d5680a5a8d7eb4fb8a94583f84a1537d.ppt

- Количество слайдов: 39

LMI Electronic Metering Pumps

Basic Pump Operation Pump Selection LMI Metering Pumps Maintenance Set-up and Installation

Basic Pump Operation • Discharge Stroke • Suction Stroke • Controls • Advantages

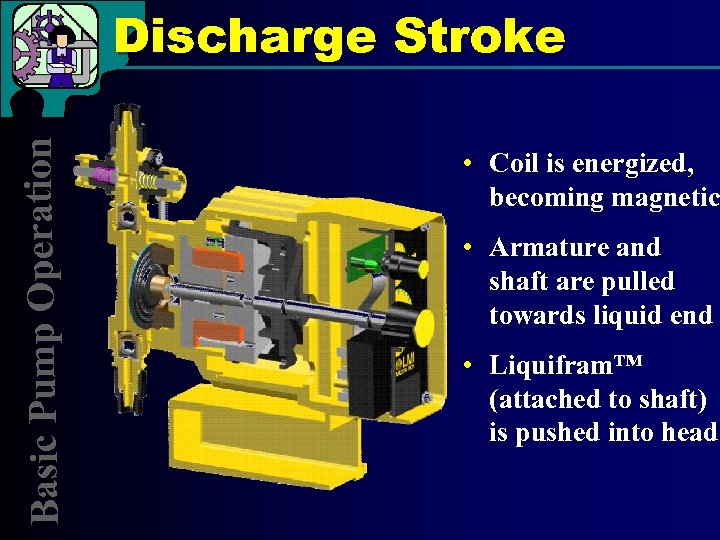

Basic Pump Operation Discharge Stroke • Coil is energized, becoming magnetic • Armature and shaft are pulled towards liquid end • Liquifram™ (attached to shaft) is pushed into head

During the discharge stroke, the suction balls seats, preventing solution from going back to the solution tank. The solution is forced through the discharge valve.

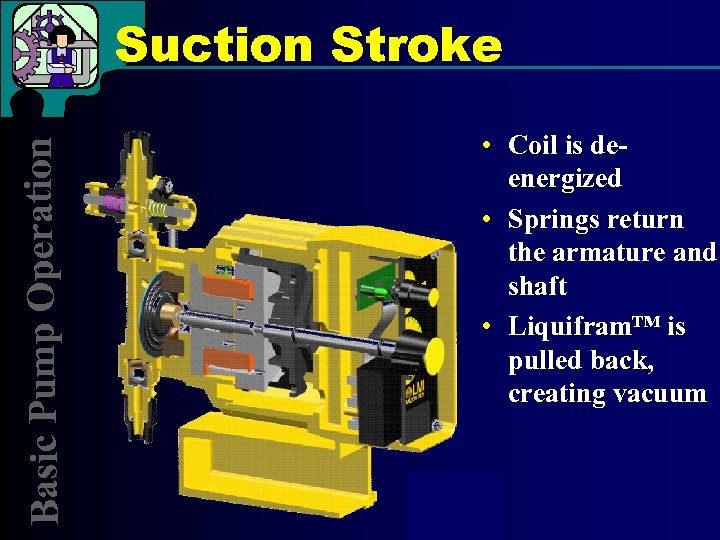

Basic Pump Operation Suction Stroke • Coil is deenergized • Springs return the armature and shaft • Liquifram™ is pulled back, creating vacuum

During the suction stroke, a vacuum is created. The head cavity fills as the Liquifram returns. The suction ball rises while the discharge ball seats.

