511cede2984b5b3b559fc4c28adbde42.ppt

- Количество слайдов: 16

Littleford Day Inc. Where Processing Ideas become Reality.

Double Arm Mixers Sanitary and Standard Designs Littleford Day Inc. Where Processing Ideas Become Reality.

Double Arm Mixers Presentation Index Page 4 5 6 7 8 9 10 11 12 13 14 15 16 Contents Littleford Bros. And J. H. Day: The Ultimate Combination. Sanitary Double Arm Mixers. Mixtruders. Tangential and Overlapping Agitator Actions. Our Blades. Sanitary Seals. Laboratory Double Arm Mixers. Applications. The “Cincinnatus” Product Range: Overlapping. Std & Heavy-Duty. The “Imperial”&“Mogul” Product Range: Tangential. Std & Heavy-Duty. The “Mixtruder” Product Range: Tangential with Extrusion Screw. Service and Spare Parts. Rental Programs. Process Development and Testing.

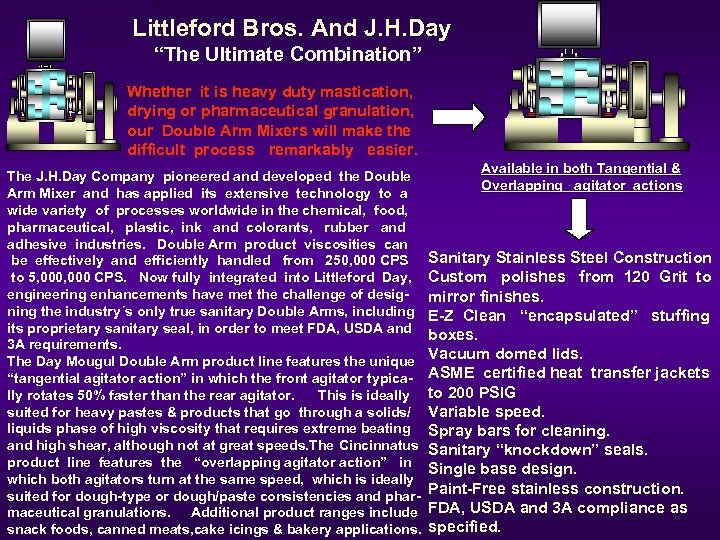

Littleford Bros. And J. H. Day “The Ultimate Combination” Whether it is heavy duty mastication, drying or pharmaceutical granulation, our Double Arm Mixers will make the difficult process remarkably easier. The J. H. Day Company pioneered and developed the Double Arm Mixer and has applied its extensive technology to a wide variety of processes worldwide in the chemical, food, pharmaceutical, plastic, ink and colorants, rubber and adhesive industries. Double Arm product viscosities can be effectively and efficiently handled from 250, 000 CPS to 5, 000 CPS. Now fully integrated into Littleford Day, engineering enhancements have met the challenge of designing the industry´s only true sanitary Double Arms, including its proprietary sanitary seal, in order to meet FDA, USDA and 3 A requirements. The Day Mougul Double Arm product line features the unique “tangential agitator action” in which the front agitator typically rotates 50% faster than the rear agitator. This is ideally suited for heavy pastes & products that go through a solids/ liquids phase of high viscosity that requires extreme beating and high shear, although not at great speeds. The Cincinnatus product line features the “overlapping agitator action” in which both agitators turn at the same speed, which is ideally suited for dough-type or dough/paste consistencies and pharmaceutical granulations. Additional product ranges include snack foods, canned meats, cake icings & bakery applications. Available in both Tangential & Overlapping agitator actions Sanitary Stainless Steel Construction Custom polishes from 120 Grit to mirror finishes. E-Z Clean “encapsulated” stuffing boxes. Vacuum domed lids. ASME certified heat transfer jackets to 200 PSIG Variable speed. Spray bars for cleaning. Sanitary “knockdown” seals. Single base design. Paint-Free stainless construction. FDA, USDA and 3 A compliance as specified.

