9de83453d0434f9d2aa82203dd11c75d.ppt

- Количество слайдов: 66

Logistics © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 1

Logistics © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 1

Logistics • Logistics defined • Logistics decision areas • Logistics strategies in action – Kraft Foods, page 336. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 2

Logistics • Logistics defined • Logistics decision areas • Logistics strategies in action – Kraft Foods, page 336. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 2

Logistics Planning, implementing, and controlling the effective flow and storage of goods and materials from the point of origin to the point of consumption (CLM) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 3

Logistics Planning, implementing, and controlling the effective flow and storage of goods and materials from the point of origin to the point of consumption (CLM) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 3

Key Decision Areas Ø Transportation Ø Warehousing (and more generally, location) Ø Packaging Ø Material handling Ø Logistics information systems Ø Logistics service providers (And some would put inventory here as well!) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 4

Key Decision Areas Ø Transportation Ø Warehousing (and more generally, location) Ø Packaging Ø Material handling Ø Logistics information systems Ø Logistics service providers (And some would put inventory here as well!) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 4

Why the Increasing Interest? • Deregulation • Globalization • Technological breakthroughs • Environmental concerns • Performance impact © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 5

Why the Increasing Interest? • Deregulation • Globalization • Technological breakthroughs • Environmental concerns • Performance impact © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 5

Deregulation • Transportation providers – – Elimination of artificial barriers Unrestricted markets Multi-modal solutions Price, schedule, and terms flexibility • Buyers have greater freedom – Negotiate prices, terms, and conditions – Ownership issues BUT… © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 6

Deregulation • Transportation providers – – Elimination of artificial barriers Unrestricted markets Multi-modal solutions Price, schedule, and terms flexibility • Buyers have greater freedom – Negotiate prices, terms, and conditions – Ownership issues BUT… © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 6

Deregulation (continued) … With greater freedom comes new responsibilities Key point Logistics has evolved from being a “tactical” area to a “strategic” one © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 7

Deregulation (continued) … With greater freedom comes new responsibilities Key point Logistics has evolved from being a “tactical” area to a “strategic” one © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 7

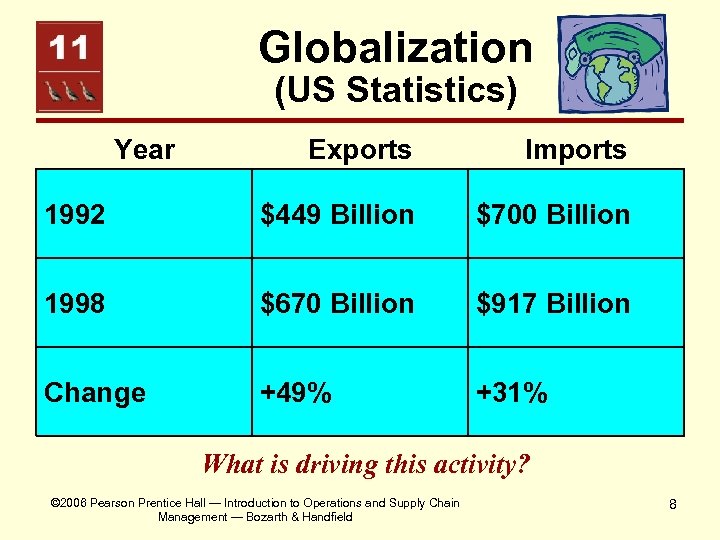

Globalization (US Statistics) Year Exports Imports 1992 $449 Billion $700 Billion 1998 $670 Billion $917 Billion Change +49% +31% What is driving this activity? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 8

Globalization (US Statistics) Year Exports Imports 1992 $449 Billion $700 Billion 1998 $670 Billion $917 Billion Change +49% +31% What is driving this activity? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 8

Technological Breakthroughs I Information Systems • Global positioning systems • Bar-coding applications – RFID on the horizon as replacement • Real-time simulation and optimization • Precise coordination of multi-modal solutions © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 9

Technological Breakthroughs I Information Systems • Global positioning systems • Bar-coding applications – RFID on the horizon as replacement • Real-time simulation and optimization • Precise coordination of multi-modal solutions © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 9

Technological Breakthroughs II Transportation Systems • Standardized containers for ease of transfer • “Roadrailers, ” etc. • Multi-modal solutions – Ship Truck Train Truck ? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 10

Technological Breakthroughs II Transportation Systems • Standardized containers for ease of transfer • “Roadrailers, ” etc. • Multi-modal solutions – Ship Truck Train Truck ? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 10

Environmental Concerns Even while certain aspects of logistics have been deregulated, other areas are being controlled more stringently ØFuel efficiency ØPollution ØRecovery, recycling, and reuse of packaging, containers, and products © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 11

Environmental Concerns Even while certain aspects of logistics have been deregulated, other areas are being controlled more stringently ØFuel efficiency ØPollution ØRecovery, recycling, and reuse of packaging, containers, and products © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 11

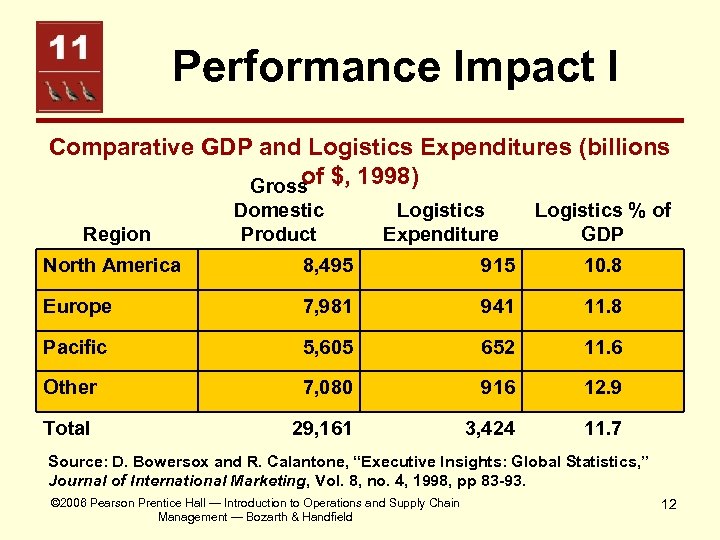

Performance Impact I Comparative GDP and Logistics Expenditures (billions of Gross $, 1998) Region Domestic Product Logistics Expenditure Logistics % of GDP North America 8, 495 915 10. 8 Europe 7, 981 941 11. 8 Pacific 5, 605 652 11. 6 Other 7, 080 916 12. 9 Total 29, 161 3, 424 11. 7 Source: D. Bowersox and R. Calantone, “Executive Insights: Global Statistics, ” Journal of International Marketing, Vol. 8, no. 4, 1998, pp 83 -93. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 12

Performance Impact I Comparative GDP and Logistics Expenditures (billions of Gross $, 1998) Region Domestic Product Logistics Expenditure Logistics % of GDP North America 8, 495 915 10. 8 Europe 7, 981 941 11. 8 Pacific 5, 605 652 11. 6 Other 7, 080 916 12. 9 Total 29, 161 3, 424 11. 7 Source: D. Bowersox and R. Calantone, “Executive Insights: Global Statistics, ” Journal of International Marketing, Vol. 8, no. 4, 1998, pp 83 -93. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 12

Performance Impact II Customer “touch points” þDelivery reliability þDelivery speed þDelivery tracking þQuality “Ford is hiring UPS” © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 13

Performance Impact II Customer “touch points” þDelivery reliability þDelivery speed þDelivery tracking þQuality “Ford is hiring UPS” © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 13

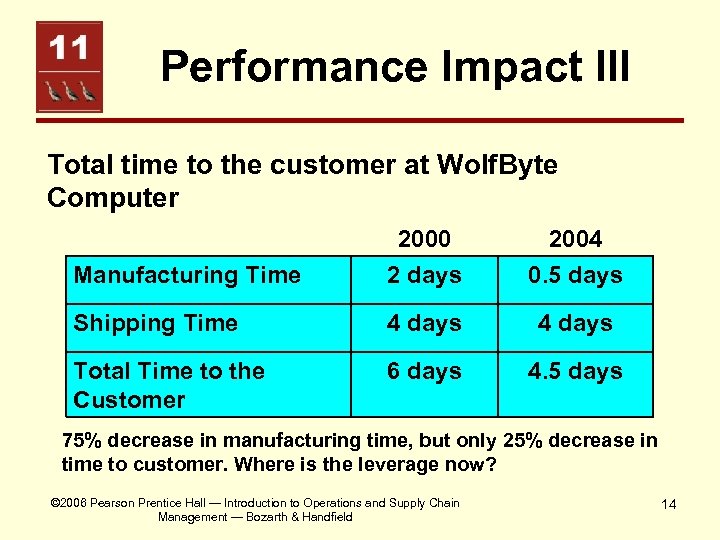

Performance Impact III Total time to the customer at Wolf. Byte Computer Manufacturing Time 2000 2 days 2004 0. 5 days Shipping Time 4 days Total Time to the Customer 6 days 4. 5 days 75% decrease in manufacturing time, but only 25% decrease in time to customer. Where is the leverage now? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 14