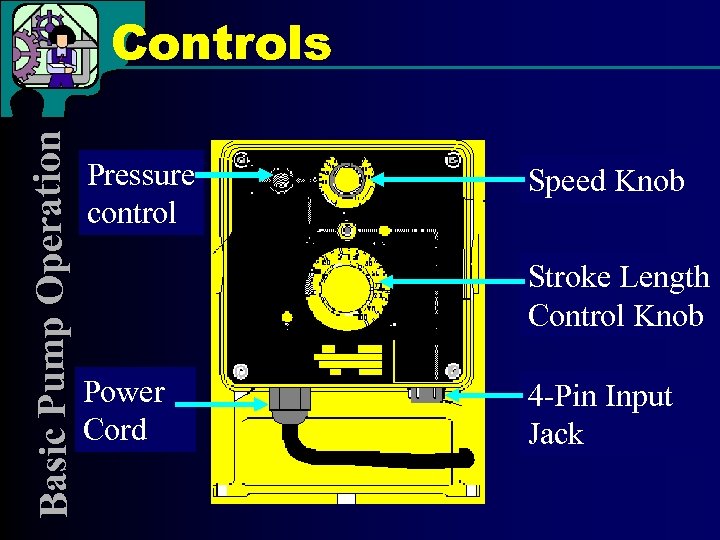

Basic Pu mp Operatio n Controls Pressure control Speed Knob Stroke Length Control Knob Power Cord 4 -Pin Input Jack

Basic Pump Operation Advantages of Electronic Pumps • No rotating motor and cam • Only one, permanently lubricated, moving part • Totally enclosed, chemically resistant • Easy and inexpensive to externally control

Pump Selection • Numbering System • Drive • Liquid End

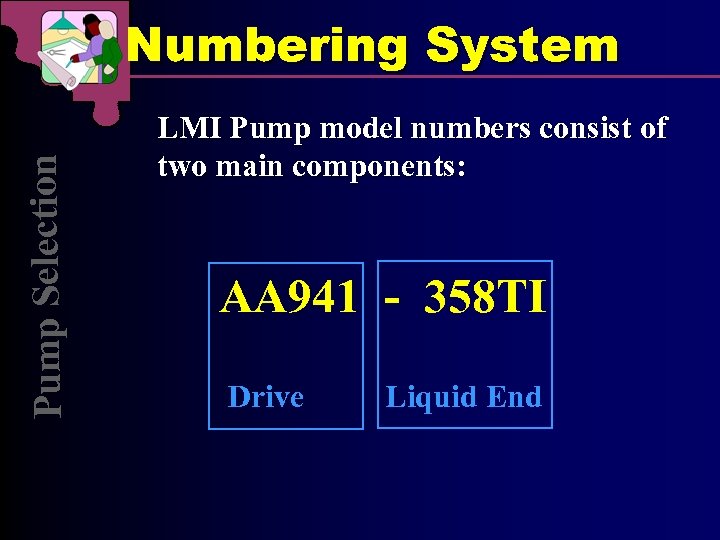

Pump Selection Numbering System LMI Pump model numbers consist of two main components: AA 941 - 358 TI Drive Liquid End

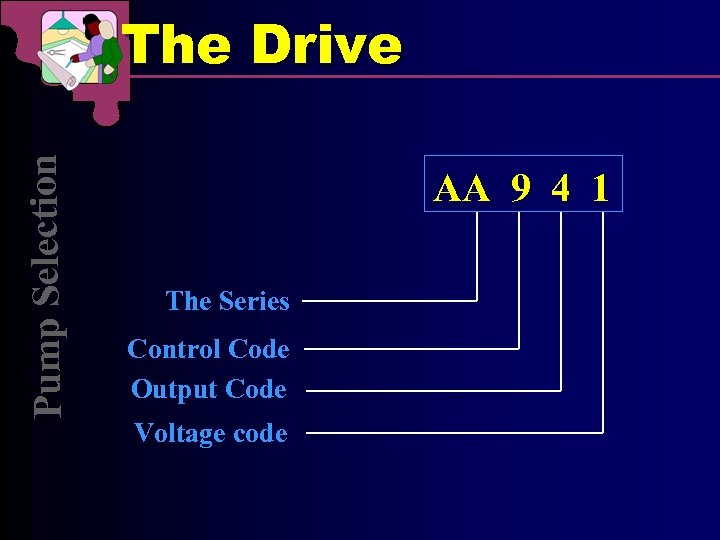

Pump Selection The Drive AA 9 4 1 The Series Control Code Output Code Voltage code