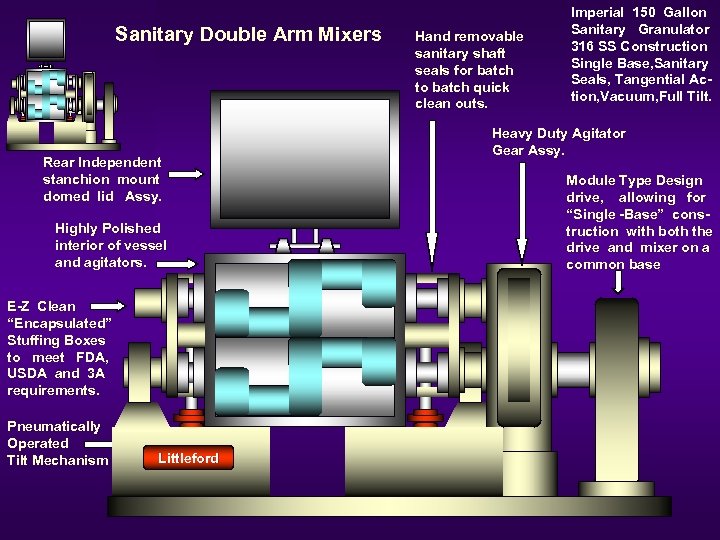

Sanitary Double Arm Mixers Rear Independent stanchion mount domed lid Assy. Highly Polished interior of vessel and agitators. E-Z Clean “Encapsulated” Stuffing Boxes to meet FDA, USDA and 3 A requirements. Pneumatically Operated Tilt Mechanism Littleford Hand removable sanitary shaft seals for batch to batch quick clean outs. Imperial 150 Gallon Sanitary Granulator 316 SS Construction Single Base, Sanitary Seals, Tangential Action, Vacuum, Full Tilt. Heavy Duty Agitator Gear Assy. Module Type Design drive, allowing for “Single -Base” construction with both the drive and mixer on a common base