Performance Impact III Total time to the customer at Wolf. Byte Computer Manufacturing Time 2000 2 days 2004 0. 5 days Shipping Time 4 days Total Time to the Customer 6 days 4. 5 days 75% decrease in manufacturing time, but only 25% decrease in time to customer. Where is the leverage now? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 14

The Evolution of Logistics Strategy From functional silos to strategic positioning © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 15

The Evolution of Logistics Strategy From functional silos to strategic positioning © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 15

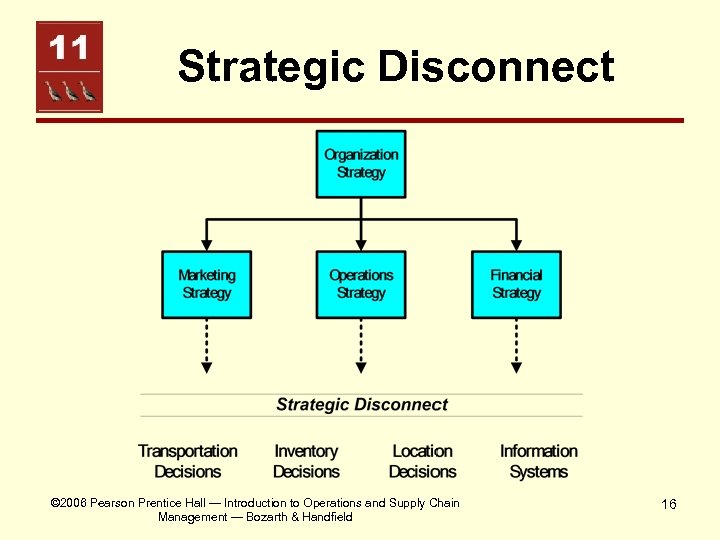

Strategic Disconnect © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 16

Strategic Disconnect © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 16

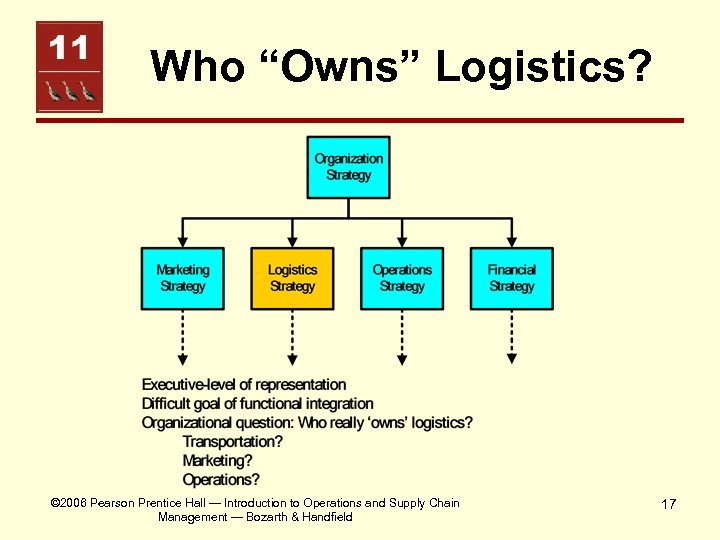

Who “Owns” Logistics? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 17

Who “Owns” Logistics? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 17

Logistics Decision Areas Transportation… – Modes – Formats – Pricing Warehousing – Consolidation – Cross Docking and Break-Bulk – Hub and Spoke – Inventory © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 18

Logistics Decision Areas Transportation… – Modes – Formats – Pricing Warehousing – Consolidation – Cross Docking and Break-Bulk – Hub and Spoke – Inventory © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 18

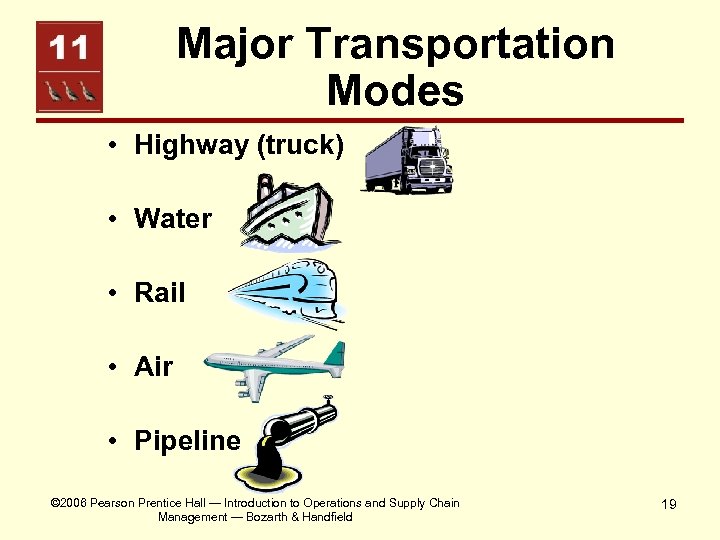

Major Transportation Modes • Highway (truck) • Water • Rail • Air • Pipeline © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 19

Major Transportation Modes • Highway (truck) • Water • Rail • Air • Pipeline © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 19

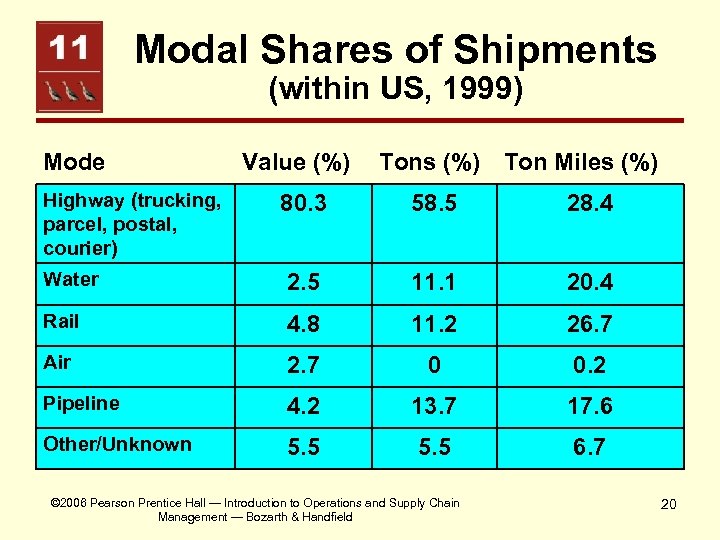

Modal Shares of Shipments (within US, 1999) Mode Highway (trucking, parcel, postal, courier) Value (%) Tons (%) Ton Miles (%) 80. 3 58. 5 28. 4 Water 2. 5 11. 1 20. 4 Rail 4. 8 11. 2 26. 7 Air 2. 7 0 0. 2 Pipeline 4. 2 13. 7 17. 6 Other/Unknown 5. 5 6. 7 © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 20

Modal Shares of Shipments (within US, 1999) Mode Highway (trucking, parcel, postal, courier) Value (%) Tons (%) Ton Miles (%) 80. 3 58. 5 28. 4 Water 2. 5 11. 1 20. 4 Rail 4. 8 11. 2 26. 7 Air 2. 7 0 0. 2 Pipeline 4. 2 13. 7 17. 6 Other/Unknown 5. 5 6. 7 © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 20

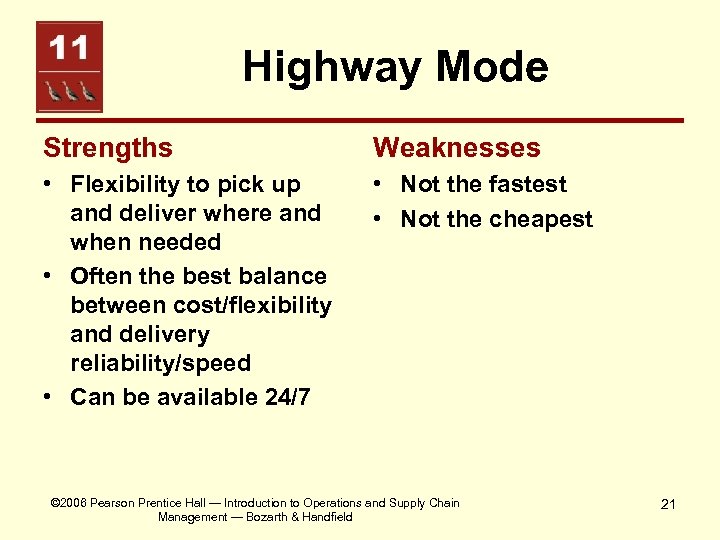

Highway Mode Strengths Weaknesses • Flexibility to pick up and deliver where and when needed • Often the best balance between cost/flexibility and delivery reliability/speed • Can be available 24/7 • Not the fastest • Not the cheapest © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 21