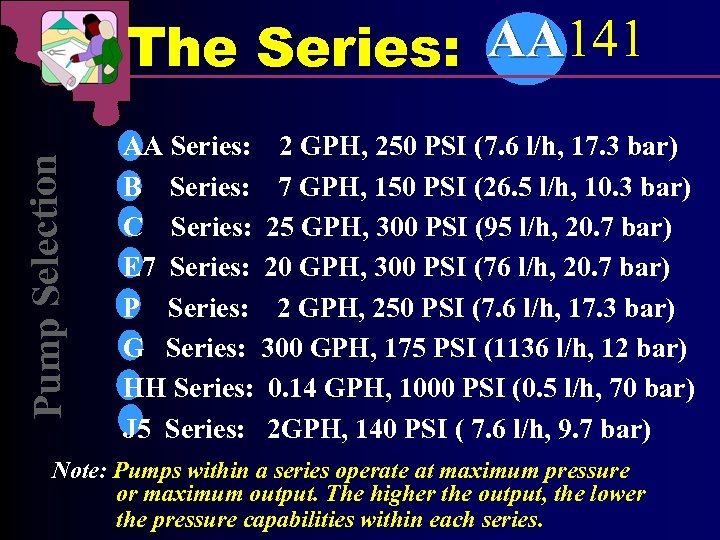

Pump Selection AA The Series: AA 141 AA Series: 2 GPH, 250 PSI (7. 6 l/h, 17. 3 bar) B Series: 7 GPH, 150 PSI (26. 5 l/h, 10. 3 bar) C Series: 25 GPH, 300 PSI (95 l/h, 20. 7 bar) E 7 Series: 20 GPH, 300 PSI (76 l/h, 20. 7 bar) P Series: 2 GPH, 250 PSI (7. 6 l/h, 17. 3 bar) G Series: 300 GPH, 175 PSI (1136 l/h, 12 bar) HH Series: 0. 14 GPH, 1000 PSI (0. 5 l/h, 70 bar) J 5 Series: 2 GPH, 140 PSI ( 7. 6 l/h, 9. 7 bar) Note: Pumps within a series operate at maximum pressure or maximum output. The higher the output, the lower the pressure capabilities within each series.

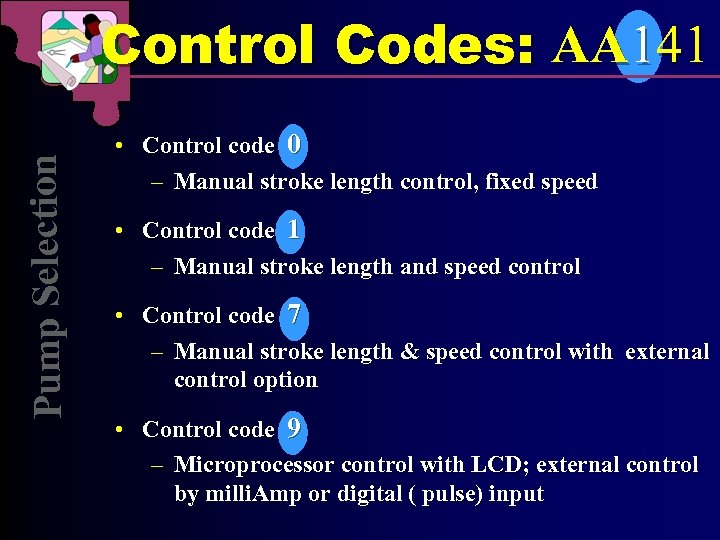

Pump Selection Control Codes: AA 141 • Control code 0 – Manual stroke length control, fixed speed • Control code 1 – Manual stroke length and speed control • Control code 7 – Manual stroke length & speed control with external control option • Control code 9 – Microprocessor control with LCD; external control by milli. Amp or digital ( pulse) input

Series AA 7/B 7/C 7/P 7 • • • Pu mp Selection MP-100 MP-400 D MP-500 M Pulse Transmitter RFP Remote Flowmeter Pulser • FC Flowmeter Contactor Methods of Triggering

