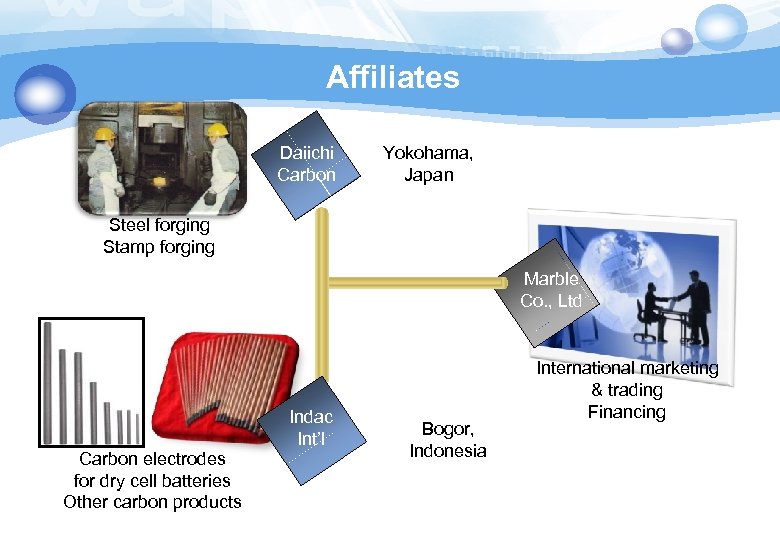

Affiliates Daiichi Carbon Yokohama, Japan Steel forging Stamp forging Marble Co. , Ltd Indac Int’l Carbon electrodes for dry cell batteries Other carbon products Bogor, Indonesia International marketing & trading Financing

Affiliates Daiichi Carbon Yokohama, Japan Steel forging Stamp forging Marble Co. , Ltd Indac Int’l Carbon electrodes for dry cell batteries Other carbon products Bogor, Indonesia International marketing & trading Financing

Recognition ISO 9001; 2008 Cert. #30137 ISO 14001; 2004 Cert. #35012 Certified by Verification New Zealand

Recognition ISO 9001; 2008 Cert. #30137 ISO 14001; 2004 Cert. #35012 Certified by Verification New Zealand

Infrastructure Land : 45, 880 m 2 Bulding : 14, 000 m 2 Employees : 261 (local) & 4 (expatriate)

Infrastructure Land : 45, 880 m 2 Bulding : 14, 000 m 2 Employees : 261 (local) & 4 (expatriate)

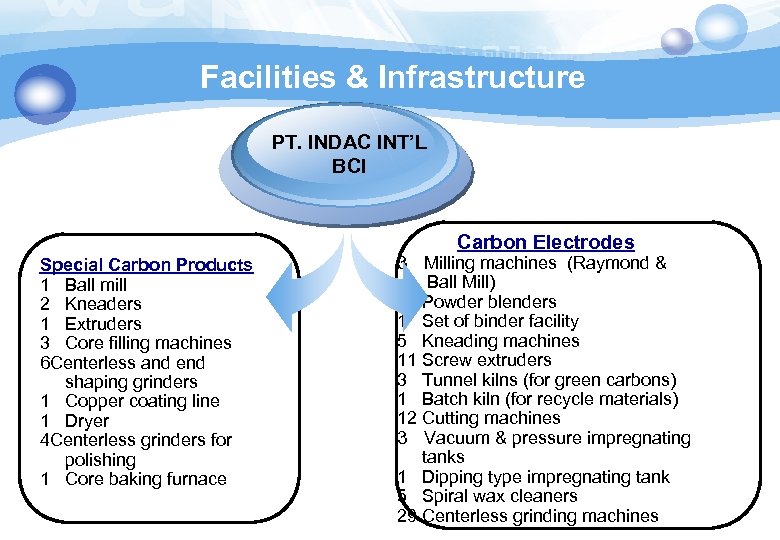

Facilities & Infrastructure PT. INDAC INT’L BCI Carbon Electrodes Special Carbon Products 1 Ball mill 2 Kneaders 1 Extruders 3 Core filling machines 6 Centerless and end shaping grinders 1 Copper coating line 1 Dryer 4 Centerless grinders for polishing 1 Core baking furnace 3 Milling machines (Raymond & Ball Mill) 2 Powder blenders 1 Set of binder facility 5 Kneading machines 11 Screw extruders 3 Tunnel kilns (for green carbons) 1 Batch kiln (for recycle materials) 12 Cutting machines 3 Vacuum & pressure impregnating tanks 1 Dipping type impregnating tank 5 Spiral wax cleaners 29 Centerless grinding machines

Facilities & Infrastructure PT. INDAC INT’L BCI Carbon Electrodes Special Carbon Products 1 Ball mill 2 Kneaders 1 Extruders 3 Core filling machines 6 Centerless and end shaping grinders 1 Copper coating line 1 Dryer 4 Centerless grinders for polishing 1 Core baking furnace 3 Milling machines (Raymond & Ball Mill) 2 Powder blenders 1 Set of binder facility 5 Kneading machines 11 Screw extruders 3 Tunnel kilns (for green carbons) 1 Batch kiln (for recycle materials) 12 Cutting machines 3 Vacuum & pressure impregnating tanks 1 Dipping type impregnating tank 5 Spiral wax cleaners 29 Centerless grinding machines