Highway Mode Strengths Weaknesses • Flexibility to pick up and deliver where and when needed • Often the best balance between cost/flexibility and delivery reliability/speed • Can be available 24/7 • Not the fastest • Not the cheapest © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 21

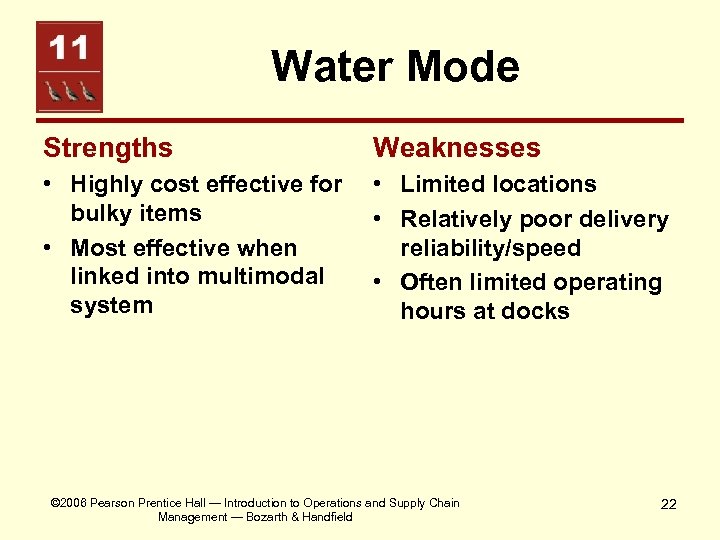

Water Mode Strengths Weaknesses • Highly cost effective for bulky items • Most effective when linked into multimodal system • Limited locations • Relatively poor delivery reliability/speed • Often limited operating hours at docks © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 22

Water Mode Strengths Weaknesses • Highly cost effective for bulky items • Most effective when linked into multimodal system • Limited locations • Relatively poor delivery reliability/speed • Often limited operating hours at docks © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 22

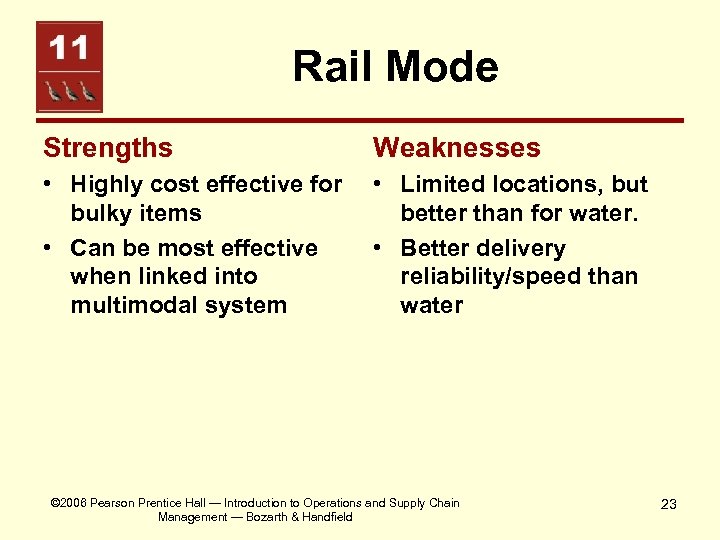

Rail Mode Strengths Weaknesses • Highly cost effective for bulky items • Can be most effective when linked into multimodal system • Limited locations, but better than for water. • Better delivery reliability/speed than water © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 23

Rail Mode Strengths Weaknesses • Highly cost effective for bulky items • Can be most effective when linked into multimodal system • Limited locations, but better than for water. • Better delivery reliability/speed than water © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 23

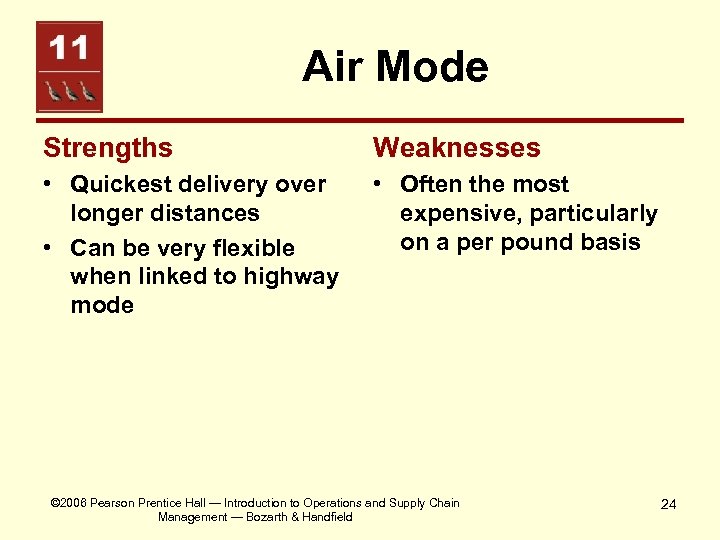

Air Mode Strengths Weaknesses • Quickest delivery over longer distances • Can be very flexible when linked to highway mode • Often the most expensive, particularly on a per pound basis © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 24

Air Mode Strengths Weaknesses • Quickest delivery over longer distances • Can be very flexible when linked to highway mode • Often the most expensive, particularly on a per pound basis © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 24

Question How can businesses design solutions that exploit the strengths of each mode? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 25

Question How can businesses design solutions that exploit the strengths of each mode? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 25

Multi-Modal Solutions North Carolina’s Global Trans. Park © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 26

Multi-Modal Solutions North Carolina’s Global Trans. Park © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 26

Justification · Shift from domestic to global economies · Emergence of just-in-time, flexible and agile manufacturing practices requiring sophisticated logistics solutions · The rapid growth of distribution via air freighters (roughly four times the growth rate of passenger service by the airlines) · The need to use air cargo, shipment by sea, and delivery by trucks and trains in an overall distribution system · The need for a commercial distribution hub in the © 2006 Pearson Prentice Hall — Introduction to Operations and Supply reach more than 60 Eastern United States that can Chain Management — Bozarth & Handfield percent of the nation’s population overnight and 27

Justification · Shift from domestic to global economies · Emergence of just-in-time, flexible and agile manufacturing practices requiring sophisticated logistics solutions · The rapid growth of distribution via air freighters (roughly four times the growth rate of passenger service by the airlines) · The need to use air cargo, shipment by sea, and delivery by trucks and trains in an overall distribution system · The need for a commercial distribution hub in the © 2006 Pearson Prentice Hall — Introduction to Operations and Supply reach more than 60 Eastern United States that can Chain Management — Bozarth & Handfield percent of the nation’s population overnight and 27

Global Trans. Park • 15, 700 acres at full development with two parallel runways of 11, 500 feet and 13, 000 feet • Integrated air, rail, road, and nearby sea transportation capabilities • Free trade zone status © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 28

Global Trans. Park • 15, 700 acres at full development with two parallel runways of 11, 500 feet and 13, 000 feet • Integrated air, rail, road, and nearby sea transportation capabilities • Free trade zone status © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 28

Kinston, NC © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 29

Kinston, NC © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 29

Transportation “Formats” • Common carriers – Published rates and schedules – “Nondiscriminatory” pricing – Increased flexibility to partner • Contract carriers – Service for select customers – Unlimited number of customers • Private carriers © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 30

Transportation “Formats” • Common carriers – Published rates and schedules – “Nondiscriminatory” pricing – Increased flexibility to partner • Contract carriers – Service for select customers – Unlimited number of customers • Private carriers © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 30

Questions What are the strengths and weaknesses of each? How does the choice of format tie into the business strategy? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 31

Questions What are the strengths and weaknesses of each? How does the choice of format tie into the business strategy? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 31