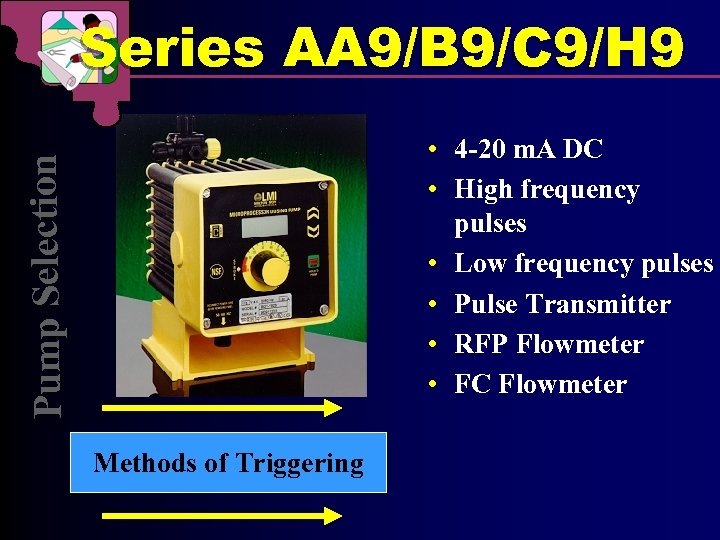

Series AA 9/B 9/C 9/H 9 Pu mp Selection • 4 -20 m. A DC • High frequency pulses • Low frequency pulses • Pulse Transmitter • RFP Flowmeter • FC Flowmeter Methods of Triggering

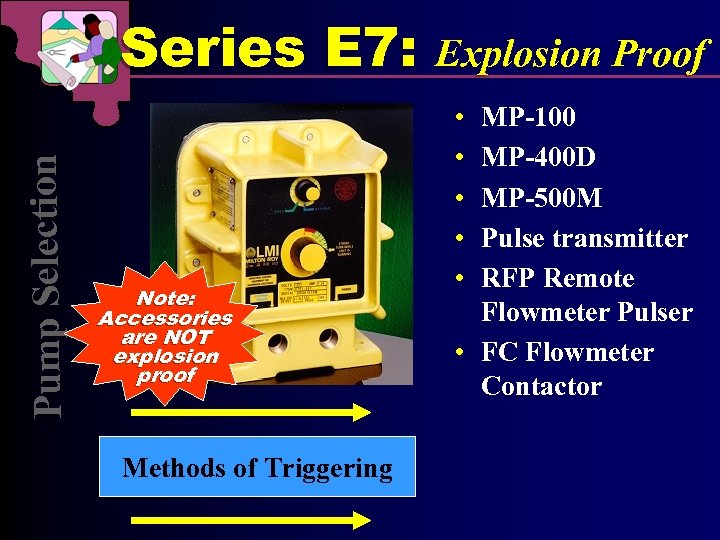

Pu mp Selection Series E 7: Note: Accessories are NOT explosion proof Methods of Triggering Explosion Proof • • • MP-100 MP-400 D MP-500 M Pulse transmitter RFP Remote Flowmeter Pulser • FC Flowmeter Contactor

Pump Selection Output Codes: AA 141 The output code determines output and pressure capability within a pump series. Select the proper output code using the LMI Pump Selection Guide.

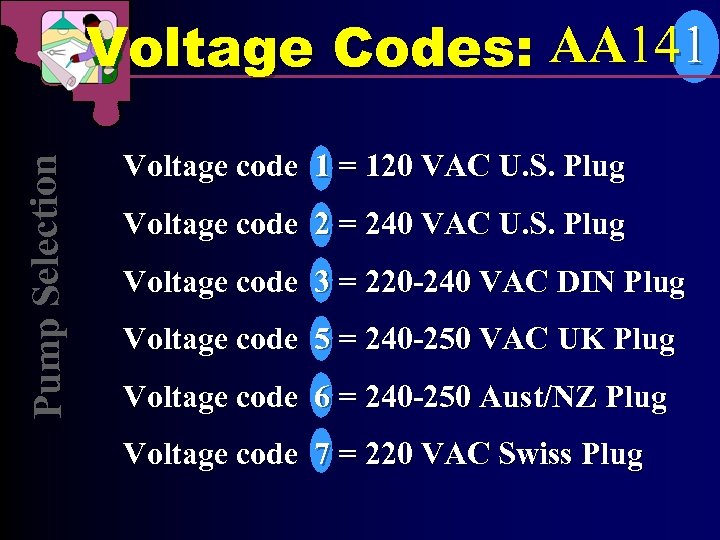

Pump Selection Voltage Codes: AA 141 Voltage code 1 = 120 VAC U. S. Plug Voltage code 2 = 240 VAC U. S. Plug Voltage code 3 = 220 -240 VAC DIN Plug Voltage code 5 = 240 -250 VAC UK Plug Voltage code 6 = 240 -250 Aust/NZ Plug Voltage code 7 = 220 VAC Swiss Plug

Pu mp Selection Liquid End • Select a liquid end compatible with the pump drive using the Pump Selection Guide. • Use the Chemical Resistance Chart to select a suitable liquid end material.