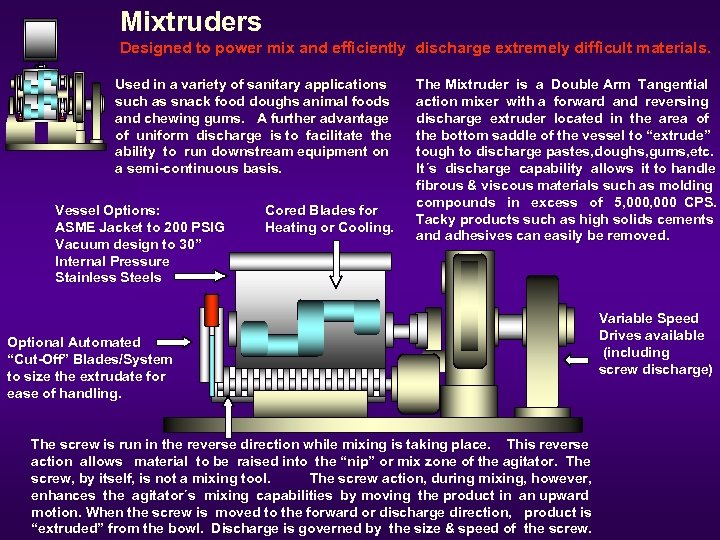

Mixtruders Designed to power mix and efficiently discharge extremely difficult materials. Used in a variety of sanitary applications such as snack food doughs animal foods and chewing gums. A further advantage of uniform discharge is to facilitate the ability to run downstream equipment on a semi-continuous basis. Vessel Options: ASME Jacket to 200 PSIG Vacuum design to 30” Internal Pressure Stainless Steels Cored Blades for Heating or Cooling. The Mixtruder is a Double Arm Tangential action mixer with a forward and reversing discharge extruder located in the area of the bottom saddle of the vessel to “extrude” tough to discharge pastes, doughs, gums, etc. It´s discharge capability allows it to handle fibrous & viscous materials such as molding compounds in excess of 5, 000 CPS. Tacky products such as high solids cements and adhesives can easily be removed. Optional Automated “Cut-Off” Blades/System to size the extrudate for ease of handling. The screw is run in the reverse direction while mixing is taking place. This reverse action allows material to be raised into the “nip” or mix zone of the agitator. The screw, by itself, is not a mixing tool. The screw action, during mixing, however, enhances the agitator´s mixing capabilities by moving the product in an upward motion. When the screw is moved to the forward or discharge direction, product is “extruded” from the bowl. Discharge is governed by the size & speed of the screw. Variable Speed Drives available (including screw discharge)

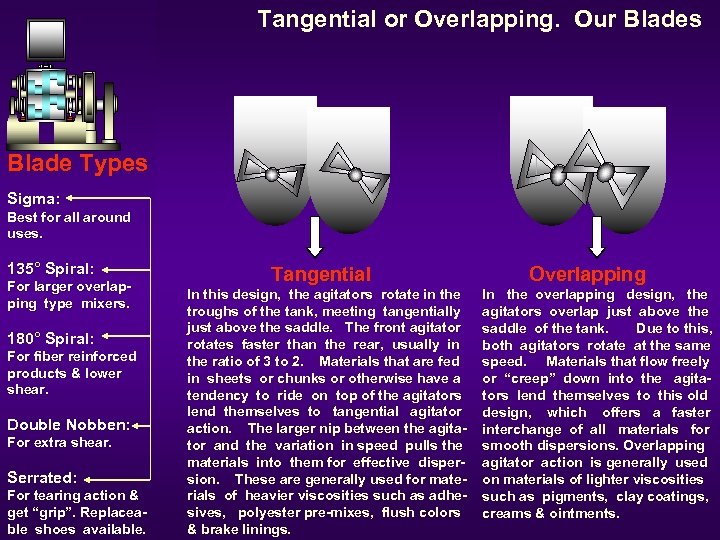

Tangential or Overlapping. Our Blades Blade Types Sigma: Best for all around uses. 135° Spiral: For larger overlapping type mixers. 180° Spiral: For fiber reinforced products & lower shear. Double Nobben: For extra shear. Serrated: For tearing action & get “grip”. Replaceable shoes available. Tangential In this design, the agitators rotate in the troughs of the tank, meeting tangentially just above the saddle. The front agitator rotates faster than the rear, usually in the ratio of 3 to 2. Materials that are fed in sheets or chunks or otherwise have a tendency to ride on top of the agitators lend themselves to tangential agitator action. The larger nip between the agitator and the variation in speed pulls the materials into them for effective dispersion. These are generally used for materials of heavier viscosities such as adhesives, polyester pre-mixes, flush colors & brake linings. Overlapping In the overlapping design, the agitators overlap just above the saddle of the tank. Due to this, both agitators rotate at the same speed. Materials that flow freely or “creep” down into the agitators lend themselves to this old design, which offers a faster interchange of all materials for smooth dispersions. Overlapping agitator action is generally used on materials of lighter viscosities such as pigments, clay coatings, creams & ointments.