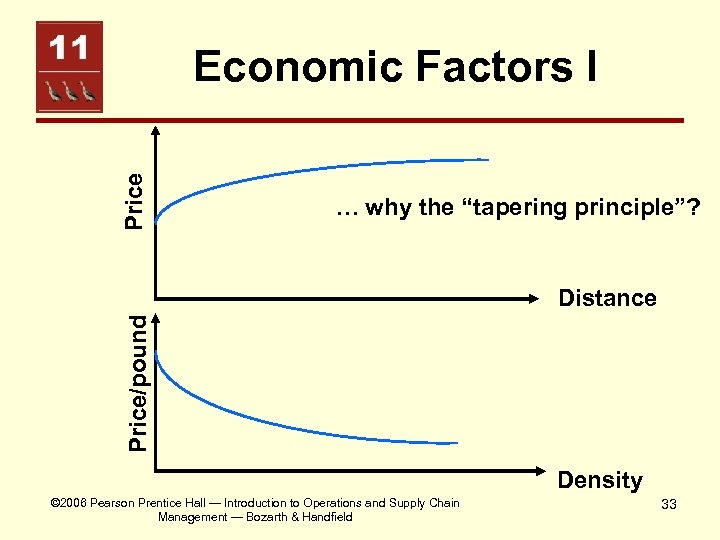

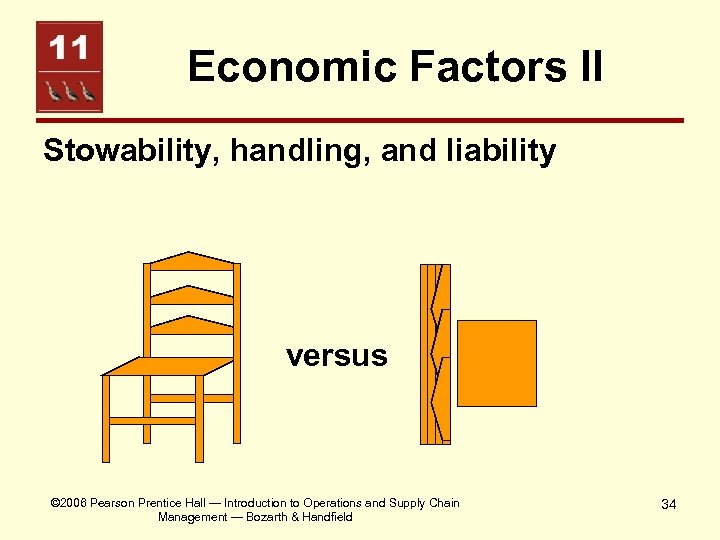

Pricing Transportation Services • Economic factors –Pricing versus distance –Price/pound versus density –Stowability, handling, and liability –Market factors • Ratings –Goods classification –Class index © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 32

Pricing Transportation Services • Economic factors –Pricing versus distance –Price/pound versus density –Stowability, handling, and liability –Market factors • Ratings –Goods classification –Class index © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 32

Price Economic Factors I … why the “tapering principle”? Price/pound Distance Density © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 33

Price Economic Factors I … why the “tapering principle”? Price/pound Distance Density © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 33

Economic Factors II Stowability, handling, and liability versus © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 34

Economic Factors II Stowability, handling, and liability versus © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 34

Economic Factors III Market factors What might this include? West Coast, USA © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield East Coast, USA 35

Economic Factors III Market factors What might this include? West Coast, USA © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield East Coast, USA 35

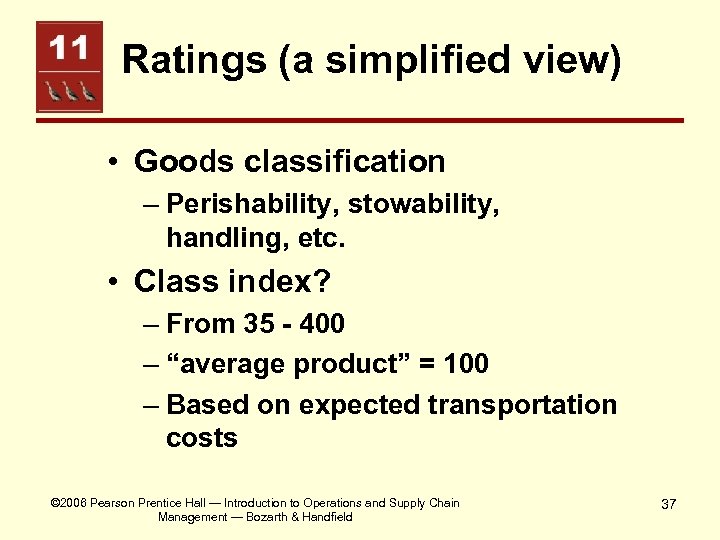

Ratings Translating economic factors into actual prices © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 36

Ratings Translating economic factors into actual prices © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 36

Ratings (a simplified view) • Goods classification – Perishability, stowability, handling, etc. • Class index? – From 35 - 400 – “average product” = 100 – Based on expected transportation costs © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 37

Ratings (a simplified view) • Goods classification – Perishability, stowability, handling, etc. • Class index? – From 35 - 400 – “average product” = 100 – Based on expected transportation costs © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 37

Determining Transportation Rates • Rate Determination – By weight (Less-than-truckload shipment) – By distance (truckload shipments) Minimum charges and surcharges • Exceptions to the rule – Seasonal commodities – FAK (freight of all kinds) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 38

Determining Transportation Rates • Rate Determination – By weight (Less-than-truckload shipment) – By distance (truckload shipments) Minimum charges and surcharges • Exceptions to the rule – Seasonal commodities – FAK (freight of all kinds) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 38

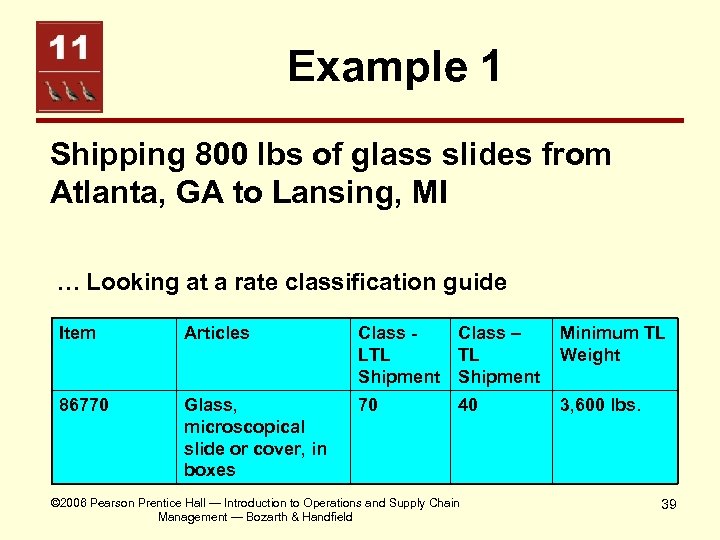

Example 1 Shipping 800 lbs of glass slides from Atlanta, GA to Lansing, MI … Looking at a rate classification guide Item Articles Class – LTL TL Shipment Minimum TL Weight 86770 Glass, microscopical slide or cover, in boxes 70 3, 600 lbs. 40 © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 39

Example 1 Shipping 800 lbs of glass slides from Atlanta, GA to Lansing, MI … Looking at a rate classification guide Item Articles Class – LTL TL Shipment Minimum TL Weight 86770 Glass, microscopical slide or cover, in boxes 70 3, 600 lbs. 40 © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 39

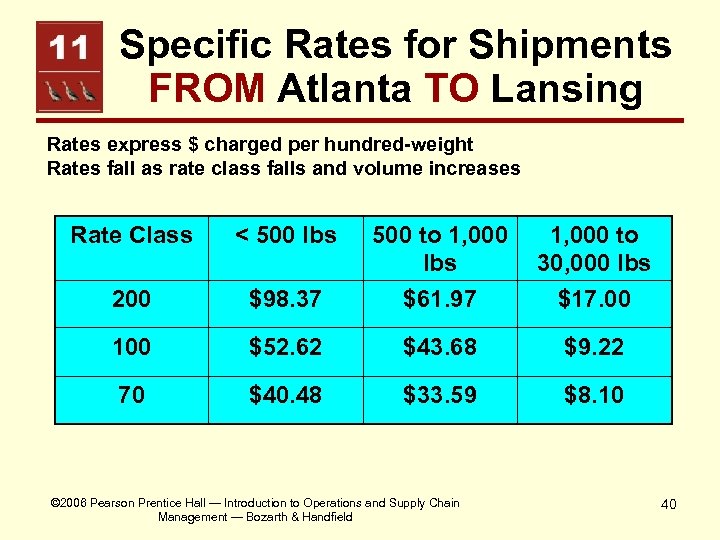

Specific Rates for Shipments FROM Atlanta TO Lansing Rates express $ charged per hundred-weight Rates fall as rate class falls and volume increases Rate Class < 500 lbs 500 to 1, 000 lbs 1, 000 to 30, 000 lbs 200 $98. 37 $61. 97 $17. 00 100 $52. 62 $43. 68 $9. 22 70 $40. 48 $33. 59 $8. 10 © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 40