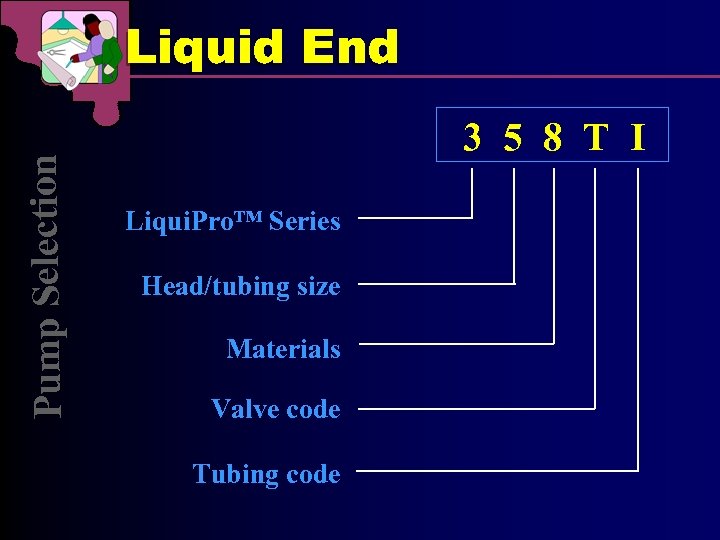

Pu mp Selection Liquid End 3 5 8 T I Liqui. Pro™ Series Head/tubing size Materials Valve code Tubing code

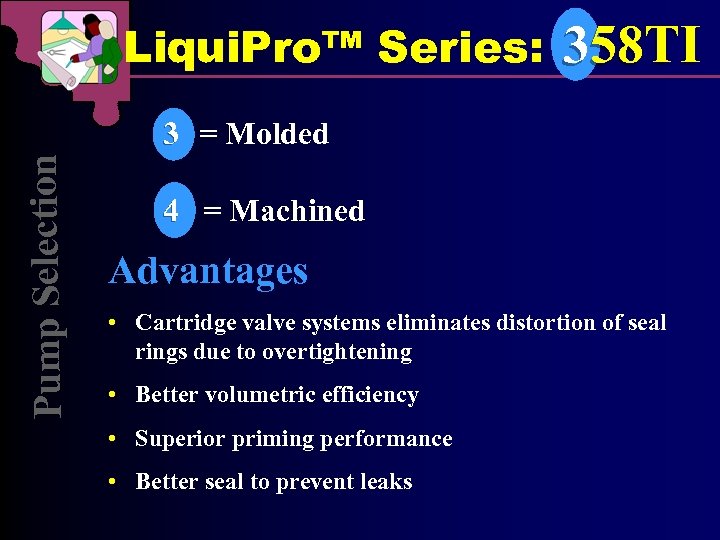

Liqui. Pro™ Series: 358 TI Pu mp Selection 3 = Molded 4 = Machined Advantages • Cartridge valve systems eliminates distortion of seal rings due to overtightening • Better volumetric efficiency • Superior priming performance • Better seal to prevent leaks