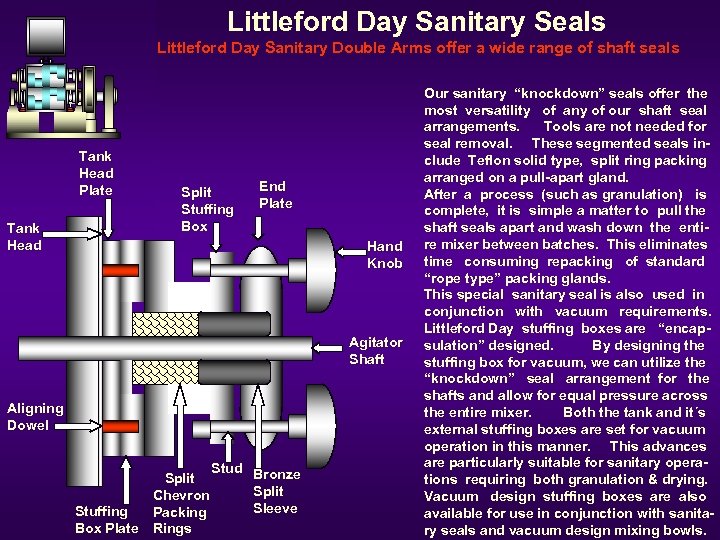

Littleford Day Sanitary Seals Littleford Day Sanitary Double Arms offer a wide range of shaft seals Tank Head Plate Tank Head Split Stuffing Box End Plate Hand Knob Agitator Shaft Aligning Dowel Split Chevron Stuffing Packing Box Plate Rings Stud Bronze Split Sleeve Our sanitary “knockdown” seals offer the most versatility of any of our shaft seal arrangements. Tools are not needed for seal removal. These segmented seals include Teflon solid type, split ring packing arranged on a pull-apart gland. After a process (such as granulation) is complete, it is simple a matter to pull the shaft seals apart and wash down the entire mixer between batches. This eliminates time consuming repacking of standard “rope type” packing glands. This special sanitary seal is also used in conjunction with vacuum requirements. Littleford Day stuffing boxes are “encapsulation” designed. By designing the stuffing box for vacuum, we can utilize the “knockdown” seal arrangement for the shafts and allow for equal pressure across the entire mixer. Both the tank and it´s external stuffing boxes are set for vacuum operation in this manner. This advances are particularly suitable for sanitary operations requiring both granulation & drying. Vacuum design stuffing boxes are also available for use in conjunction with sanitary seals and vacuum design mixing bowls.

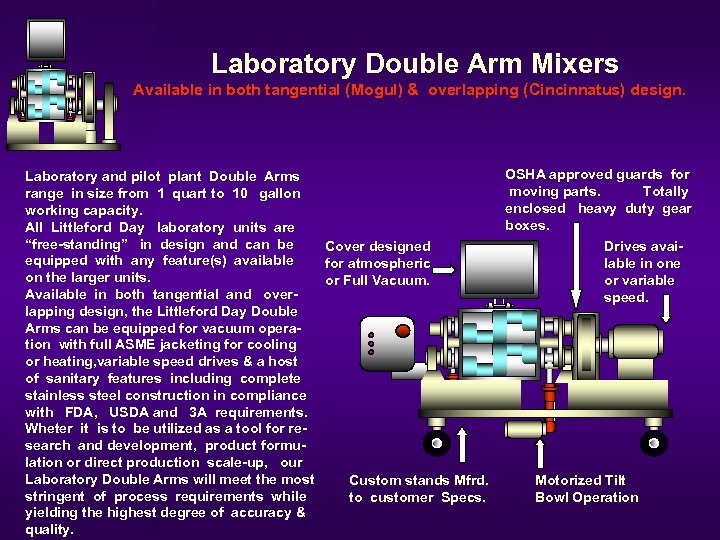

Laboratory Double Arm Mixers Available in both tangential (Mogul) & overlapping (Cincinnatus) design. Laboratory and pilot plant Double Arms range in size from 1 quart to 10 gallon working capacity. All Littleford Day laboratory units are “free-standing” in design and can be Cover designed equipped with any feature(s) available for atmospheric on the larger units. or Full Vacuum. Available in both tangential and overlapping design, the Littleford Day Double Arms can be equipped for vacuum operation with full ASME jacketing for cooling or heating, variable speed drives & a host of sanitary features including complete stainless steel construction in compliance with FDA, USDA and 3 A requirements. Wheter it is to be utilized as a tool for research and development, product formulation or direct production scale-up, our Laboratory Double Arms will meet the most Custom stands Mfrd. stringent of process requirements while to customer Specs. yielding the highest degree of accuracy & quality. OSHA approved guards for moving parts. Totally enclosed heavy duty gear boxes. Drives available in one or variable speed. Motorized Tilt Bowl Operation

