27fa56f61d6edac92db704e5b3b5539b.ppt

- Количество слайдов: 17

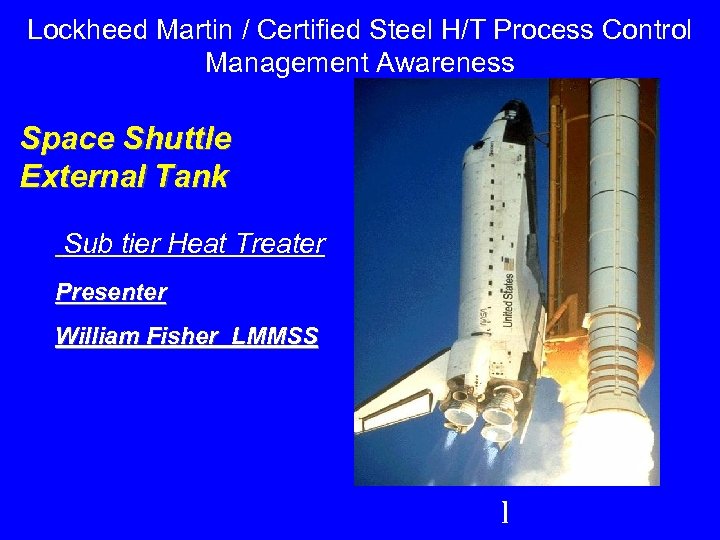

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Space Shuttle External Tank Sub tier Heat Treater Presenter William Fisher LMMSS l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Space Shuttle External Tank Sub tier Heat Treater Presenter William Fisher LMMSS l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness External Tank Components Liquid Oxygen Tank Intertank Liquid Hydrogen Tank LO 2 Tank (Welded Pressure Vessel) • 1, 385, 000 lbs. Oxidizer • Temperature = -297 Degrees Fahrenheit • Delivery Rate = 17, 656 Gallons / Minute Intertank (Riveted Structure) • Splice ET LO 2 and LH 2 Tanks LH 2 Tank (Welded Pressure Vessel) • • • 231, 000 lbs. Fuel Temperature = -423 Degrees Fahrenheit Delivery Rate = 47, 125 Gallons / Minute Carries all Shuttle Loads at Liftoff

Lockheed Martin / Certified Steel H/T Process Control Management Awareness External Tank Components Liquid Oxygen Tank Intertank Liquid Hydrogen Tank LO 2 Tank (Welded Pressure Vessel) • 1, 385, 000 lbs. Oxidizer • Temperature = -297 Degrees Fahrenheit • Delivery Rate = 17, 656 Gallons / Minute Intertank (Riveted Structure) • Splice ET LO 2 and LH 2 Tanks LH 2 Tank (Welded Pressure Vessel) • • • 231, 000 lbs. Fuel Temperature = -423 Degrees Fahrenheit Delivery Rate = 47, 125 Gallons / Minute Carries all Shuttle Loads at Liftoff

Lockheed Martin / Certified Steel H/T Process Control Management Awareness External Tank Components

Lockheed Martin / Certified Steel H/T Process Control Management Awareness External Tank Components