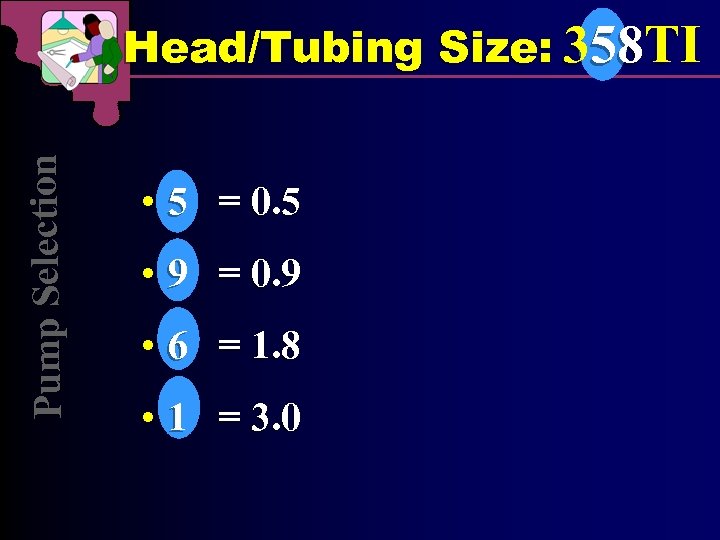

Pu mp Selection Head/Tubing Size: 358 TI • 5 = 0. 5 • 9 = 0. 9 • 6 = 1. 8 • 1 = 3. 0

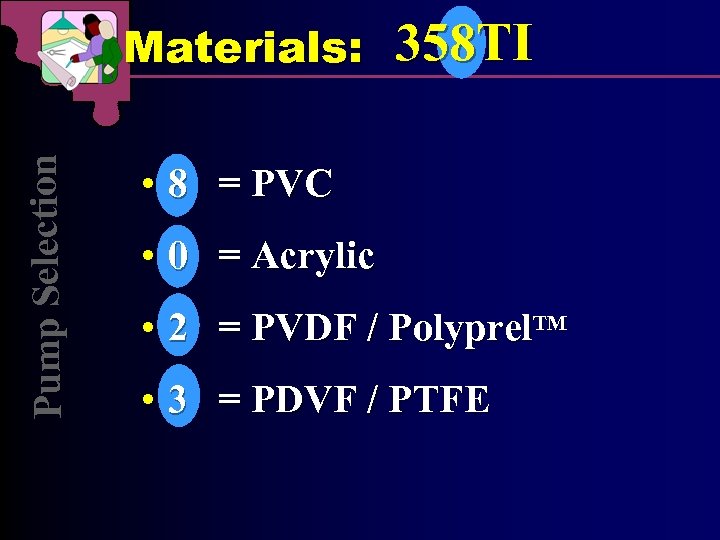

Pump Selection Materials: 358 TI • 8 = PVC • 0 = Acrylic • 2 = PVDF / Polyprel. TM • 3 = PDVF / PTFE

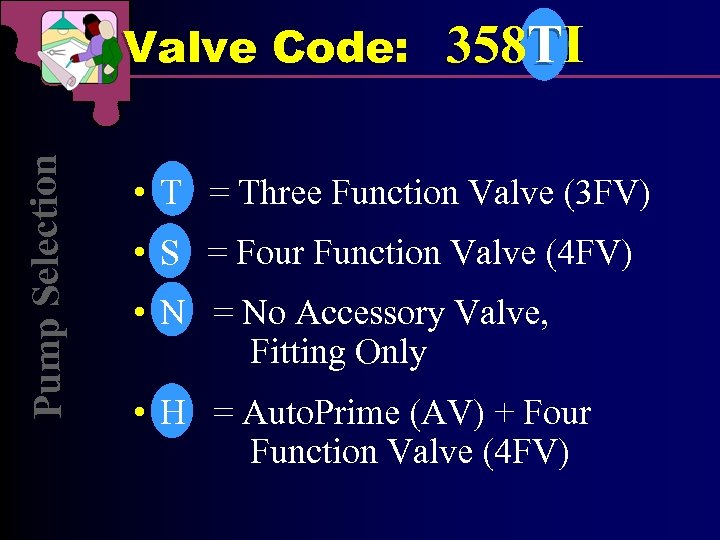

Pu mp Selection Valve Code: 358 TI • T = Three Function Valve (3 FV) • S = Four Function Valve (4 FV) • N = No Accessory Valve, Fitting Only • H = Auto. Prime (AV) + Four Function Valve (4 FV)

Set-up and Installation • Box Contents • Installation Tips • Priming • Calibration

Set-up and Installation Box Contents • Pump • 16 feet (5 m) of tubing • Foot valve • Injection check valve • Discharge valve (4 FV, B 4 FV, 3 FV, 4 FV+AV or straight fitting) • Instruction manuals • Ceramic weight

Set-up and Installation Pre-Installation Precautions • Always wear protective clothing • Pump is pre-primed with water • Verify solution compatibility • Do not reduce tubing connection • Do not use Teflon® tape • Adhere to local plumbing & electrical codes • Use grounded receptacle