Adhesives & Sealants Foods Chewing Gums Candies Bakery Doughs Canned Processed Meats Pet Foods Nutritional Bars Beef & Chicken Extracts Chocolates Sausage Mixes Gluten Dewatering Rubber And Plastics Double Arm Mixers Applications Butyl Sealants Fiberglass Filled Mats Polyester Sheeting Thermosetting Plastic Resin Epoxy Resins Bulk Molded Composites Reinforced Polyester Resin Alkyd Glass Pastes Auto Body Epoxies Pharmaceuticals Wet Granulations Intermediates Cosmetic Bar Soaps Dental Adhesives/Fixtures Ointments & Pastes Medical Adhesives Medicated Gums Candied Laxatives Hot Melt Adhesives Puttys Acrylic Polymer Adhesives Butyl Tape Adhesives Contact Cements Caulks Water Based Adhesives Reactive Plastisols Concrete Sealants Chemicals Graphite Pastes Friction Linings Battery Pastes Wood Fillers High Viscosity Greases Polymer Based Explosives Soap Compounds Ceramics & Metallurgical Ceramic Compounds Molding Compounds Ceramic Frits Aluminum Red. Carbon Paste Metals For Injection Molding Grinding Wheel Compounds Tungsten Carbides Inks & Dyes Color Flushing Magnetic Inks Glass Enamels Textile Dyes

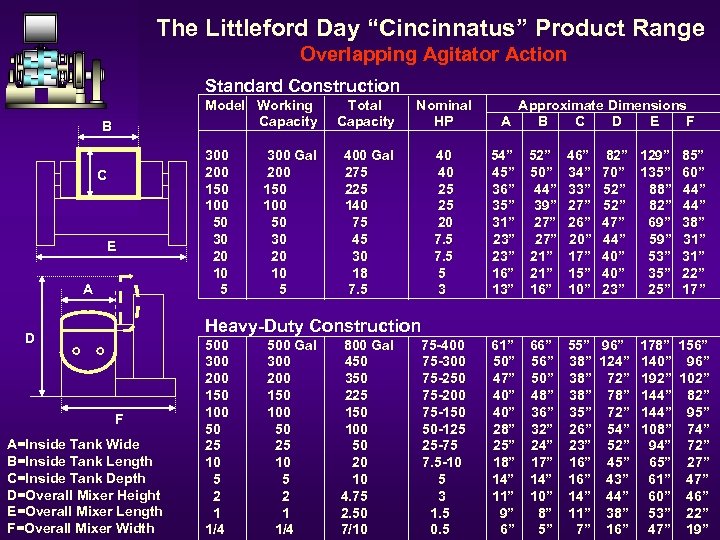

The Littleford Day “Cincinnatus” Product Range Overlapping Agitator Action Standard Construction Model Working Capacity B C E A 300 200 150 100 50 30 20 10 5 300 Gal 200 150 100 50 30 20 10 5 Total Capacity Nominal HP Approximate Dimensions A B C D E F 400 Gal 275 225 140 75 45 30 18 7. 5 40 40 25 25 20 7. 5 5 3 54” 52” 45” 50” 36” 44” 35” 39” 31” 27” 23” 21” 16” 21” 13” 16” 46” 34” 33” 27” 26” 20” 17” 15” 10” 82” 129” 85” 70” 135” 60” 52” 88” 44” 52” 82” 44” 47” 69” 38” 44” 59” 31” 40” 53” 31” 40” 35” 22” 23” 25” 17 ” 75 -400 75 -300 75 -250 75 -200 75 -150 50 -125 25 -75 7. 5 -10 5 3 1. 5 0. 5 61” 66” 50” 56” 47” 50” 48” 40” 36” 28” 32” 25” 24” 18” 17” 14” 11” 10” 9” 8” 6” 5” 55” 38” 38” 35” 26” 23” 16” 14” 11” 7” 96” 124” 72” 78” 72” 54” 52” 45” 43” 44” 38” 16” Heavy-Duty Construction D F A=Inside Tank Wide B=Inside Tank Length C=Inside Tank Depth D=Overall Mixer Height E=Overall Mixer Length F=Overall Mixer Width 500 300 200 150 100 50 25 10 5 2 1 1/4 500 Gal 300 200 150 100 50 25 10 5 2 1 1/4 800 Gal 450 350 225 150 100 50 20 10 4. 75 2. 50 7/10 178” 140” 192” 144” 108” 94” 65” 61” 60” 53” 47” 156” 96” 102” 82” 95” 74” 72” 27” 46” 22” 19”