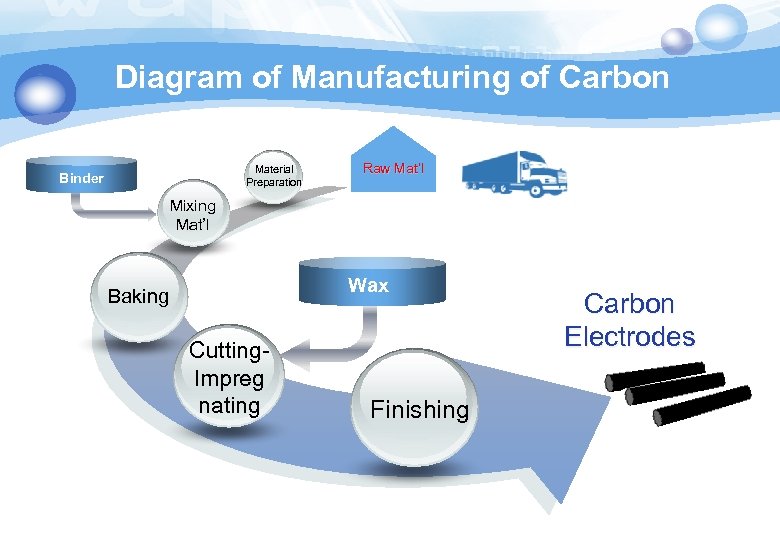

Diagram of Manufacturing of Carbon Material Preparation Binder Raw Mat’l Mixing Mat’l Wax Baking Cutting. Impreg nating Finishing Carbon Electrodes

Diagram of Manufacturing of Carbon Material Preparation Binder Raw Mat’l Mixing Mat’l Wax Baking Cutting. Impreg nating Finishing Carbon Electrodes

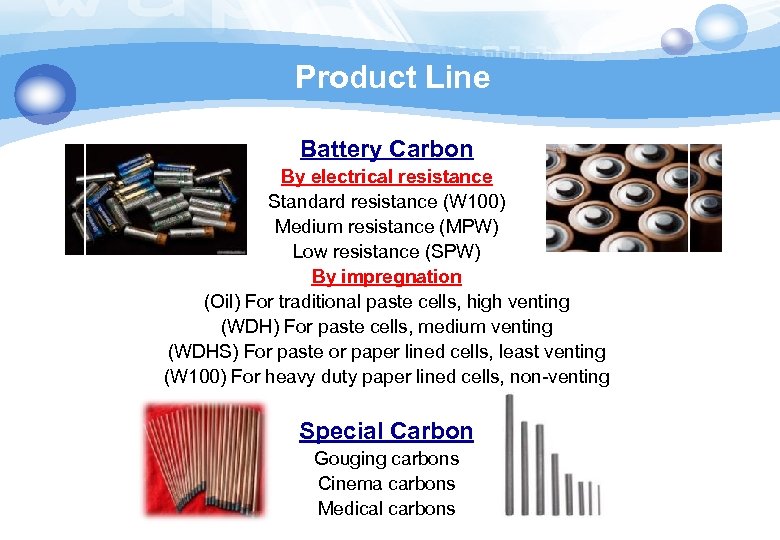

Product Line Battery Carbon By electrical resistance Standard resistance (W 100) Medium resistance (MPW) Low resistance (SPW) By impregnation (Oil) For traditional paste cells, high venting (WDH) For paste cells, medium venting (WDHS) For paste or paper lined cells, least venting (W 100) For heavy duty paper lined cells, non-venting Special Carbon Gouging carbons Cinema carbons Medical carbons

Product Line Battery Carbon By electrical resistance Standard resistance (W 100) Medium resistance (MPW) Low resistance (SPW) By impregnation (Oil) For traditional paste cells, high venting (WDH) For paste cells, medium venting (WDHS) For paste or paper lined cells, least venting (W 100) For heavy duty paper lined cells, non-venting Special Carbon Gouging carbons Cinema carbons Medical carbons

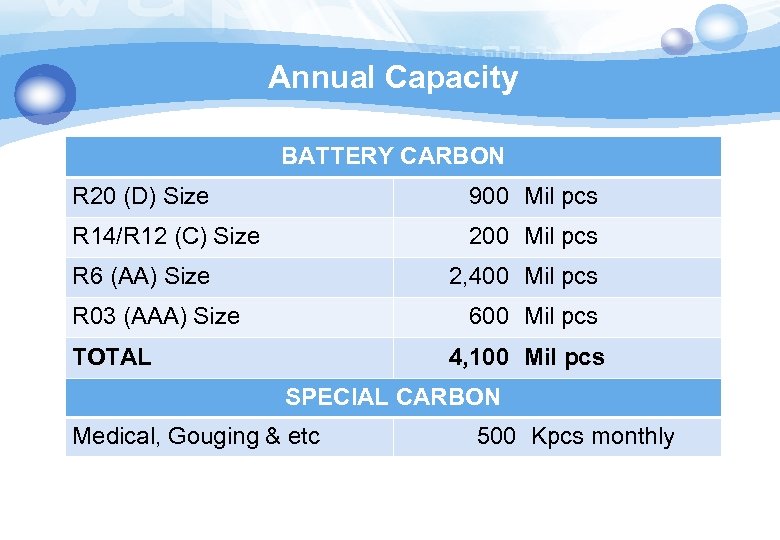

Annual Capacity BATTERY CARBON R 20 (D) Size 900 Mil pcs R 14/R 12 (C) Size 200 Mil pcs R 6 (AA) Size 2, 400 Mil pcs R 03 (AAA) Size 600 Mil pcs TOTAL 4, 100 Mil pcs SPECIAL CARBON Medical, Gouging & etc 500 Kpcs monthly

Annual Capacity BATTERY CARBON R 20 (D) Size 900 Mil pcs R 14/R 12 (C) Size 200 Mil pcs R 6 (AA) Size 2, 400 Mil pcs R 03 (AAA) Size 600 Mil pcs TOTAL 4, 100 Mil pcs SPECIAL CARBON Medical, Gouging & etc 500 Kpcs monthly