Specific Rates for Shipments FROM Atlanta TO Lansing Rates express $ charged per hundred-weight Rates fall as rate class falls and volume increases Rate Class < 500 lbs 500 to 1, 000 lbs 1, 000 to 30, 000 lbs 200 $98. 37 $61. 97 $17. 00 100 $52. 62 $43. 68 $9. 22 70 $40. 48 $33. 59 $8. 10 © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 40

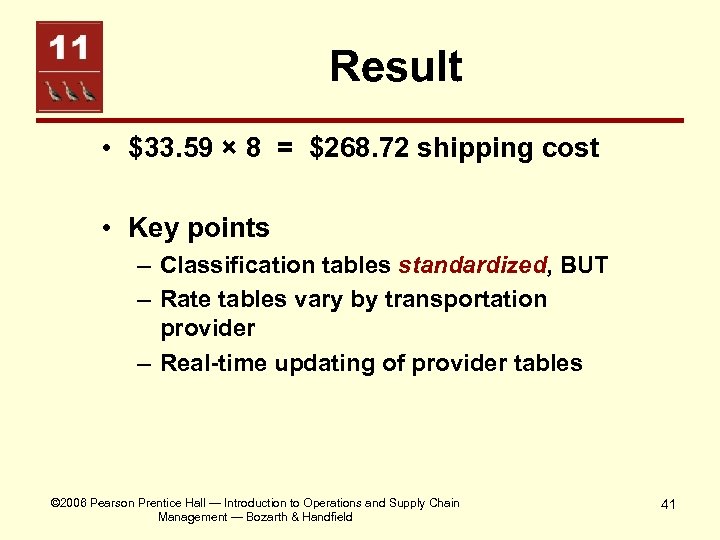

Result • $33. 59 × 8 = $268. 72 shipping cost • Key points – Classification tables standardized, BUT – Rate tables vary by transportation provider – Real-time updating of provider tables © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 41

Result • $33. 59 × 8 = $268. 72 shipping cost • Key points – Classification tables standardized, BUT – Rate tables vary by transportation provider – Real-time updating of provider tables © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 41

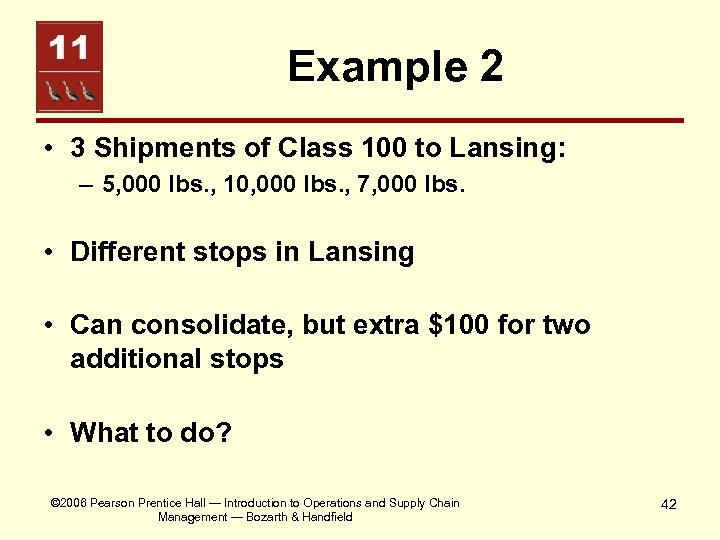

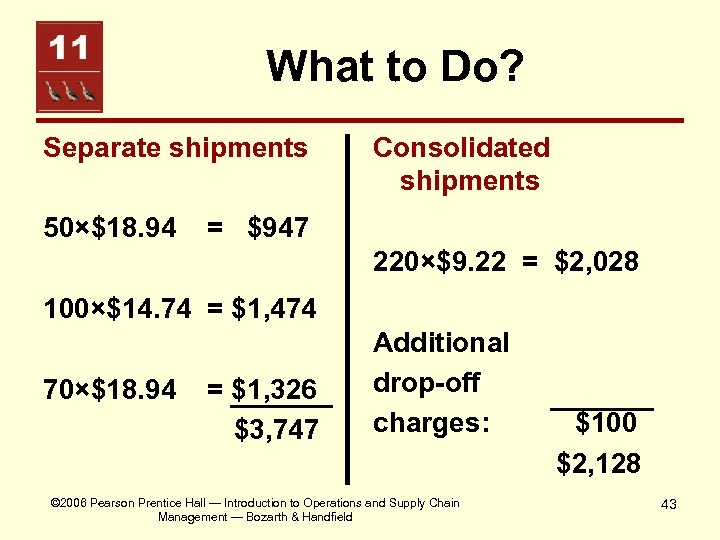

Example 2 • 3 Shipments of Class 100 to Lansing: – 5, 000 lbs. , 10, 000 lbs. , 7, 000 lbs. • Different stops in Lansing • Can consolidate, but extra $100 for two additional stops • What to do? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 42

Example 2 • 3 Shipments of Class 100 to Lansing: – 5, 000 lbs. , 10, 000 lbs. , 7, 000 lbs. • Different stops in Lansing • Can consolidate, but extra $100 for two additional stops • What to do? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 42

What to Do? Separate shipments 50×$18. 94 Consolidated shipments = $947 220×$9. 22 = $2, 028 100×$14. 74 = $1, 474 70×$18. 94 = $1, 326 $3, 747 Additional drop-off charges: © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield $100 $2, 128 43

What to Do? Separate shipments 50×$18. 94 Consolidated shipments = $947 220×$9. 22 = $2, 028 100×$14. 74 = $1, 474 70×$18. 94 = $1, 326 $3, 747 Additional drop-off charges: © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield $100 $2, 128 43

Key Points • Choosing a mode – Five choices – Speed? Cost? Flexibility? • Choosing a format – Flexibility versus control • Controllable factors affecting cost – Density, stowability, packaging, and containerization © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 44

Key Points • Choosing a mode – Five choices – Speed? Cost? Flexibility? • Choosing a format – Flexibility versus control • Controllable factors affecting cost – Density, stowability, packaging, and containerization © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 44

Warehousing Any operation that stores, repackages, stages, sorts, or centralizes goods or materials © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 45

Warehousing Any operation that stores, repackages, stages, sorts, or centralizes goods or materials © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 45

New View Warehousing a key piece of logistics strategy – Proctor & Gamble – Kraft – Lowe’s • More than just storage – “Warehousing” “Distribution Centers” © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 46

New View Warehousing a key piece of logistics strategy – Proctor & Gamble – Kraft – Lowe’s • More than just storage – “Warehousing” “Distribution Centers” © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 46

Warehousing Benefits Economic benefits: þAccrue directly to company þMust consider total system costs Service benefits: þSupport customer service needs þMay or may not reduce costs © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 47

Warehousing Benefits Economic benefits: þAccrue directly to company þMust consider total system costs Service benefits: þSupport customer service needs þMay or may not reduce costs © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 47