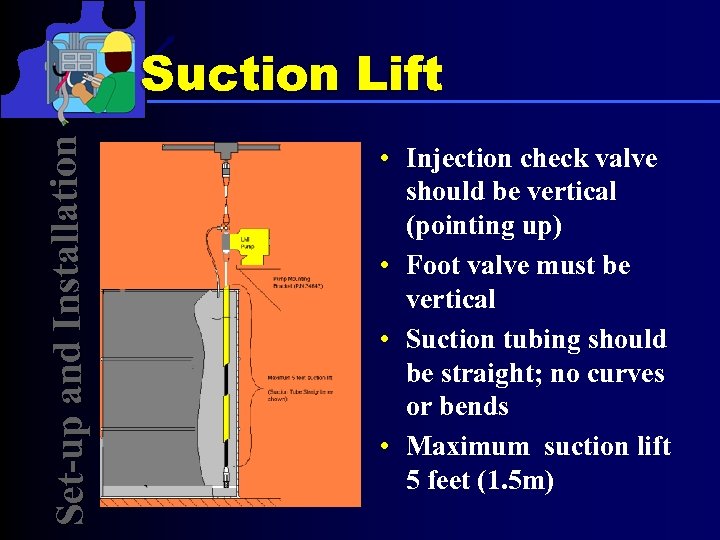

Set-up and Installation Suction Lift • Injection check valve should be vertical (pointing up) • Foot valve must be vertical • Suction tubing should be straight; no curves or bends • Maximum suction lift 5 feet (1. 5 m)

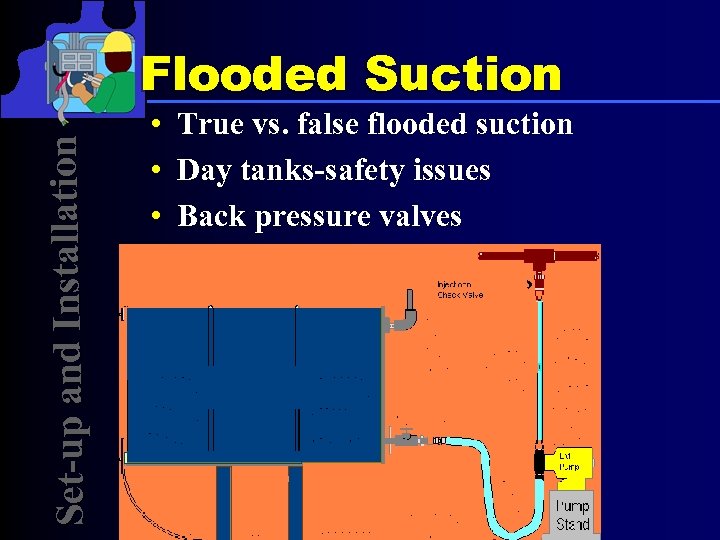

Set-up and Installation Flooded Suction • • • True vs. false flooded suction Day tanks-safety issues Back pressure valves

Set-up and Installation Determining Pump Output • Determine required pump output • Determine percent of pump output • Determine stroke and speed settings

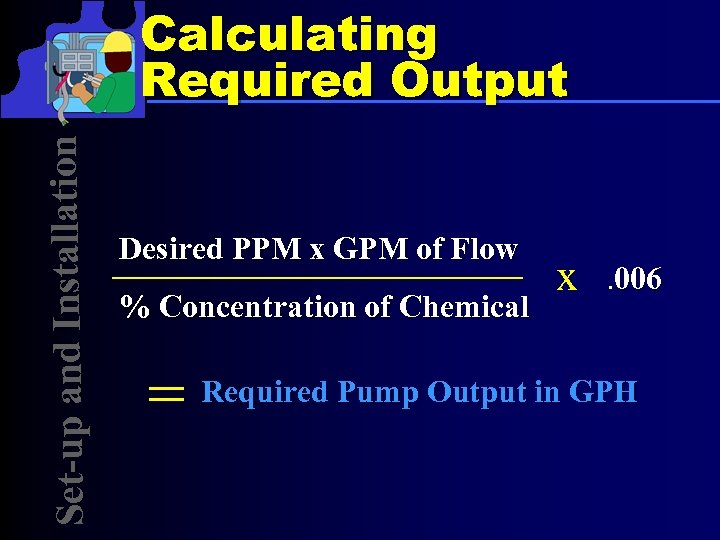

Set-up and Installation Calculating Required Output Desired PPM x GPM of Flow % Concentration of Chemical = x . 006 Required Pump Output in GPH