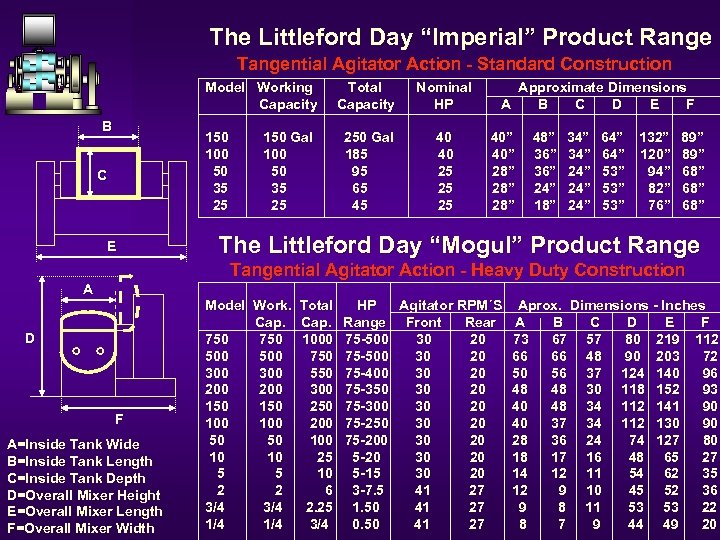

The Littleford Day “Imperial” Product Range Tangential Agitator Action - Standard Construction Model Working Capacity B 150 100 50 35 25 C E 150 Gal 100 50 35 25 Total Capacity Nominal HP 250 Gal 185 95 65 45 40 40 25 25 25 Approximate Dimensions A B C D E F 40” 28” 28” 48” 36” 24” 18” 34” 24” 24” 64” 132” 89” 64” 120” 89” 53” 94” 68” 53” 82” 68” 53” 76” 68” The Littleford Day “Mogul” Product Range Tangential Agitator Action - Heavy Duty Construction A D F A=Inside Tank Wide B=Inside Tank Length C=Inside Tank Depth D=Overall Mixer Height E=Overall Mixer Length F=Overall Mixer Width Model Work. Cap. 750 500 300 200 150 100 50 50 10 10 5 5 2 2 3/4 1/4 Total Cap. 1000 750 550 300 250 200 100 25 10 6 2. 25 3/4 HP Agitator RPM´S Range Front Rear 75 -500 30 20 75 -400 30 20 75 -350 30 20 75 -300 30 20 75 -250 30 20 75 -200 30 20 5 -20 30 20 5 -15 30 20 3 -7. 5 41 27 1. 50 41 27 0. 50 41 27 Aprox. Dimensions - Inches A B C D E F 73 67 57 80 219 112 66 66 48 90 203 72 50 56 37 124 140 96 48 48 30 118 152 93 40 48 34 112 141 90 40 37 34 112 130 90 28 36 24 74 127 80 18 17 16 48 65 27 14 12 11 54 62 35 12 9 10 45 52 36 9 8 11 53 53 22 8 7 9 44 49 20