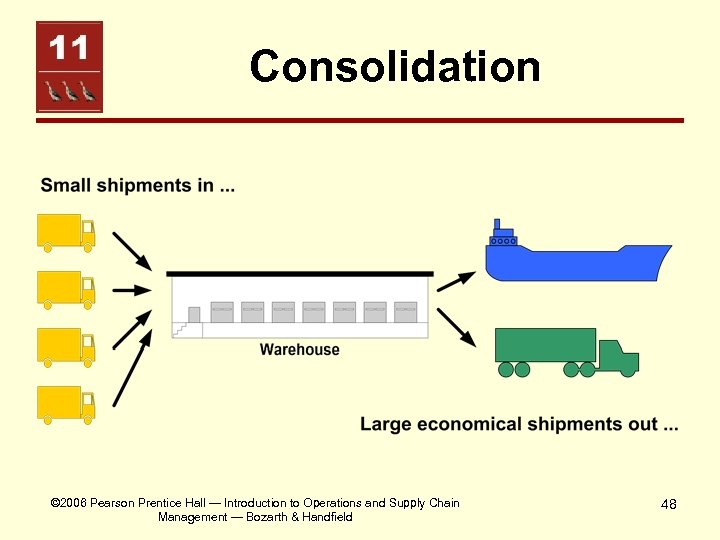

Consolidation © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 48

Consolidation © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 48

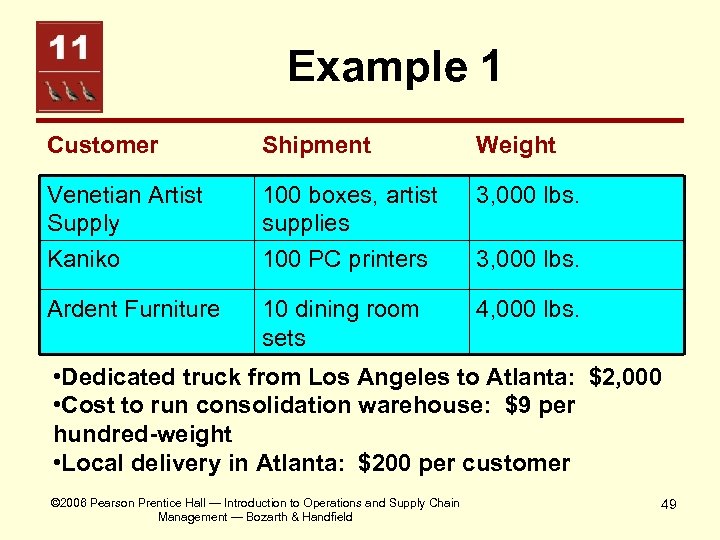

Example 1 Customer Shipment Weight Venetian Artist Supply Kaniko 100 boxes, artist supplies 100 PC printers 3, 000 lbs. Ardent Furniture 10 dining room sets 4, 000 lbs. 3, 000 lbs. • Dedicated truck from Los Angeles to Atlanta: $2, 000 • Cost to run consolidation warehouse: $9 per hundred-weight • Local delivery in Atlanta: $200 per customer © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 49

Example 1 Customer Shipment Weight Venetian Artist Supply Kaniko 100 boxes, artist supplies 100 PC printers 3, 000 lbs. Ardent Furniture 10 dining room sets 4, 000 lbs. 3, 000 lbs. • Dedicated truck from Los Angeles to Atlanta: $2, 000 • Cost to run consolidation warehouse: $9 per hundred-weight • Local delivery in Atlanta: $200 per customer © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 49

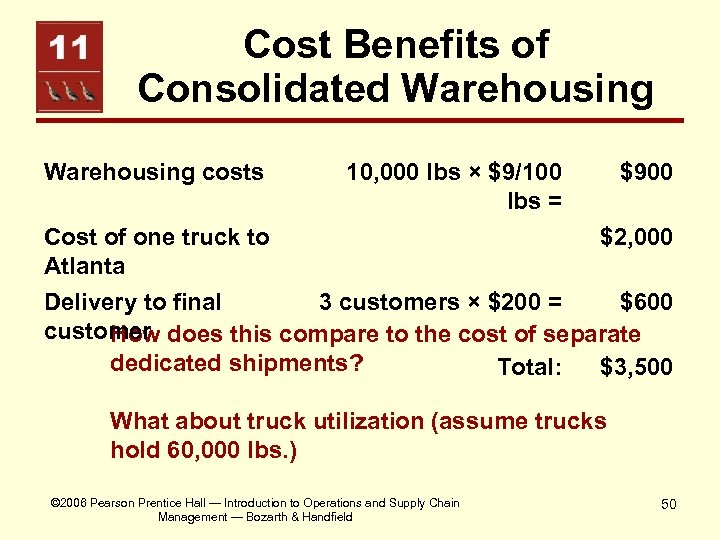

Cost Benefits of Consolidated Warehousing costs 10, 000 lbs × $9/100 lbs = Cost of one truck to Atlanta $900 $2, 000 Delivery to final 3 customers × $200 = $600 customer does this compare to the cost of separate How dedicated shipments? Total: $3, 500 What about truck utilization (assume trucks hold 60, 000 lbs. ) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 50

Cost Benefits of Consolidated Warehousing costs 10, 000 lbs × $9/100 lbs = Cost of one truck to Atlanta $900 $2, 000 Delivery to final 3 customers × $200 = $600 customer does this compare to the cost of separate How dedicated shipments? Total: $3, 500 What about truck utilization (assume trucks hold 60, 000 lbs. ) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 50

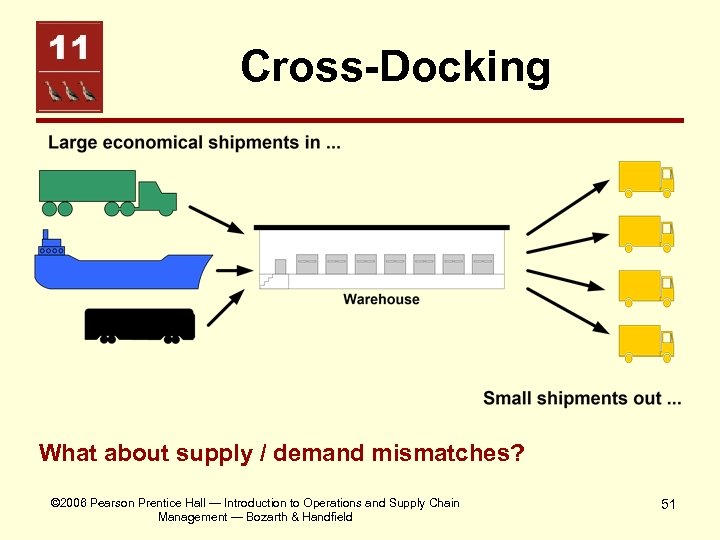

Cross-Docking What about supply / demand mismatches? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 51

Cross-Docking What about supply / demand mismatches? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 51

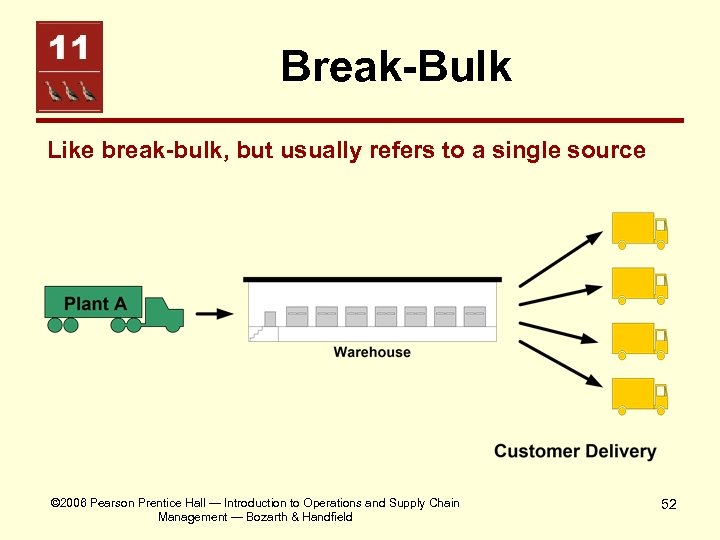

Break-Bulk Like break-bulk, but usually refers to a single source © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 52

Break-Bulk Like break-bulk, but usually refers to a single source © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 52

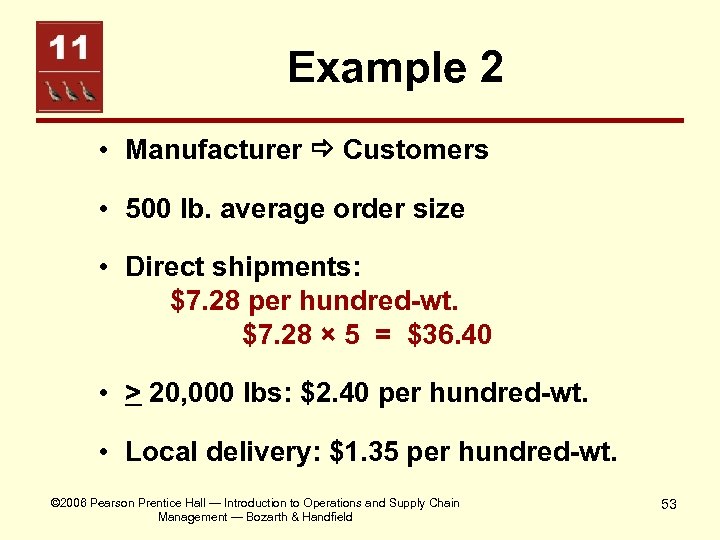

Example 2 • Manufacturer Customers • 500 lb. average order size • Direct shipments: $7. 28 per hundred-wt. $7. 28 × 5 = $36. 40 • > 20, 000 lbs: $2. 40 per hundred-wt. • Local delivery: $1. 35 per hundred-wt. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 53