Lockheed Martin / Certified Steel H/T Process Control Management Awareness External Tank Information • Structural backbone of the vehicle - Absorbs 6. 6 million pounds of thrust loads at launch • 154 feet long; 27. 5 feet diameter • Weight (Loaded) = 1, 676, 000 Pounds • Propellant feed rate = 1, 035 gallons per second - It takes 8 1/2 minutes to empty. • Thickness is approximately. 080 in some areas • Moves really fast !! = 10 x M-16 speeding bullet! From Meggitt Thermal Systems (Avica) Prime Supplier Hardware: PD 4800180 G 02 PD 4800205 GH 2 Pressurization lines l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness External Tank Information • Structural backbone of the vehicle - Absorbs 6. 6 million pounds of thrust loads at launch • 154 feet long; 27. 5 feet diameter • Weight (Loaded) = 1, 676, 000 Pounds • Propellant feed rate = 1, 035 gallons per second - It takes 8 1/2 minutes to empty. • Thickness is approximately. 080 in some areas • Moves really fast !! = 10 x M-16 speeding bullet! From Meggitt Thermal Systems (Avica) Prime Supplier Hardware: PD 4800180 G 02 PD 4800205 GH 2 Pressurization lines l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Process Control • Essential element of managing risk to guarantee the continued safety and reliability of the Space Shuttle Program • Process Control measures can aid in the prevention of process escapes (Process Creep) which may result in, or contribute to, in-flight anomalies, mishaps, incidents and nonconformance's l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Process Control • Essential element of managing risk to guarantee the continued safety and reliability of the Space Shuttle Program • Process Control measures can aid in the prevention of process escapes (Process Creep) which may result in, or contribute to, in-flight anomalies, mishaps, incidents and nonconformance's l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Process Control Best Practices • 1) Early Detection of Variability – Examples – Statistical Process Control, Material Fingerprinting • 2) Audits (Practice = Instructions) – Examples – Quality System Audits, Product / Process Integrity Audit, NASA Engineering and Quality Audit • 3) Maintenance to Mitigate Process Risks – Examples – Failure Modes and Effects Analysis (FEMA) • 4) Lessons Learned / Critical Characteristic Process Control – Examples – Product Fact sheets l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Process Control Best Practices • 1) Early Detection of Variability – Examples – Statistical Process Control, Material Fingerprinting • 2) Audits (Practice = Instructions) – Examples – Quality System Audits, Product / Process Integrity Audit, NASA Engineering and Quality Audit • 3) Maintenance to Mitigate Process Risks – Examples – Failure Modes and Effects Analysis (FEMA) • 4) Lessons Learned / Critical Characteristic Process Control – Examples – Product Fact sheets l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Process Control Best Practices (cont’d) • 5) Personal Accountability – Examples – Stamp Warranty • 6) Motivational Programs – Examples – Space Flight Awareness Program (SFA), Video, Brochures and posters, Motivational Visits • 7) Change Control – Examples – E 43 clause • 8) Maintaining Process Knowledge / Skill – Examples – Training and certification l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Process Control Best Practices (cont’d) • 5) Personal Accountability – Examples – Stamp Warranty • 6) Motivational Programs – Examples – Space Flight Awareness Program (SFA), Video, Brochures and posters, Motivational Visits • 7) Change Control – Examples – E 43 clause • 8) Maintaining Process Knowledge / Skill – Examples – Training and certification l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness STAMP WARRANTY • Stamp (or signature) MUST be a professional, individual warranty (guarantee) that the operator/inspector PERSONALLY saw or performed the work LITERALLY as stated in the work instructions. – If work instructions are incorrect, unclear, out of sequence or unverifiable - report them for correction. – If you are not trained/certified/authorized to perform a function don’t. – YOU have the responsibility and authority to implement stamp warranty. l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness STAMP WARRANTY • Stamp (or signature) MUST be a professional, individual warranty (guarantee) that the operator/inspector PERSONALLY saw or performed the work LITERALLY as stated in the work instructions. – If work instructions are incorrect, unclear, out of sequence or unverifiable - report them for correction. – If you are not trained/certified/authorized to perform a function don’t. – YOU have the responsibility and authority to implement stamp warranty. l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Process Control • Video Presentation Choose from one of the following • “Changes” • Process Control – “Know Change” – “Knowledge” – “Gets us There” _“To The Future” l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Process Control • Video Presentation Choose from one of the following • “Changes” • Process Control – “Know Change” – “Knowledge” – “Gets us There” _“To The Future” l

The Process Creep Methods/Instructions People Materials Equipment Environment The Process Creep

The Process Creep Methods/Instructions People Materials Equipment Environment The Process Creep