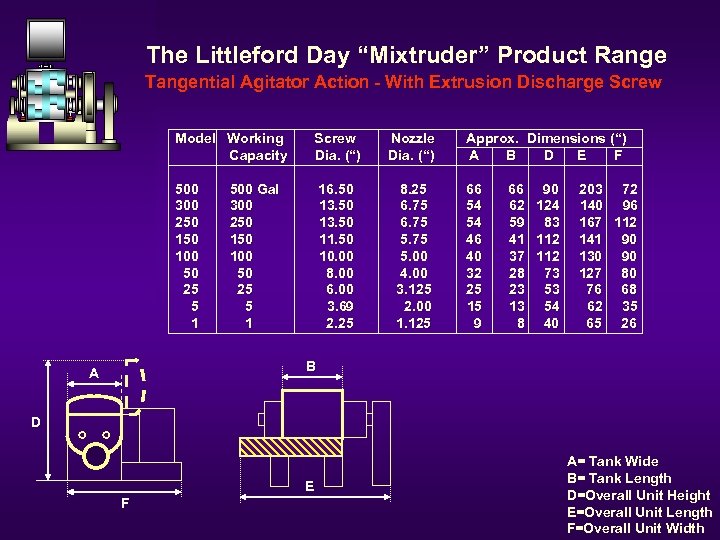

The Littleford Day “Mixtruder” Product Range Tangential Agitator Action - With Extrusion Discharge Screw Model Working Capacity Screw Dia. (“) Nozzle Dia. (“) 500 300 250 100 50 25 5 1 16. 50 13. 50 11. 50 10. 00 8. 00 6. 00 3. 69 2. 25 8. 25 6. 75 5. 00 4. 00 3. 125 2. 00 1. 125 500 Gal 300 250 100 50 25 5 1 Approx. Dimensions (“) A B D E F 66 54 54 46 40 32 25 15 9 66 90 62 124 59 83 41 112 37 112 28 73 23 53 13 54 8 40 203 72 140 96 167 112 141 90 130 90 127 80 76 68 62 35 65 26 B A D E F A= Tank Wide B= Tank Length D=Overall Unit Height E=Overall Unit Length F=Overall Unit Width

Service & Spare Parts u u u Exclusive Dept. for customer assistance. Laboratory formulations & optimization. Specialized Field Service Engineers. u u u The Best Service Department. Direct Sales Force. No Reps. Own Manufacturing Facilities. Stock of common required parts. Top American Mfrd. Parts: SKF, Falk, Chesterton, etc. Assistance in Spanish, if required.