Example 2 • Manufacturer Customers • 500 lb. average order size • Direct shipments: $7. 28 per hundred-wt. $7. 28 × 5 = $36. 40 • > 20, 000 lbs: $2. 40 per hundred-wt. • Local delivery: $1. 35 per hundred-wt. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 53

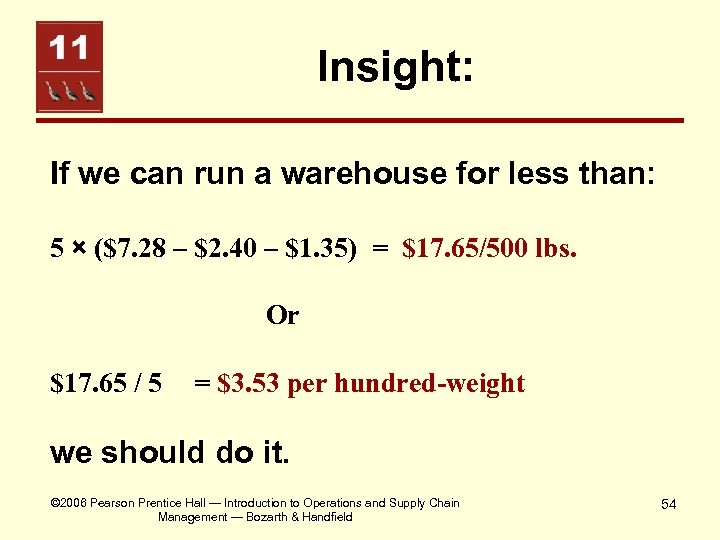

Insight: If we can run a warehouse for less than: 5 × ($7. 28 – $2. 40 – $1. 35) = $17. 65/500 lbs. Or $17. 65 / 5 = $3. 53 per hundred-weight we should do it. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 54

Insight: If we can run a warehouse for less than: 5 × ($7. 28 – $2. 40 – $1. 35) = $17. 65/500 lbs. Or $17. 65 / 5 = $3. 53 per hundred-weight we should do it. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 54

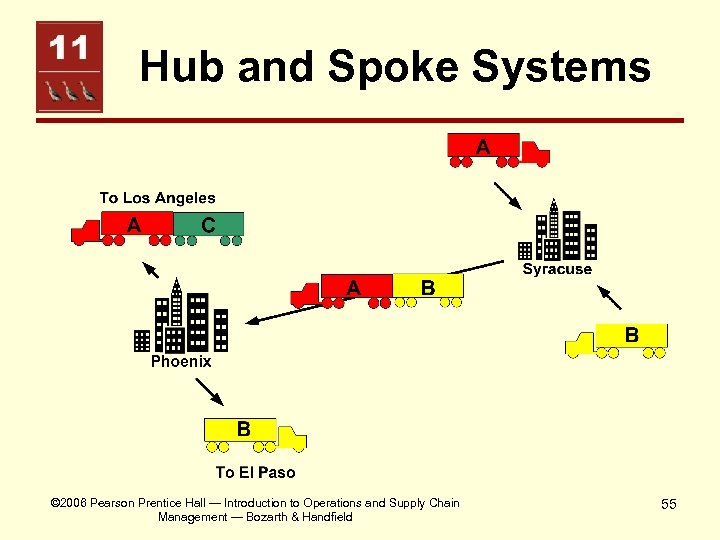

Hub and Spoke Systems © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 55

Hub and Spoke Systems © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 55

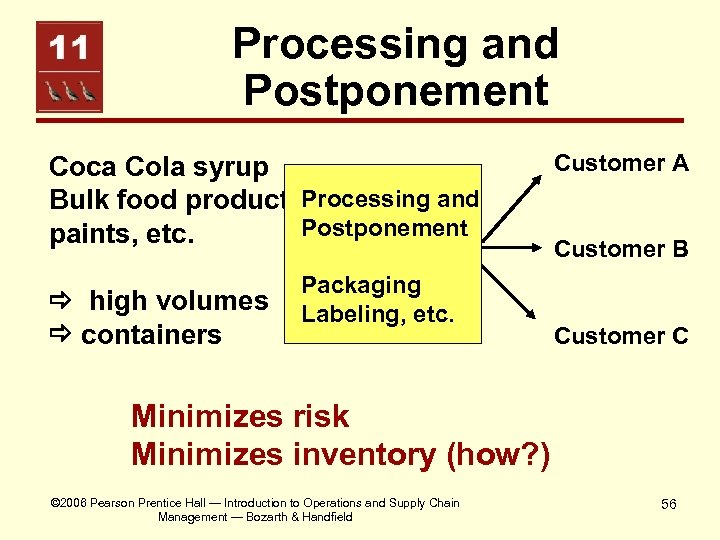

Processing and Postponement Coca Cola syrup Processing and Bulk food products, Postponement paints, etc. high volumes containers Packaging Labeling, etc. Customer A Customer B Customer C Minimizes risk Minimizes inventory (how? ) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 56

Processing and Postponement Coca Cola syrup Processing and Bulk food products, Postponement paints, etc. high volumes containers Packaging Labeling, etc. Customer A Customer B Customer C Minimizes risk Minimizes inventory (how? ) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 56

Service Benefits: üSpot stock üAssortment © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 57

Service Benefits: üSpot stock üAssortment © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 57

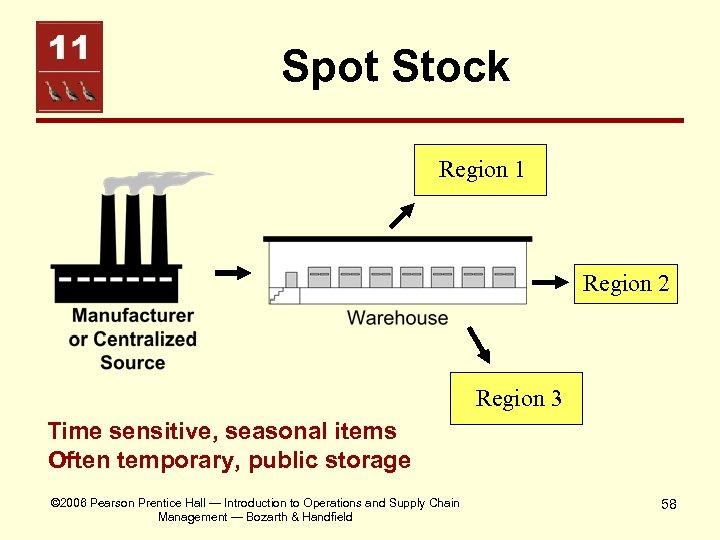

Spot Stock Region 1 Region 2 Region 3 Time sensitive, seasonal items Often temporary, public storage © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 58

Spot Stock Region 1 Region 2 Region 3 Time sensitive, seasonal items Often temporary, public storage © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 58

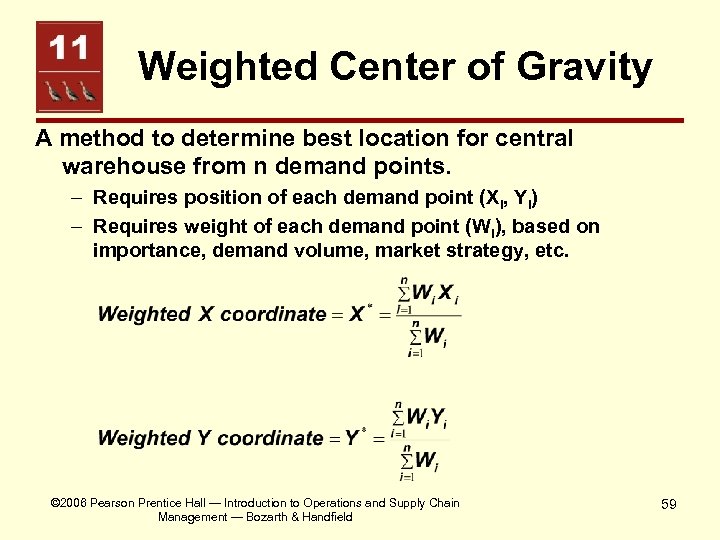

Weighted Center of Gravity A method to determine best location for central warehouse from n demand points. – Requires position of each demand point (Xi, Yi) – Requires weight of each demand point (Wi), based on importance, demand volume, market strategy, etc. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 59

Weighted Center of Gravity A method to determine best location for central warehouse from n demand points. – Requires position of each demand point (Xi, Yi) – Requires weight of each demand point (Wi), based on importance, demand volume, market strategy, etc. © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 59