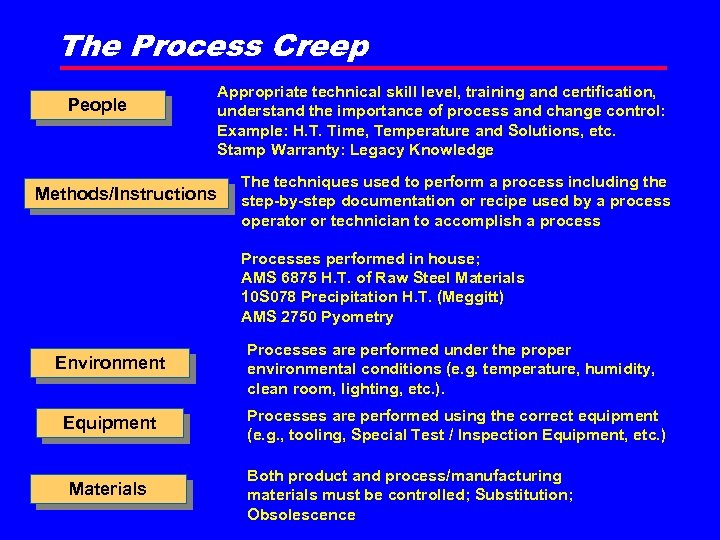

The Process Creep People Methods/Instructions Appropriate technical skill level, training and certification, understand the importance of process and change control: Example: H. T. Time, Temperature and Solutions, etc. Stamp Warranty: Legacy Knowledge The techniques used to perform a process including the step-by-step documentation or recipe used by a process operator or technician to accomplish a process Processes performed in house; AMS 6875 H. T. of Raw Steel Materials 10 S 078 Precipitation H. T. (Meggitt) AMS 2750 Pyometry Environment Equipment Materials Processes are performed under the proper environmental conditions (e. g. temperature, humidity, clean room, lighting, etc. ). Processes are performed using the correct equipment (e. g. , tooling, Special Test / Inspection Equipment, etc. ) Both product and process/manufacturing materials must be controlled; Substitution; Obsolescence

The Process Creep People Methods/Instructions Appropriate technical skill level, training and certification, understand the importance of process and change control: Example: H. T. Time, Temperature and Solutions, etc. Stamp Warranty: Legacy Knowledge The techniques used to perform a process including the step-by-step documentation or recipe used by a process operator or technician to accomplish a process Processes performed in house; AMS 6875 H. T. of Raw Steel Materials 10 S 078 Precipitation H. T. (Meggitt) AMS 2750 Pyometry Environment Equipment Materials Processes are performed under the proper environmental conditions (e. g. temperature, humidity, clean room, lighting, etc. ). Processes are performed using the correct equipment (e. g. , tooling, Special Test / Inspection Equipment, etc. ) Both product and process/manufacturing materials must be controlled; Substitution; Obsolescence

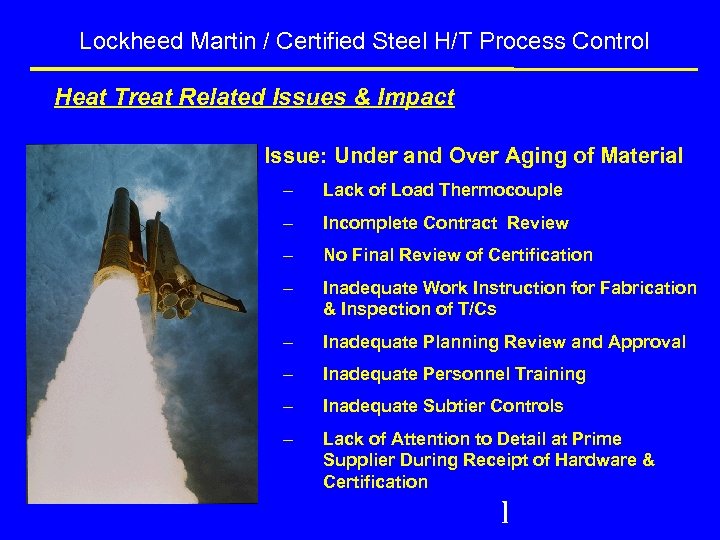

Lockheed Martin / Certified Steel H/T Process Control Heat Treat Related Issues & Impact Issue: Under and Over Aging of Material – Lack of Load Thermocouple – Incomplete Contract Review – No Final Review of Certification – Inadequate Work Instruction for Fabrication & Inspection of T/Cs – Inadequate Planning Review and Approval – Inadequate Personnel Training – Inadequate Subtier Controls – Lack of Attention to Detail at Prime Supplier During Receipt of Hardware & Certification l