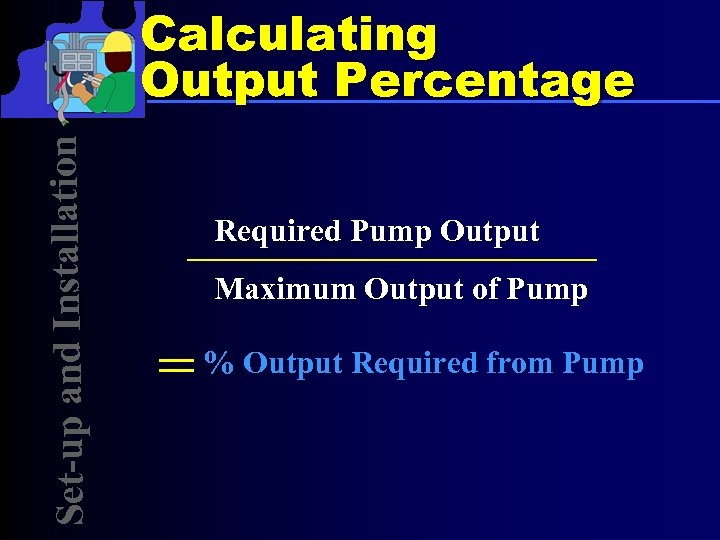

Set-up and Installation Calculating Output Percentage Required Pump Output Maximum Output of Pump = % Output Required from Pump

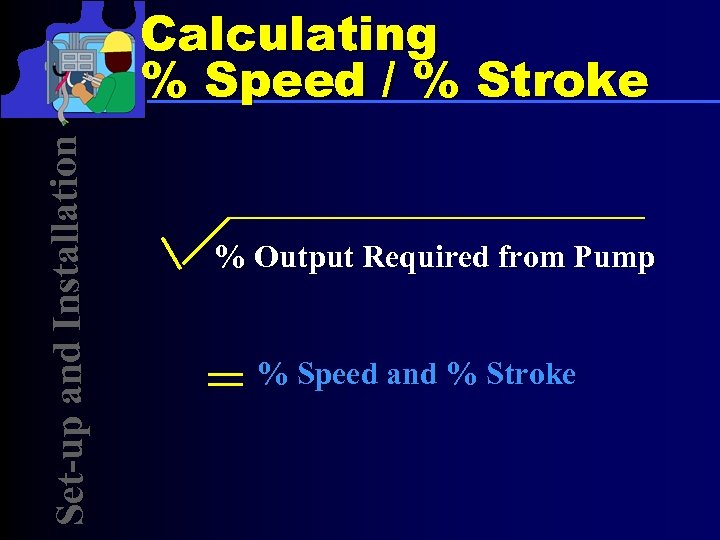

Set-up and Installation Calculating % Speed / % Stroke % Output Required from Pump = % Speed and % Stroke

Set-up and Installation Priming LMI pumps are pre-primed with water to assist in priming: • Output adjustment= 80% speed, 100% stroke • Vent pump to atmosphere via 3 FV or 4 FV • Vent tubing to supply tank

Set-up and Installation Calibration LMI Pumps should be calibrated during installation or whenever the output is adjusted • Verify that the pump is primed • Use a graduated cylinder on suction side of pump • Run 60 second test • Adjust pump as necessary

Maintenance • RPM Pro Pac™ Kits • Liquifram™ Replacement

Maintenance Preventative Maintenance Spare parts should be replaced annually including: • Cartridge valves (balls/seal rings) • Liquifram™ • Clamp rings • • • Ferrules Head screws Shaft seal

RPM Pro Pac™ Kits Mainten ance • Liquifram™ • Cartridge valves • Clamp rings / Ferrules • Head Screws • Instructions • Shaft seal

d5680a5a8d7eb4fb8a94583f84a1537d.ppt