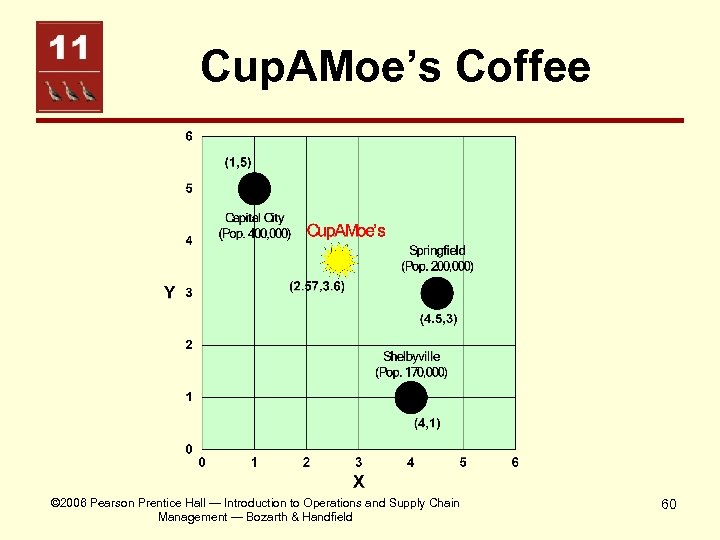

Cup. AMoe’s Coffee © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 60

Cup. AMoe’s Coffee © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 60

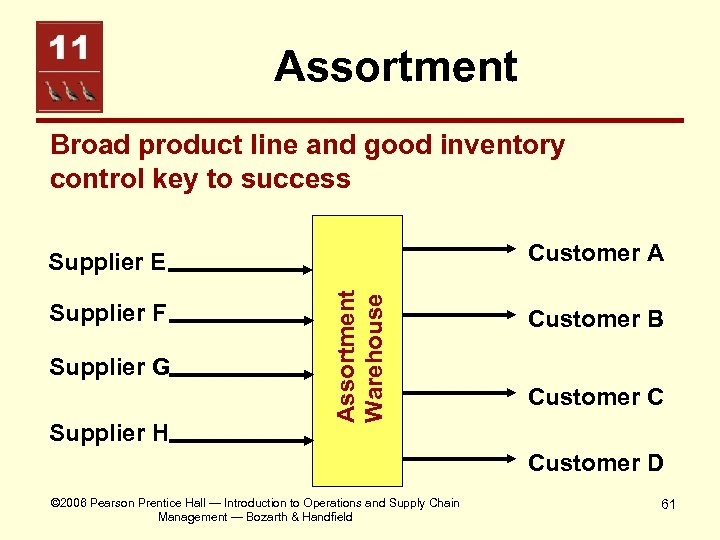

Assortment Broad product line and good inventory control key to success Customer A Supplier F Supplier G Supplier H Assortment Warehouse Supplier E Customer B Customer C Customer D © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 61

Assortment Broad product line and good inventory control key to success Customer A Supplier F Supplier G Supplier H Assortment Warehouse Supplier E Customer B Customer C Customer D © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 61

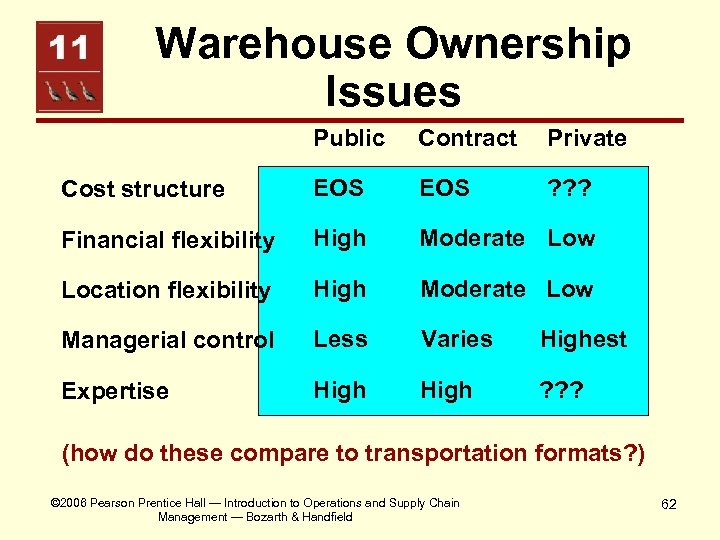

Warehouse Ownership Issues Public Contract Private Cost structure EOS ? ? ? Financial flexibility High Moderate Low Location flexibility High Moderate Low Managerial control Less Varies Highest Expertise High ? ? ? (how do these compare to transportation formats? ) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 62

Warehouse Ownership Issues Public Contract Private Cost structure EOS ? ? ? Financial flexibility High Moderate Low Location flexibility High Moderate Low Managerial control Less Varies Highest Expertise High ? ? ? (how do these compare to transportation formats? ) © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 62

Question: When would it make sense to combine private and public ownership? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 63

Question: When would it make sense to combine private and public ownership? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 63

Packaging and Unitization What are the typical marketing criteria? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 64

Packaging and Unitization What are the typical marketing criteria? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 10, Slide 64

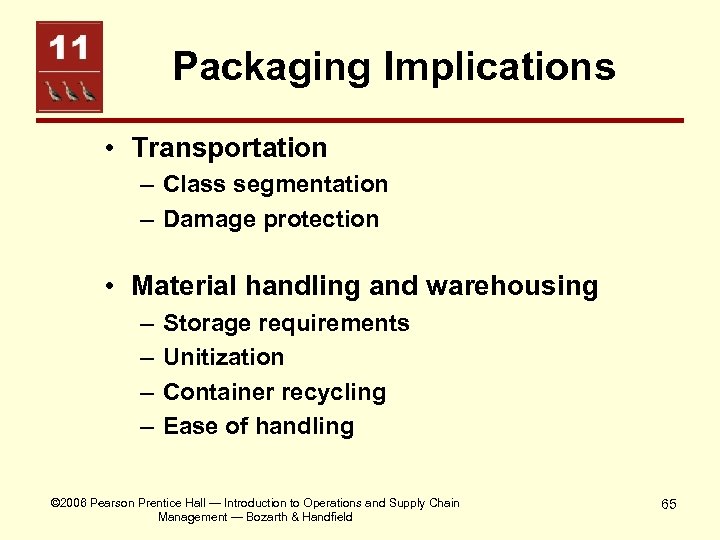

Packaging Implications • Transportation – Class segmentation – Damage protection • Material handling and warehousing – – Storage requirements Unitization Container recycling Ease of handling © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 65

Packaging Implications • Transportation – Class segmentation – Damage protection • Material handling and warehousing – – Storage requirements Unitization Container recycling Ease of handling © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 65

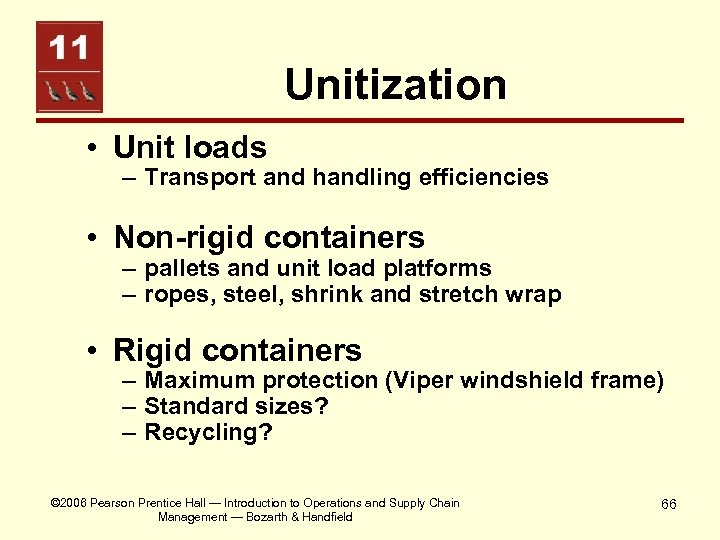

Unitization • Unit loads – Transport and handling efficiencies • Non-rigid containers – pallets and unit load platforms – ropes, steel, shrink and stretch wrap • Rigid containers – Maximum protection (Viper windshield frame) – Standard sizes? – Recycling? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 66

Unitization • Unit loads – Transport and handling efficiencies • Non-rigid containers – pallets and unit load platforms – ropes, steel, shrink and stretch wrap • Rigid containers – Maximum protection (Viper windshield frame) – Standard sizes? – Recycling? © 2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield 66