Lockheed Martin / Certified Steel H/T Process Control Heat Treat Related Issues & Impact Issue: Under and Over Aging of Material – Lack of Load Thermocouple – Incomplete Contract Review – No Final Review of Certification – Inadequate Work Instruction for Fabrication & Inspection of T/Cs – Inadequate Planning Review and Approval – Inadequate Personnel Training – Inadequate Subtier Controls – Lack of Attention to Detail at Prime Supplier During Receipt of Hardware & Certification l

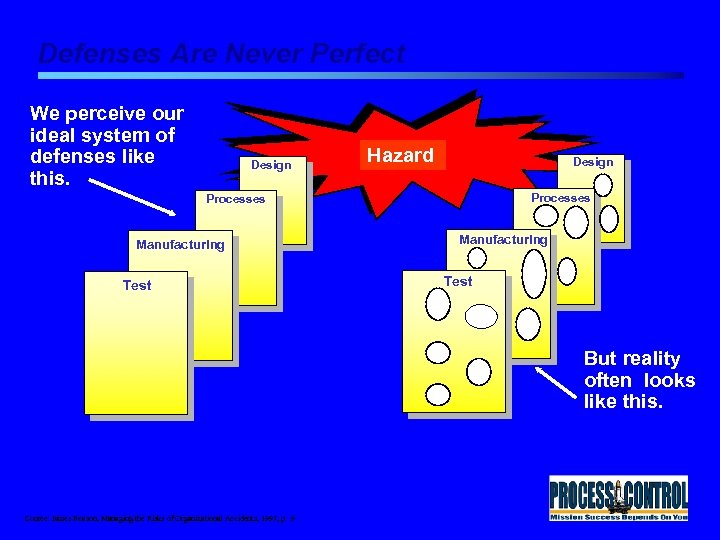

Defenses Are Never Perfect We perceive our ideal system of defenses like this. Design Hazard Design Processes Manufacturing Test But reality often looks like this. Source: James Reason, Managing the Risks of Organizational Accidents, 1997, p. 9

Defenses Are Never Perfect We perceive our ideal system of defenses like this. Design Hazard Design Processes Manufacturing Test But reality often looks like this. Source: James Reason, Managing the Risks of Organizational Accidents, 1997, p. 9

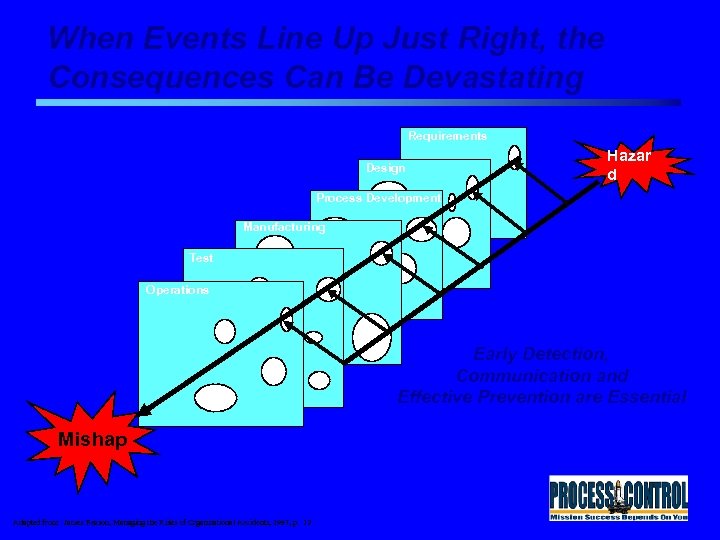

When Events Line Up Just Right, the Consequences Can Be Devastating Requirements Design Hazar d Process Development Manufacturing Test Operations Early Detection, Communication and Effective Prevention are Essential Mishap Adapted from : James Reason, Managing the Risks of Organizational Accidents, 1997, p. 12

When Events Line Up Just Right, the Consequences Can Be Devastating Requirements Design Hazar d Process Development Manufacturing Test Operations Early Detection, Communication and Effective Prevention are Essential Mishap Adapted from : James Reason, Managing the Risks of Organizational Accidents, 1997, p. 12