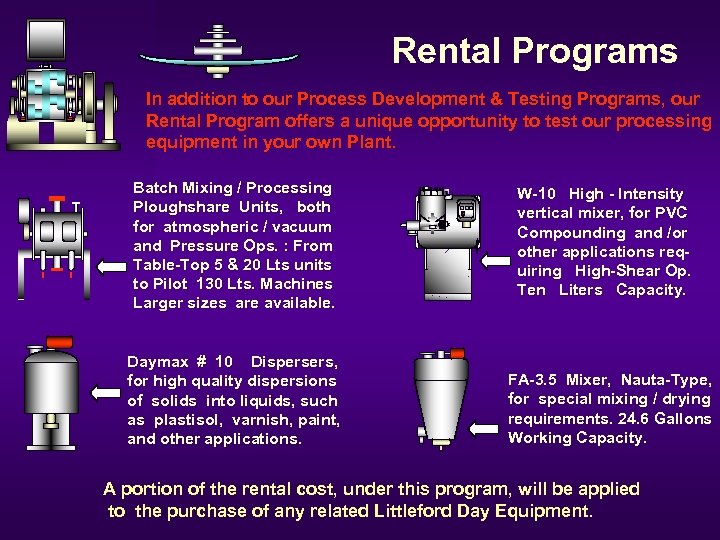

Rental Programs In addition to our Process Development & Testing Programs, our Rental Program offers a unique opportunity to test our processing equipment in your own Plant. Batch Mixing / Processing Ploughshare Units, both for atmospheric / vacuum and Pressure Ops. : From Table-Top 5 & 20 Lts units to Pilot 130 Lts. Machines Larger sizes are available. Daymax # 10 Dispersers, for high quality dispersions of solids into liquids, such as plastisol, varnish, paint, and other applications. W-10 High - Intensity vertical mixer, for PVC Compounding and /or other applications requiring High-Shear Op. Ten Liters Capacity. FA-3. 5 Mixer, Nauta-Type, for special mixing / drying requirements. 24. 6 Gallons Working Capacity. A portion of the rental cost, under this program, will be applied to the purchase of any related Littleford Day Equipment.

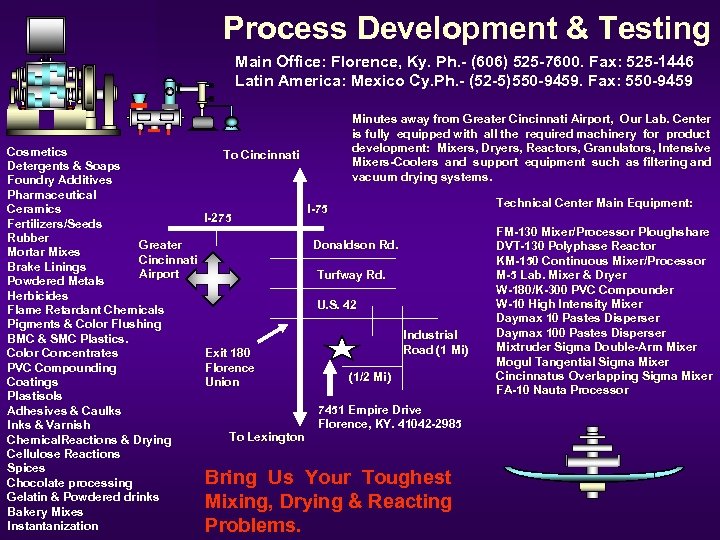

Process Development & Testing Main Office: Florence, Ky. Ph. - (606) 525 -7600. Fax: 525 -1446 Latin America: Mexico Cy. Ph. - (52 -5)550 -9459. Fax: 550 -9459 Cosmetics Detergents & Soaps Foundry Additives Pharmaceutical Ceramics Fertilizers/Seeds Rubber Greater Mortar Mixes Cincinnati Brake Linings Airport Powdered Metals Herbicides Flame Retardant Chemicals Pigments & Color Flushing BMC & SMC Plastics. Color Concentrates PVC Compounding Coatings Plastisols Adhesives & Caulks Inks & Varnish Chemical. Reactions & Drying Cellulose Reactions Spices Chocolate processing Gelatin & Powdered drinks Bakery Mixes Instantanization Minutes away from Greater Cincinnati Airport, Our Lab. Center is fully equipped with all the required machinery for product development: Mixers, Dryers, Reactors, Granulators, Intensive Granulators, Mixers-Coolers and support equipment such as filtering and vacuum drying systems. To Cincinnati I-275 Technical Center Main Equipment: I-75 Donaldson Rd. Turfway Rd. U. S. 42 Exit 180 Florence Union To Lexington Industrial Road (1 Mi) (1/2 Mi) 7451 Empire Drive Florence, KY. 41042 -2985 Bring Us Your Toughest Mixing, Drying & Reacting Problems. FM-130 Mixer/Processor Ploughshare DVT-130 Polyphase Reactor KM-150 Continuous Mixer/Processor M-5 Lab. Mixer & Dryer W-180/K-300 PVC Compounder W-10 High Intensity Mixer Daymax 10 Pastes Disperser Daymax 100 Pastes Disperser Mixtruder Sigma Double-Arm Mixer Mogul Tangential Sigma Mixer Cincinnatus Overlapping Sigma Mixer FA-10 Nauta Processor

511cede2984b5b3b559fc4c28adbde42.ppt