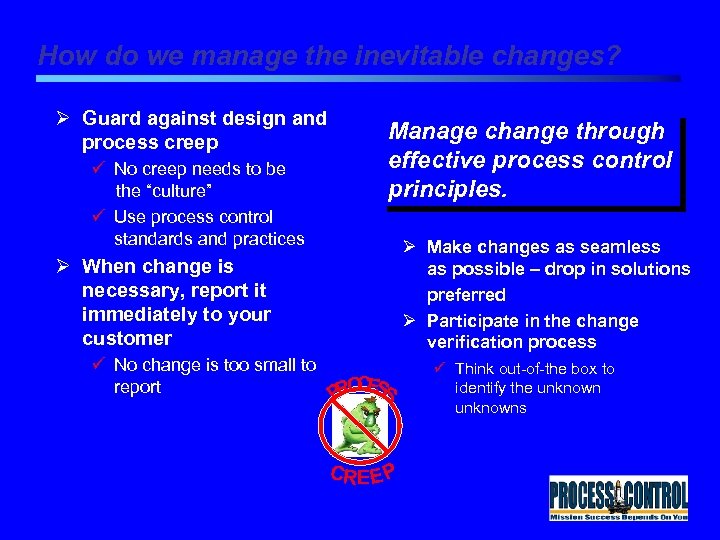

How do we manage the inevitable changes? Ø Guard against design and process creep ü No creep needs to be the “culture” ü Use process control standards and practices Manage change through effective process control principles. Ø Make changes as seamless as possible – drop in solutions preferred Ø Participate in the change verification process Ø When change is necessary, report it immediately to your customer ü No change is too small to report R CS P OES CRE E P ü Think out-of-the box to identify the unknowns

How do we manage the inevitable changes? Ø Guard against design and process creep ü No creep needs to be the “culture” ü Use process control standards and practices Manage change through effective process control principles. Ø Make changes as seamless as possible – drop in solutions preferred Ø Participate in the change verification process Ø When change is necessary, report it immediately to your customer ü No change is too small to report R CS P OES CRE E P ü Think out-of-the box to identify the unknowns

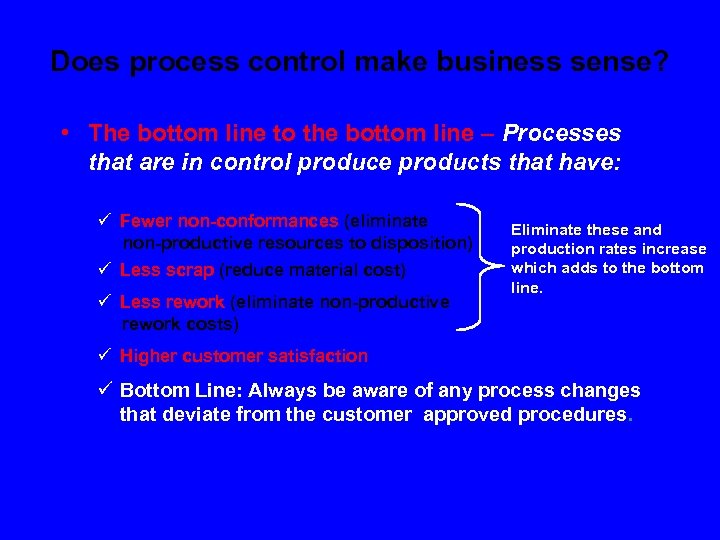

Does process control make business sense? • The bottom line to the bottom line – Processes that are in control produce products that have: ü Fewer non-conformances (eliminate non-productive resources to disposition) ü Less scrap (reduce material cost) ü Less rework (eliminate non-productive rework costs) Eliminate these and production rates increase which adds to the bottom line. ü Higher customer satisfaction ü Bottom Line: Always be aware of any process changes that deviate from the customer approved procedures.

Does process control make business sense? • The bottom line to the bottom line – Processes that are in control produce products that have: ü Fewer non-conformances (eliminate non-productive resources to disposition) ü Less scrap (reduce material cost) ü Less rework (eliminate non-productive rework costs) Eliminate these and production rates increase which adds to the bottom line. ü Higher customer satisfaction ü Bottom Line: Always be aware of any process changes that deviate from the customer approved procedures.

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Greg Harbaugh - Astronaut l

Lockheed Martin / Certified Steel H/T Process Control Management Awareness Greg Harbaugh - Astronaut l